Page 1

Rosemount™ 1066

Smart-Enabled, 2-Wire Transmitter

Reference Manual

00809-0100-3166

ev. AD

R

March 2020

Page 2

Page 3

Essential Instructions

Read this page before proceeding

Emerson designs, manufactures, and tests its Rosemount products to meet many national and

international standards. Because these instruments are sophisticated technical products, you must

properly install, use, and maintain them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered to and integrated into your safety

program when installing, using, and maintaining Rosemount products. Failure to follow the proper

instructions may cause any one of the following situations to occur: Loss of life; personal injury;

property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product. If this Reference

Manual is not the correct manual, telephone 1-800-854-8257 and the requested manual will

be provided. Save this Reference Manual for future reference.

• If you do not understand any of the instructions, contact your Emerson representative for

clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of

the product.

• Install your equipment as specified in the Installation Instructions of the appropriate Reference

Manual and per applicable local and national codes. Connect all products to the proper

electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and

maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s

performance and place the safe operation of your process at risk. Look alike substitutions may

result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and personal

injury.

WARNING: EXPLOSION HAZARD

DO NOT OPEN WHILE CIRCUIT IS LIVE. ONLY CLEAN WITH DAMP CLOTH.

NOTICE

If a 475 Universal HART®Communicator is used with these transmitters, the software within the 475 may

require modification. If a software modification is required, please contact your local Emerson Service Group

or National Response Center at 1-800-654-7768.

Electrostatic ignition hazard.

Special condition for safe use (when installed in hazardous area)

1. The plastic enclosure, excepting the front panel, must only be cleaned with a damp cloth. The

surface resistivity of the non-metallic enclosure materials is greater than one gigaohm. Care

must be taken to avoid electrostatic charge build-up. The 1066 Transmitter must not be

rubbed or cleaned with solvents or a dry cloth.

2. The panel mount gasket has not been tested for type of protection IP66 or Class II and III.

Type of protection IP66 and Class II, III refer the enclosure only.

Essential Instructions I

Page 4

3. The surface resistivity of the non-metallic enclosure materials is greater than one gigaohm.

Care must be taken to avoid electrostatic charge build-up. The Model 1066 Transmitter must

not be rubbed or cleaned with solvents or a dry cloth.

4. Special Condition of Use of 1066 C FF/FII5 and 1066T FF/FII5. For use with simple apparatus

model series 140, 141, 142, 150, 400, 401, 402, 402VP, 403, 403VP, 404, and 410VP contacting conductivity sensors and model series 222, 225, 226, 228 toroidal sensors.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of

end users’ equipment. This could be intentional or unintentional and needs to be protected

against.

Physical security is an important part of any security program and fundamental to protecting

your system. Restrict physical access by unauthorized personnel to protect end users’ assets.

This is true for all systems used within the facility.

II

Page 5

Reference Manual Table of Contents

00809-0100-3166 March 2020

Contents

Section 1: Quick Start Guide

1.1 Quick start guide..........................................................................................................1

Section 2: Description and Specifications

2.1 Features and Applications...........................................................................................3

2.2 Specifications - General................................................................................................4

2.3 pH/ORP ........................................................................................................................4

2.3.1 Performance Specifications - Transmitter (pH input)......................................6

2.2.2 Performance Specifications - Transmitter (ORP input)....................................6

2.4 Contacting Conductivity (Codes - C) ............................................................................7

2.4.1 Performance Specifications.............................................................................7

2.4.2 Recommended Sensors for Conductivity .......................................................8

2.5 Toroidal Conductivity (Codes - T).................................................................................8

2.5.1 Performance Specifications.............................................................................8

2.5.2 Recommended Sensors for Conductivity........................................................9

2.6 Chlorine (Codes - L)......................................................................................................9

2.6.1 Free and Total Chlorine ...................................................................................9

2.6.2 Performance Specifications.............................................................................9

2.6.3 Recommended Sensors .................................................................................9

2.6.4 Monochloromine ............................................................................................9

2.6.5 Performance Specifications ..........................................................................10

2.6.6 Recommended Sensors ...............................................................................10

2.7 Dissolved Oxygen (Codes - DO).................................................................................10

2.7.1 Performance Specification............................................................................10

2.7.2 Recommended Sensors................................................................................10

2.8 Dissolved Oxygen (Codes - DO) .................................................................................10

2.8.1 Performance Specification............................................................................10

2.8.2 Recommended Sensors................................................................................10

2.9 Ordering Information.................................................................................................11

Section 3: Installation

3.1 Unpacking and Inspection..........................................................................................13

3.2 Installation – General Information .............................................................................13

3.3 Preparing Conduit Openings......................................................................................13

Section 4: Wiring

4.1 General...................................................................................................................... 17

4.1.1 General Information......................................................................................17

4.1.2 Digital Communication.................................................................................17

4.2 Power Supply/Current Loop – 1066 HT......................................................................17

Table of Contents III

Page 6

Table of Contents Reference Manual

March 2020 00809-0100-3166

4.2.1 Power Supply and Load Requirements..........................................................17

4.2.2 Power Supply-Current Loop Wiring...............................................................18

.2.3Current Output Wiring..................................................................................19

4

4.3 Power Supply Wiring For 1066 FF...............................................................................20

4.3.1 Power Supply Wiring.....................................................................................20

4.4 Sensor Wiring to Main Board......................................................................................21

Section 5: Intrinsically Safe Installation

5.1 All Intrin sically Safe Installations ................................................................................27

Section 6: Display and operation

6.1 User Interface.............................................................................................................33

6.2 Instrument Keypad ....................................................................................................33

6.3 Main Display...............................................................................................................34

6.4 Menu System .............................................................................................................35

Section 7: Programming – Basics

7.1 General.......................................................................................................................37

7.2 Changing the Startup Settings...................................................................................37

7.2.1 Purpose.........................................................................................................37

7.2.2 Procedure......................................................................................................38

7.3 Choosing Temperature Units and Automatic/Manual Temperature Compensation.38

7.3.1 Purpose.........................................................................................................38

7.4 Configuring and Ranging Current Outputs................................................................38

7.4.1 Purpose.........................................................................................................38

7.4.2 Definitions.....................................................................................................38

7.4.3 Procedure: Configure Outputs......................................................................38

7.4.4 Procedure: Ranging the Current Outputs .....................................................38

7.5 Setting a Security Code ..............................................................................................38

7.5.1 Purpose.........................................................................................................39

7.5.2 Procedure......................................................................................................39

7.6 Security Access...........................................................................................................40

7.6.1 How the Security Code Works ......................................................................40

7.6.2 Procedure......................................................................................................40

7.7 Using Hold..................................................................................................................40

7.7.1 Purpose.........................................................................................................40

7.7.2 Using the Hold Function................................................................................40

7.8 Resetting Factory Default Settings.............................................................................41

7.8.1 Purpose.........................................................................................................41

7.8.2 Procedure......................................................................................................41

Section 8: Programming – Measurements

8.1 Introduction ..............................................................................................................44

IV Table of Contents

Page 7

Reference Manual Table of Contents

00809-0100-3166 March 2020

8.2 pH Measurement Programming................................................................................44

8.2.1 Description....................................................................................................44

8.2.2 Measurement................................................................................................44

8.2.3 Preamp..........................................................................................................44

8.2.4 Solution Temperature Correction ................................................................45

8.2.5 Temperature Coefficient...............................................................................45

8.2.6 Resolution.....................................................................................................45

8.2.7 Filter..............................................................................................................45

8.2.8 Reference Impedance...................................................................................45

8.3 ORP Measurement Programming..............................................................................45

8.3.1 Measurement................................................................................................46

8.3.2 Preamp..........................................................................................................46

8.3.3 Filter..............................................................................................................46

8.3.4 Reference Impedance...................................................................................46

8.4 Contacting Conductivity ............................................................................................47

8.4.1 Description....................................................................................................47

8.4.2 Sensor Type...................................................................................................47

8.4.3 Measure ........................................................................................................48

8.4.4 Range............................................................................................................48

8.4.5 Cell Constant.................................................................................................48

8.4.6 RTD Offset.....................................................................................................48

8.4.7 RTD Slope......................................................................................................48

8.4.8 Temp Comp..................................................................................................48

8.4.9 Slope .............................................................................................................49

8.4.10 Reference Temp............................................................................................49

8.4.11 Filter ..............................................................................................................49

8.4.12 Custom Setup ...............................................................................................49

8.4.13 Cal Factor ......................................................................................................49

8.5 Toroidal Conductivity Measurement Programming..................................................50

8.5.1 Description....................................................................................................50

8.5.2 Sensor Type...................................................................................................50

8.5.3 Measure ........................................................................................................51

8.5.4 Range............................................................................................................51

8.5.5 Cell Constant.................................................................................................51

8.5.6 Temp Comp..................................................................................................51

8.5.7 Slope .............................................................................................................52

8.5.8 Reference Temp............................................................................................52

8.5.9 Filter..............................................................................................................52

8.5.10 Custom Setup ...............................................................................................52

8.6 Chlorine Measurement Programming .......................................................................53

8.6.1 Free Chlorine Measurement Programming ..................................................53

8.6.1.1 Measure..........................................................................................54

8.6.1.2 Units ...............................................................................................54

Table of Contents V

Page 8

Table of Contents Reference Manual

March 2020 00809-0100-3166

8.6.1.3 Filter................................................................................................54

8.6.1.4 Free Chlorine pH Correction...........................................................54

.6.1.5Manual pH Correction ....................................................................54

8

8.6.1.6 Resolution ......................................................................................54

8.6.2 Total Chlorine Measurement Programming.................................................55

8.6.2.1 Description.....................................................................................55

8.6.2.2 Measure..........................................................................................55

8.6.2.3 Units ...............................................................................................55

8.6.2.4 Filter................................................................................................55

8.6.2.5 Resolution ......................................................................................55

8.6.3 Monochloramine Measurement Programming............................................56

8.6.3.1 Measure: Monochloramine ............................................................56

8.6.3.2 Units ...............................................................................................56

8.6.3.3 Filter................................................................................................57

8.6.3.4 Resolution ......................................................................................57

8.7 Oxygen Measurement Programming ........................................................................57

8.7.1 Oxygen Measurement Application.................................................58

8.7.2 Units ...............................................................................................58

8.7.3 Partial Press ....................................................................................58

8.7.4 Salinity............................................................................................58

8.7.5 Filter................................................................................................58

8.7.6 Pressure Units.................................................................................58

8.8 Ozone Measurement Programming..........................................................................59

8.8.1 Units ...............................................................................................59

8.8.2 Filter................................................................................................59

8.8.3 Resolution ......................................................................................59

Section 9: Calibration

9.1 Introduction ..............................................................................................................67

9.2 Calibration..................................................................................................................67

9.2.1 Auto Calibration.........................................................................................................68

9.2.2 Manual Calibration – pH................................................................................68

9.2.3 Entering a Known Slope Value – pH..............................................................68

9.2.4 Standardization – pH ....................................................................................69

9.2.5 SMART sensor auto calibration upload – pH .................................................69

9.3 ORP and Redox Calibration ........................................................................................70

9.4 Contacting Conductivity Calibration..........................................................................71

9.4.1 Entering the Cell Constant ............................................................................72

9.4.2 Zeroing the Instrument.................................................................................72

9.4.3 Calibrating the Sensor in a Conductivity Standard (in process cal)................72

9.4.4 Calibrating the Sensor To A Laboratory Instrument (meter cal)....................73

9.4.5 Cal Factor ......................................................................................................73

VI Table of Contents

Page 9

Reference Manual Table of Contents

00809-0100-3166 March 2020

9.5 Toroidal Conductivity Calibration...............................................................................74

9.5.1 Entering the Cell Constant ............................................................................74

9.5.2 Zeroing the Instrument.................................................................................75

9.5.3 Calibrating the Sensor in a Conductivity Standard (in process cal)................75

9.6 Calibration –Chlorine.................................................................................................76

9.6.1 Calibration –Free Chlorine............................................................................76

9.6.1.1 Zeroing the Sensor .........................................................................77

9.6.1.2 In Process Calibration .....................................................................77

9.6.2 Calibration –Total Chlorine...........................................................................77

9.6.2.1 Zeroing the Sensor .........................................................................78

9.6.2.2 In Process Calibration .....................................................................78

9.6.3 Calibration –Monochloromine..................................................................................79

9.6.4 Zeroing the Sensor........................................................................................80

9.6.5 In Process Calibration....................................................................................80

9.7 Calibration –Oxygen..................................................................................................80

9.7.1 Zeroing the Sensor........................................................................................82

9.7.2 Calibrating the Sensor in Air..........................................................................82

9.7.3 Calibrating the Sensor Against A Standard Instrument (in process cal) ........83

9.8 Calibration –Ozone....................................................................................................83

9.8.1 Zeroing the Sensor........................................................................................84

9.8.2 In Process Calibration....................................................................................84

9.9 Calibrating Temperature............................................................................................85

9.9.1 Calibration.....................................................................................................85

Section 10: HART®Communications

10.1 Introduction ...............................................................................................................93

10.2 Physical Installation and Configuration......................................................................94

10.3 Measurements Available via HART.............................................................................96

10.4 Diagnostics Available via HART ..................................................................................96

10.5 HART Hosts ................................................................................................................97

10.6 Wireless Communication using the 1066................................................................100

10.7 Field Device Specification (FDS)...............................................................................100

10.1 Device Variables........................................................................................................101

10.2 Additional Transmitter Status – Command 48 Status Bits ........................................103

10.3 1066 HART Configuration Parameters.......................................................................108

10.4 475 Menu Tree for 1066 HART 7................................................................................115

Section 11: Return of Material

11.1 General.....................................................................................................................121

11.2 Warranty Repair.......................................................................................................121

11.3 Non-Warranty Repair...............................................................................................121

Table of Contents VII

Page 10

Table of Contents Reference Manual

March 2020 00809-0100-3166

VIII

Page 11

Reference Manual Section 1: Quick Start Guide

00809-0100-3166 March 2020

Section 1: Quick Start Guide

1.1

1. For mechanical installation instructions, see page 14 for panel mounting and page 15 for pipe

or wall mounting.

2. Wire the sensor to the main circuit board. See pages 21-23 for wiring instructions. Refer to the

sensor instruction sheet for additional details. Make loop power connections.

3. Once connections are secured and verified, apply DC power to the transmitter.

4. When the transmitter is powered up for the first time, Quick Start screens appear. Quick Start

operating tips are as follows:

a. A highlighted field shows the position of the cursor.

b. To move the cursor left or right, use the keys to the left or right of the ENTER key. To scroll

up or down or to increase or decrease the value of a digit use the keys above and below the

ENTER key. Use the left or right keys to move the decimal point.

c. Press ENTER to store a setting. Press EXIT to leave without storing changes. Pressing EXIT

during Quick Start returns the display to the initial start-up screen (select language).

5. Choose the desired language and press ENTER.

6. Choose measurement and press ENTER.

a. For pH, choose preamplifier location. Select Analyzer to use the integral preamplifier in the

transmitter; select Sensor/J-Box if your sensor is SMART or has an integral preamplifier or if

you are using a remote preamplifier located in a junction box.

5. If applicable, choose units of measurement.

6. For contacting and toroidal conductivity, choose the sensors type and enter the numeric cell

constant using the keys.

7. Choose temperature units: °C or °F.

8. After the last step, the main display appears. The outputs are assigned to default values.

9. To change output settings, to scale the 4-20 mA current outputs, to change measurementrelated settings from the default values, and to enable pH diagnostics, press MENU. Select

Program and follow the prompts. Refer to the appropriate menu.

10. To return the transmitter to the factory default settings, choose Program under the main

menu, and then scroll to Reset.

11. Please call the Rosemount Customer Support Center at 1-800-854-8257 if you need further

support.

Quick Start Guide 1

Page 12

Section 2: Description and Specifications Reference Manual

March 2020 00809-0100-3166

2 Description and Specifications

Page 13

Reference Manual Section 2: Description and Specifications

00809-0100-3166 March 2020

Section 2: Description and Specifications

2.1

Features and Applications

This loop-powered multi-parameter unit serves industrial, commercial and municipal applications

with the widest range of liquid measurement inputs available for a two-wire liquid transmitter.

The 1066 Smart transmitter supports continuous measurement of one liquid analytical input. The

design supports easy internal access and wiring connections.

Analytical Inputs

Total Chlorine, Free Chlorine, Monochloramine, Dissolved Oxygen, and Ozone.

Large Display

up to four additional variables or diagnostic parameters.

Digital Communications

Menus

: Menu screens for calibrating and programming are simple and intuitive. Plain language

prompts and help screens guide the user through the procedures. All menu screens are available in

eight languages. Live process values are displayed during programming and calibration.

Quick Start Programming

instrument prompts the user to configure the sensor loop in a few quick steps for immediate commissioning.

User Help Screens

provide useful troubleshooting tips to the user. These on-screen instructions are intuitive and easy

to use.

: Ordering options for pH/ORP, Resistivity/Conductivity, % Concentration,

: The high-contrast LCD provides live measurement readouts in large digits and shows

: HART 7 and FOUNDATION Fieldbus options.

: Popular Quick Start screens appear the first time the unit is powered. The

: Fault and warning messages include help screens similar to PlantWeb™alerts that

Diagnostics:

banner on the screen alerts Technicians to Fault and/or Warning conditions.

Languages

German, Italian, Spanish, Portuguese, Chinese and Russian.

Current Outputs

ability to transmit the live measurement value and the process temperature reported from the sensor.

Input Dampening

Smart-Enabled pH

through automatic upload of calibration data and history.

Automatic Temperature Compensation

The 1066 will automatically recognize Pt100, Pt1000 or 22k NTC RTDs built into the sensor.

Smart Wireless Thum Adaptor Compatible

diagnostics from hard-to-reach locations.

The transmitter continuously monitors itself and the sensor for problems. A display

: Emerson extends its worldwide reach by offering eight languages – English, French,

: HART units include two 4-20 mA electrically isolated current outputs giving the

: is automatically enabled to suppress noisy process readings.

: Rosemount SMART pH capability eliminates field calibration of pH probes

: Most measurements require temperature compensation.

: Enable wireless transmissions of process variables and

Specifications 3

Page 14

Section 2: Description and Specifications Reference Manual

March 2020 00809-0100-3166

2.2

Specifications - General

Case: Polycarbonate. IP66 (CSA, FM), Type 4X (CSA)

Dimensions: Overall 155 x 155 x 131mm (6.10 x 6.10 x 5.15 in.). Cutout: 1/2 DIN 139mm x

139mm (5.45 x 5.45 in.)

Conduit openings: Six. Accepts PG13.5 or 1/2 in. conduit fittings

Display: Monochromatic graphic liquid crystal display. No backlight. 128 x 96 pixel display resolu-

tion. Active display area: 58 x 78mm (2.3 x 3.0 in.). All fields of the main instrument display can be

customized to meet user requirements.

Ambient temperature and humidity: -20 to 65 °C (-4 to 149°F), RH 5 to 95% (non-condensing).

Storage Temperature: -20 to 70 °F (-4 to 158 °F)

®

HART

HART diagnostics.

EMI/RFI effect

Meets all basic environment requirements of EN61326.

Analog and digital communications

No effect on the values being given if using a 4-20 mA analog, FOUNDATION Fieldbus digital, or

HART digital signal with shielded, twisted pair wiring.

Note 1:

Communications: PV, SV, TV, and 4V assignable to measurement, temperature and all live

During EMI disturbance, maximum deviation is ±0.006 ppm (6 ppb) for model options

CL, DO, and OZ.

Note 2:

Hazardous Location Approvals

Intrinsic Safety (with appropriate safety barrier):

Class I, II, III, Div. 1*

Groups A-G

T4 Tamb = -20 °C to 65 °C

Enclosure 4X, IP66

For Intrincically Safe Installation,

see drawing 1400669

ATEX

1180 II 1 G

Baseefa11ATEX0195X

Ex ia IIC T4 Ga

T4 Tamb = -20 °C to 65 °C

Non-Incendive:

Class I, Div. 2, Groups A-D*

Dust Ignition Proof Class II & III, Div 1, Groups EFG

Class II & III, Div. 1, Groups E-G

Type 4/4X Enclosure

T4 Tamb = -20 °C to 65 °C

For Non-Incendive Field Wiring Installation, see drawing 1400669

*Additionally approved as a system with models 140,141,142, 150, 400, 400VP, 401, 402, 402VP, 403,403VP, 404 & 410VP contacting conductivity

sensors and models 222, 225, 226 & 228 inductive conductivity sensors.

During EMI disturbance, maximum deviation is ±150 µS/cm for model option T.

IECEx BAS 11.0098X

Ex ia IIC T4 Ga

T4 Tamb = -20 °C to 65 °C

Class I, II & III, Division 1, Groups A-G T4

Tamb = -20 °C to 65 °C

IP66 enclosure

Class I, Zone 0, AEx ia IIC T4

Tamb = -20°C to 65°C

For Intrinsically Safe Installation, see drawing 1400670

Class I, Division 2 Groups A-D

Dust Ignition proof Class II & III, Div 1, Groups EFG

Class II & III, Division 1, Groups E-G

Tamb = -20°C to 65°C, IP66 enclosure

For Non-Incendive Field Wiring Installation, see drawing 1400670

4 Specifications

Page 15

Reference Manual Section 2: Description and Specifications

1500

1250

1000

750

500

250

0

Load, ohm s

with HART

com m uni cation

without HART

com m uni cation

12 18 24 30 36 42

545

ohm s

1364

ohm s

Pow e r supp l y vol tag e, Vdc

HART option

00809-0100-3166 March 2020

Complies with the following Standards:

CSA: C22.2 No 0 – 10; C22.2 No 0.4 – 04; C22.2 No. 25-M1966: , C22.2 No. 94-M91: , C22.2

No.142-M1987: , C22.2 No. 157-M1992: , C22.2 No. 213-M1987: , C22.2 No. 60529:05.

UL: 50:11th Ed.; 508:17th Ed.; 913:7th Ed.; 1203:4th Ed.. ANSI/ISA: 12.12.10-2013.

ATEX: EN 60079-0:2012+A11:2013, 60079-11:2012

IECEx: IEC 60079-0: 2011 Edition: 6.0, I EC 60079-11 : 2011-06 Edition: 6.0

FM: 3600: 2011, 3610: 2010, 3611: 2004, 3810: 2005, IEC 60529:2004, ANSI/ISA 60079-0: 2009,

ANSI/ISA 60079-11: 2009Input: One isolated sensor input. Measurement choices of pH/ORP, resis-

tivity/conductivity/TDS, % concentration, total and free chlorine, monochloramine, dissolved oxygen, dissolved ozone, and temperature. For contacting conductivity measurements, temperature

element can be a PT1000 RTD or a PT100 RTD. Other measurements (except ORP) and use PT100

or PT1000 RTDs or a 22k NTC (D.O. only).

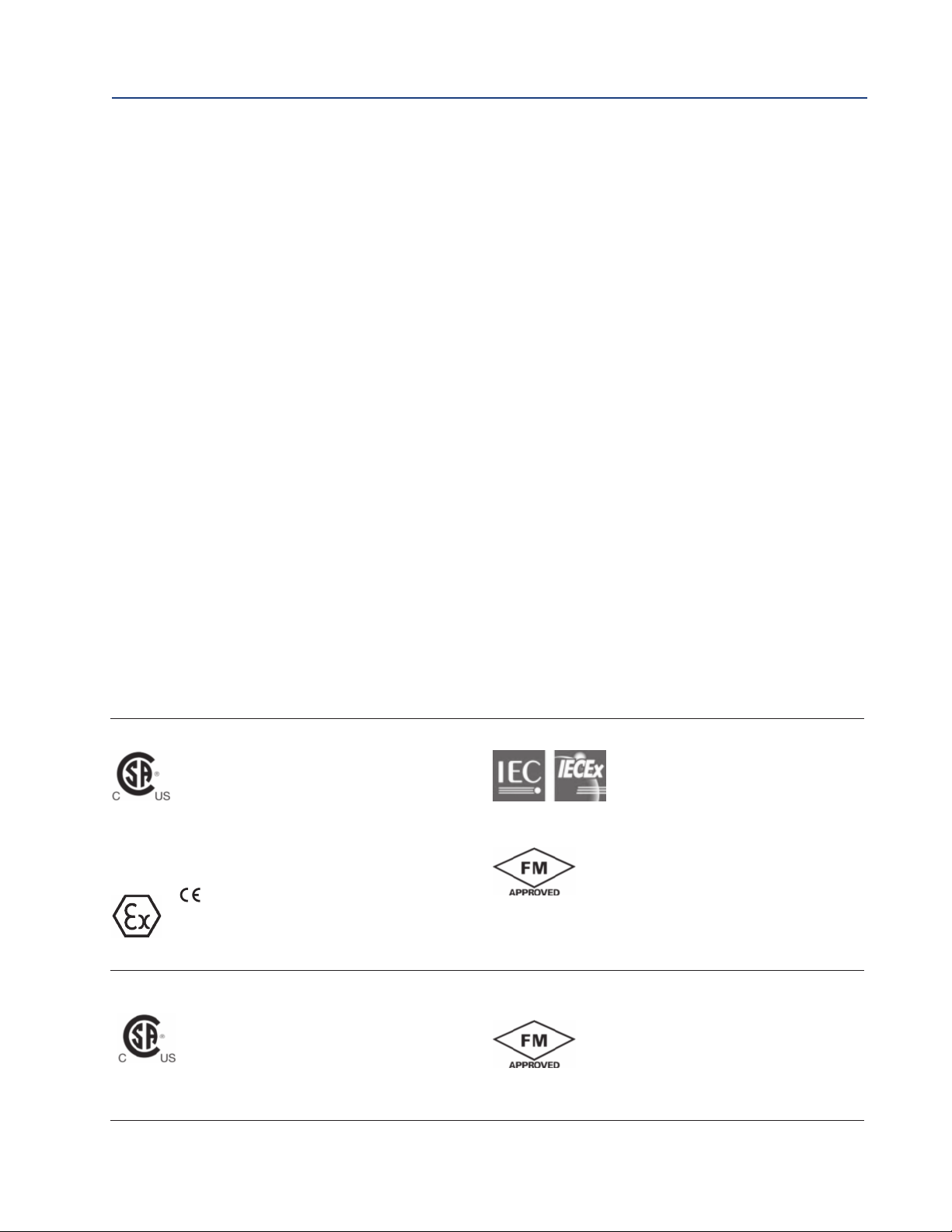

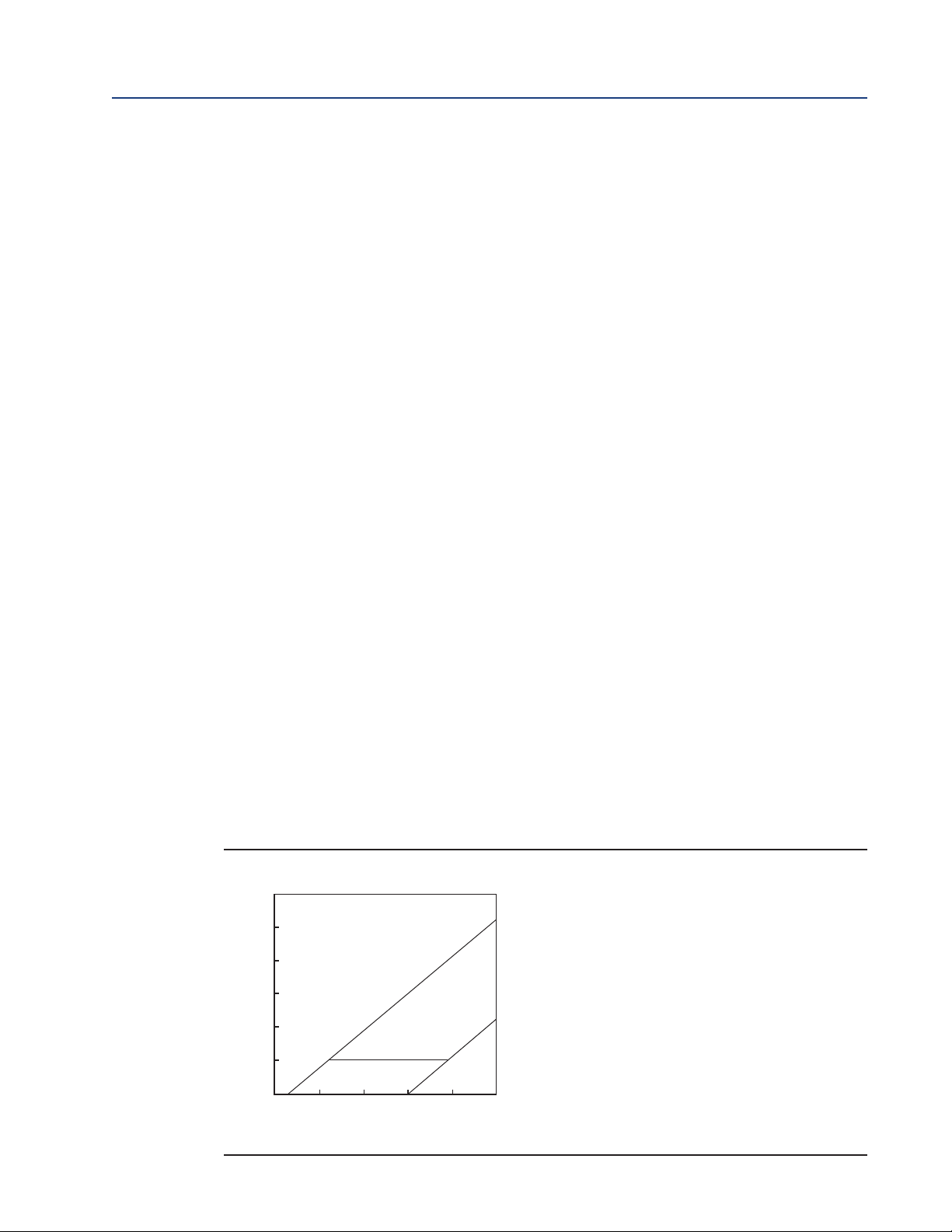

Power and Load Requirements:Supply voltage at the transmitter terminals should be at least 12.7

Vdc. Power supply voltage should cover the voltage drop on the cable plus the external load resistor required for HART communications (250 Ω minimum). Minimum power supply voltage is 12.7

Vdc. Maximum power supply voltage is 42.4 Vdc (30 Vdc for intrinsically safe operation). The

graph shows the supply voltage required to maintain 12 Vdc (upper line) and 30 Vdc (lower line)

at the transmitter terminals when the current is 22 mA.

FIGURE 2-1. Load/Power Supply Requirements

Analog Outputs: Two-wire loop powered (Output 1 only). Two 4-20 mA electrically isolated cur-

rent outputs (Output 2 must be externally powered). Superimposed HART digital signal on

Output 1. Fully scalable over the operating range of the sensor.

Weight/Shipping Weight: 2 lbs/3 lbs (1 kg/1.5 kg)

Specifications 5

Page 16

Section 2: Description and Specifications Reference Manual

March 2020 00809-0100-3166

2.3

2.3.1

2.3.2

pH/ORP (Codes – P)

For use with any standard pH or ORP sensor. SMART pH sensor with SMART pre-amplifiers from

Rosemount. Measurement choices are pH, ORP, or Redox. The automatic buffer recognition feature uses stored buffer values and their temperature curves for the most common buffer standards available worldwide. The transmitter will recognize the value of the buffer being measured

and perform a self stabilization check on the sensor before completing the calibration. Manual or

automatic temperature compensation is menu selectable. Change in pH due to process temperature can be compensated using a programmable temperature coefficient.

Performance Specifications - Transmitter (pH input)

Measurement Range [pH]: 0 to 14 pH

Accuracy: ±0.01 pH

Buffer recognition: NIST, DIN 19266, JIS 8802, and BSI.

Input filter: Time constant 1 - 999 sec, default 4 sec.

Response time: 5 seconds to 95% of final reading

Recommended Sensors for pH:

All standard pH sensors. Supports SMART pH sensors from Rosemount.

Performance Specifications - Transmitter (ORP input)

Measurement Range [ORP]: -1400 to +1400 mV

Accuracy: ± 1 mV

Input filter: Time constant 1 - 999 sec, default 4 sec.

Response time: 5 seconds to 95% of final reading

Recommended Sensors for ORP: All standard ORP sensors

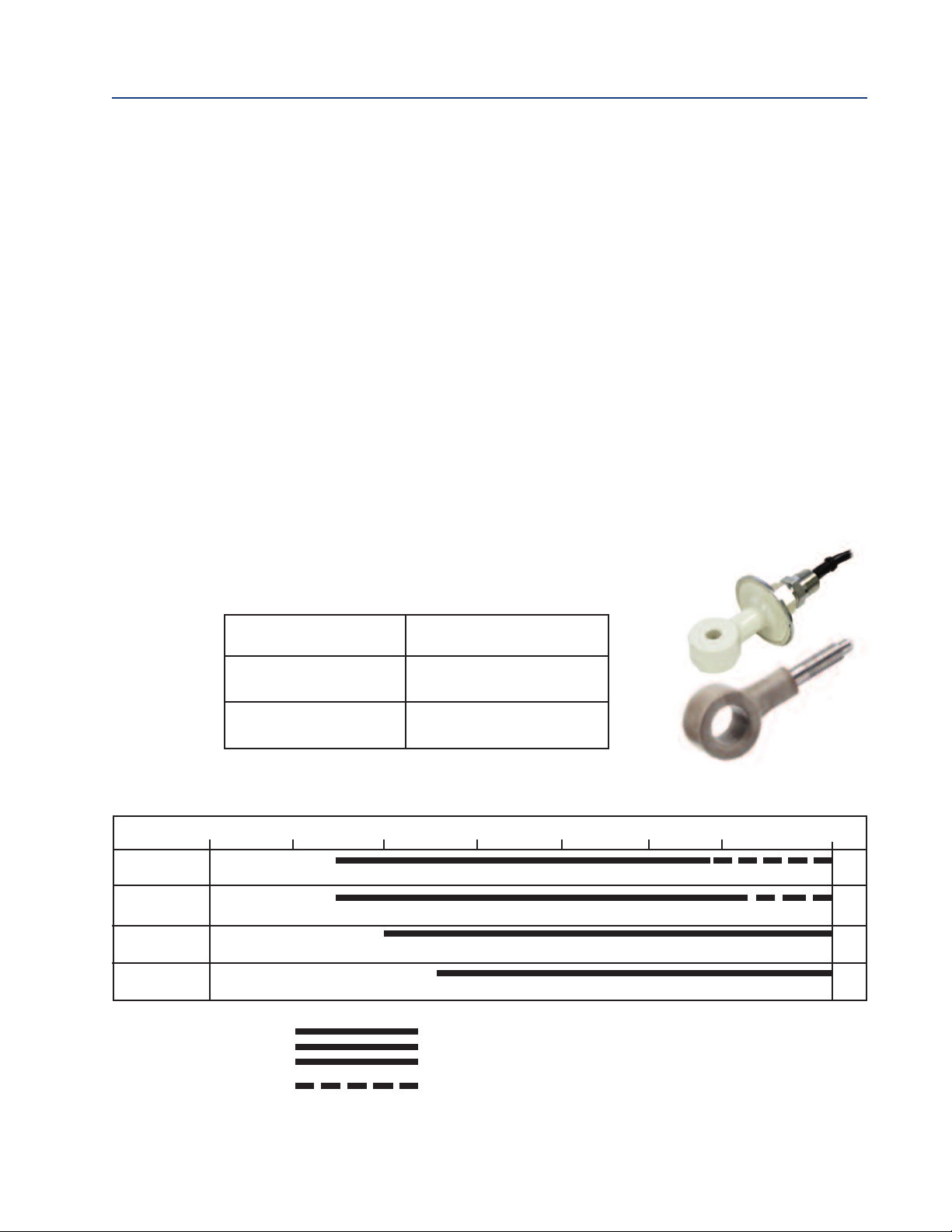

FIGURE 2-2. General purpose and high performance pH sensors 3900, 396PVP

and 3300HT

6 Specifications

Page 17

Reference Manual Section 2: Description and Specifications

00809-0100-3166 March 2020

2.4

2.4.1

Contacting Conductivity (Codes – C)

Measures conductivity in the range 0 to 600,000 µS/cm (600mS/cm). Measurement choices are

conductivity, resistivity, total dissolved solids, salinity, and % concentration. In addition, the

“Custom Curve” feature allows users to define a three to five point curve to measure ppm, %, or a

no unit variable. The % concentration selection includes the choice of five common solutions (012% NaOH, 0-15% HCl, 0-20% NaCl, and 0-25% or 96-99.7% H2SO4). The conductivity concentration algorithms for these solutions are fully temperature compensated. Three temperature compensation options are available: manual slope (X% / °C), high purity water (dilute sodium chloride), and cation conductivity (dilute hydrochloric acid). Temperature compensation can be disabled, allowing the transmitter to display raw conductivity. For more information concerning the

use of the contacting conductivity sensors, refer to the product data sheets.

Note: The 410VP 4-electrode high-range conductivity sensor is compatible with the 1066.

Performance Specifications

Temperature specifications:

Temperature range 0-200 °C

Temperature Accuracy,

Pt-1000, 0-50 °C

Temperature Accuracy,

Pt-1000, Temp. > 50 °C

± 0.1 °C

± 0.5 °C

ENDURANCETMseries of

conductivity sensors

Input filter: Time constant 1 - 999 sec, default 2 sec.

Response time: 3 seconds to 95% of final reading using the default input filter

Salinity: Uses Practical Salinity Scale

Total Dissolved Solids: Calculated by multiplying conductivity at 25 °C by 0.65

Table 2-1. Performance Specifications: Recommended Range – Contacting Conductivity

Cell 0.01S/cm 0.1µS/cm 1.0µS/cm 10µS/cm 100µS/cm 1000µS/cm 10mS/cm 100mS/cm 1000mS/cm

Constant

0.01

0.1

1.0

4-electrode

Linearity for Standard

Cable ≤ 50 ft (15 m)

Specifications 7

0.01µS/cm to 200µS/cm

0.1µS/cm to 2000µS/cm

1 µS/cm to 20mS/cm

±0.6% of reading in recommended range

±2% of reading outside high recommended range

±5% of reading outside low recommended range

±4% of reading in recommended range

200µS/cm to 2000µS/cm

2000µS/cm to 20mS/cm

20mS/cm to 200mS/cm

2µS/cm to

1400mS/cm

Page 18

Section 2: Description and Specifications Reference Manual

March 2020 00809-0100-3166

2.4.2

2.5

2.5.1

Recommended Sensors for Conductivity

All Rosemount 400 series conductivity sensors (Pt 1000 RTD) and 410VP 4-electrode sensor.

Toroidal Conductivity (Codes – T)

Measures conductivity in the range of 1 µS/cm to 2,000,000 µS/cm (2 S/cm). Measurement choices

are conductivity, resistivity, total dissolved solids, salinity, and % concentration. The % concentration

selection includes the choice of five common solutions (0-12% NaOH, 0-15% HCl, 0-20% NaCl, and 025% or 96-99.7% H2SO4). The conductivity concentration algorithms for these solutions are fully

temperature compensated. For other solutions, a simple-to-use menu allows the customer to enter

his own data. The transmitter accepts as many as five data points and fits either a linear (two points)

or a quadratic function (three to five points) to the data. Reference temperature and linear temperature slope may also be adjusted for optimum results. Two temperature compensation options are

available: manual slope (X% / °C) and neutral salt (dilute sodium chloride). Temperature compensation can be disabled, allowing the transmitter to display raw conductivity. For more information concerning use of the toroidal conductivity sensors, refer to the product data sheets.

Performance Specifications

Temperature specifications:

High performance 225 Toroidal &

226 Conductivity sensors

Temperature range -25 to 210 °C (-13 to 410 °F)

Temperature Accuracy,

Pt-100, -25 to 50 °C

Temperature Accuracy,

Pt-100, 50 to 210 °C

± 0.5 °C

± 1 °C

Repeatability: ±0.25% ±5 µS/cm after zero cal

TABLE 2-2. Performance Specifications: Recommended Range – Toroidal Conductivity

Model 1µS/cm 10µS/cm 100µS/cm 1000µS/cm 10mS/cm 100mS/cm 1000mS/cm 2000mS/cm

226

225 & 228

242

222

(1in & 2in)

Loop Performance

(Following Calibration)

50µS/cm to 500mS/cm

50µS/cm to 1500mS/cm

100µS/cm to 2000mS/cm

500µS/cm to 2000mS/cm

226: ±1% of reading ±5µS/cm in recommended range

225 & 228: ±1% of reading ±15

222, 242: ±4% of reading ±5mS/cm in recommended range

225, 226 & 228: ±5% of reading outside high recommended range

µS/cm in recommended range

500mS/cm to 2000mS/cm

1500mS/cm to 2000mS/cm

8 Specifications

Page 19

Reference Manual Section 2: Description and Specifications

00809-0100-3166 March 2020

Input filter: time constant 1 - 999 sec, default 2 sec.

esponse time: 3 seconds to 95% of final reading

R

Salinity: Uses Practical Salinity Scale

Total Dissolved Solids: Calculated by multiplying conductivity at 25 °C by 0.65

2.5.2

2.6

2.6.1

2.6.2

Recommended Sensors for Conductivity

All Rosemount submersion/immersion and flow-through toroidal sensors.

Chlorine (Codes – CL)

Free and Total Chlorine

The 1066 is compatible with the 499ACL-01 free chlorine sensor and the 499ACL-02 total chlorine

sensor. The 499ACL-02 sensor must be used with the TCL total chlorine sample conditioning system.

The 1066 fully compensates free and total chlorine readings for changes in membrane permeability

caused by temperature changes. For free chlorine measurements, both automatic and manual pH

correction are available. For automatic pH correction select an appropriate pH sensor. For more

information concerning the use and operation of the amperometric chlorine sensors and the TCL

measurement system, refer to the product data sheets.

Performance Specifications

Resolution: 0.001 ppm or 0.01 ppm – selectable

Input Range: 0nA – 100 µA

Automatic pH correction for Free Chlorine: (user selectable for

code -CL): 6.0 to 10.0 pH

Temperature compensation: Automatic (via RTD) or manual (050 °C).

Input filter: Time constant 1 - 999 sec, default 5 sec.

Response time: 6 seconds to 95% of final reading

499ACL-01

Chlorine sensor

2.6.3

2.6.4

Specifications 9

Recommended Sensors

Chlorine: 499ACL-01 Free Chlorine or 499ACL-02Total Residual Chlorine

pH: These pH sensors are recommended for automatic pH correction of free chlorine readings:

3900-02-10, 3900-01-10, and 3900VP-02-10.

Monochloramine

The 1066 is compatible with the 499A CL-03 Monochloramine sensor. The 1066 fully compensates

readings for changes in membrane permeability caused by temperature changes. Because

monochloramine measurement is not affected by pH of the process, no pH sensor or correction is

required. For more information concerning the use and operation of the amperometric chlorine

sensors, refer to the product data sheets.

Page 20

Section 2: Description and Specifications Reference Manual

March 2020 00809-0100-3166

2.6.5

2.6.6

2.7

2.7.1

Performance Specifications

esolution: 0.001 ppm or 0.01 ppm – selectable

R

Input Range: 0nA – 100µA

Temperature compensation: Automatic (via RTD) or manual (0-50 °C).

Input filter: Time constant 1 - 999 sec, default 5 sec.

Response time: 6 seconds to 95% of final reading

Recommended Sensors

Rosemount 499ACL-03 Monochloramine sensor

Dissolved Oxygen (Codes –DO)

The 1066 is compatible with the 499ADO, 499ATrDO, Hx438, Gx438 and Bx438 dissolved oxygen

sensors and the 4000 percent oxygen gas sensor. The 1066 displays dissolved oxygen in ppm, mg/L,

ppb, µg/L, % saturation, % O2in gas, ppm O2in gas. The transmitter fully compensates oxygen readings for changes in membrane permeability caused by temperature changes. Automatic air calibration, including salinity correction, is standard. The only required user entry is barometric pressure.

For more information on the use of amperometric oxygen sensors, refer to the product data sheets.

Performance Specifications

2.7.2

2.8

2.8.1

2.8.2

Resolution: 0.01 ppm; 0.1 ppb for 499A TrDO sensor (when O2<1.00 ppm); 0.1%

Input Range: 0nA – 100 µA

Temperature Compensation: Automatic (via RTD) or manual (0-50 °C).

Input filter: Time constant 1 - 999 sec, default 5 sec.

Response time: 6 seconds to 95% of final reading

Recommended Sensors

Rosemount amperometric membrane and steam-sterilizable sensors listed above

Dissolved Oxygen

499ADO sensor with

Variopol connection

Ozone (Codes –OZ)

The 1066 is compatible with the 499AOZ sensor. The 1066 fully compensates ozone readings for

changes in membrane permeability caused by temperature changes. For more information concerning the use and operation of the amperometric ozone sensors, refer to the product data sheets.

Performance Specifications

Resolution: 0.001 ppm or 0.01 ppm – selectable

Input Range: 0nA – 100A

Temperature Compensation: Automatic (via RTD) or manual (0-35 °C)

Input filter: Time constant 1 - 999 sec, default 5 sec.

Response time: 6 seconds to 95% of final reading

Recommended Sensors

Dissolved Ozone

499AOZ sensors with

Variopol connection

Rosemount 499A OZ ozone sensor

10 Specifications

Page 21

Reference Manual Section 2: Description and Specifications

00809-0100-3166 March 2020

2.9

Ordering Information

The 1066 2-Wire Transmitter is intended for the continuous determination of pH, ORP (Redox),

conductivity, (both contacting and toroidal), and for measurements using membrane-covered

amperometric sensors (oxygen, ozone, free and total chlorine, and monochloramine). For free

chlorine measurements, which often require continuous pH correction a second input for a pH

sensor is available. Two 4-20mA analog outputs are standard on HART units. The 1066 is compatible with SMART pH sensors from Rosemount. HART digital communications is standard and

F

OUNDATION

Communication with the 1066 is through:

Local keypad interface

475 HART

HART protocol version 7

FOUNDATION fieldbus

AMS (Asset Management Solutions) Aware

SMART Wireless THUM™Adapter

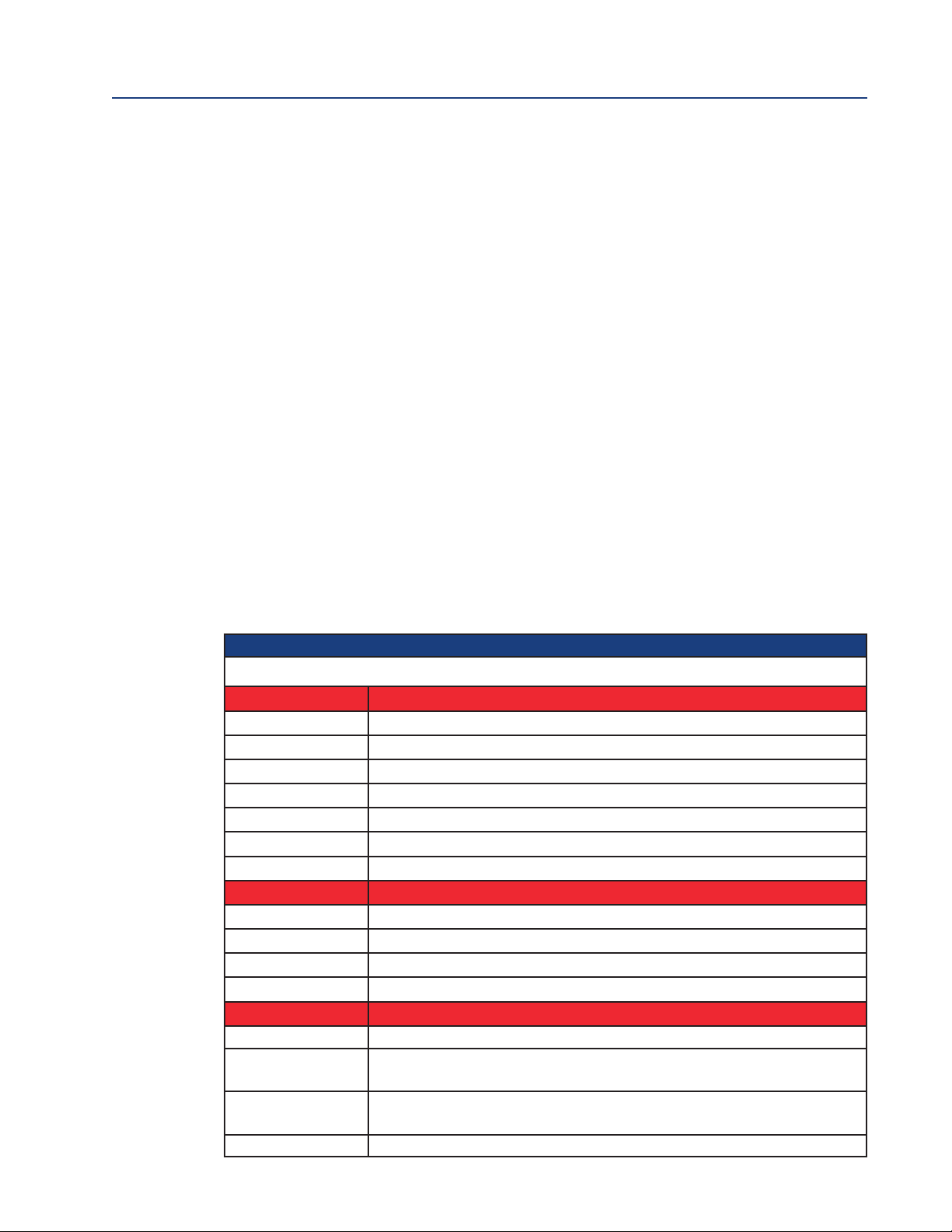

TABLE 2-3. Ordering Information

®

fieldbus digital communication is offered as an option.

®

and FO

UNDATION

fieldbus Communicator

Description

1066 pH/ORP, Conductivity, Chlorine, Oxygen, and Ozone 2-Wire Transmitter

Measurement

P pH/ORP

C Contacting Conductivity

T Toroidal Conductivity

CL Chlorine

DO Dissolved Oxygen

OZ Ozone

Communication

HT HART® Digital Communication Superimposed on 4-20mA Output

FF FOUNDATION™ fieldbus Digital Output

FI FOUNDATION™ fieldbus Digital Output with FISCO

Agency Approval

60 None Required

67

69

73 ATEX/IECEx Approved, Intrinsically Safe (safety barrier required)

FM Approved, Intrinsically Safe (appropriate sensor & safety barrier

required), and Non-Incendive

CSA Approved , Intrinsically Safe (appropriate sensor & safety barrier

required), and Non-Incendive

Specifications 11

Page 22

Section 2: Description and Specifications Reference Manual

March 2020 00809-0100-3166

12 Specifications

Page 23

Reference Manual Section 3: Installation

00809-0100-3166 March 2020

Section 3: Installation

3.1

3.2

Unpacking and inspection

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions.

Save the box. If there is no apparent damage, unpack the container. Be sure all items shown on the

packing list are present. If items are missing, notify Rosemount immediately.

Installation – General Information

1. Although the transmitter is suitable for outdoor use, installation is direct sunlight or in areas

of extreme temperatures is not recommended unless a sunshield is used.

2. Install the transmitter in an area where vibration and electromagnetic and radio frequency

interference are minimized or absent.

3. Keep the transmitter and sensor wiring at least one foot from high voltage conductors. Be

sure there is easy access to the transmitter.

4. The transmitter is suitable for panel, pipe, or surface mounting.

5. The transmitter case has six 1/2-inch (PG13.5) conduit openings. Use separate conduit

openings for the power/output cable, the sensor cable, and the other the sensor cable as

needed (pH input for free chlorine with continuous pH correction).

6. Use weathertight cable glands to keep moisture out to the transmitter. If conduit is used, plug

and seal the connections at the transmitter housing to prevent moisture from getting inside

the instrument.

3.3

Preparing Conduit Openings

There are six conduit openings in all configurations of 1066.

Conduit openings accept 1/2-inch conduit fittings or PG13.5 cable glands. To keep the case

watertight, block unused openings with Type 4X or IP66 conduit plugs.

To maintain ingress protection for outdoor use, seal unused conduit holes with suitable conduit

plugs.

NOTE: Use watertight fittings and hubs that comply with your requirements. Connect the conduit

hub to the conduit before attaching the fitting to the transmitter.

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-70) and/or any

other applicable national or local codes.

Installation 13

Page 24

Section 3: Installation Reference Manual

March 2020 00809-0100-3166

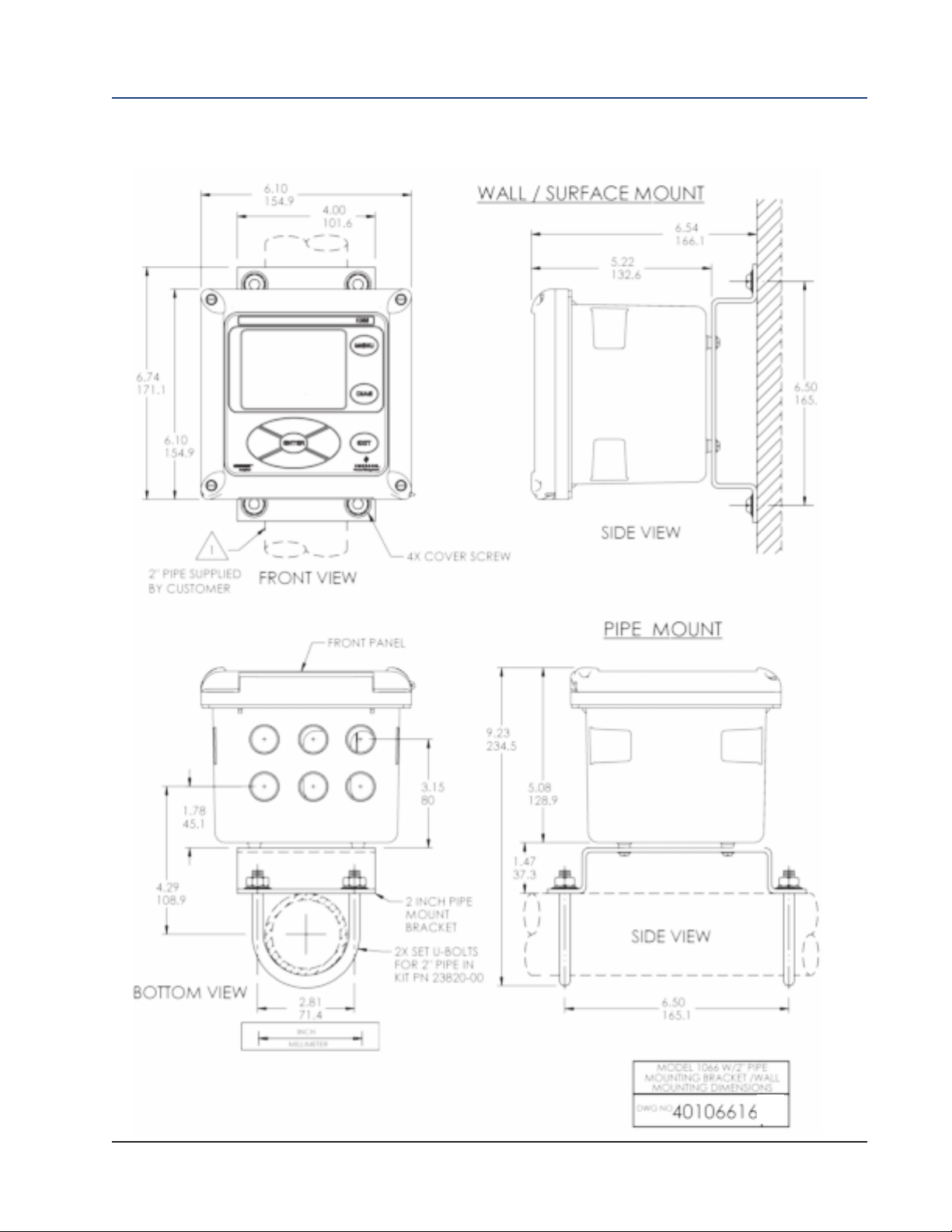

FIGURE 3-1. Panel Mounting Dimensions

14 Installation

Page 25

Reference Manual Section 3: Installation

00809-0100-3166 March 2020

FIGURE 3-2. Pipe and wall mounting dimensions (Mounting bracket PN: 23820-00)

Installation 15

Page 26

Section 3: Installation Reference Manual

March 2020 00809-0100-3166

16 Installation

Page 27

1500

1250

1000

750

500

250

0

Load, ohm s

with HART

com m uni cat i on

without HART

com m uni cat i on

12 18 24 30 36 42

545

ohm s

1364

ohm s

Pow er su pp l y vol tag e, Vdc

HART option

Reference Manual Section 4: Wiring

00809-0100-3166 March 2020

Section 4: Wiring

4.1

4.1.1

4.1.2

4.2

4.2.1

General

General Information

The 1066 is easy to wire. All wiring connections are located on the main circuit board. The front

panel is hinged at the bottom. The panel swings down for easy access to the wiring locations.

Digital Communication

HART and FO

units support Bell 202 digital communications over analog 4-20mA current output 1.

UNDATION

fieldbus communications are available as ordering options for 1066. HART

Power Supply/Current Loop – 1066 - HT

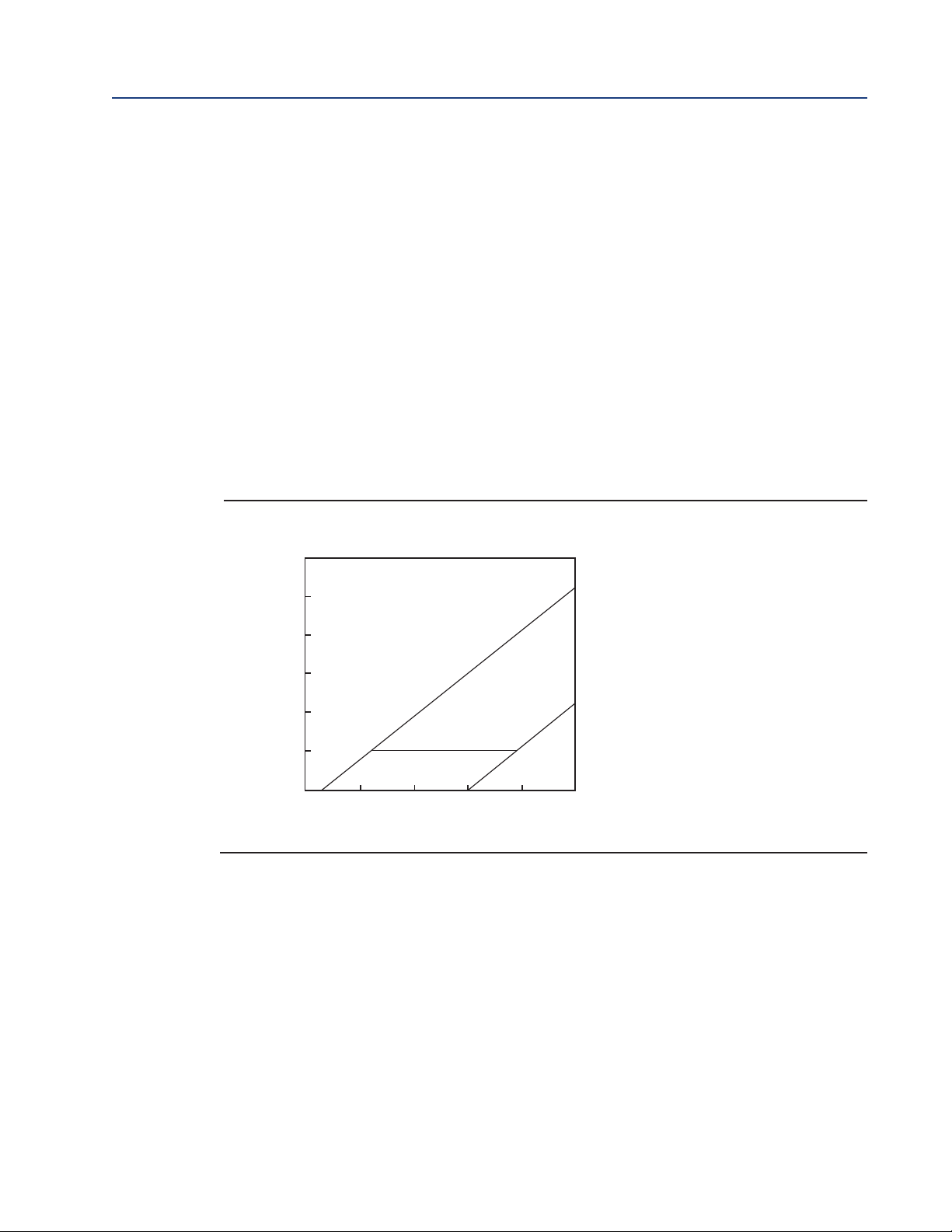

Power Supply and Load Requirements

Refer to Figure 4-1. The supply voltage must be at least 12.7 Vdc at the transmitter terminals.. The

power supply must be able to cover the voltage drop on the cable as well as the load resistor (250 Ω

minimum) required for HART communications. The maximum power supply voltage is 42.0 Vdc.

For intrinsically safe installations, the maximum power supply voltage is 30.0 Vdc. The graph shows

load and power supply requirements. The upper line is the power supply voltage needed to provide

12.7 Vdc at the transmitter terminals for a 22 mA current. The lower line is the power supply volt-

age needed to provide 30 Vdc for a 22 mA current. The power supply must provide a surge current

during the first 80 milliseconds of startup. The maximum current is about 24 mA.

Wiring 17

For digital communications, the load must be at least 250 ohms. To supply the 12.7 Vdc lift off

voltage at the transmitter, the power supply voltage must be at least 17.5 Vdc.

FIGURE 4-1. Load/Power Supply Requirements

Page 28

Section 4: Wiring Reference Manual

March 2020 00809-0100-3166

4.2.2

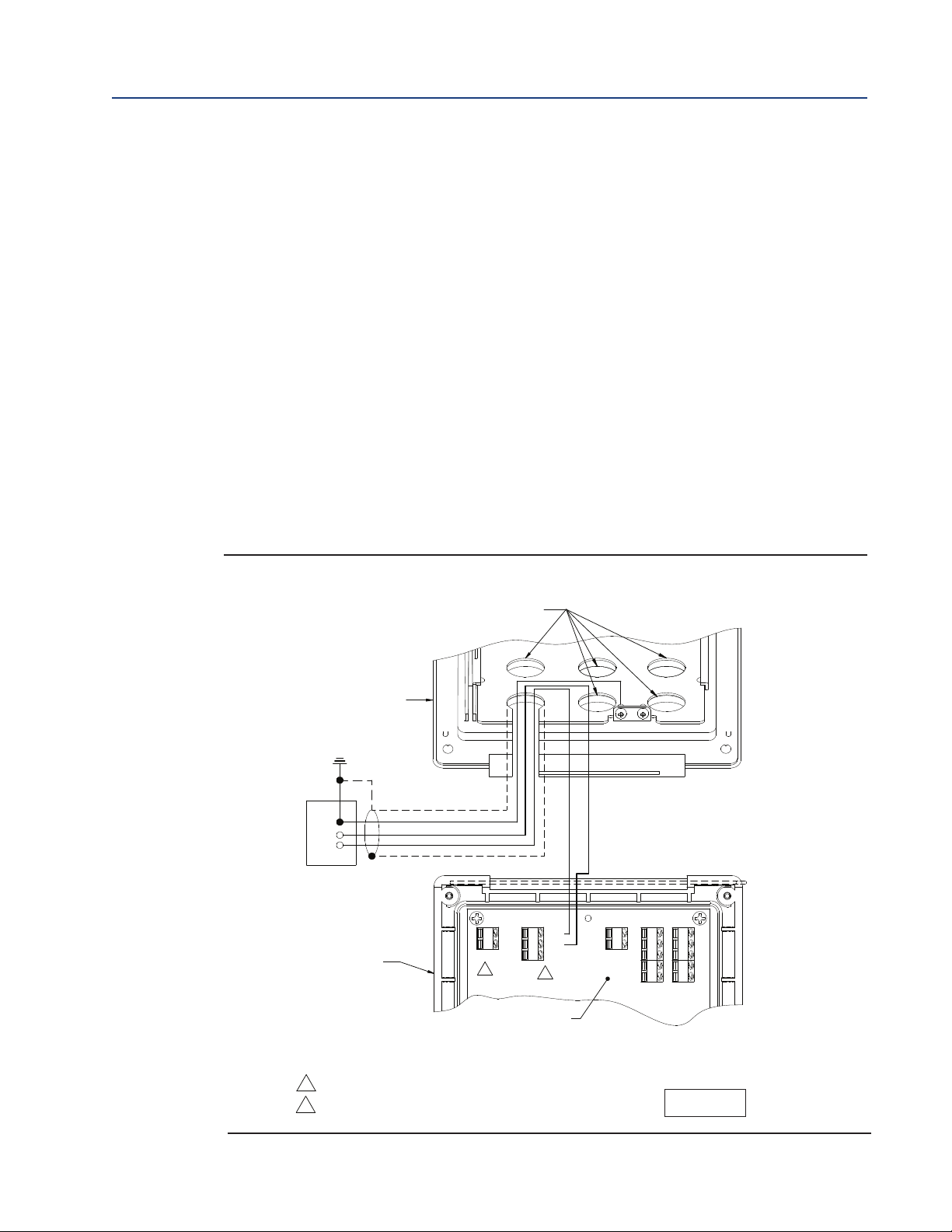

Power Supply-Current Loop Wiring

Refer to Figure 4-2.

Run the power/signal wiring through the opening nearest TB-2.

For optimum EMI/RFI protection:

1. Use shielded power/signal cable and ground the shield at the power supply.

2. Use a metal cable gland and be sure the shield makes good electrical contact with the gland.

3. Use the metal backing plate when attaching the gland to transmitter enclosure. The

power/signal cable can also be enclosed in an earth-grounded metal conduit.

Do not run power supply/signal wiring in the same conduit or cable tray with loop power lines.

Keep power supply/signal wiring at least 6 ft (2 m) away from heavy electrical equipment.

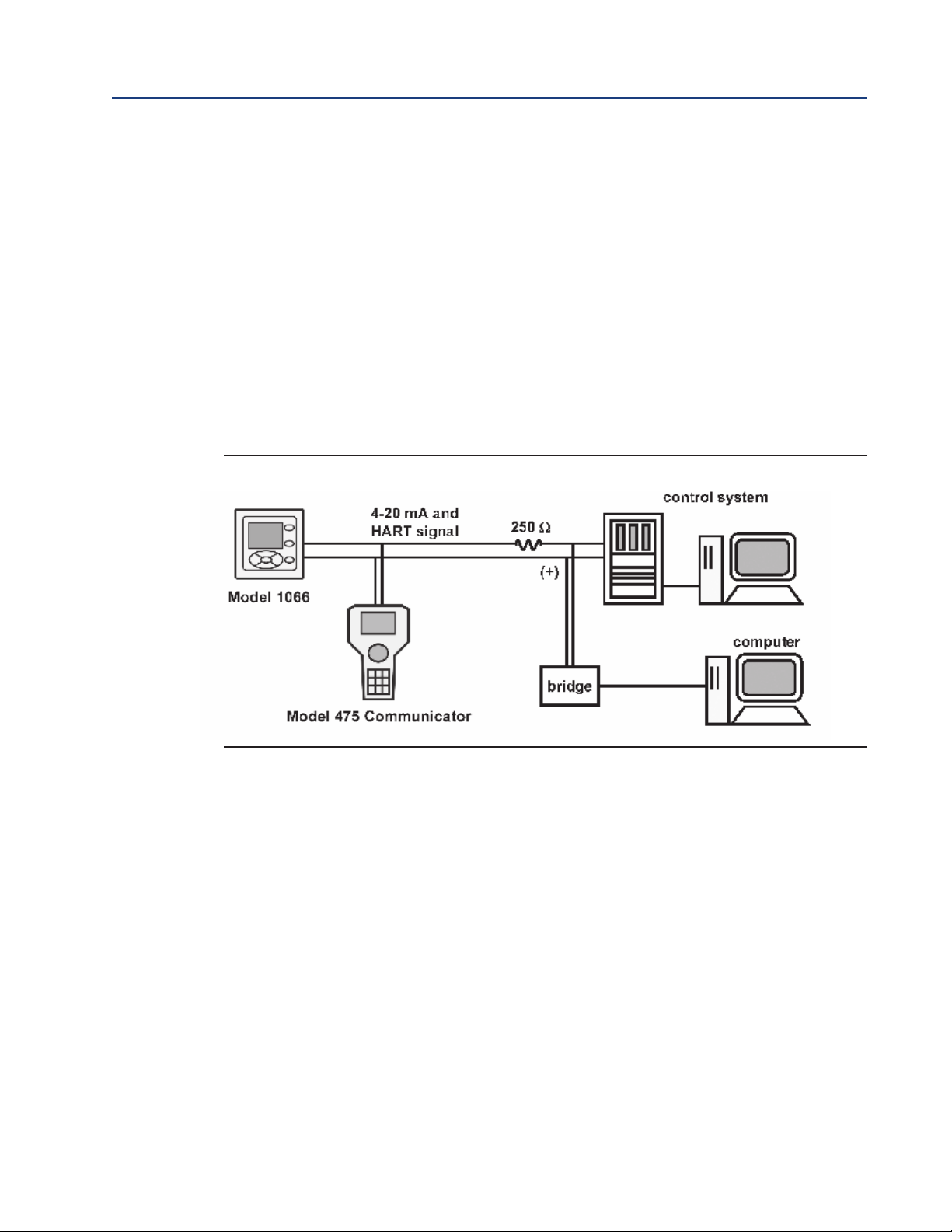

FIGURE 4-2. HART Communications

18 Wiring

Page 29

OUTPUT 2

TB5 TB3 TB2

TB4 TB1

+24V

GND

GND

+24V

THUM

ANODE

CATHODE

RTN

SNS

RTD IN

+V

-V

REF

SHLD

SENSOR WIRING

TB7

TB6

_

+

GND

SOL

SHLD

pH

(OUTPUT1)

LOOP PWR

4-20mA / -24VDC RETURN

4-20mA / +24VDC

INSTALL PLUGS IN ALL OTHER

OPENINGS AS NEEDED

INNER ENCLOSURE

HINGE SIDE OF FRON T PANEL

1

TB7

/OUTPUT 2 REQUIRES EXTERNAL DC POWER.

2

TB6/

THUM T ERMINAL IS USED ONLY FOR

WIRELESS THUM ADA PT OR INSTALLATIONS

.

1

2

1066 HART CIRCUIT BO ARD

(pH/CL/DO/OZ)

ASS Y 24406-xx

HINGED PANEL

DW G NO.

40106613

Reference Manual Section 4: Wiring

00809-0100-3166 March 2020

4.2.3 Current Output wiring

The 1066 HART units are shipped with two 4-20mA current outputs. Current Output 1 is loop

power; it is the HART communications channel. Current output 2 is available to report process

temperature measured by the temperature sensing element or RTD within the sensor.

Wiring locations for the outputs are on the main board which is mounted on the hinged door of

the instrument. Wire the output leads to the correct position on the main board using the lead

markings (+/positive, -/negative) on the board.

Note:

Twisted pairs are required to minimize noise pickup in the 4-20 mA current outputs. For high

EMI/RFI environments, shielded sensor wire is required and recommended in all other installations.

FIGURE 4-3. 1066 HART Loop Power Wiring

Wiring 19

Page 30

Section 4: Wiring Reference Manual

March 2020 00809-0100-3166

4.3

4.3.1

Power Supply Wiring For 1066-FF

Power Supply Wiring

Run the power/signal wiring through the opening nearest TB2. Use shielded cable and ground the

shield at the power supply. To ground the transmitter, attach the shield to TB2-3.

Note: For optimum EMI/RFI immunity, the power supply/output cable should be shielded and

enclosed in an earth-grounded metal conduit. Do not run power supply/signal wiring in the same

conduit or cable tray with loop power lines. Keep power supply/signal wiring at least 6 ft (2 m)

away from heavy electrical equipment.

UNDATION

FO

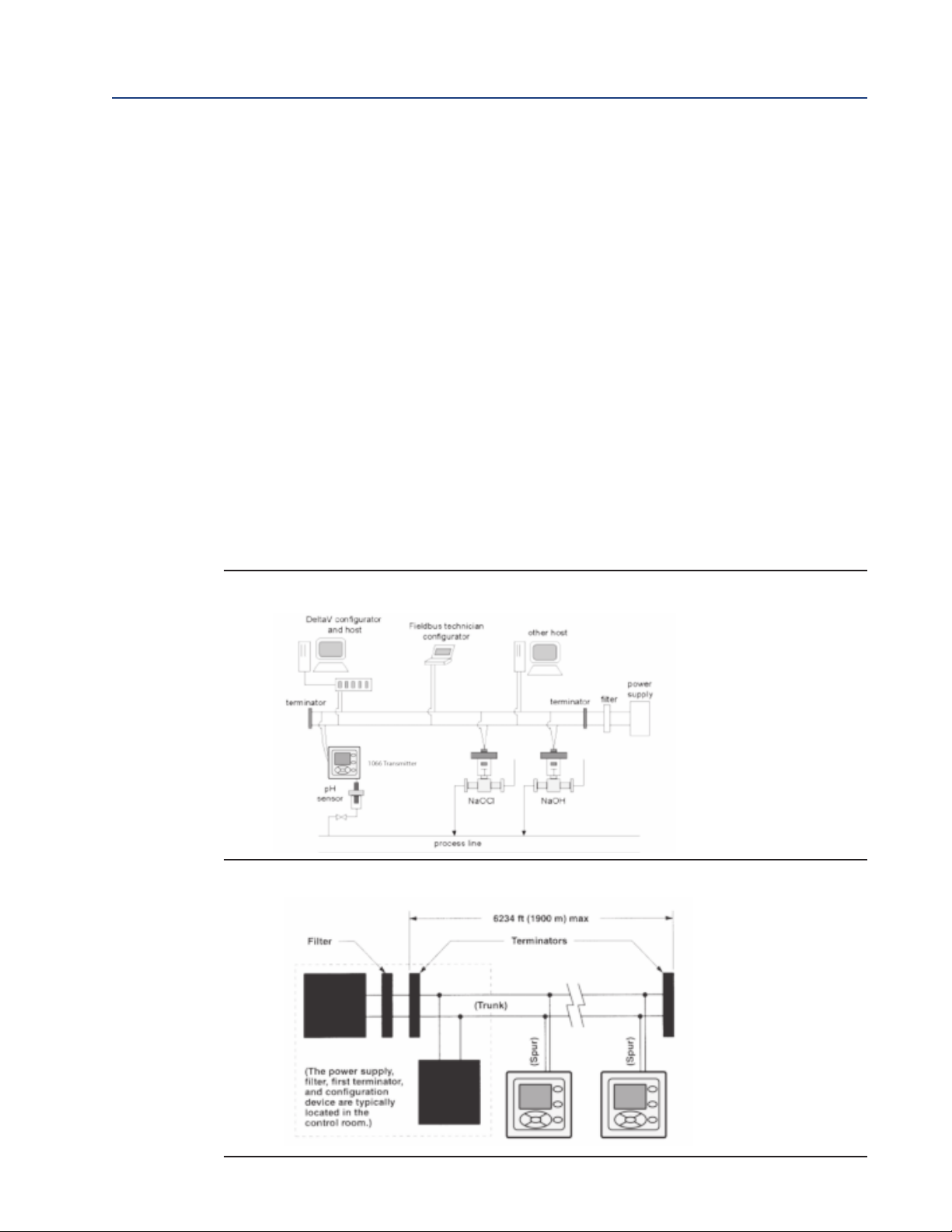

Figure 4-4 shows a 1066PFF being used to measure and control pH and chlorine levels in drinking

water. The figure also shows three ways in which Fieldbus communication can be used to read

process variables and configure the transmitter.

FIGURE 4-4. Configuring 1066P Transmitter with FOUNDATION fieldbus

Fieldbus

FIGURE 4-5. Typical Fieldbus Network Electrical Wiring Configuration

20 Wiring

Page 31

DWG NO.

40106612

Reference Manual Section 4: Wiring

00809-0100-3166 March 2020

4.4

Sensor Wiring to Main Board

Wire the correct sensor leads to the main board using the lead locations marked directly on

the board. Rosemount SMART pH sensors can be wired to the 1066 using integral cable SMART

sensors or compatible VP8 pH cables. After wiring the sensor leads, carefully take up the

excess sensor cable through the cable gland.

Keep sensor and output signal wiring separate from loop power wiring. Do not run sensor and

power wiring in the same conduit or close together in a cable tray.

FIGURE 4-6. pH/ORP sensor wiring to the 1066 printed circuit board

Wiring 21

Page 32

Section 4: Wiring Reference Manual

DWG NO.

40106615

March 2020 00809-0100-3166

FIGURE 4-7. Contacting and Toroidal Conductivity sensor wiring to the 1066 circuit board

22 Wiring

Page 33

Reference Manual Section 4: Wiring

OUTPU T 2

(OUTPUT1)

LOOP PWR

TB5 TB3 TB2

TB4 TB1

+24V

GND

GND

+24V

THUM

ANODE

CATHO DE

RTN

SNS

RTD IN

+V

-V

REF

SHLD

SENSOR WIRING

TB7

TB6

GND

SOL

SHLD

pH

HINGE SIDE OF FRONT PANEL

CHLORINE, OXYGEN , OZ ONE SENSOR WIRING

(FOLLOW RECOM M ENDED ORDER)

ANODE

CA THODE

1)

TB5

/ANODE

& CATH ODE

RETURN

SENSE

2)

TB3

/RTD

SOLU TION GROU ND

3)

TB2

/ SOLUT IO N

GROUND

RTD IN

NO CONNECTION

NO CONNECTION

NOTE:

A) TB1, TB4, TB6 AND TB7 NOT USED F O R OXYGEN AND OZONE SENSO R WIRING

B) TB1, TB2 A ND TB4 MAY BE USED FOR p H SENSOR WIRING IF FREE CHLORINE MEASUREMENT REQ UIRES

LIVE pH INPU T.

1066 CIRCUIT BOARD

ASSY 24406-xx

DWG NO.

40106611

00809-0100-3166 March 2020

FIGURE 4-8. Chlorine, oxygen, ozone sensor wiring to 1066 printed circuit board (1066-CL, 1066-DO,

066-OZ)

1

Wiring 23

Page 34

Section 4: Wiring Reference Manual

OUTPUT 2

T

B5 TB3 TB2

TB4 TB1

+24V

GND

GND

+24V

THUM

A

NODE

CATHODE

RTN

SNS

RTD IN

+V

-V

REF

SHLD

GND

SOL

SHLD

pH

SENSOR WIRING

TB7

TB6

_

+

RED / +VDC

YELLO W / OUTPUT 1 +24V

BLACK / OUTPUT 1 GND

GREEN / GROUND SCREW

W HITE

WIRE NUT

LOOP POWER/THUM

(OUTPUT1)

LOOP PWR

4-20mA / -24VDC RETURN

4-20m A / +24VDC

1

TB7

/OUTPUT 2 REQUIRES EXTERNAL DC POWER.

2

TB6/

THUM TERMINAL IS USED ONL Y FOR

WIRELESS THUM ADAPTOR INSTALLATIONS.

250 OHM RESISTOR IS PRE-INSTALLED IN-CIRCUIT.

3 SPLICE CONNECTOR - PROVIDED BY END USER.

INSTALL PLUGS IN ALL OTHER

OPENINGS AS NEE D ED

INNER ENCLOSURE

HINGE S IDE OF FRONT PANEL

1

2

WIRELESS

THUM

ADAPTOR

1066 HART CIRCUIT BOARD

(pH/CL/DO/OZ)

ASSY 24406-xx

3

DWG NO.

40106614

March 2020 00809-0100-3166

FIGURE 4-9. Power/Current Loop wiring with wireless THUM Adaptor

24 Wiring

Page 35

Reference Manual Section 4: Wiring

OUTPU T 2

TB5 TB3 TB2

TB4 TB1

+24V

GND

GND

+24V

THUM

ANODE

CATHODE

RTN

SNS

RTD IN

+V

-V

REF

SHLD

SENSOR WIRING

TB7

TB6

_

+

GND

SOL

SHLD

pH

(OUTPUT1)

LOOP PW R

4-20mA / -24VDC RETURN

4-20m A / +24VDC

INSTALL PLUGS IN ALL OTHER

OPENINGS AS NEEDED

INNER ENCLOSURE

HINGE SIDE O F FR ONT PANEL

1

TB7

/OUTPUT 2 REQUIRES EXTERNAL DC POWER.

2

TB6/

THUM TERMINAL IS USED ONLY FOR

WIRELESS THUM ADAPTOR INSTALLATIONS

.

1

2

1066 HART CIRCUIT BOARD

(pH/CL/DO/OZ)

ASS Y 24406-xx

HINGED PANEL

DWG NO.

40106613

00809-0100-3166 March 2020

FIGURE 4-10. HART Loop Power Wiring

Wiring 25

Page 36

Section 4: Wiring Reference Manual

March 2020 00809-0100-3166

26 Wiring

Page 37

Reference Manual Section 4: Wiring

C

i

(

F

)

Li

(

m

H

)

3

0

2

0

0

1

.0

M

O

D

E

L

N

O

.

3

7

5

O

R

4

7

5

V

m

a

x

I

N

:

V

d

c

I

m

a

x

I

N

:m

A

P

m

a

x

I

N

:

W

V

o

c

m

a

x

O

U

T

:

V

d

c

I

s

c

m

a

x

O

U

T

:

A

E

N

T

I

T

Y

P

ARAM

E

T

E

RS

:

RE

M

O

T

E

T

RAN

S

M

I

T

T

E

R

I

N

T

E

RF

AC

E

1

.9

3

2

0

.0

0

.0

(

4

7

5

I

N

S

T

ALLAT

I

O

N

D

RAW

I

N

G

I

S

0

0

4

7

5

-

1

1

3

0

)

1

0

6

6

S

U

P

P

L

Y

E

N

T

I

T

Y

P

A

RA

ME

T

E

RS

M

O

D

E

L

N

O

.

1

0

6

6

.

.

.

F

I

.

.

.

F

I

S

C

O

L

O

O

P

P

O

W

E

R

S

I

G

N

AL

T

E

RMI

N

ALS

T

B6

-

1

&

-

2

1

0

6

6

.

.

.

F

F

/F

I

...

E

N

T

I

T

Y

L

O

O

P

P

O

W

E

R

S

I

G

N

AL

T

E

RMI

N

ALS

T

B6

-

1

&

-

2

1

0

6

6

...H

T

...

A

N

ALO

G

O

U

T

P

U

T

2

S

I

G

N

A

L

T

E

RMI

N

A

L

S

T

B7

-

1

&

-

2

1

0

6

6

.

.

.

H

T

.

.

.

L

O

O

P

P

O

W

E

R

S

I

G

N

A

L

T

E

RM

I

N

A

L

S

T

B6

-

1

,

-

2

&

-

3

V

m

a

x

(

V

D

C

)

3

0

3

0

3

0

1

7

.

5

I

m

a

x

(

m

A)

2

0

0

2

0

0

3

0

0

3

8

0

P

m

a

x

(

W

)

0

.9

0

.9

1

.3

5

.

3

2

C

i

(

n

F

)

0

0

0

0

L

i

(

m

H

)

0

0

0

0

T

ABLE

I

I

I

O

U

T

P

U

T

P

ARAME

T

E

RS

I

o

U

o

P

o

A

,

B

T

ABLE

I

I

(

F

O

R

1

0

6

6

-

P

/C

L

/

D

O

/

O

Z

...)

D

C

C

a

(

F

)

La

(

m

H

)

O

U

T

P

U

T

P

A

RA

ME

T

E

RS

G

A

S

G

RO

U

P

S

M

O

D

E

L

1

0

6

6

T

B1

-

1

T

H

R

U

1

2

1

.

4

4

1

1

.8

8

V

1

5

3

.4

m

A

2

3

1

m

W

1

.5

1

9

.

3

9

6

.0

4

3

8

.

5

1

2

.0

8

T

ABLE

S

I

A

N

D

I

I

A

RE

F

O

R

p

H

,

C

H

L

O

RI

N

E

,

D

I

S

S

O

L

V

E

D

O

X

YG

E

N

AN

D

O

Z

O

N

E

O

P

T

I

O

N

S

T

ABLE

I

(

F

O

R

1

0

6

6

-

P

/

C

L/D

O

/O

Z

.

.

.)

AP

P

RO

V

E

D

M

O

D

E

LS

1

066-AA-BB-C

C

XM

T

R

1

8

1

7

1

6

1

5

S

O

LON G

A

S

T

H

E

C

AP

AC

I

T

A

N

C

E

AN D

I

ND

U

C

T

AN C

E

O

F

T

H

E

L

O

A

D

C

O NN EC

T

ED

T

O

T

H

E

S

EN

S

O R

T

ER

M

I

N

A

L

S

DO

N

O

T

EXC

EED

T

H

E

V

A

L

U

ES

S

P

EC

I

F

I

ED

I

N

T

A

B

LE

I

F

I

EL

D

DEV

I

C

E

I

N

P

U

T

A

S

S

O

C

I

AT

ED

AP

P

A

R

A

T

U

S

O

U

T

P

U

T

C

o

L

o

3

7

6

2

p

F

1

5

1

.9

5

n

H

D

W

G

N

O

R

EV

E

A

G E

N

C

Y C

O N

T

R

O L

L

E

D

D

O C

UM

E

N

T

C

E

R

T

I

FI

C

A

T

I

O

N

A

G E

N

C

Y

S

U

B

M

I

T

T

A

L

/

A

PPR

O VA

L

00809-0100-3166 March 2020

Section 5: Intrinsically Safe Installation

5.1

All Intrin sically Safe Installations

FIGURE 5-1. CSA Installation

Intrinsically Safe Installation 27

Page 38

Section 4: Wiring Reference Manual

SHLD

SOL

GND

TB6

TB7

SENSOR W IRING

SHLD

REF

RTD IN

SNS

RTN

CATHODE

ANO DE

THUM

GND

GND

TB1

TB4

TB2TB3

TB5

LOOP PWR

(OUTPUT1)

OUTPUT 2

SHLD

SOL

GND

TB6

TB7

SENSOR W IRING

SHLD

REF

RTD IN

SNS

RTN

CATHODE

ANO DE

THUM

GND

GND

TB1

TB4

TB2TB3

TB5

LOOP PWR

(OUTPUT1)

OUTPUT 2

SHLD

SOL

GND

TB6

TB7

SENSOR W IRING

SHLD

REF

RTD IN

SNS

RTN

CATHODE

ANO DE

THUM

GND

GND

TB1

TB4

TB2TB3

TB5

LOOP PWR

(OUTPUT1)

OUTPUT 2

W ARNING- SUBSTITUTION OF CO M PONENTS M AY IM PAIR INTRINSIC SAFETY O R

SUITABILITY FOR DIVISION 2.

W ARNING- TO PREVENT IGNITION OF FLAM M ABLE OR COM BUSTIBLE ATMO SPHERES,

DISCONNECT POW ER BEFORE SERVICING.

ROSEMOUN T M O DEL 375 OR 475

FIELD CO M M UNICATOR REMOTE TRANSMITTER

INTERFACE FOR USE IN CLASS I AREA

(SEE NOTE 3 AND TABLE III)

PH SENSOR

CSA APPROVED DEVICE OR

SIM PLE APPARATUS

NI CLASS I, DIV 2

GRPS A-D

CLASS II, DIV 2

GRPS E-G

AM PEROM ETRIC SENSOR

CSA APPROVED DEVICE OR

SIM PLE APPARATUS

1066-CL/D O/OZ...O NLY

EITHER O R BOTH

MAY BE INSTALLED

ROSEMOUN T M O DEL 375 OR 475

FIELD CO M M UNICATOR REMOTE TRANSMITTER

INTERFACE FOR USE IN CLASS I AREA

(SEE NOTE 3 AND TABLE III)

LOAD

UNSPECIFIED

POW ER SUPPLY

30 VDC M AX FOR IS

24V TYPICAL

SAFETY BARRIER

(SEE NOTES 10 & 11)

_

+

SPLICE CONNECTOR

RED

SMART THUM

W IRELESS

ADAPTER

ALTERNATE POW ER CONN ECTION IF SM ART

THUM W IRELESS AD APTER IS USED

(SENSOR AND SECOND ANALOG O UTPUT

CONNECTION U NCHANGED FROM ABOVE)

ROSEMOUN T M O DEL 375 OR 475

FIELD CO M M UNICATOR REMOTE TRANSMITTER

INTERFACE FOR USE IN CLASS I AREA

(SEE NOTE 3 AND TABLE III)

AM PEROM ETRIC SENSOR

CSA APPROVED DEVICE

OR SIM PLE APPARATUS

1066-CL/D O/OZ...O NLY

EITHER O R

BOTH MAY BE

INSTALLED

OPTIO NAL

CSA APPROVED PREAMP THAT

MEETS REQUIREMENTS O F

NOTE 4

PH SENSOR

CSA APPROVED DEVICE OR

SIM PLE APPARATUS

RECOMM ENDED CABLE PN 9200273

(UNPREPED) PN 23646-01 (PREPPED)

10 CO ND, 2 SHIELDS, 24 AW G. SEE NOTE 2

ANALOG OUTPUT 2 ONLY AVAILABLE

ON 1066...HT...

ANALOG OUTPUT 2 ONLY AVAILABLE

ON 1066...HT...

LOAD

UNSPECIFIED POW ER SUPPLY

30 VDC M AX FOR INTRINSIC SAFETY (24 VDC TYPICAL)

17.5 VDC M AX. FOR FISCO OPTION

LOAD

UNSPECIFIED POW ER SUPPLY

30 VDC M AX FOR INTRINSIC SAFETY (24 VDC TYPICAL)

17.5 VDC M AX. FOR FISCO OPTION

SAFETY BARRIER

(SEE NOTES 2 & 8 FOR FISCO,

SEE NO TES 2, 8, 9 & 10

FOR ALL O THER OPTIONS.)

LOAD

UNSPECIFIED POW ER SUPPLY

30 VDC M AX FOR INTRINSIC SAFETY (24 VDC TYPICAL)

17.5 VDC M AX. FOR FISCO OPTION

SAFETY BARRIER

(SEE NOTES 2 & 8 FOR FISCO,

SEE NO TES 2, 8, 9 & 10

FOR ALL O THER OPTIONS.)

LOAD

SAFETY BARRIER

(SEE NOTES 2 & 8 FOR FISCO,

SEE NO TES 2, 8, 9 & 10

FOR ALL O THER OPTIONS.)

GREEN

BLACK

YELLOW

W HITE

N/C

N/C

O R

O R

SAFETY BARRIER

(SEE NOTES 2 & 8 FOR FISCO,

SEE NO TES 2, 8, 9 & 10

FOR ALL O THER OPTIONS.)

UNSPECIFIED POW ER SUPPLY

30 VDC M AX FOR INTRINSIC SAFETY (24 VDC TYPICAL)

17.5 VDC M AX. FOR FISCO OPTION

IS CLASS I, GRPS A-D

CLASS II, GRPS E-G

CLASS III

REV

E

DW G NO

D

October 2017 00809-0100-3166

FIGURE 5-2. CSA Installation

28 Intrinsically Safe Installation

Page 39

Reference Manual Section 5: Intrinsically Safe Installation

OUTPUT2

TB2

TB1

LOOP PWR

DSHLD

DRV_A

RTN

DRV_B

RSHLD

RCV_A

SHLD

RTDIN

TB7

TB6

GND

+24V

THUM

RCV_B

SENSE

+24V

OUTPUT2

TB2

TB1

LOOP PWR

DSHLD

DRV_A

RTN

DRV_B

RSHLD

RCV_A

SHLD

RTDIN

TB7

TB6

GND

GND

+24V

T

HUM

RCV_B

SENSE

OUTPUT 2

(OUTPUT1)

LOOP PWR

TB5

TB3 TB2

TB4

TB1

GND

GND

THUM

ANO DE

CATHODE

RTN

SNS

RTD IN

REF

SHLD

SENSOR W IRING

TB7

TB6

GND

SOL

SHLD

W ARNING- SUBSTITUTION OF COM PONENTS M AY IM PAIR INTRINSIC SAFETY OR

SUITABILITY FOR DIVISION 2.

W ARNING- TO PREVENT IGNITION O F FLAMM ABLE O R CO M BUSTIBLE ATMOSPHERES,

DISCONNECT POW ER BEFORE SERVICING.