Page 1

Quick Start Guide

00825-0100-2555, Rev AB

January 2020

Rosemount™ 2555 Solids Level Switches

Capacitance Probe

Page 2

Quick Start Guide January 2020

Contents

Introduction.................................................................................................................................3

Mechanical installation.................................................................................................................8

Electrical installation.................................................................................................................. 12

Configuration.............................................................................................................................17

Troubleshooting........................................................................................................................ 36

Maintenance.............................................................................................................................. 41

2 Quick Start Guide

Page 3

January 2020 Quick Start Guide

1 Introduction

The level switch detects the presence and absence of a process media at its

installation point, and reports it as a switched electrical output.

Note

Other language versions of this Quick Start Guide can be found at

Emerson.com/Rosemount.

1.1 Safety messages

NOTICE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, ensure you thoroughly

understand the contents before installing, using, or maintaining this

product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

• United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

• Asia Pacific- 65 777 8211

North American Response Center

Equipment service needs.

• 1-800-654-7768 (24 hours a day — includes Canada)

• Outside of these areas, contact your local Emerson representative.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

Quick Start Guide 3

Page 4

Quick Start Guide January 2020

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the level switch is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the level switch only as specified in this manual. Failure to do so may

impair the protection provided by the level switch.

Explosions could result in death or serious injury.

• In explosion-proof/flameproof, non-Incendive/type n, and dust ignition-

proof installations, do not remove the housing cover when power is

applied to the level switch.

• The housing cover must be fully engaged to meet flameproof/explosion-

proof requirements.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the power to the level switch is off, and the lines to any other

external power source are disconnected or not powered while wiring the

level switch.

• Ensure the wiring is suitable for the electrical current and the insulation is

suitable for the voltage, temperature, and environment.

Process leaks could result in death or serious injury.

• Ensure the level switch is handled carefully. If the process seal is

damaged, gas or dust might escape from the silo (or other vessel)

Any substitution of non-recognized parts may jeopardize safety. Repair

(e.g. substitution of components) may also jeopardize safety and is not

allowed under any circumstances.

• Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize

safety. Unauthorized changes that interfere with the integrity of the

welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified

without the prior written permission of Emerson. Any continued use of

product that has been damaged or modified without the written

authorization is at the customer’s sole risk and expense.

4 Quick Start Guide

Page 5

January 2020 Quick Start Guide

CAUTION

The products described in this document are NOT designed for nuclearqualified applications.

• Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

• For information on Rosemount nuclear-qualified products, contact your

local Emerson Sales Representative.

Individuals who handle products exposed to a hazardous substance can

avoid injury if they are informed of and understand the hazard.

• If the product being returned was exposed to a hazardous substance as

defined by Occupational Safety and Health Administration (OSHA), a

copy of the required Safety Data Sheet (SDS) for each hazardous

substance identified must be included with the returned level switch.

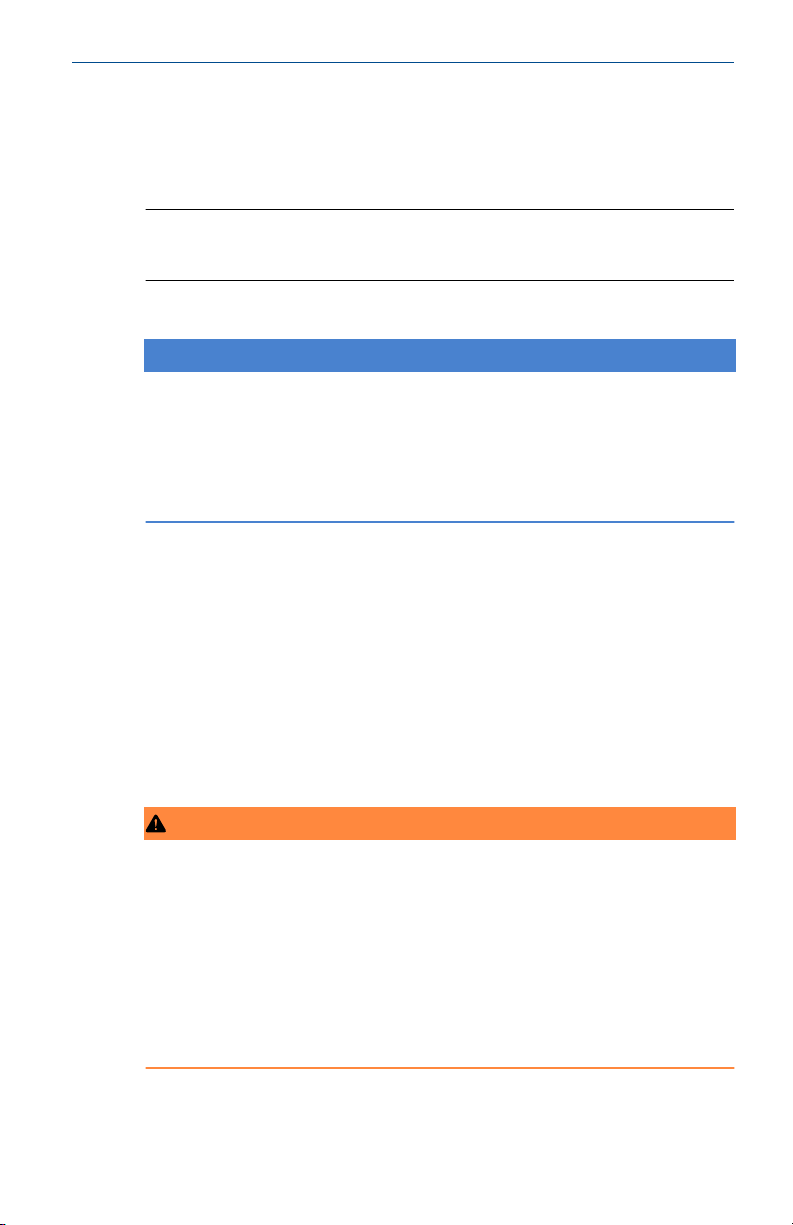

1.2 Applications

A Rosemount™ 2555 Solids Level Switch is used for monitoring the level of

bulk materials in all types of containers and silos.

Typical applications are:

• Building materials

— Lime, extruded polystyrene foam (XPS), molding sand, etc.

• Food and beverage

— Milk powder, flour, salt, etc.

• Plastics

— Plastic granulates, etc.

• Timber

• Chemicals

The level switch has a threaded, flanged, or Tri Clamp process connection for

mounting it onto a silo (or other vessel). You can mount it on a side wall of

the silo, so that it is level with the filling limit to be monitored. Alternatively,

if it has an extended length, mount it vertically on top of a silo to monitor the

maximum filling limit.

The length of the capacitance probe can be up to 98.4 in. (2.5 m) with a rod

extension tube or up to 787 in. (20 m) with an extension rope.

The use of a sliding sleeve is recommended so that the switching point can

be changed easily during the live operation of the level switch.

Quick Start Guide 5

Page 6

A

B

C

D

E

F

G

H

I

J

B

K

Quick Start Guide January 2020

Figure 1-1: Typical Installation Examples

A. Inactive length to reach distance from silo wall

B. Inactive length due to long mounting nozzle

C. Short length (full-silo detection)

D. Short length (on-demand detection)

E. Short length (empty-silo detection)

F. Application in down pipe

G. Inactive length to bring active probe to required level

H. Inactive length and sliding sleeve for adjustable height

I. Rope version (full-silo detection)

J. Rope version (empty-silo detection)

K. Optional sliding sleeve

Active and inactive probe lengths

The active length is always inside the silo and generates an electrical field

between the probe and the silo wall. With active shield technology, the RF

measurements are unaffected by product build-up on the probe. The

inactive length is used to extend the overall probe length.

Note

See the Rosemount 2555 Product Data Sheet for extended length options.

6 Quick Start Guide

Page 7

January 2020 Quick Start Guide

1.3 Measurement principles

Using the principle of measuring capacitance through RF (Radio Frequency),

the presence or absence of a solids medium is detected by monitoring the

change in capacitance between the probe and the container wall.

When the solids medium in the vessel (silo) falls away from the probe level, it

causes an increase in capacitance that is detected by the electronics and the

output switches to indicate an 'uncovered' state.

When the solids medium in the vessel (silo) rises and covers the rod, it

causes a decrease of capacitance that is detected by the electronics and the

output switches to indicate a 'covered' state.

The electrical output will vary depending on the electronics selected when

the Rosemount 2555 was ordered.

Quick Start Guide 7

Page 8

Quick Start Guide January 2020

2 Mechanical installation

2.1 Mounting considerations

Before mounting the level switch on a silo (or other vessel), review the safety

and pre-mounting sections.

2.1.1 Safety

General safety

Installation of this equipment shall be carried out by suitably trained

1.

personnel, in accordance with the applicable code of practice.

2. If equipment is likely to come into contact with aggressive

substances, it is the user’s responsibility to take suitable precautions

that prevent it from being adversely affected, thus ensuring the type

of protection is not compromised.

a. Aggressive substances: Acidic liquids or gases that may

attack metals or solvents that may affect polymeric materials.

b. Suitable precautions: Regular checks as part of routine

inspections or establishing from a material's data sheet that it

is resistant to specific chemicals.

3. It is the responsibility of the installer to:

a. Take protective measures, such as fitting an angled shield

(reverse V shape) to the silo or selecting an extension tube

option, when there are high mechanical forces.

b. Ensure that the process connection is tightened by the

correct amount of torque and sealed to prevent process

leaks.

4. Technical data

a. The Rosemount 2555 Product Data Sheet has all the technical

specifications. See Emerson.com/Rosemount for other

language versions.

Hazardous area safety

The Rosemount 2555 Product Certifications document has safety

instructions and control drawings for hazardous area installations. See

Emerson.com/Rosemount for other language versions.

8 Quick Start Guide

Page 9

A

B

January 2020 Quick Start Guide

2.1.2 Tightening threaded process connections

When tightening the threaded process connection of a Rosemount 2555:

• Use an open-ended wrench on the hexagonal boss of the level switch or

the sliding sleeve.

• Never tighten by using the housing.

• Do not exceed the maximum torque of 80 Nm.

2.1.3 Sliding sleeve

Tighten both M8 screws with a torque of 20 Nm to establish a seal and

maintain the process pressure.

2.1.4 Mechanical load

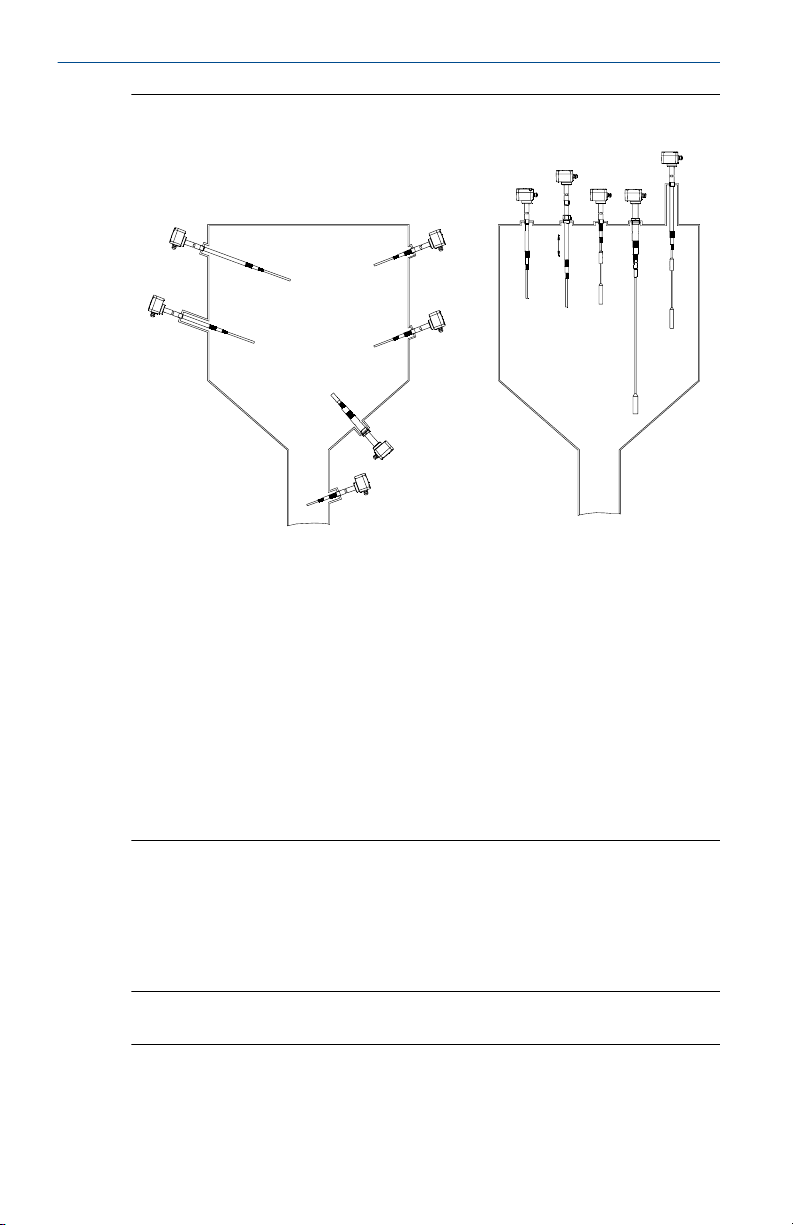

The load at points A and B (Figure 2-1) must not be exceeded. All ratings are

for 104 °F (40 °C).

Figure 2-1: Maximum Mechanical Loads

Table 2-1: Maximum Mechanical Loads

Rosemount 2555S

Rosemount 2555R

Rosemount 2555M

Rosemount 2555P

Rosemount 2555E

Rosemount 2555V

Rod version:

Rope version:

Rod version:

Rope version:

Rod version:

Rope version:

A: 125 Nm

4 kN tensile load

A: 525 Nm

40 kN tensile load

A: 525 Nm

10 kN tensile load

B: 20 Nm

B: 90 Nm

B: 20 Nm

2.1.5 Orientation of cable glands

When the level switch is mounted horizontally, ensure the cable glands are

pointed downwards to avoid water getting inside the housing. Unused

conduit entries must be completely sealed with a suitably rated stopping

(blanking) plug.

Quick Start Guide 9

Page 10

> 2 (50)

> 3.9

(100)

> 3.9

(100)

> 7.9

(200)

Quick Start Guide January 2020

2.1.6 Future maintenance

It is advisable to grease the screws of the housing cover (lid) when a

corrosive atmosphere is present. This will help prevent difficulties when the

cover needs to be removed during future maintenance tasks.

2.1.7 Hygienic applications

The food-grade materials are suitable for use under normal and predictable

hygienic applications (according to directive 1935/2004 Art.3). There are

currently no hygienic certifications for the Rosemount 2555.

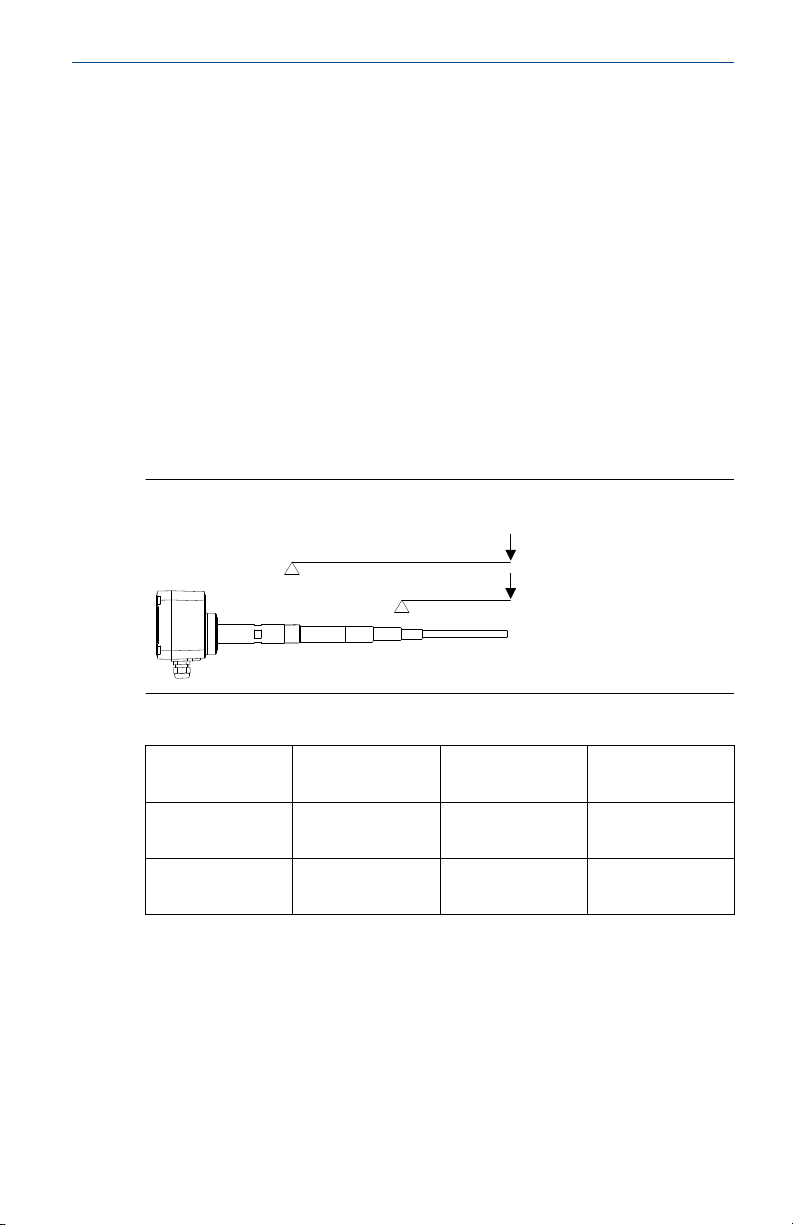

2.1.8 Minimum distances

Figure 2-2 shows the minimum distances required between installed level

switches, the walls of a silo, and a protective shield. The installation of a

protective angled shield above the level switch is recommended depending

on the type of bulk solids.

Figure 2-2: Minimum Distances

Note

Avoid installing the level switch directly under the flow of solids material

(filling point).

2.1.9 Grounding (earthing)

10 Quick Start Guide

The external ground screw must be connected to a grounding point at the

installation site. An internal ground screw is already connected internally and

requires no further action.

Page 11

> 1.8

(50)

A

> 1.8

(50)

A

> 1.8

(50)

A

> 1.8

(50)

A

OK

OK OK

OK

E

F

G

C

D

B

January 2020 Quick Start Guide

See Wiring the level switch for further information about grounding

(earthing) the level switch.

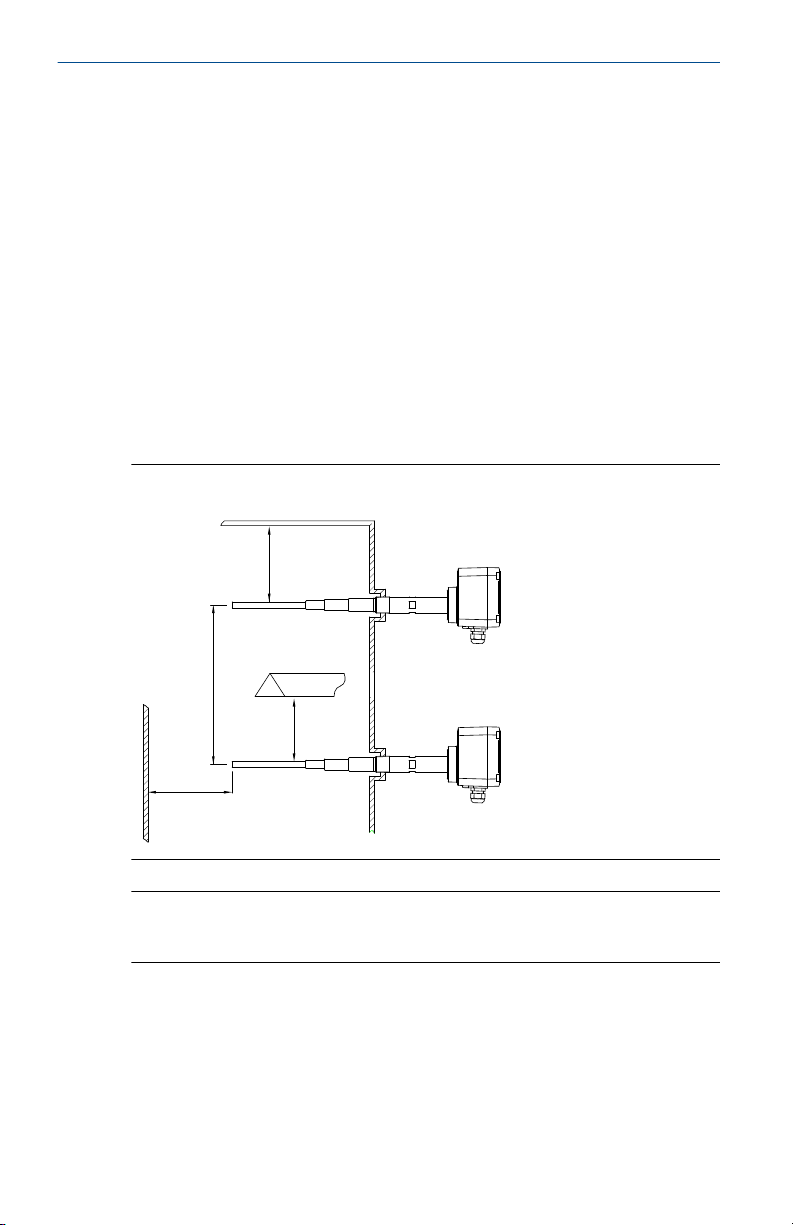

2.2 Mounting the level switch

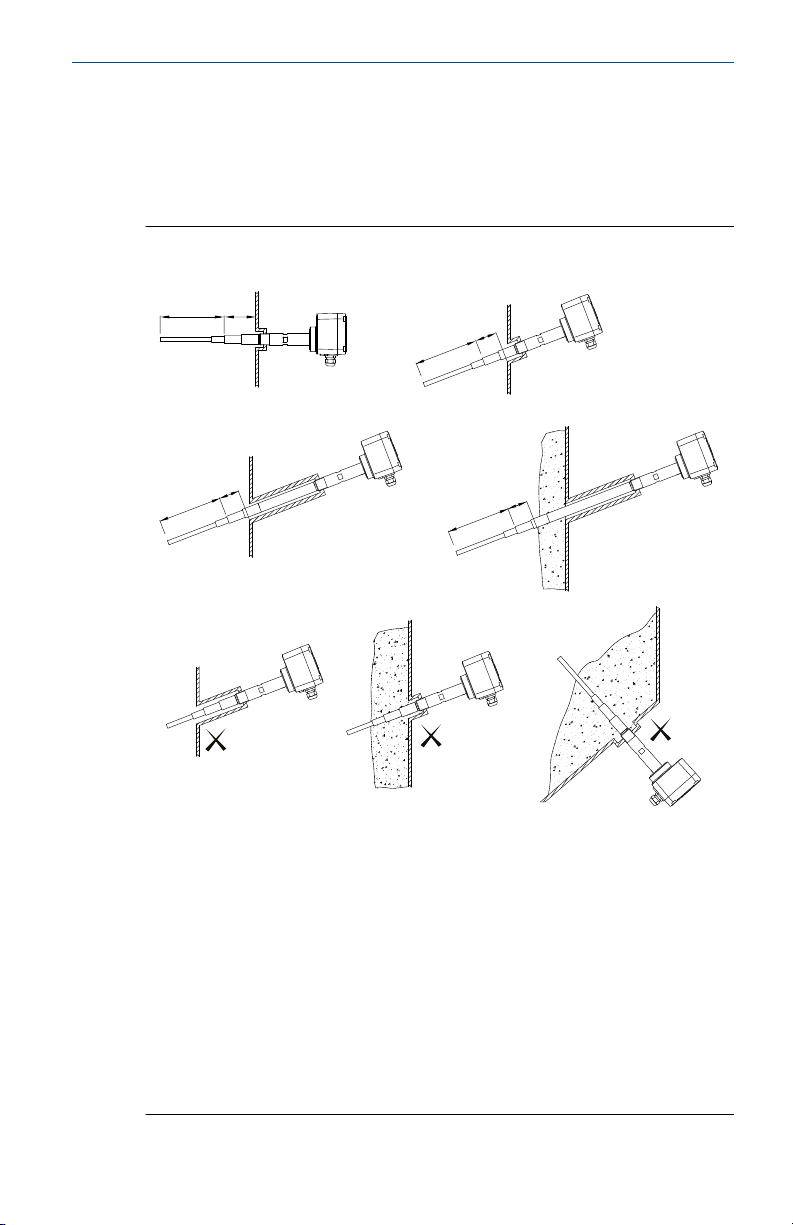

Figure 2-3 shows how the level switch should be mounted.

Figure 2-3: Correct and Incorrect Mounting

A. Active probe

B. Mounting the level switch at an angle helps solids material to fall away

and prevent build-up

C. Correct installation: The inactive length is correctly used with a long

socket

D. Correct installation: The inactive length is correctly used even though

there is a build-up of solids material

E. Incorrect installation: The active probe is inside the socket

F. Incorrect installation: The active probe is covered by a build-up of

material and is not detecting the true level

G. Incorrect installation: The active probe is located where solids material

would remain, even in an empty silo

Quick Start Guide 11

Page 12

Quick Start Guide January 2020

3 Electrical installation

3.1 Wiring considerations

Note

See the Rosemount 2555 Product Data Sheet for the full electrical

specifications.

3.1.1 Handling

In cases of improper handling or handling malpractice, the electrical safety

of the device cannot be guaranteed.

3.1.2 Protective earthing

Before any electrical installation, the device must be connected to the

protective earthing terminal inside the housing.

3.1.3 Installation regulations

Local regulations or VDE 0100 (Regulations of German Electrotechnical

Engineers) must be observed.

When using 24 V supply voltage, an approved power supply with reinforced

insulation to mains is required.

3.1.4 Fuse

Use a fuse as stated in the connection diagrams.

For details, see Wiring the level switch.

3.1.5 Residual Current Circuit Breaker (RCCB) protection

In case of a defect, the distribution voltage must automatically be cut-off by

an RCCB protection switch to protect against indirect contact with

dangerous voltages.

3.1.6 Power supply

Power supply switch

A voltage disconnection switch must be provided near the device.

Supply voltage

Compare the supply voltage applied with the specifications given on the

electronic module and nameplate before switching on the device.

12 Quick Start Guide

Page 13

January 2020 Quick Start Guide

3.1.7 Wiring

Field wiring cables

The diameter has to match the clamping range of the used cable gland.

The cross-section has to match the clamping range of the connection

terminals and the maximum current must be considered.

All field wiring must have insulation suitable for at least 250 Vac.

The temperature rating must be at least 194 °F (90 °C).

Use a shielded cable when there are electrical interferences present that are

higher than stated in the EMC standards. Otherwise, an unshielded

instrumentation cable can be used.

Wiring diagram

The electrical connections are made in accordance with the wiring diagram.

Guiding the cables in the terminal box

The field wiring cables must be cut to a length to be able to properly fit them

into the terminal box.

3.1.8 Cable glands

The screwed cable gland and stopping plug must have the following

specifications:

• Ingress protection IP67

• Temperature range from -40 °C to +80 °C

• Hazardous area certification (depending on where the unit is installed)

• Pull relief

Ensure the screwed cable gland safely seals the cable and is tight enough to

prevent water ingress. Unused conduit or cable entries must be sealed with a

stopping (blanking) plug.

A strain relief must be provided for the field wiring cables when the device is

installed with the factory-provided cable glands.

Cable glands and conduit system for ATEX or IECEx

The installation must comply with the regulations of the country where the

level switch is installed.

Unused entries have to be closed with suitably rated stopping (blanking)

plugs.

Where available, the factory-provided parts must be used.

Quick Start Guide 13

Page 14

Quick Start Guide January 2020

The diameter of the field wiring cable must match the clamping range of the

cable clamp.

If factory-provided parts are not used, the following must be ensured:

• The parts must have an approval adequate to the approval of the level

sensor (certificate and type of protection).

• The approved temperature range must be between the minimum

ambient temperature of the level sensor and the maximum ambient

temperature of the level sensor increased by 10 K.

• The parts must be mounted according to the instructions of the

manufacturer.

3.1.9 Conduit system

When a threaded conduit system is used instead of a cable gland, the

regulations of the country must be observed. The conduit must have a ½-in.

NPT tapered thread to match a NPT threaded conduit entry of the level

switch and comply with ANSI B 1.20.1. Unused conduit entries must be

closed tightly with a metal stopping (blanking) plug.

Conduit system for FM

The regulations of the country must be observed. The flameproof seals and

stopping (blanking) plugs must have an adequate type approval and a

temperature range of at least -40 to 176 °F (–40 to +80 °C). In addition, they

must be suitable for the conditions and correctly installed. Where available,

the original provided parts of the manufacturer must be used.

3.1.10 Connection terminals

When preparing cable wires for connection to terminals, the wire insulation

must be stripped to show no more than 0.31 in. (8 mm) of the copper

strands. Always check that the power supply is disconnected or switched-off

to avoid coming into contact with dangerous live parts.

3.1.11 Relay and transistor protection

Provide protection for relay contacts and output transistors to protect the

device against inductive load surges.

3.1.12 Static charging

The Rosemount 2555 must be grounded to avoid a static electrical build-up.

This is particularly important for applications with pneumatic conveying and

non-metallic containers.

14 Quick Start Guide

Page 15

A

1

A

B

1 2 3 4 5 6 7 8

January 2020 Quick Start Guide

3.1.13 Opening the lid

Before opening the lid, ensure no dust deposits, no airborne dusts, and no

hazardous atmosphere are present.

Do not remove the lid (cover) while circuits are alive.

3.1.14 External equipotential bonding terminal

Connect with equipotential bonding of the plant.

Figure 3-1: External Equipotential Bonding Terminal

A. Equipotential bonding terminal on the Rosemount 2555

3.2 Wiring the level switch

Figure 3-2: Connections

A. Protective conductor terminal

B. Connection terminals

Wiring the power supply and the DPDT relay

Power supply:

• 21 to 230 Vac (50/60 Hz) or Vdc ±10%

Quick Start Guide 15

• 1.5 VA or 1.5 W

Page 16

1 1 2 3 4 5 6 7 8

PE

+

-

L N

A

B

Quick Start Guide January 2020

• Fuse on power supply: maximum 10 A, 250 V, HBC, fast or slow

Signal output:

• Floating relay DPDT:

— Maximum 250 Vac, 8 A (non-inductive)

— Maximum 30 Vdc, 5 A (non-inductive)

• Fuse on signal output:

— Maximum 10 A, 250 V, HBC, fast or slow

Figure 3-3: Power Supply and Signal Output

A. Power supply

B. Signal output

16 Quick Start Guide

Page 17

1 1 2 6 7 8 3 4 5

CAL

TEST

MENU

LED

Display

January 2020 Quick Start Guide

4 Configuration

4.1 User interface

Figure 4-1: Features of the User Interface

Table 4-1: LEDs

Green Relay is energized

Yellow Relay is de-energized

Red Maintenance (flashing) or error (not flashing)

4.2 Powering up the first time (calibration)

Calibration automatically starts when the Rosemount 2555 is powered up

for the first time. If the level switch is powered off and then on again, this

calibration procedure is not repeated when starting up.

Prerequisites

• The level switch must be correctly mounted and wired.

• The level of the solids material must be below the probe.

Procedure

1.

Ensure the level of the solids material is not covering the probe.

Quick Start Guide 17

Page 18

Quick Start Guide January 2020

2. Power up the level switch.

a)

The calibration is in progress when the displays indicate

CAL

and the LED is red and flashing.

b) After approximately 45 seconds, the calibration completes

and indicates the actual measured capacitance and the letter

u is indicated for the uncovered probe status.

3. Check the quick-start settings.

a) Use the quick-start menu (see Quick-start menus) to review

and change the factory settings for Fail Safe High and Low,

signal output delay, and sensitivity.

Postrequisites

The Rosemount 2555 is now calibrated and ready to be configured.

4.3 Measurement mode

The level switch indicates the actual measured capacitance and the status of

the signal output.

(1)

Display

*** u

*** c

LED Description

Green or yellow

(2)

Actual measured

capacitance in pF

Actual signal output:

states uncovered probe u

or covered probe c.

(3)

.

(1) If unexpected messages are displayed, see Maintenance and error messages.

(2) Green or yellow depending on setting of FSH and FSL.

(3) Resolution is 0.1 pF (< 100 pF) or 0.5 pF (> 100 pF). If values are > 100 pF, a dot

behind the number means 0.5 pF (e.g. 100. means 100.5 pF)

Note

If the actual measured capacitance is higher than electronics can measure

(i.e. > 400 pF with sensitivity setting >= 2 pF or > 100 pF with sensitivity

setting <= 1 pF), the level switch will state 400c or 100c. The measurement

is valid, since the actual capacitance is well above the calibrated switch

point. Also, the output signal indicates the probe is covered by showing c.

18 Quick Start Guide

Page 19

MENU

CAL

TEST

January 2020 Quick Start Guide

4.4 Quick-start menus

Note

The LED is flashing red while the quick-start menu is displayed.

Table 4-2: In Measurement Mode

When the level switch is in Measurement mode, press and hold the

MENU button for 3 seconds to enter the quick-start menu. If Code is

displayed, a Lock Code is required. Set the code number with the arrow

buttons and confirm with the Menu button. Then press and hold the

Menu button again for 3 seconds to enter the quick-start menu.

While in the quick-start menu, press and hold the Menu button for 3

seconds to return to Measurement mode.

Press the Menu button for less than 1 second to store a new setting and

proceed to the next menu item.

Use the arrowed buttons, CAL and TEST, to increase and decrease the

value of a setting.

Table 4-3: Quick-start Menus

Display Description Menu item

FSL

C-U

U-C

2

5

to 60

1

(2)

2

4

10

15

25

35

(1)

Fail Safe High

Signal output, Fail safe setting

Fail Safe Low

(1)

Covered-to-uncovered-to-

Signal output, Delay direction

covered probe

Covered-to-uncovered probe

Uncovered-to-covered probe

(1)

Seconds Signal output, Delay time

Adjustable in steps (increment in 5

seconds).

pF

Sensitivity

Required capacitance increase

between uncovered probe (after

calibration) and switch to output

covered probe.

Change the preset value only if

required by the application. See

Guide to push-button calibration.

The D menu item is not valid, and is

not shown if Manual calibration

(menu item G) is set to ON.

A. FSH

B. ALL

C. 0.5

D. 0.5

(1) Factory default setting.

Quick Start Guide 19

Page 20

6 7 8 3 4 5 6 7 8 3 4 5 6 7 8 3 4 5 6 7 8 3 4 5 6 7 8 3 4 5

FSL FSH FSL FSH

Yellow LED Yellow LED Power failureGreen LED Green LED

Quick Start Guide January 2020

(2) Standard factory setting is 2 pF. Optional standard settings if ordered.

4.4.1 FSH and FSL settings

• FSH:

— Use the FSH setting for full-silo detection applications.

— Power failure or line break is considered by the electronics to be as

full signal (as protection against overfilling).

• FSL:

— Use the FSL setting for empty-silo detection applications.

— Power failure or line break is considered by the electronics to be as

empty signal (as protection against running dry).

Figure 4-2: FSH and FSL settings

20 Quick Start Guide

Page 21

January 2020 Quick Start Guide

4.5 Guide to push-button calibration

Push-button calibration needs to be done if Power up calibration at first

time operation was not successful or the unit was changed to another

location or a significant change of DK was present after changing the

material.

Calibration with uncovered probe only This is the simplest method and,

Calibration with uncovered and covered

probe

therefore, is recommended.

If a too small change of capacitance

between uncovered and covered probe

is present, a higher sensitivity can be

selected (1 pF or 0.5 pf).

For a higher change of capacitance and

excessive build-up, the sensitivity can be

reduced (4 pF or more).

For the calibration procedure, see

Powering up the first time (calibration).

Sets the switching-point in the middle

between uncovered and covered probe

capacitances. It ensures the maximum

switching distance to both uncovered

and covered probe capacitance, and

helps to prevent material build-up.

For materials with low DK values and

therefore smaller capacitance

differences for covered and uncovered

states, this method is recommended.

The DK values are not required to be

known.

For the calibration procedure, see

Powering up the first time (calibration).

Quick Start Guide 21

Page 22

A C D

B

CAL

Quick Start Guide January 2020

4.5.1 Push-button calibration for an uncovered probe only

Prerequisites

• The level switch must be correctly mounted and wired.

• The level of the solids material must be below the probe.

Procedure

1. Review the stages in the calibration procedure.

A. Capacitance of uncovered probe

B.

Sensitivity

Switching-point

C.

D. Capacitance of covered probe

2. Ensure the solids material is not covering the probe.

3. Set the sensitivity.

This is only required in certain circumstances. See Guide to push-

button calibration.

Use the quick-start menu item D to set the sensitivity. See Quick-

start menus.

4. Press and hold the

CAL button for three seconds.

The LED is red and flashing when the calibration is started.

a) Wait approximately 10 seconds until the calibration is

completed.

The display then indicates the actual measured capacitance

b)

and a u for the uncovered probe state.

22 Quick Start Guide

Page 23

January 2020 Quick Start Guide

Need help?

If Code is displayed:

1. Enter the code using the arrow buttons and confirm it with the Menu

button.

2. Press and hold the CAL button again for three seconds to restart the

calibration.

If any other messages are displayed, see Maintenance and error messages.

Postrequisites

The Rosemount 2555 is now calibrated and ready to be configured.

Quick Start Guide 23

Page 24

A C D

B

CAL

Quick Start Guide January 2020

4.5.2 Push-button calibration for uncovered and covered probes

Prerequisites

• The level switch must be correctly mounted and wired.

• The level of the solids material must be below the probe.

Procedure

1. Review the stages in the calibration procedure.

A. Capacitance of uncovered probe

B.

Sensitivity

Switching-point

C.

D. Capacitance of covered probe

2. Ensure the solids material is not covering the probe.

3. Press and hold the CAL button for three seconds.

The LED is red and flashing when the calibration is started.

Wait approximately 10 seconds until the calibration is

a)

completed.

b)

The display then indicates the actual measured capacitance

and a u for the uncovered probe state.

4. Make a note of the actual measured capacitance displayed when the

probe is uncovered.

5. Make a note of the actual measured capacitance displayed when the

probe is covered.

For vertical mounting (rope version), the solids material must cover

the probe by 4 - 8 in. (10 - 20 cm).

24 Quick Start Guide

Page 25

January 2020 Quick Start Guide

6. Set the sensitivity.

Calculate the capacitance difference between the uncovered and

covered probe.

Set the sensitivity as follows (quick-start menu item D):

Horizontal mounting Vertical mounting

(rope version)

Capacitance

0.8 to 1.5 pF 0.5 pF 0.5 to 1.0 pF 0.5 pF

1.5 to 3 pF 1 pF 1.0 to 2 pF 1 pF

3 to 6 pF 2 pF 2 to 4 pF 2 pF

6 to 15 pF 4 pF 4 to 10 pF 4 pF

15 to 23 pF 10 pF 10 to 15 pF 10 pF

23 to 38 pF 15 pF 15 to 25 pF 15 pF

38 to 53 pF 25 pF 25 to 35 pF 25 pF

> 53 pF 35 pF > 35 pF 35 pF

(1)

Sensitivity

(2)

Capacitance

(1)

Sensitivity

(3)

(1) Capacitance difference between uncovered and covered probe.

(2) The difference between uncovered and covered should be well above

the sensitivity setting, i.e. approximately > 50 percent.

(3) The difference between uncovered and covered does not need to be

above the sensitivity setting, since with the capacitance will increase

with rising solids material.

If different materials need to be measured in the same bin without

recalibration, the sensitivity must be set for the material with the

lowest DK.

Need help?

If Code is displayed:

1. Enter the code using the arrow buttons and confirm it with the

Menu

button.

Quick Start Guide 25

Page 26

TEST

Quick Start Guide January 2020

2. Press and hold the CAL button again for three seconds to restart the

calibration.

If any other messages are displayed, see Maintenance and error messages.

Postrequisites

The Rosemount 2555 is now calibrated and ready to be configured.

4.6 Resetting the first power-up calibration

An already calibrated level switch can be reset to perform a new power-up

calibration. This may be needed if installing it in a different silo or if it has to

be pre-configured before being shipped.

To do a reset:

1. Press and hold the

2. Switch off the voltage supply when CAL appears on the display.

Since the calibration was started, but not successfully finished, it

automatically starts again when the level switch is powered-up.

Note

Only the calibration is affected. The settings in the menus are not changed.

CAL button for three seconds.

4.7 Data storage of the last valid calibration values

If the power supply is switched off, the last valid calibration values are

stored, and are still valid, when power is switched on again.

4.8 Manual function test (proof test)

The Rosemount 2555 can self-test the internal electronics and external

connected signal evaluation.

Prerequisites

The proof-test must be operated in Measurement mode.

Procedure

1.

Press and hold the

The display shows TEST when the testing is started.

2. Wait approximately 20 seconds until the test is completed.

During the test, the LED turns yellow and the signal output relay

changes state for approximately 10 seconds before returning to

normal operation.

26 Quick Start Guide

TEST button for three seconds.

Page 27

MENU

CAL

TEST

January 2020 Quick Start Guide

Need help?

If Code is displayed:

Enter the code using the arrow buttons and confirm it with the Menu

1.

button.

2. Press and hold the CAL button again for three seconds to restart the

calibration.

If ERR is displayed, see Maintenance and error messages.

Postrequisites

The Rosemount 2555 is now calibrated and ready to be configured.

4.9 Advanced menu

Note

The LED will be red and flashing while the menu is displayed.

Table 4-4: In Measurement Mode

When the level switch is in Measurement mode, press and hold the

MENU button for 10 seconds to enter the Advanced menu. Keep

holding the MENU button even when the Quick-start menu (item:

A.FSx) appears after 3 seconds.

If Code is displayed, a Lock Code is required. Set the code number

with the arrow buttons, CAL and TEST, and confirm with the MENU

button. Then, press and hold the MENU button again for 10

seconds to enter the Advanced menu.

While in the Advanced menu, press and hold the menu button for

3 seconds to return to Measurement mode.

Press the MENU button for less than 1 second to store a new

setting and proceed to the next menu item.

Use the arrowed buttons, CAL and TEST, to increase and decrease

the value of a setting.

4.9.1 Auto recalibration

Note

The LED is red and flashing while the menu is displayed.

Quick Start Guide 27

Page 28

Quick Start Guide January 2020

Table 4-5: Auto Recalibration Menu (Advanced Menu)

Display Description Menu item

(1)

F.

(1) Menu item "F" is not valid, and will not appear on the display, if manual

calibration (Menu item "G") is set to "ON".

(2) Factory default setting.

OFF

ON

(2)

Auto recalibration to uncovered probe.

It is possible to commission an already filled silo

(covered probe). A proper calibration is not

possible with covered probe. A solution is to do

an auto calibration as soon as the silo becomes

empty (uncovered probe).

To do this, set Auto recalibration to ON and do a

push-button calibration with a covered probe

(press and hold the CAL button for 3 seconds).

The level switch will recalibrate (as an uncovered

probe) when the measured capacitance is 50% of

the sensitivity setting (menu item D) for more

than two minutes.

Do not set to ON if excessive solids material

build-up is present, since this build-up may

decrease the measured capacitance and cause

an incorrect calibration.

4.9.2 Manual calibration

Note

The LED will be red and flashing while the menu is displayed.

Table 4-6: Manual calibration menu (Advanced menu)

Display Description Menu item

(1)

G.

OFF

ON

Manual calibration ON/OFF.

If set to ON:

• Menu items H,K and L appear.

• Menu items D (Quick-start menu) and F

(Auto re-calibration) are no longer valid and

are hidden.

• Push-button calibration is not possible (if

CAL button is pressed, the display shows

G.ON).

28 Quick Start Guide

Page 29

A C E F

B

January 2020 Quick Start Guide

Table 4-6: Manual calibration menu (Advanced menu) (continued)

Display Description Menu item

(1)

H.

K. *** pF

L. *** pF

LO

HI

Low

High

Sensitivity range.

Low sensitivity range allows to detect a

capacitance change of >= 2 pF.

High sensitivity range allows to detect a

capacitance change of >= 0.5 pF.

See also Guide to manual calibration

Switching-point covered-to-uncovered

A. Capacitance of uncovered probe

B. Covered-to-uncovered switching-point (Menu

item "K")

C. Hysteresis (Menu item L)

D. Uncovered-to-covered switching-point

E. Capacitance of covered probe

Factory setting for the lowest pF value is 3 pF.

Resolution is 0.1 pF (< 100 pF) or 0.5 pF (> 100

pF). If values are > 100 pF, a dot behind the

number means 0.5 pF (e.g. 100. means 100.5

pF).

Hysteresis

Hysteresis can be adjusted to minimize constant

switching of the signal output. This can happen

when there are unstable capacitance

measurements due to movement of solids

materials.

The lowest value (factory setting) is 0.5/0.2 pF

(for Low/High sensitivity).

The maximum value is limited by the maximum

measurable capacitance.

For resolution, see menu item K.

(1) Factory default setting.

Quick Start Guide 29

Page 30

Quick Start Guide January 2020

4.9.3 Diagnostics

Note

The LED is red and flashing while the menu is displayed.

Table 4-7: Diagnostics Menu (Advanced Menu)

Display Description Menu item

OFF

(1)

Auto Function Test.

This function automatically tests the internal

electronics. Testing runs in the background and

does not affect the normal measurement

functions.

If a failure is detected:

• The display shows ERR. See Table 5-1.

• The LED turns red and starts flashing.

• The status output relay is de-energized.

M. ON

N. *** pF

P. *** pF

Q. *** °C

R. *** °C

S. ***

T. ***

(1) Factory default setting.

Auto calibrated switch-point (covered-touncovered).

If OR or UR is displayed, there is no valid

calibration.

See Troubleshooting.

Auto calibrated switching-point(uncovered-tocovered).

If OR or UR is displayed, there is no valid

calibration.

See Troubleshooting.

Minimum Stored Electronics Temperature

Maximum Stored Electronics Temperature

Software version

Service data

This manufacturer data is for the use of Emerson

and not covered in this manual.

30 Quick Start Guide

Page 31

January 2020 Quick Start Guide

4.9.4 Security and factory reset

Note

The LED is red and flashing while the menu is displayed.

Table 4-8: Security and Factory Reset Menu (Advanced Menu)

Display Description Menu item

V. *** Lock code.

The locking code (password) can be set to

prevent unauthorized persons from accessing

the menu system, starting a push-button

calibration, or a manual function test (proof

test).

The locking code can be any number from 1 to

9999.

A locking code of 000 disables the password

protection.

if a locking code was set but

W. NO

YES

Contact Emerson

has been forgotten.

(1)

Factory reset.

This resets all user-entered data to the factory

defaults. The level switch automatically starts a

calibration.

(1) Factory default setting.

4.10 Guide to manual calibration

Manual calibration is recommended for special purposes.

Calibration with uncovered probe only

This is the simplest method and, therefore, is recommended. It is applicable

for higher DK values, which give a higher change of capacitance between an

uncovered and covered probe. The DK value of the solids material is required

to be known, to set the sensitivity range and an increase to the switchingpoint.

For the calibration procedure, see Powering up the first time (calibration).

Calibration with uncovered and covered probe

This method is the safest, since it sets the switching-point in the middle

between uncovered and covered probe capacitances. It ensures the

maximum switching distance to both uncovered and covered probe

capacitance, and helps prevent material build-up.

For materials with low DK values, and therefore smaller capacitance

differences for covered and uncovered states, this method is recommended.

Quick Start Guide 31

Page 32

A C E F

B D

Quick Start Guide January 2020

The DK values are required only to be roughly known, so as to set the

sensitivity range.

For the calibration procedure, see Powering up the first time (calibration).

Table 4-9: Manual Calibration Guide

DK Sensitivity

range

< 1.5 - - - -

1.5 to 1.6 High - - Required

1.7 to 1.9 High Recommended +1 pF Possible

2.0 to 2.9 Low Recommended +2 pF Possible

3.0 to 4.9 Low Recommended +4 pF Possible

5.0 to 10 Low Recommended +10 pF Possible

> 10 Low Recommended +15 pF Possible

Calibration:

Uncovered probe

only

4.10.1 Manual calibration for an uncovered probe

Prerequisites

• The level switch must be correctly mounted and wired.

• The level of the solids material must be below the probe.

• The signal output delay should be set to 0.5 seconds.

Procedure

1.

Review the stages in the calibration procedure.

Increase to

switchingpoint

Calibration:

Uncovered

and covered

probe

A. Capacitance of uncovered probe

B. Increase to switch-point

C.

Switching-point for covered-to-uncovered probe

D. Hysteresis

E. Switching-point for uncovered-to-covered probe

F. Capacitance of covered probe

2. Ensure the level of the solids material is well below the probe.

32 Quick Start Guide

Page 33

January 2020 Quick Start Guide

3. Set the sensitivity.

Check for the required sensitivity range (low or high) depending on

the material to be measured. Use the calibration guide. See Guide to

manual calibration.

Use the Advanced menu item H to set the sensitivity. See Advanced

menu.

4. Establish the capacitance of the uncovered probe.

a) Navigate to the menu item K in the Advanced menu.

b) Starting with the lowest capacitance (factory setting is 3 pF),

increase the displayed capacitance until the output just

changes from covered to uncovered states.

In measurement mode, the actual measured capacitance is

displayed. This gives an indication of which capacitance the output

changes from a covered to uncovered state.

If the output has once changed to uncovered and changes back to

covered, the value must be decreased by setting the Hysteresis

(menu item L).

5. Set a switch-point for the covered-to-uncovered change.

Use the Advanced menu item K to set the switch-point to the

established capacitance of an uncovered probe + an increase to the

switch-point. See Advanced menu.

6. Set the Hysteresis.

Use the Advanced menu item L to set the hysteresis. The factory

setting is normally sufficient and does not need to be changed.

Need help?

If the actual measured capacitance is close to the limits of what the

electronic can measure (400 pF with sensitivity setting Low or 100 pF with

sensitivity setting High). See Maintenance and error messages.

Postrequisites

The Rosemount 2555 is now calibrated and ready to be used.

Quick Start Guide 33

Page 34

A CDE F

50% 50%

Quick Start Guide January 2020

4.10.2 Manual calibration for uncovered and covered probes

Prerequisites

• The level switch must be correctly mounted and wired.

• The level of the solids material must be below the probe.

• Manual calibration must be set to ON (Advanced menu, item K)

Procedure

1. Review the stages in the calibration procedure.

A. Capacitance of uncovered probe

B. Switching-point for covered-to-uncovered probe

Hysteresis

C.

D. Switching-point for uncovered-to-covered probe

E. Capacitance of covered probe

2. Set the sensitivity.

Check for the required sensitivity range (low or high) depending on

the material to be measured. Use the calibration guide. See Guide to

manual calibration.

Use the Advanced menu item H to set the sensitivity. See Advanced

menu.

3. Make a note of the actual measured capacitance displayed when the

probe is uncovered.

4. Make a note of the actual measured capacitance displayed when the

probe is covered.

For vertical mounting (rope version), the solids material must cover

the probe by 4 to 8 in. (10 to 20 cm).

34 Quick Start Guide

Page 35

January 2020 Quick Start Guide

5. Set a switch-point for the covered-to-uncovered change.

Use the Advanced menu item K to set the switch point to:

(Capacitance

uncovered

(0.5 * (Capacitance

+

covered

- Capacitance

uncovered

))

With Low sensitivity range (Advanced menu item H): If the difference

between uncovered and covered probe is smaller than 4 pF, set

either to High sensitivity or use a more sensitive probe (longer active

probe). For rope version only a setting to High sensitivity range is

possible.

With High sensitivity range (Advanced menu item H): If the

difference between uncovered and covered probe is smaller than 1

pF, use a more sensitive probe (longer active probe). For rope

version, call factory.

6.

Set the Hysteresis.

Use the Advanced menu item L to set the hysteresis. The factory

setting is normally sufficient and does not need to be changed.

Need help?

If the actual measured capacitance is close to the limits of what the

electronic can measure (400 pF with sensitivity setting Low or 100 pF with

sensitivity setting High). See Maintenance and error messages.

Postrequisites

The Rosemount 2555 is now calibrated and ready to be configured.

Quick Start Guide 35

Page 36

Quick Start Guide January 2020

5 Troubleshooting

5.1 Maintenance and error messages

The level switch indicates error messages while in measurement mode and

during calibration routines.

Table 5-1: In Measurement Mode

Display LED Description Possible causes and

UR Flashing red Under Range

Actual measured

capacitance is lower

than 3 pF.

OR Flashing red Over Range

After changing the

sensitivity from >= 2

pF to <= 1 pF.

ERR Constant red Auto or Manual

Function Test error

solutions

Probe is defective or

the probe is

incorrectly wired.

The signal output

relay is de-energized.

Actual calibrated

capacitance is higher

than 100 pF and

cannot be measured

with Sensitivity

setting <= 1 pF.

Change to Sensitivity

2 pF (if DK of the

material is high

enough) or

recalibrate.

Electronics fault.

Replace the

electronics.

The output signal

relay is de-energized.

36 Quick Start Guide

Page 37

January 2020 Quick Start Guide

Table 5-2: During Power-up or Push-button Calibration

Display LED Description Possible causes and

UR Flashing red Under Range

Actual measured

capacitance is lower

than 3 pF.

Calibration is not

possible.

OR Flashing red Over Range.

Actual measured

capacitance is higher

than 400 pF

(sensitivity setting >=

2 pF) or 100 pF

(sensitivity setting <=

1 pF).

Calibration is not

possible.

G.ON Flashing red CAL button pressed

with Manual

calibration set to ON.

Starting a calibration

using the push

button is not

possible.

solutions

Probe is defective or

the probe is

incorrectly wired.

The signal output

relay is de-energized.

A long rope version in

an empty silo may

exceed 100 pF

capacitance. Change

Sensitivity setting to

2 pF if DK of the

material is high

enough.

Probe may be

covered with

material. Ensure that

the probe is

uncovered.

The probe may be

faulty or incorrectly

wired.

Set Manual

calibration to OFF

when the push

button is to be used

for starting a

calibration.

Quick Start Guide 37

Page 38

Quick Start Guide January 2020

Table 5-3: During Manual Calibration

Display LED Description Possible causes and

solutions

(1)

100

Yellow or green With the sensitivity

range set to high.

Actual measured

capacitance is close

to, or higher than,

100 pF (depending on

the capability of

electronics).

Calibration not

possible.

A long rope version in

an empty silo may

exceed 100 pF

capacitance. Change

the sensitivity range

to low if DK of the

material is high

enough.

Probe may be

covered with

material. Ensure that

probe is uncovered.

The probe may be

faulty or incorrectly

wired.

(2)

400

Yellow or green With the sensitivity

range set to low.

Actual measured

capacitance is close

to, or higher than,

400 pF (depending on

capability of

electronics).

Probe may be

covered with

material. Ensure that

the probe is

uncovered.

The probe may be

faulty or incorrectly

wired.

Calibration is not

possible.

(1) The display is showing 100 or close to 100.

(2) The display is showing 400 or close to 400.

38 Quick Start Guide

Page 39

January 2020 Quick Start Guide

5.2 General items

Table 5-4: General Items

Situation Behavior of the

electronic

Signal output state

is 'probe covered'

even though the

solids material is

below the probe.

The actual

measured

capacitance

(1)

greater than the

calibrated

switching-point

for an uncoveredto-covered probe

change of state.

Signal output state

is 'uncovered

probe' even though

the solids material

is above the probe.

The actual

measured

capacitance

less than the

calibrated

(3)

switching-point

for an covered-touncovered probe

change of state.

Possible reason Possible solution

The level switch is

Recalibrate.

not properly

is

calibrated.

Excessive material

build-up on active

(2)

probe.

Increase distance

to wall (longer

inactive length).

Change the

installation

location.

Recalibrate with

less sensitivity

Faulty or incorrect

probe wiring.

Calibration was

Check the probe

wiring (see below).

Recalibrate

done with covered

is

probe.

Calibration was

performed with a

(4)

sensitivity that was

too low.

Recalibrate with

higher

sensitivity

Increase active

probe length and

recalibrate

Faulty or incorrect

probe wiring.

Check the probe

wiring (see below).

(3)

(3)

.

(3)

.

(3)

.

(3)

.

(1) The value can be seen on the display in Measurement mode.

(2) The value can be seen in Advanced menu item P.

(3) See the calibration guides.

(4) The value can be seen in Advanced menu item N.

5.3 Check the probe wiring

Prerequisites

The power supply to the level switch must be switched off.

Procedure

Clean away any deposits on the probe.

1.

2. Take out the electronic board and disconnect internal wires.

Quick Start Guide 39

Page 40

A

B

C

D

E

Quick Start Guide January 2020

3. Check the orange, yellow, and green/yellow wires with a

multimeter.

A. Orange (probe) and yellow (shield)

B. Green/yellow (ground)

Ground

C.

D. Shield

E. Probe

Less than 5 ohm must be present between:

• Orange wire and probe

• Yellow wire and shield

• Green/yellow wire and ground

More than 1 MΩ resistance must be present between:

• Orange and yellow wires

• Orange and green/yellow wires

If other values are present, the wiring of the probe is incorrect or

defective.

40 Quick Start Guide

Page 41

January 2020 Quick Start Guide

6 Maintenance

6.1 Opening the lid (cover)

Before opening the lid for maintenance reasons, consider the following:

• Do not remove the lid while circuits are live.

• Ensure that no dust deposits or airborne dusts are present.

• Ensure that rain does not enter the housing.

6.2 Regular checks for safety

To ensure robust safety in hazardous locations and with electrical safety, the

following items must be regularly checked depending on the application:

• Mechanical damage or corrosion of the field wiring cables or any other

components (housing side and sensor side).

• Tight sealing of the process connection, cable glands, and enclosure lid.

• Properly connected external PE cable (if present).

6.3 Cleaning

If cleaning is required by the application, consider the following:

• The cleaning agent must comply with the materials of the unit (chemical

resistance). Mainly the shaft sealing, lid sealing, cable gland, and the

surface of the unit must be considered.

The cleaning process must be done in a way that:

• The cleaning agent cannot enter into the unit through the shaft sealing,

lid sealing, or cable gland.

• No mechanical damage of the shaft sealing, lid sealing, cable gland, or

other parts can happen.

A possible accumulation of dust on the unit does not increase the maximum

surface temperature and must therefore not be removed for purposes of

maintaining the surface temperature in hazardous locations.

6.4 Function test

Depending on the application, frequent functional testing may be required.

See Manual function test (proof test) for details.

6.5 Production date

The production year is shown on the nameplate.

Quick Start Guide 41

Page 42

Quick Start Guide January 2020

6.6 Spare parts

Refer to the Rosemount 2555 Product Data Sheet for all spare parts.

42 Quick Start Guide

Page 43

January 2020 Quick Start Guide

Quick Start Guide 43

Page 44

*00825-0100-2555*

00825-0100-2555, Rev. AB

Quick Start Guide

January 2020

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...