Emerson Rosemount 3051S FOUNDATION Series, Rosemount 3051SF FOUNDATION Series Quick Start Manual

Quick Start Guide

00825-0100-4805, Rev FD

March 2018

Rosemount™ 3051S Series Pressure Transmitter

and Rosemount 3051SF Series Flow Meter

with FOUNDATION™ Fieldbus Protocol

Quick Start Guide

March 2018

NOTICE

This guide provides basic guidelines for Rosemount 3051S Series Pressure Transmitters. It also provides the

basic electronics guidelines for the Rosemount 3051SFA Reference Manual

Reference Manual

troubleshooting. Refer to the Rosemount 3051S F

instruction. This document is also available electronically on Emerson.com/Rosemount

Explosions can result in death or serious injury.

Do not remove the transmitter covers in explosive environments when the circuit is live.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Make sure the instrument is installed in accordance with intrinsically safe or nonincendive field wiring

practices.

Process leaks may cause harm or result in death.

To avoid process leaks, only use the O-ring designed to seal with the corresponding flange adaptor.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals. High voltage that may be present on leads can cause electrical

shock.

. It does not provide instructions for configuration, diagnostics, maintenance, service,

OUNDATION Fieldbus Reference Manual for more

and Rosemount 3051SFC

.

Contents

Mount the transmitter . . . . . . . . . . . . . . . . . . . . 3

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Consider housing rotation . . . . . . . . . . . . . . . . . 8

Connect wiring and power up . . . . . . . . . . . . . . 8

2

Verify configuration . . . . . . . . . . . . . . . . . . . . . 10

To display level or flow, use AI block out. . . . . 11

Product Certifications . . . . . . . . . . . . . . . . . . . 13

March 2018

Flow

Flow

Flow

1.0 Mount the transmitter

1.1 Liquid flow applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the

drain/vent valves are oriented upward.

1.2 Gas flow applications

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

Quick Start Guide

Flow

1.3 Steam flow applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

3

Quick Start Guide

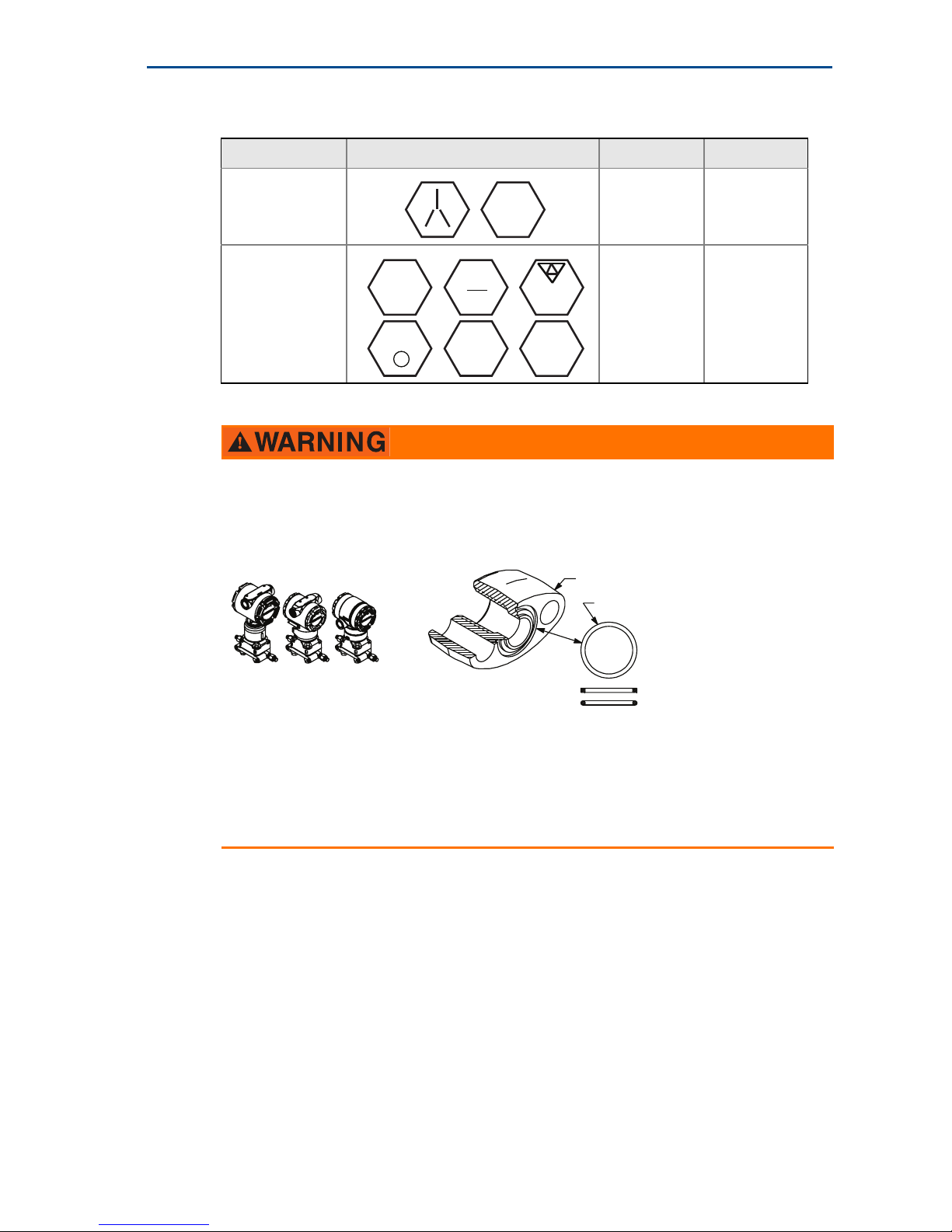

Figure 1. Panel and Pipe Mounting

March 2018

Panel mount Pipe mount

Coplanar flange

Traditional flange

Plantweb

In-line

Housings

™

Junction box Remote mount display

4

March 2018

A

4 × 1.75-in.

(44 mm)

D

4 × 1.75-in.

(44 mm)

4 × 2.25-in.

(57 mm)

C

4 × 1.75-in.

(44 mm)

4 × 1.50-in.

(38 mm)

B

4 × 2.88-in.

(73 mm)

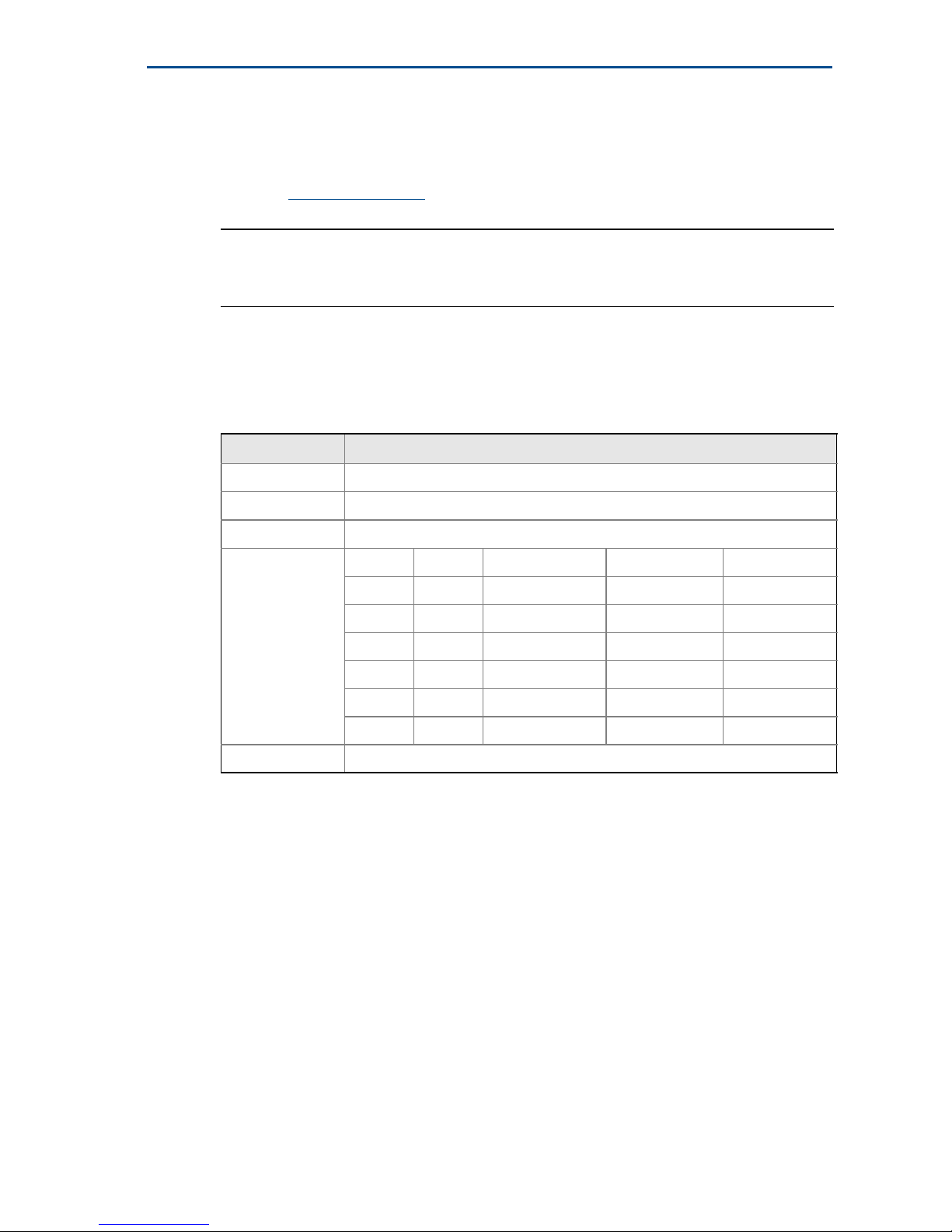

1.4 Bolting considerations

If the transmitter installation requires assembly of the process flanges,

manifolds, or flange adaptors, follow these assembly guidelines to ensure a

tight seal for optimal performance characteristics of the transmitters. Use only

bolts supplied with the transmitter or sold by Emerson

illustrates common transmitter assemblies with the bolt length required for

proper transmitter assembly.

Figure 2. Common Transmitter Assemblies

Quick Start Guide

™

as spare parts. Figure 2

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adaptors

C. Transmitter with traditional flange and optional flange adaptors

D. Transmitter with coplanar flange and optional manifold and flange adaptors

Bolts are typically carbon steel or stainless steel. Confirm the material by

viewing the markings on the head of the bolt and referencing Table 1 on page 6.

If bolt material is not shown in Table 1 on page 6, contact the local Emerson

representative for more information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel bolts are

coated with a lubricant to ease installation. However, no additional lubricant

should be applied when installing either type of bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern.

See Table 1 on page 6 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing pattern.

See Table 1 on page 6 for final torque value.

5. Verify the flange bolts are protruding through the isolator plate before

applying pressure.

5

Quick Start Guide

316

316

316

SW

316

STM

316

R

B8M

A

B

C

Rosemount 3051S/3051/2051/4088

D

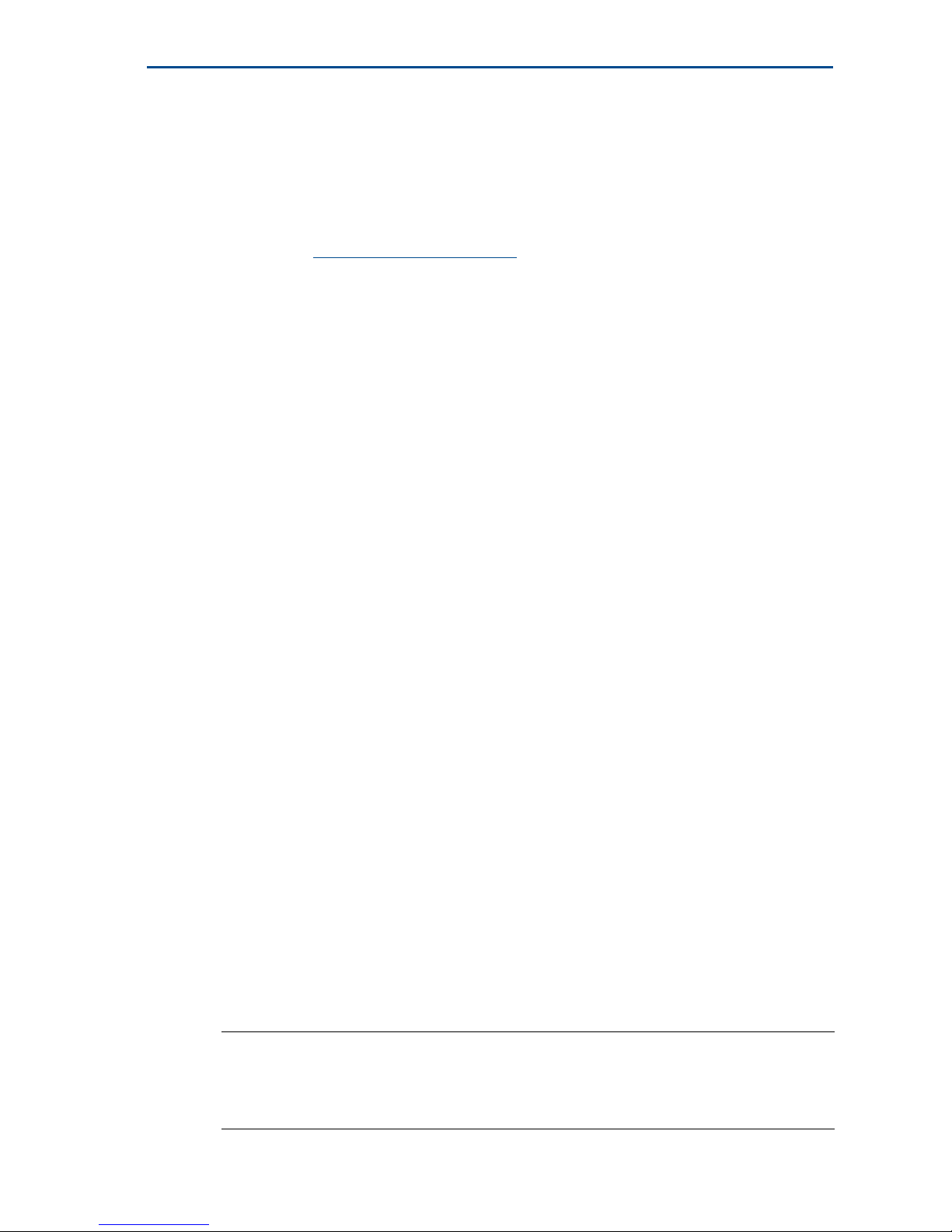

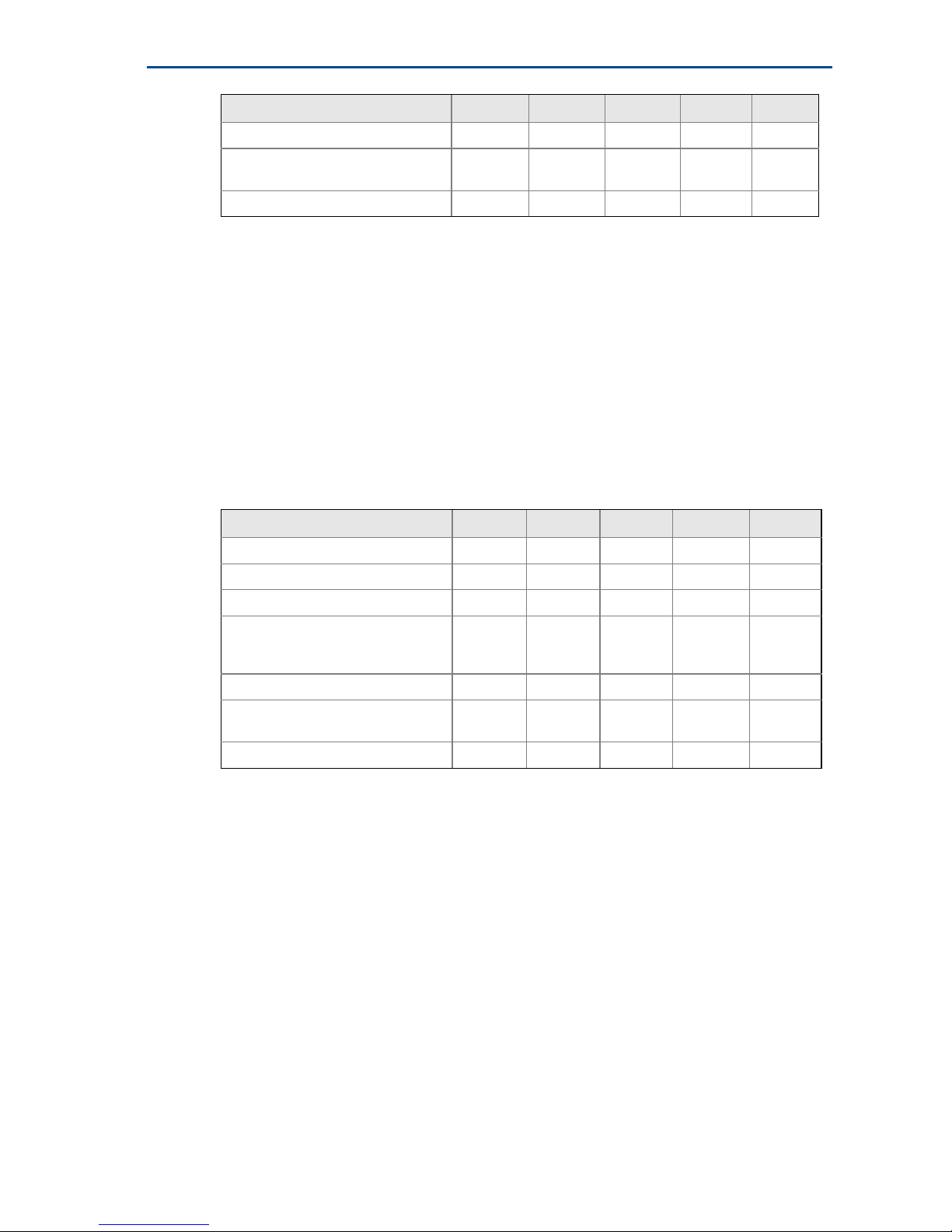

Table 1. Torque Values for the Flange and Flange Adaptor Bolts

Bolt material Head markings Initial torque Final torque

March 2018

Carbon Steel (CS) 300 in-lb 650 in-lb

Stainless Steel

(SST)

1.5 O-rings with flange adaptors

Failure to install proper flange adaptor O-rings may cause process leaks, which can result in death or

serious injury. The two flange adaptors are distinguished by unique O-ring grooves. Only use the

O-ring that is designed for its specific flange adaptor, as shown below:

B7M

150 in-lb 300 in-lb

A. Flange adaptor

B. O-ring

C. PTFE based (profile is square)

D. Elastomer (profile is round)

Whenever the flanges or adaptors are removed, visually inspect the O-rings. Replace them if there

are any signs of damage, such as nicks or cuts. If you replace the O-rings, re-torque the flange bolts

and alignment screws after installation to compensate for seating of the PTFE O-ring.

6

March 2018

1.6 In-line gage transmitter orientation

The low side pressure port (atmospheric reference) on the in-line gage

transmitter is located under the sensor module neck label. (See Figure 3.)

Keep the vent path free of any obstruction, including but not limited to paint,

dust, and lubrication by mounting the transmitter so that any contaminants

can drain away.

Figure 3. In-line Gage Transmitter

A

A. Low side pressure port (under neck label)

Quick Start Guide

2.0 Tagging

2.1 Commissioning (paper) tag

To identify which device is at a particular location, use the removable tag

provided with the transmitter. Ensure the physical device tag (PD Tag field) is

properly entered in both places on the commissioning tag. Tear off the

bottom portion of the tag and write “physical tag” on this portion. This can

now be given to the person who can associate the device ID to the desired

tag.

Figure 4. Commissioning Tag

Foundation Fieldbus revision ITK5

(default option)

COMMISSIONING TAG

Device ID:

0011513051010001440-121698091725

PD Tag:

PT- 101

Revision: 23

Support files available at

Emerson.com/Rosemount

Tear H ere

Revision: 23

Support files available at

Emerson.com/Rosemount

Device Serial Number:

XXXXXXXXXX

Device ID:

0011513051010001440-121698091725

PD Tag:

PT-101

Foundation Fieldbus revision ITK6

(option code IT6)

COMMISSIONING TAG

Device ID:

001151AA00010001440-121698091725

PD Tag:

PT- 101

Revision: 24

Support files available at

Emerson.com/Rosemount

Revision: 24

Support files available at

Emerson.com/Rosemount

Device Serial Number:

XXXXXXXXXX

Device ID:

001151AA00010001440-121698091725

PD Tag:

PT-101

Tear H ere

7

Quick Start Guide

A

Note

The device description loaded in the host system must be at the same revision as this

device. The device description can be downloaded from Emerson.com/Rosemount

Fieldbus.org.

3.0 Consider housing rotation

To improve field access to wiring or to better view the optional LCD display:

1. Loosen the housing rotation set screw.

2. First, rotate the housing clockwise to the desired location. If the desired

location cannot be achieved due to thread limit, rotate the housing

counter clockwise to the desired location (up to 360° from thread limit).

3. Retighten the housing rotation set screw.

Figure 5. Transmitter Housing Set Screw

PlantWeb

March 2018

or

A. Housing rotation set screw (3/32-in.)

4.0 Connect wiring and power up

4.1 Cable connection

The segment cable can enter the transmitter through either conduit

connection on the housing. Cable entering the housing vertically should be

avoided. Drip loops are recommended for installations where moisture can

accumulate and enter the terminal compartment.

4.2 Power supply

The transmitter requires between 9 and 32 Vdc (9 and 17.5 Vdc for FISCO) at

the terminals to operate and provide complete functionality.

4.3 Power conditioner

A Fieldbus segment requires a power conditioner to isolate the power supply

filter and decouple the segment from other segments attached to the same

power supply.

8

March 2018

FIELDBUS WIRING

DP

B

D

A

C

Minimize distance

4.4 Signal termination

Every Fieldbus segment requires terminators at each end of the segment.

Failure to properly terminate segments may cause communication errors with

devices on the segment.

4.5 Transient protection

Transient protection devices require the transmitter be grounded for proper

operation. Refer to Grounding for further information.

4.6 Grounding

Grounding terminations are provided on the sensor module and inside the

terminal compartment. These grounds are used when transient protect

terminal blocks are installed or to fulfill local regulations.

1. Remove the FIELD TERMINALS housing cover.

2. Connect the wiring pair and ground as indicated in Figure 6.

a. The terminals are not polarity sensitive.

b. The cable shield should be:

Trimmed close and insulated from touching the transmitter housing

Continuously connected to the termination point

Connected to a good earth ground at the power supply end

Quick Start Guide

Figure 6. Wiring

A. Connect shield back to power supply ground C. Ground for transient protection

B. Trim shield and insulate D. Insulate shield

3. Replace the housing cover. It is recommended the cover be tightened until

there is no gap between the cover and the housing.

4. Plug and seal unused conduit connections.

NOTICE

The enclosed pipe plug must be installed in unused conduit open ing wit h a minimum of five thr ead

engagement to comply with explosion-proof requirements. Refer to the Rosemount 3051S

OUNDATION Fieldbus Reference Manual for more information. This manual is also available

F

electronically on Emerson.com/Rosemount

.

9

Quick Start Guide

5.0 Verify configuration

Use the following block examples to do basic configuration to the transmitter.

For more advanced configurations see the Rosemount 3051S FOUNDATION

Fieldbus Reference Manual

Note

DeltaV™ users should use DeltaV Explorer for the resource and transducer blocks and

Control Studio for the function blocks.

5.1 To configure the AI block

AI block configuration parameters

Use the Pressure, DP Flow, and DP Level examples for guides.

Parameters Enter data

Channel 1 = Pressure or 2 = Sensor temp

.

March 2018

L_Type Direct, indirect, or square root

XD_Scale Scale and engineering units

Pa bar inH2O @ 68 °F cmH2O @ 4 °C

kPa mbar mmH2O @ 68 °F ftH2O

MPa atm ftH2O @ 68 °F inH2O

(1)

hPa

psi °C ftH2O @ 60 °F

torr °F ftH2O @ 4 °C

Out_Scale Scale and engineering units

1. Only available with option IT6.

psf

(1)

inH2O @ 60 °F

(1)

inHg @ 0 °C

(1)

(1)

(1)

(1)

(1)

g/cm

kg/m2

kg/cm

2

(1)

2

mmHg @ 0 °C

mmH2O @ 4 °C

inH2O @ 4 °C

mHg @ 0 °C

cmHg @ 0 °C

mH2O @ 4 °C

(1)

(1)

(1)

10

March 2018

Quick Start Guide

Pressure example

Parameters Enter data

Channel 1

L_Type Direct

XD_Scale See list of supported engineering units.

Out_Scale Set values outside operating range.

DP Flow example

Parameters Enter data

Channel 1

L_Type Square root

XD_Scale 0–100 inH2O @ 68 °F

Out_Scale 0–20 GPM

DP Level example

Parameters Enter data

Channel 1

L_Type Indirect

XD_Scale 0–300 inH2O @ 68 °F

Out_Scale 0–25 ft

To display pressure on the LCD meter

Parameters Enter data

Display parameter 1

Block type #1 Sensor transducer block

Block tag Tra ns du cer

Param index Primary variable

Units type Auto

With option code IT6, select the “Pressure” check box on the display

configuration screen.

Note

To display level or flow, use AI block out.

11

Quick Start Guide

6.0 Trim the transmitter

Note

Transmitters are shipped fully calibrated per request or by the factory default of full

scale (span = upper range limit).

6.1 Zero trim

A zero trim is a single-point adjustment used for compensating mounting

position and line pressure effects. When performing a zero trim, ensure the

equalizing valve is open and all wet legs are filled to the correct level.

The transmitter will only allow three to five percent URL zero error to be

trimmed. For greater zero errors, compensate for the offset by using the

XD_Scaling, Out_Scaling and Indirect L_Type which are part of the AI block.

Using the host system

Perform a zero trim method if the host system supports methods associated

with the Transducer 1100 block. Otherwise, if the host system does not

support methods, see Rosemount 3051S FOUNDATION Fieldbus Reference

Manual.

March 2018

12

March 2018

7.0 Product Certifications

Rev 1.15

7.1 European Directive Information

A copy of the EU Declaration of Conformity can be found at the end of the Quick

Start Guide. The most recent revision of the EU Declaration of Conformity can

be found at Emerson.com/Rosemount

7.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine that

the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited by

the Federal Occupational Safety and Health Administration (OSHA).

7.3 Installing Equipment in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code (CEC)

permit the use of Division marked equipment in Zones and Zone marked

equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined in

the respective codes.

.

Quick Start Guide

7.4 USA

E5 FM Explosionproof (XP) and Dust-Ignitionproof (DIP)

Certificate: FM16US0090

Standards: FM Class 3600 – 2011, FM Class 3615 – 2006, FM Class 3616 – 2011,

FM Class 3810 – 2005, ANSI/NEMA

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II, DIV 1, GP E, F, G; CL III;

T5(–50 °C ≤ T

I5 FM Intrinsic Safety (IS) and Nonincendive (NI)

Certificate: FM16US0089X

Standards: FM Class 3600 – 2011, FM Class 3610 – 2010, FM Class 3611 – 2004,

FM Class 3810 – 2005, NEMA 250 – 2003

Markings: IS CL I, DIV 1, GP A, B, C, D; CL II, DIV 1, GP E, F, G; Class III; Class 1,

Zone 0 AEx ia IIC T4; NI CL 1, DIV 2, GP A, B, C, D;

T4(–50 °C ≤ T

when connected per Rosemount drawing 03151-1006; Type 4X

Special Condition for Safe Use:

1. The Rosemount 3051S/3051S-ERS Pressure Transmitter contains aluminum and is

considered to constitute a potential risk of ignition by impact or friction. Care must be

taken into account during installation and use to prevent impact and friction.

≤ +85 °C); Factory Sealed; Type 4X

a

≤ +70 °C) [HART]; T4(–50 °C ≤ Ta ≤ +60 °C) [Fieldbus];

a

®

250 – 2003

Note

Transmitters marked with NI CL 1, DIV 2 can be installed in Division 2 locations using

general Division 2 wiring methods or Nonincendive Field Wiring (NIFW). See Drawing

03151-1006.

13

Quick Start Guide

IE FM FISCO

Certificate: FM16US0089X

Standards: FM Class 3600 – 2011, FM Class 3610 – 2010, FM Class 3611 – 2004,

FM Class 3810 – 2005, NEMA 250 – 2003

Markings: IS CL I, DIV 1, GP A, B, C, D; T4(–50 °C ≤ T

per Rosemount drawing 03151-1006; Type 4X

Special Condition for Safe Use:

1. The Rosemount 3051S/3051S-ERS Pressure Transmitter contains aluminum and is

considered to constitute a potential risk of ignition by impact or friction. Care must

be taken into account during installation and use to prevent impact and friction.

7.5 Canada

E6 CSA Explosionproof, Dust-Ignitionproof, and Division 2

Certificate: 1143113

Standards: CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 25-1966,

CSA Std C22.2 No. 30-M1986, CAN/CSA C22.2 No. 94-M91,

CSA Std C22.2 No. 142-M1987, CSA Std C22.2 No. 213-M1987, ANSI/ISA

12.27.01-2003, CSA Std C22.2 No. 60529:05

Markings: Explosionproof Class I, Division 1, Groups B, C, D; Dust-Ignitionproof Class II,

Division 1, Groups E, F, G; Class III; suitable for Class I, Zone 1, Group IIB+H2,

T5; suitable for Class I, Division 2, Groups A, B, C, D; suitable for Class I, Zone

2, Group IIC, T5; when connected per Rosemount drawing 03151-1013;

Type 4X

≤ +60 °C); when connected

a

March 2018

I6 CSA Intrinsically Safe

Certificate: 1143113

Standards: CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 30-M1986,

CAN/CSA C22.2 No. 94-M91, CSA Std C22.2 No. 142-M1987,

CSA Std C22.2 No. 157-92, ANSI/ISA 12.27.01-2003,

CSA Std C22.2 No. 60529:05

Markings: Intrinsically Safe Class I, Division 1; Groups A, B, C, D; suitable for

Class 1, Zone 0, IIC, T3C; when connected per Rosemount drawing

03151-1016 [3051S] 03151-1313 [ERS]; Type 4X

IF CSA FISCO

Certificate: 1143113

Standards: CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 30-M1986,

CAN/CSA C22.2 No. 94-M91, CSA Std C22.2 No. 142-M1987,

CSA Std C22.2 No. 157-92, ANSI/ISA 12.27.01-2003,

CSA Std C22.2 No. 60529:05

Markings: FISCO Intrinsically Safe Class I, Division 1; Groups A, B, C, D; suitable for Class

1, Zone 0, IIC, T3C; when connected per Rosemount drawing 03151-1016

[3051S] 03151-1313 [ERS]; Type 4X

14

March 2018

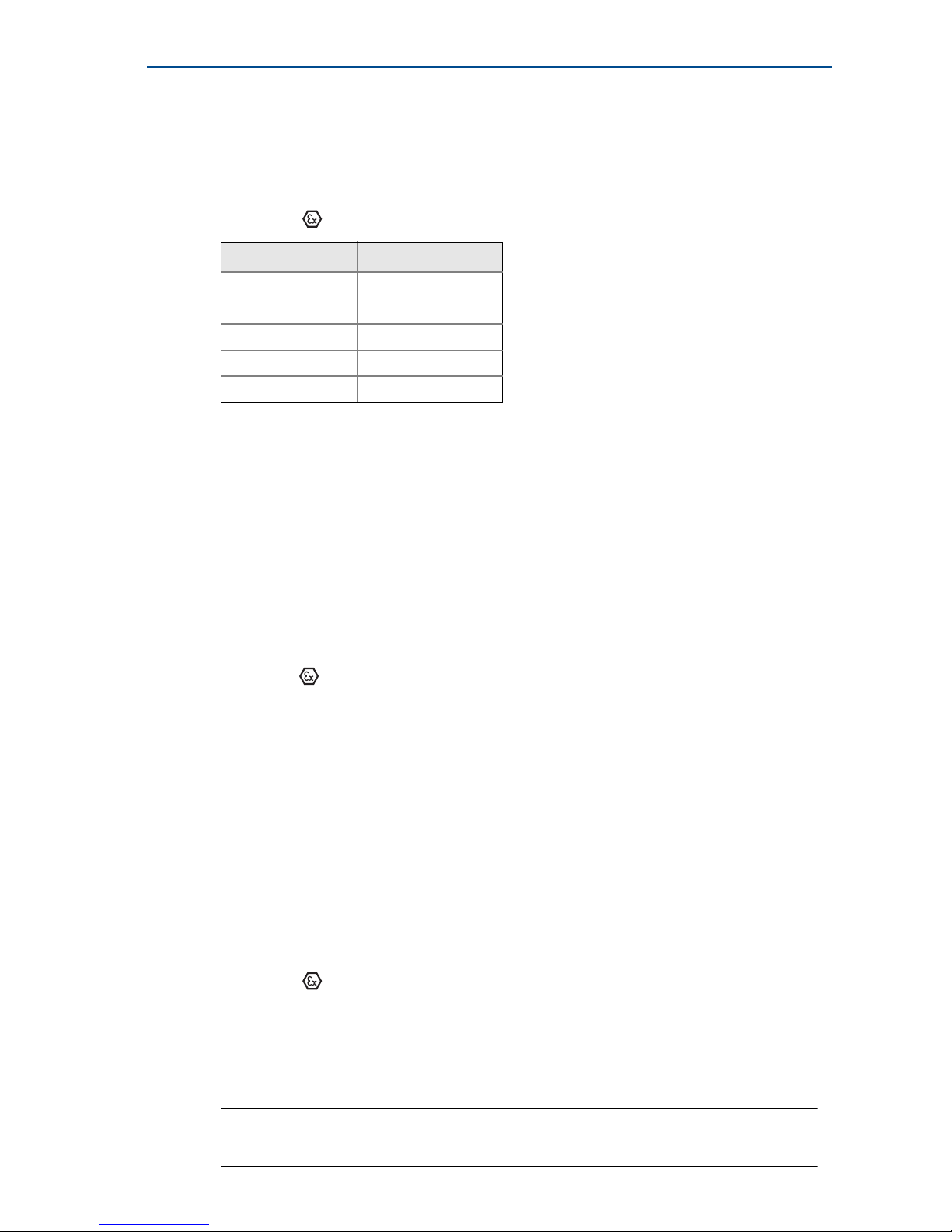

7.6 Europe

E1 ATEX Flameproof

Certificate: KEMA 00ATEX2143X

Standards: EN 60079-0:2012+A11:2013, EN 60079-1:2014, EN 60079-26:2015

Markings: II 1/2 G Ex d IIC T6…T4 Ga/Gb, T6(–60 °C ≤ T

Temperature class Process temperature

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm less than 1 mm thickness that forms a

boundary between EPL Ga (process connection) and EPL Gb (all other parts of the

equipment). The model code and data sheet are to be consulted for details of the

diaphragm material. Installation, maintenance and use shall take into account the

environmental conditions to which the diaphragm will be subjected. The

manufacturer's instructions for installation and maintenance shall be followed in

detail to assure safety during its expected lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic discharge. Avoid

installations that could cause electrostatic build-up on painted surfaces, and only

clean the painted surfaces with a damp cloth. If paint is ordered through a special

option code, contact the manufacturer for more information.

4. Appropriate cable, glands and plugs need to be suitable for a temperature of 5 °C

greater than maximum specified temperature for location where installed.

T5/T4(–60 °C ≤ T

T6 –60 °C to +70 °C

T5 –60 °C to +80 °C

T4 –60 °C to +120 °C

≤ +80 °C)

a

≤ +70 °C),

a

Quick Start Guide

I1 ATE X Intrinsic Safet y

Certificate: BAS01ATEX1303X

Standards: EN 60079-0: 2012+A11:2013, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T4 Ga, T4(–60 °C ≤ T

Model U

SuperModule

3051S...A; 3051SF…A; 3051SAL…C 30 V 300 mA 1.0 W 12 nF 0

3051S…F; 3051SF…F 30 V 300 mA 1.3 W 0 0

3051S …A…M7, M8, or M9;

3051SF …A…M7, M8, or M9;

3051SAL…C… M7, M8, or M9

3051SAL or 3051SAM 30 V 300 mA 1.0 W 12 nF 33 μH

3051SAL…M7, M8, or M9

3051SAM…M7, M8, or M9

RTD Option for 3051SF 5 V 500 mA 0.63 W N/A N/A

™

i

30 V 300 mA 1.0 W 30 nF 0

30 V 300 mA 1.0 W 12 nF 60 μH

30 V 300 mA 1.0 W 12 nF 93 μH

≤ +70 °C)

a

I

i

P

i

C

i

Special Conditions for Safe Use (X):

1. The Model 3051S Transmitters fitted with transient protection are not capable of

withstanding the 500V test as defined in Clause 6.3.13 of EN 60079-11:2012. This

must be taken into account during installation.

2. The terminal pins of the Model 3051S SuperModule must be provided with a degree

of protection of at least IP20 in accordance with IEC/EN 60529.

L

i

15

Quick Start Guide

3. The Model 3051S enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it from impact

or abrasion if located in a zone 0 area.

IA ATEX FISCO

Certificate: BAS01ATEX1303X

Standards: EN 60079-0: 2012+A11:2013, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T4 Ga, T4(–60 °C ≤ T

≤ +70 °C)

a

March 2018

Parameter

Voltage U

Current I

Power P

Capacitance C

Inductance L

i

i

i

i

i

FISCO

17.5 V

380 mA

5.32 W

0

0

Special Conditions for Safe Use (X):

1. The Model 3051S Transmitters fitted with transient protection are not capable of

withstanding the 500V test as defined in Clause 6.3.13 of EN 60079-11:2012. This

must be taken into account during installation.

2. The terminal pins of the Model 3051S SuperModule must be provided with a degree

of protection of at least IP20 in accordance with IEC/EN 60529.

3. The Model 3051S enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it from impact

or abrasion if located in a zone 0 area.

ND ATEX Dust

Certificate: BAS01ATEX1374X

Standards: EN 60079-0: 2012+A11:2013, EN 60079-31: 2009

Markings: II 1 D Ex ta IIIC T105 °C T

V

= 42.4 V

max

95 °C Da, (–20 °C ≤ Ta ≤ +85 °C),

500

Special Conditions for Safe Use (X):

1. Cable entries must be used which maintain the ingress protection of the enclosure

to at least IP66.

2. Unused cable entries must be filled with suitable blanking plugs which maintain the

ingress protection of the enclosure to at least IP66.

3. Cable entries and blanking plugs must be suitable for the ambient temperature

range of the apparatus and capable of withstanding a 7 J impact test.

4. The SuperModule(s) must be securely screwed in place to maintain the ingress

protection of the enclosure(s).

N1 ATEX Type n

Certificate: BAS01ATEX3304X

Standards: EN 60079-0: 2012+A11:2013, EN 60079-15: 2010

Markings: II 3 G Ex nA IIC T5 Gc, (–40 °C ≤ T

Special Condition for Safe Use (X):

1. The equipment is not capable of withstanding the 500 V insulation test required by

clause 6.5 of EN 60079-15:2010. This must be taken into account when installing

the equipment.

Note

RTD Assembly is not included with the Rosemount 3051SFx Type n Approval.

16

≤ +85 °C), V

a

max

= 45 V

March 2018

7.7 International

E7 IECEx Flameproof and Dust

Certificate: IECEx KEM 08.0010X (Flameproof)

Standards: IEC 60079-0:2011, IEC 60079-1:2014, IEC 60079-26:2014

Markings: Ex db IIC T6…T4 Ga/Gb, T6(–60 °C ≤ T

Temperature class Process temperature

T6 –60 °C to +70 °C

T5 –60 °C to +80 °C

T4 –60 °C to +120 °C

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm less than 1 mm thickness that forms a

boundary between EPL Ga (process connection) and EPL Gb (all other parts of the

equipment). The model code and data sheet are to be consulted for details of the

diaphragm material. Installation, maintenance and use shall take into account the

environmental conditions to which the diaphragm will be subjected. The

manufacturer's instructions for installation and maintenance shall be followed in

detail to assure safety during its expected lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic discharge. Avoid

installations that could cause electrostatic build-up on painted surfaces, and only

clean the painted surfaces with a damp cloth. If paint is ordered through a special

option code, contact the manufacturer for more information.

4. Appropriate cable, glands and plugs need to be suitable for a temperature of 5 °C

greater than maximum specified temperature for location where installed.

Quick Start Guide

≤ +70 °C), T5/T4(–60 °C ≤ Ta ≤ +80 °C)

a

Certificate: IECEx BAS 09.0014X (Dust)

Standards: IEC 60079-0:2011, IEC 60079-31:2008

Markings: Ex ta IIIC T 105 °C T

95 °C Da, (–20 °C ≤ Ta ≤ +85 °C), V

500

max

= 42.4 V

Special Conditions for Safe Use (X):

1. Cable entries must be used which maintain the ingress protection of the enclosure

to at least IP66.

2. Unused cable entries must be filled with suitable blanking plugs which maintain the

ingress protection of the enclosure to at least IP66.

3. Cable entries and blanking plugs must be suitable for the ambient temperature

range of the apparatus and capable of withstanding a 7 J impact test.

4. The Rosemount 3051S SuperModule must be securely screwed in place to maintain

the ingress protection of the enclosure.

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 04.0017X

Standards: IEC 60079-0: 2011, IEC 60079-11:2011

Markings: Ex ia IIC T4 Ga, T4(–60 °C ≤ T

Model U

SuperModule 30 V 300 mA 1.0 W 30 nF 0

3051S...A; 3051SF…A; 3051SAL…C 30 V 300 mA 1.0 W 12 nF 0

3051S…F; 3051SF…F 30 V 300 mA 1.3 W 0 0

3051S …A…M7, M8, or M9;

3051SF …A…M7, M8, or M9;

3051SAL…C… M7, M8, or M9

≤ +70 °C)

a

i

30 V 300 mA 1.0 W 12 nF 60 μH

I

i

P

i

C

i

L

i

17

Quick Start Guide

March 2018

Model U

3051SAL or 3051SAM 30 V 300 mA 1.0 W 12 nF 33 μH

3051SAL…M7, M8, or M9

3051SAM…M7, M8, or M9

RTD Option for 3051SF 5 V 500 mA 0.63 W N/A N/A

i

30 V 300 mA 1.0 W 12 nF 93 μH

I

i

P

i

C

i

Special Conditions for Safe Use (X):

1. The Model 3051S Transmitters fitted with transient protection are not capable of

withstanding the 500V test as defined in Clause 6.3.13 of EN 60079-11:2012. This

must be taken into account during installation.

2. The terminal pins of the Model 3051S SuperModule must be provided with a degree

of protection of at least IP20 in accordance with IEC/EN 60529.

3. The Model 3051S enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it from impact or

abrasion if located in a zone 0 area.

I7 IECEx Intrinsic Safety – Group I - Mining (I7 with Special A0259)

Certificate: IECEx TSA 14.0019X

Standards: IEC 60079-0:2011, IEC 60079-11:2011

Markings: Ex ia I Ma (–60 °C ≤ T

Model U

SuperModule 30 V 300 mA 1.0 W 30 nF 0

3051S...A; 3051SF…A; 3051SAL…C 30 V 300 mA 1.0 W 12 nF 0

3051S…F; 3051SF…F 30 V 300 mA 1.3 W 0 0

3051S …A…M7, M8, or M9;

3051SF …A…M7, M8, or M9;

3051SAL…C… M7, M8, or M9

3051SAL or 3051SAM 30 V 300 mA 1.0 W 12 nF 33 μH

3051SAL…M7, M8, or M9

3051SAM…M7, M8, or M9

RTD Option for 3051SF 5 V 500 mA 0.63 W N/A N/A

≤ +70 °C)

a

i

30 V 300 mA 1.0 W 12 nF 60 μH

30 V 300 mA 1.0 W 12 nF 93 μH

I

i

P

i

C

i

L

i

L

i

Special Conditions for Safe Use (X):

1. If the apparatus is fitted with optional 90 V transient suppressor, it is not capable of

withstanding the 500 V insulation test required by Clause 6.3.13 of

IEC60079-11:2011. This must be taken into account when installing the apparatus.

2. It is a condition of safe use that the above input parameters shall be taken into

account during installation.

3. It is a condition of manufacture that only the apparatus fitted with housing, covers

and sensor module housing made out of stainless steel are used in Group I

applications.

IG IECEx FISCO

Certificate: IECEx BAS 04.0017X

Standards: IEC 60079-0:2011, IEC 60079-11:2011

Markings: Ex ia IIC T4 Ga, T4(–60 °C ≤ T

18

≤ +70 °C)

a

March 2018

Quick Start Guide

Parameter

Volta ge U

Current I

Power P

Capacitance C

Inductance L

i

i

i

i

i

FISCO

17.5 V

380 mA

5.32 W

0

0

Special Conditions for Safe Use (X):

1. The Model 3051S Transmitters fitted with transient protection are not capable of

withstanding the 500V test as defined in Clause 6.3.13 of EN 60079-11:2012. This

must be taken into account during installation.

2. The terminal pins of the Model 3051S SuperModule must be provided with a degree of

protection of at least IP20 in accordance with IEC/EN 60529.

3. The Model 3051S enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it from impact or

abrasion if located in a zone 0 area.

IG IECEx Intrinsic Safety – Group I - Mining (IG with Special A0259)

Certificate: IECEx TSA 14.0019X

Standards: IEC 60079-0:2011, IEC 60079-11:2011

Markings: FISCO FIELD DEVICE Ex ia I Ma (–60 °C ≤ T

≤ +70 °C)

a

Parameter

Volta ge U

Current I

Power P

Capacitance C

Inductance L

i

i

i

i

i

FISCO

17.5 V

380 mA

5.32 W

0

0

Special Conditions for Safe Use (X):

1. If the apparatus is fitted with optional 90 V transient suppressor, it is not capable of

withstanding the 500 V insulation test required by Clause 6.3.13 of

IEC60079-11:2011. This must be taken into account when installing the apparatus.

2. It is a condition of safe use that the above input parameters shall be taken into account

during installation.

3. It is a condition of manufacture that only the apparatus fitted with housing, covers and

sensor module housing made out of stainless steel are used in Group I applications.

N7 IECEx Type n

Certificate: IECEx BAS 04.0018X

Standards: IEC 60079-0:2011, IEC 60079-15:2010

Markings: Ex nA IIC T5 Gc, (–40 °C ≤ T

≤ +85 °C)

a

Special Condition for Safe Use (X):

1. The equipment is not capable of withstanding the 500 V insulation test required by

clause 6.5 of EN 60079-15:2010. This must be taken into account when installing the

equipment.

19

Quick Start Guide

7.8 Brazil

E2 INMETRO Flameproof

Certificate: UL-BR15.0393X

Standards: ABNT NBR IEC 60079-0:2008 + Corrigendum 1:2011,

ABNT NBR IEC 60079-1:2009 + Corrigendum 1:2011,

ABNT NBR IEC 60079-26:2008 + Corrigendum 1:2008

Markings: Ex d IIC T* Ga/Gb, T6(–60 °C ≤ T

IP66

Special Conditions for Safe Use (X):

1. The device contains a thin wall diaphragm. Installation, maintenance and use shall

take into account the environmental conditions to which the diaphragm will be

subjected. The manufacturer's instructions for installation and maintenance shall be

followed in detail to assure safety during its expected lifetime.

2. For information on the dimensions of the flameproof joints, the manufacturer shall

be contacted.

I2/IB INMETRO Intrinsic Safety/FISCO

Certificate: UL-BR 15.0392X

Standards: ABNT NBR IEC 60079-0:2008 + Errata 1:2011, ABNT NBR IEC 60079-11:2009

Markings: Ex ia IIC T4 Ga (–60 °C ≤ T

Special Condition for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1 GÙ. To avoid electrostatic

charge build-up, it must not be rubbed or cleaned with solvents or a dry cloth.

2. The Model 701PBKKF Power Module may be replaced in a hazardous area. The

Power Module has a surface resistivity greater than 1 GÙ and must be properly

installed in the wireless device enclosure. Care must be taken during transportation

to and from the point of installation to prevent electrostatic charge build-up.

3. The 3051S enclosure may be made of aluminium alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it from impact

or abrasion if located in areas that requires EPL Ga.

≤ +70 °C), T5/T4(–60 °C ≤ Ta ≤ +80 °C),

a

≤ +70 °C), IP66

a

March 2018

Model U

SuperModule 30 V 300 mA 1.0 W 30 nF 0

3051S...A; 3051SF…A; 3051SAL…C 30 V 300 mA 1.0 W 12 nF 0

3051S…F; 3051SF…F 30 V 300 mA 1.3 W 0 0

3051S…F…IB; 3051SF…F…IB 17.5V 380 mA 5.32 W 0 0

3051S …A…M7, M8, or M9;

3051SF …A…M7, M8, or M9;

3051SAL…C… M7, M8, or M9

3051SAL or 3051SAM 30 V 300 mA 1.0 W 12 nF 33 μH

3051SAL…M7, M8, or M9

3051SAM…M7, M8, or M9

RTD Option for 3051SF 5 V 500 mA 0.63 W N/A N/A

7.9 China

E3 China Flameproof and Dust Ignition-proof

Certificate: 3051S: GYJ16.1249X

3051SFx: GYJ16.1466X

3051S-ERS: GJY15.1406X

20

i

30 V 300 mA 1.0 W 12 nF 60 μH

30 V 300 mA 1.0 W 12 nF 93 μH

I

i

P

i

C

i

L

i

March 2018

Quick Start Guide

Standards: 3051S: GB3836.1-2010, GB3836.2-2010, GB3836.20-2010,

GB12476.1-2013, GB12476.5-2013

3051SFx: GB3836.1-2010, GB3836.2-2010, GB3836.20-2010,

GB12476.1-2013, GB 12476.5-2013

Markings: 3051S: Ex d IIC T6…T4; Ex tD A20 T 105 °C T

3051SFx: Ex d IIC T5/T6 Ga/Gb; DIP A20 T

95 °C; IP66

500

105 °C; IP66

A

3051S-ERS: Ex d IIC T4 ~ T6 Ga/Gb

Special Conditions for Safe Use (X):

1. Only the pressure transmitters, consisting of Rosemount 3051SC Series, 3051ST

Series, 3051SL Series and 300S Series, are certified.

2. Flameproof joints are not intended for repair.

3. The ambient temperature range for the 3051S and 3051SFx in a dust environment is

(

–20 °C ≤ Ta ≤ 85 °C).

4. The relation between temperature class and maximum temperature of process

medium is as follows:

Table 2. Rosemount 3051S

Temperature class Ambient temperature (°C) Process temperature (°C)

T6 –60 °C ≤ Ta ≤ +70 °C –60 °C ≤ Ta ≤ +70 °C

T5 –60 °C ≤ Ta ≤ +80 °C –60 °C ≤ Ta ≤ +80 °C

T4 –60 °C ≤ Ta ≤ +80 °C –60 °C ≤ Ta ≤ +120 °C

5. The earth connection facility in the enclosure should be connected reliably.

6. During installation, use and maintenance of transmitter, observe the warning

“Don’t open the cover when the circuit is alive”.

7. During installation, there should be no mixture harm to flameproof housing.

8. Cable entry, certified by NEPSI with type of protection Ex d IIC in accordance with

GB3836.1-2000 and GB3836.2-2000, should be applied when installation in

hazardous location. Five full threads should be in engagement when the cable entry

is assembled onto the transmitter. When pressure transmitter is used in the

presence of combustible dust, the ingress of protection of the cable entry should be

IP66.

9. The diameter of cable should observe the instruction manual of cable entry. The

compressing nut should be fastened. The aging of seal ring should be changed in

time.

10. Maintenance should be done in non-hazardous location.

11. End users are not permitted to change any components inside.

12. When installation, use and maintenance of transmitter, observe following

standards:

GB3836.13-1997 “Electrical apparatus for explosive gas atmospheres Part 13:Repair

and overhaul for apparatus used in explosive gas atmospheres”

GB3836.15-2000 “Electrical apparatus for explosive gas atmospheres Part 15:

Electrical installations in hazardous area (other than mines)”

GB50257-1996 “Code for construction and acceptance of electric device for

explosion atmospheres and fire hazard electrical equipment installation

engineering”

GB15577-1995 “Safe regulation for explosive dust atmospheres”

GB12476.2-2006 “Electrical apparatus for use in the presence of combustible dust –

Part 1-2: Electrical apparatus protected by enclosures and surface temperature

limitation – Selection, installation and maintenance”

21

Quick Start Guide

I3 China Intrinsic Safety

Certificate: 3051S: GYJ16.1250X [Mfg USA, China, Singapore]

Standards: 3051S: GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

Markings: 3051S, 3051SFx: Ex ia IIC T4 Ga

Special Conditions for Safe Use (X):

1. Symbol “X” is used to denote specific conditions of use:

For output code A and F: This apparatus is not capable of withstanding the 500V r.m.s.

insulation test required by Clause 6.4.12 of GB3836.4-2000.

2. The ambient temperature range is:

March 2018

3051SFx: GYJ11.1707X [Mfg USA, China, Singapore]

3051S-ERS: GYJ16.1248X [Mfg USA, China, Singapore]

3051SFx: GB3836.1/4-2010, GB3836.20-2010, GB12476.1-2013,

GB12476.5-2013 3051S-ERS: GB3836.1-2010, GB3836.4-2010,

GB3836.20-2010

3051S-ERS: Ex ia IIC T4

Output code Ambient temperature

A –50 °C ≤ Ta ≤ +70 °C

F –50 °C ≤ Ta ≤ +60 °C

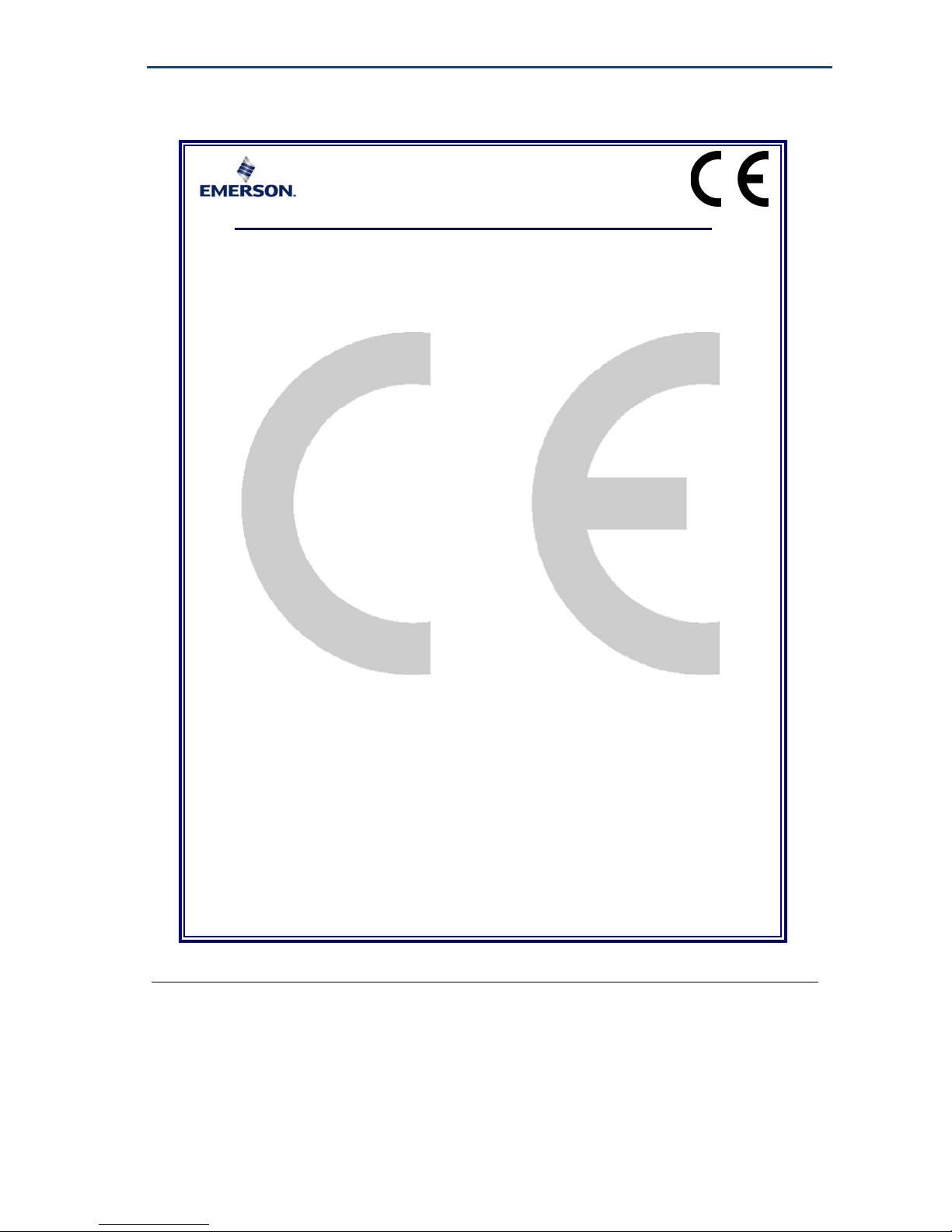

3. Intrinsically safe parameters:

Maximum

Output

FISCO

Housing

code

code

A =00 / 30 300 1 38 0

A ≠00 / 30 300 1 11.4 2.4

A ≠00 M7/M8/M9 30 300 1 0 58.2

F ≠00 / 30 300 1.3 0 0

F

≠00 / 17.5 500 5.5 0 0

Display

code

input

vol tag e:

(V)

U

i

Maximum

input

current:

(mA)

I

i

Maximum

input

power:

(W)

P

i

Maximum

internal

parameter:

(nF)

C

i

Maximum

internal

parameter:

(uH)

L

i

4. The product should be used with Ex-certified associated apparatus to establish

explosion protection system that can be used in explosive gas atmospheres. Wiring

and terminals should comply with the instruction manual of the product and

associated apparatus.

5. The cable between this product and associated apparatus should be shielded cables

(the cables must have insulated shield). The shield has to be grounded reliably in

non-hazardous area.

6. The product complies to the requirements for FISCO field devices specified in

IEC60079-27:2008. For the connection of an intrinsically safe circuit in accordance

FISCO model, FISCO parameters of this product are as above.

7. End users are not permitted to change any components inside, but to settle the

problem in conjunction with manufacturer to avoid damage to the product.

8. When installation, use and maintenance of this product, observe the following

standards:

GB3836.13-1997 “Electrical apparatus for explosive gas atmospheres Part 13: Repair

and overhaul for apparatus used in explosive gas atmospheres”

22

March 2018

GB3836.15-2000 “Electrical apparatus for explosive gas atmospheres Part 15:

Electrical installations in hazardous area (other than mines)”

GB3836.16-2006 “Electrical apparatus for explosive gas atmospheres Part 16:

Inspection and maintenance of electrical installation (other than mines)”

GB50257-1996 “Code for construction and acceptance of electric device for

explosion atmospheres and fire hazard electrical equipment installation

engineering”

N3 China Type n

Certificate: 3051S: GYJ17.1354X

3051SFX: GYJ17.1355X

Markings: Ex nL IIC T5 Gc

Special Conditions for Safe Use (X):

1. When transient protection board is chosen (Option Code T1), this apparatus is not

capable of withstanding the 500V r.m.s insulation test, this must be taken into

account when installing the component.

7.10 EAC – Belarus, Kazakhstan, Russia

EM Technical Regulation Customs Union (EAC) Flameproof

Certificate: RU C-US.AA87.B.00378

Markings: Ga/Gb Ex d IIC T6…T4 X

Ex tb IIIC T105 °C T

Ex ta IIIC T105 °C T

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate: RU C-US.AA87.B.00094

Markings: 0Ex ia IIC T4 Ga X

95 °C Db X

500

95 °C Da X

500

Quick Start Guide

7.11 Japan

E4 Japan Flameproof

Certificate: TC15682, TC15683, TC15684, TC15685, TC15686, TC15687, TC15688,

TC15689, TC15690, TC17099, TC17100, TC17101, TC17102, TC18876

3051ERS: TC20215, TC20216, TC20217, TC20218, TC20219, TC20220,

TC20221

Markings: Ex d IIC T6

7.12 Republic of Korea

EP Republic of Korea Flameproof

Certificate: 12-KB4BO-0180X [Mfg USA], 11-KB4BO-0068X [Mfg Singapore]

Markings: Ex d IIC T6…T4

IP Republic of Korea Intrinsic Safety

Certificate: 12-KB4BO-0202X [HART – Mfg USA],

12-KB4BO-0204X [Fieldbus – Mfg USA],

12-KB4BO-0203X [HART – Mfg Singapore],

13-KB4BO-0296X [Fieldbus – Mfg Singapore]

Markings: Ex ia IIC T4

23

Quick Start Guide

7.13 Combinations

K1 Combination of E1, I1, N1, and ND

K2 Combination of E2 and I2

K5 Combination of E5 and I5

K6 Combination of E6 and I6

K7 Combination of E7, I7, and N7

KA Combination of E1, I1, E6, and I6

KB Combination of E5, I5, E6, and I6

KC Combination of E1, I1, E5, and I5

KD Combination of E1, I1, E5, I5, E6, and I6

KG Combination of IA, IE, IF, and IG

KM Combination of EM and IM

KP Combination of EP and IP

7.14 Additional Certifications

SBS American Bureau of Shipping (ABS) Type Approval

Certificate: 00-HS145383-6-PDA

Intended Use: Measure gauge or absolute pressure of liquid, gas or vapor applications on

ABS classed vessels, marine, and offshore installations.

March 2018

SBVBureau Veritas (BV) Type Approval

Certificate: 31910 BV

Requirements: Bureau Veritas Rules for the Classification of Steel Ships

Application: Class Notations: AUT-UMS, AUT-CCS, AUT-PORT and AUT-IMS

SDNDet Norske Veritas (DNV) Type Approval

Certificate: A-14186

Intended Use: Det Norske Veritas’ Rules for Classification of Ships, High Speed & Light

Craft, and Det Norske Veritas’ Offshore Standards

Application:

Location classes

Ty pe 3051S

Tem pe r at ur e D

Humidity B

Vibration A

EMC A

Enclosure D/IP66/IP68

SLL Lloyds Register (LR) Type Approval

Certificate: 11/60002

Application: Environmental categories ENV1, ENV2, ENV3, and ENV5

D3 Custody Transfer – Measurement Canada Accuracy Approval [3051S Only]

Certificate: AG-0501, AV-2380C

24

March 2018

EU Declaration of Conformity

No: RMD 1044 Rev. AA

Page 1 of 4

We,

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

declare under our sole responsibility that the product,

Rosemount 3051S Series Pressure Transmitters

Rosmeount 3051SFx Series Flowmeter Transmitters

Rosemount 300S Housings

manufactured by,

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

to which this declaration relates, is in conformity with the provisions of the European Union

Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Union notified body certification, as shown in the attached

schedule.

(signature)

Vice President of Global Quality

(function name - printed)

Chris LaPoint

(name - printed)

13-April-2017

(date of issue)

Figure 7. Rosemount 3051S Declaration of Conformity

Quick Start Guide

25

Quick Start Guide

EU Declaration of Conformity

No: RMD 1044 Rev. AA

Page 2 of 4

EMC Directive (2014/30/EU)

Harmonized Standards:

EN 61326-1:2013, EN 61326-2-3:2013

PED Directive (2014/68/EU)

Rosemount 3051S Series Pressure Transmitters

Rosemount 3051S_CA4; 3051S_CD2, 3, 4, 5 (also with P0 & P9 option) Pressure

Transmitters

QS Certificate of Assessment – EC Certificate No. 59552-2009-CE-HOU-DNV

Module H Conformity Assessment

Evaluation standards:

ANSI / ISA 61010-1:2004

All other Rosemount 3051S Pressure Transmitters

Sound Engineering Practice

Transmitter Attachments: Diaphragm Seal, Process Flange, or Manifold

Sound Engineering Practice

Rosemount 3051SFx Series Flowmeter Pressure Transmitters

See DSI 1000 Declaration of Conformity

March 2018

26

March 2018

EU Declaration of Conformity

No: RMD 1044 Rev. AA

Page 3 of 4

ATEX Directive (2014/34/EU)

BAS01ATEX1303X – Intrinsic Safety Certificate

Equipment Group II, Category 1 G

Ex ia IIC T4 Ga

Harmonized Standards Used:

EN 60079-0:2012+A11:2013, EN 60079-11:2012

BAS01ATEX3304X – Type n Certificate

Equipment Group II, Category 3 G

Ex nA IIC T5 Gc

Harmonized Standards Used:

EN 60079-0:2012+A11:2013, EN 60079-15:2010

BAS01ATEX1374X – Dust Certificate

Equipment Group II, Category 1 D

Ex ta IIIC T105°C T

500

95°C Da

Harmonized Standards Used:

EN 60079-0:2012+A11:2013

Other Standards Used:

EN 60079-31:2009 (a review against EN 60079-31:2014, which is

harmonized, shows no significant changes relevant to this equipment

so EN 60079-31:2009 continues to represent “State of the Art”)

BAS04ATEX0181X – Mining Certificate

Equipment Group I, Category M1

Ex ia I Ma

Harmonized Standards Used:

EN 60079-0:2012, EN 60079-11:2012

BAS04ATEX0193U – Mining Certificate: Component

Equipment Group I, Category M1

Ex ia I Ma

Harmonized Standards Used:

EN 60079-0:2012, EN 60079-11:2012

KEMA00ATEX2143X – Flameproof Certificate

Equipment Group II, Category 1/2 G

Ex db IIC T6…T4 Ga/Gb

Harmonized Standards:

EN 60079-0:2012+A11:2013, EN 60079-1:2014, EN 60079-26:2015

Quick Start Guide

27

Quick Start Guide

EU Declaration of Conformity

No: RMD 1044 Rev. AA

Page 4 of 4

PED Notified Body

Rsoemount 3051S Series Pressure Transmitters

DNV GL AS [Notified Body Number: 0575]

Veritasveien 1, N-1322

Hovik, Norway

ATEX Notified Bodies for EU Type Examination Certificate

DEKRA Certification B.V. [Notified Body Number: 0344]

Utrechtseweg 310

Postbus 5185

6802 ED Arnhem

Netherlands

SGS Baseefa Limited [Notified Body Number: 1180]

Rockhead Business Park, Staden Lane

Buxton, Derbyshire SK17 9RZ

United Kingdom

ATEX Notified Body for Quality Assurance

SGS Baseefa Limited [Notified Body Number: 1180]

Rockhead Business Park, Staden Lane

Buxton, Derbyshire SK17 9RZ

United Kingdom

March 2018

28

March 2018

ᴹ

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

䜘Ԧ〠

ᴹᇣ⢙䍘䍘

䫵

⊎

䭹

ޝԧ䬜䬜

ཊⓤ㚄㚄㤟

ཊⓤ㚄㚄㤟䟊

China RoHS

Rosemount 3051S

List of Rosemount 3051S Parts with China RoHS Concentration above MCVs

/ Hazardous Substances

Quick Start Guide

Part Name

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr +6)

Polybrominated

biphenyls

(PBB)

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

XO O O O O

Assembly

༣փ㓴Ԧ

Housing

XO O X O O

Assembly

Րᝏಘ㓴Ԧ

Sensor

XO O X O O

Assembly

ᵜ㺘Ṭ㌫ᦞ

This table is proposed in accordance with the provision of SJ/T11364.

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

O:

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

X:

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

29

Quick Start Guide

March 2018

30

March 2018

Quick Start Guide

31

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

*00825-0100-4805*

Quick Start Guide

00825-0100-4805, Rev FD

March 2018

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/ user/RosemountMeasurement

Google.com/+RosemountMeasurement

Emerson Terms and Conditions of Sale are available upon request.

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount is a mark of one of the Emerson family of companies.

All other marks are the property of their respective owners.

© 2018 Emerson. All rights reserved.

Loading...

Loading...