Page 1

00809-0100-4140, Rev AA

Rosemount™ 2140 Level Detector

Vibrating Fork

Reference Manual

January 2017

Page 2

Page 3

Reference Manual

00809-0100-4140, Rev AA

Contents

1Section 1: Introduction

2Section 2: Configuration

Contents

January 2017

1.1 Models covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Point level detector overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Using this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Product recycling/ disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Get started with your preferred configuration tool . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 AMS Device Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.2 Field Communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.3 Local Operator Interface (LOI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Switching HART Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.4.1 Switching HART revision with a generic menu . . . . . . . . . . . . . . . . . . . . . . 8

2.4.2 Switching HART revision with Field Communicator . . . . . . . . . . . . . . . . . . 9

2.4.3 Switching HART Revision with AMS Device Manager . . . . . . . . . . . . . . . . . 9

2.4.4 Switching HART revision with Local Operator Interface. . . . . . . . . . . . . . . 9

2.5 Configuration basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5.1 Setting the security switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.2 Setting the loop to manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.6 Configure device using Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.6.1 Guided setup on the AMS Device Manager . . . . . . . . . . . . . . . . . . . . . . . .10

2.6.2 Guided setup on the Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.3 Guided setup on the LOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Verify the configuration before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.7.1 Verifying configuration (Field Communicator or AMS) . . . . . . . . . . . . . . 11

2.7.2 Verifying configuration (LOI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.3 Dynamic variables configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 Basic setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.8.1 Sensor operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Contents

2.8.2 Sensor output delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.8.3 Media density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.8.4 Media learn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.8.5 Allowable change in dry fork frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

I

Page 4

Contents

January 2017

Reference Manual

00809-0100-4140, Rev AA

2.8.6 Sensor fault delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

2.8.7 Analog output type and operating modes . . . . . . . . . . . . . . . . . . . . . . . . .23

2.8.8 Analog output range points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.8.9 Scaled Variable damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.9 Local Operator Interface (LOI) display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2.9.1 Electronics temperature units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2.10Detailed setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2.10.1 HART (re-mapping dynamic variables) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.10.2 Configuring alarm and saturation levels . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.10.3 Configuring process alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.10.4 Configuring Scaled Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

2.11Configuring burst mode (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2.12System readiness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2.12.1 Confirm correct Device Driver (DD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2.13Establishing multi-drop communications (optional) . . . . . . . . . . . . . . . . . . . . . .40

2.13.1 Communicating with a multi-dropped level detector . . . . . . . . . . . . . . .41

2.13.2 Changing a level detector polling address . . . . . . . . . . . . . . . . . . . . . . . . .42

2.14Configuring level detector security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

2.14.1 Setting the security switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.14.2 HART Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.14.3 Configuration button lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2.14.4 Local Operator Interface (LOI) password . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.15Setting the alarm switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

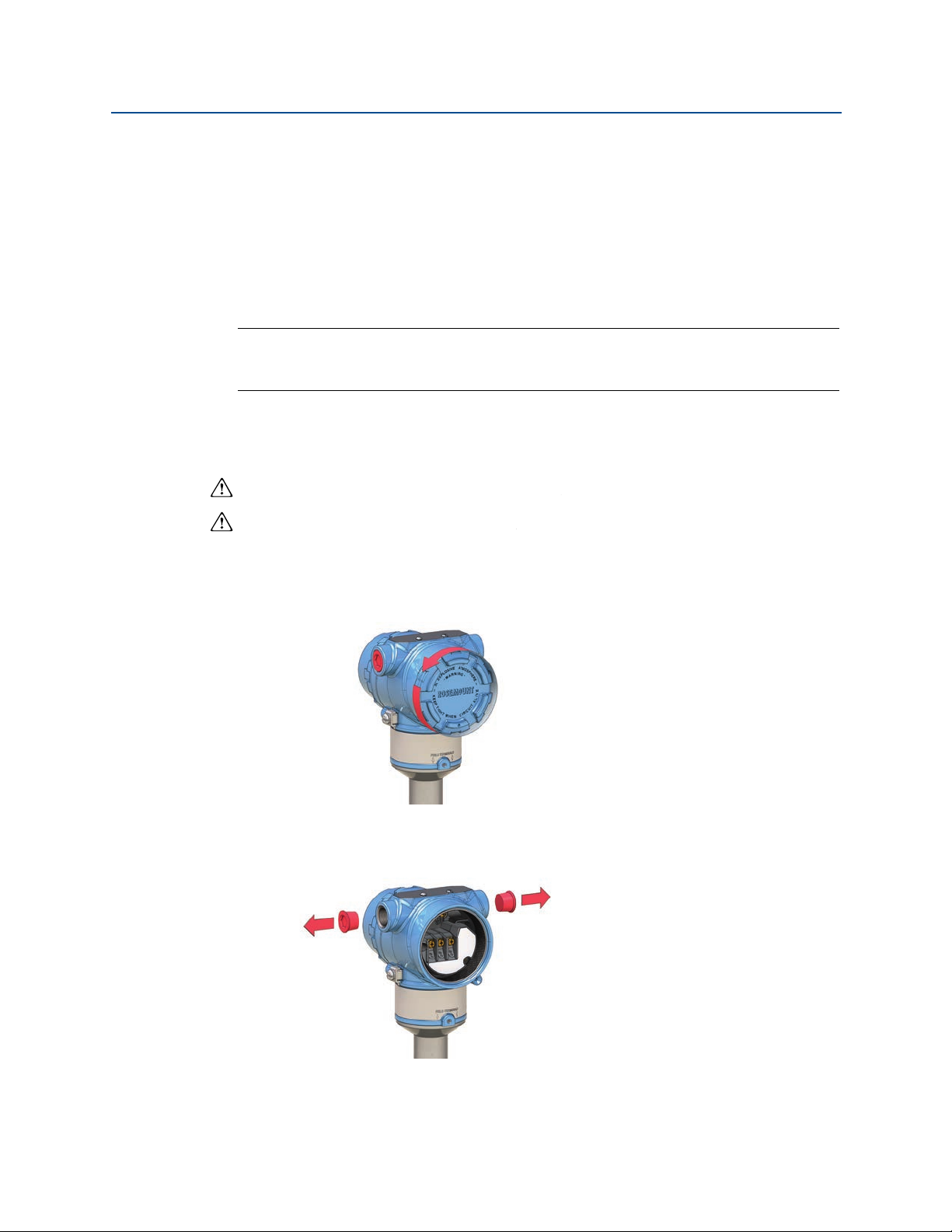

3Section 3: Hardware Installation

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.2 Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.2.1 Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.2.2 Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.2.3 Application considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

3.2.4 Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.5 Installation examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

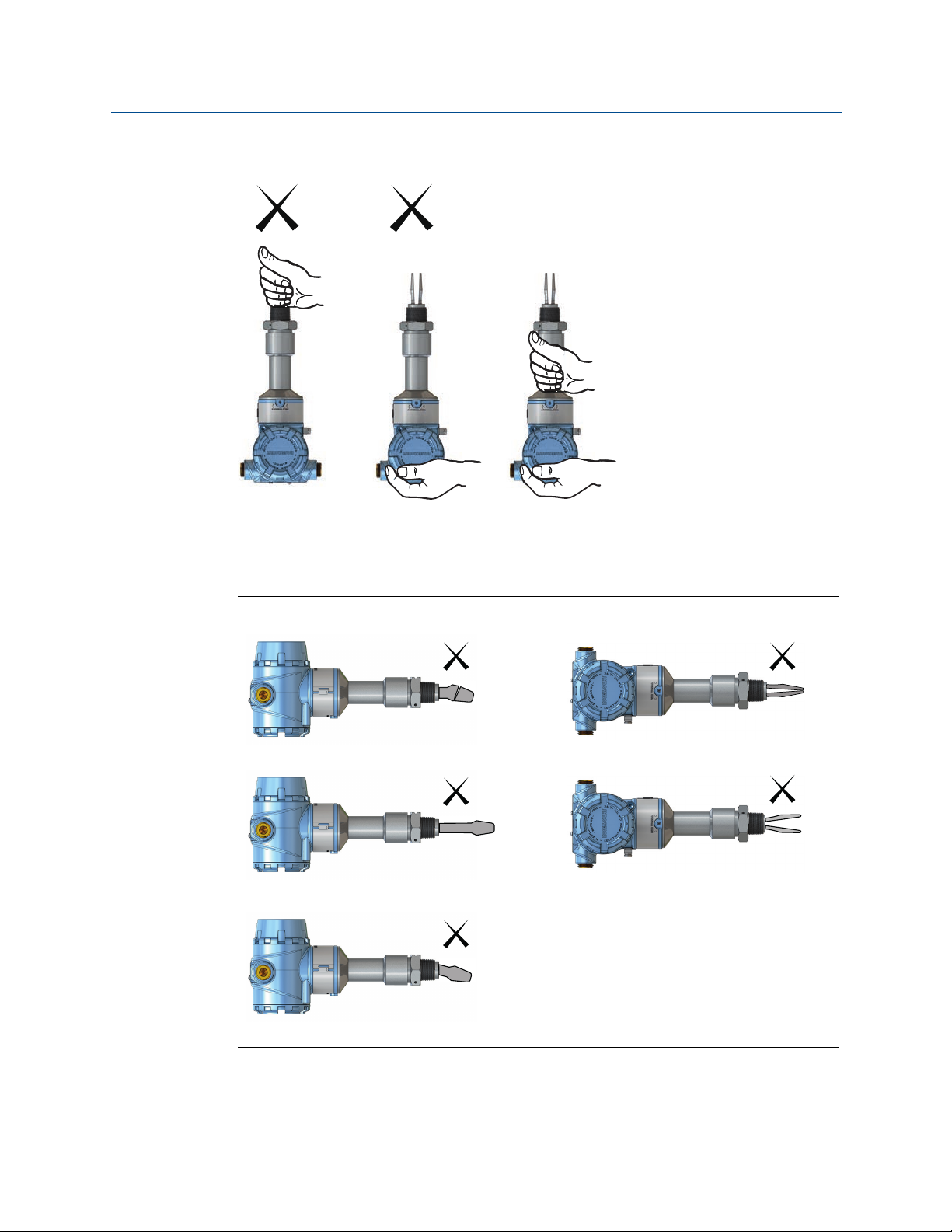

3.3 Installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

3.3.1 Process connection seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

3.3.2 Correct fork alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

3.3.3 Tightening the threaded Rosemount 2140 . . . . . . . . . . . . . . . . . . . . . . . . 60

3.3.4 Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

II

Contents

Page 5

Reference Manual

00809-0100-4140, Rev AA

4Section 4: Electrical Installation

5Section 5: Operation and Maintenance

Contents

January 2017

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.2 Cable selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

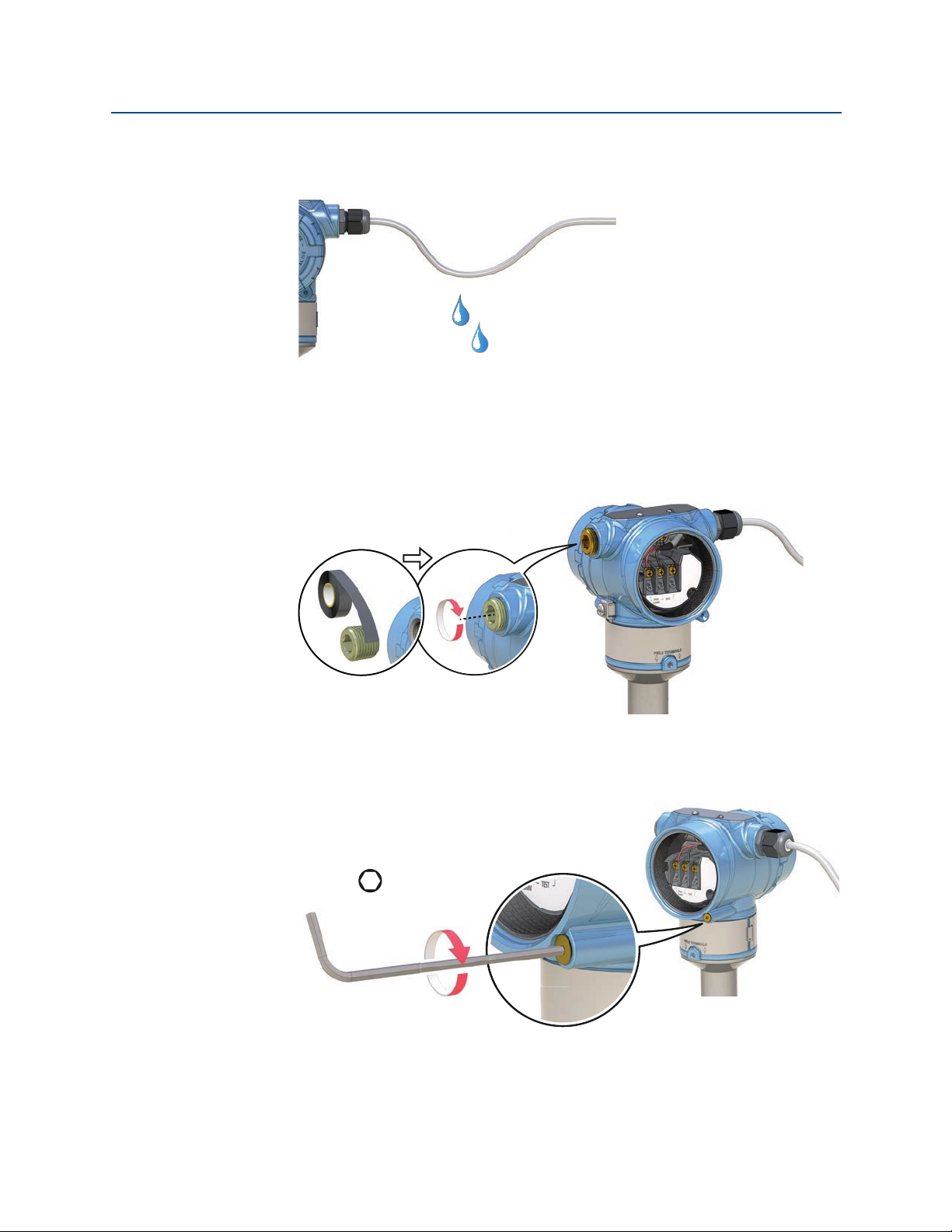

4.3 Cable gland/conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4.4 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4.5 Hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.6 Wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.7 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.7.1 Level switch grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.7.2 Signal cable shield grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.7.3 Transient protection terminal block grounding . . . . . . . . . . . . . . . . . . . .65

4.8 Wiring and power-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

5.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

5.3 Analog output calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

5.3.1 Trimming the analog output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.3.2 Site calibration of analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.3.3 Restoring factory calibration of the analog output. . . . . . . . . . . . . . . . . .72

5.4 Performing tests and simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5.4.1 Device tests (partial proof test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4.2 Proof tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4.3 Verifying alarm level (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4.4 Analog loop test (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.5 Simulate device variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

5.5 Diagnostics and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.5.1 Restart device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.5.2 Load user defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

5.5.3 Sensor frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.5.4 Sensor compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.5.5 Sensor state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

5.5.6 Sensor status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Contents

5.5.7 Dry fork frequency and switching points . . . . . . . . . . . . . . . . . . . . . . . . . .85

5.5.8 Counters and timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

5.6 Dry fork calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.6.1 Site calibration of dry fork sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.6.2 Restoring factory calibration of dry fork sensor. . . . . . . . . . . . . . . . . . . . . 88

III

Page 6

Contents

January 2017

Reference Manual

00809-0100-4140, Rev AA

5.6.3 Sensor calibration status and calibration count. . . . . . . . . . . . . . . . . . . . .90

5.6.4 Configuring Power Advisory Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.7 Frequency profiling functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

5.8 Upgrading to Extended Features Package (EFP). . . . . . . . . . . . . . . . . . . . . . . . . . .95

6Section 6: Troubleshooting

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

6.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

6.3 Troubleshooting for 4-20 mA Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

6.4 Diagnostic messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

6.4.1 Diagnostic message: failed - fix now . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6.4.2 Diagnostic message: maintenance - fix soon. . . . . . . . . . . . . . . . . . . . . . .99

6.4.3 Diagnostic message: advisory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

6.5 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

AAppendix A: Specifications and Reference Data

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

A.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.1.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.1.3 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

A.1.4 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

A.1.5 Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

A.2 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

A.3 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

A.3.1 Rosemount 2140 Spares and Accessories . . . . . . . . . . . . . . . . . . . . . . . .119

BAppendix B: Product Certifications

B.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.2 European directive information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.3 Ordinary locations certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.4 Hazardous locations certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.4.1 North America and Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

B.4.2 Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

B.4.3 International. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

CAppendix C: Field Communicator Menu Tree

C.1 Field Communicator menu trees. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

IV

Contents

Page 7

Reference Manual

00809-0100-4140, Rev AA

DAppendix D: Local Operator Interface

Contents

January 2017

D.1 LOI menu trees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

D.2 Number entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

D.3 Text entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Contents

V

Page 8

Contents

January 2017

Reference Manual

00809-0100-4140, Rev AA

VI

Contents

Page 9

Reference Manual

NOTICE

00809-0100-4140, Rev AA

Rosemount 2140 Level Detector

Vibrating Fork

Read this manual before working with the product. For personal and system safety, and

for optimum product performance, make sure you thoroughly understand the

contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

United States: 1 800 999 9307 (7:00 am to 7:00 pm CST)

Asia Pacific: 65 777 8211

Europe/ Middle East/ Africa: 49 (8153) 9390

North American Response Center

Equipment service needs.

1 800 654 7768 (24 hours — includes Canada)

Outside of these areas, contact your local Emerson™ representative.

Title Page

January 2017

Title Page

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on nuclear-qualified products, contact your local Emerson

representative.

Replacement equipment or spare parts not approved by Emerson for use as spare parts

could reduce the capabilities of the Rosemount 2140 and 2140:SIS Level Detectors

(“level detectors”), and may render the instrument dangerous.

Use spare parts supplied or sold by Emerson.

VII

Page 10

Title Page

January 2017

Reference Manual

00809-0100-4140, Rev AA

Failure to follow these installation guidelines could result in death or serious

injury.

The Rosemount 2140 and 2140:SIS Level Detectors (“level detectors”) must be

installed, connected, commissioned, operated, and maintained by suitably

qualified personnel only, observing any national and local requirements that may

apply.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

The weight of a level detector with a heavy flange and extended fork length may

exceed 37 lb. (18 kg). A risk assessment is required before carrying, lifting, and

installing the level detector.

Explosions could result in death or serious injury.

Please review the approvals section of this reference manual for any restrictions

associated with an installation.

Electrical shock could cause death or serious injury.

If the level detector is installed in a high voltage environment and a fault condition

or installation error occurs, high voltage may be present on leads and terminals.

Use extreme caution when making contact with the leads and terminals.

Make sure that power to the level detector is off while making connections.

External surface may be hot.

Care must be taken to avoid possible burns. The flange and process seal may be

hot at high process temperatures. Allow time to cool before servicing.

VIII

Title Page

Page 11

Reference Manual

00809-0100-4140, Rev AA

Section 1 Introduction

1.1 Models covered

The following point level detectors are covered by this manual:

Rosemount 2140 Level Detector – Vibrating Fork

Rosemount 2140:SIS Level Detector Vibrating Fork

Note

For detailed information about proof-testing the Rosemount 2140:SIS, refer to the

Rosemount 2140:SIS Functional Safety Manual.

1.2 Point level detector overview

Introduction

January 2017

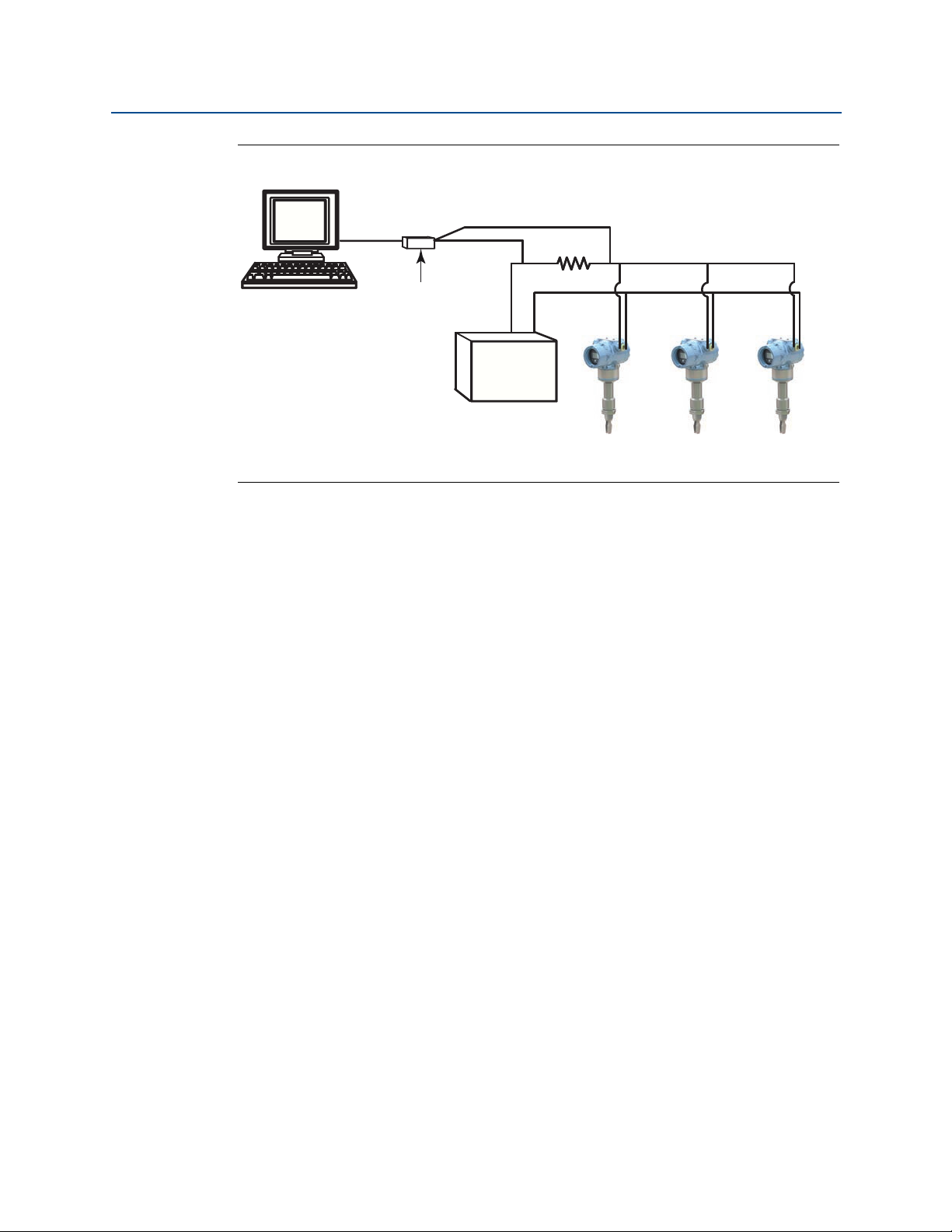

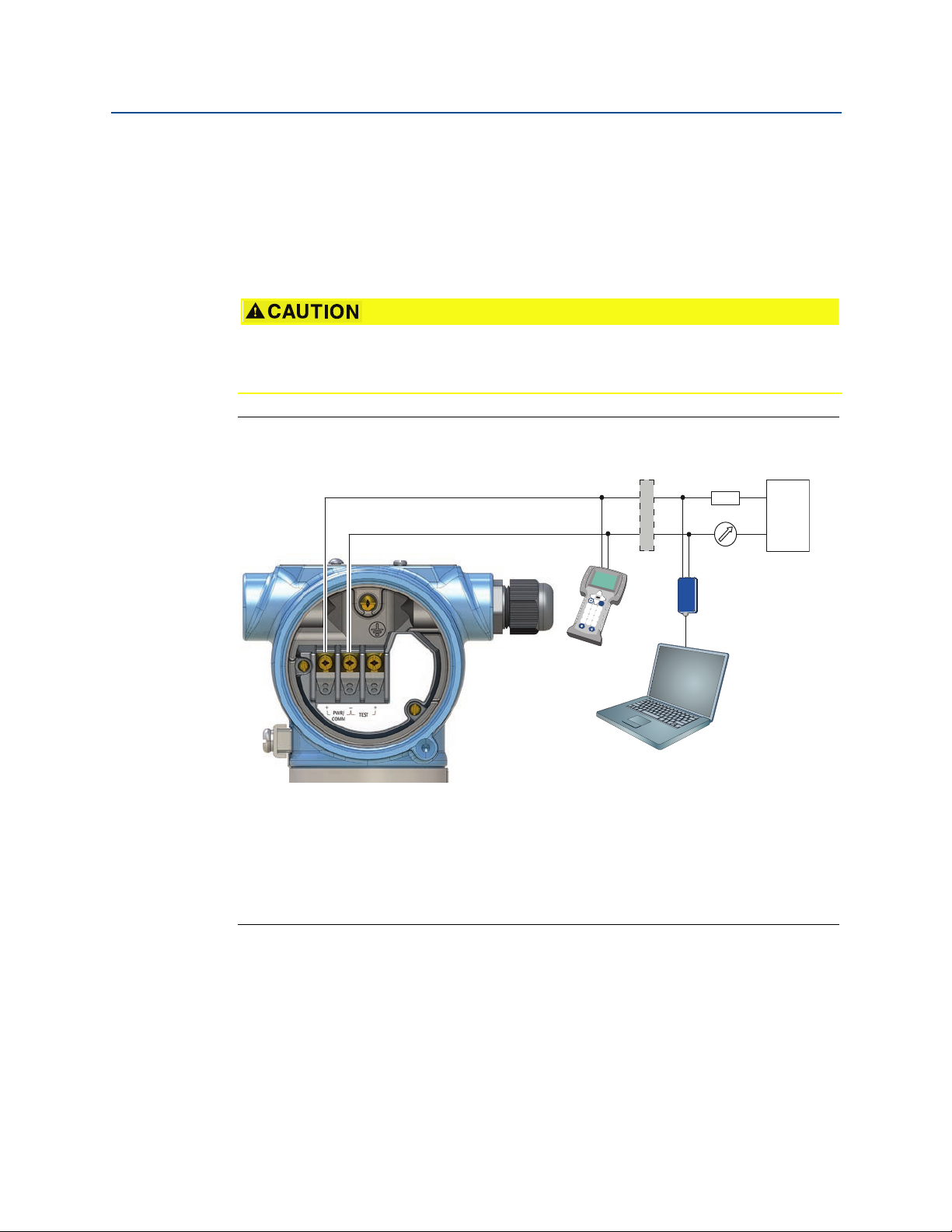

The Rosemount 2140 and Rosemount 2140:SIS are point level detectors, and are designed

to use the principle of a tuning fork. A piezo-electric crystal oscillates the forks at their

natural frequency, and changes to this frequency are continuously monitored by

electronics. The frequency of the vibrating fork sensor changes depending on the liquid

medium in which it is immersed. The denser the liquid, the lower the frequency.

When the level detector is used as a low level alarm, the liquid medium in the tank or pipe

drains down past the fork, causing a change of frequency that is detected by the electronics

and it indicates a dry condition.

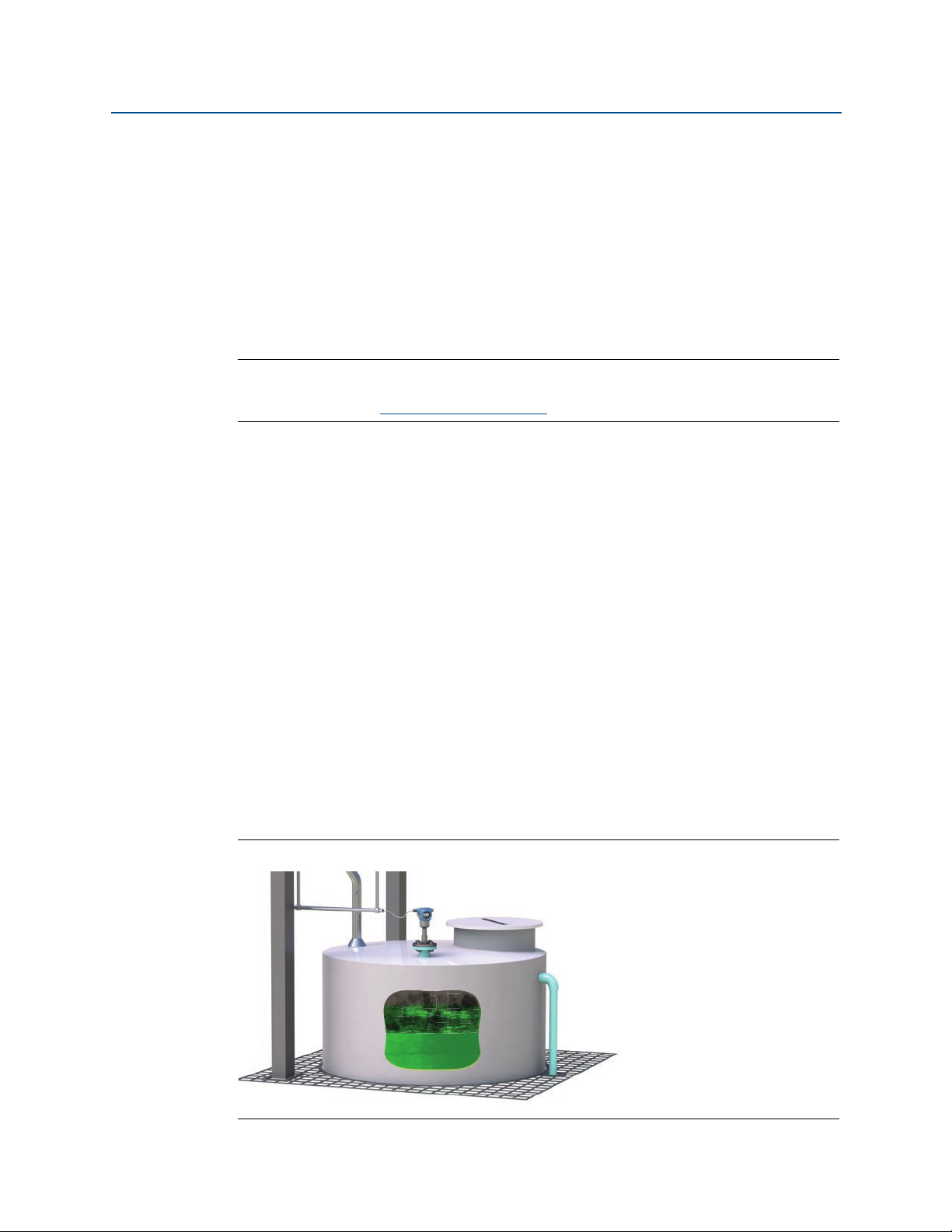

When the level detector is used as a used as a high level alarm or for overfill detection

(Figure 1-1), the liquid medium rises in the tank or pipe, making contact with the fork which

then causes the electronics to indicate a wet condition.

®

The wet and dry conditions can be transmitted digitally as a HART

output using the analog output. See “Analog output type and operating modes” on

page 23 for details.

Figure 1-1. Typical Application

signal or as a discrete

Introduction

1

Page 12

Introduction

January 2017

Reference Manual

00809-0100-4140, Rev AA

Major components of the point level detector are the fork and the electronics housing.

The electronics housing contains the output electronics board, optional external

configuration buttons, and terminal block.

An optional Local Operator Interface (“LOI”) uses a character display (Figure 1-2) to indicate

the live output state, diagnostic messages, and menus. There are two rows of characters,

with 8 on the upper row and 6 on the lower row. The LOI also comes with two integral

buttons (“internal buttons”) for using the menu system.

Figure 1-2. Local Operator Interface (LOI) Display

1.3 Using this manual

The sections in this manual provide information on installing, operating, and maintaining

the Rosemount 2140 and Rosemount 2140:SIS Level Detectors (“level detectors”).

The sections are organized as follows:

Section 2: Configuration provides instruction on basic and advanced configuration tasks

when commissioning and operating the level detectors.

Section 3: Hardware Installation contains mechanical installation instructions.

Section 4: Electrical Installation contains electrical installation instructions.

Section 5: Operation and Maintenance provides information on calibrating and testing.

Section 6: Troubleshooting provides troubleshooting techniques for common operating

problems.

Appendix A: Specifications and Reference Data contains specifications, dimension

drawings, and ordering information.

Appendix B: Product Certifications contains intrinsic safety approval information.

Appendix C: Field Communicator Menu Tree provides full menu trees to assist with

commissioning, operating, and maintenance tasks.

Appendix D: Local Operator Interface provides detailed LOI menu trees to assist with

commissioning, operating, and maintenance tasks.

2

Introduction

Page 13

Reference Manual

00809-0100-4140, Rev AA

1.4 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Introduction

January 2017

Introduction

3

Page 14

Introduction

January 2017

Reference Manual

00809-0100-4140, Rev AA

4

Introduction

Page 15

Reference Manual

00809-0100-4140, Rev AA

Section 2 Configuration

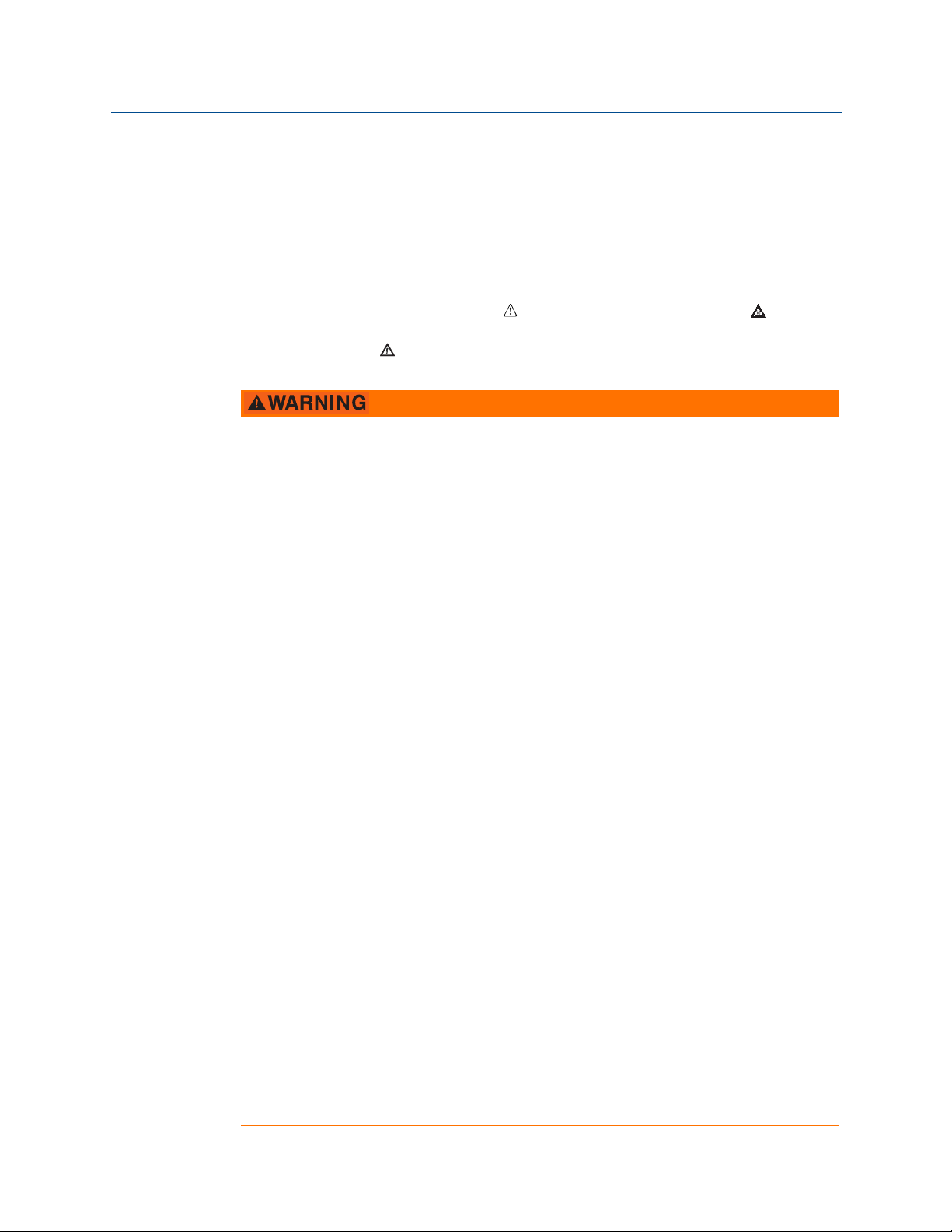

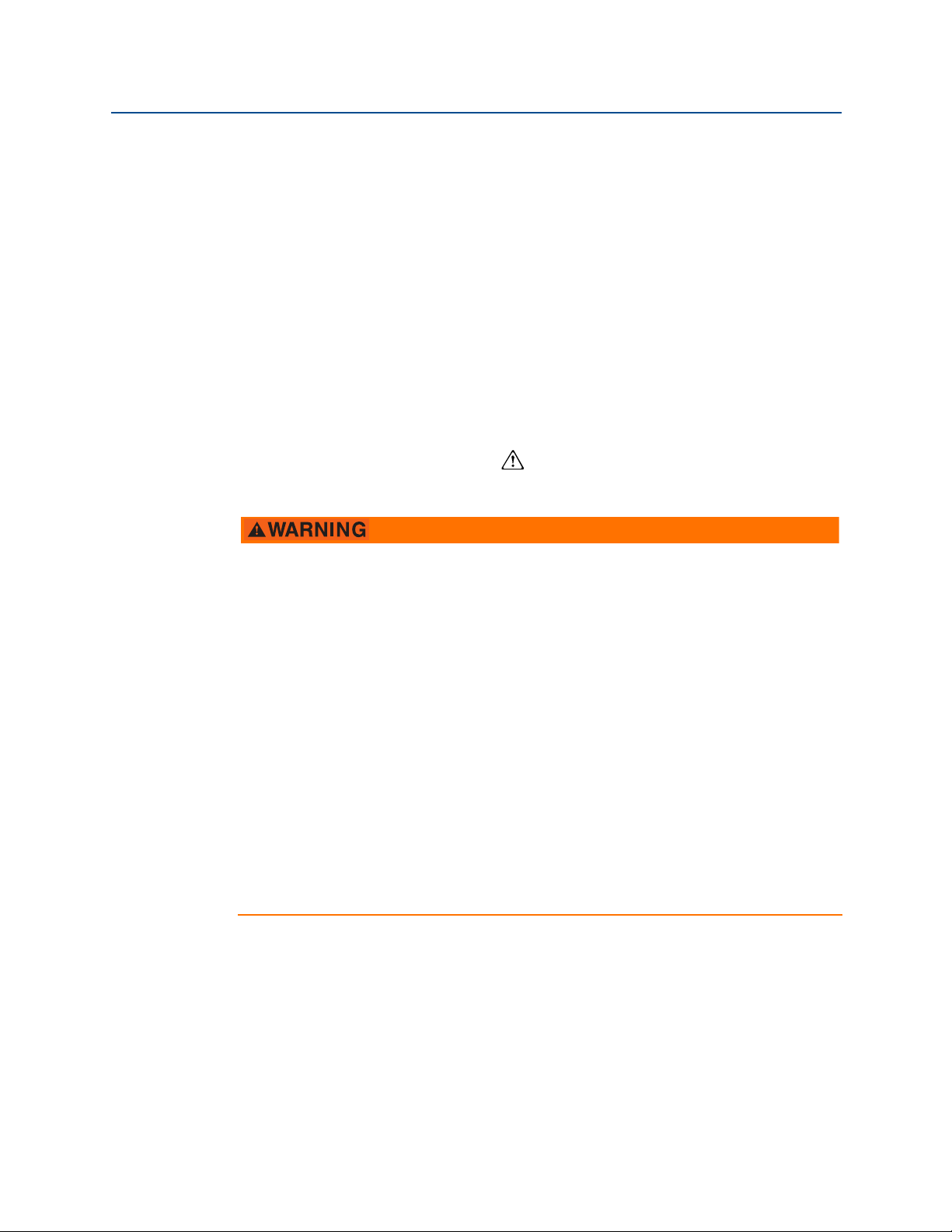

2.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that raises potential safety

issues is indicated by a warning symbol ( ). Refer to the following safety messages before

performing an operation preceded by this symbol.

Explosions could result in death or serious injury.

Installation of this Rosemount 2140 and Rosemount 2140:SIS Level Detectors (“level

detectors”) in an explosive environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices.

Please review Appendix B: Product Certifications for any restrictions associated with a

safe installation.

Before connecting a Field Communicator in an explosive atmosphere, ensure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

In an explosion-proof/flameproof installation, do not remove the level detector covers

when power is applied to the unit.

Process leaks may cause harm or result in death.

Install and tighten process connectors before applying pressure.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

Configuration

January 2017

2.2 Overview

This section provides instructions for using a Field Communicator, AMSTM Device Manager,

or Local Operator Interface (LOI) to configure the Rosemount 2140 or Rosemount 2140:SIS

Level Detectors.

For convenience, Field Communicator fast key sequences are labeled “Fast keys”.

Full Field Communicator menu trees are in Appendix C: Field Communicator Menu Tree.

Local Operator Interface menu trees are in Appendix D: Local Operator Interface.

Configuration

5

Page 16

Configuration

January 2017

2.3 Get started with your preferred configuration tool

The Rosemount 2140 Level Detector and Rosemount 2140:SIS Level Detector can easily be

configured by using:

Device Description (DD) based systems

e.g. AMS Device Manager and the 475 Field Communicator

Local Operator Interface (LOI)

2.3.1 AMS Device Manager

Get the latest Device Description (DD)

The Device Description (DD) is a configuration tool that is developed to assist the user

through the configuration tasks. The Rosemount 2140 DD is typically installed together

with AMS Device Manager.

To download the latest HART DD, visit the Emerson Process Management Device Install Kit

site at Emerson.com/devicefiles

Reference Manual

00809-0100-4140, Rev AA

After downloading, add the DD to AMS Device Manager:

1. Close AMS Device Manager.

2. Click the Start button, and then select All Programs > AMS Device Manager >

Add Device Type.

3. Browse to the downloaded DD files and select OK.

In the Add Device Type application, select the Help button for more information on how to

complete this operation.

Configure the HART® modem interface

Before connecting to the device using a HART modem, the HART modem interface must be

configured in AMS Device Manager:

1. Close AMS Device Manager.

2. Click the Start button, and then select All Programs > AMS Device Manager >

Network Configuration.

3. Select Add.

4. In the drop down list, select HART modem and select Install.

5. Follow the on-screen instructions.

In the Network Configuration application, select the Help button for more information on

how to complete this operation.

6

Configuration

Page 17

Reference Manual

A

B

C

D

E

F

G

00809-0100-4140, Rev AA

2.3.2 Field Communicator

An overview of the Field Communicator is shown in Figure 2-1.

See “Field Communicator menu trees” on page 125 for the menu tree diagrams.

Figure 2-1. 475 Field Communicator

Configuration

January 2017

A. Power key E. Enter key

B. Navigation keys F. Function key

C. Tab key G. Alphanumeric keypad

D. Backlight key

Get the latest Device Description (DD)

If the Rosemount 2140 DD is not included in your 475, then use the Easy Upgrade Utility to

update the Field Communicator with the latest DD.

For more information on how to update the DD and all the capabilities, see the 475 Field

Communicator User’s Manual

, available at www.fieldcommunicator.com.

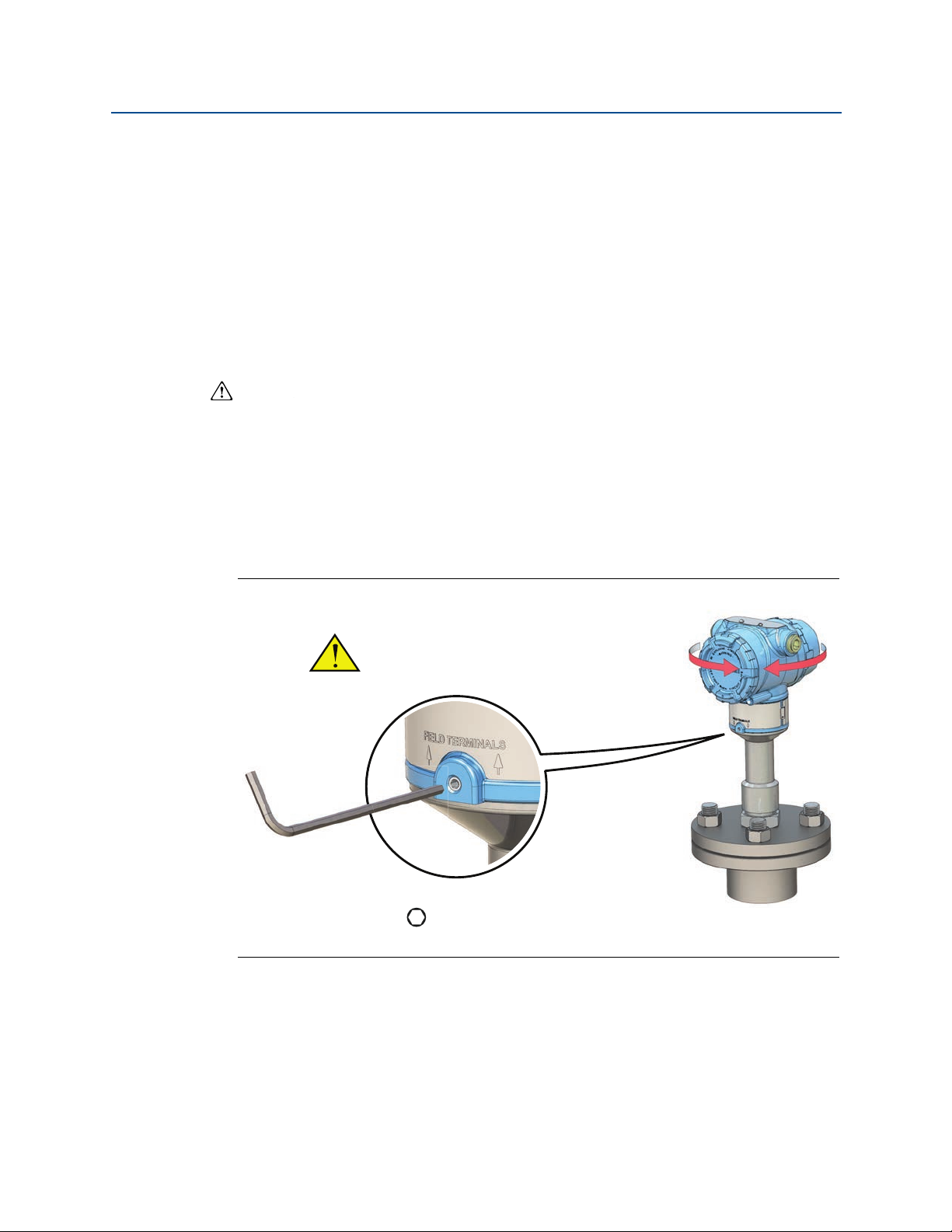

2.3.3 Local Operator Interface (LOI)

The LOI requires option code M4 to be ordered.

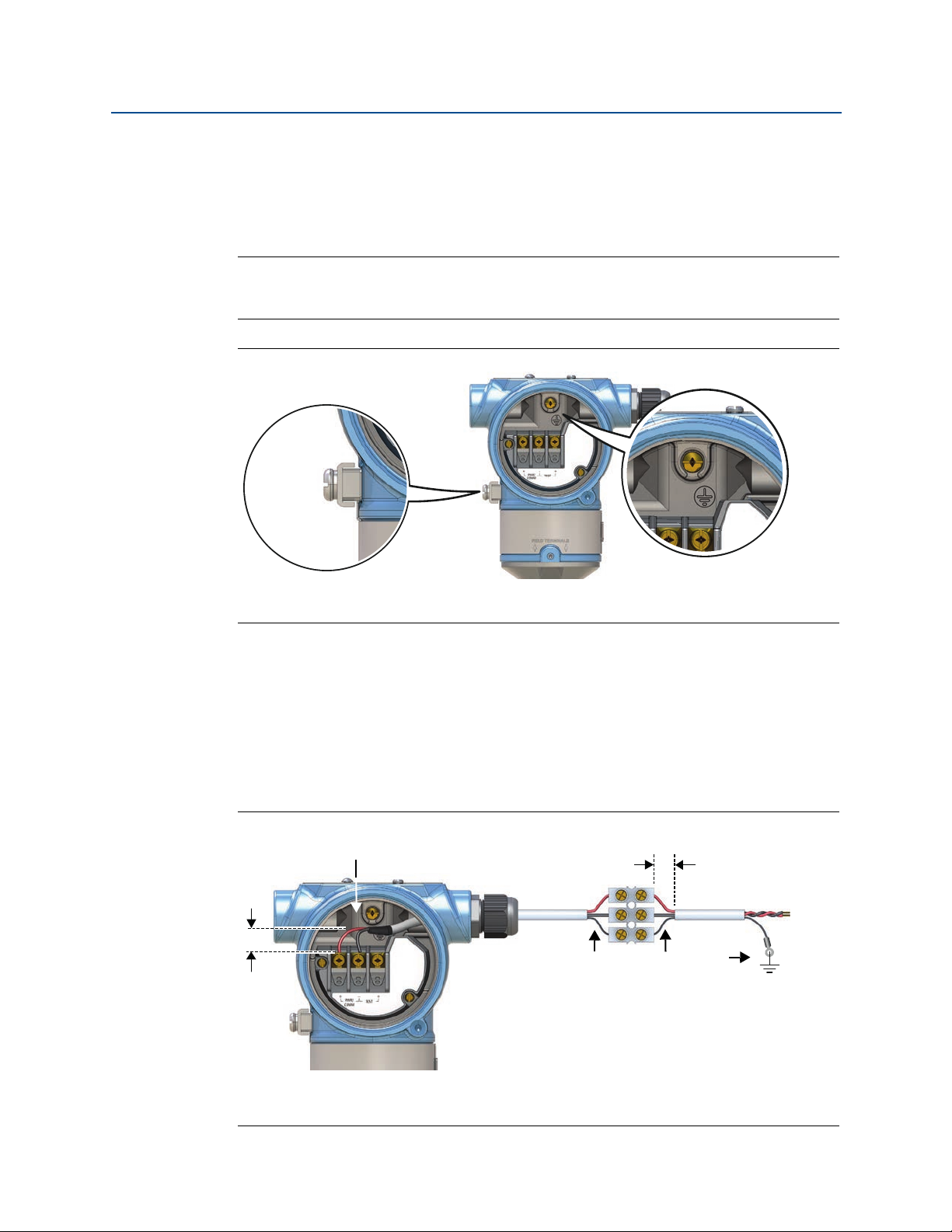

To activate the LOI, push either configuration button. Configuration buttons are located on

the LCD display (after removing the housing cover to access), or underneath the top tag of

the point level detector. See Table 2-1 for configuration button functionality and Figure 2-2

for configuration button location.

When using the LOI for configuration, several features require multiple screens for a

success ful con fig uratio n. Data entered w ill be saved on a screen-by-screen basis; the LOI will

indicate this by flashing “SAVED” on the LCD display each time.

Configuration

7

Page 18

Configuration

B

January 2017

Reference Manual

00809-0100-4140, Rev AA

LOI menu trees are available in Appendix D: Local Operator Interface.

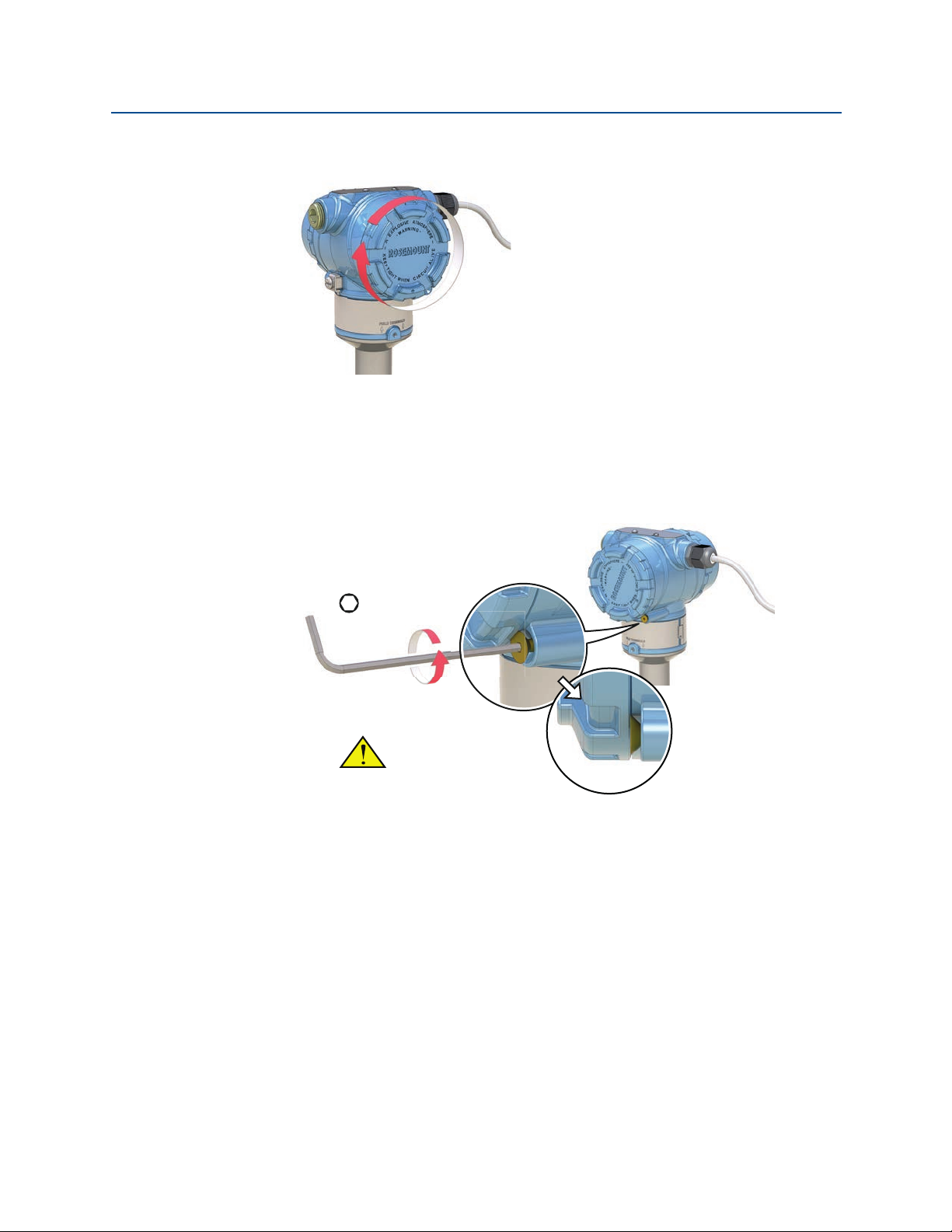

Figure 2-2. LOI Configuration Buttons

A

A. Internal configuration buttons

B. External configuration buttons

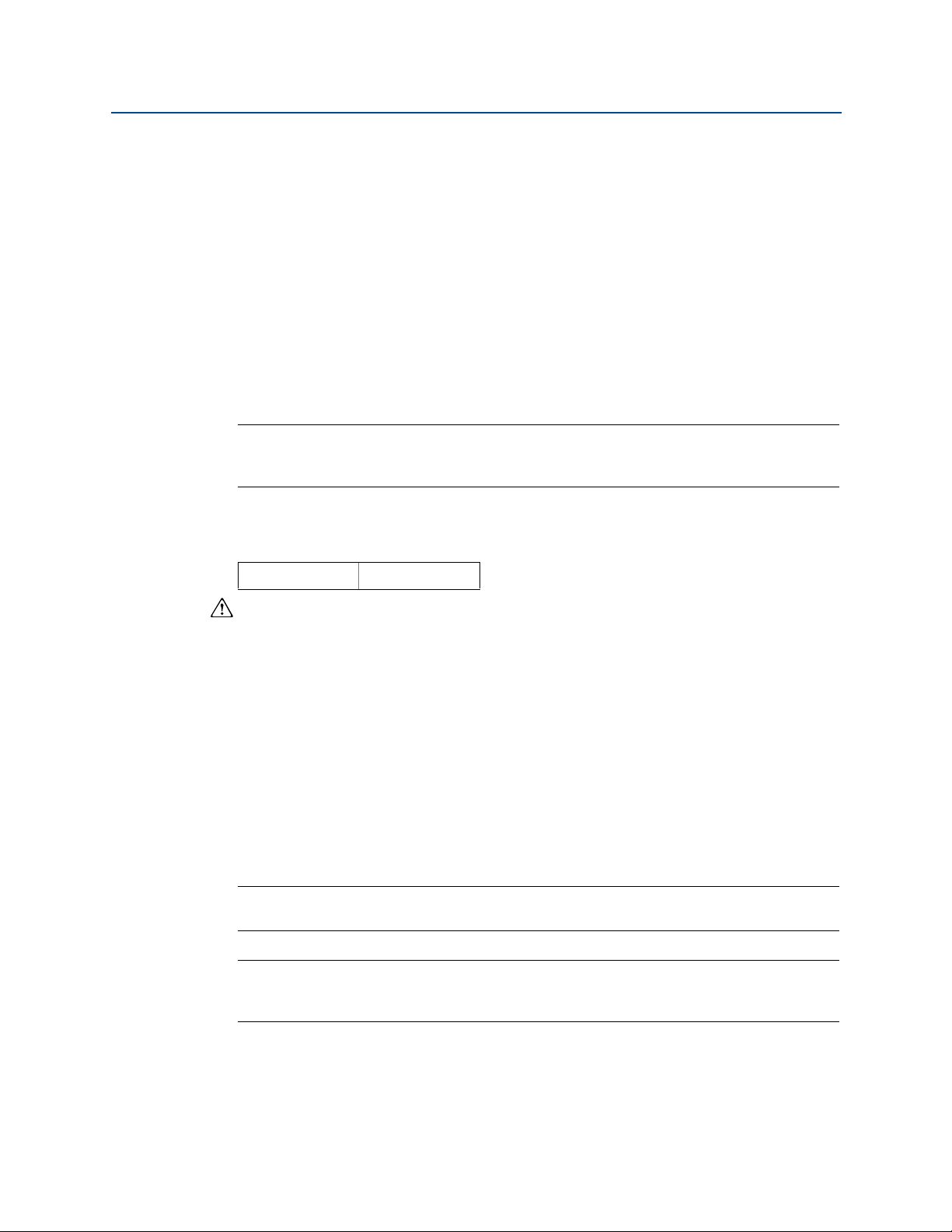

Table 2-1. LOI Button Operation

Button

Left No (SCROLL

Right Yes (ENTER

2.4 Switching HART Revision

2.4.1 Switching HART revision with a generic menu

If the HART configuration tool is not capable of communicating with a HART Revision 7

device, it should load a generic menu with limited capability. The following procedures

allow for switching between HART Revision 7 and HART Revision 5 from a generic menu.

1. Locate “Message” field.

a. To change to HART Revision 5, enter HART5 and 27 spaces in the message field.

b. To change to HART Revision 7, Enter: HART7 and 27 spaces in the message field.

8

Configuration

Page 19

Reference Manual

00809-0100-4140, Rev AA

Configuration

January 2017

2.4.2 Switching HART revision with Field Communicator

Fast keys

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 5: HART (or 6: HART if Scaled Variable is available).

3. Select 2: Communication Settings > 4: Change HART Revision.

4. Change the HART revision.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

2, 2, 5 [or 6], 2, 4

2.4.3 Switching HART Revision with AMS Device Manager

1. Click on Manual Setup, and then select the HART tab.

2. Select Change HART Revision and then follow the on screen prompts.

Note

AMS Device Manager versions 10.5 or greater are compatible with HART Revision 7.

Note

When messages about the loop appear, take appropriate safe action and select “Next >”.

See “Configuration basics” on page 10 for further information.

2.4.4 Switching HART revision with Local Operator Interface

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. Scroll down (

3. Scroll down (

4. To change HART revision:

a. Select HART REV 5 () or scroll down (

5. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

) and then select EXTENDED MENU ().

) and then select HART REV().

) and select HART REV 7() to switch.

Configuration

9

Page 20

Configuration

January 2017

2.5 Configuration basics

The Rosemount 2140 and 2140:SIS Level Detectors (“level detectors”) can be configured

before or after installation. Configuring the point level detector before installation ensures

all level detector components are in working order before installation.

2.5.1 Setting the security switch

Verify that the security switch is set in the unlock position ( ) to proceed with

configuration. See Figure 2-6 on page 43 for the switch location.

2.5.2 Setting the loop to manual

When sending or requesting data that would disrupt the loop or change the point level

detector output, set the process application loop to manual control. The Field

Communicator, AMS Device Manager, or the LOI prompts you to set the loop to manual

when necessary. The prompt is only a reminder. Acknowledging this prompt does not set

the loop to manual. It is necessary to set the loop to manual control as a separate operation.

Reference Manual

00809-0100-4140, Rev AA

2.6 Configure device using Guided Setup

The options available in the Guided Setup wizard include all items required for basic

operation. All basic configuration parameters are described in “Basic setup” on page 14.

2.6.1 Guided setup on the AMS Device Manager

1. Click the Start button, and then select All Programs > AMS Device Manager >

AMS Device Manager.

2. Select View > Device Connection View.

3. In the Device Connection View, double-click the HART modem icon.

4. Double-click the device icon.

5. From the Home screen, select Configure > Guided Setup.

6. Select Basic Setup and follow the on-screen instructions.

2.6.2 Guided setup on the Field Communicator

1. Turn on the Field Communicator.

10

2. From the Main Menu, tap the HART symbol. The Field Communicator now

connects to the device.

3. From the Home screen, select Configure > Guided Setup.

4. Select Basic Setup and follow the on-screen instructions.

Configuration

Page 21

Reference Manual

00809-0100-4140, Rev AA

Configuration

January 2017

2.6.3 Guided setup on the LOI

The Guided Setup wizard is not available on the LOI. Turn to “Basic setup” on page 14 for the

LOI instructions to configure basic parameters, and then return here to verify configuration.

2.7 Verify the configuration before installation

It is recommended that various configuration parameters are verified prior to installation

into the process. The various parameters are detailed out for each configuration tool.

2.7.1 Verifying configuration (Field Communicator or AMS)

Configuration parameters, listed in Table 2-2, are to be reviewed before the level detector is

installed. From the HOME screen of the Field Communicator, enter the fast key sequences

listed. Alternatively, turn to the page for detailed instructions.

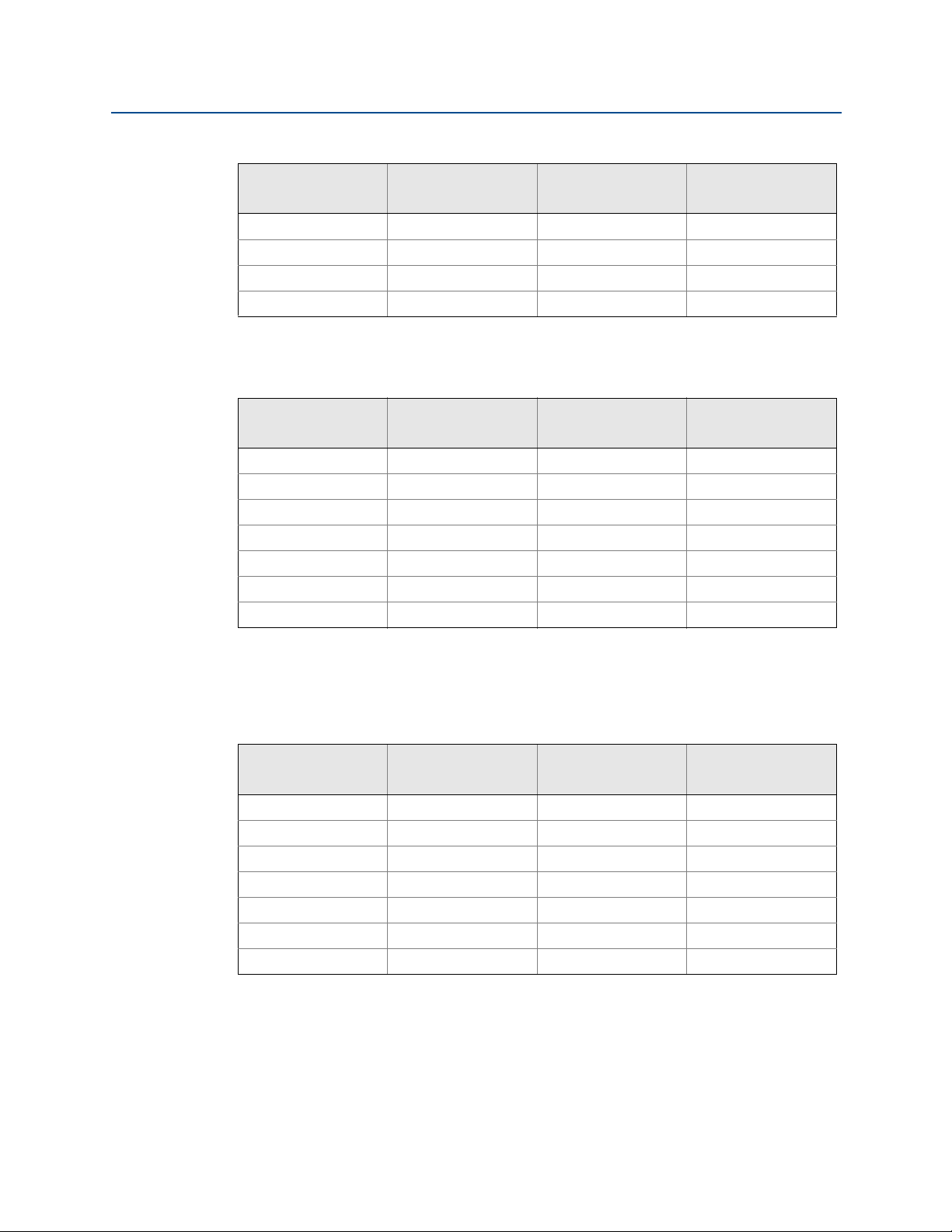

Table 2-2. Verifying Configuration (Fast Key Sequences)

Fast key sequence

Parameter

Tag 1, 8, 1, 2 1,8, 1, 1

Model 1, 8, 1, 3 1,8, 1, 3

Primary Variable (page 11) 3, 2, 1, 1 3, 2, 1, 1

Sensor Operating Mode (page 14) 2, 2, 1, 1, 1 2, 2, 1, 1, 1

Sensor Output Delay (page 16) 2, 2, 1, 1, 2 2, 2, 1, 1, 2

Media Density (page 17) 2, 2, 1, 1, 3 2, 2, 1, 1, 3

Sensor Fault Delay (page 22) 2, 2, 1, 3, 2 2, 2, 1, 3, 2

Current Output Type

Custom Off Current

Custom On Current

Upper Range Value

Lower Range Value

High Alarm Level

Low Alarm Level

High Saturation Level

Low Saturation Level

Alarm Switch Position/Direction (page 46) 2, 2, 2, 5, 2 2, 2, 2, 5, 2

1. Only applicable when the Primary Variable is mapped to the Output State variable.

2. Only applicable when Current Output Type is set to “Custom”.

3. Only applicable when the Primary Variable is mapped to the Sensor Frequency or Scaled Variable variables.

See “Dynamic variables configuration” on page 13 and “Analog output range points” on page 26 for details.

4. Alarm level and saturation level indicated depends on the setting of alarm level switch (page 46) and the ordered Alarm

Level code (Table A-6 on page 115).

(1)

(page 23)

(2)

(page 23)

(2)

(page 23) 2, 2, 2, 1, 4 2, 2, 2, 1, 4

(3)

(page 26)

(3)

(page 26) 2, 2, 2, 2, 3 2, 2, 2, 2, 3

(4)

(page 33)

(4)

(page 33) 2, 2, 2, 5, 6 2, 2, 2, 5, 6

(3)(4)

(page 33) 2, 2, 2, 5, 4 2, 2, 2, 5, 4

(3)(4)

(page 33) 2, 2, 2, 5, 5 2, 2, 2, 5, 5

HART 7 HART 5

2, 2, 2, 1, 1 2, 2, 2, 1, 1

2, 2, 2, 1, 3 2, 2, 2, 1, 3

2, 2, 2, 2, 2 2, 2, 2, 2, 2

2, 2, 2, 5, 3 2, 2, 2, 5, 3

Configuration

11

Page 22

Configuration

January 2017

2.7.2 Verifying configuration (LOI)

1. Press any configuration button to activate the LOI.

2. Select VIEW CONFIG ().

Reference Manual

00809-0100-4140, Rev AA

3. Scroll down (

TAG

MODEL – e.g. “2140”.

T Range – Operating temperature range (page 115)

EFP – Extended Features Package enabled (Yes/No)

(1)

IS PV

(1)

S UNIT

(2)

T UNIT

OP MODE – Operating mode (page 14).

DENSITY – Media density (page 17).

O DLY – Sensor output delay (page 16).

F DLY – Fault output delay (page 22).

AOMODE

OFF MA

ON MA

S-START – Device test (page 73)/proof test (page 75) at start.

URV

LRV

DAMPING

HIALRM

LOALRM

HI SAT

LO SAT

(3)

(4)

(4)

(5)

(5)

(1)

(6)

(6)

(5)(6)

(5)(6)

) to review the following parameters prior to installation:

– Primary Variable mapping (page 11)

– Secondary Variable units (page 129)

– Electronics temperature units (page 30)

– Analog Output operating mode (page 23)

– Custom mA output for ‘off’ output state (page 23)

– Custom mA output for ‘on’ output state (page 23)

– Upper range value for analog output (page 26)

– Lower range value for analog output (page 26)

– Scaled Variable damping (page 28)

– High alarm level (page 33)

– Low alarm level (page 33)

– High saturation level (page 33)

– Low saturation level (page 33)

12

ALARM – Alarm switch position/direction (page 46)

SECURE – Security switch position (page 43)

1. Only available when the Extended Features Package (EFP) is enabled.

2. SI units only.

3. Only visible when the Primary Variable (“PV”) is mapped to the Output State variable.

4. Only visible when the Analog Output operating mode is set to custom.

5. Only visible when the Primary Variable (“PV”) is mapped to the Sensor Frequency or Scaled Variable variables.

6. Alarm level and saturation level indicated depends on the setting of hardware alarm level switch (page 46)

and the ordered Alarm Level code (Table A-6 on page 115).

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

Configuration

Page 23

Reference Manual

00809-0100-4140, Rev AA

2.7.3 Dynamic variables configuration

This section describes how to verify that the four dynamic variables are mapped correctly.

If incorrectly mapped, see “HART (re-mapping dynamic variables)” on page 31.

Default mapped dynamic variables

By default, the four mapped dynamic variables are:

Primary Variable (“PV”)

Mapped to: Output State – the level detector output state is off (0.0) or on (1.0).

Secondary Variable (“SV”)

Mapped to: Sensor State – indicates the state of the sensor as dry (0.0) or wet (1.0).

Tertiary Variable (“TV”)

Mapped to: Sensor Frequency – the frequency of the vibrating fork in units of Hz.

Quaternary Variable (“QV”)

Mapped to: Electronics Temperature – the temperature inside the housing in °F/°C.

Configuration

January 2017

Verifying dynamic variables (Field Communicator)

Fast keys

To view the Variables menu:

1. From the Home screen, select 3: Service Tools.

2. Select 2: Variables > 2: Mapped Variables

3. Select a dynamic variable:

a. Select 1: Primary Variable.

b. Select 2: Secondary Variable.

c. Select 3: Tertiary Variable.

d. Select 4: Quaternary Variable.

3, 2, 2

Verifying dynamic variables (AMS Device Manager)

1. Right click on the device and select Overview from the menu.

2. Click the Mapped Variables button to display the primary, secondary, tertiary, and

quaternary variables.

Verifying dynamic variables (LOI)

Configuration

The mapping of dynamic variables is not viewable on the LOI.

13

Page 24

Configuration

January 2017

Reference Manual

00809-0100-4140, Rev AA

Optional re-mapping of PV

Versions of the Rosemount 2140 with the Extended Features Package (EFP)

can re-map the PV to:

Sensor Frequency

Scaled Variable

Optional re-mapping of SV, TV, or QV

The Rosemount 2140 and Rosemount 2140:SIS can re-map the SV, TV, or QV to:

Output State

Sensor State

Sensor Frequency

Electronics Temperature

Terminal Voltage

Versions of the Rosemount 2140 with the Extended Features Package (EFP)

can also re-map the SV, TV, or QV to:

Scaled Variable

Note

See “HART (re-mapping dynamic variables)” on page 31 for related information.

2.8 Basic setup

2.8.1 Sensor operation mode

Fast keys

The level detector has three operation modes:

Normal (Rosemount 2140 only)

Default mode with no sensor fault detection enabled.

Enhanced wet

Optional mode where the Sensor State device variable is forced to a ‘wet state’

while sensor faults are detected. (Default mode on Rosemount 2140:SIS).

Enhanced dry

Optional mode where the Sensor State device variable is forced to a ‘dry state’

while sensor faults are detected.

2, 2, 1, 1, 1

14

Note

Sensor State (page 82) is used to derive the Output State (page 13).

Configuration

Page 25

Reference Manual

00809-0100-4140, Rev AA

To change or view the mode (Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 1: Operation > 1: Application.

3. Select 1: Sensor Operation Mode.

4. If changing the mode setting:

a. Select a mode: “Normal”, “Enhanced (Fault=Wet)”, or “Enhanced (Fault=Dry)”.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

To change or view the mode (AMS Device Manager)

1. Right click on the device and select Configure.

Configuration

January 2017

2. Select Manual Setup, and then select the Operation tab.

3. If changing the mode setting:

a. Select a mode: “Normal”, “Enhanced (Fault=Wet)”, or “Enhanced (Fault=Dry)” at

the Sensor Operation Mode field.

Note

When messages about the loop appear, take appropriate safe action and select “Next >”.

See “Configuration basics” on page 10 for further information.

To change or view the mode (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. If changing the mode setting:

a. Scroll down (

b. Scroll down (

c. Select SENSOR OPMODE ().

d. Follow on-screen instructions to select a new mode:

NORM (normal), EN WET (enhanced wet), or EN DRY (enhanced dry).

) and then select EXTENDED MENU ().

) and then select SENSOR ().

Configuration

3. If viewing the mode setting:

a. Select VIEW CONFIG ().

b. Scroll down (

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

) until OPMODE and the mode setting appears.

15

Page 26

Configuration

January 2017

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

2.8.2 Sensor output delay

Reference Manual

00809-0100-4140, Rev AA

Fast keys

When there is a detected change in process conditions, from wet-to-dry or

dry-to-wet, the Sensor Output Delay variable can action a delay of up to 3600 seconds

before the new state change is indicated. The default delay is one second.

Depending on the application, a suitable delay can prevent constant switching of the

output state. If, for example, there are waves in a tank, then there may be splashes causing

intermittently detected changes in process conditions. The sensor output delay ensures

that the fork is dry or wet for a suitable period before switching.

2, 2, 1, 1, 2

To change or view the delay setting (Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 1: Operation > 1: Application.

3. Select 2: Sensor Output Delay.

4. If changing the delay setting:

a. Edit a delay value in the range 0 to 3600 seconds.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

16

To change or view the delay setting (AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then the select the Operation tab.

3. If changing the delay setting:

a. Edit a delay in the range 0 to 3600 seconds at the Sensor Output Delay field.

To change or view the delay setting (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. If changing the mode setting:

a. Scroll down (

b. Scroll down (

) and then select EXTENDED MENU ().

) and then select SENSOR ().

Configuration

Page 27

Reference Manual

00809-0100-4140, Rev AA

c. Scroll down () and then select OUTPUT DELAY ().

d. Follow on-screen instructions and edit a new delay setting in the range 0 to 3600.

Entering a delay outside this range results in ERROR being displayed.

3. If viewing the mode setting:

a. Select VIEW CONFIG ().

b. Scroll down (

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

2.8.3 Media density

Configuration

January 2017

) until O DELAY and the delay setting appears.

Fast keys

2, 2, 1, 1, 3

The measured frequency of the fork, when immersed in process medium, can be affected

by liquid density variations. As a result, the dry-to-wet and wet-to-dry switching points are

different for all types and varieties of process medium (Figure 2-3 on page 18).

To overcome this, accurate switching points can be calculated by the Rosemount 2140 and

Rosemount 2140:SIS after a suitable density band is selected for the process medium.

Media Density options the Rosemount 2140 and Rosemount 2140:SIS are:

0.4 – 0.6 SG (for a 400 to 600 kg/m

0.5 – 0.9 SG (for a 500 to 900 kg/m

0.8 – 1.3 SG (for a 800 to 1300 kg/m

1.2 – 3.0 SG (for a 1200 to 3000 kg/m

3

range – e.g. propane)

3

range – e.g. alcohol)

3

range – e.g. water) (default selection)

3

range – e.g. acid)

Extra options on the Rosemount 2140 are:

Low compacted sediment

Medium compacted sediment

High compacted sediment

Extreme compacted sediment

Configuration

Note

Versions of the Rosemount 2140 and Rosemount 2140:SIS with the Extended Features

Package (EFP) can use Media Learn (page 19) to automatically select a density band.

For all other versions, keep the default setting for Media Density when the liquid specific

gravity is unknown.

17

Page 28

Configuration

Liquid Density (SG)

00.5

1.0

1.5

2.0

2.5 3.0

Switch Frequency

A

B

C

D

January 2017

Reference Manual

00809-0100-4140, Rev AA

Figure 2-3. Example of Calculated Switching Points for a Process Media

A. Top limit boundary (allowing for variations in fork manufacture).

B. Nominal switching point frequencies for this process medium.

C. Bottom limit boundary (allowing for variations in fork manufacture).

D. Dry fork frequency – see “Dry fork frequency and switching points” on page 85 for details.

To change or view the media density (Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 1: Operation > 1: Application.

3. Select 3: Media Density.

4. Select the option that is closest to the process medium density range.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

To change or view the media density (AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Operation tab.

3. Select the Media Density option that is closest to the process medium density

range.

Note

When messages about the loop appear, take appropriate safe action and select “Next >”.

See “Configuration basics” on page 10 for further information.

18

Configuration

Page 29

Reference Manual

OK

Tines Fully

Immersed

00809-0100-4140, Rev AA

To change or view the media density (LOI)

1. Press any LOI button to activate the menu.

Configuration

January 2017

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. Scroll down (

3. Scroll down (

4. Select DENSITY ().

5. Follow on-screen instructions to select an option that is closest to the process

medium density range.

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

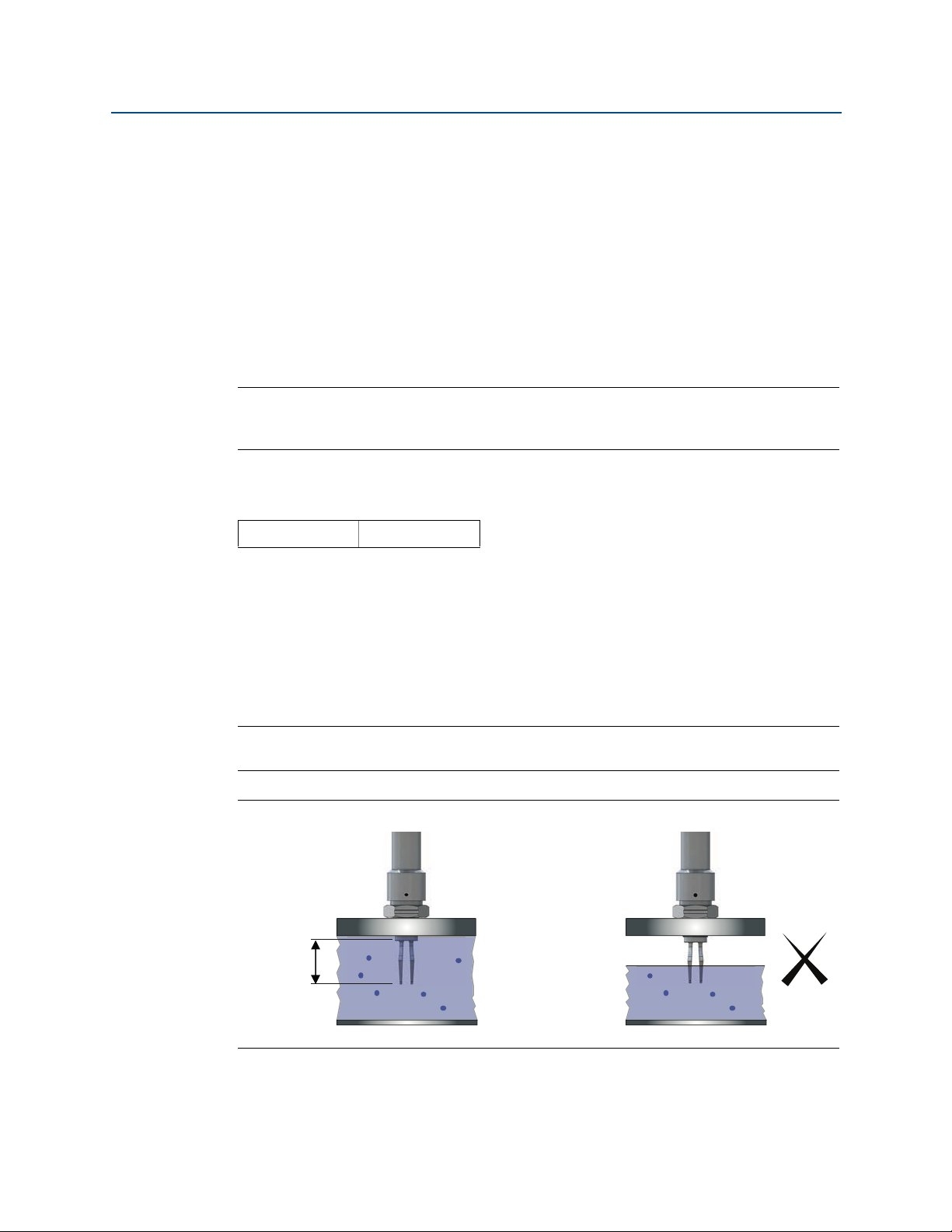

2.8.4 Media learn

Fast keys

Versions of the Rosemount 2140 and Rosemount 2140:SIS with the Extended Features

Package (EFP) can use the Media Learn function.

Media Learn makes configuring the Media Density variable (page 17) even easier.

This procedure requires the fork tines to be fully immersed in the process medium for a

short period to gather the frequency data, calculate the liquid density, and then auto-select

the option for the Media Density variable.

) and then select EXTENDED MENU ().

) and then select MEDIA ().

2, 2, 1, 1, 5

Configuration

Note

Media Learn may have unexpected results in high temperatures.

Figure 2-4. Fully Immersed Tines for Media Learn

19

Page 30

Configuration

January 2017

Reference Manual

00809-0100-4140, Rev AA

To use Media Learn (Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 1: Operation > 1: Application.

3. Select 5: Media Learn.

4. Follow on-screen instructions until the learning procedure is completed.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

To use Media Learn (AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Operation tab.

3. Click on the Media Learn button (in the Application box).

4. Follow on-screen instructions until the learning procedure is completed.

(The “Recall Learnt” option restores a previously learnt media density).

5. In the Application box, the Learnt box is now marked.

Note

When messages about the loop appear, take appropriate safe action and select “Next >”.

See “Configuration basics” on page 10 for further information.

To use Media Learn (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. Scroll down (

3. Scroll down (

4. Scroll down (

5. Follow on-screen instructions until the learning procedure is completed.

) and select EXTENDED MENU ().

) and select MEDIA ().

) and select LEARN ().

20

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

Configuration

Page 31

Reference Manual

00809-0100-4140, Rev AA

2.8.5 Allowable change in dry fork frequency

Configuration

January 2017

Fast keys

When the level detector is re-calibrated in the field, a comparison is made between the new

dry fork frequency and original factory-set Dry Fork Frequency value. If the difference is

greater than the allowable change value, the re-calibration is rejected. Check the fork for

damage, corrosion, or coating, and clean the fork if necessary before re-trying.

The default setting is 100 Hz, but can be set to a value in the range 0 to 255 Hz.

Setting the value to 0 Hz switches off the allowable change monitoring.

Note

Fast key sequence is 3, 4, 1, 2, 1 for the original factory-set Dry Fork Frequency.

2, 2, 1, 3, 1

To change or view the allowable change

(Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 1: Operation > 3: Sensor.

3. Select 1: Allowable Change In Dry Fork Frequency.

4. Follow the on-screen instructions to configure the allowable change.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

To change or view the allowable change

(AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Operation tab.

3. If changing the allowable change setting:

a. Edit a frequency in the range 0 to 255 Hz at the Allowable Change In Dry Fork

Frequency field.

Note

When messages about the loop appear, take appropriate safe action and select “Next >”.

See “Configuration basics” on page 10 for further information.

To change or view the allowable change (LOI)

This configuration parameter is not available on the LOI.

Configuration

21

Page 32

Configuration

January 2017

2.8.6 Sensor fault delay

Reference Manual

00809-0100-4140, Rev AA

Fast keys

When the level detector is operating in Enhanced Mode and detects a fork sensor fault,

Sensor State (page 82) indicates a fault state after a delay.

The default setting is 5 seconds. It can be set to a value in the range 0 to 3600 seconds.

Note

When the Rosemount 2140 is operating in Normal mode, a fork sensor fault is not detected

and Sensor State continues to indicate a valid state.

2, 2, 1, 3, 2

To change or view the sensor fault delay

(Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 1: Operation > 3: Sensor.

3. Select 2: Sensor Fault Delay.

4. Follow the on-screen instructions to configure the delay.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

To change or view the sensor fault delay

(AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Operation tab.

3. If changing the delay setting:

a. Edit the number of seconds at the Sensor Fault Delay field.

Note

When messages about the loop appear, take appropriate safe action and select “Next >”.

See “Configuration basics” on page 10 for further information.

To change or view the sensor fault delay (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. If changing the mode setting:

a. Scroll down (

b. Scroll down (

) and then select EXTENDED MENU ().

) and then select SENSOR ().

22

Configuration

Page 33

Reference Manual

00809-0100-4140, Rev AA

c. Scroll down () and then select FAULT DELAY ().

d. Follow on-screen instructions and edit a new delay setting in the range 0 to 3600.

Entering a delay outside this range results in ERROR being displayed.

3. If viewing the mode setting:

a. Select VIEW CONFIG ().

b. Scroll down (

) until F DELAY and the delay setting appears.

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

2.8.7 Analog output type and operating modes

The analog output is driven by a device variable mapped to the Primary Variable (“PV”).

Carefully read displayed warnings that appear before applying changes.

Configuration

January 2017

This sub-section is for establishing how the analog output will operate.

Current output type

Fast keys

Options to select are:

4 and 20 mA – i.e. 4mA = ‘off’ and 20 mA = ‘on’ switched output states.

Continue reading this sub-section for related configuration steps.

8 and 16 mA – i.e. 8 mA = ‘off’ and 16 mA = ‘on’ switched output states.

Continue reading this sub-section for related configuration steps.

Custom– i.e. user-set output currents for ‘off’/‘on’ switched output states.

The output current levels for ‘off’ and ‘on’ output states are user-entered under the

Custom Off Current and Custom On Current variables. Continue reading this

sub-section for related configuration steps.

LEVELTESTER– compatibility mode

See Table 2-3 for output current information.

Table 2-3. LEVELTESTER Output Current

Output current Wet on Dry on

2, 2, 2, 1, 1

Configuration

Wet 18.5±0.5 mA @ 0.5 Hz 6 mA

Dry 9 mA 13.5±0.5 mA @ 0.5 Hz

23

Page 34

Configuration

January 2017

Reference Manual

00809-0100-4140, Rev AA

Current output operating mode

Fast keys

2, 2, 2, 1, 2

This selects the fork sensor state associated with the Output State device variable

indicating ‘on’. Options to select are:

Dry on

Wet on

Custom “off” current

Fast keys

When the Current Output Type is set to “Custom”, this parameter is for entering the

output current to be applied when:

The Current Output Operating Mode variable is set to “Dry on”

and the fork is immersed in liquid or sand/sediment.

The Current Output Operating Mode variable is set to “Wet on”

and the fork is not immersed in liquid or sand/sediment.

2, 2, 2, 1, 3

Custom “on” current

Fast keys

2, 2, 2, 1, 4

When the Current Output Type is set to “Custom”, this parameter is for entering the

output current to be applied when:

The Current Output Operating Mode variable is set to “Wet on”

and the fork is immersed in liquid or sand/sediment.

The Current Output Operating Mode variable is set to “Dry on”

and the fork is not immersed in liquid or sand/sediment.

To change current output type and operating mode

(Field Communicator

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 2: Analog Output > 1: Mode Setup.

3. If changing the current output type:

a. Select 1: Current Output Type.

b. Make the type selection.

c. If the type is set to Custom, enter output current levels in the

3: Custom Off Current and 4: Custom On Current screens.

4. If changing the current output operating mode:

a. Select 2: Current Output Operating Mode.

b. Make the mode selection.

)

24

Configuration

Page 35

Reference Manual

00809-0100-4140, Rev AA

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

To change the current output type and operating mode

(AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Analog Output tab.

3. If changing the current output type:

a. Select an option for the Current Output Type field.

b. If the type selected is Custom, enter output currents for ‘off’/‘on’ output states at

4. If changing the current output operating mode:

a. Select an option for the Current Output Operating Mode field.

Configuration

January 2017

the Custom Off Current and Custom On Current fields.

5. Click on Send.

6. Carefully read the warning and click Yes if it is safe to apply the changes.

Note

When messages about the loop appear, take appropriate safe action.

See “Configuration basics” on page 10 for further information.

To change the current output type and operating mode (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. If changing the current output type:

a. Scroll down (

b. Scroll down (

c. Scroll down (

d. Follow on-screen instructions and select a current output type

(“4 and 20 mA”, “8 and 16 mA”, or “Custom”).

e. If the type selected is “Custom”, enter output currents for ‘off’ and ‘on’ output

states at the CUSTOM OFF and CUSTOM ON menus.

3. If changing the current output operating mode:

) and then select EXTENDED MENU ().

) and then select ANALOG OUTPUT ().

) and then select OUTPUT TYPE ().

Configuration

a. Scroll down (

b. Scroll down (

c. Scroll down (

d. Follow on-screen instructions and select a current output operating mode

(“Wet on” or “Dry on”).

) and then select EXTENDED MENU ().

) and then select ANALOG OUTPUT ().

) and then select OPERATE MODE ().

25

Page 36

Configuration

January 2017

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

2.8.8 Analog output range points

The analog output is driven by a device variable mapped to the Primary Variable (“PV”).

Carefully read displayed warnings that appear before applying changes.

This section is for entering the range points for the PV to be output using the analog output.

The Lower Range Value (LRV) variable is the PV represented by 4 mA, and the Upper

Range Value (URV) variable is the PV represented by 20 mA. This PV range can be a sub-set

of the sensor limits defined by Upper PV Limit and Lower PV Limit variables (see Table 2-4

on page 28).

However, by default, the Output State is mapped to the PV. The range points for this are

read-only and identical to the associated sensor limits (see “Sensor limits” on page 28).

If supported, Sensor Frequency or Scaled Variable can instead be re-mapped to the PV.

The range points then automatically change from read-only to editable, allowing range

points to be changed, but are subject to the sensor limits (see “Sensor limits” on page 28).

Reference Manual

00809-0100-4140, Rev AA

Optionally, use Scaled Variable Damping (page 28) to smooth out large steps in output

current changes when the PV is a scaled variable.

See also “Site calibration of analog output” on page 70 for other related information.

Entering range points (Field Communicator)

Fast keys

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 2: Analog Output > 2: Set Range Points.

3. Enter the PV value at 20 mA in the 2: Upper Range Value variable.

4. Enter the PV value at 4 mA in the 3: Lower Range Value variable.

Note

At the 4: Readings menu (2, 2, 2, 4), the 1: Analog Output item indicates the live output

current. The 2: Percent of Range item indicates the percentage of that output current in

terms of the complete 4–20 mA range. For example, 8 mA is 25% of range, 12 mA is 50%

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

2, 2, 2, 2

26

Configuration

Page 37

Reference Manual

00809-0100-4140, Rev AA

Entering range points (AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Analog Output tab.

3. Enter the PV at 4 mA in the Lower Range Value field.

4. Enter the PV at 20 mA in the Upper Range Value field.

5. Click Send.

6. Carefully read the warning and click Yes if it is safe to apply the changes.

Note

In the Readings box, the Analog Output device variable indicates the live output current.

The Percent of Range device variable indicates a percentage of th at output curren t in ter ms

of the complete 4–20 mA range. For example, 8 mA is 25% of range, 12 mA is 50%, etc.

Note

When messages about the loop appear, take appropriate safe action.

See “Configuration basics” on page 10 for further information.

Configuration

January 2017

Entering range points (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. If changing the range points:

a. Scroll down (

b. Select ENTER VALUES ().

c. Select LRV ().

d. Follow on-screen instructions and edit a new PV value at 4 mA.

(Attempting to enter an invalid value results in ERROR being displayed).

e. Scroll down (

f. Follow on-screen instructions and edit a new PV value at 20 mA.

(Attempting to enter an invalid value results in ERROR being displayed).

3. If viewing the range points:

a. Select VIEW CONFIG ().

b. Scroll down (

c. Scroll down (

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt,

or scrolling down menus to find and select BACK TO MENU and EXIT MENU.

) and then select RERANGE ().

) and then select URV ().

) until LRV and the lower range value setting appears.

) until URV and the upper range value setting appears.

Configuration

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

27

Page 38

Configuration

January 2017

Reference Manual

00809-0100-4140, Rev AA

Sensor limits

Table 2-4 shows the sensor limits applied when a device variable is mapped to the PV

dynamic variable. They are used for scaling gauges in a Host system (e.g. AMS Device

Manager) and for validating the range points in the analog output (page 26).

Note

See also “Dynamic variables configuration” on page 13 for related information.

Table 2-4. Sensor Limits for Device Variables

Device Variables Lower PV Limit Upper PV Limit

Output State 0.0 1.0

Sensor State 0.0 1.0

Sensor Frequency 250.0 Hz 1800.0 Hz

Electronics Temperature –40 °C 85 °C

Terminal Voltage 10.5 V 42.4 V

Scaled Variable Defined by sensor frequency limits and scaling data.

2.8.9 Scaled Variable damping

Damping is an optional parameter for changing the response time of the level detector

when the PV is mapped to the Scaled Variable. Increasing the damping value can smooth

wide variations in the output caused by rapid input changes, but at the cost of decreasing

response times.

Damping settings range from 0.0 to 60.0 seconds. An appropriate damping setting is a

balance of the necessary response time, signal stability, and other requirements of the loop

dynamics within your system.

Carefully read displayed warnings that appear before applying changes.

Note

Versions of the Rosemount 2140 with the Extended Features Package (EFP) can re-map the

PV to Scaled Variable.

Damping with a Field Communicator

Fast keys

2, 2, 2, 2, 4

28

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 2: Analog Output > 2: Set Range Points.

3. Select 4: Damping.

4. Enter the damping setting.

Configuration

Page 39

Reference Manual

00809-0100-4140, Rev AA

Note

When messages about the loop appear, take appropriate safe action.

See “Configuration basics” on page 10 for further information.

Damping with AMS Device Manager

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Analog Output tab.

3. Enter the damping setting, and click Send.

4. Carefully read the warning and click Yes if it is safe to apply the changes.

Damping with a LOI

1. Press any LOI button to activate the menu.

2. If changing the damping setting:

Configuration

January 2017

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

a. Scroll down (

b. Scroll down (

) and then select EXTENDED MENU ().

) and then select DAMPING ().

c. Follow on-screen instructions and edit a new damping setting in the range 0 to 60.

Attempting to enter a value outside this range results in ERROR being displayed.

If viewing the damping setting:

a. Select VIEW CONFIG ().

b. Scroll down (

) until DAMPING and the damping setting appears.

3. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT TO MENU.

2.9 Local Operator Interface (LOI) display

Fast keys

The LOI display configuration allows customization of the displayed information to suit

application requirements. The LOI alternates between selected items.

Output State (page 13) Electronics Temperature (page 13)

Sensor State (page 13) Terminal Voltage (page 13)

Sensor Frequency (page 13) Percent of Range (page 26)

Scaled Variable

1. This is selectable only if the Rosemount 2140 has the Extended Features Package enabled.

(1)

2, 2, 2

(page 13)

Analog Output (page 26)

Configuration

Note

The LOI can also be configured to display configuration information during the device

startup. Select Review Parameters at Startup to enable this functionality.

29

Page 40

Configuration

January 2017

Reference Manual

00809-0100-4140, Rev AA

Configuring LOI display (using Field Communicator)

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 5: Display.

3. For items 1 to 8, select or de-select the parameters to show on the LOI display.

Optionally, select 9: Review Parameters at Startup.

Configuring LOI display (using AMS Device Manager)

1. Right click on the device and select Configure.

2. Click Manual Setup, and then select the Display tab.

3. Select or de-select the parameters to show on the LOI display, and then click Send.

4. Optionally, select Review Parameters at Startup.

Configuring LOI display (using LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. Scroll down (

3. Scroll down (

a. Use the select () to change the setting to ON or OFF

b. Answer YES () to confirm the change or NO (

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT TO MENU.

) and then select DISPLAY ().

), and then for each item:

2.9.1 Electronics temperature units

Note

Available on SI units only.

Changing temperature units (Field Communicator)

Fast keys

1. From the Home screen, select 2: Configure.

2, 2, 4, 3

) to abandon the change.

30

2. Select 2: Manual Setup > 4: Device Temperature > 3: Units.

3. Select the measurement units.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

Configuration

Page 41

Reference Manual

00809-0100-4140, Rev AA

Changing temperature units (AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then select the Device Temperature tab.

3. Select the measurement units at the Setup Unit box, and click Send.

Note

When messages about the loop appear, take appropriate safe action.

See “Configuration basics” on page 10 for further information.

Changing temperature units (LOI)

1. Press any LOI button to activate the menu.

Configuration

January 2017

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. Scroll down (

3. Select DEG C or scroll down (

4. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

Note

When messages about the loop appear, take appropriate safe action and select “”.

See “Configuration basics” on page 10 for further information.

) and then select UNITS ().

) and select DEG F ().

2.10 Detailed setup

2.10.1 HART (re-mapping dynamic variables)

The re-mapping of process variables to the primary, secondary, tertiary, and quaternary

variables (“PV”, “SV”, “TV”, and “QV” respectively) can be performed here, if supported.

See “Dynamic variables configuration” on page 13 to find out what is supported.

The PV can be re-mapped with a Field Communicator, AMS Device Manager, or a LOI.

However, the other three variables (SV, TV, and QV) can only be re-mapped using a Field

Communicator or the AMS Device Manager.

Configuration

Note

The process variable assigned to the PV drives the analog output.

See “Analog output type and operating modes” on page 23 for further information.

31

Page 42

Configuration

January 2017

Reference Manual

00809-0100-4140, Rev AA

Re-mapping process variables (Field Communicator)

Fast keys

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup > 5: (or 6:) HART.

3. Select 1: Variable Mapping.

4. Assign Primary Variable, Secondary Variable, Tertiary Variable and Quaternary

Variable to supported process variables.

Note

When messages about the loop appear, take appropriate safe action and select “OK”.

See “Configuration basics” on page 10 for further information.

2, 1, 5 (or 6), 1

Re-mapping process variables (AMS Device Manager)

1. Right click on the device and select Configure.

2. Select Manual Setup, and then click on the HART tab.

3. In the Variable Mapping box, assign Primary Variable, Secondary Variable,

Tertiary Variable and Quaternary Variable to supported process variables.

4. Click Send.

5. Carefully read the warning and click Yes if it is safe to apply the changes.

Note

When messages about the loop appear, take appropriate safe action.

See “Configuration basics” on page 10 for further information.

Re-mapping process variables (LOI)

1. Press any LOI button to activate the menu.

(See Table 2-1 on page 8 for assistance with using the LOI buttons).

2. Scroll down (

3. Scroll down (

4. Scroll down (

5. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or