Page 1

00825-0200-4825, Rev EA

Rosemount™ 248 Head Mount

Temperature Transmitter

Quick Start Guide

February 2021

Page 2

Quick Start Guide February 2021

Contents

About this guide...........................................................................................................................3

Configuration...............................................................................................................................5

Mount the transmitter..................................................................................................................7

Connect the wiring.....................................................................................................................11

Perform a loop test.....................................................................................................................16

Certified installations................................................................................................................. 17

Product certifications................................................................................................................. 18

2

Page 3

February 2021 Quick Start Guide

1 About this guide

This guide provides basic guidelines to install the Rosemount 248 Head

Mount Temperature Transmitter. It does not provide instructions for

detailed configuration, diagnostics, maintenance, service, troubleshooting,

or installations. Refer to the Rosemount 248 Temperature Transmitter

Reference Manual for more instruction. The manual and this guide are also

available electronically at Emerson.com/Rosemount.

1.1 Safety messages

WARNING

Explosions

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance

with appropriate local, national, and international standards, codes, and

practices.

Review the Hazardous Locations Certifications for any restrictions

associated with a safe installation.

Process leaks

Process leaks could result in death or serious injury.

Install and tighten thermowells and sensors before applying pressure.

Do not remove the thermowell while in operation.

Electrical shock

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

Unless marked, the conduit/cable entries in the housing use a ½–14 NPT

thread form. Entries marked “M20” are M20 × 1.5 thread form. On

devices with multiple conduit entries, all entries will have the same

thread form. Only use plugs, adapters, glands, or conduit with a

compatible thread form when closing these entries.

When installing in a hazardous location, use only appropriately listed or

Ex certified plugs, glands, or adapters in cable/conduit entries.

Quick Start Guide 3

Page 4

Quick Start Guide February 2021

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

4

Page 5

February 2021 Quick Start Guide

2 Configuration

2.1 Bench calibration

There are three ways to configure the transmitter:

• Field Communicator

• Rosemount 248 PC Programming Kit

• Custom at the factory using the C1 option code

Refer to the Rosemount 248 Reference Manual and the Field Communicator

User Guide for more information.

Connecting a field communicator

The Field Communicator Field Device Revision Dev v1, DD v1or later is

required for complete functionality.

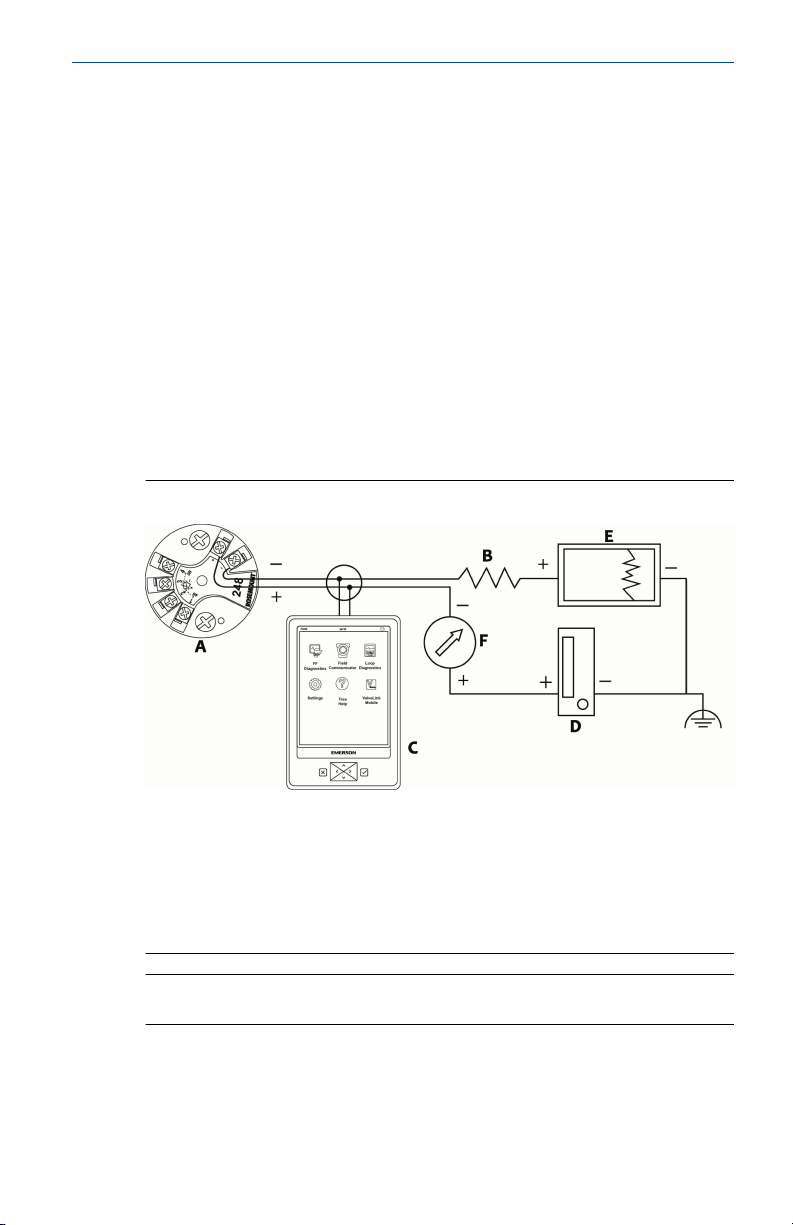

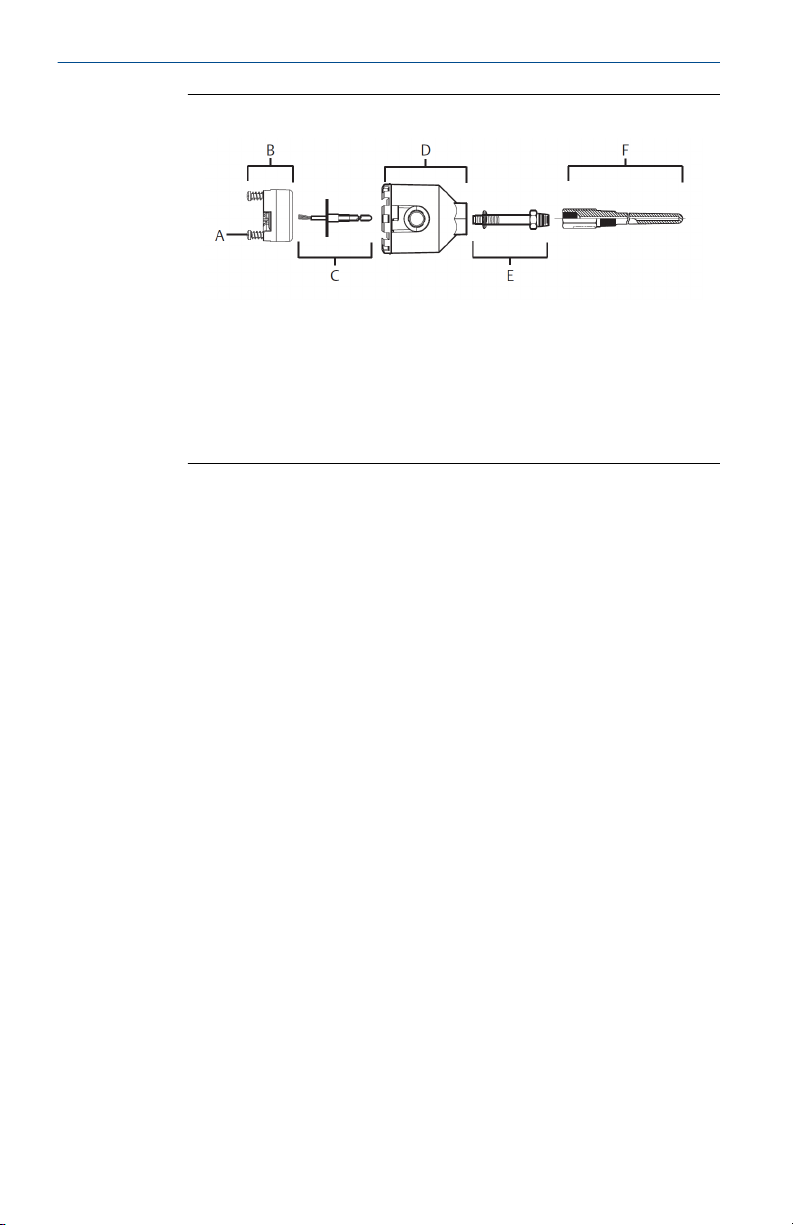

Figure 2-1: Connecting a Field Communicator to a Bench Loop

A. Rosemount 248 Transmitter

B. 250 Ω ≤ RL ≤ Ω 1100

C. Field Communicator

D. Power supply

E. Recorder (optional)

F. Ammeter (optional)

Note

Do not operate when power is below 12 Vdc at the transmitter terminal.

Quick Start Guide 5

Page 6

Quick Start Guide February 2021

2.2 Verify transmitter configuration

To verify operation using a Field Communicator, refer to the Rosemount 248

Reference Manual for more detailed description.

2.3 Install PC programmer kit (HART® 5 only)

Procedure

1. Install all necessary software for PC configuration:

a) Install the Rosemount 248C software

1. Place the CD-Rom in the drive.

2. Run setup.exe from Windows™ 7, 8, 10, or XP.

b) Install the MACTek® HART modem drivers completely before

beginning bench configuration with the Rosemount 248 PC

Programming system.

Note

For USB modem: Upon first use, configure appropriate COM ports

within the Rosemount 248 PC software by selecting Port Settings

from the Communicate menu. The USB modem driver emulates a

COM port and will add to available port selections in the software’s

drop-down box. Otherwise software defaults to first available COM

port, which may not be correct.

2. Set up configuration system hardware:

a) Hook up the transmitter and load resistor (250-1100 ohms)

wired in series with the power supply.

The device will need an external power supply of 12-42.4 Vdc

for configuration.

b) Attach the HART modem in parallel with the load resistor and

connect it to the PC.

2.3.1 Spares kit and re-order numbers

Table 2-1: Programming Kit Spare Part Numbers

Product description Part number

Programming software (CD) 00248-1603-0002

Rosemount 248 Programmer Kit - USB 00248-1603-0003

Rosemount 248 Programmer Kit - Serial 00248-1603-0004

For more information, refer to the Rosemount 248 Reference Manual.

6

Page 7

February 2021 Quick Start Guide

3 Mount the transmitter

3.1 Overview

Mount the transmitter at a high point in the conduit run to prevent moisture

from draining into the transmitter housing.

3.2 Typical European and Asia Pacific installation

Head mount transmitter with DIN plate style sensor

Procedure

1. Attach the thermowell to the pipe or process container wall. Install

and tighten thermowells before applying process pressure.

2. Assemble the transmitter to the sensor.

a) Push the transmitter mounting screws through the sensor

mounting plate.

3. Wire the sensor to the transmitter.

4. Insert the transmitter-sensor assembly into the connection head.

a) Thread the transmitter mounting screw into the connection

head mounting holes.

b) Assemble the extension to the connection head.

c) Insert the assembly into the thermowell.

5. Slip the shielded cable though the cable gland.

6. Attach a cable gland into the shielded cable.

7. Insert the shielded cable leads into the connection head through the

cable entry. Connect and tighten the cable gland.

8. Connect the shielded power cable leads to the transmitter power

terminals. Avoid contact with sensor leads and sensor connections.

9. Install and tighten the connection head cover. Enclosure covers must

be fully engaged to meet explosion-proof requirements.

Quick Start Guide 7

Page 8

Quick Start Guide February 2021

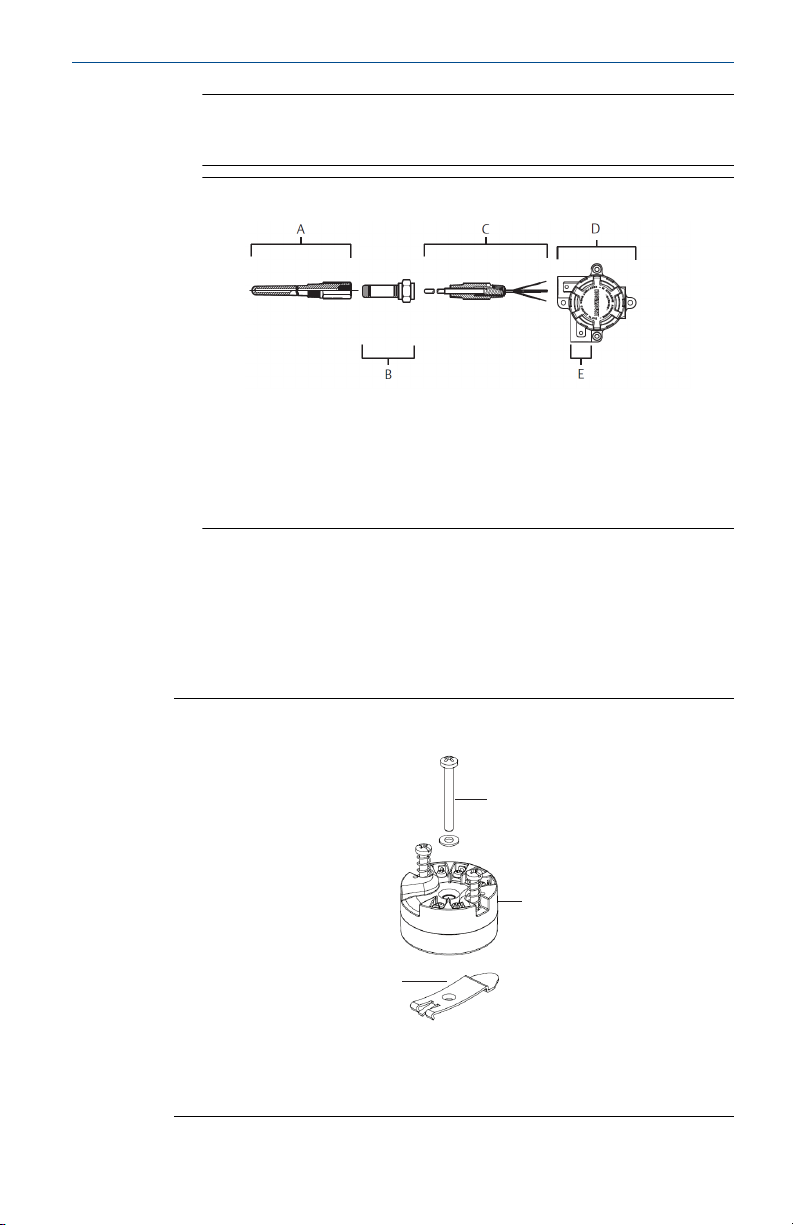

Figure 3-1: Typical European and Asia Pacific Installation

A. Transmitter mounting screws

B. Rosemount 248 Transmitter

C. Integral mount sensor with flying leads

D. Connection head

E. Extension

F. Thermowell

3.3 Typical North and South American installation

Head mount transmitter with threaded sensor

Procedure

1. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying process pressure.

2. Attach necessary extension nipples and adapters to the thermowell.

3. Seal the nipple and adapter threads with silicone tape.

4. Screw the sensor into the thermowell. Install drain seals if required

for severe environments or to satisfy code requirements.

5. Pull the sensor wiring leads through the universal head and

transmitter.

6. Mount the transmitter in the universal head by threading the

transmitter mounting screws into the universal head mounting

holes.

7. Mount the transmitter-sensor assembly into the thermowell. Seal

adapter threads with silicone tape.

8. Install conduit for field wiring to the conduit entry of the universal

head. Seal conduit threads with silicone tape.

9. Pull the field wiring leads through the conduit into the universal

head.

10. Attach the sensor and power leads to the transmitter. Avoid contact

with other terminals.

11. Install and tighten the universal head cover.

8

Page 9

C

B

A

February 2021 Quick Start Guide

Note

Enclosure covers must be fully engaged to meet explosion-proof

requirements.

Figure 3-2: Typical North and South American Installation

A. Threaded thermowell

B. Standard extension

C. Threaded style sensor

D. Universal head

E. Conduit entry

3.4 Mounting to a DIN rail

Procedure

• To attach a head mount transmitter to a DIN rail, assemble the

appropriate rail mounting kit (part number 00248-1601-0001) .

Figure 3-3: Assembling Rail Clip Hardware

A. Mounting hardware

B. Transmitter

C. Rail clip

Quick Start Guide 9

Page 10

Quick Start Guide February 2021

3.4.1 Rail mount transmitter with remote mount sensor

The least complicated assembly uses:

• a remote mounted transmitter

• an integral mount sensor with terminal block

• an integral style connection head

• a standard extension

• a threaded thermowell

Refer to the Metric Sensor Product Data Sheet for complete sensor and

mounting accessory information.

3.4.2 Rail mount transmitter with threaded sensor

The least complicated assembly uses:

• a threaded sensor with flying heads

• a threaded sensor connection head

• a union and nipple extension assembly

• a threaded thermowell

Refer to Rosemount Sensor Product Data Sheet for complete sensor and

mounting accessory information.

10

Page 11

February 2021 Quick Start Guide

4 Connect the wiring

4.1 Diagrams and power

• Wiring diagrams are located on the top label of the transmitter.

• An external power supply is required to operate the transmitter.

• The power required across the transmitter power terminals is 12 to 42.4

Vdc (the power terminals are rated to 42.4 Vdc).

Note

To prevent damaging the transmitter, do not allow terminal voltage to drop

below 12.0 Vdc when changing the configuration parameters.

4.1.1 Power the transmitter

Procedure

1. Connect the positive power lead to the “+” terminal.

2. Connect the negative power lead to the “–” terminal.

3. Tighten the terminal screws.

4. Apply power (12–42 Vdc).

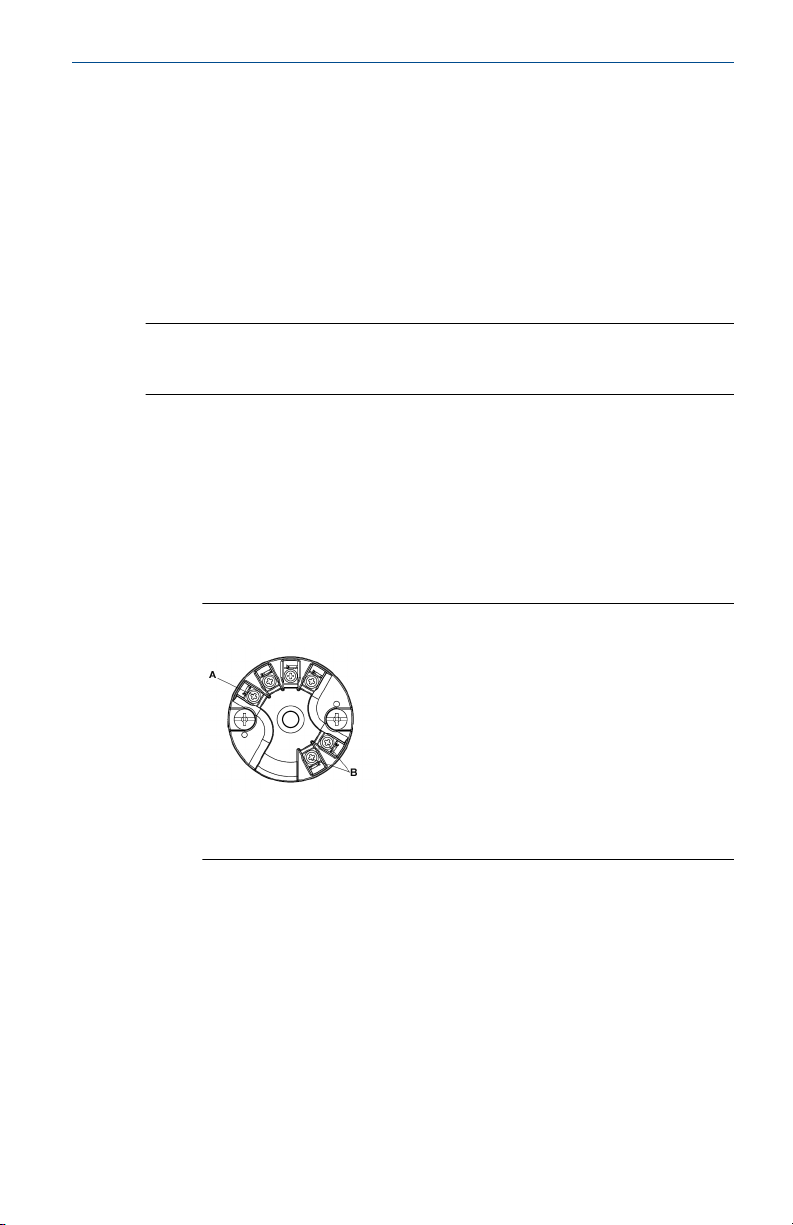

Figure 4-1: Power, Communication, and Sensor Terminals

A. Sensor terminals

B. Power/communication terminals

4.1.2 Ground the transmitter

Ungrounded thermocouple, mV, and RTD/Ohm inputs

Each process installation has different requirements for grounding. Use the

grounding options recommended by the facility for the specific sensor type,

or begin with grounding Option 1 (the most common).

Quick Start Guide 11

Page 12

A

B

D

C

Quick Start Guide February 2021

4.1.3 Ground the transmitter: Option 1

Use this method for grounded housing.

Procedure

1. Connect sensor wiring shield to the transmitter housing.

2. Ensure the sensor shield is electrically isolated from surrounding

fixtures that may be grounded.

3. Ground signal wiring shield at the power supply end.

Figure 4-2: Option 1: Grounded Housing

A. Sensor wires

B. Transmitters

C. DCS host system

D. Shield ground point

4.1.4 Ground the transmitter: Option 2

Use this method for grounded housing.

Procedure

1. Connect signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from

the transmitter housing.

3. Ground shield at the power supply end only.

4. Ensure the sensor shield is electrically isolated from the surrounding

12

grounded fixtures.

Page 13

D

B

A

C

February 2021 Quick Start Guide

Figure 4-3: Option 2: Grounded Housing

A. Sensor wires

B. Transmitters

C. DCS host system

D. Shield ground point

4.1.5 Ground the transmitter: Option 3

Use this method for grounded or ungrounded housing.

Procedure

1. Ground sensor wiring shield at the sensor, if possible.

2. Ensure that the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing.

Do not connect the signal wiring shield to the sensor wiring shield.

3. Ground signal wiring shield at the power supply end.

Quick Start Guide 13

Page 14

A

B

D

C

Quick Start Guide February 2021

Figure 4-4: Option 3: Grounded or Ungrounded Housing

A. Sensor wires

B. Transmitters

C. DCS host system

D. Shield ground point

4.1.6 Ground the transmitter: Option 4

Use this method for grounded thermocouple inputs.

14

Procedure

1. Ground sensor wiring shield at the sensor.

2. Ensure that the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing.

Do not connect the signal wiring shield to the sensor wiring shield.

3. Ground signal wiring shield at the power supply end.

Page 15

A

B

D

C

February 2021 Quick Start Guide

Figure 4-5: Option 4: Grounded Thermocouple Inputs

A. Sensor wires

B. Transmitters

C. DCS host system

D. Shield ground point

Quick Start Guide 15

Page 16

Quick Start Guide February 2021

5 Perform a loop test

5.1 Overview

The loop test command verifies transmitter output, loop integrity, and

operation of any recorders or similar devices installed in the loop.

Note

This is not available with the Rosemount 248C Configuration Interface.

5.2 Initiate loop test

Procedure

1. Connect an external ampere meter in series with the transmitter loop

(so the power to the transmitter goes through the meter at some

point in the loop).

2. From the Home screen, select: 1. Device Setup → 2. Diag/Serv → 1.

Test Device → 1. Loop Test

3. Select a discrete milliampere level for the transmitter to output. At

Choose Analog Output, select 1. 4 mA, 2. 20 mA, or 3. Other to

manually input a value between 4 and 20 mA.

4. Select Enter to show the fixed output.

5. Select OK.

6. In the test loop, check that the fixed mA input and the transmitter’s

mA output are the same value.

5.3

16

Note

If the readings do not match, either the transmitter requires an

output trim or the current meter is malfunctioning.

After completing the test, the display returns to the loop test screen and

allows you to choose another output value.

End the loop test

Procedure

1. Select 5. End.

2. Select Enter.

Page 17

February 2021 Quick Start Guide

6 Certified installations

For Safety Certified installations, refer to the Rosemount 248 Reference

Manual. You can access this manual electronically at Emerson.com/

Rosemount or by contacting an Emerson representative.

Quick Start Guide 17

Page 18

Quick Start Guide February 2021

7 Product certifications

Rev: 1.7

7.1 European Directive information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

7.2 Ordinary location certification

As standard, the device has been examined and tested to determine that the

design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

7.3 North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

7.4 USA

7.4.1 E5 USA Explosionproof and Dust-Ignitionproof

Certificate

Standards

Markings

7.4.2 I5 USA Intrinsic Safety and Nonincendive

Certificate

Standards

Markings

18

1091070

FM Class 3600-2011, FM Class 3611-2004, FM Class

3615-2006, FM 3616-2011, UL Std. No. 60079-0: Ed.6, UL Std.

No. 50E

CL I/II/III, DIV 1, GP, B, C, D, E, F, G; when installed per

Rosemount drawing 00644-1059; Type 4X; IP66/68

1091070

FM Class 3600-2011, FM Class 3610-2010, FM Class

3611-2004, UL Std. No. 60079-0: Ed.6, UL Std. No. 60079-11:

Ed. 6, UL Std. No. 50E

CL I/II/III, DIV 1, GP A, B, C, D, E, F, G; NI CL1, DIV 2, GP A, B, C,

D when installed per Rosemount drawing 00248-1056; Type

4X; IP66/68

Page 19

February 2021 Quick Start Guide

7.5 Canada

7.5.1 I6 Canada Intrinsically Safe

Certificate

Standards

Markings

1091070

CAN/CSA C22.2 No. 0-10, CSA Std. C22.2 No. 25-1966,

CAN/CSA C22.2 No. 94-M91, CAN/CSA C22.2 No. 157-92, CSA

C22.2 No. 213-M1987, CAN/CSA C22.2 No. 60079-11:14,

C22.2 No 60529-05

IS CL I, DIV 1 GP A, B, C, D when installed per Rosemount

drawing 00248-1056; CL I DIV 2 GP A, B, C, D; Type 4X,

IP66/68

7.5.2 K6 Canada Intrinsically Safe, Explosionproof, and Division 2

Certificate

Standards

Markings

1091070

CAN/CSA C22.2 No. 0-10, CSA Std. C22.2 No. 25-1966, CSA

Std. C22.2 No. 30-M1986, CAN/CSA C22.2 No. 94-M91, CSA

Std. C22.2 No.142-M1987, CAN/CSA C22.2 No. 157-92, CSA

C22.2 No. 213-M1987, CAN/CSA C22.2 No. 60079-11:14,

C22.2 No 60529-05

XP CL I/II/III, DIV 1, GP B, C, D, E, F, G when installed per

Rosemount drawing 00644-1059; IS CL I, DIV 1 GP A, B, C, D

when installed per Rosemount drawing 00248-1056; CL I DIV

2 GP A, B, C, D; Type 4X, IP66/68; Conduit Seal not required

7.6 Europe

7.6.1 E1 ATEX Flameproof

Certificate

Standards

Markings

Specific Conditions of Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than

Quick Start Guide 19

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-1: 2014, EN

60529:1991 +A1:2000 + A2:2013

II 2 G Ex db IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…

T1(-50 °C ≤ Ta ≤ +60 °C)

See Table 7-2 for process temperatures.

a source of ignition in Group III environments.

four joules.

Page 20

Quick Start Guide February 2021

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

7. Non-standard paint options may cause risk of electrostatic discharge.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

7.6.2 I1 ATEX Intrinsic Safety

Certificate

Standards

Markings

Special Condition for Safe Use (X):

The equipment, if supplied without an enclosure, must be installed in an

enclosure which affords it a degree of protection of at least IP20. Nonmetallic enclosures must have a surface resistance of less than 1G Ω; light

alloy or zirconium enclosures must be protected from impact and friction if

located in a Zone 0 environment.

Baseefa18ATEX0090X

EN IEC 60079-0: 2018, EN 60079-11: 2012

II 1 G Ex ia IIC T5/T6 Ga, T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60 °C

≤ Ta ≤ +60 °C)

See Table 7-3 for entity parameters.

7.6.3 N1 ATEX Zone 2 - with enclosure

Certificate

Standards

Markings

Baseefa18ATEX0091X

EN IEC 60079-0:2018, EN 60079-15:2010

II 3 G Ex nA IIC T5/T6 Gc, T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60

°C ≤ Ta ≤ +60 °C)

7.6.4 NC ATEX Zone 2 - without enclosure

Certificate

Standards

Markings

Baseefa18ATEX0091X

EN IEC 60079-0:2018, EN 60079-15:2010

II 3 G Ex nA IIC T5/T6 Gc, T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60

°C ≤ Ta ≤ +60 °C)

20

Page 21

February 2021 Quick Start Guide

Special Condition for Safe Use (X):

The equipment, if supplied without an enclosure, must be installed in a

suitably certified enclosure such that it is afforded a degree of protection of

at least IP54 in accordance with IEC 60529 and EN 60079-15 and be located

in an area of pollution degree 2 or better as defined in IEC 60664-1.

7.6.5 ND ATEX Dust

Certificates

Standards

Markings

Specific Conditions of Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-standard paint options may cause risk of electrostatic discharge.

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-31:2014, EN

60529:1991 +A1:2000 +A2:2013

II 2 D Ex tb IIIC T130 °C Db, (-40 °C ≤ Ta ≤ +70 °C); IP66

See Table 7-2 for process temperatures.

a source of ignition in Group III environments.

four joules.

to temperature probes with Enclosure option "N".

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

7.7

International

7.7.1 E7 IECEx Flameproof and Dust

Certificate

Standards

Markings

Quick Start Guide 21

IECEx FMG 12.0022X

IEC 60079-0:2011, IEC 60079-1:2014-06, IEC 60079-31:2013

Ex db IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50 °C ≤

Ta ≤ +60 °C); Ex tb IIIC T130 °C Db Ta = -40 °C to +70 °C; IP66

See Table 7-2 for process temperatures.

Page 22

Quick Start Guide February 2021

Specific Conditions of Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than

four joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

7. Non-standard paint options may cause risk of electrostatic discharge.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

7.7.2 I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

Special Condition for Safe Use (X):

The equipment, if supplied without an enclosure, must be installed in an

enclosure which affords it a degree of protection of at least IP20. Nonmetallic enclosures must have a surface resistance of less than 1G Ω; light

alloy or zirconium enclosures must be protected from impact and friction if

located in a Zone 0 environment.

IECEx BAS 18.0062X

IEC 60079-0:2017, IEC 60079-11:2011

Ex ia IIC T5/T6 Ga, T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60 °C ≤ Ta ≤

+60 °C);

See Table 7-3 for entity parameters.

7.7.3 N7 IECEx Zone 2 - with enclosure

Certificate

Standards

Markings

22

IECEx BAS 18.0063X

IEC 60079-0:2017, IEC 60079-15:2010

Ex nA IIC T5/T6 Gc; T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60 °C ≤ Ta ≤

+60 °C)

Page 23

February 2021 Quick Start Guide

7.7.4 NG IECEx Zone 2 - without enclosure

Certificate

Standards

Markings

Special Condition for Safe Use (X):

The equipment, if supplied without an enclosure, must be installed in a

suitably certified enclosure such that it is afforded a degree of protection of

at least IP54 in accordance with IEC 60529 and IEC 60079-15 and be located

in an area of pollution degree 2 or better as defined in IEC 60664-1.

IECEx BAS 18.0063X

IEC 60079-0:2017, IEC 60079-15:2010

Ex nA IIC T5/T6 Gc; T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60 °C ≤ Ta ≤

+60 °C)

7.8 Brazil

7.8.1 E2 Flameproof and Dust-Ignitionproof

Certificate

Standards

Markings

Specific Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

UL-BR 13.0535X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-1:2016,

ABNT NBR IEC 60079-31:2014

Ex db IIC T6…T1 Gb; T6…T1(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50

°C ≤ Ta ≤ +60 °C) Ex tb IIIC T130 °C Db; IP66; (-40 °C≤ Ta ≤ +70

°C)

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than

four joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

7. Non-standard paint options may cause risk of electrostatic discharge.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

Quick Start Guide 23

Page 24

Quick Start Guide February 2021

7.8.2 I2 Intrinsic Safety

Certificate

Standards

Markings

Special Condition for Safe Use (X):

The equipment, if supplied without an enclosure, must be installed in an

enclosure which affords it a degree of protection of at least IP20. Nonmetallic enclosures must have a surface resistance of less than 1G Ω; light

alloy or zirconium enclosures must be protected from impact and friction

when installed if located in a Zone 0 environment (areas that required EPL

Ga).

UL-BR 19.0202X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-11:2013

Ex ia IIC T5 Ga (-60 °C ≤ Ta ≤ +80 °C)

Ex ia IIC T6 Ga (-60 °C ≤ Ta ≤ +60 °C)

See Table 7-3 at the end of the product certifications section

for entity parameters.

7.8.3 N2 Brazil Zone2

Certificate

Standards

Markings

Special Condition for Safe Use (X):

The equipment, if supplied without an enclosure, must be installed in a

suitably certified enclosure such that it is afforded a degree of protection of

at least IP54 in accordance with ABNT NBR IEC 60529 and ABNT NBR IEC

60079-15 and be located in an area of pollution degree 2 or better as

defined in IEC 60664-1.

UL-BR 19.0203X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-15:2012

Ex nA IIC T5 Gc (-60 °C ≤ Ta ≤ +80 °C)

Ex nA IIC T6 Gc (-60 °C ≤ Ta ≤ +60 °C)

7.9

China

7.9.1 E3 NEPSI Flameproof

Certificate

Standards

Markings

• 产品安全使用特殊条件

24

GYJ16.1335X

GB3836.1-2010, GB3836.2-2010

Ex d IIC T6~T1 Gb: T6…T1(-50 °C ≤ Ta ≤ +40 °C) T5…T1 (-50 °C

≤ Ta ≤ +60 °C)

Page 25

February 2021 Quick Start Guide

证书编号后缀“X”表明产品具有安全使用特殊条件:涉及隔爆接合面的

维修须联系产品制造商

• 产品使用注意事项

Table 7-1: 产品使用环境温度与温度组别的关系为

1.

温度组别 环境温度

T6~T1 -50 °C ≤ Ta ≤ +40 °C

T5~T1 -50 °C ≤ Ta ≤ +60 °C

2. 产品外壳设有接地端子,用户在使用时应可靠接地

3. 安装现场应不存在对产品外壳有腐蚀作用的有害气体

4. 现场安装时,电缆引入口须选用国家指定的防爆检验机构按检

验认可、具有 Ex dⅡC 防爆等级的电缆引入装置或堵封件,冗余

电缆引入口须用堵封件有效密封

5. 现场安装、使用和维护必须严格遵守“断电后开盖!”的警告语

用户不得自行更换该产品的零部件,应会同产品制造商共同解

决运行中出现的故障,以杜绝损坏现象的发生

产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、

修复和改造”、GB3836.15-2000“爆炸性气体环境用电气设备 第

15 部分:危险场所电气安装(煤矿除外)”、GB3836.16-2006

“爆炸性气体环境用电气设备 第 16 部分:电气装置的检查和维

护(煤矿除外)”和 GB50257-2014“电气装置安装工程爆炸和火

灾危险环境电力装置施工及验收规范”的有关规定

7.9.2 I3 NEPSI Intrinsic Safety

Certificate

Standards

Markings

Special Condition for Safe Use (X):

See certificate for special conditions

GYJ19.1126X

GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

Ex ia IIC T5/T6 Ga; T6(-60 °C ≤ Ta ≤ +60 °C) T5(-60 °C ≤ Ta ≤ +80

°C)

See Table 7-3 for Entity Parameters and Temperature

Classifications.

7.9.3 N3 NEPSI Zone 2

Certificate

Standards

Quick Start Guide 25

GYJ19.1127

GB3836.1-2010, GB3836.8-2014

Page 26

Quick Start Guide February 2021

Markings

Special Condition for Safe Use (X):

See certificate for special conditions

Ex nA IIC T5/T6 Gc; T6(-60 °C ≤ Ta ≤ +60 °C) T5(-60 °C ≤

Ta ≤ +80 °C); Vmax = 42.4 Vdc

7.10 EAC

7.10.1 EM Technical Regulation Customs Union (EAC) Flameproof

Markings

Special Condition for Safe Use (X):

See certificate for special conditions.

7.10.2 IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Markings

Special condition for safe use (X):

See certificate for special conditions.

7.10.3 KM Technical Regulation Customs Union TR CU 012/2011 (EAC) Flameproof, Intrinsic Safety, and Dust-Ignitionproof

1Ex d IIC T6…T1 Gb X, T6(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50 °C ≤

Ta ≤ +60 °C); IP66/IP68

0Ex ia IIC T6…T5 Ga X, T6(-60 °C ≤ Ta ≤ +60 °C), T5(-60 °C ≤ Ta ≤

+80 °C); IP66/IP68

7.11

Markings

Special Condition for Safe Use (X)

See certificate for special conditions.

Korea

Ex tb IIIC T130 °C Db X (-40 °C ≤ Ta ≤ +70 °C); IP66/IP68

See EM for Flameproof Markings and see IM for Intrinsic Safety

Markings.

7.11.1 EP Korea Explosionproof/Flameproof

Certificate

Markings

Special Condition for Safe Use (X):

See certificate for special conditions.

26

20-KA4BO-0917X

Ex d IIC T6…T1; -50 °C ≤ T

amb

≤ +40 °C

Page 27

February 2021 Quick Start Guide

7.12 Combinations

K1

K5

K6

K7

KM

Combination of E1, I1, N1, and ND

Combination of E5 and I5

Combination of I6 and Canada Explosionproof

Combination of E7, I7, and N7

Combination of EM and IM with Dust

Quick Start Guide 27

Page 28

Quick Start Guide February 2021

7.13 Tables

Table 7-2: Process Temperatures

Temperature

class

T6 -50 °C to +40 °C 55 55 60 65

T5 -50 °C to +60 °C 70 70 70 75

T4 -50 °C to +60 °C 100 110 120 130

T3 -50 °C to +60 °C 170 190 200 200

T2 -50 °C to +60 °C 280 300 300 300

T1 -50 °C to +60 °C 440 450 450 450

T130 °C -40 °C to +70 °C 100 110 110 120

Ambient

temperatures

Process temperature without LCD display cover (°C)

No ext. 3-in. 6-in. 9-in.

Table 7-3: Entity Parameters

Parameters Loop terminals + and - Sensor terminals 1 to 4

Voltage U

Current I

Power P

Capacitance C

Inductance L

i

i

i

i

i

30 V 30 V

266 mA 26 mA

1 W 191 mW

0 nF 1.54 nF

0 mH 0 µH

7.14 Additional certification (Rosemount 248 Head Mount only)

28

SBV Bureau Veritas (BV) Type Approval

Certificate:

Requirements:

Application:

26325

Bureau Veritas Rules for the Classification of Steel Ships

Class notations: AUT-UMS, AUT-CCS, AUT-PORT and AUTIMS; Temperature transmitter cannot be installed on

diesel engines.

Page 29

February 2021 Quick Start Guide

7.15 Declaration of Conformity

Quick Start Guide 29

Page 30

Quick Start Guide February 2021

30

Page 31

February 2021 Quick Start Guide

Quick Start Guide 31

Page 32

Quick Start Guide February 2021

7.16 China RoHS

32

Page 33

February 2021 Quick Start Guide

Quick Start Guide 33

Page 34

Quick Start Guide February 2021

34

Page 35

February 2021 Quick Start Guide

Quick Start Guide 35

Page 36

*00825-0200-4825*

00825-0200-4825, Rev. EA

Quick Start Guide

February 2021

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...