Page 1

00825-0100-3226, Rev AA

Rosemount™ 226

Toroidal Conductivity Sensors

Quick Start Guide

May 2020

Page 2

Quick Start Guide May 2020

Safety information

WARNING

High pressure and temperature hazard

Failure to reduce the pressure and temperature may cause serious injury to personnel.

Before removing the sensor, reduce the process pressure to 0 psig and cool down the process

temperature.

CAUTION

Equipment damage

The wetted sensor materials may not be compatible with process composition and operating

conditions.

Application compatibility is entirely the operator's responsibility.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end

users’ equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end users’ assets. This is true for

all systems used within the facility.

Contents

Description and specifications......................................................................................................3

Install........................................................................................................................................... 4

Calibration................................................................................................................................. 14

Maintaining and troubleshooting............................................................................................... 19

Accessories................................................................................................................................ 24

2 Emerson.com/Rosemount

Page 3

May 2020 Quick Start Guide

1 Description and specifications

1.1 Overview

The Rosemount 226 Sensor is a toroidal (inductive) conductivity sensor.

These sensors work well for measuring in highly conductive liquids up to 2

S/cm (2,000,000 μS/cm). Unlike metal electrode based conductivity sensors,

toroidal conductivity sensors, like the Rosemount 226, are resistant to

fouling, coating, and chemical attack.

Sensors are molded with highly corrosion-resistant glass-filled PEEK

(polyetheretherketone). The sensors include an integral Pt-100 RTD for

temperature compensation. With a large bore hole opening, the Rosemount

226 greatly resists plugging when used in liquids containing high amounts of

suspended solids. PEEK is not recommended for greater than 50 percent

concentrations (at 77 °F [25 °C]) of H2SO4, HNO3, and H3PO4. PEEK is not

recommended for use with HF at all.

1.2 Specifications

Table 1-1: Rosemount 226 Toroidal Conductivity Sensor Specifications

Description Material and units

Conductivity range Refer to transmitter Product Data Sheet.

Wetted materials Glass-filled PEEK, EPDM Gasket

Operating temperature 32 to 248 °F (0 to 120 °C)

Maximum pressure 295 psig (2135 kPa [abs])

Standard cable length 20 ft. (6.1 m)

Maximum cable length 200 ft. (61 m)

Process connections ⅞-in. 9 UNC threads for flange mounting

Weight/shipping weight 2 lb./3 lb. (1.0 kg/1.5 kg)

and 1-in. MNPT (with -80 option); see

Dimensional drawings for more details.

Quick Start Guide 3

Page 4

Quick Start Guide May 2020

2 Install

2.1 Unpack and inspect

Procedure

1. Inspect the shipping container(s). If there is damage, contact the

shipper immediately for instructions.

2. If there is no apparent damage, unpack the container(s).

3. Ensure that all items shown on the packing list are present.

If items are missing, contact your local Customer Care representative

4. Save the shipping container and packaging.

They can be used to return the instrument to the factory in case of

damage.

2.2 Install sensor

To ensure accurate readings, it is recommended the sensor be installed so

that there is at least 2.4 inches of clearance between the sensor and tank or

pipe walls. If installed too closely to the walls, an error in readings will be

induced by wall effects. Wall effects arise from the interaction between the

current induced in the sample by the sensor and nearby pipe or vessel walls.

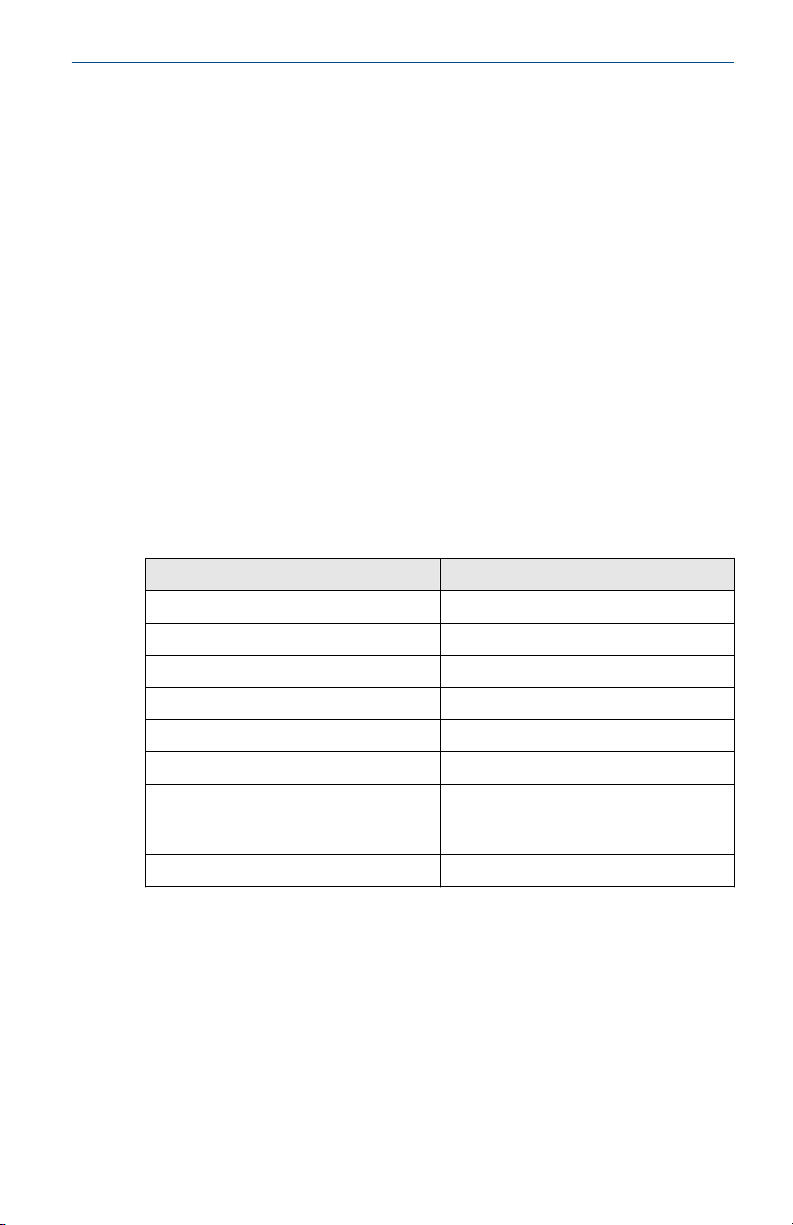

As Figure 2-1 shows, the measured conductivity can either increase or

decrease depending on the wall material. This effect can be seen by

watching the conductivity readings change as the sensor is moved closer to

the sides of the pipe, tank, or beaker.

Ensure that the sensor is completely submerged in the process liquid.

Mounting the sensor in a vertical pipe run with flow running from bottom to

top is recommended. If the sensor must be installed in a horizontal pipe run,

mount the sensor in the 3 o’clock or 9 o’clock position.

4 Emerson.com/Rosemount

Page 5

May 2020 Quick Start Guide

Figure 2-1: Measured Conductivity as a Function of Clearance between

Sensor and Walls

A. Measured conductivity

B. Metal pipe

C. True conductivity

D. Plastic pipe

E. Distance to wall

Quick Start Guide 5

Page 6

Quick Start Guide May 2020

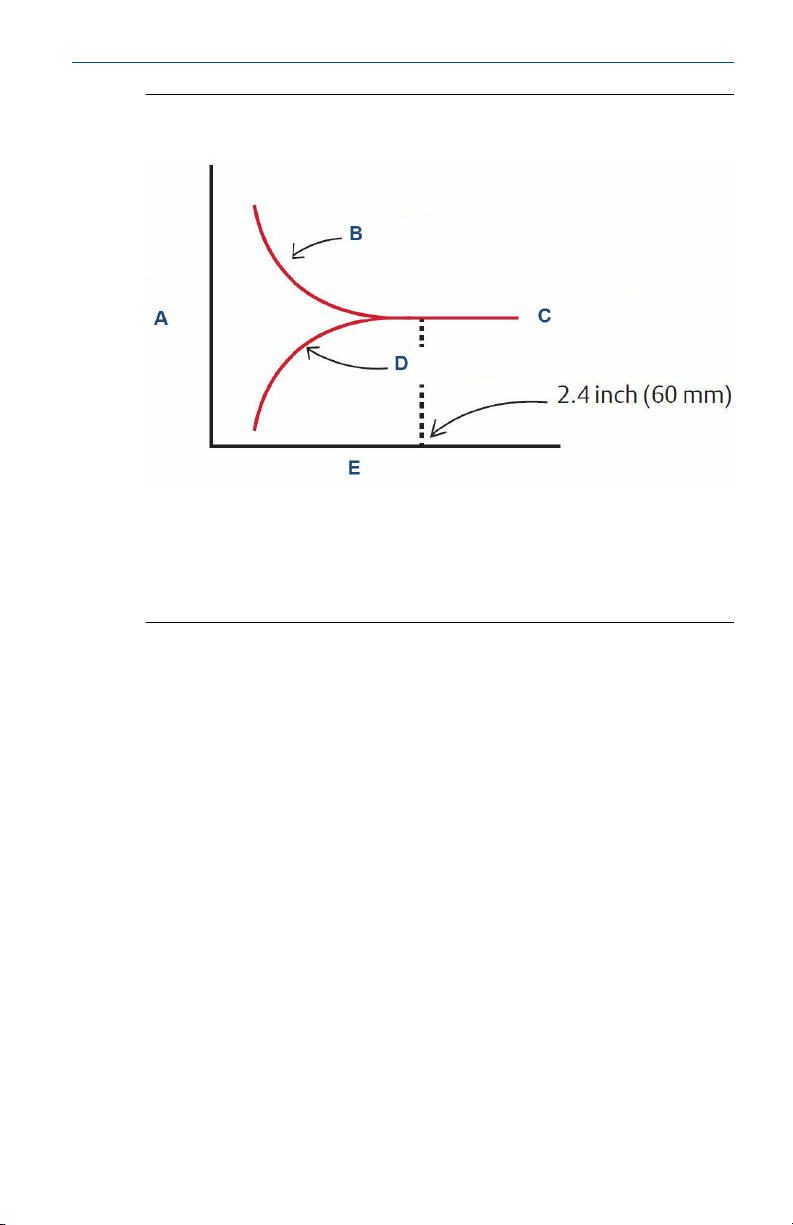

Figure 2-2: Rosemount 226 with 1-in. MNPT Process Connection

Mounting Adapter (-80 option) Dimensional Drawing

A. Boot

B. 20-ft. (6.1 m) cable

C. Adapter, PEEK, PN 33185-01 (included with code 80)

D. EPDM gasket

E. Wrench opening

F. One piece molded housing, PEEK

6 Emerson.com/Rosemount

Page 7

May 2020 Quick Start Guide

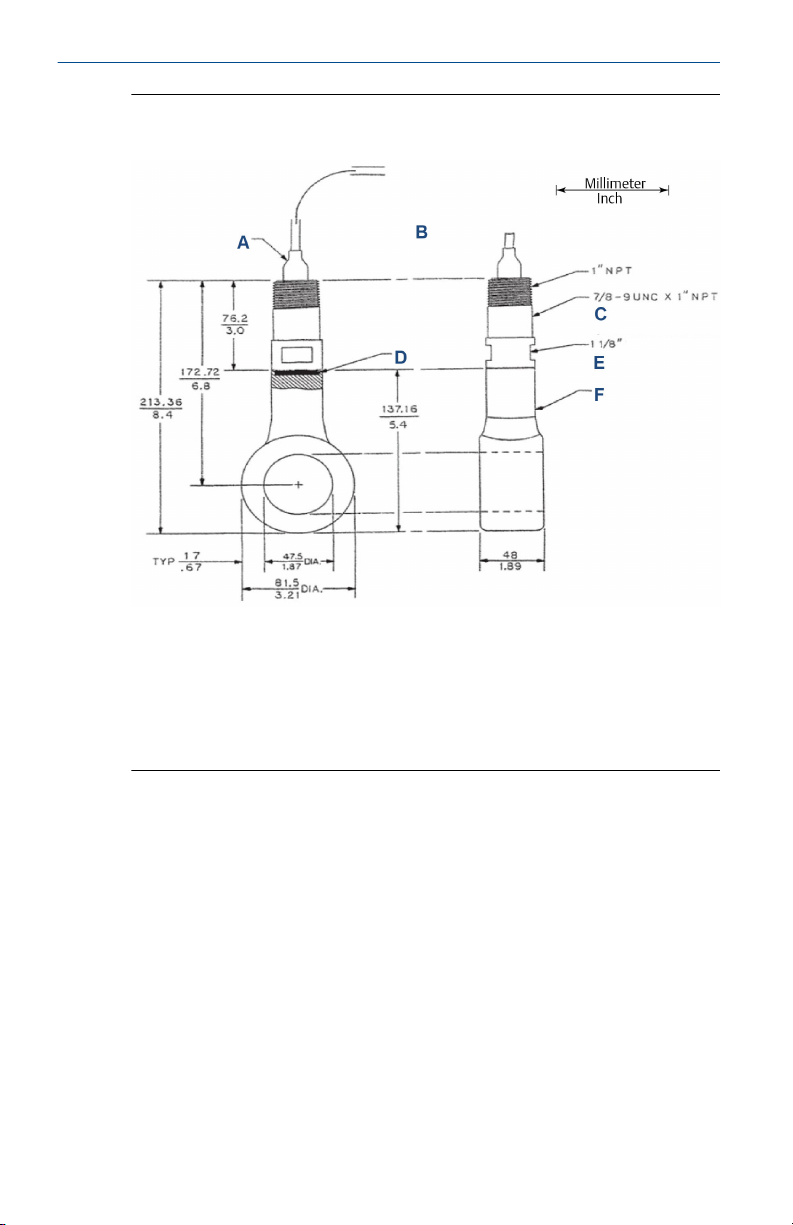

Figure 2-3: Rosemount 226 with ⅞-in. 9 UNC Thread and Insertion

through Flange Mounting Adapter (-81 option) Dimensional Drawing

A. Steel flange

B. Gasket

C. EPDM gaskets

D. One piece molded housing, PEEK

E. Welding neck steel flange

F. PEEK flange spacer 1-in. long

G. 304 stainless steel adapter for conduit

H. Boot

I. 20-ft. (6.1 m) cable

2.2.1 Submersion mounting

The sensor must be mounted in conduit or stand pipe to protect the back

end from process leakage. Use PTFE tape for a good seal.

2.2.2 Insertion Mounting

The sensor is designed to be mounted through any user-supplied flange. The

user is responsible for cutting a hole through the flange to fit the sensor. The

flange may be drilled and tapped for the sensor’s ⅞-in. 9 UNC thread.

Alternatively, a simple 15/16-in. (2.4 cm) drilled hole will accommodate the

⅞-in. 9 UNC thread.

Quick Start Guide 7

Page 8

Quick Start Guide May 2020

2.2.3 Sensor cable precautions

CAUTION

ELECTRICAL HAZARD

Cables run in the same conduit with power wiring or near heavy electrical

equipment may cause measurement errors and damage the sensor.

Do not run sensor cable in same conduit as the AC power wiring or near

heavy electrical equipment.

CAUTION

MOISTURE DAMAGE

Failure to properly seal the conduit may allow accumulated moisture in the

transmitter housing and damage the sensor and the transmitter.

Sensor cables routed in conduit must be sealed or plugged with sealing

compound.

8 Emerson.com/Rosemount

Page 9

May 2020 Quick Start Guide

2.3 Wire the sensor

For additional wiring information on this product, including sensor

combinations not shown here, please refer to Emerson.com/Rosemount-

Liquid-Analysis-Wiring.

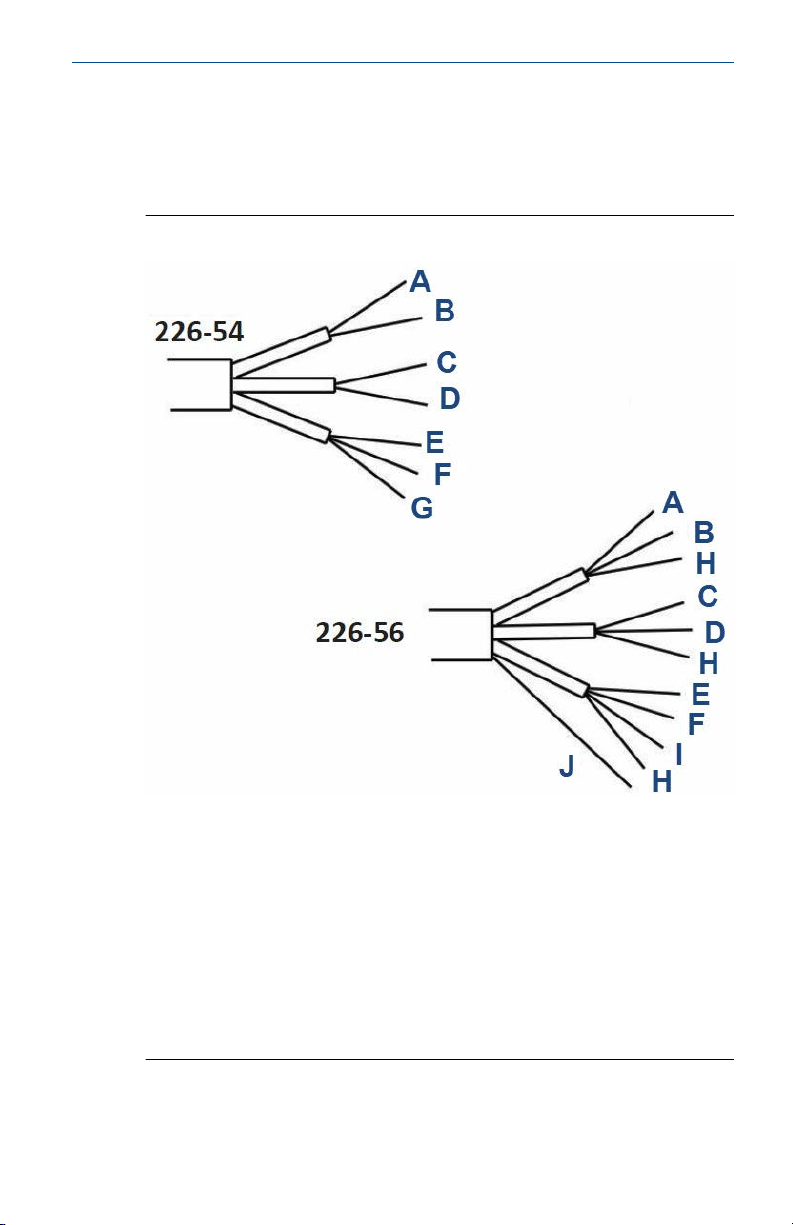

Figure 2-4: Wire Functions

A. Green - receive

B. Black - receive common

C. White - drive

D. Black - drive common

E. Green - resistance temperature device (RTD) in

F. White - RTD sense

G. Clear - RTD common

H. Clear - shield

I. Black - RTD common

J. Clear

Quick Start Guide 9

Page 10

Quick Start Guide May 2020

Figure 2-5: Wiring for Rosemount 226-54 and 226-56 Sensors to

Rosemount 1056 and 56 Transmitters

A. Clear

B. White

C. Green

D. Black

E. RTD return

F. RTD sense

G. RTD in

H. RTD shield

I. Receive common

J. Receive

K. Receive shield

L. Outer shield

M. Drive shield

N. Drive

O. Drive common

10 Emerson.com/Rosemount

Page 11

May 2020 Quick Start Guide

Figure 2-6: Wiring for Rosemount 226-54 and 226-56 Sensors to

Rosemount 1066 Transmitter

A. RTD return

B. RTD sense

C. RTD in

D. RTD shield

E. Green

F. White

G. Clear

H. Black

I. Receive B

J. Receive A

K. Receive shield

L. Drive B

M. Drive A

N. Drive shield

Quick Start Guide 11

Page 12

Quick Start Guide May 2020

Figure 2-7: Wiring for Rosemount 226-54 and 226-56 Sensors to

Rosemount 5081-T transmitter

A. Reserved

B. RTD shield

C. RTD common

D. RTD sense

E. RTD in

F. Receive shield

G. Receive common

H. Receive

I. Drive shield

J. Drive common

K. Drive

L. Clear

M. White

N. Green

O. Black

12 Emerson.com/Rosemount

Page 13

May 2020 Quick Start Guide

Figure 2-8: Wiring Sensors through a Remote Junction Box

A. Clear

B. White

C. Green

D. Black

E. Junction box

F. Interconnect cable

Quick Start Guide 13

Page 14

Quick Start Guide May 2020

3 Calibration

3.1 Sensor calibration

The nominal cell constant of the sensor is 1.2/cm. The error in cell constant

is about ± 10%, so conductivity readings made using the nominal cell

constant will have an error of at least ± 10%.

Wall effects as shown in Figure 2-1 will likely make the error greater.

There are two basic ways to calibrate a toroidal sensor: against a standard

solution or against a referee meter and sensor. A referee meter and sensor is

an instrument that has been previously calibrated and is known to be

accurate and reliable.

The referee instrument can be used to perform either an in-process or a grab

sample calibration. Regardless of the calibration method used, the

connected transmitter automatically calculates the cell constant once the

known conductivity is entered.

3.2 Calibrate against a standard solution

Calibration against a standard solution requires removing the sensor from

process piping. This calibration method is practical only if wall effects are

absent or if the sensor can be calibrated in a container identical to the

process piping. Ideally, the conductivity of the standard used should be close

to the middle of the range that the sensor will be used in. Generally, toroidal

conductivity sensors have good linearity and so standards greater than 5000

μS/cm at 25 °C may also be used.

Prerequisites

CAUTION

Before removing the sensor, be absolutely certain that the process pressure

is reduced to 0 psig and the process temperature is lowered to a safe level!

Immerse the rinsed sensor in the standard solution and adjust the

transmitter reading to match the conductivity of the standard. For an

accurate calibration several precautions are necessary:

Procedure

1. If wall effects are absent in the process installation, use a sufficiently

large container for calibration to ensure that wall effects are absent.

2. To check for wall effects, fill the container with solution and place the

sensor in the center submerged at least ¾ of the way up the stem.

3. Note the reading. Then move the sensor small distances from the

center and note the reading in each position.

14 Emerson.com/Rosemount

Page 15

May 2020 Quick Start Guide

The readings should not change.

4. If wall effects are present, be sure the vessel used for calibration has

exactly the same dimensions as the process piping.

5. Also, ensure that the orientation of the sensor with respect to the

piping is exactly the same in the process and calibration vessels.

Figure 3-1: Calibration Installation Orientation

A. Sensor in process piping

B. Flow

C. Blank flange

D. Pipe tee identical to process pipe tee

E. Sensor being calibrated

F. Standard solution

6. Turn off automatic temperature compensation in the transmitter.

This eliminates error in the cell constant.

7. Use a good quality calibrated thermometer to measure the

temperature of the standard solution.

The thermometer error should be less than ±0.1°C.

8. Allow adequate time for the solution and sensor to reach thermal

equilibrium.

If the sensor is being calibrated in an open beaker, keep the

thermometer far enough away from the sensor so it does not

introduce wall effects.

Quick Start Guide 15

Page 16

Quick Start Guide May 2020

If the sensor is being calibrated in a pipe tee or similar vessel, it will

probably be impractical to place the thermometer in the standard

solution.

9. Instead, put the thermometer in a beaker of water placed next to the

calibration vessel.

10. Let both come to thermal equilibrium with the ambient air before

continuing calibration.

Figure 3-2: Measuring Standard Temperature

A. Standard thermometer

B. Standard solution

C. Pipe tee

11. Make sure that the air bubbles are not adhering to the sensor.

An air bubble trapped in the toroid opening has a particularly severe

effect on the reading.

3.3

16 Emerson.com/Rosemount

Calibrate against a referee – in process

This method involves connecting the process and referee sensors in series

and allowing the process liquid to flow through both sensors. The process

sensor is calibrated by adjusting the process analyzer reading to match the

conductivity measured by the referee instrument.

Prerequisites

For a successful calibration, several precautions are necessary:

Procedure

1. If possible, adjust the conductivity of the process liquid so that it is

near the midpoint of the operating range.

Page 17

May 2020 Quick Start Guide

If this is not possible, adjust the conductivity so that it is at least 5000

μS/cm.

2. Orient the referee sensor so that air bubbles always have an easy

escape path and cannot get trapped.

Figure 3-3: Calibration with a Referee Instrument Example

A. Flow

B. Sensor in process piping

C. Sample valve

D. Referee sensor in flow cell

3. Tap and hold the flow cell in different positions to allow bubbles to

escape.

4. Turn off automatic temperature compensation in the transmitter.

This eliminates error in the cell constant.

Quick Start Guide 17

Page 18

Quick Start Guide May 2020

5. Keep tubing runs between the sensors short and adjust the sample

flow to as high a rate as possible.

Short tubing runs and high flow ensure that the temperature of the

liquid does not change as it flows from one sensor to another.

6. Wait for readings to stabilize before starting the calibration.

3.4 Calibrating against a referee - grab sample

This method is useful when calibration against a standard is impractical or

when in-process calibration is not feasible because the sample is hot,

corrosive, or dirty, making handling the waste stream from the referee

sensor difficult.

Prerequisites

The method involves taking a sample of the process liquid, measuring its

conductivity using a referee instrument, and adjusting the reading from the

process analyzer to match the measured conductivity. For a successful

calibration, several precautions are necessary:

Procedure

1. If possible, adjust the conductivity of the process liquid so that it is

near the midpoint of the operating range.

If this is not possible, adjust the conductivity so that it is at least 5000

μS/cm.

2. Take the sample from a point as close to the process sensor as

possible.

Be sure the sample is representative of what the sensor is measuring.

3. Keep temperature compensation with the transmitter turned on.

4. Confirm that the temperature measurements in both the process

and referee instruments are accurate, ideally to within ±0.5 °C.

5. Wait until readings are stable before starting the calibration.

18 Emerson.com/Rosemount

Page 19

May 2020 Quick Start Guide

4 Maintaining and troubleshooting

4.1 Maintaining the sensor

Generally, the only maintenance required is to keep the opening of the

sensor clear of deposits. Cleaning frequency is best determined by

experience.

CAUTION

Make sure that the sensor is cleaned of process liquid before handling.

4.2 Troubleshoot

4.2.1 Off-scale reading

Potential cause

Wiring is incorrect.

Recommended action

Verify and correct wiring.

Potential cause

Temperature element is open or shorted.

Recommended action

Check temperature element for open or short circuits.

See Figure 4-1.

Quick Start Guide 19

Page 20

Quick Start Guide May 2020

Figure 4-1: Sensor Resistance Check

Resistance between shield and any other wire: > 40 MΩ

A. Receive

B. Drive

C. Resistance temperature device (RTD)

D. Green

E. Black

F. White

G. Clear

Potential cause

Sensor is not in process stream.

Recommended action

Submerge sensor completely in process stream.

20 Emerson.com/Rosemount

Page 21

May 2020 Quick Start Guide

Potential cause

Sensor is damaged.

Recommended action

Perform isolation checks.

See Figure 4-1.

4.2.2 Noisy reading

Potential cause

Sensor is improperly installed in process stream.

Recommended action

Submerge sensor completely in process stream.

See Install.

Potential cause

Sensor cable is run near high voltage process stream.

Recommended action

Move cable away from high voltage conductors.

Potential cause

Sensor cable is moving.

Recommended action

Keep sensor cable stationary.

4.2.3 Reading seems wrong (lower or higher than expected)

Potential cause

Bubbles trapped in sensor.

Recommended actions

1. Install the sensor in a vertical pipe run with the flow against the

toroidal opening.

2. Increase flow if possible.

Potential cause

Sensor is not completely submerged in the process stream.

Recommended action

Confirm that the sensor is fully submerged in the process stream.

Quick Start Guide 21

Page 22

Quick Start Guide May 2020

See Install.

Potential cause

Wrong temperature correction algorithm is being used.

Recommended action

Check that the temperature correction is appropriate for the sample.

See transmitter Reference Manual for more information.

Potential cause

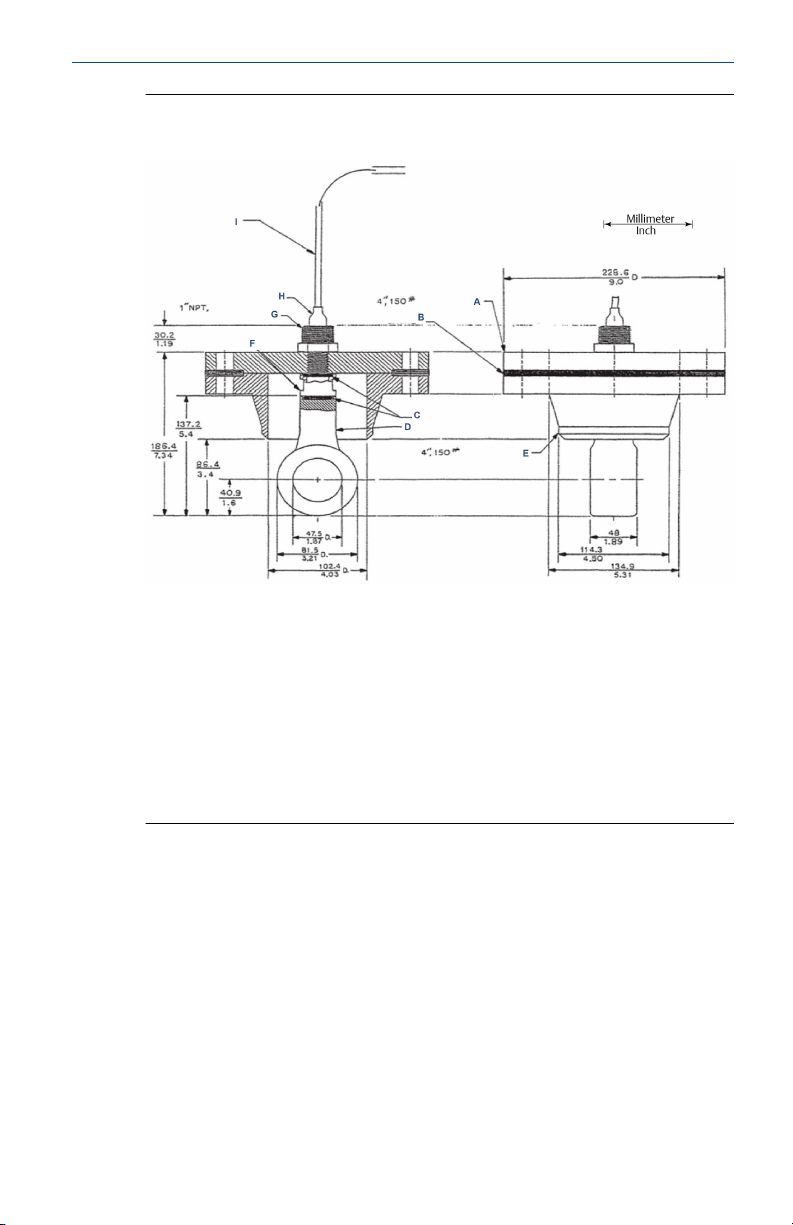

Temperature reading is inaccurate.

Recommended action

Disconnect the resistance temperature device leads and measure the

resistance between the in and common leads.

See Figure 4-1.

Resistance should be close to the value in Table 4-1.

Table 4-1: Resistance vs. Temperature for Temperature

Compensation (PT-100 RTD)

Temperature Resistance

10 °C (50 °F) 103.9 Ω

20 °C (68 °F) 107.8 Ω

25 °C (77 °F) 109.7 Ω

30 °C (86 °F) 111.7 Ω

40 °C (104 °F) 115.5 Ω

50 °C (122 °F) 119.4 Ω

Potential cause

The temperature response to sudden changes in temperature is slow.

Recommended action

Use a resistance temperature device (RTD) in a metal thermowell for

temperature compensation.

4.2.4 Sluggish response

Potential cause

Sensor is installed in dead area in piping.

22 Emerson.com/Rosemount

Page 23

May 2020 Quick Start Guide

Recommended action

Move sensor to a location more representative of the process liquid.

Potential cause

Slow temperature response to sudden changes in temperature.

Recommended action

Use a resistance temperature device in a metal thermowell for

temperature compensation.

Quick Start Guide 23

Page 24

Quick Start Guide May 2020

5 Accessories

Part number Description

23550-00 Remote junction box without preamplifier

23294-00 Unshielded interconnecting cable for Rosemount 1054A,

23294-05 Shielded interconnecting cable with additional shield wire for

33151-00 Gasket, EPDM (standard)

33151-01 Gasket, Viton®, Rosemount 226

33185-01 Mounting adapter, submersion, 9.8 ft. (3 m) length, 3.3 ft. (1

33185-02 Mounting adapter, insertion, 3.3 ft. (1 m) length, PEEK (with

33219-00 Mounting adapter, 304 stainless steel flange nut, 3.3 ft. (1 m)

9200276 Extension cable, unprepped (specify length) per foot

1054B, and 2054C. Can also be used with Rosemount 1056,

56, 5081, and 1066-T, but not recommended. Prepped,

specify length, per ft.

-03 option. For use with Rosemount 1056, 1066-T, 56, and

5081T. Prepped, specify length, per ft.

m) male national pipe thread (MNPT), PEEK

gasket)

MNPT for conduit

24 Emerson.com/Rosemount

Page 25

May 2020 Quick Start Guide

Quick Start Guide 25

Page 26

Quick Start Guide May 2020

26 Emerson.com/Rosemount

Page 27

May 2020 Quick Start Guide

Quick Start Guide 27

Page 28

GLOBAL HEADQUARTERS

6021 Innovation Blvd.

Shakopee, MN 55379

+1 866 347 3427

+1 952 949 7001

RMTNA.RCCPO@Emerson.com

00825-0100-3226, Rev. AA

Quick Start Guide

May 2020

NORTH AMERICA

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

Toll Free +1 800 999 9307

F +1 952 949 7001

RMTNA.RCCPO@Emerson.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box

17033

+971 4 811 8100

+971 4 886 5465

RMTNA.RCCPO@Emerson.com

LinkedIn.com/company/Emerson-

Automation-Solutions

Twitter.com/rosemount_news

Facebook.com/Rosemount

Youtube.com/RosemountMeasurement

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RMTNA.RCCPO@Emerson.com

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

+65 6 777 8211

+65 6 777 0947

RMTNA.RCCPO@Emerson.com

©

2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service

mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies.

All other marks are the property of their

respective owners.

Loading...

Loading...