Emerson Rosemount 3051N Reference Manual

Reference Manual

00809-0100-4808, Rev EA

March 2021

Rosemount™ 3051N Smart Pressure Transmitter

for Nuclear Service

This page intentionally left blank

Reference Manual

00809-0100-4808, Rev EA

1Section 1: Introduction

2Section 2: Transmitter Functions

Contents

March 2021

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Failure mode alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.1 Alarm level verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Transmitter security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.1 Security jumper (write protect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.2 Local zero and span (local keys) software lock out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.3 Physical removal of local zero and span (local keys) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Configuring transmitter alarm and security jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Commissioning transmitter with a HART-based communicator . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.1 Setting the loop to manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.2 Wiring diagrams (bench hook-up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.3 Wiring diagrams (field hook-up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Review configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Check output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.1 Process variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.2 Sensor temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9 Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9.1 Set process variable units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9.2 Set output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.9.3 Rerange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.9.4 Rerange with a communicator only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.9.5 Rerange with a pressure input source and a communicator . . . . . . . . . . . . . . . . . . . . . . 11

2.9.6 Rerange with a pressure input source and the local zero and span buttons . . . . . . . . . 11

2.9.7 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9.8 LCD display meter options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.10 Detailed setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.10.1 Local span and zero control (local keys) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.10.2 Sensor temperature output unit selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11Diagnostics and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11.1 Transmitter test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.11.2 Loop test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Contents

2.12 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.12.1 Calibration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

iii

Contents

March 2021

Reference Manual

00809-0100-4808, Rev EA

2.12.2 Deciding which trim procedure to use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.12.3 Sensor trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.12.4 Zero trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.12.5 Full trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.12.6 Recall factory trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.12.7 Recall factory trim– sensor trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.12.8 Recall factory trim– analog output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.12.9 Analog output trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.12.10 Digital-to-analog trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.12.11 Digital-to-analog trim using other scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.12.12 Compensating Rosemount 3051N Range 4 and 5 Differential Transmitters for

line pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3Section 3: Installation

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 General considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.1 Special draft range considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Mechanical considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4.1 Rosemount 3051ND0 and 3051ND1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4.2 Steam service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.3 Side mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.4 Independent seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.6 Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4.7 Housing rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5 Electrical considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5.3 Grounding the transmitter case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6 Environmental considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6.1 Access requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6.2 Cover installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4Section 4: Troubleshooting

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.1 Returning Rosemount products and materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

iv

Contents

Reference Manual

00809-0100-4808, Rev EA

AAppendix A: Specifications and Reference Data

Contents

March 2021

A.1 Nuclear specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A.1.1 Seismic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A.1.2 Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A.1.3 Quality Assurance program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A.1.4 Nuclear cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A.1.5 Hydrostatic testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.2 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.2.1 Reference accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.2.2 Drift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.2.3 Ambient temperature effect

A.2.4 Overpressure effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.2.5 Static pressure effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.2.6 Power supply effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.2.7 Load effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.2.8 Mounting position effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.3 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.3.1 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.3.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.3.3 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.3.4 Temperature limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A.3.5 Span and zero, zero elevation, and suppression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.3.6 Humidity limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.3.7 Volumetric displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.3.8 Turn-on time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.3.9 Response time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.3.10 Maximum working pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.3.11 Static pressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.3.12 Overpressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.3.13 Burst pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.4 Physical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.4.1 Materials of construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.5 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

A.6 Configuration information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

A.6.1 Rosemount 3051N 4-20 mA/HART Output Smart Pressure Transmitters

Typical Configuration Data Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Contents

v

Contents

March 2021

Reference Manual

00809-0100-4808, Rev EA

BAppendix B: Options

B.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

B.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

B.3 LCD display meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

B.3.1 Custom meter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

B.3.2 Installing the meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.3.3 Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

B.3.4 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

B.3.5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

B.4 Mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

B.4.1 Traditional flange (H2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

B.5 Transient protection terminal block (T1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

CAppendix C: HART® Communicator

C.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

C.3 Connections and hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

C.4 Menus and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C.4.1 Main menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C.4.2 Online menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

C.4.3 Fast Key sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

C.4.4 Hot Key options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

C.5 Diagnostic messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

DAppendix D: Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

vi

Contents

Reference Manual

00809-0100-4808, Rev EA

Rosemount™ 3051N Smart Pressure Transmitter for nuclear service

Rosemount 3051 HART® Universal Revision 5

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

Within the United States, contact Rosemount Nuclear Instruments, Inc. at

1-952-949-5200 for assistance.

Outside of the United States, contact your local Emerson Process Management Sales Representative.

Rosemount Nuclear Instruments, Inc. warranty and limitations of remedy

The warranty and limitations of remedy applicable to this Rosemount equipment are as stated on the

reverse of the current Rosemount quotation and customer acknowledgment forms.

Return of material

Authorization for return is required from Rosemount Nuclear Instruments, Inc. prior to shipment.

Contact Rosemount Nuclear Instruments, Inc. (1-952-949-5200) for details on obtaining Return Material

Authorization (RMA). Rosemount Nuclear Instruments will not accept any returned material without a

Returned Material Authorization. Material returned without authorization is subject to return to

customer.

Title Page

March 2021

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Rosemount Nuclear Instruments, Inc.

8200 Market Blvd.

Chanhassen, MN 55317

USA

Important

The Rosemount 3051N Pressure Transmitter is qualified for nuclear use per IEEE Std 344-1987 and IEEE

Std 323-1983 (mild environment) as documented in Rosemount Report D2001019, and is supplied in

accordance with 10CFR50 Appendix B and ISO 9001:2008 quality assurance programs. To ensure

compliance with 10CFR Part 21, the transmitter must comply with the requirements herein and in

Report D2001019 throughout its installation, operation, and maintenance. It is incumbent upon the user

to ensure that the Rosemount Nuclear Instruments, Inc. component traceability program where

applicable is continued throughout the life of the transmitter.

Where the manual uses the terms requirements, mandatory, must, or required, the instructions so

referenced must be carefully followed. Rosemount Nuclear Instruments, Inc. expressly disclaims all

responsibility and liability for transmitters for which the foregoing has not been complied with by the

user.

Title Page

vii

Title Page

This page intentionally left blank

March 2021

Reference Manual

00809-0100-4808, Rev EA

viii

Title Page

Reference Manual

00809-0100-4808, Rev EA

Section 1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining devices from

the Rosemount

Section 2: Transmitter Functions provides instruction on commissioning and operating Rosemount

3051N Pressure Transmitters. Information on software functions, configuration parameters, and online

variables is also included.

Section 3: Installation provides mechanical and electrical installation instructions.

Section 4: Troubleshooting provides troubleshooting techniques for the most common Rosemount

3051N Transmitter operating problems.

Appendix A: Specifications and Reference Data provides reference and specification data for the

Rosemount 3051N Smart Pressure Transmitter Family.

Appendix B: Options describes the mounting and configuration options available for Rosemount 3051N

Transmitters.

™

3051N Smart Pressure Transmitter Family. The sections are organized as follows:

Introduction

March 2021

Appendix C: HART® Communicator provides an overview of the HART Communicator, defines its partial

command menu tree for the Rosemount 3051N Family, and provides a table of typical Fast Key

sequences. A table of typical diagnostic messages is also included.

Introduction

1

Introduction

This page intentionally left blank

March 2021

Reference Manual

00809-0100-4808, Rev EA

2

Introduction

Reference Manual

00809-0100-4808, Rev EA

Section 2 Transmitter Functions

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Failure mode alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Transmitter security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Configuring transmitter alarm and security jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Commissioning transmitter with a HART-based communicator . . . . . . . . . . . . . . . . . . . . . . . . page 6

Review configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Check output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Detailed setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Diagnostics and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Transmitter Functions

March 2021

2.1 Overview

This section contains information on commissioning and operating Rosemount™ 3051N Smart Pressure

Transmitters. Tasks that should be performed on the bench prior to installation are explained in this

section.

When the HART

documented in Rosemount Report D2001019.

For your convenience, typical HART Communicator Fast Key sequences are listed for most software

functions. These Fast Key sequences are the same for the 275, 375, and 475 Field Communicators. If you

are unfamiliar with the communicator or how to follow Fast Key sequences, refer to Appendix C: HART®

Communicator for communicator operations.

A typical transmitter software configuration data worksheet is provided in Appendix A: Specifications

and Reference Data.

®

Communicator is referenced, it refers to the 275, 375, or 475 Field Communicator as

2.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety of the

personnel performing the operations. Information that raises potential safety issues is indicated by a

warning symbol ( ). Refer to the following safety messages before performing an operation preceded

by this symbol.

Transmitter Functions

Explosions can result in death or serious injury.

Do not remove the transmitter covers in explosive environments when the circuit is alive.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause

electrical shock.

3

Transmitter Functions

March 2021

2.3 Failure mode alarm

Rosemount 3051N Transmitters automatically and continuously perform self-diagnostic routines. If the

self-diagnostic routines detect a failure, the transmitter drives its output outside of the normal

saturation values. The transmitter will drive its output low or high based on the position of the failure

mode alarm jumper. See Table 2-1 for failure mode and saturation output levels. To select alarm

position, see “Configuring transmitter alarm and security jumper” on page 5.

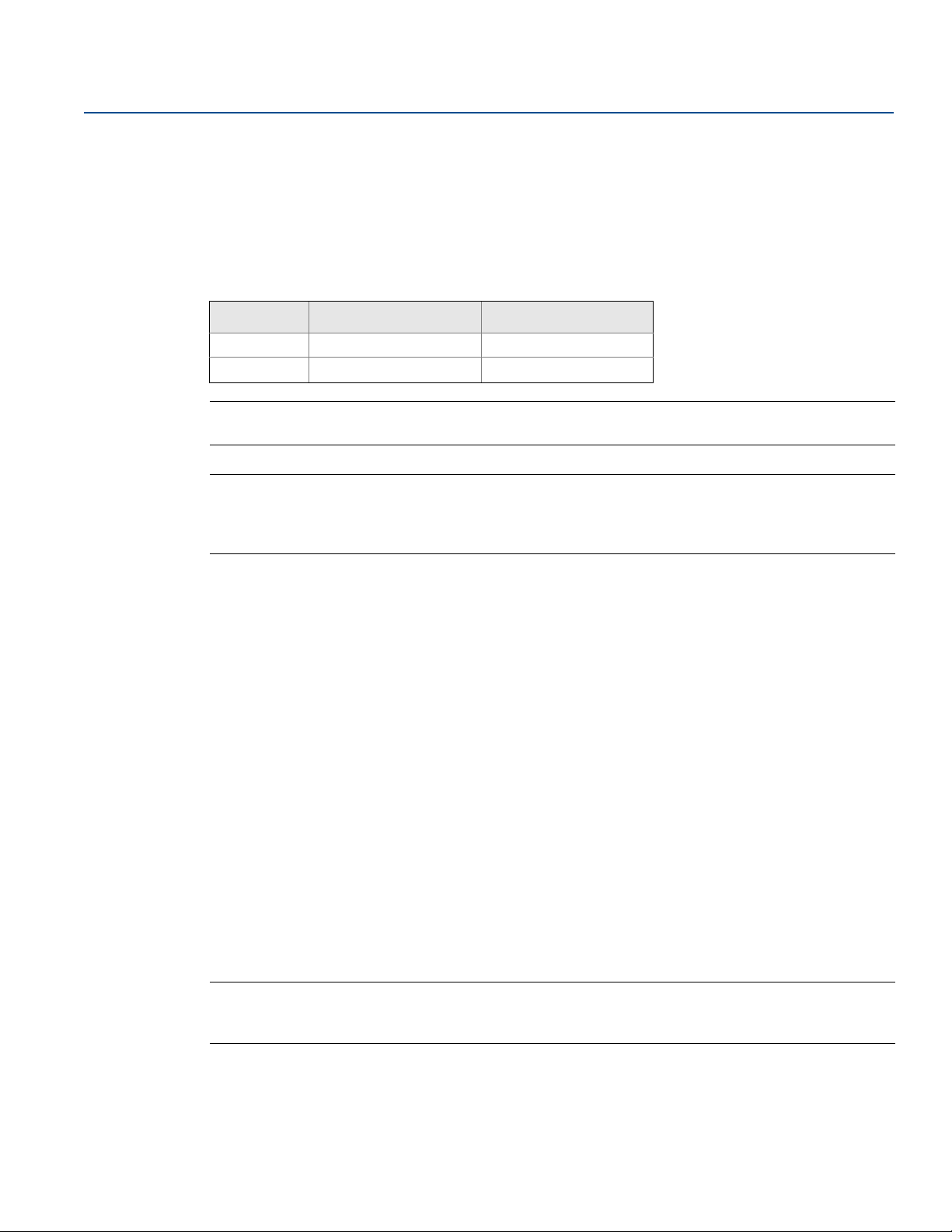

Table 2-1. Standard Alarm and Saturation Values

Level 4—20 mA Saturation 4—20 mA Alarm

Low 3.9 mA ≤ 3.75 mA

High 20.8 mA ≥ 21.75 mA

Note

The actual transmitter mA output values can be altered by performing an analog output trim.

Note

When a transmitter is in an alarm condition, the hand-held HART Communicator indicates the analog

output the transmitter would drive if the alarm condition did not exist. The transmitter will alarm high in

the event of failure if the alarm jumper is removed.

Reference Manual

00809-0100-4808, Rev EA

2.3.1 Alarm level verification

Transmitters allow verification testing of alarm current levels. If you replace the LCD display meter,

reconfigure or make any changes to the transmitter, verify the transmitter alarm level before you return

the transmitter to service. This feature is also useful in testing the reaction of your control system to a

transmitter in an alarm state. To verify the transmitter alarm values, perform a loop test and set the

transmitter output to the alarm value (see Table 2-1 and “Loop test” on page 14).

2.4 Transmitter security

There are three security methods with the Rosemount 3051N Transmitter.

1. Security Jumper: prevents all writes to transmitter configuration.

2. Local Keys (Local Zero and Span) Software Lock Out: prevents changes to transmitter range points via

local zero and span adjustment keys. With local keys security enabled, changes to configuration are

possible via HART.

3. Physical Removal of Local Keys (Local Zero and Span) Magnetic Buttons: removes ability to use local

keys to make transmitter range point adjustments. With local keys security enabled, changes to

configuration are possible via HART.

Note

If the security jumper is not installed, the transmitter will continue to operate in the security OFF

configuration.

4

Transmitter Functions

Reference Manual

A

B

00809-0100-4808, Rev EA

Transmitter Functions

2.4.1 Security jumper (write protect)

You can prevent changes to the transmitter configuration data with the write protection jumper.

Security is controlled by the security (write protect) jumper located on the electronics board or meter

face. Position the jumper on the transmitter circuit board in the ON position to prevent accidental or

deliberate change of configuration data.

If the transmitter write protection jumper is in the ON position, the transmitter will not accept any

“writes” to its memory. Configuration changes, such as digital trim and reranging, cannot take place

when the transmitter security is on.

2.4.2 Local zero and span (local keys) software lock out

To enable this feature, see “Local span and zero control (local keys)” on page 13.

2.4.3 Physical removal of local zero and span (local keys)

To remove the magnetic buttons used to activate the local zero and span, use a small slotted head

screwdriver and pry off the small, plastic cap located under the approval tag. Remove button assemblies

and discard.

March 2021

2.5 Configuring transmitter alarm and security jumper

To reposition the jumpers, follow the procedure described below.

1. If the transmitter is installed, secure the loop and remove power.

2. Remove the housing cover opposite the field terminal side. Do not remove the transmitter covers in

explosive atmospheres when the circuit is alive.

3. Reposition the jumpers as desired.

Figure 2-1 shows the jumper positions for electronics boards.

Figure 2-2 shows transmitters with an optional LCD display meter.

4. Reattach the transmitter cover. Transmitter covers must be fully engaged to meet explosionproof

requirements.

Figure 2-1. Electronics Board

Transmitter Functions

A. Security

B. Alarm

5

Transmitter Functions

March 2021

Figure 2-2. Rosemount 3051N Transmitter with Optional LCD Display Meter

Note

Security jumper not installed = not write protected

Alarm jumper not installed = high alarm

Reference Manual

00809-0100-4808, Rev EA

2.6 Commissioning transmitter with a HART-based communicator

Commissioning consists of testing the transmitter and verifying transmitter configuration data. You may

commission Rosemount 3051N Transmitters either before or after installation. Commissioning the

transmitter on the bench before installation using a HART-based Communicator ensures that all

transmitter components are in good working order and acquaints you with the operation of the device.

To commission on the bench, connect the transmitter and the communicator as shown in Figure 2-3.

Make sure the instruments in the loop are installed in accordance with intrinsically safe or nonincendive

field wiring practices before connecting a communicator in an explosive atmosphere. Connect the

communicator leads at any termination point in the signal loop. It is most convenient to connect them to

the terminals labeled “COMM” on the terminal block. Connecting across the “TEST” terminals will

prevent successful communication. To avoid exposing the transmitter electronics to the plant

environment after installation, set all transmitter jumpers during the commissioning stage on

the bench.

For 4—20 mA transmitters, you will need a power supply capable of providing 10.5 to 55 V dc at the

transmitter, and a meter to measure output current. To enable communication, a resistance of at least

250 ohms, but within the transmitter load limitations (see Figure 3-7 on page 35) must be present

between the communicator loop connection and the power supply. Do not use inductive-based

transient protectors with the Rosemount 3051N Transmitter.

2.6.1 Setting the loop to manual

Whenever you are preparing to send or request data that would disrupt the loop or change the output of

the transmitter, you must set your process application loop to manual. The HART Communicator will

prompt you to set the loop to manual when necessary. Keep in mind that acknowledging this prompt

does not set the loop to manual. The prompt is only a reminder; you have to set the loop to manual

yourself as a separate operation.

6

Transmitter Functions

Reference Manual

A

B

C

A

B

C

00809-0100-4808, Rev EA

2.6.2 Wiring diagrams (bench hook-up)

Connect the bench equipment as shown in Figure 2-3 and turn on the HART-based Communicator by

pressing the ON/OFF key. The communicator will search for a HART-compatible device and will indicate

when the connection is made. If the communicator fails to connect, it will indicate that no device was

found. If this occurs, refer to Section 4: Troubleshooting.

Figure 2-3. Bench Hook-up (4—20 mA Transmitters)

Transmitter Functions

March 2021

A. Current meter

≥ 250 ohms (necessary for HART communication only)

B. R

L

C. 24 Vdc power supply

See “Safety messages” on page 3 for warning information.

2.6.3 Wiring diagrams (field hook-up)

The following diagrams illustrate wiring loops for a field hook-up with a HART-based Communicator.

Figure 2-4. Field Hook-up (4—20 mA Transmitters)

Transmitter Functions

A. Current meter

B. R

≥ 250 ohms (necessary for HART communication only)

L

C. Power supply

7

Transmitter Functions

March 2021

Do not use inductive-based transient protectors.

Note

Signal point may be grounded at any point or left ungrounded

2.7 Review configuration data

Reference Manual

00809-0100-4808, Rev EA

HART Fast Keys

1, 5

Note

Information and procedures in this section that make use of HART Communicator Fast Key sequences

assume that the transmitter and communicator are connected, powered, and operating correctly. Refer

to Appendix C: HART® Communicator for more details on the HART Communicator or Fast Key

sequences.

Before placing the transmitter into operation, it is recommended to review the transmitter configuration

data that was set at the factory. Review the following configuration data:

Transmitter Model Type

Tag Range

Date Descriptor

Message Minimum and Maximum Sensor Limits

Minimum Span Units

4 and 20 mA points Output (linear or sq. root)

Damping Alarm Setting (high, low)

Security Setting (on, off) Local Zero/Span Keys (enabled, disabled)

Integral Meter Sensor Fill

Isolator Material Flange (type, material)

O-Ring Material Drain/Vent

Remote Seal (type, fill fluid, isolator material, number) Transmitter S/N

Address Sensor S/N

8

Transmitter Functions

Reference Manual

00809-0100-4808, Rev EA

2.8 Check output

Before performing other transmitter online operations, review the digital output parameters to ensure

that the transmitter is operating properly and is configured to the appropriate process variables.

2.8.1 Process variables

Transmitter Functions

March 2021

HART Fast Keys

2

The process variables for the Rosemount 3051N Transmitter provide the transmitter output, and are

continuously updated. The process variable menu displays the following process variables:

Pressure

Percent of Range

Analog Output

The pressure reading in both Engineering Units and Percent of Range will continue to track with

pressures outside of the defined range from the lower to the upper range limit of the sensor module.

Note

Regardless of the range points, the Rosemount 3051N Transmitter will measure and report all readings

within the digital limits of the sensor. For example, if the 4 and 20 mA points are set to 0 and 10 in H

on a range code 1 Rosemount 3051N Transmitter, and the transmitter detects a pressure of 25 inH

digitally outputs the 25 inH

O reading and a 250% of span reading. However, there may be up to ±5.0%

2

error associated with output outside of the range points.

2.8.2 Sensor temperature

HART Fast Keys

The Rosemount 3051N Transmitter contains a temperature sensor just above its pressure sensor in the

sensor module. When reading this temperature, keep in mind that this is not a process temperature

reading.

1, 1, 4

2

O, it

2

O

2.9 Basic setup

2.9.1 Set process variable units

Transmitter Functions

HART Fast Keys

The PV Unit command sets the process variable units to allow you to monitor your process using the

appropriate units of measure. Select from the following engineering units:

inH

inHg psi mbar kPa

ftH

mmH

O mmHg bar Pa

2

O torr g/cm

2

O inH2O at 4 °C kg/cm

2

1, 3, 2

2

2

atm

mmH2O at 4 °C

9

Transmitter Functions

Sq. Root

Curve

Transition Point

Linear Section

Slope=1

Slope=42

Transition Point

Sq. Root Curve

Full Scale Flow

(%)

Full Scale Output

(mA dc)

March 2021

2.9.2 Set output

Reference Manual

00809-0100-4808, Rev EA

HART Fast Keys

1, 3, 5

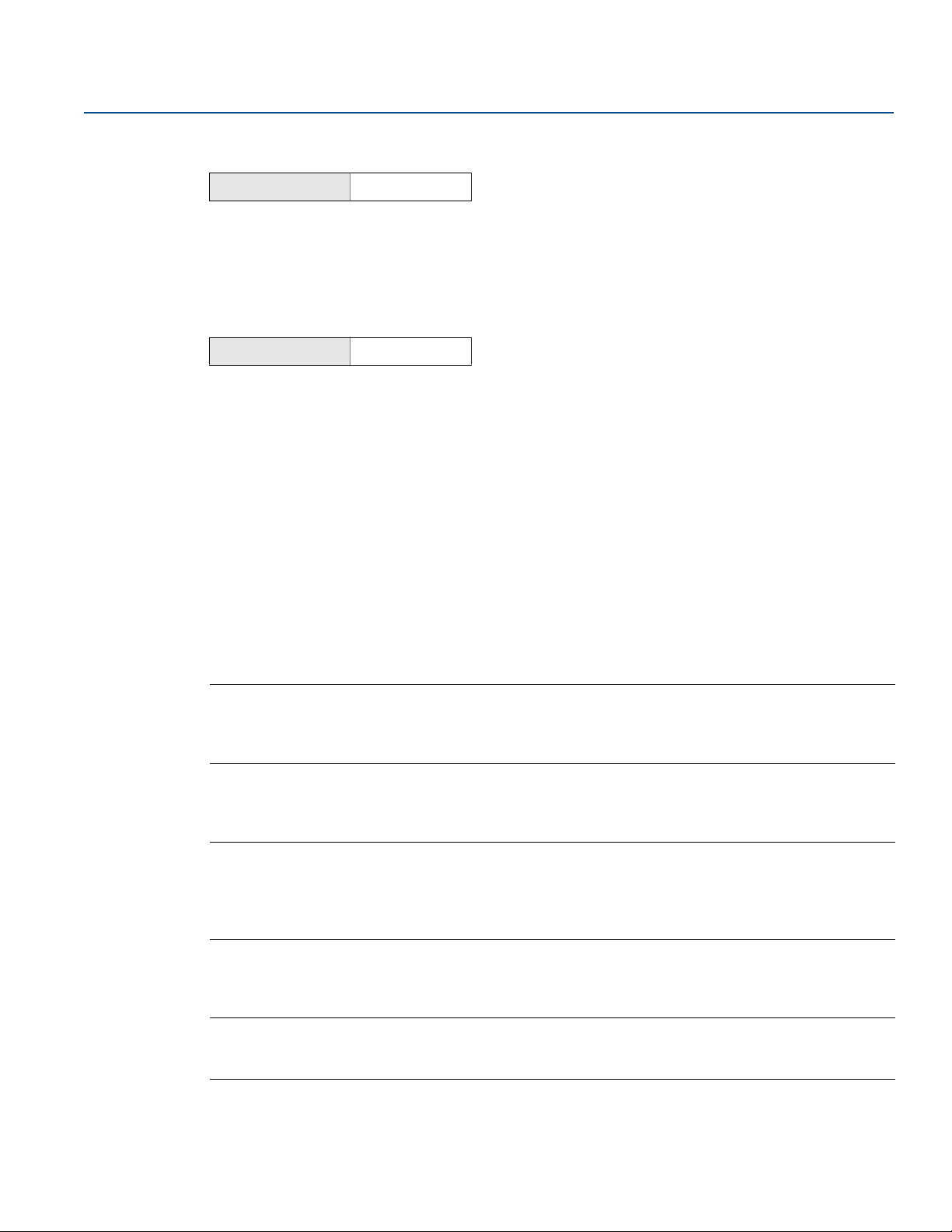

Activate the transmitter square root output option to make the analog output proportional to flow. As

the input approaches zero, the Rosemount 3051N Transmitter automatically switches to a linear output

in order to ensure a more smooth, stable output near zero. See Figure 2-5.

The transition from linear to square root is not adjustable. It occurs at 0.8 percent of ranged pressure

input or 8.9 percent of full-scale flow output.

From 0 percent to 0.6 percent of the ranged pressure input, the slope of the curve is unity

(y = x). This allows accurate calibration near zero. Greater slopes would cause large changes in output for

small changes at input. From 0.6 percent to 0.8 percent, the slope of the curve equals 42 (y = 42x) to

achieve continuous transition from linear to square root at the transition point.

Figure 2-5. Square Root Output Transition Point

2.9.3 Rerange

10

The Range Values command sets the 4 and 20 mA points (lower and upper range values). Setting the

range values to the limits of expected readings maximizes transmitter performance. In practice, you may

reset the transmitter range values as often as necessary to reflect changing process conditions.

There are three methods available to rerange the transmitter. Each method is unique; examine all three

closely before deciding which method to use.

Transmitter Functions

Reference Manual

00809-0100-4808, Rev EA

2.9.4 Rerange with a communicator only

Transmitter Functions

March 2021

HART Fast Keys

Reranging using only the communicator changes the values of the analog 4 and 20 mA points

independently without a pressure input.

Note

Changing the lower or upper range point results in similar changes to the span.

To rerange using only the communicator, enter the Fast Key sequence above, select 1 Keypad input, and

follow the online instructions. Or enter the values directly from the ONLINE screen.

Note

If the transmitter security jumper is in the ON position, you will not be able to make adjustments to the

zero and span. Refer to Figure 2-1 on page 5 for the appropriate placement of the transmitter security

jumper.

1, 2, 3, 1, 1

2.9.5 Rerange with a pressure input source and a communicator

HART Fast Keys

Reranging using the communicator and a pressure source or process pressure is a way of reranging the

transmitter with a pressure input. When specific 4 and 20 mA points are not known process input can be

used. This method changes the values of the analog 4 and 20 mA points.

1, 2, 3, 1, 2

Note

When setting the 4 mA point, the span is maintained; when setting the 20 mA point, the span changes. If

setting the lower range point to a value that causes the upper range point to exceed the sensor limit, the

upper range point is automatically set to the sensor limit, and the span is adjusted accordingly.

To rerange using the communicator and a pressure source or process pressure, enter the Fast Key

sequence above, select 2 Apply values, and follow the online instructions.

Note

If the transmitter security jumper is in the ON position, no adjustments can be made to the zero and

span. Refer to Figure 2-1 on page 5 for the appropriate placement of the transmitter security jumper.

2.9.6 Rerange with a pressure input source and the local zero and span buttons

Reranging using the local zero and span adjustments (see Figure 2-6 on page 12) and a pressure source

or process pressure is a way of reranging the transmitter with a pressure input and when a

communicator is not available. When specific 4 and 20 mA points are not known process input can be

used.

Note

When setting the 4 mA point, the span is maintained; when setting the 20 mA point, the span changes. If

setting the lower range point to a value that causes the upper range point to exceed the sensor limit, the

upper range point is automatically set to the sensor limit and the span is adjusted accordingly.

Transmitter Functions

11

Transmitter Functions

March 2021

To rerange the transmitter using the span and zero buttons, perform the following procedure.

1. Loosen the screw holding the label on top of the transmitter housing, and rotate the label to expose

the zero and span buttons (see Figure 2-6 on page 12).

2. Using a pressure source with an accuracy three to ten times the desired calibrated accuracy, apply a

pressure equivalent to the lower range value to the high side of the transmitter.

3. To set the 4 mA point, press and hold the zero button for at least two seconds, then verify the output

is 4 mA. If a meter is installed, it will display ZERO PASS.

4. Apply a pressure equivalent to the upper range value to the high side of the transmitter.

5. To set the 20 mA point, press and hold the span button for at least two seconds, then verify the

output is 20 mA. If a meter is installed, it will display SPAN PASS.

Note

If the transmitter security jumper is in the ON position, or if the local zero and span adjustments are

disabled through the software, adjustments to the zero and span cannot be made using the local

buttons. Refer to Figure 2-1 on page 5 for the proper placement of the transmitter security jumper. Or

refer to “Local span and zero control (local keys)” on page 13 in Section 2 for instructions on how to

enable the span and zero buttons.

Reference Manual

00809-0100-4808, Rev EA

Figure 2-6. Local Zero and Span Adjustments

A. Span and Zero Adjustment buttons

After reranging the transmitter using the span and zero adjustments, it is possible to disable the

adjustments to prevent further reranging. Refer to “Local span and zero control (local keys)” below for

more information.

2.9.7 Damping

HART Fast Keys

A

1, 3, 6

The process variable (PV) Damp command changes the response time of the transmitter to smooth

variations in output readings caused by rapid changes in input. Determine the appropriate damping

setting based on the necessary response time, signal stability, and other requirements of the of loop

dynamics of your system. The default damping value is 0.4 seconds,

(1)

and can be reset to any of eleven

pre-configured, nominal damping values between 0 and 25.6 seconds.

1. Rosemount 3051ND0 default damping is 3.2 seconds. Rosemount 3051ND1, with calibrations below 2.5 inH2O (0,62 kPa), have damping set at 3.2 sec-

onds.

12

Transmitter Functions

Reference Manual

00809-0100-4808, Rev EA

2.9.8 LCD display meter options

Transmitter Functions

March 2021

HART Fast Keys

The Meter Options command allows you to customize the LCD display meter for use in your application.

The meter can be configured to display the following information:

Engineering units

Percent of range

User-configurable LCD display scale

Alternating between any two of the above

The user-configurable scale is a feature that enables you to configure the LCD display meter to a custom

scale using a HART Communicator. This feature can be used to define the decimal point position, the

upper range value, the lower range value, the engineering units, and transfer function. Refer to “Custom

meter configuration” on page 52 for complete configuration information.

1, 4, 3, 4

2.10 Detailed setup

2.10.1 Local span and zero control (local keys)

HART Fast Keys

The Local keys command allows software control over the use of the local span and zero adjustments. To

enable or disable the span and zero adjustment buttons on the transmitter, perform the Fast Key

sequence above.

1, 4, 4, 1, 7

Note

Disabling the local keys does not disable all transmitter configuration changes. With the local keys

disabled, changes to the transmitter configuration can still be made–including range values–using a

HART Communicator.

2.10.2 Sensor temperature output unit selection

HART Fast Keys

The Sensor Temperature Output Unit Selection command selects between Celsius and Fahrenheit units for

output of the sensor temperature. The sensor temperature output is accessible via HART only.

1, 4, 1, 2, 2

2.11 Diagnostics and service

The diagnostics and service functions listed here are primarily for use after installing the transmitter in

the field. The transmitter test feature is designed to verify the transmitter is operating properly, and can

be performed either on the bench or in the field. The loop test feature is designed to verify proper loop

wiring and transmitter output, and should only be performed after installing the transmitter.

Transmitter Functions

13

Transmitter Functions

March 2021

2.11.1 Transmitter test

Reference Manual

00809-0100-4808, Rev EA

HART Fast Keys

The transmitter Self Test command initiates a more extensive diagnostics routine than that performed

continuously by the transmitter. The transmitter test routine can quickly identify potential electronics

problems. If the transmitter test detects a problem, messages to indicate the source of the problem are

displayed on the communicator screen.

2.11.2 Loop test

HART Fast Keys

The Loop Test command verifies the output of the transmitter, the integrity of the loop, and the

operations of any recorders or similar devices installed in the loop. To initiate a loop test, perform the

following procedure.

1. Connect a reference meter to the transmitter. To do so, either connect the meter to the test terminals

on the transmitter terminal block, or shunt the power to the transmitter through the meter at some

point in the loop.

2. From the ONLINE screen, select 1 Device Setup > 2 Diagnostics and Service > 2 Loop Test, to

prepare to perform a loop test.

3. Set the control loop to manual (see “Setting the loop to manual” on page 6). The communicator

displays the loop test menu.

4. Select OK.

1, 2, 1, 1

1, 2, 2

5. Select a discreet milliamp level for the transmitter to output. At the CHOOSE ANALOG OUTPUT prompt,

select 1 4mA > 2 20mA, or select 3 other to manually input a value.

Note

If performing a loop test to verify the transmitter output, enter a value between 4 and 20 mA. If

performing a loop test to verify the transmitter alarm levels, enter the milliamp value representing an

alarm state (Table 2-1 on page 4).

6. Check the electrical current meter installed in the test loop to verify it reads the value commanded

the transmitter to output.

Note

If the readings match, then the transmitter and loop are configured and functioning properly. If the

readings do not match, then the current meter may be attached to the wrong loop, there may be a fault

in the wiring or elsewhere in the loop, the transmitter may require an output trim, or the electrical

current meter may be malfunctioning.

After completing the test procedure, the display returns to the loop test screen and allows selection of

another output value or exit loop testing.

Note

If the HART Communicator is disconnected from the process loop or loses power prior to exiting loop

testing, output will remain fixed at the loop test value.

14

Transmitter Functions

Reference Manual

00809-0100-4808, Rev EA

2.12 Calibration

Calibrating a smart transmitter is different from calibrating an analog transmitter. The one-step

calibration process of an analog transmitter is done in three steps with a smart transmitter.

Rerange–sets the 4 and 20 mA points at the desired pressures;

Sensor Trim–Adjusts the position of the factory characterization curve to optimize the transmitter

performance over a specified pressure range or to adjust for mounting effects;

Analog Output Trim–Adjusts the analog output to match the plant standard or the control loop.

Smart transmitters operate differently than analog transmitters. A smart transmitter uses a

microprocessor and sensor memory that contains information about the sensor’s specific characteristics

in response to pressure and temperature inputs. A smart transmitter compensates for these sensor

variations. The process of generating the sensor performance profile is called factory characterization.

Factory characterization also provides the ability to readjust the 4 and 20 mA points without applying

pressure to the transmitter.

The trim and rerange functions also differ. Reranging sets the transmitter analog output to the selected

upper and lower range points and can be done with or without an applied pressure. Reranging does not

change the factory characterization curve stored in the microprocessor. Sensor trimming requires an

accurate pressure input and adds additional compensation that adjusts the position of the factory characterization curve to optimize transmitter performance over a specific pressure range.

Transmitter Functions

March 2021

Note

Sensor trimming adjusts the position of the factory characterization curve. It is possible to degrade the

performance of the transmitter if the sensor trim is done improperly or with inaccurate equipment.

Contact Rosemount Nuclear Instruments, Inc. at 952-949-5200 if there are questions.

Table 2-2. Standard Alarm and Saturation Values

Transmitter Bench calibration tasks Field calibration tasks

1. Reconfigure parameters if

necessary.

2. Zero trim the transmitter to

compensate for mounting effects or

static pressure effects.

1. Reconfigure parameters if

necessary.

2. Perform low trim value section of

the full sensor trim procedure to

correct for mounting position

effects.

Rosemount

3051ND

Rosemount

3051NG

Rosemount

3051NA

1. Set output configuration parameters.

a. Set the process variable units.

b. Set the output type.

c. Set the range points.

d. Set the damping value.

2. Optional: Perform a full sensor trim (accurate multimeter required).

3. Optional: Perform an analog output trim (accurate multimeter required).

1. Set output configuration parameters:

a. Set the process variable units.

b. Set the output type.

c. Set the range points.

d. Set the damping value.

2. Optional: Perform a full sensor trim if equipment available (accurate

absolute pressure source required), otherwise perform the low trim value

section of the full sensor trim procedure.

3. Optional: Perform an analog output trim (accurate multimeter required).

Transmitter Functions

15

Transmitter Functions

March 2021

Note

A HART Communicator is required for all sensor and output trim procedures.

Rosemount 3051N Transmitter Range 4 and Range 5 Transmitters require a special calibration procedure

when used in differential pressure applications under high static line pressure (see “Compensating

Rosemount 3051N Range 4 and 5 Differential Transmitters for line pressure” on page 22).

2.12.1 Calibration overview

Complete calibration of the Rosemount 3051N Pressure Transmitter involves the following tasks.

Configure the analog output parameters

Set Process Variable Units (page 9)

Set Output Type — Linear or Square Root (page 10)

Set the Range Points (page 10)

Set Damping (page 12)

Calibrate the sensor

Full Trim (page 19)

Zero Trim (page 18)

Reference Manual

00809-0100-4808, Rev EA

Calibrate the 4—20 mA output (digital-to-analog [D/A]

signal conversion)

4—20 mA Output Trim (page 21) or

4—20 mA Output Trim using other scale (page 21)

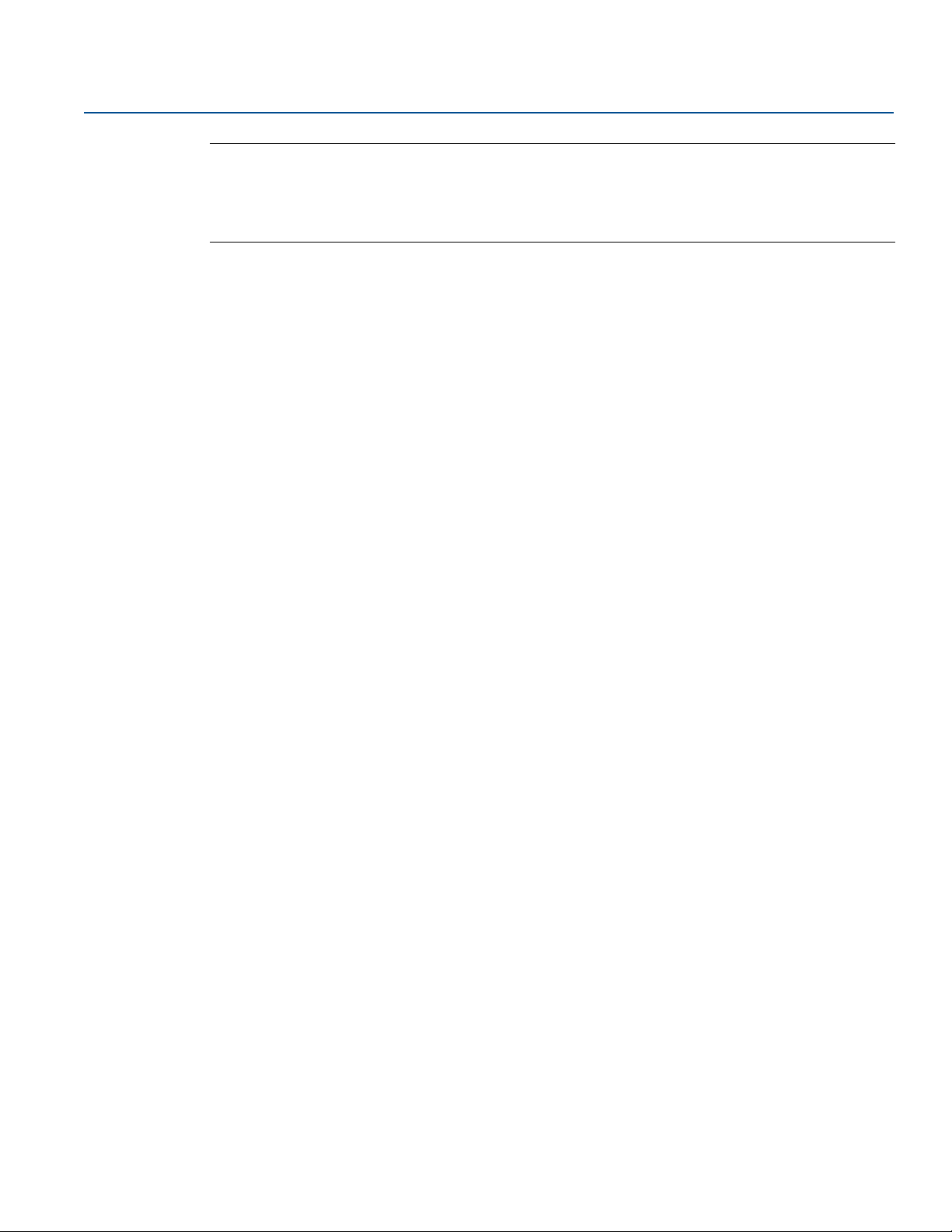

Figure 2-7 on page 17 illustrates the Rosemount 3051N Transmitter data flow. This data flow can be

summarized in four major steps.

1. A change in pressure is measured by a change in the sensor output (Sensor Signal).

2. The sensor signal is converted to a digital format that can be understood by the microprocessor

(Analog-to-Digital Signal Conversion).

3. Corrections are performed in the microprocessor to obtain a digital representation of the process

input (Digital PV).

4. The Digital PV is converted to an analog value (Digital-to-Analog Signal Conversion).

Figure 2-7 also identifies the approximate transmitter location for each calibration task. Note the data

flows from left to right, and a parameter change affects all values to the right of the changed parameter.

Not all calibration procedures should be performed for each Rosemount 3051N Transmitter. In addition,

some procedures are appropriate for bench calibration but should not be performed during field

calibration. Table 2-2 identifies the recommended calibration procedures for each type of Rosemount

3051N Transmitter for both bench and field calibration.

16

Transmitter Functions

Reference Manual

C

D

A

H

F

20.00 mA

3051:PT-4001

1 ?Device Setup

Online

2PV100.00 inH2O

3AO20.00 mA

4LRV0.00 inH2O

5URV100.00 inH2O

Transmitter Ranged 0 to 100 inH2O

I

B

E

G

00809-0100-4808, Rev EA

Figure 2-7. Transmitter Data Flow with Calibration Options

Transmitter Functions

March 2021

A. Sensor

B. Sensor signal

C. Transmitter electronics module

D. Microprocessor digital PV

E. Analog output

F. Output device

G. HART Communicator

H. Input device

I. Input pressure

Note

Value on PV line should equal the input pressure. Value on AO line should equal the output device

reading.

2.12.2 Deciding which trim procedure to use

To decide which trim procedure to use, first determine whether the analog-to-digital section or the digital-to-analog section of the transmitter electronics is in need of calibration. To do so, refer to Figure 2-7

and perform the following procedure.

1. Connect a pressure source, a HART Communicator, and a digital readout device to the transmitter.

2. Establish communication between the transmitter and the communicator.

3. Apply pressure equal to the upper range point pressure (100 inH

4. Compare the applied pressure to the Process Variable (PV) line on the Communicator Online Menu. If

the PV reading on the communicator does not match the applied pressure, and the test equipment is

accurate, perform a sensor trim.

5. Compare the Analog Output (AO) line on the communicator online menu to the digital readout

device. If the AO reading on the communicator does not match the digital readout device, and the

test equipment is accurate, perform an output trim.

0, for example).

2

Transmitter Functions

17

Transmitter Functions

20 mA Point

4 mA Point

20 mA Point

4 mA Point

March 2021

2.12.3 Sensor trim

The sensor can be trimmed using either the full trim or the zero trim function. The trim functions vary in

complexity, and their use is application-dependent. Both trim functions alter the transmitter’s

interpretation of the input signal.

A zero trim is a single-point adjustment. It is useful when compensating for mounting position effects

and is most effective when performed with the transmitter installed in its final mounting position. Since

this correction maintains the slope of the characterization curve, it should not be used in place of a full

trim over the full sensor range.

When performing a zero trim, ensure the equalizing valve is open and all wet legs are filled to the correct

levels.

Note

Do not perform a zero trim on Rosemount 3051N Absolute Pressure Transmitters. A zero trim is

zero-based, and absolute pressure transmitters reference absolute zero. To correct mounting position

effects on a Rosemount 3051N Absolute Pressure Transmitter, perform a low trim within the full sensor

trim function. The low trim function provides a “zero” correction similar to the zero trim function but it

does not require the input to be zero-based.

Reference Manual

00809-0100-4808, Rev EA

Figure 2-8. Typical Zero vs. Non-Zero-Based Application

Nonzero-based level

application

A full trim is a two-point sensor calibration where two end-point pressures are applied, and all output is

linearized between them. Always adjust the low trim value first to establish the correct offset.

Adjustment of the high trim value provides a slope correction to the characterization curve based on the

low trim value. The factory-established characterization curve is not changed by this procedure. The trim

values allows performance to be optimized over a specified measuring range at the calibration

temperature.

Zero-based level application Zero-based flow application

2.12.4 Zero trim

HART Fast Keys

To calibrate the sensor with a HART Communicator using the Zero Trim function, perform the following

procedure.

1, 2, 3, 3, 1

18

1. Vent the transmitter and attach a communicator to the measurement loop.

2. From the communicator menu select 1Device setup > 2 Diagnostics and service > 3Calibration >

3Sensor trim > 1Zero trim to prepare to adjust the zero trim.

Transmitter Functions

Loading...

Loading...