Page 1

00825-0100-4130, Rev DA

Rosemount™ 2130 Level Switch

Vibrating Fork

Quick Start Guide

June 2020

Page 2

Quick Start Guide June 2020

Contents

About this guide...........................................................................................................................3

Installation................................................................................................................................... 5

Prepare the electrical connections..............................................................................................10

Connect wiring and power up.....................................................................................................26

Configuration.............................................................................................................................30

Operation...................................................................................................................................33

Servicing and troubleshooting................................................................................................... 34

2 Quick Start Guide

Page 3

June 2020 Quick Start Guide

1 About this guide

This Quick Start Guide provides basic guidelines for the Rosemount 2130.

Refer to the Rosemount 2130 Reference Manual for more instructions. The

manual and this guide are also available electronically at Emerson.com/

Rosemount.

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the level switch is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the level switch only as specified in this manual. Failure to do so may

impair the protection provided by the level switch.

• The weight of a level switch with a heavy flange and extended fork length

may exceed 37 lb. (18 kg). A risk assessment is required before carrying,

lifting, and installing the level switch.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the level switch is consistent

with the appropriate hazardous locations certifications.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure that the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

• In explosion-proof/flameproof and non-Incendive/type n installations, do

not remove the housing cover when power is applied to the level switch.

• The housing cover must be fully engaged to meet flameproof/explosion-

proof requirements.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the power to the level switch is off, and the lines to any other

external power source are disconnected or not powered while wiring the

level switch.

• Ensure the wiring is suitable for the electrical current and the insulation is

suitable for the voltage, temperature, and environment.

Quick Start Guide 3

Page 4

Quick Start Guide June 2020

WARNING

Process leaks could result in death or serious injury.

• Ensure the level switch is handled carefully. If the process seal is

damaged, gas might escape from the vessel (tank) or pipe.

Any substitution of non-recognized parts may jeopardize safety. Repair (e.g.

substitution of components) may also jeopardize safety and is not allowed

under any circumstances.

• Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize

safety. Unauthorized changes that interfere with the integrity of the

welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified

without the prior written permission of Emerson. Any continued use of

product that has been damaged or modified without the written

authorization is at the customer’s sole risk and expense.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process

temperatures.

Allow to cool before servicing.

4 Quick Start Guide

Page 5

OK

OK

A

B

A

B

OK

OK

OK

A

B

C

June 2020 Quick Start Guide

2 Installation

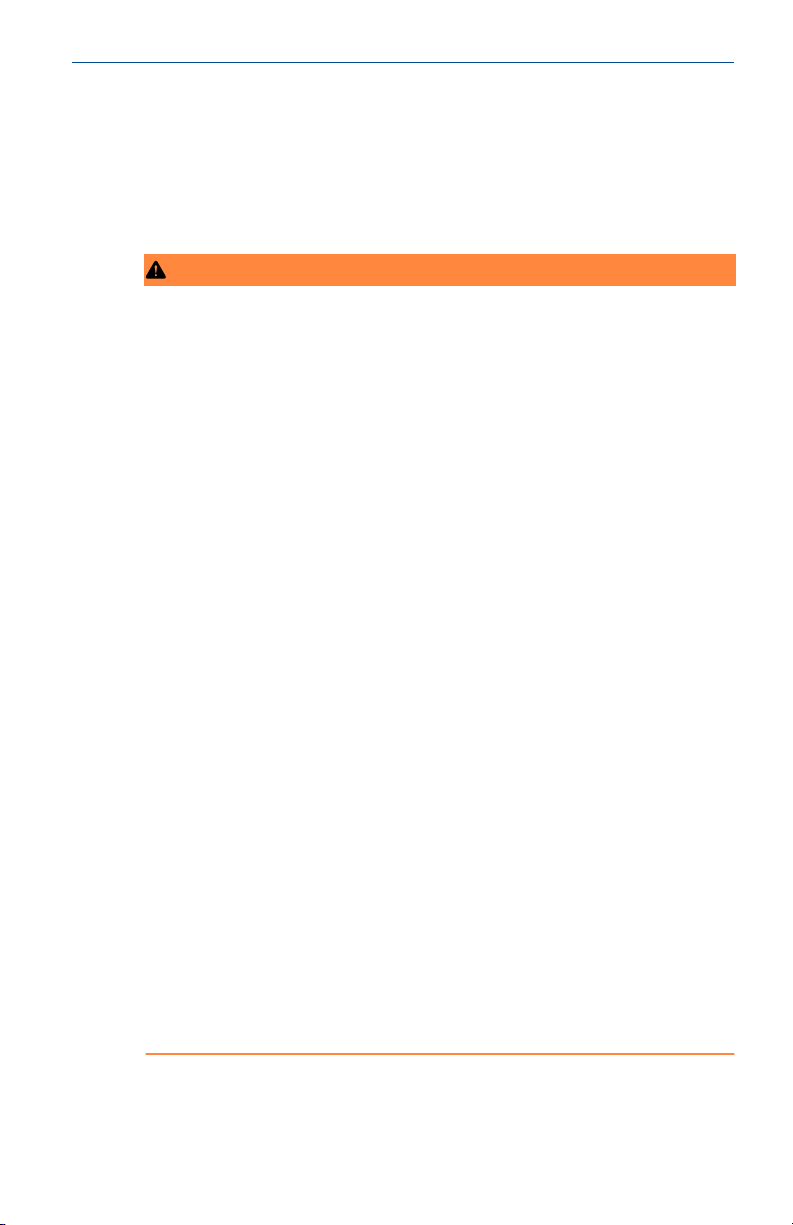

2.1 Fork alignment in a pipe installation

Figure 2-1: Correct Fork Alignment for Pipe Installation

A. Tri Clamp process connections have a circular notch

B. Threaded process connections have a groove

2.2

Quick Start Guide 5

Fork alignment in a vessel (tank) installation

Figure 2-2: Correct Fork Alignment for Vessel (Tank) Installation

A. Tri Clamp process connections have a circular notch

B. Threaded process connections have a groove

C. Flanged process connections have a circular notch

Page 6

A gasket may be used as a sealant for BSPP (G) threaded connections.

Tighten using the hexagon only

Gasket for BSPP (G) threaded connection

Tighten using the hexagon only

Gasket for BSPP (G) threaded connection

Quick Start Guide June 2020

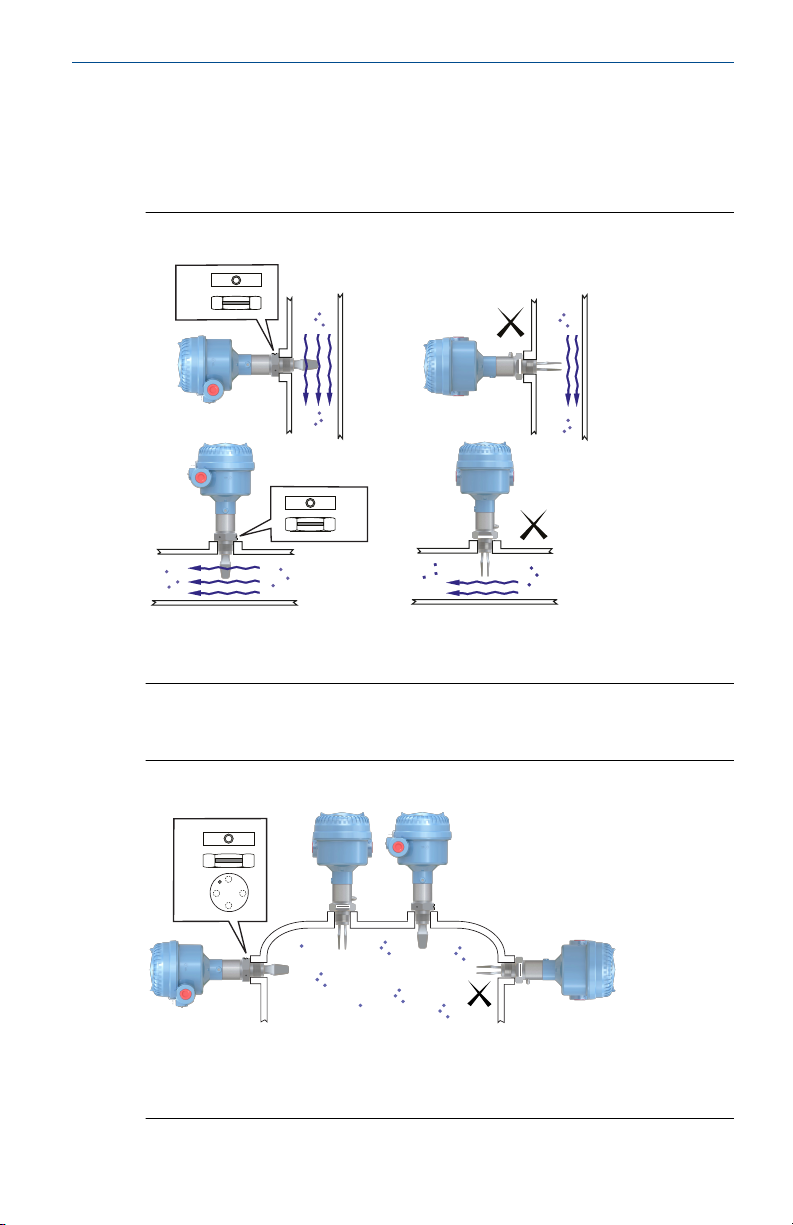

2.3 Mounting the threaded version

2.3.1 Seal and protect the threads

• Use anti-seize paste or PTFE tape according to site procedures.

2.3.2 Threaded vessel (tank) or pipework connection

• Vertical installation.

• Horizontal installation.

6 Quick Start Guide

Page 7

Gasket (customer supplied)

Tighten using the hexagon only

Gasket for BSPP (G) threaded connection

June 2020 Quick Start Guide

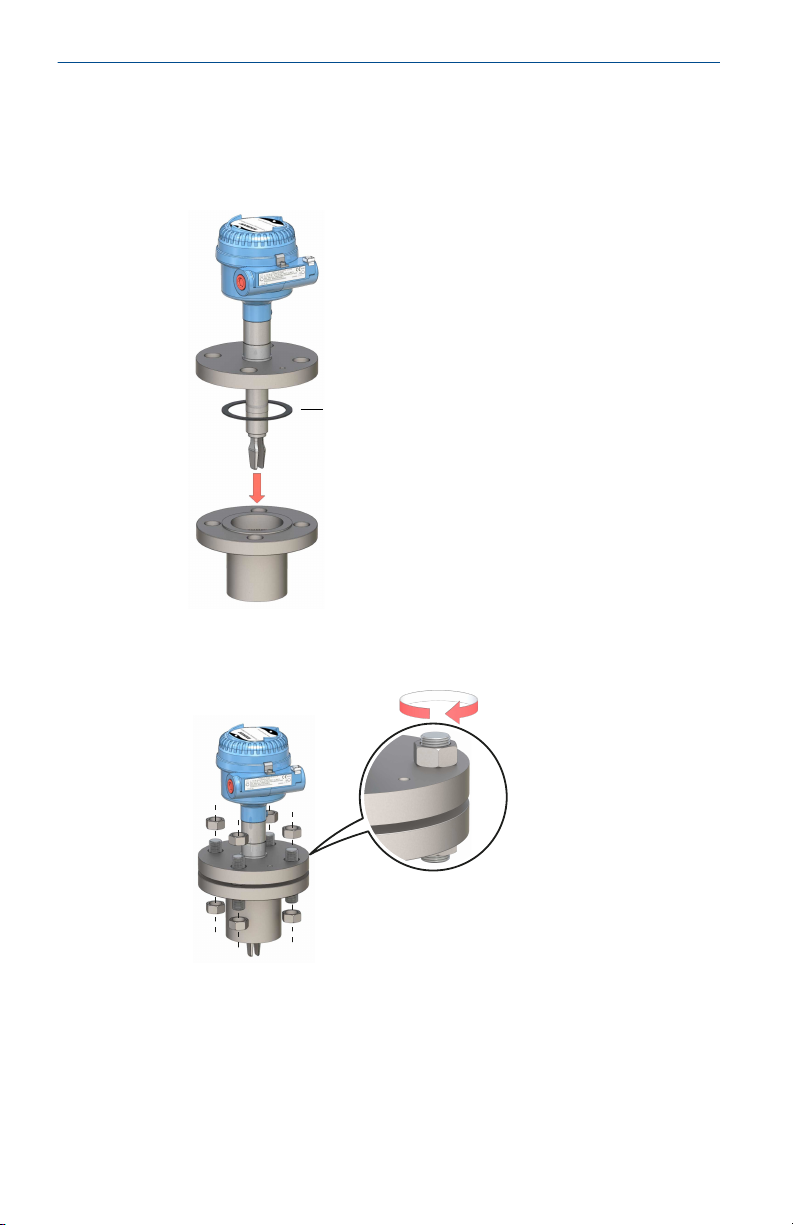

2.3.3 Threaded flange connection

Procedure

1. Place the customer-supplied flange and gasket on the vessel (tank)

nozzle.

2. Tighten the bolts and nuts with sufficient torque for the flange and

gasket.

3. Screw the level switch into the flange thread.

Quick Start Guide 7

Page 8

Gasket (customer supplied)

Quick Start Guide June 2020

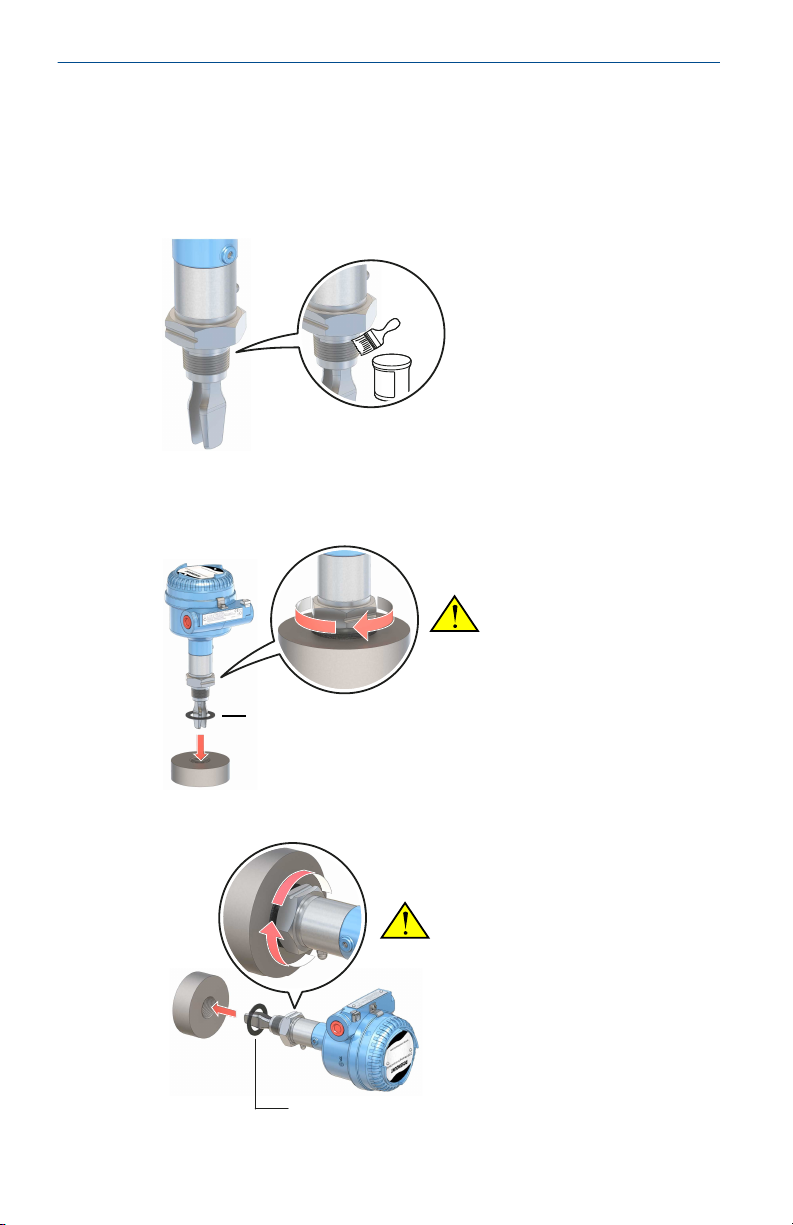

2.4 Mounting the flanged version

Procedure

1. Lower the level switch into the nozzle.

2. Tighten the bolts and nuts with sufficient torque for the flange and

gasket.

8 Quick Start Guide

Page 9

Seal (supplied with Tri Clamp)

June 2020 Quick Start Guide

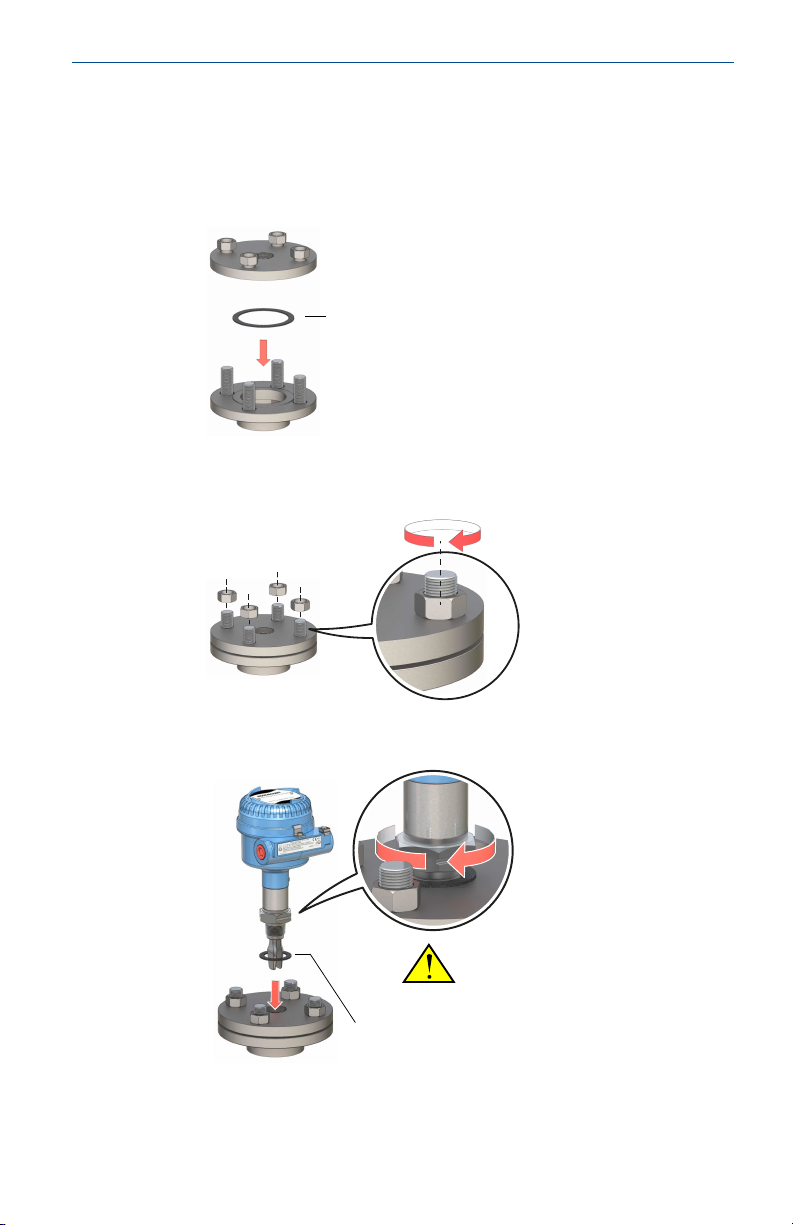

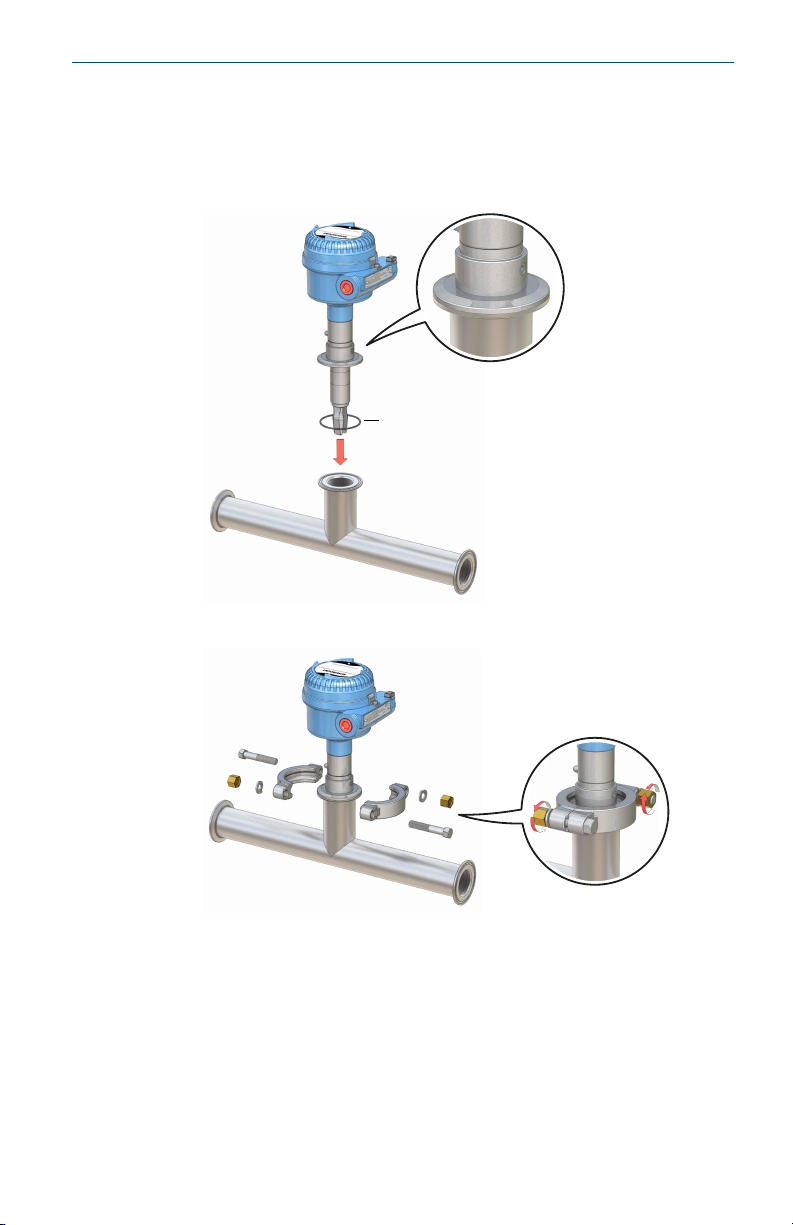

2.5 Mounting the Tri Clamp version

Procedure

1. Lower the level switch into the flange face.

2. Fit the Tri Clamp.

Quick Start Guide 9

Page 10

Quick Start Guide June 2020

3 Prepare the electrical connections

Note

See the Rosemount 2130 Product Data Sheet for all electrical specifications.

3.1 Cable selection

Use 26–14 AWG (0.13 to 2.5 mm2 wiring. Twisted-pairs and shielded wiring

is recommended for environments with high EMI (electromagnetic

interference). Two wires can be safely connected to each terminal screw.

3.2 Cable glands/conduits

For intrinsically safe, explosion-proof/flameproof, and dust-proof

installations, only use certified cable glands or conduit entry devices.

Ordinary location installations can use suitably rated cable glands or conduit

entry devices to maintain the Ingress Protection (IP) rating.

Unused conduit entries must always be sealed with a suitably rated

blanking/stopping plug.

Note

Do not run signal wiring in conduit or open trays with power wiring or near

heavy electrical equipment.

3.3 Power supply

The power supply requirements are dependent on the electronics selected.

• Direct Load electronics: 20 - 264 Vdc or 20 - 264 Vac (50/60 Hz).

• PNP electronics: 18 - 60 Vdc

• Standard Relay electronics: 20 - 264 Vdc or 20 - 264 Vac (50/60 Hz)

• NAMUR electronics: 8 Vdc

• 8/16 mA electronics: 24 Vdc

• Fault and Alarm Relays: 20 - 264 Vdc or 20 - 264 Vac (50/60 Hz)

3.4

10 Quick Start Guide

Hazardous areas

When the level switch is installed in hazardous areas (classified locations),

local regulations and the conditions-of-use specified in applicable

certificates must be observed. Review the Rosemount 2130 Product

Certifications document for information.

Page 11

1 2 3

1

2

PE

(Ground)

I

L

Example of external wiring

R

0 V

+ V

Neutral Live

Fuse

2A(T)

3

DPST

Isolate supply before making connections.

R = External load (must be fitted)

U = 20 - 264 V ~ (ac) (50/60 Hz)

I

OFF

< 4 mA

IL= 20 - 500 mA

U = 20 - 60 V (dc)

I

OFF

< 4 mA

IL= 20 - 500 mA

= 5 A, 40 ms (inrush)

I

PK

= 5 A, 40 ms (inrush)

I

PK

June 2020 Quick Start Guide

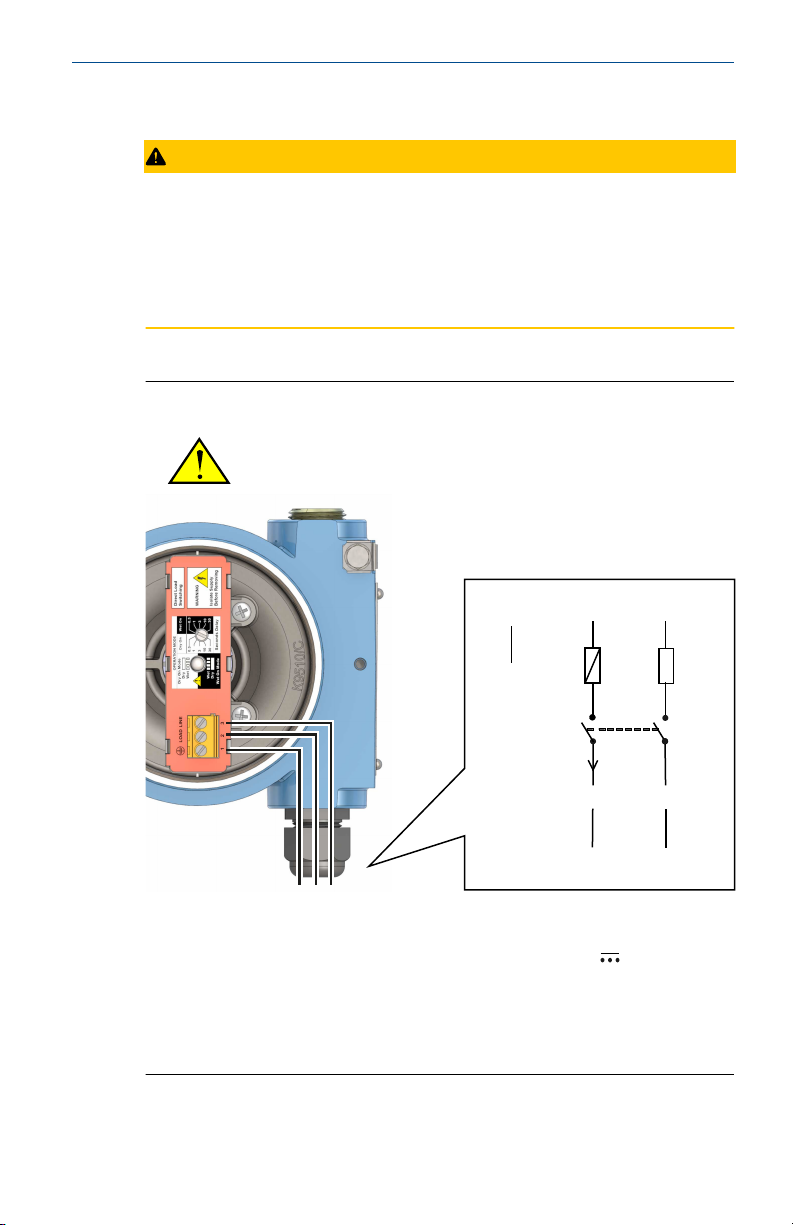

3.5 Wiring diagrams

CAUTION

• Before use, check the cable glands and blanking plugs are suitably rated.

• Isolate supply before connecting the switch or removing the electronics.

• The Protective Earth (PE) terminal must be connected to an external

earthing system.

3.5.1 Direct load switching electronics cassette

Figure 3-1: Direct Load Switching (Two-wire, Red Label)

Quick Start Guide 11

Page 12

1 2

PE

(Ground)

I

L

R

0 V

+ V

N

L

Fuse

2A(T)

3

DPST

DU

12 V

1 2

PE

(Ground)

I

L

R

0 V

+ V

N L

Fuse

2A(T)

3

DPST

< 4 mA

1 2

PE

(Ground)

I

L

R

0 V

+ V

N

L

Fuse

2A(T)

3

DPST

DU

12 V

1 2

PE

(Ground)

I

L

R

0 V

+ V

N L

Fuse

2A(T)

3

DPST

< 4 mA

= Load off= Load on

Quick Start Guide June 2020

Table 3-1: Direct Load Functions

Mode: dry on, high level alarm Mode: wet on, low level alarm

12 Quick Start Guide

Page 13

1

1 2

234

PE

(Ground)

Example of external wiring

0 VO/P

+ V

Fuse

2A(T)

3 4

Isolate supply before making connections.

I

L (MAX)

= 0 - 500 mA

I

L (OFF)

< 100 mA

I

PK

= 5 A, 40 ms (inrush)

U

OUT(ON)

= U - 2.5 Vac (20 °C)

U

OUT(ON)

= U - 2.75 Vac (-40 to 80 °C)

U

= 20 - 60 V (dc)

I < 4 mA + I

L

June 2020 Quick Start Guide

3.5.2 PNP/PLC electronics cassette

Figure 3-2: PNP Output for Load and Direct PLC Switching (Yellow Label)

Quick Start Guide 13

Page 14

1

2

PE

(Ground)

-

I/P

PLC

+

3 4

I

L

DU

< 3 V

1

2

PE

(Ground)

-I/P

PLC

+

3 4

I

L

<100 mA

1

2

PE

(Ground)

-

I/P

PLC

+

3 4

I

L

DU

< 3 V

1

2

PE

(Ground)

-I/P

PLC

+

3 4

I

L

<100 mA

1 2

PE

(Ground)

-+

3 4

I

L

DU

< 3 V

Fuse

1A(T)

R

1 2

PE

(Ground)

-

+

3 4

I

L

Fuse

1A(T)

R

<100 mA

1 2

PE

(Ground)

-+

3 4

I

L

DU

< 3 V

Fuse

1A(T)

R

1 2

PE

(Ground)

-

+

3 4

I

L

Fuse

1A(T)

R

<100 mA

= Load off= Load on

Quick Start Guide June 2020

Table 3-2: PNP/PLC Cassette Functions

Mode: dry on, high level alarm Mode: wet on, low level alarm

PLC (positive input)

PNP dc

14 Quick Start Guide

Page 15

1 2 3

Example of external wiring

1

2

PE

(Ground)

0 V

+ V

N

L

Fuse

0.5 (T)

3

DPST

Isolate supply before making connections.

U =

20 - 264 V ~ (ac) (50/60 Hz)

I

<

6 mA

U = 20 - 60 V (dc)

I < 6 mA

456789

cos f = 1;

L/R = 0 ms

I

MAX

= 5 A

Resistive load

cos f = 0.4;

L/R = 7 ms

I

MAX

= 3.5 A

U

MAX

= 250 V U

MAX

= 250 V

P

MAX

= 1250 VA P

MAX

= 875 VA

Inductive load

ac: ac:

U

MAX

= 30 V U

MAX

= 30 V

P

MAX

= 240 W P

MAX

= 170 W

dc: dc:

4

5 6

NC

C

NO

7

8 9

NC C NO

June 2020 Quick Start Guide

3.5.3 Relay output electronics cassette (standard version)

Figure 3-3: Relay Output, DPCO (Green Label, Standard Cassette)

Note

A Double Pole, Single Throw on/off switch must be fitted for safe

disconnection of the power supply. Fit the DPST switch as near as possible to

the Rosemount 2130. Keep the DPST switch free of obstructions. Label the

DPST switch to indicate it is the supply disconnection device for the

Rosemount 2130.

Quick Start Guide 15

Page 16

NC C NO NC C NO

NC C NO NC C NO

NC C NO NC C NO

NC C NO NC C NO

Quick Start Guide June 2020

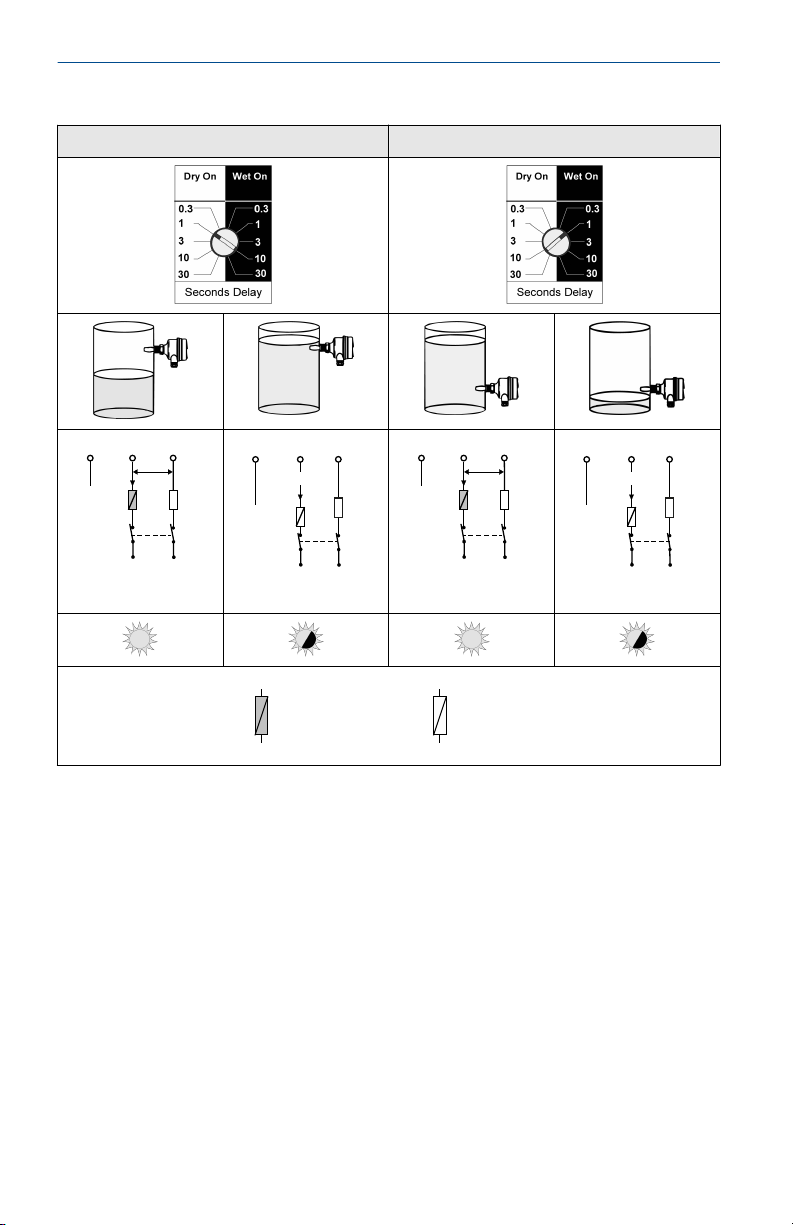

Table 3-3: Relay Cassette Functions

Mode: dry on, high level alarm Mode: wet on, low level alarm

16 Quick Start Guide

Page 17

1 2 3

Example of external wiring

1

2

PE

(Ground)

0 V

+ V

N

L

Fuse

0.5 (T)

3

DPST

Isolate supply before making connections.

U

= 20 - 264 V ~ (ac) (50/60 Hz)

I < 6 mA

U = 20 - 60 V (dc)

I

< 6 mA

456789

cos f = 1;

L/R = 0 ms

I

MAX

= 5 A

Resistive load

cos f = 0.4;

L/R = 7 ms

I

MAX

= 3.5 A

U

MAX

= 250 V U

MAX

= 250 V

P

MAX

= 1250 VA P

MAX

= 875 VA

Inductive load

ac: ac:

U

MAX

= 30 V U

MAX

= 30 V

P

MAX

= 240 W P

MAX

= 170 W

dc: dc:

4 5 6

NC C NO

7 8 9

NC C NO

(Alarm) (Fault)

June 2020 Quick Start Guide

3.5.4 Fault and Alarm Relays (2 x SPCO) electronics cassette

Figure 3-4: Fault and Alarm Relay Outputs (Light Green Label)

Note

A Double Pole, Single Throw on/off switch must be fitted for safe

disconnection of the power supply. Fit the DPST switch as near as possible to

the Rosemount 2130. Keep the DPST switch free of obstructions. Label the

DPST switch to indicate it is the supply disconnection device for the

Rosemount 2130.

Quick Start Guide 17

Page 18

NC C NO NC C NO

(No alarm) (No fault)

NC

C

NO

NC

C

NO

(Alarm) (No fault)

NC C NO NC C NO

(No alarm) (No fault)

NC

C

NO

NC

C

NO

(Alarm) (No fault)

Quick Start Guide June 2020

Table 3-4: Relay Cassette Functions

Mode: dry on, high level alarm Mode: wet on, low level alarm

18 Quick Start Guide

Page 19

1

1

2

2

Isolate supply before making connections.

I

ON

= 2.2 - 2.5 mA

I

OFF

= 0.8 - 1.0 mA

I

FAULT

< 1.0 mA

+

-

A

June 2020 Quick Start Guide

3.5.5 NAMUR electronics cassette

Figure 3-5: NAMUR Output (Light Blue Label)

A. A certified intrinsically safe isolating amplifier to IEC 60947-5-6

Note

• This cassette is suitable for Intrinsically Safe (IS) applications and requires

a certified isolating barrier. See the Rosemount 2130 Product

Certifications document for Intrinsically Safe approvals.

• This electronics cassette is also suitable for non-hazardous (safe) area

applications. It can only be interchanged with the 8/16 mA cassette.

• Do not exceed 8 Vdc.

Quick Start Guide 19

Page 20

1 2

(+)(-)

> 2.2 mA

1 2

(+)(-)

< 1.0 mA

1 2

(+)(-)

> 2.2 mA

1 2

(+)(-)

< 1.0 mA

Quick Start Guide June 2020

Table 3-5: NAMUR Cassette Functions

Mode: dry on, high level alarm Mode: wet on, low level alarm

20 Quick Start Guide

Page 21

1 2 3

Isolate supply before making connections.

I

ON

= 15 - 17 mA

U = 24 Vdc Nominal

I

OFF

= 7.5 - 8.5 mA

I

FAULT

< 3.7 mA

+

-

A

PE

(Ground)

(+)(-)

21 3

June 2020 Quick Start Guide

3.5.6 8/16 mA electronics cassette

Figure 3-6: 8/16 mA Output (Dark Blue Label)

A. A certified intrinsically safe isolating amplifier to IEC 60947-5-6

Note

• This cassette is suitable for Intrinsically Safe (IS) applications and requires

a certified isolating barrier. See the Rosemount 2130 Product

Certifications document for Intrinsically Safe approvals.

• This electronics cassette is also suitable for non-hazardous (safe) area

applications. It can only be interchanged with the NAMUR cassette.

• Do not exceed 8 Vdc.

Quick Start Guide 21

Page 22

21 3

(+)(-)

> 15 mA

PE

(Ground)

21 3

(+)(-)

< 8.5 mA

PE

(Ground)

21 3

(+)(-)

> 15 mA

PE

(Ground)

21 3

(+)(-)

< 8.5 mA

PE

(Ground)

Quick Start Guide June 2020

Table 3-6: 8/16 mA Cassette Functions

Mode: dry on, high level alarm Mode: wet on, low level alarm

3.5.7 Fault condition detection (self-check mode only)

When a fault condition is detected in the self-check operating mode, the

heartbeat LED flashes once every half a second and every third flash is

missed. The output from the level switch will then be as Table 3-7.

Note

See LED indication for causes of other LED flashing rates.

22 Quick Start Guide

Page 23

I

L

R

0 V

+ V

N

L

Fuse

2A(T)

DPST

< 4 mA

1

2 3

(=Fault)

1

2

-

I/P

PLC

+

3 4

I

L

< 100 mA

(=Fault)

1 2 3 4

I

L

Fuse

1A(T)

R

< 100 mA

(=Fault)

(+)

(-)

NC NOCNC NO

(=Fault)

C

1 2

(+)(-)

< 1.0 mA

(=Fault)

< 3.7 mA

(=Fault)

1

2 3

(+)

(-)

Load off

Load on

NC NOCNC NO

(=No alarm) (=Fault)

C

Alarm relay Fault relay

June 2020 Quick Start Guide

Table 3-7: Fault Condition Detection (Self-check Mode Only)

Direct load PLC PNP dc

DPCO relay NAMUR 8/16 mA

Quick Start Guide 23

Fault and alarm (2 x SPCO) relays

Page 24

B

A

CCD

B

Quick Start Guide June 2020

3.6 Grounding

Always ground the housing in accordance with national and local

electrical codes.

3.6.1 Grounding using the cable shield

Make sure the instrument cable shield is:

• Trimmed close and insulated from touching the level switch housing.

• Continuously connected throughout the segment.

• Connected to a good earth ground at the power supply end.

Figure 3-7: Signal Cable Shield Grounding at Power Supply End

A. Trim shield and insulate

B. Minimize distance

C. Trim shield

D. Connect shield back to the power supply ground

24 Quick Start Guide

Page 25

A

June 2020 Quick Start Guide

3.6.2 Grounding the housing of a level switch

Figure 3-8: Ground Screws

A. External ground screw

Quick Start Guide 25

Page 26

¾-in. ANPTM20 x 1.5

Identification of thread size and type

(No marking)

M20

Quick Start Guide June 2020

4 Connect wiring and power up

Procedure

1. Verify the power supply is disconnected.

2. Remove the field terminals cover.

In an explosion-proof/flameproof installation, do not remove the

level switch cover when power is applied to the unit. The cover must

also not to be removed in extreme environmental conditions.

• Versions of the Rosemount 2130 with explosion-proof/

flameproof approvals have a cover-lock to be undone first.

3. Remove the plastic plugs.

4. Pull cables through the cable gland/conduits.

• Cassettes with a single terminal only require one cable.

26 Quick Start Guide

Page 27

June 2020 Quick Start Guide

5. Connect the cable wires (see Wiring diagrams for other cassettes).

6. Ensure proper grounding (see Grounding).

7. Tighten the cable glands.

Apply PTFE tape or other sealant to the threads.

Note

Make sure to arrange the wiring with a drip loop.

Quick Start Guide 27

Page 28

Quick Start Guide June 2020

8. Plug and seal the unused conduit connection to avoid moisture and

dust accumulation inside the housing.

Apply PTFE tape or other sealant to the threads.

28 Quick Start Guide

Page 29

June 2020 Quick Start Guide

9. Attach and tighten the cover.

Make sure the cover is fully engaged.

10. Required for explosion-proof/flameproof installations only:

The cover must be fully engaged to comply with explosion-proof

requirements.

11. Re-lock the cover.

12. Connect the power supply.

Quick Start Guide 29

Page 30

OPERATION MODE

Dry On Mode

Dry

Wet

Wet On Mode

Dry

Wet

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

1 2

3

OUT

+

-

4

PLC/PNP

Isolate Supply

Before Removing

A

B

Quick Start Guide June 2020

5 Configuration

5.1 Set the mode and time delay for the output

All electronics cassettes have a rotating switch for setting the electrical

output to be on when the fork is sufficiently dry ("Dry On") or when the fork is

sufficiently wet ("Wet On").

The electronics uses hysteresis to help prevent constant switching of the

output due to splashing or intermediate conditions. To further prevent this

constant switching, the rotating switch also sets a time delay of up to 30

seconds before the output changes.

A small cut-out on the rotating switch indicates the present mode and time

delay.

The recommended mode for high level alarm installations is the "Dry On"

mode (Figure 5-2). The "Wet On" mode is recommended for low level alarm

installations (Figure 5-3).

Note

There is a five second delay before changes to the mode and time delay

become active.

Figure 5-1: Top-down View: Example Cassette Inside Housing

A. 'Heartbeat' LED

B. Rotating switch for setting output mode and time delay

30 Quick Start Guide

Page 31

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

A

Dry On Wet On

Seconds Delay

0.3 0.3

30

10

3

30

10

1

3

1

A

June 2020 Quick Start Guide

Figure 5-2: Typical Settings for High Level Applications

A. Mode “Dry On” and 1 second time delay

Figure 5-3: Typical Settings for Low Level Applications

A. Mode “Dry On” and 1 second time delay

Quick Start Guide 31

Page 32

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

1 second

< 3 seconds

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

1 second

< 3 seconds

Quick Start Guide June 2020

5.2 Set the operating mode

All versions of the Rosemount 2130 have two operating modes:

• Normal mode (Red LED)

• Self-check mode (Yellow LED)

Note

For SIL 2 compliance, self-check mode must be enabled. Review the

Rosemount 2130 Functional Safety Manual for more SIL information.

Figure 5-4: Selecting Self-check Operating Mode

The ‘heartbeat’ LED is yellow when self-check mode is operating (Table 6-2).

Figure 5-5: Selecting Normal Operating Mode

The ‘heartbeat’ LED is red when normal mode is operating (Table 6-2).

32 Quick Start Guide

Page 33

June 2020 Quick Start Guide

6 Operation

6.1 LED indication

Table 6-1: LED Indications (Operating Mode)

LED

color

Red Normal When the LED is red and flashing, it indicates that

Yellow Self-check When the LED is yellow and flashing, it indicates the

(1) See Set the operating mode.

Operating

(1)

modes

Description of mode

the Rosemount 2130 may be uncalibrated,

successfully calibrated, has an electrical load

problem, or has an internal PCB fault. See Table 6-2

for further information.

same as Normal mode, but also indicates there

could be external damage to forks, corroded forks,

or internal sensor damage. See Table 6-2 for further

information.

Table 6-2: LED Indications (Operating Status)

LED LED flash rate Switch status

Continuous Output state is on

1 every ½ second,

and every third

flash is missing.

1 every second Output state is off

1 every 2 seconds Uncalibrated

External damage to forks, corroded forks, internal

wire damage,or internal sensor damage (self-check

mode only

(1)

)

1 every 4 seconds Load fault; load current too high; load short circuit

2 times / second Indication of successful calibration

3 times / second Contact Emerson to report an internal PCB fault is

Off Problem (e.g. supply)

(1) See Set the operating mode.

Quick Start Guide 33

being indicated.

Page 34

TP

TP

TP

S

N

S

N

No magnet Magnet

Output off

Output on

Output on

Output off

OK

Quick Start Guide June 2020

7 Servicing and troubleshooting

7.1 Magnetic test point

A magnetic test point is marked on the side of the housing to allow a

functional test of the Rosemount 2130 in the overall system. By touching a

magnet to the target, the output from the level switch will change state

while the magnet is present.

Figure 7-1: Magnetic Test-point Function

7.2 Visual inspection

Visually examine the level switch and do not use if it is damaged. Check:

• The housing cover, cable glands, and blanking plugs are fitted securely.

Figure 7-2: Visual Inspection

34 Quick Start Guide

Page 35

OK

June 2020 Quick Start Guide

7.3 Maintenance

Figure 7-3: Maintenance

Note

Only use a soft type brush for cleaning.

7.4 Spare parts

See the Rosemount 2130 Product Data Sheet for the latest information

about spare parts.

7.5

Replacement and calibration of cassettes

When replacing a damaged or faulty electronics cassette, it is necessary to

calibrate the replacement cassette to the operating frequency of the fork

sensor.

See the Rosemount 2130 Reference Manual or supplied instructions for the

replacement and calibration procedures.

Quick Start Guide 35

Page 36

Quick Start Guide June 2020

7.6 Troubleshooting

If there is a malfunction, troubleshoot the problem using Table 7-1.

Table 7-1: Troubleshooting Chart

Fault Symptom or indication Recommended actions

Does not switch LED is not lit, no power. • Check the power supply.

• Check the load on direct

load switching electronics

model.

LED is flashing once per

second.

LED is flashing once every two

seconds.

LED is flashing once every four

seconds.

Visual inspection found fork

damage.

Visual inspection found thick

encrustation on the forks.

There is always a five second

delay after changing the

mode or delay.

Incorrect switching Dry = On, Wet = On is set

correctly.

Faulty switching Turbulence. • Set a longer switching

• Contact Emerson to

report an internal failure

is being indicated.

• Contact Emerson to

report an uncalibrated

device is being indicated.

• Check the electrical

installation for a load fault

(current is too high or a

short-circuit).

• Contact Emerson to

report the damage and

discuss how to get a

replacement.

• Carefully clean the fork

(See Maintenance).

• This is a normal function

when making any

changes to the settings.

• Check wiring connections

(see Wiring diagrams ).

time delay.

Excessive electrical noise. • Suppress the cause of the

Cassette has been fitted from

another Rosemount 2130.

36 Quick Start Guide

interference.

• Fit the factory supplied

cassette and then

calibrate. (See

Replacement and

calibration of cassettes).

Page 37

June 2020 Quick Start Guide

Quick Start Guide 37

Page 38

Quick Start Guide June 2020

38 Quick Start Guide

Page 39

June 2020 Quick Start Guide

Quick Start Guide 39

Page 40

*00825-0100-4130*

00825-0100-4130, Rev. DA

Quick Start Guide

June 2020

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...