Page 1

00825-0600-2654, Rev AD

Rosemount™ 214A2A Sensor

Quick Start Guide

March 2021

Page 2

Quick Start Guide March 2021

Safety messages

NOTICE

This guide provides basic guidelines for Rosemount™ 214A2A Sensor models.

Complications can arise if sensors are assembled to transmitters that have different, but compatible

approval option codes. Be aware of the following situations:

• If an I.S. approved sensor is ordered with a housing, a transmitter enclosed in that housing may

have a different I.S. approval rating. Refer to the transmitter IS certificate if applicable.

• If a sensor and transmitter have different certifications, or if either has more certifications than the

other, installation must comply with the most restrictive requirements required by either

component. This is especially (but not exclusively) relevant when combination approvals are

ordered on either the sensor or transmitter. Review certifications on both the sensor and

transmitter for installation requirements and ensure installation of the sensor/transmitter

assembly complies with a single certification that is shared by both of these components and that

meets the requirements of the application.

WARNING

Explosions

Explosions could result in death or serious injury.

Installation of sensor in an explosive environment must be in accordance with appropriate local,

national, and international standards, codes, and practices.

Conduit/cable entries

Unless marked, the conduit/cable entries in the housing use a ½–14 NPT thread form. Entries

marked “M20” are M20 × 1.5 thread form. On devices with multiple conduit entries, all entries will

have the same thread form. Only use plugs, adapters, glands, or conduit with a compatible thread

form when closing these entries.

When installing in a hazardous location, use only appropriately listed or Ex certified plugs, glands,

or adapters in cable/conduit entries.

Only use plugs, adapters, glands, or conduit with a compatible thread form when closing these

entries.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end

users’ equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end users’ assets. This is true for

all systems used within the facility.

Contents

Wiring diagram for RTDs.............................................................................................................. 3

Wiring diagram for thermocouples.............................................................................................. 4

Product certifications................................................................................................................... 5

Declaration of Conformity..........................................................................................................12

2 Emerson.com/Rosemount

Page 3

Red

White

Red

Red

White

White

Red

Red

White

Red

White

Black

Yellow

Red

Red

White

Black

Black

Yellow

Yellow

Yellow

Black

Black

Red

Red

White

White

March 2021 Quick Start Guide

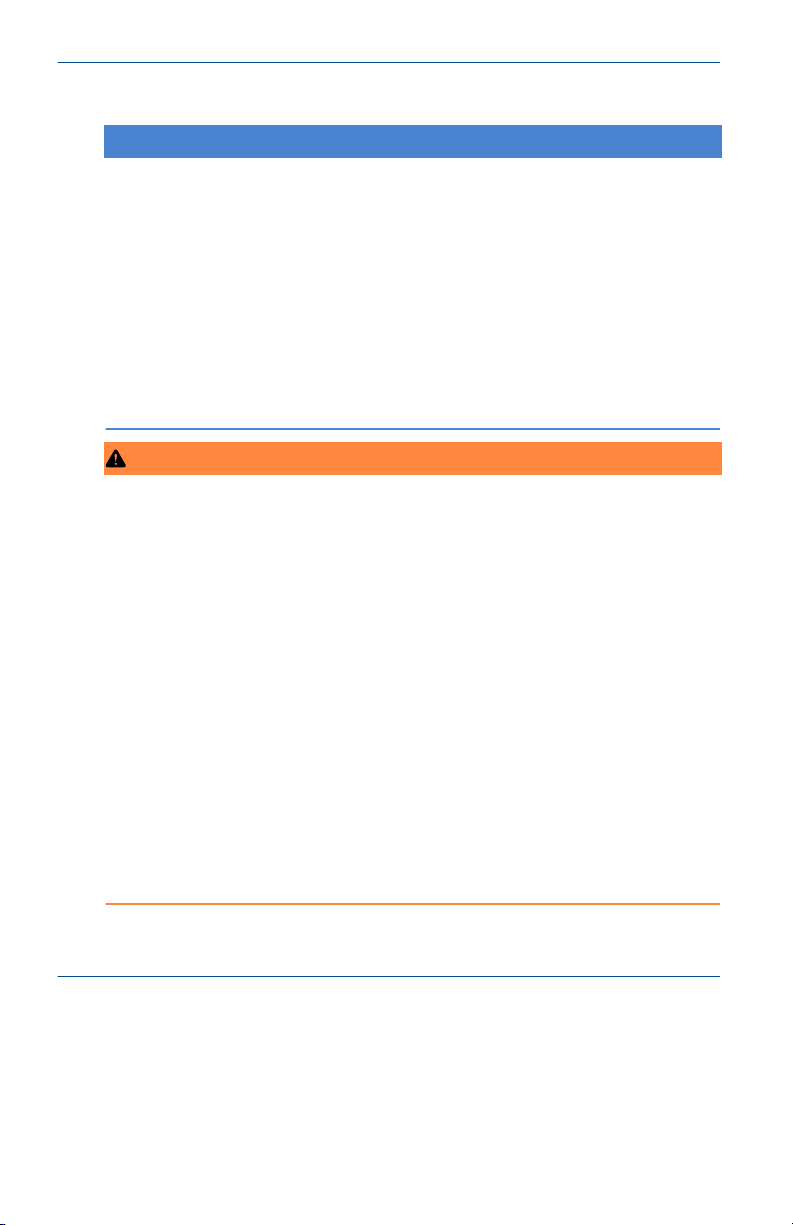

1 Wiring diagram for RTDs

Figure 1-1: RTD Lead Wire Configuration per IEC 60751 - Single Element

2-wire 3-wire 4-wire

Note

To configure a single element, 4-wire RTD as a 3-wire system, connect only

one white lead. Insulate or terminate the unused white lead in a manner that

prevents shorting to the ground. To configure a single element, 4-wire RTD

as a 2-wire system, connect matching colored wires first and then connect

the paired wires to the terminal.

Figure 1-2: RTD Lead Wire Configuration per IEC 60751 - Dual Element

3-wire 4-wire

2-wire

Quick Start Guide 3

Page 4

( – )

( + )

( + )

( + )

( – )

( – )

Quick Start Guide March 2021

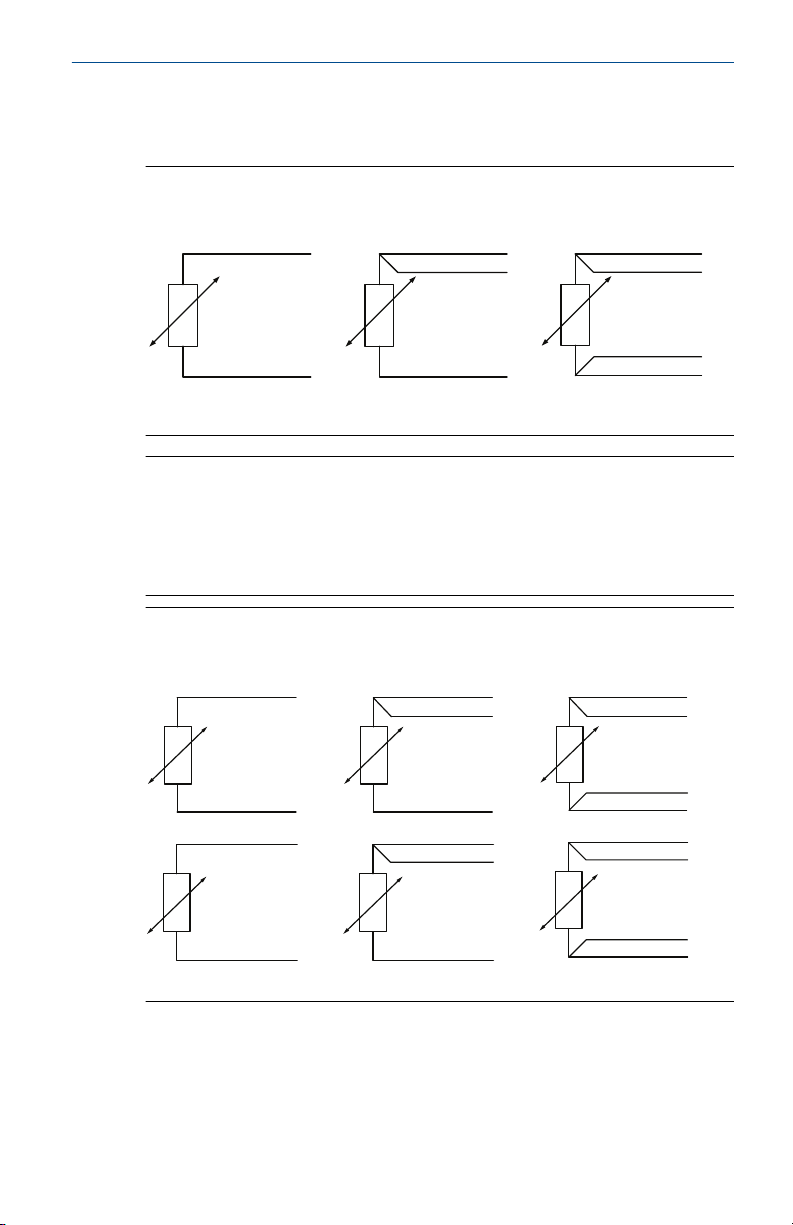

2 Wiring diagram for thermocouples

Figure 2-1: Thermocouple Lead Wire Configuration

Single thermocouple, 2-wire Dual thermocouple, 4-wire

Table 2-1: Thermocouple Wire Color

IEC 60584 Themocouple ASTM E230 Thermocouple

Type POS (+) NEG (-) POS (+) NEG (-)

E Violet White Purple Red

J Black White White Red

K Green White Yellow Red

N Pink White Orange Red

T Brown White Blue Red

4 Emerson.com/Rosemount

Page 5

March 2021 Quick Start Guide

3 Product certifications

Rev 1.0

European Directive information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

3.1 E1 ATEX Flameproof

Certificate

Standards

Markings

DEKRA 20ATEX0045X

EN 60079-0:2012+A11:2013, EN 60079-1:2014

II 2 G Ex db IIC T6…T1 Gb

3.2 E7 IECEx Flameproof

Certificate

Standards

Markings

The process side of the assembly is for the responsibility of the user. The

assembly should always be used in a closed system.

No changes are allowed on the product.

Flameproof enclosure “d”;

In type of explosion protection Ex d, certified entry devices shall be used that

are suitable for the application and correctly installed.

Unused openings shall be closed by suitable blanking elements. Only

suitable thread adapters shall be used. Thread adapters will not be used in

combination with blanking elements.

Verify the entry size (M20, ½-in. ¾-in., etc).

The degree of protection of IP66 or IP67 to EN 60529 is only achieved if

certified Ex d entry devices are used that are suitable for the application and

correctly installed.

Only use approved inserts.

For external earthing or bonding connection of the connection head a cable

lug shall be used so that the conductor is secured against loosening and

twisting and that contact pressure is permanently secured.

IECEx DEK 20.0023X

IEC 60079-0:2011, IEC 60079-1:2014-06

Ex db IIC T6…T1 Gb

Quick Start Guide 5

Page 6

Quick Start Guide March 2021

3.2.1 Electrical data

Thermocouple sensing element

RTD sensing element

Transmitter data

5 Vdc, 10 mA

5 Vdc, 10 mA

max. 45 Vdc, max 50 mA, max 1.9 W

For the electrical data of a sensor in combination with a transmitter, see

electrical data of the transmitter.

Special Conditions for Safe Use:

1. Ambient temperature range of sensor assembly with PTFE cable

insulation: -40 to +80 °C, and for Silicon cable insulation: -25 to +80

°C.

2. Service temperatures wire: Silicon -25/+160 °C, PTFE -40/+180 °C.

3. Service temperatures connection box and head: -40 to +80 °C, except

for T6 maximum temperature is 70 °C.

4. When the process temperature range exceeds the service

temperature range of the connection head, the connection box and

the cable (the maximum ambient temperature (Tamax) is +80 °C

except for T6 (Tamax) is +70 °C), it shall be verified by on-site

temperature measurements, taking the worst case conditions into

account, that the service temperature of these parts does not exceed

the range as listed above.

5. The measurement report with the conclusions shall be filed together

with the certificate to prove that this condition is met.

6. For information about the dimensions of the flameproof joints,

contact the manufacturer.

7. When a flameproof nipple is used (e.g. ISSeP06ATEX042 U) use

thread sealant with connection to connection head or transmitter.

8. Inserts with a diameter smaller than 3 mm and inserts with notarmored wire shall be protected against mechanical danger.

9. For an ambient temperature exceeding 70 °C, heat resistant cables

and cable glands suitable for at least 90 °C shall be used.

10. For parameters see transmitter or by terminal block U-max: 5V, Imax: 10mA p/channel.

11. The inserts should always be used with a mechanical protection.

12. Minimum and maximum wire temperature: Silicon -25/+160 °C, PTFE

-40/+180 °C. Maximum transition temperature: +80 °C.

6 Emerson.com/Rosemount

Page 7

March 2021 Quick Start Guide

3.2.2 Thermal data

The maximum surface temperature due to process conditions (Tp) is the

maximum surface temperature of any part of the assembly in contact with

the explosive atmosphere.

The temperature class and the maximum surface temperature of the

assembly depend on Tp, as listed in the table.

Tp (°C)

80 T6 85

95 T5 100

130 T4 135

195 T3 200

295 T2 300

445 T1 450

>445 - Tp + 5

Temperature class of the

3.3 I1 ATEX Intrinsic Safety

Certificate

Standards

Markings

DEKRA 20ATEX0047X

EN 60079-0:2012+A11:2013, EN 60079-11:2012

II 2 G Ex ia IIC T6...T1 Gb (SEE CERTIFICATE FOR SCHEDULE)

3.4 I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

IECEx DEK 20.0023X

IEC 60079-0:2011, IEC 60079-11:2011

Ex ia IIC T6...T1 Gb (SEE CERTIFICATE FOR SCHEDULE)

assembly

Maximum surface

temperature of the

assembly (°C)

Any type of connection head can be used, only during installation the proper

certified cable and cable gland should be used. Any type of extension can be

used which insures a protection for the connection head of minimum IP20.

Any type of insert can be used, the terminal-block must have Ex approved

terminals. Any type of thermowell can be used. The process side of the

assembly is for the responsibility of the user. The assembly should always be

used in a closed system.

• Inserts with RTD sensing elements

Quick Start Guide 7

Page 8

Quick Start Guide March 2021

Output circuits in type of protection intrinsic safety Ex ia IIC, only to be

connected to a certified intrinsically safe circuit, with the following

maximum values for each insert:

Ui = 14 V, Ii = 1.2 A, Pi = 140 mW, Ci ≤60 nF, Li = 0 mH.

• Inserts with thermocouple sensing elements

Output circuits in type of protection intrinsic safety Ex ia IIC, only to be

connected to a certified intrinsically safe circuit, with the following

maximum values for each insert:

Ui = 14 V, Ii = 1.2 mA, Pi = 140 mW, Ci ≤60 nF, Li = 0 mH.

• Transmitters data: Ui =45 Vdc max., Ii = 50 mA max., Pi = 2.25 W max.

In type of protection intrinsic safety Ex ia IIC or Ex ib IIC, only to be

connected to a certified intrinsically safe circuit, with the maximum

values according to the data listed in the certificate of the transmitter.

The sensor input parameters of the transmitter shall comply with the

parameters of the inserts.

3.4.1 Thermal data

The maximum surface temperature due to process conditions (Tp) is the

maximum surface temperature of any part of the assembly in contact with

the explosive atmosphere.

The temperature class and the maximum surface temperature of the

assembly depend on Tp and, when mounted, on the temperature class of

the integrally mounted transmitter, as listed in the table.

Tp (°C)

75 T6 T6 85

90 T5 T5 100

125 T4 T4 135

190 T3 T3 200

290 T2 T2 300

440 T1 T1 450

>440 T1 - Tp + 10

Temperature class

of the transmitter

Temperature class

of the assembly

Maximum surface

temperature of

the assembly (°C)

Installation instructions

In order to prevent voltage and/or current addition, the output circuits of

each insert shall be wired separately, in accordance with EN 60079-11 and

EN 60079-14.

If a temperature transmitter is mounted, the data of the transmitter shall be

taken from the instructions of the transmitter. The level of protection Ex ia

8 Emerson.com/Rosemount

Page 9

March 2021 Quick Start Guide

IIC or Ex ib IIC of the assembly is determined by the level of protection of the

transmitter. The equipment category is 2 G.

During installation the proper cable and cable gland should be used,

mounted in the conduit (M20, ½-in., ¾-in., etc.).

Special Conditions for Safe Use:

1. Ambient temperature range of sensor assembly with PTFE cable

insulation: -40 to +75 °C, and for Silicon cable insulation: -25 to +75

°C.

2. For versions with an integrally mounted certified intrinsically safe

transmitter:

• The highest minimum ambient temperature as mentioned above

and as mentioned on the transmitter, is decisive. The maximum

ambient temperature (Tamax) is +80 °C.

• The maximum ambient temperature of the assembly is +75 °C or

the maximum ambient temperature as mentioned on the

transmitter -10 K, which ever is smaller.

3. When the process temperature range exceeds the specified ambient

temperature range, it shall be verified by on-site temperature

measurements, taking the worst case conditions into account, that

the service temperature of the connection head and the connection

box does not exceed the ambient temperature range. The

measurement report with the conclusions shall be filed together with

the certificate to prove that this condition is met.

4. From a safety point of view,

• The thermocouple inserts with a nominal tip diameter less than

3.0 mm,

• All inserts with a grounded thermocouple, and

• The RTD inserts with a nominal tip diameter less than 4.8 mm

shall be considered to be connected to ground.

5. Minimum and maximum wire temperature: Silicon -25/+160 °C, PTFE

-40/+180 °C.

6. Maximum transition temperature: +80 °C.

3.5

Quick Start Guide 9

N1 ATEX Increased Safety

Certificate

Standards

Markings

DEKRA 20ATEX0046X

EN 60079-0:2012, EN 60079-7:2007

II 2 G Ex e IIC T6…T1 Gb

Page 10

Quick Start Guide March 2021

3.6 N7 IECEx Increased Safety

Certificate

Standards

Markings

Increased safety enclosure “e”;

In type of explosion protection Ex e, the degree of protection of at least IP54

to EN 60529 is only achieved if certified Ex e cable entries are used that are

suitable for the application and correctly installed.

The degree of protection of IP66 or IP67 to EN 60529 is only achieved if

certified Exe cable entries are used that are suitable for the application and

correctly installed.

When connection head is used the cover will be locked with a lock screw.

Special Conditions for Safe Use:

1. Ambient temperature range of sensor assembly with PTFE cable

insulation: -40 to +80 °C, and for Silicon cable insulation: -25 to +80

°C.

2. Service temperatures transition: -25 to +80 °C for Silicon wire and -40

to +80 °C for PTFE wire.

3. Service temperatures wire: Silicon -25/+160 °C, PTFE -40/+180 °C.

4. Service temperatures connection box and head: -40 to +80 °C.

5. When the process temperature range exceeds the service

temperature range of the transition part, the connection head, the

connection box and the cable (the maximum ambient temperature

(Tamax) is +80 °C), it shall be verified by on-site temperature

measurements, taking the worst case conditions into account, that

the service temperature of these parts does not exceed the range as

listed above.

IECEx DEK 20.0023X

IEC 60079-0:2011, IEC 60079-7:2006-07

Ex e IIC T6…T1 Gb

6. The measurement report with the conclusions shall be filed together

with the certificate to prove that this condition is met.

7. The sensor assembly with connection head and extension part shall

have a degree of protection of at least IP54, provided by the user

with a thermowell or equivalent component at the process side of

the assembly, or direct mounted sensor.

3.6.1 Electrical data

Thermocouple sensing element

10 Emerson.com/Rosemount

5 Vdc, 10 mA

Page 11

March 2021 Quick Start Guide

RTD sensing element

Installation instructions

The degree of protection of at least IP 54 to EN 60529 is only achieved if

certified Exe cable glands or conduit entry devices are used that are suitable

for the application and correctly installed.

Unused openings shall be closed by suitable blanking elements.

Inserts with a diameter smaller than 3mm and inserts with not-armored wire

shall be protected against mechanical danger.

For an ambient temperature exceeding 80 °C, heat resistant cables and cable

glands suitable for at least 90 °C shall be used.

During installation the proper certified cable and cable gland should be

used, mounted in the conduit (M20, ½-in., ¾-in., etc.).

For parameters see terminal block U-max: 5 V, I-max: 10 mA p/channel.

Torque values and wire size

For torque values end wire size for terminal blocks, see Examination

Certificate FTZU 04 ATEX 0003U and EN 60079-0:2012 and EN

60079-7:2007, for rail mounted terminals see IEC 60947-1/EN 60947-1.

3.6.2 Thermal data

The maximum surface temperature due to process conditions (Tp) is the

maximum surface temperature of any part of the assembly in contact with

the explosive atmosphere.

The temperature class and the maximum surface temperature of the

assembly depend on Tp, as listed in the table.

5 Vdc, 10 mA

Tp (°C)

80 T6 85

95 T5 100

130 T4 135

195 T3 200

295 T2 300

445 T1 450

>445 - Tp + 5

Quick Start Guide 11

Temperature class of the

assembly

Maximum surface

temperature of the

assembly (°C)

Page 12

Quick Start Guide March 2021

4 Declaration of Conformity

12 Emerson.com/Rosemount

Page 13

March 2021 Quick Start Guide

Quick Start Guide 13

Page 14

Quick Start Guide March 2021

14 Emerson.com/Rosemount

Page 15

March 2021 Quick Start Guide

Quick Start Guide 15

Page 16

*00825-0600-2654*

00825-0600-2654, Rev. AD

Quick Start Guide

March 2021

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

Loading...

Loading...