Emerson C471, 1098H-EGRs, 1301, 299Hs, 627 User Guide

...

LP-Gas Equipment Buyers Guide LP-31

The Industry Leader for Durability and Quality

Fisher® LP-Gas Equipment

Global Technology Leadership

Our commitment to providing customers with customized solutions, dependable products, along with uncompromising quality standards and exceptional service is a tradition dating back to our beginnings in 1880, when William Fisher invented the fi rst regulator. Today, Fisher LP-Gas Equipment is a part of Emerson Process Management’s

Regulator Technologies Division, the World Leader in valve and regulator design and manufacturing. Emerson, a $24.4 billion company, invests over $800 million in research and development annually. Being a part of Emerson provides Fisher LP-Gas Equipment with the resources of a Global Technology Leader.

Domestic Regulators

Commercial/Industrial Regulators

Laboratory Tests Simulate Field Conditions

Commitment to the LP-Gas Industry

With a focus on Safety and Reliability, Fisher LP-Gas Equipment continues a tradition of delivering innovative, high performance products utilizing the latest technologies. From the development of the fi rst rubber diaphragm for regulators by Fisher in 1928 to the development of the fi rst true internal valve in 1959, we proudly continue this tradition by introducing our new line of Jet Bleed InternalTM Valves, as well as our expanded line of commercial service regulators, providing the broadest line of regulator products offered in the LP-Gas industry today.

Commitment to our Customers

In addition to continually developing improved products for our |

Bulk Storage and Transportation Equipment |

||

customers, we are active in promoting and supporting the industry. |

|

||

Through our role in world and national organizations, we continue to |

|

||

promote increased safety throughout the entire industry. |

|

||

|

|

|

|

|

|

|

|

TaBle of conTenTs

REGULATOR APPLICATION MAP . . . . . . . . . . . . . . . . . . . . . . . . . 2 VALVE APPLICATION MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 REGULATOR SELECTION GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . .6 VALVE SELECTION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 ACCESSORIES SELECTION GUIDE. . . . . . . . . . . . . . . . . . . . . . .16

RESIDENTIAL REGULATORS

TWO-STAGE SYSTEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

FIRST-STAGE REGULATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Types R122H and R622H

SECOND-STAGE REGULATORS. . . . . . . . . . . . . . . . . . . . . . . . . .25

Types HSRL, R222, R622, R642 and R652

Two–psi SERVICE REGULATORS . . . . . . . . . . . . . . . . . . . . . . . .26

Types R622E and R652E

INTEGRAL TWO-STAGE REGULATORS. . . . . . . . . . . . . . . . . . . .27

Types R232A and R632A

INTEGRAL TWO-PSI REGULATORS. . . . . . . . . . . . . . . . . . . . . . .28

Types R232E and R632E

AUTOMATIC CHANGEOVER REGULATORS . . . . . . . . . . . . . . . .29

Types 64SR, 749B, 803 and R130

COMMERCIAL REGULATORS

COMMERCIAL/INDUSTRIAL

HIGH-PRESSURE REGULATORS . . . . . . . . . . . . . . . . . . . . . . . . .30

Types 67CW, 67CH, 67CD, 67CN, 64, 64SR, 627, 630, 99 and 1098-EGR

COMMERCIAL LOW-PRESSURE

REGULATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36 to 37, 40

Types CS200, CS400, CS800, 133L, 133H, 299H and 99L

COMMERCIAL SERVICE OVERPRESSURE PROTECTION . . . .38

Types CS403, CS404 and CS803

MONITOR OVERPRESSURE PROTECTION . . . . . . . . . . . . . . . .41

Types 627M, 99M and 1098

BACKPRESSURE REGULATORS/RELIEF VALVES . . . . . . . . . . .42

Types 98H, 289H, 1805 and 1808

REGULATOR ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

INTERNAL VALVES

INTERNAL VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Types C404-32, C407-10, C471, C477, C483, C484 and C486 Types C804-32, C807-10, C871, C877, C883, C884, C897 and C891

INTERNAL VALVE ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . .59

P600 Series Brake Chamber Actuators

P700 Series Rotary Actuators

EMERGENCY SHUTOFF VALVES

EMERGENCY SHUTOFF VALVES . . . . . . . . . . . . . . . . . . . . . . . . .61

Types N550 and N562

Types N850 and N862

EXCESS FLOW VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Types F100, F130, F170, F190 and F202

RELIEF VALVES

INTERNAL/EXTERNAL/BULK PLANT RELIEF VALVES . . . 65 to 68

Types H110, H120, H123, H124, H125, H144, H148, H150,

H173, H174, H185, H284, H722, H733, H5114 and 63EGLP Series

GLOBE AND ANGLE VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Types N301, N310, N310F, N350, N401, N410, N410F and N450 Types N801, N810, N810F, N901, N910 and N910F

BACK CHECK VALVES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Types G100, G101, G102, G104, G105, G106, G107, G109, G112, G200 and G201

HOSE END, FILLER, AND LIQUID TRANSFER VALVES . . . . . . .71

Types D138, D139, D140, D141, M455, N456, N480 and N481

BYPASS AND BACKPRESSURE VALVES. . . . . . . . . . . . . . . . . . .72

Types N100, N110 and N120

LIQUID LEVEL INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Types J31, J402S, J403S, J415, J415-1 and J700

COUPLINGS AND ADAPTORS . . . . . . . . . . . . . . . . . . . . . . . . . . .75

M Series, Types P174 and P104-24

MISCELLANEOUS EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . .79 COMPLIANCE SYSTEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 CONVERSION FACTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81 INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Where applicable, Fisher® brand products presented in this catalog are listed by Underwriters Laboratories (UL®). Use of these products may provide compliance with standards developed by the National Fire Protection Association’s Pamphlets

54 and 58. They may also assist in meeting guidelines established by the Department of Transportation, ASME and other third party agencies. Contact your Fisher brand LP-Gas Regulators and Equipment Distributor for assistance in determining product applications.

R

MEMBER

NPGA

National PROPANE GAS Association

1

lP-gas RegulaToRs

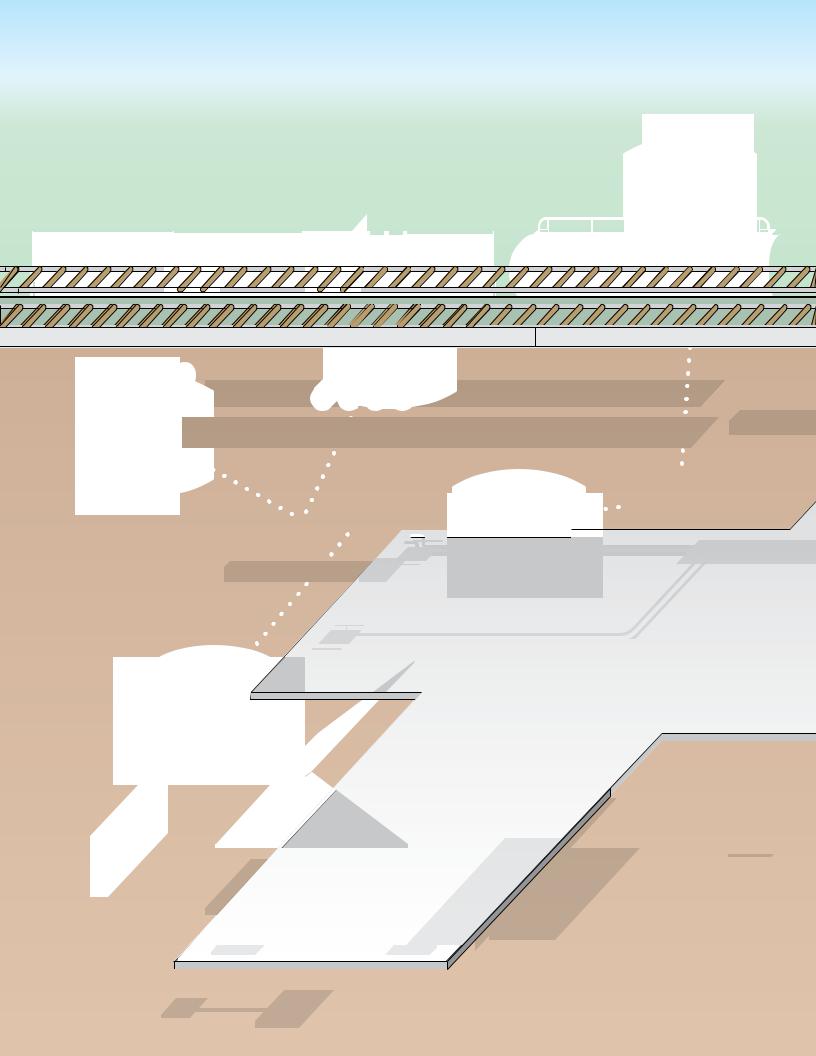

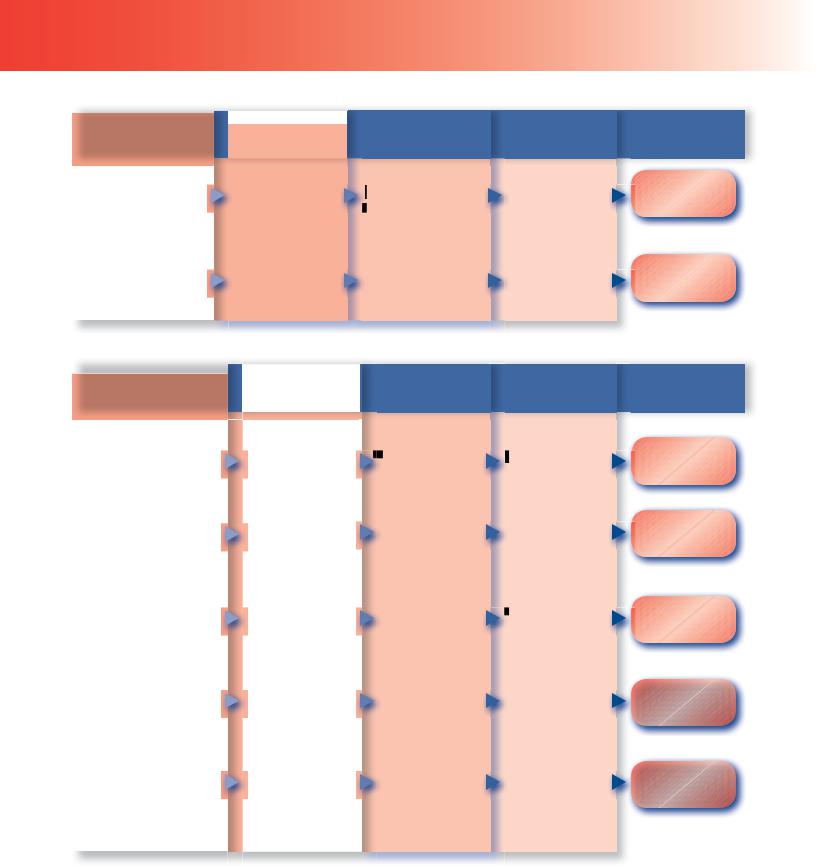

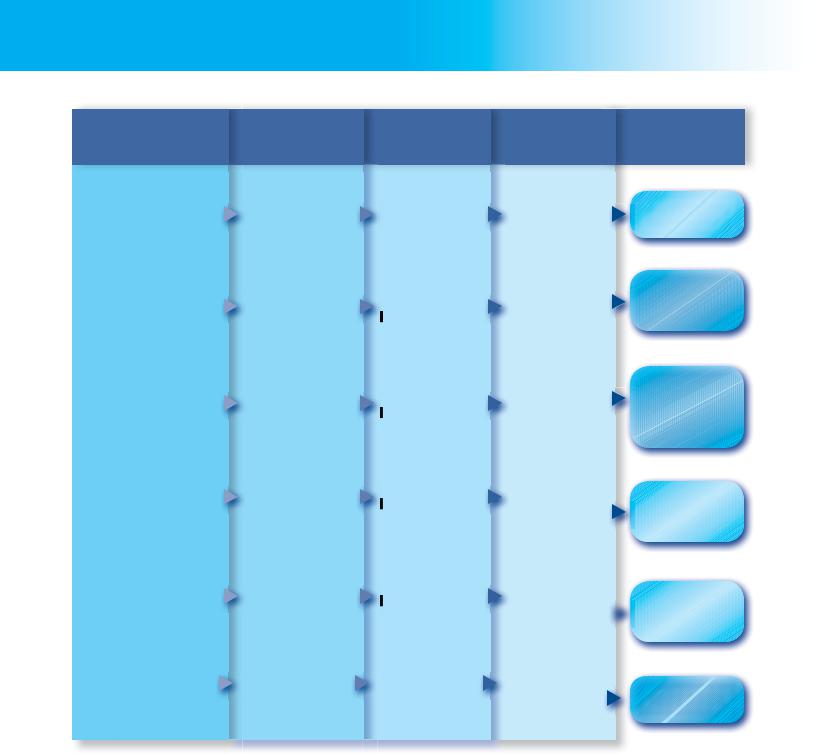

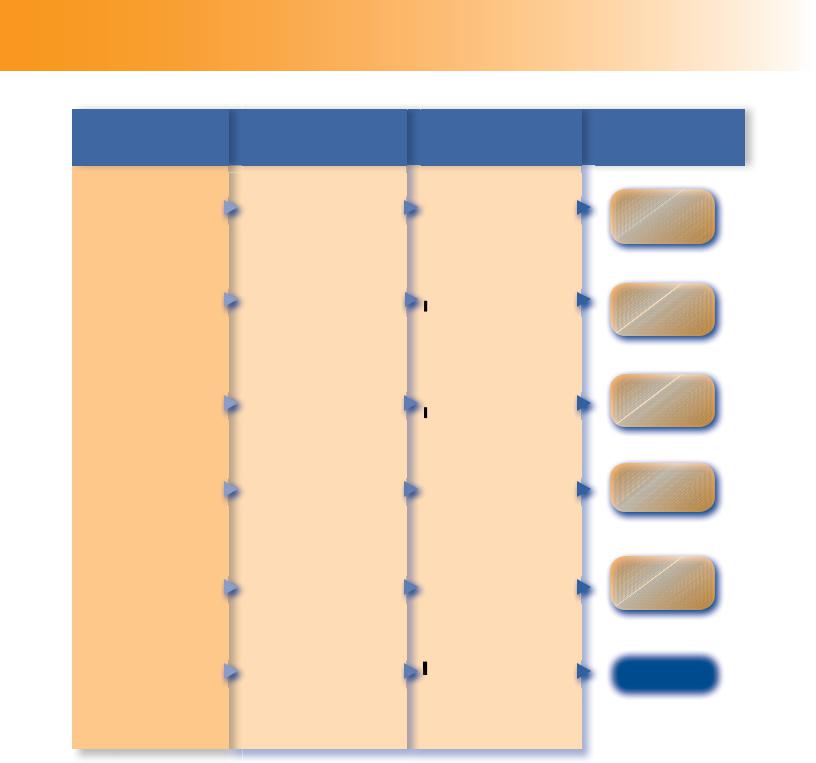

Application: Regulators

R622

Second-

Stage

67CW

High

Pressure

Introduction

The regulator truly is the heart of an LP-Gas installation. It must compensate for variations in tank pressure from 8 to 250 psig / 0.55 to

R62

Fir

Sta

Features*

•Corrosion-Resistant and Wear-Resistant Materials

|

• |

|

|

|

|

|

|

|

|

|

|

99 |

Stainless Steel Inlet Screen |

|

|

||||||||

• Large Drip-Lip Vent |

|

|

|

||||||||

High Pressure |

|

|

|||||||||

• |

High Capacity Relief |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

• |

Easy Installation |

|

|

|

|

|

|

|

|

|

|

• Improved Regulation |

|

|

|

|

|

|

|

|

|

|

|

• Built-in Gauge Taps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Features Vary By Model.

17.2 bar and deliver a constant outlet pressure of LP-Gas typically at 11 inches w.c. / 27 mbar

to consuming appliances. The regulator must deliver this pressure despite the intermittent use of the appliances.

In propane service, NFPA 58 requires Two-Stage regulation on all fi xed piping systems that serve

14 inches w.c. / 35 mbar appliance systems (normally operated at 11 inches w.c. / 27 mbar pressure). Two-Stage regulation produces a nearly

lP-gas RegulaToRs

constant pressure to the appliance and can result in a more effi cient LP-Gas operation for the dealer resulting in less maintenance and fewer installation call-backs.

With properly selected regulators, the internal relief valve provides 2 psig / 0.14 bar overpressure protection as required by NFPA 58.

Emerson Process Management Regulator Technologies Inc. (Regulator Technologies) is a

leading international supplier of cost-effective products, services and solutions used in the propane industry. Around the world, Regulator Technologies and its distributors offer quality products as well as applications engineering, education programs, and after sales service. For any of the products described in this catalog, contact the Fisher® LP-Gas Equipment distributor near you.

R232E |

R632A |

CS800 |

Joe™ |

|

|

ressure

ressure

CS403

Low Pressure

High

CS404

Low Pressure

1098

High Pressure

Fisher Regulator Color Code

First-Stage.......................................... |

Red |

Second-Stage..................................... |

Palm Green |

2-psi Service ...................................... |

White* |

Integral Two-Stage.............................. |

Gray |

Pounds to Pounds ............................... |

Red |

Industrial ............................................ |

Black or Gray |

*Types R622E and R652E are green with white closing caps

3

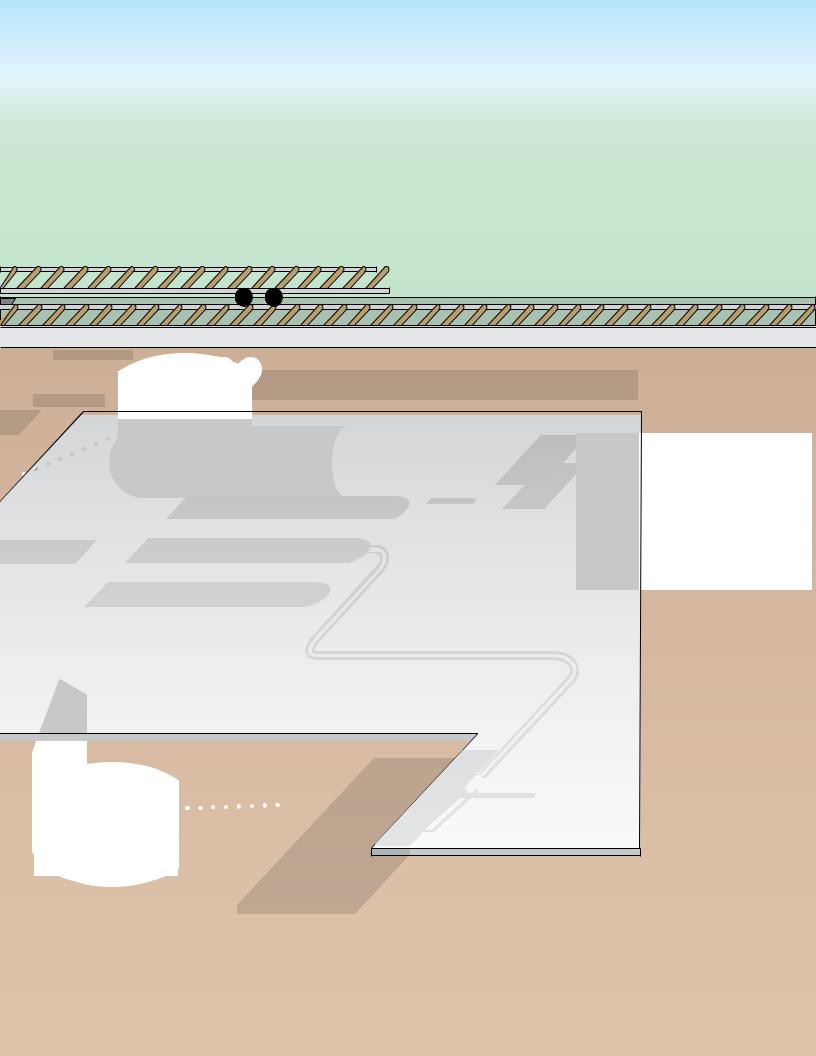

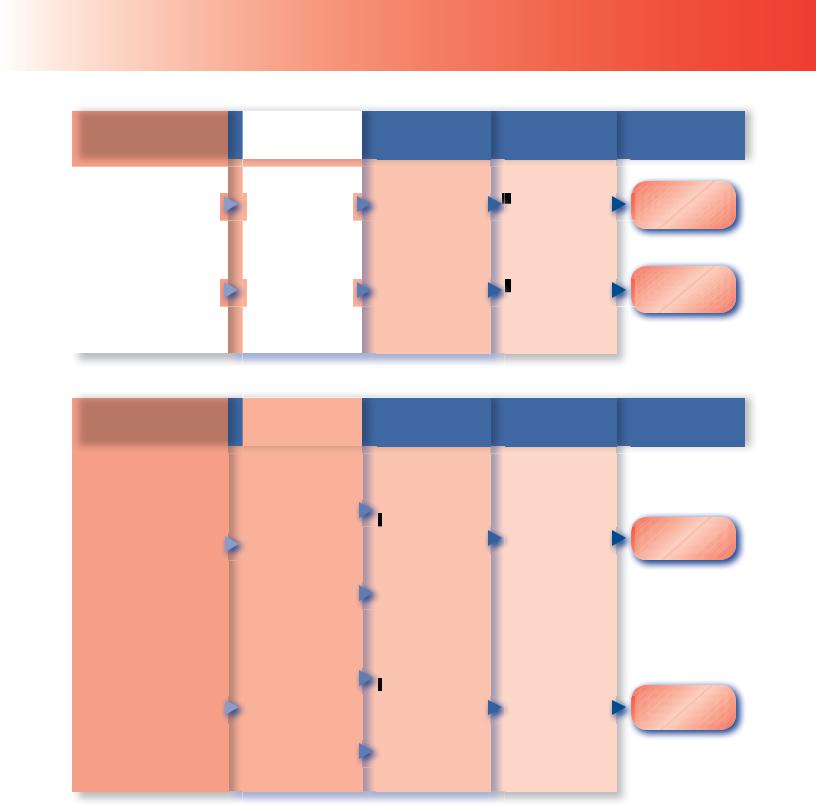

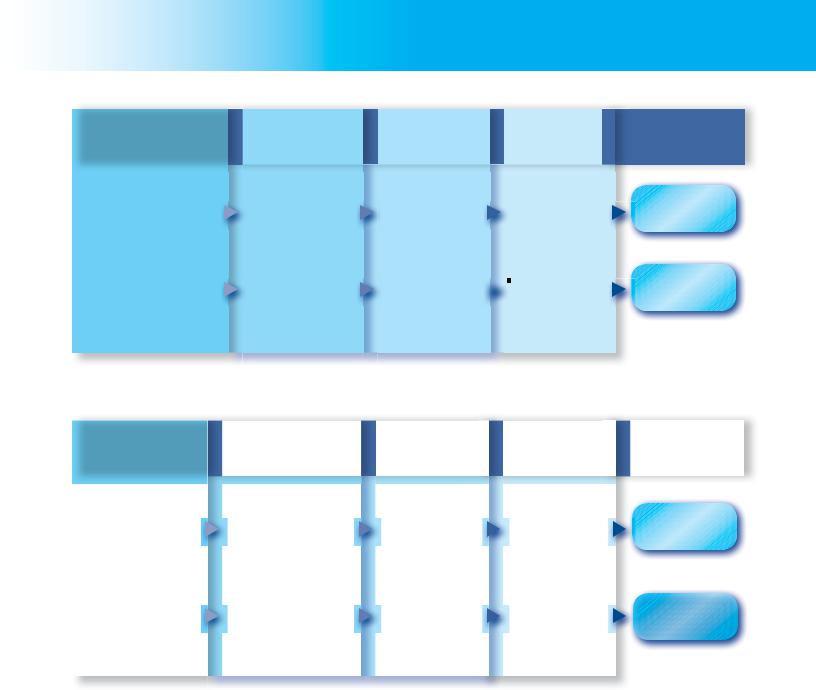

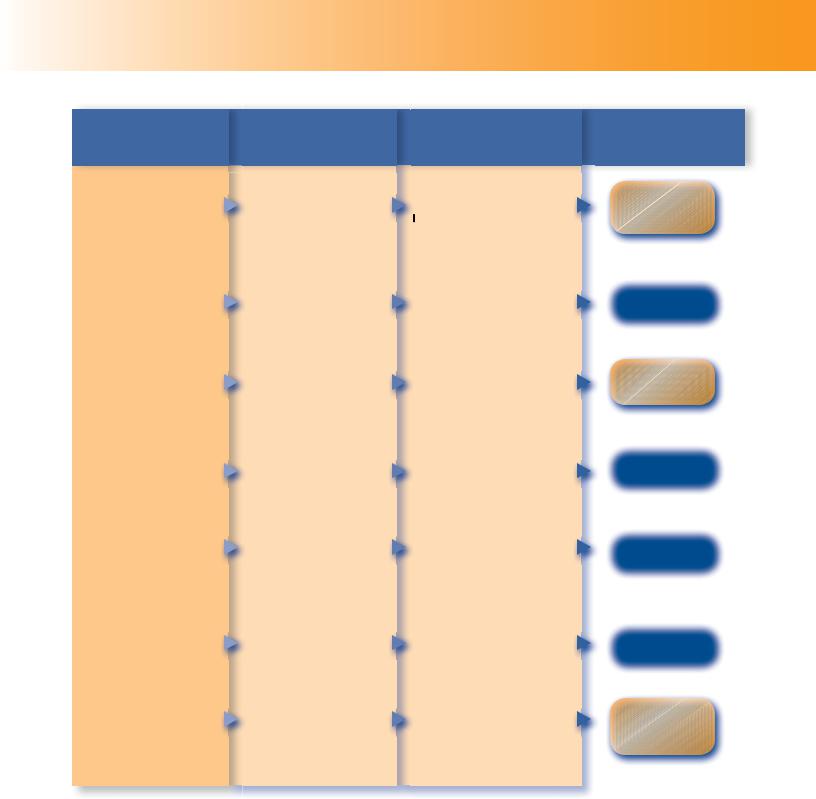

lP-gas ValVes

Application: Valves and Relief Valves

J

C484-24 |

et Bleed

et Bleed  ternal™ Valve

ternal™ Valve

-24

-24

P723

P723

otary

otary

uator

uator

N550 with P539A

Pneumatic Actuator

H722

Relief Valve

C407-10 with P731

Internal Valve with

Rotary Actuator

4

lP-gas ValVes

Introduction

Fisher® brand internal valves, relief valves, emergency shutoff valves and globe and angle valves are installed in the inlets and outlets (liquid or vapor) of pressure vessels and in piping systems to control the fl ow of LP-Gas and

Anhydrous Ammonia (NH3). These valves are frequently used on bobtails, transport truck tanks, large stationary storage tanks and in-line installations.

The valves provide a means of withdrawing and fi lling product with or without pumps and compressors. These valves may be used as primary shutoff valves, excess fl ow valves and back check valves. No one offers a more complete line of LP-Gas Equipment to match your job specifi cation.

N562 Emergency

Shutoff Valve

H733

Relief Valve

C404-32

Internal Valve

with P614A

Actuator

Features*

|

• Truck Relief Valves – |

|

|

|

All Stainless Steel Construction |

|

• |

High Flow Capacities |

|

• |

Positive Shutoff Valves |

N550 with P327D |

• |

Rugged Construction |

• |

Ease of Service |

|

Emergency Shutoff Valve |

• |

Wide Range of Products for |

|

|

Varying Applications |

|

*Features Vary By Model. |

|

N410-10

Angle

Valve

G201

Back Check Valve

N310-10

Globe

Valve

5

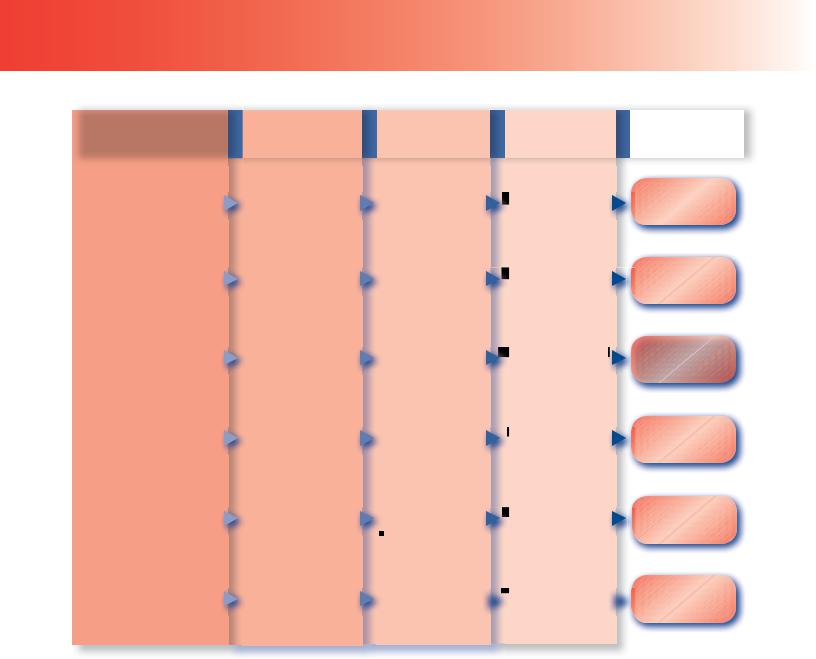

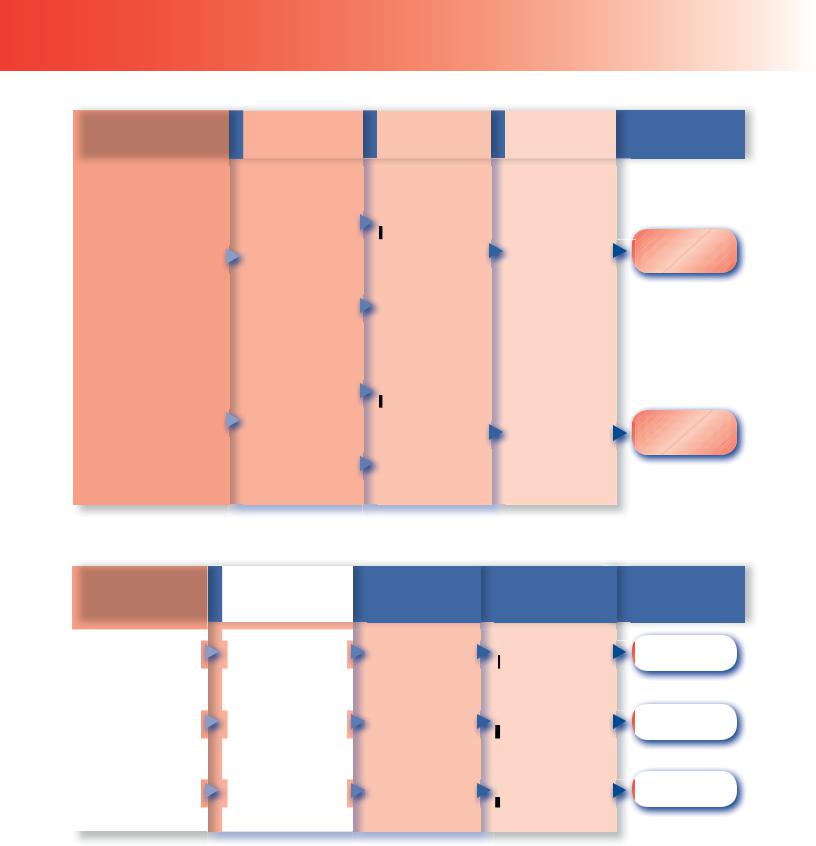

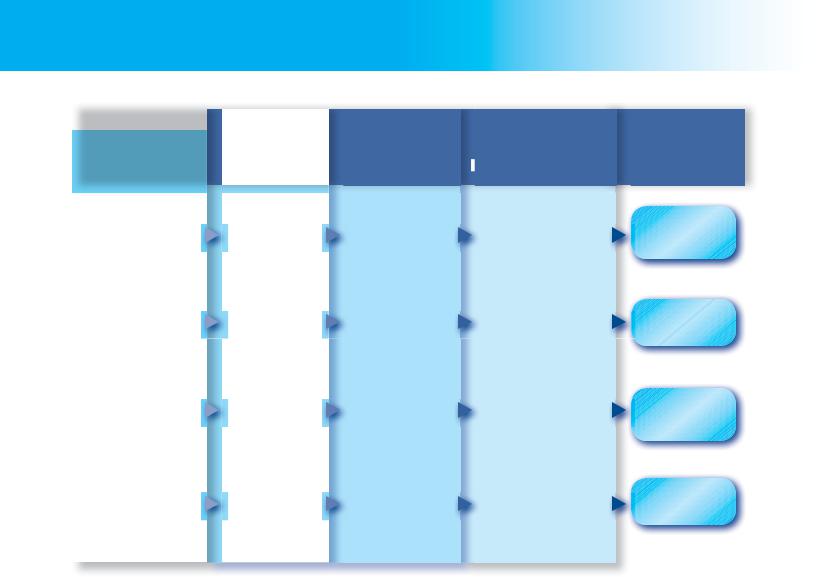

RegulaToRs QuicK selecTion guide

MAXIMUM INLET |

OUTLET |

RATED |

TYPE |

PRESSURE |

PRESSURE RANGE |

CAPACITY*(1) |

NUMBER |

|

250 psig / |

|

17.2 bar |

|

250 psig / |

|

17.2 bar |

|

250 psig / |

|

17.2 bar |

COMMERCIAL/ |

|

INDUSTRIAL |

250 psig / |

HIGH-PRESSURE |

|

REGULATORS |

17.2 bar |

|

300 psig / |

|

20.7 bar |

|

400 psig / |

|

27.6 bar |

3 to 120 psig /

0.21 to 8.3 bar

3 to 100 psig /

0.21 to 6.9 bar

5 to 40 psig /

0.35 to 2.8 bar

8 to 20 psig /

0.55 to 1.4 bar

7 inches w.c. to 65 psig /

17 mbar to 4.5 bar

3 to 100 psig /

0.21 to 6.9 bar

1.2M BTU per hour /

13.5 SCMH

5.25M BTU per hour /

59.1 SCMH

20.95M BTU per hour /

235 SCMH

14M BTU per hour /

158 SCMH

74.3M BTU per hour /

836 SCMH

1.2B BTU per hour /  13,481 SCMH

13,481 SCMH

67C Series

Page 30

64 Series

Page 31

627 Series

Page 32

630 Series

Page 32

99 Series

Page 34

1098 Series

Page 35

*See capacity tables in the following sections for expanded rating information.

1.Based on inlet pressure 20 psig / 1.4 bar greater than outlet with 20% droop, unless otherwise noted.

2.Based on 2000 psig / 138 bar inlet pressure setting.

6

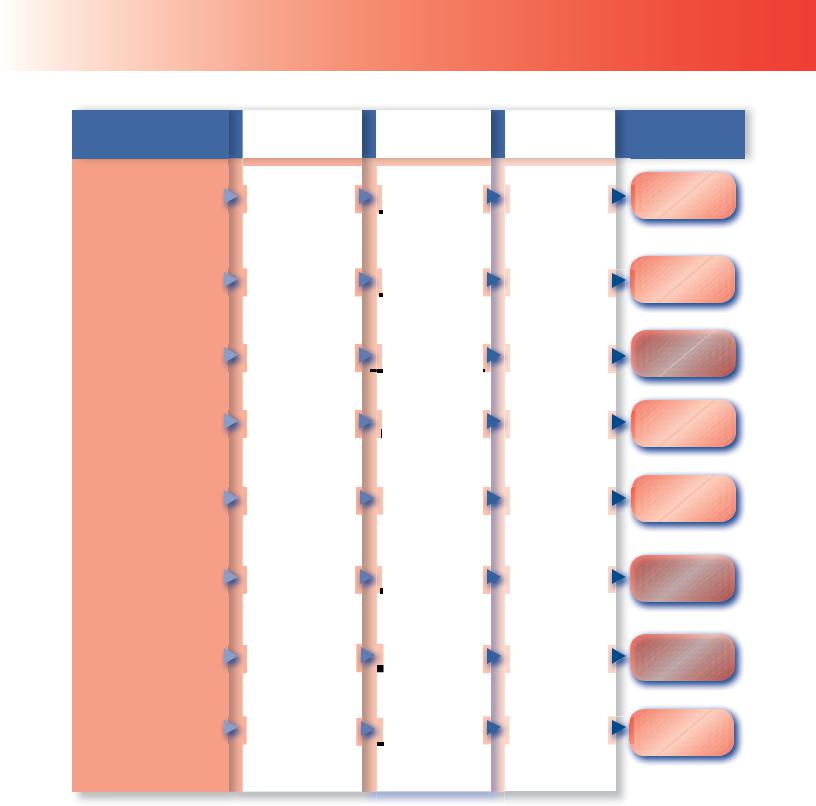

RegulaToRs QuicK selecTion guide

COMMERCIAL/ INDUSTRIAL LOW-PRESSURE REGULATORS

MAXIMUM INLET |

OUTLET |

RATED |

|

PRESSURE |

PRESSURE RANGE |

CAPACITY*(1) |

|

125 psig / |

3.5 inches w.c. |

3.9M BTU per hour / |

|

to 2 psig / |

|||

8.6 bar |

43.8 SCMH(3) |

||

|

9 mbar to 0.14 bar |

|

|

125 psig / |

3.5 inches w.c. |

8.9M BTU per hour / |

|

to 5.5 psig / |

|||

8.6 bar |

100 SCMH(2) |

||

|

9 mbar to 0.38 bar |

|

|

125 psig / |

8 inches w.c |

20M BTU per hour/ |

|

to 5.5 psig / |

|||

8.6 bar |

224 SCMH |

||

20 mbar to 0.38 bar |

|||

|

|

||

60 psig / |

1.5 to 3 psig / |

66.15M BTU per hour / |

|

4.1 bar |

0.10 to 0.21 bar |

745 SCMH(2) |

|

|

8.5 to |

70.8M BTU per hour / |

|

60 psig / |

18 inches w.c. / |

||

797 SCMH(3) |

|||

4.1 bar |

21 to 45 mbar |

||

|

|||

|

9 inches w.c. |

38M BTU per hour / |

|

150 psig / |

to 16 psig / |

||

428 SCMH |

|||

10.3 bar |

22 mbar to 1.1 bar |

||

|

|||

|

7 inches w.c. |

63.25M BTU per hour/ |

|

150 psig / |

to 5 psig / |

||

712 SCMH |

|||

10.3 bar |

18 mbar to 0.35 bar |

||

|

|||

|

3 inches w.c. |

556,000 |

|

|

BTU per hour / |

||

250 psig / |

to 5 psig / |

||

6.2 SCMH(4) |

|||

17.2 bar |

7 mbar to 0.35 bar |

|

|

|

|

|

TYPE

NUMBER

CS200 Series

Page 36

CS400 Series

Page 36

CS800 Series

Page 36

Type 133H

Page 40

Type 133L

Page 40

299H Series

Page 40

99-500P Series

Page 40

912 Series

Page 43

*See capacity tables in the following sections for expanded rating information.

1.Based on inlet pressure 20 psig / 1.4 bar greater than outlet with 20% droop, unless otherwise noted.

2.Based on 10 psig / 0.69 bar inlet pressure setting and 20% droop.

3.Based on 10 psig / 0.69 bar inlet pressure setting and 2-inches w.c. / 5 mbar droop.

4.Types 912-101 and -104 rating at 30 psig / 2.1 bar inlet.

7

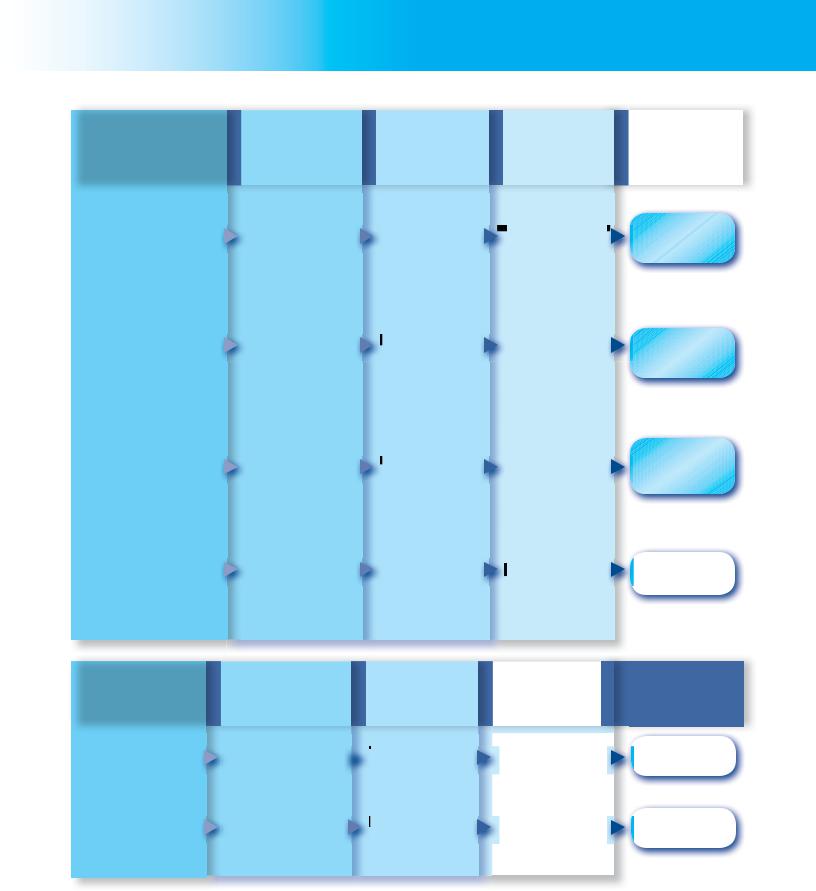

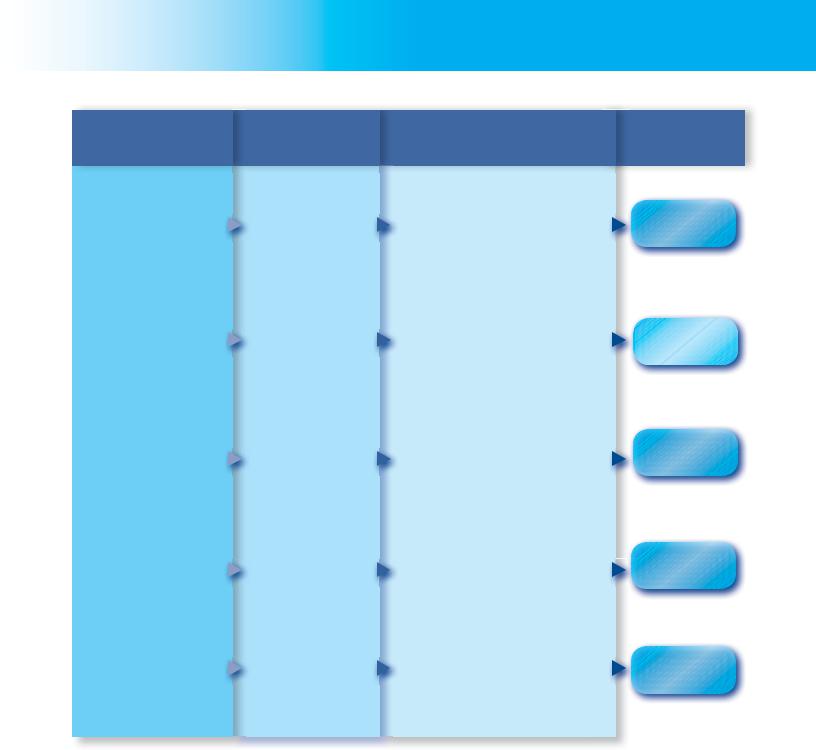

RegulaToRs QuicK selecTion guide

|

MAXIMUM INLET |

OUTLET PRESSURE |

|

PRESSURE |

SETTING/SETPOINTS |

|

|

10 psig / 0.69 bar |

|

250 psig / |

|

|

17.2 bar |

+/- 1 psig / 69 mbar |

|

|

nominal outlet setting |

FIRST-STAGE |

|

(non-adjustable) |

REGULATORS |

|

|

|

250 psig / |

5 or 10 psig / |

|

17.2 bar |

0.35 or 0.69 bar |

|

|

standard setpoints |

|

|

|

|

MAXIMUM INLET |

STANDARD |

|

|

PRESSURE |

SETPOINT |

|

|

|

|

|

|

10 psig / |

9 to 13 inches w.c. / |

|

|

0.69 bar |

||

|

22 to 32 mbar |

||

|

|

||

|

10 psig / |

11 inches w.c. / |

|

|

0.69 bar |

||

|

27 mbar |

||

|

|

||

SECOND-STAGE |

10 psig / |

11 inches w.c. / |

|

REGULATORS(3) |

0.69 bar |

||

27 mbar |

|||

|

10 psig / |

11 inches w.c. / |

|

|

0.69 bar |

27 mbar |

|

|

10 psig / |

11 inches w.c. / |

|

|

0.69 bar |

||

|

27 mbar |

||

|

|

||

|

|

|

RATED

CAPACITY*(1)

1.1M BTU per hour /

12.4 SCMH

2.4M BTU per hour /

27.0 SCMH

RATED

CAPACITY*(2)

2.6M BTU per hour /

29.3 SCMH

650,000 BTU per hour / 7.3 SCMH

1.4M BTU per hour /

15.8 SCMH

920,000 BTU per hour/ 10.4 SCMH

1M BTU per hour /

11.2 SCMH

TYPE

NUMBER

R122H Series

Page 24

R622H Series

Page 24

TYPE

NUMBER

Type HSRL

Page 25

R222 Series

Page 25

R622 Series

Page 25

R642 Series

Page 25

R652 Series

Page 25

*See capacity tables in the following sections for expanded rating information.

1.Based on 30 psig / 2.1 bar inlet pressure and 20% droop.

2.Based on 10 psig / 0.69 bar inlet pressure setting.

3.Second-Stage regulators are UL® rated.

8

RegulaToRs QuicK selecTion guide

|

MAXIMUM INLET |

STANDARD |

|

PRESSURE |

SETPOINT |

|

|

|

|

10 psig / |

2 psi / |

|

0.69 bar |

0.14 bar |

2-PSI SERVICE |

|

|

REGULATORS |

|

|

|

10 psig / |

2 psi / |

|

0.69 bar |

0.14 bar |

|

|

|

MAXIMUM INLET |

STANDARD |

PRESSURE |

SETPOINT |

|

|

INTEGRAL TWO-STAGE REGULATORS

First-Stage:

Approximately 10 psig / 0.69 bar

250 psig / (non-adjustable)

17.2 bar

Second-Stage:

11 inches w.c. /

27 mbar

First-Stage:

Approximately 10 psig / 0.69 bar

250 psig / (non-adjustable)

17.2 bar

Second-Stage:

11 inches w.c. / 27 mbar

RATED

CAPACITY*(1)

1 68M BTU per hour /

18.9 SCMH

.5M BTU per hour /

16.9 SCMH

RATED

CAPACITY*(2)

550,000 BTU per hour / 6.2 SCMH

950,000 BTU per hour / 10.7 SCMH

TYPE

NUMBER

R622E Series

Page 26

R652E Series

Page 26

TYPE

NUMBER

R232A Series

Page 27

R632A Series

Page 27

*See capacity tables in the following sections for expanded rating information.

1.Based on 10 psig / 0.69 bar inlet pressure setting and 20% droop.

2.Based on 30 psig / 2.1 bar inlet pressure setting and 2 inches w.c. / 5 mbar droop.

9

RegulaToRs QuicK selecTion guide

MAXIMUM INLET |

STANDARD |

RATED |

PRESSURE |

SETPOINT |

CAPACITY*(3) |

250 psig /

17.2 bar

INTEGRAL TWO-PSIG

REGULATORS

250 psig /

17.2 bar

|

MAXIMUM WORKING |

|

PRESSURE |

|

|

|

300 psig / |

|

20.7 bar |

BACKPRESSURE |

25 psig / |

REGULATORS/ |

|

RELIEF VALVES |

1.7 bar |

|

|

|

150 psig / |

|

10.3 bar |

|

|

First-Stage:

Approximately 10 psig / 0.69 bar (non-adjustable)

Second-Stage:

2 psi / 0.14 bar

First-Stage:

Approximately 10 psig / 0.69 bar (non-adjustable)

Second-Stage:

2 psi / 0.14 bar

RELIEF PRESSURE

SETTING

500,000 BTU per hour / 5.6 SCMH

900,000 BTU per hour / 10.1 SCMH

RELIEF

CAPACITY*

100 psig / |

93.1 GPM / |

6.9 bar |

352 l/min Propane |

15 psig / |

20,000 SCFH / |

1.0 bar |

566 SCMH Propane |

30 psig / |

12,000 SCFH / |

2.1 bar |

340 SCMH Propane |

TYPE

NUMBER

R232E Series

Page 28

R632E Series

Page 28

TYPE

NUMBER

Type 98H

Page 42

Type 289H

Page 42

Type 1805

Page 42

*See capacity tables in the following sections for expanded rating information. 3. Based on 30 psig / 2.1 bar inlet pressure setting and 20% droop.

10

ValVes and Relief ValVes QuicK selecTion guides

|

MAXIMUM INLET |

STANDARD |

CAPACITY* |

|

TYPE |

|

PRESSURE |

|

|||

|

SETPOINTS |

|

NUMBER |

||

|

(BODY RATING) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

INTERNAL/EXTERNAL

RELIEF VALVES

480 psig / |

|

|

85 to 375 psig / |

Up to 47,164 SCFM / |

|

||||

33.1 bar |

|

|

5.9 to 26 bar |

84,170 SCMH |

|

|

|

|

UL: Up to |

|

|

|

|

11,635 SCFM / |

480 psig / |

125 to 312 psig / |

20,764 SCMH Air |

||

33.1 bar |

|

|

8.6 to 21.5 bar |

ASME: Up to |

|

|

|

|

15,286 SCFM / |

|

|

|

|

18,097 SCMH Air |

|

|

|

|

UL: |

|

|

|

|

Up to 11,315 SCFM / |

480 psig / |

125 to 312 psig / |

19,940 SCMH Air |

||

33.1 bar |

|

|

8.6 to 21.5 bar |

ASME: |

|

|

|

|

Up to 13,876 SCFM / |

|

|

|

|

16,400 SCMH Air |

Type 63EGLP

Page 67

H282 and

H5112 Series

Page 66

H722 and

H733 Series

Page 65

420 psig / |

35 to 350 psig / |

|

2.4 to 23.8 bar |

||

29.0 bar |

||

Fixed Setting |

||

|

|

MAXIMUM WORKING |

DIFFERENTIAL / |

|

RELIEF PRESSURE |

|

|

PRESSURE |

|

|

SETTING |

|

|

|

|

|

|

|

|

300 psig / |

BYPASS AND |

20.7 bar |

|

|

BACKPRESSURE |

|

VALVES |

400 psig / |

|

|

|

27.6 bar |

50 psig / 0.83 bar  or 100 psig /

or 100 psig /

6.9 bar Setting

12 psig / 0.83 bar Setting

Up to 2456 SCFM / |

H-100 Series |

4173 SCMH |

|

|

Page 68 |

BODY SIZE AND END |

TYPE |

|

CONNECTION STYLE |

NUMBER |

|

|

|

|

1/2, 3/4, and |

98 Series |

|

1-inch FNPT |

||

|

||

|

Page 42 |

|

3/4 and |

N120 Series |

|

1-inch FNPT |

||

|

||

|

Page 73 |

|

|

|

*See capacity tables in the following sections for expanded rating information.

11

ValVes and Relief ValVes QuicK selecTion guides

PRESSURE

RATING

400 psig /

27.6 bar WOG

400 psig /

27.6 bar WOG

400 psig /

27.6 bar WOG

INTERNAL

VALVES

400 psig /

27.6 bar WOG

400 psig /

27.6 bar WOG

400 psig /

27.6 bar

EXCESS FLOW

SPRING

30 to 80 GPM /

113 to 302 l/min

60 to 460 GPM /

227 to 1741 l/min

100 to 460 GPM /

379 to 1741 l/min

160 to 400 GPM /

606 to 1514 l/min

160 to 400 GPM /

606 to 1514 l/min

340 to 1000 GPM /

1287 to

3785 l/min

TYPE CAPACITY* NUMBER

19,200 SCFH /

544 SCMH

Propane

178,000 SCFH /

5040 SCMH

Propane

178,000 SCFH /

5040 SCMH

Propane

190,000 SCFH /

5380 SCMH

Propane

190,000 SCFH /

5380 SCMH

Propane

356,200 SCFH /

10,088 SCMH

C407-10 Series

Page 46

C471-16, -24

Jet Bleed

Internal™ Series

Page 46

C477-16, -24 and

C486-24

Jet Bleed Internal™

Series

Page 46

C483-24

Jet Bleed Internal™

Series

Page 52

C484-24

Jet Bleed Internal™

Jet Bleed Internal™

Series

Page 52

Type C404-32

Page 54

*See capacity tables in the following sections for expanded rating information.

12

ValVes and Relief ValVes QuicK selecTion guides

|

SEAT |

PRESSURE |

CAPACITY* |

|

CONSTRUCTION |

RATING |

|

|

|

||

|

|

|

|

Soft Seat and |

250 psi / |

Metal Seat |

17.2 bar |

BACK CHECK |

|

|

VALVES |

|

400 psig / |

|

Soft Seat |

|

|

27.6 bar WOG |

|

|

|

254 GPM /

961 l/min Propane

Up to 1620 GPM /  6132 l/min

6132 l/min

Propane

TYPE

NUMBER

G100 Series

Page 70

G200 Series

Page 70

|

BODY SIZES AND END |

MAXIMUM INLET |

|

CAPACITY* |

|

TYPE |

|

CONNECTION STYLE |

PRESSURE |

|

|

NUMBER |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

1-1/4, 2, or |

400 psig / |

|

up to 850 GPM / |

N550 Series |

|

|

3-inch FNPT |

27.6 bar |

|

3127 l/min |

||

|

|

|

||||

EMERGENCY |

|

|

|

Propane |

Page 61 |

|

SHUTOFF VALVES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 psig / |

|

200 GPM / |

|

|

|

2-inch FNPT |

|

757 l/min |

N562 Series |

||

|

27.6 bar |

|

||||

|

|

|

Propane |

|

||

|

|

|

|

|

||

|

|

|

|

|

|

Page 63 |

|

|

|

|

|

|

|

*See capacity tables in the following sections for expanded rating information.

13

ValVes and Relief ValVes QuicK selecTion guides

|

SELECTION |

MAXIMUM |

|

OPERATING |

|

|

DESCRIPTION |

|

|

PRESSURE |

|

|

|

|

|

|

|

|

Globe Valve |

400 psig / |

|

(Heavy Duty |

27.6 bar |

|

Version) |

|

|

Globe Valve |

400 psig / |

|

(Economy |

|

|

27.6 bar |

|

|

Version) |

|

GLOBE AND |

|

|

|

|

|

ANGLE VALVES |

|

|

|

Angle Valve |

400 psig / |

|

(Heavy Duty |

|

|

27.6 bar |

|

|

Version) |

|

|

|

|

|

Angle Valve |

400 psig / |

|

(Heavy Duty |

|

|

27.6 bar |

|

|

Version) |

|

|

|

|

|

|

|

BODY SIZES

AND END

CONNECTION STYLES

1/2 to 3-inch FNPT

and 3-inch / DN 80 CL300 RF Flange

1/2 to 3/4-inch FNPT

1/2 to 3-inch FNPT and 3-inch / DN 80 CL300 RF Flanged

1/2 to 3/4-inch FNPT

TYPE

NUMBER

N301, N310

Series

Page 69

N350 Series

Page 69

N401,

N410 Series

Page 69

N450 Series

Page 69

*See capacity tables in the following sections for expanded rating information.

14

ValVes and Relief ValVes QuicK selecTion guides

PRODUCT/

FUNCTION

Excess Flow Valve

Filler Valve

VALVES

Hose End Valve

Bypass Valves

Cylinder Filling Valve

SELECTION

INFORMATION

Brass or Steel body in a variety of Inlet and Outlet Connection Sizes and Styles; Up to 10.7 psi / 0.74 bar differential pressure

2-inch MNPT x 2-1/4-inch ACME or 3-inch MNPT x 3-1/4-inch ACME; Single or Double Back Check style; 275 GPM / 1041 l/min filling capacity

1-3/4-inch ACME x 1-inch NPT;

Ductile iron body

1 through 2-1/2-inch FNPT; 25 to 150 psig / 1.7 to 10.3 bar Pressure range; 40 GPM / 151 l/min pumping capacity

30 psig / 2.1 bar Recommended Supply Pressure; Aluminum Body

TYPE

NUMBER

F Series

Page 64

D Series

Page 71

Type N480

Page 71

N100 Series

Page 72

Type N201

Page 79

*See capacity tables in the following sections for expanded rating information.

15

lP-gas eQuiPMenT and accessoRies

|

PRODUCT/ |

SELECTION |

TYPE |

|

FUNCTION |

INFORMATION |

NUMBER |

|

|

|

|

|

Screened Vents for |

1/4-Inch FNPT to |

Y602 Series |

|

Regulator |

1-Inch MNPT |

|

|

|

|

Page 43 |

|

Regulator Mounting |

Triangular, Bowtie, |

Type P100 |

|

or Strap Design |

||

|

Brackets |

|

|

|

|

|

|

|

|

|

Page 44 |

|

Test Pressure Gauge for |

1/4-Inch NPT or |

50 Series |

|

Appliance Line Pressure |

Female Hose |

|

|

|

||

REGULATOR |

|

|

Page 44 |

ACCESSORIES |

|

1/4-Inch MNPT; |

|

|

Pressure Gauge |

|

|

|

to 400 psi / 0 to 27.6 bar; |

J500 Series |

|

|

|

||

|

|

Ranges in |

|

|

|

MPa, kg/cm2, Bar |

Page 45 |

|

Adjustable Orifice |

Drill Size No. 80 |

Type P520L |

|

Reamer |

||

|

through No. 50 |

||

|

|

|

|

|

|

|

Page 79 |

|

|

|

|

16

lP-gas eQuiPMenT and accessoRies

BULK STORAGE TANK AND VALVE ACCESSORIES

PRODUCT/

FUNCTION

Liquid Transfer Valve

Rotary Level Gauge for Stational or Mobile Tank

Liquid Level Vent Valves

Container (Tank)

Thermometer

Female ACME

Filler Couplings

Female ACME Vapor

Return Couplings

SELECTION

INFORMATION

3/4 by 3/4-Inch MNPT

68 to 140-Inch /

1727 to 3556 mm Lengths

3/4-Inch MNPT for FNPT Connection; with or without Pressure Gauge

1/2-Inch MNPT; -40 to 120°F / -40 to 49°C

1-3/4-Inch Female ACME by 1/2-Inch MNPT through 4-1/4-Inch Female ACME by 3-Inch MNPT

1-3/4-Inch Female ACME by 3/4-Inch MNPT through 2-1/4-Inch Female ACME by 1-1/4-Inch MNPT

TYPE

NUMBER

Type M455

Page 71

Type J31

Page 74

J400 Series

Page 74

J700 Series

Page 74

Type M631

Page 75

Types M151,

M160

Page 75

17

lP-gas eQuiPMenT and accessoRies

PRODUCT/

FUNCTION

O-ring for Male

Adaptors

Adaptor Caps

BULK STORAGE |

|

TANK AND VALVE |

|

ACCESSORIES |

POL Filler Coupling |

|

Filler Valve Adaptor

SELECTION

INFORMATION

For 2-1/4 or 3-1/4-Inch Adaptors to Give a Better Seal than Washers

2-1/4 through 4-1/4-Inch Female ACME by

1-3/4 through 3-1/4-Inch Male ACME

Soft-Nose Male POL by 1/4-Inch MNPT

For Filler Valves with 1-3/4-Inch Male ACME Filler Connection and a 3/4-Inch FNPT Outlet

TYPE

NUMBER

T12655T0012 / 1H291706562

Page 75

Type M611

Page 75

Type M390

Page 75

Type M450A

Page 76

18

lP-gas eQuiPMenT and accessoRies

BULK STORAGE TANK AND VALVE ACCESSORIES

PRODUCT/ |

SELECTION |

FUNCTION |

INFORMATION |

|

|

Swivel POL Adaptor

with Metal Seats

Auxiliary Remote Cable Release for Internal Valves

Handleor Cable-Operated  Latch/Remote Release for

Latch/Remote Release for

Internal Valves

Primary Cable Control

for Internal Valves

Cable Control, Release Mechanism, and Cable Assembly for Internal Valves

Relief Valve Pipeaway

Adaptors for DOT

Filler Hose Adaptor with Back Check Valve

Straight or Angle Male

POL by 1/4-Inch MNPT

With 25 or 50-Feet / 7.6 or 15.2 m Cable or without Cable

Built-In Fusible Link

to Close Valve in

Case of Fire

4, 5, or 6-Inch / 102, 137 or 152 mm Travel

For 1-1/4, 2, 3 and 4-Inch /  DN 32, 50, 80 and 100

DN 32, 50, 80 and 100

Internal Valves

For Use with Types H282, H5112, H125, H150, H148 and H173 Valves

1-3/4-Inch Female ACME by 1-3/4-Inch Male ACME

TYPE

NUMBER

Type M318

Type P163A

Page 59

Type P313

Page 59

Type P650

Page 59

Type P314

Page 59

Types P104-24,

P174

Page 66

Type M570

Page 76

19

lP-gas eQuiPMenT and accessoRies

BULK STORAGE TANK AND VALVE ACCESSORIES

PRODUCT/

FUNCTION

Pneumatic Actuator

Pneumatic Actuator

Pneumatic Actuator

Pneumatic Actuator

Pneumatic Actuator

Pneumatic Actuator

SELECTION

INFORMATION

For Use with

C407-10 Series Only

For Type C484-24

Jet Bleed Internal™ Valve

For Type C483-24

Jet Bleed Internal™ Valve

For Types C471 and

C477 Jet Bleed

Internal™ Valves

(2 and 3-Inch NPT Sizes)

For Type C404-32

4-Inch / DN 100 Single

Flanged Valve

For Closing and Opening of

N550 Series Snappy Joe™

Emergency Shutoff

Valves (ESVs)

TYPE

NUMBER

Types P389

and P731

Page 60

Types P613

and P713

Page 60

Types P623

and P723

Page 60

Types P639

and P739

Page 60

Types P614A

and P714

Page 60

Type P539A

Page 61

20

lP-gas eQuiPMenT and accessoRies

BULK STORAGE TANK AND VALVE ACCESSORIES

PRODUCT/

FUNCTION

Fuse Plug

Protective Caps for Relief Valves

Seals and Plugs for Female ACME Threads

Female ACME Caps

Clamp Hose Couplings

Spanner Wrench for Large Female ACME Caps and Couplings

Ring and Chain

Assemblies

SELECTION

INFORMATION

208 to 220°F /

98 to 104°C Melting Temperature, Available in 1/8 and 1/4-inch MNPT Sizes

For Types H110 through

H174 Valves

1-1/4 to 4-1/4-Inch Male ACME

Hand or Wrench

Installation

Swivel or Standard: 1/2-Inch MNPT through 4-1/4-Inch Female ACME for 1/2 through 3-Inch Hose

For Use with 2-1/4 through 4-1/4-Inch ACME Threads

For 1-1/4 through 4-1/4-Inch ACME Caps or Dust Seals

TYPE

NUMBER

T1140399982/

T1033699982

Page 60

Type P206

Page 68

Types M178,

M535-34

Page 76

Type M108

Page 77

Type M3162

Page 78

Type P120B

Page 79

Types P147,

P167, and P183

Page 78

21

RealWorldConditions

Demand Fisher® Solutions

TYPE R232A |

TYPE R632A |

TYPE R232E |

TYPE R632E |

• FlowTestedat-40°F for Functional Performance |

• NewFull-Size2-psigModel |

• Designed to Resist Gas Impurities |

• NewCompact2-psigModel—an Industry First |

Therealworldisn’talwaysreliable.Fortunately,Fisheris. Thenew2-psigoutletmodels,TypeR632Eandtheindustry’s first 2-psig compact regulator-Type R232E, utilize a specially formulated double-diaphragm design for enhanced flow capacity at -40°F and provide greater resistance to gas impurities. The enhanced double-diaphragm design is implemented on the original integral two-stage regulators as well, creating the new and improved Types R632A and R232A regulators. With Fisher, you get real solutions and reliable performance, every time.

www.fisherregulators.com

22

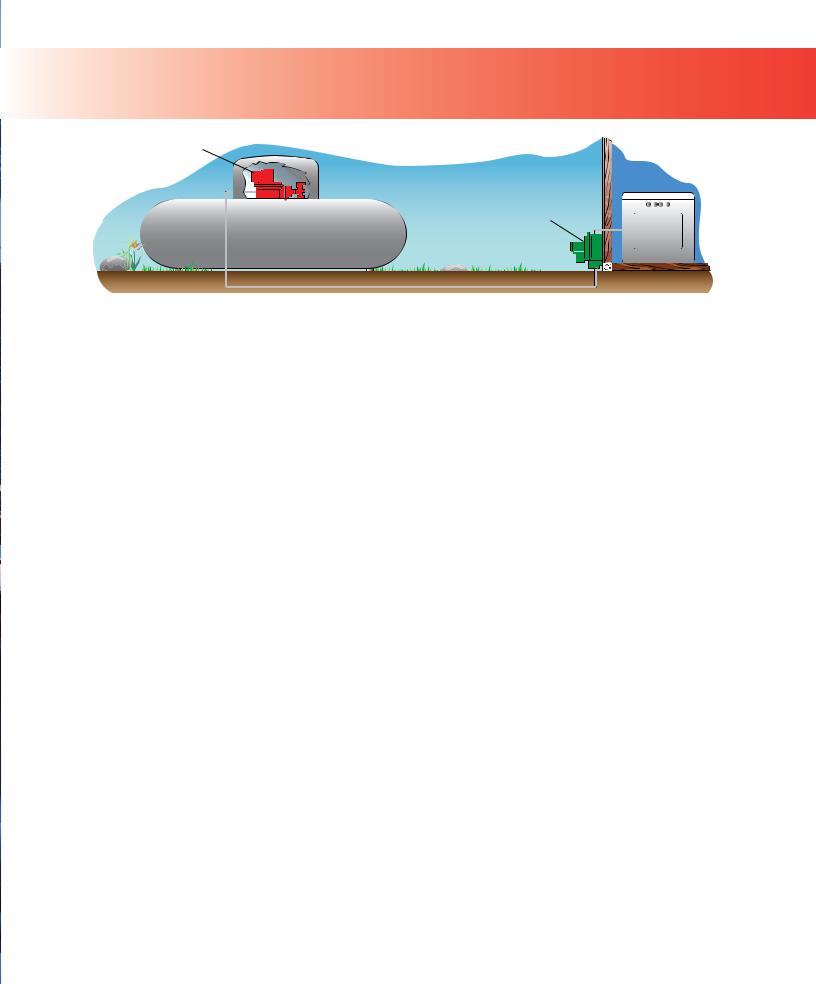

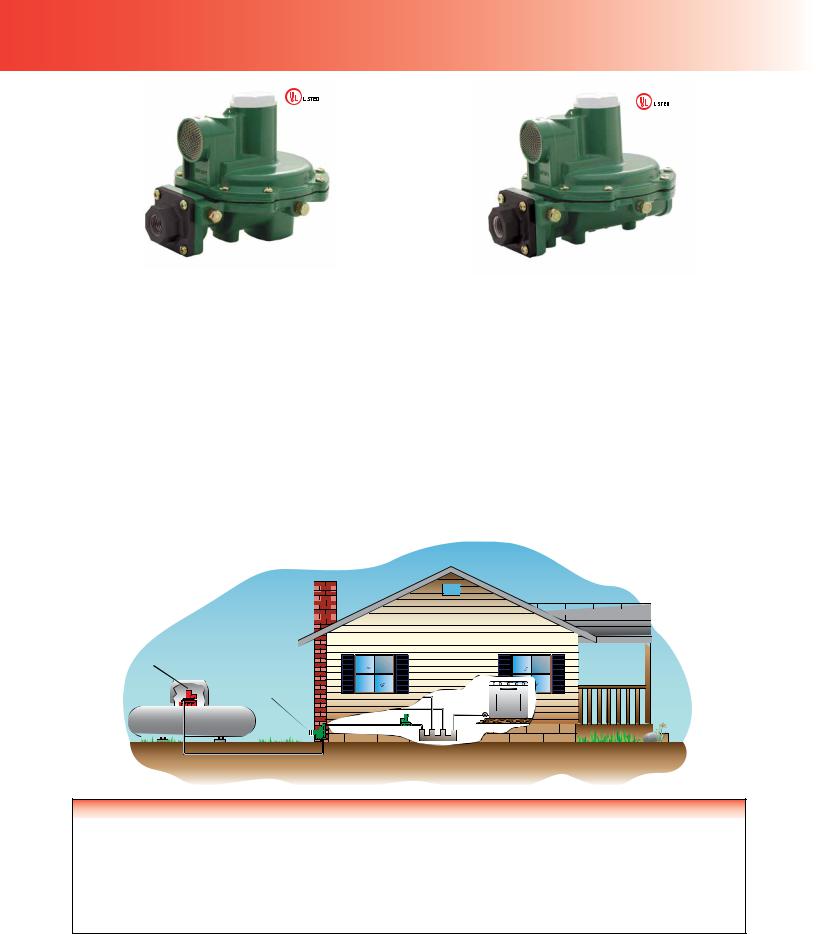

TWo-sTage sYsTeM

FIRST–STAGE REGULATOR USUALLY 10 psig /

0.69 bar

SECOND–STAGE REGULATOR 11 INCHES W.C. / 27 mbar

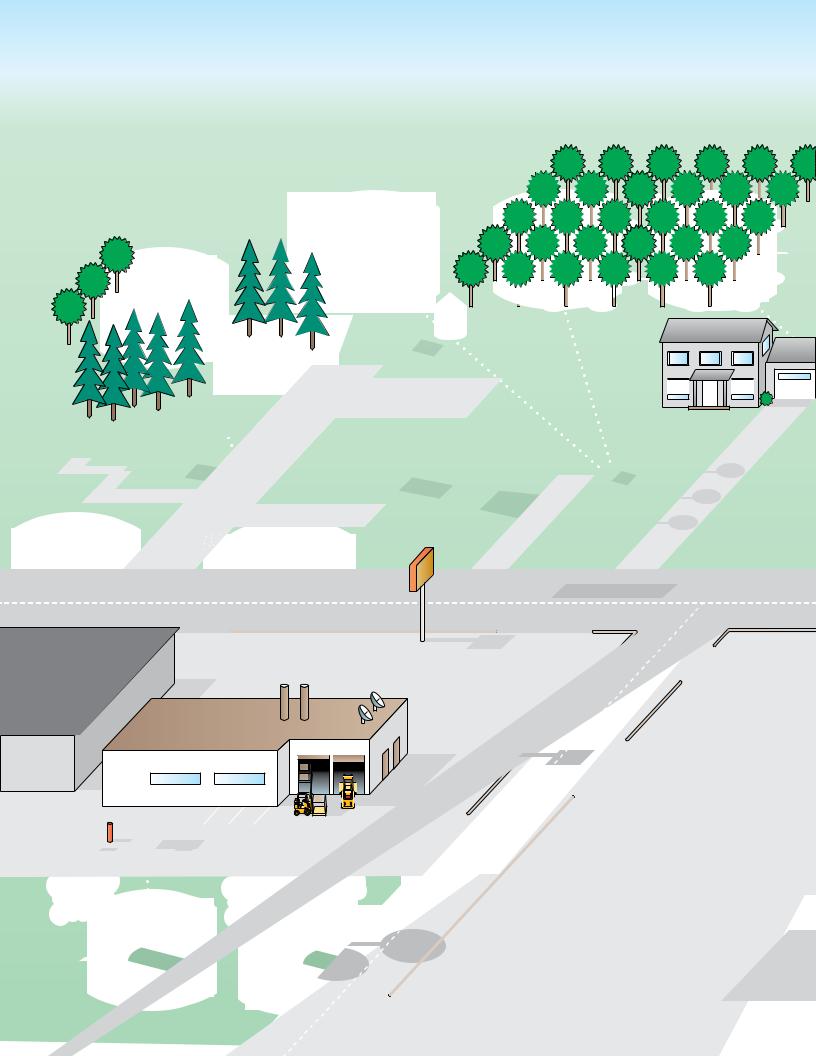

Figure 1. Two-Stage Regulation, One at Tank and One at Building, Reduce Pressure Down to Burner Pressure (11 inches w.c. / 27 mbar)

Two-Stage Systems

Regulator Technologies Fisher® brand makes the LP-Gas industry’s largest variety of First and Second-Stage regulators for domestic and commercial/industrial applications.

A Two-Stage system (Figure 1) uses two regulators to cut the supply pressure from the storage tank to the appliance. The Two-Stage system supplies a constant outlet pressure to the appliance. With more uniform pressure, appliances work better. Single-Stage regulators should be replaced with Two-Stage or Integral Two-Stage systems to comply with code requirements such as NFPA 58.

With a Two-Stage system, a First-Stage regulator supplies a nearly constant inlet pressure around 8 to 10 psig / 0.55 to 0.69 bar to

a Second-Stage regulator. This means the Second-Stage unit does not have to attempt to compensate for widely varying inlet pressures. Second-Stage pressure can be adjusted at the building as desired.

First-Stage Regulators

First-Stage regulators reduce tank pressure to a lower pressure (usually 10 psig / 0.69 bar) for a Second-Stage regulator. Fisher brand

First-Stage regulators are painted red for easy identifi cation. Vents are screened with standard orientation over the outlet.

Two-psi Service Regulators

Two-psi Service regulators serve as an intermediate regulator after the First-Stage regulator. These regulators are designed for

2 psig / 0.14 bar LP-Gas regulator systems. Fisher brand 2-psi regulators are painted white or are green with white closing caps for easy identifi cation.

Second-Stage Regulators

Second-Stage regulators reduce the pressure from a First-Stage unit to 11 inches w.c. / 27 mbar in domestic installations. Vents are screened with standard orientation over the inlet; however, other vent orientations are available. Fisher brand Second-Stage regulators are normally painted palm green for easy identifi cation.

Integral Two-Stage Regulators

Integral Two-Stage units combine a First-Stage regulator and Second-Stage regulator into one compact unit and are

recommended for installations where piping distance between the building being served and the tank is short. Integral Two-Stage regulators provide all the advantages of Two-Stage regulation.

These units are color coded gray for easy identifi cation. Vents are screened with standard orientation over the outlet.

Five Reasons to Two-Stage

1.Compliance with Code Requirements such as NFPA 58

2.Fewer Trouble Calls

With a Two-Stage system, one can expect fewer customer trouble calls due to regulator freeze-ups from too much water in the gas. A Two-Stage regulator reduces these possibilities in two ways:

a)a larger orifi ce can be used, making it more diffi cult for ice to build up and block the orifi ce, and

b)more heat can be transferred through the walls of two regulators than one

3.Smaller Pipe or Tubing

Due to the higher pressure between the First and Second-Stage units, smaller pipe or tubing can be used on a Two-Stage system. These savings can make a Two-Stage system more economical to install than a Single-Stage.

4. Constant Appliance Pressure

With a Two-Stage system, a First-Stage regulator supplies a nearly constant inlet pressure of 8 to 10 psig / 0.55 bar to 0.69 bar to a Second-Stage regulator. This means that the Second-Stage

regulator does not have to attempt to compensate for widely varying inlet pressures. With more uniform pressure, appliances work better and customers are less likely to experience problems that result in service calls.

5. Keep Downstream Pressure Below 2 psig / 0.14 bar

Second-Stage and Integral Two-Stage regulators have internal pressure relief valves, which limit the outlet pressure to 2 psig /

0.14 bar when the seat disc is removed and the inlet pressure is 10 psig / 0.69 bar or less as specifi ed in UL 144, STANDARD

FOR LP-GAS REGULATORS.

When to Two-Stage

Two-Stage systems whenever the following conditions exist:

1.Compliance with regulation codes.

2.There is a possibility of moisture in the LP-Gas.

3.Wide fl uctuations in gas demand exist.

4.Winter and summer temperatures vary greatly.

23

First-stage regulators

TYPE R122H

Types R122H and R622H First-Stage Regulators are Underwriters

Laboratories (UL®) listed regulators designed for Two-Stage

LP-Gas Regulator systems. These First-Stage regulators reduce tank pressure to a lower pressure (usually 10 psig / 0.69 bar) for a

Second-Stage regulator. Fisher® brand First-Stage regulators are painted red for easy identifi cation. Vents are screened with standard orientation over the outlet. The Types R122H and R622H regulators have a temperature rating of -20 to 160°F / -29 to 71°C, but have passed Fisher internal testing for lockup, relief start-to-discharge and reseal down to -40°F / -40°C.

Type R122H – Designed for use as a First-Stage regulator for domestic applications, the Type R122H’s size makes it perfect for tight installations. Stainless steel internal parts and corrosion resistant coatings provide a recommended replacement life of 20 years. Its non-adjustable setpoint makes the unit virtually tamper proof. Inlet and outlet gauge taps allow easy system testing. Large inlet and outlet wrench fl ats provide for easy installation, even in underground tanks.

The outlet pressure setpoint remains at a nominal factory setting of 10 psig / 0.69 bar. The designs superior relief performance exceeds

22H

22H

UL requirements and provides double failure overpressure protection when used with R600 Series Second-Stage regulator. The unit’s

Fluorocarbon (FKM) valve disc provides better lockup performance and durability in contaminated gas. The vent is with

3/8-inch NPT for easy installation of vent piping. A large fabricreinforced diaphragm provides accurate regulation. The large orifi ce assists in minimizing freeze problems.

Type R622H – Time proven design constructed of corrosionresistant and wear-resistant materials, the Type R622H is designed to provide a recommended replacement life of 20 years. Built-in 1/8-inch FNPT gauge taps on both the inlet and outlet pressure sides allow for easy system checks. A large 3/4-inch FNPT drip-lip vent reduces the chance of blockage by freezing rain or sleet when properly installed with the vent pointing down. Each Type R622H is equipped for overpressure protection with a corrosion-resistant internal relief valve that provides high capacity relief and a travel stop on the closing cap. Its size and confi guration make it ideal for under-the-dome installations.

First-Stage Regulators

|

CAPACITIES (PROPANE) |

(1)(3) |

INLET |

OUTLET |

OUTLET |

OUTLET |

|

|||

|

|

ADJUSTMENT RANGE |

PRESSURE SETTING |

|||||||

TYPE NUMBER |

|

|

|

CONNECTION, |

CONNECTION, |

|

|

|

|

|

|

BTU / hour |

SCMH |

INCH |

INCH |

psig |

bar |

psig |

|

bar |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

R122H-AAJ |

|

|

|

|

|

|

|

|

|

|

|

1,100,000 |

12.4 |

1/4 FNPT |

1/2 FNPT |

Non-Adjustable |

10 |

|

0.69 |

||

R122H-AAJXB(2) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R622H-BGK |

|

|

|

1/2 FNPT |

|

|

|

|

|

|

|

2,000,000 |

22.5 |

|

1/2 FNPT |

4 to 6 |

0.28 to |

5 |

|

0.34 |

|

R622H-HGK |

FPOL |

|

||||||||

|

|

|

|

|

||||||

|

|

|

|

0.41 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R622H-JGK |

2,250,000 |

25.3 |

FPOL |

3/4 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R622H-BGJ |

2,100,000 |

23.6 |

1/2 FNPT |

1/2 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R622H-DGJ |

2,400,000 |

27.0 |

3/4 FNPT |

3/4 FNPT |

|

0.55 to |

|

|

|

|

|

|

|

|

|

|

8 to 12 |

10 |

|

0.69 |

|

R622H-HGJ |

2,100,000 |

23.6 |

|

1/2 FNPT |

0.83 |

|

||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|||||

|

|

|

|

FPOL |

|

|

|

|

|

|

R622H-JGJ |

2,250,000 |

25.3 |

3/4 FNPT |

|

|

|

|

|

||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

1.Based on 30 psig / 2.1 bar inlet pressure and 20% droop.

2.Vent over gauge taps.

3.Metric conversion is based on 2516 BTU/ft3 of gas at 60°F / 16°C.

24

seCond-stage regulators

TYPE HSRL

TYPE R642

TYPE R622 |

TYPE R652 |

Types R222, R622, R642, R652 and HSRL Second-Stage regulators are Underwriters Laboratories (UL®) listed regulators designed to reduce the outlet pressure from a First-Stage regulator, usually 10 psig / 0.69 bar to 11 inches w.c. / 27 mbar, in domestic installations. Vents are screened with standard orientation over the inlet, but other orientations are available. Fisher® brand Second-

Stage regulators are painted palm green for easy identifi cation.

Types R222, R622, R642 and R652 are equipped with a stainless steel inlet screen to reduce the amount of debris entering the regulator and have a temperature rating of -20 to 160°F / -29

to 71°C, but have passed Fisher internal testing for lockup, relief start-to-discharge and reseal down to -40°F / -40°C.

Type R222 is designed for small domestic applications up to 650,000 BTU per hour / 7.3 SCMH. The unit provides the same features as the Type R622 in a smaller package and its design provides a recommended replacement life of 20 years.

Type R622 is designed for Two-Stage domestic applications up to 1,400,000 BTU per hour / 15.8 SCMH. The Type R622’s time proven design and corrosion resistant materials, provide a recommended replacement life of 20 years.

Type R622 contains a high performance relief valve and a large

3/4-inch screened vent to limit downstream pressure to less than

2 psig / 0.14 bar in an overpressure situation as required by NFPA 58.

The relief valve design exceeds the industry standard by limiting the downstream pressure to 2 psig / 0.14 bar even in a double failure situation when used with a Type R622H or R122H First-Stage regulator. The Type R622 is adjustable from 9 to 20 inches w.c. / 22 to 50 mbar.

For easy system checks, the Type R622 has 1/8-inch NPT built-in gauge taps orifi ced to a No. 54 drill size, on both the upstream and downstream sides. This regulator also features a large 3/4-inch driplip vent design.

Types R642 and R652 are designed for domestic applications up to 920,000 / 10.4 and 1,000,000 BTU per hour / 11.3 SCMH, respectively. These units provide all the same features as the

Type R622, including the 20-year recommended replacement life and double failure protection, in an angle body for the Type R642 and backmounted design for the Type R652.

Type HSRL is an UL listed regulator designed for light commercial applications up to 2,600,000 BTU per hour / 29.3 SCMH. It utilizes a high strength cast iron body and a 3/4-inch NPT drip lip vent design. The PFC and SFC feature an angle-body design. The design also includes a high capacity internal relief valve and a 20-year recommended replacement life.

Second-Stage Regulators

|

CAPACITIES (PROPANE)(1) |

INLET |

OUTLET |

OUTLET |

OUTLET |

||||

TYPE NUMBER |

|

|

CONNECTION, |

CONNECTION, |

PRESSURE RANGE |

PRESSURE SETTING |

|||

|

BTU / hour |

SCMH |

INCH |

INCH |

Inch w.c. |

mbar |

Inch w.c. |

|

mbar |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

R222-BAF |

650,000 |

7.3 |

1/2 FNPT |

1/2 FNPT |

9.5 to 13 |

24 to 32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

R622-BCF |

875,000 |

9.8 |

1/2 FNPT |

1/2 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R622-CFF |

1,400,000 |

15.8 |

1/2 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

R622-DFF |

3/4 FNPT |

|

9 to 13 |

22 to 32 |

11 / 27 |

|

|||

|

|

|

|

||||||

|

|

|

|

|

|

|

|||

R642-DFF |

920,000 |

10.4 |

3/4 FNPT |

|

|

|

|||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

R652-CFF |

1,000,000 |

11.3 |

1/2 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

R652-DFF |

3/4 FNPT |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

R622-CFGXA |

1,125,000 |

12.7 |

1/2 FNPT |

3/4 FNPT |

13 to 20 |

32 to 50 |

18 / 45 |

|

|

|

|

|

|

|

|

|

|

|

|

HSRL-BFC |

2,300,000 |

25.9 |

3/4 FNPT |

3/4 FNPT |

|

|

|

|

|

|

|

|

|

|

|

||||

HSRL-PFC |

9 to 13 |

22 to 32 |

11 / 27 |

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|

||||

HSRL-CFC |

2,600,000 |

29.3 |

1 FNPT |

1 FNPT |

|

||||

|

|

|

|

|

|||||

|

|

|

|

|

|

||||

HSRL-SFC |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Based on 10 psig / 0.69 bar inlet pressure and 2 inches w.c. / 5 mbar droop.

25

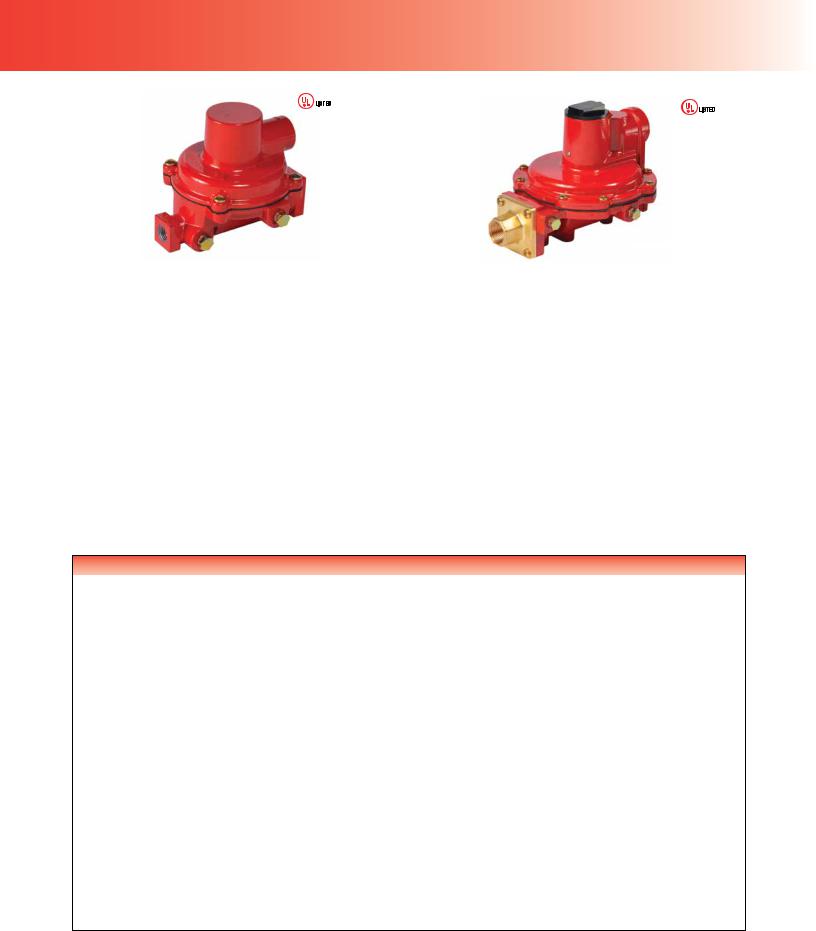

two-psi regulators

|

|

|

|

TYPE R652E |

|

TYPE R622E |

|

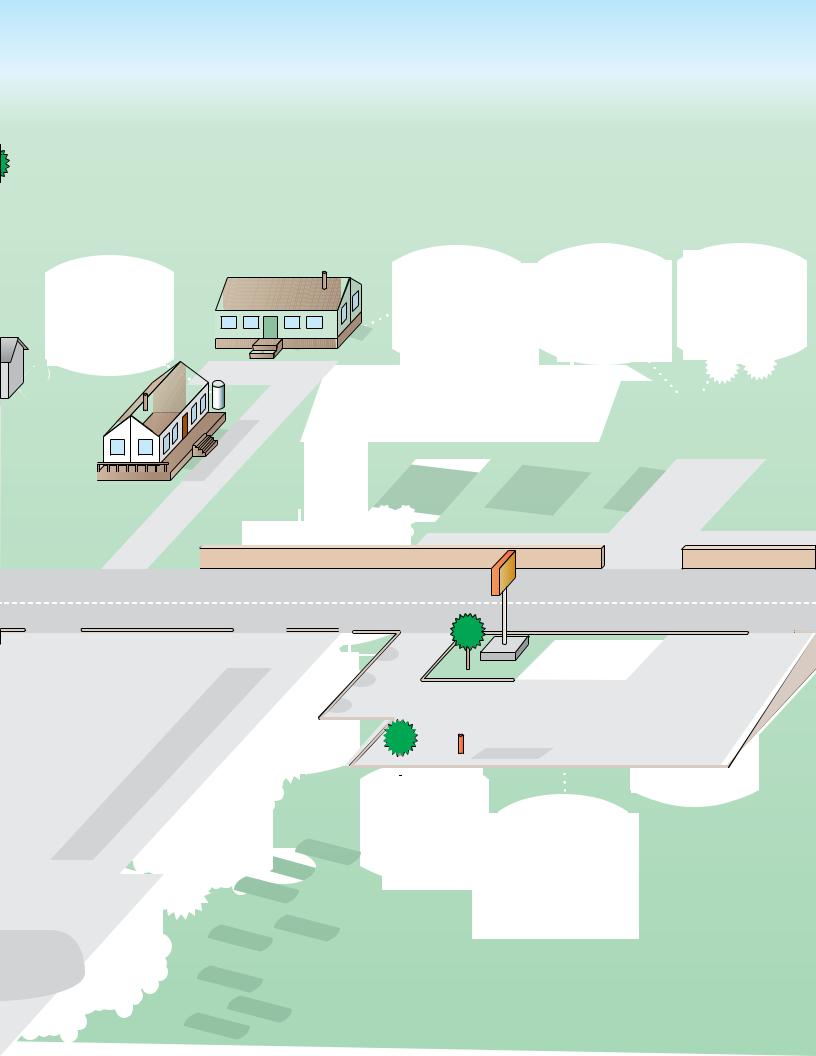

Types R622E and R652E, Two-psi Service Regulators, are designed for Two-psi LP-Gas Regulator Systems and listed by Underwriters Laboratories (UL®). These units are installed downstream from

a First-Stage regulator and reduce an inlet pressure of 10 psig / 0.69 bar to a nominal 2 psig / 0.14 bar outlet pressure. Two-psi Service Regulators are designed for domestic applications that supply 2 psig / 0.14 bar LP-Gas to a line regulator located inside the building. In most cases a manifold is used with corrugated stainless steel tubing (CSST) as well as other acceptable piping materials

for routing to the line pressure regulator supplying approximately 11 inches w.c. / 27 mbar to appliance regulators.

Types R622E and R652E Two-psi Service Regulators feature a combination relief valve and large vent that provide overpressure protection and exceed UL requirements. Both units have a stainless steel inlet screen to reduce the amount of debris from entering them.

Fisher® brand Types R622E and R652E are painted green with a white closing cap for easy identifi cation and have a temperature rating of -20 to 160°F / -29 to 71°C, but have passed Fisher internal testing for lockup, relief start-to-discharge and reseal down to -40°F / -40°C.

Type R622E – Time proven design constructed of corrosion resistant materials, the Type R622E is designed to provide a recommended replacement life of 20 years. Fisher brand’s fabricreinforced diaphragm and large diaphragm area provide accurate regulation at increased capacities. All components provide superior resistance to fi eld conditions that may cause wear and corrosion.

Built-in 1/8-inch taps (orifi ced to a number 54-drill size) on the upstream and downstream sides allow for easy gas system checks.

Type R652E – Provides the same features as the Type R622E, includes a 20-year recommended replacement life with a back mount design.

Typical Two-psi Installation

TYPE R122H OR R622H |

10 psig / 0.69 bar |

TYPE R622E OR R652E |

2 psig / 0.14 bar |

Two-psi Service Regulators

|

CAPACITIES (PROPANE)(1) |

CONNECTIONS |

|

OUTLET |

|

OUTLET |

|||

TYPE NUMBER |

|

|

PRESSURE RANGE |

PRESSURE SETTING |

|||||

|

|

INLET X OUTLET, INCH |

|

|

|

|

|

|

|

|

BTU / hour |

SCMH |

psig |

|

bar |

psig |

|

bar |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

R622E-BCH |

1,460,000 |

16.4 |

1/2 x 1/2 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

69 mbar to |

|

|

|

R622E-DCH |

1,680,000 |

18.9 |

|

1 to 2.2 |

|

2 |

|

0.14 |

|

3/4 x 3/4 FNPT |

|

0.15 |

|

||||||

|

|

|

|

|

|

|

|

||

R652E-DFH |

1,500,000 |

16.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

1. Based on 10 psig / 0.69 bar inlet pressure and 20% droop.

26

integral two-stage regulators

TYPE R232A |

R632A |

|

Integral Two-Stage regulators combine a First-Stage regulator and a Second-Stage regulator into one compact unit. Recommended for installations where piping distance is short, integral Two-Stage regulators provide all of the advantages of Two-Stage regulation (refer to page 23). Fisher® brand integral Two-Stage regulators are color coded gray for easy identifi cation. Vents are screened with standard Second-Stage vent orientation over the outlet.

The Types R632A and R232A fi rst-stage screened vent is threaded to accept a 1/4-inch OD copper tube inverted fl are with a

7/16-24 UN thread. The Types R232A and R632A have a temperature rating of -20 to 160°F / -29 to 71°C, but have passed

Fisher internal testing for lockup, relief start-to-discharge and reseal down to -40°F / -40°C.

Type R632A – is an Underwriters Laboratories (UL®) listed regulator with a capacity of up to 950,000 BTU per hour / 10.7 SCMH, recommended for on-site cylinder installations, mobile homes and domestic installations, where separation of the First and SecondStage is not cost effective. This unit offers a POL inlet connection for the easy drop-in replacement of Single-Stage regulators.

Type R632A’s high capacity relief valve and large 3/4-inch screened vent limit downstream pressure to less than 2 psig / 0.14 bar in

an overpressure situation as required by NFPA 58. Type R632A is adjustable from 9 to 13 inches w.c. / 22 to 32 mbar, with a factory setpoint of 11 inches w.c. / 27 mbar. The Type R632A features include the 20-year recommended replacement life.

Type R632A has 1/8-inch NPT built-in gauge taps orifi ced to a

No. 54 drill size, on the upstream and downstream sides. These taps provide easy access for testing the proper operation of the

First and Second-Stage while the system is pressurized. This regulator also features a large 3/4-inch drip-lip vent to reduce the chance of blockage by freezing rain or sleet when properly installed with the vent pointing down.

Type R232A – Designed for installations with small capacity loads up to 550,000 BTU per hour / 6.2 SCMH. With an overall length of 6.5 or 7 inches / 165 or 178 mm for NPT or FPOL connections respectively, this compact unit fi ts easily into confi ned spaces and is ideal for ASME tanks used on small domestic loads. Intermediate and outlet gauge taps facilitate easy system testing.

A 3/8-inch NPT vent allows easy installation of vent piping. Use of a valve stem and lever provide stable regulation and excellent durability. A large fabric-reinforced diaphragm provides accurate regulation. The large orifi ce assists in minimizing freeze problems.

Stainless steel internal and corrosion resistant coatings provide excellent corrosion resistance. The Type R232A also has the design that provides a recommended replacement life of 20 years.

Twin Cylinder Installations – The Type R232A can also be used on twin cylinder hook-ups found on travel trailers and stationary applications. These units offer a drip-lip vent style for installations without a vent protector. Proper installation requires the vent to be pointed down in a vertical position. Additional protection may be required if road splatter is a problem.

Integral Two-Stage Regulators

|

CAPACITIES (PROPANE)(1) |

INLET |

OUTLET |

OUTLET |

OUTLET |

|

|||

TYPE NUMBER |

|

|

CONNECTION, |

CONNECTION, |

ADJUSTMENT |

RANGE |

PRESSURE |

SETTING |

|

|

BTU / hour |

SCMH |

INCH |

INCH |

Inch w.c. |

mbar |

Inch w.c. |

|

mbar |

|

|

|

|

|

|

|

|

|

|

R232A-BBF |

|

|

1/4 FNPT |

|

|

|

|

|

|

R232A-BBFXA(2) |

550,000 |

6.2 |

1/2 FNPT |

9.5 to 13 |

24 to 32 |

|

|

|

|

|

|

|

|

||||||

R232A-HBF |

FPOL |

|

|

|

|||||

|

|

|

|

|

|

|

|

||

R232A-HBFXA(2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R632A-BCF |

850,000 |

9.6 |

|

1/2 FNPT |

|

|

|

|

|

R632A-BCFXA(2) |

1/4 FNPT |

|

|

11 |

|

27 |

|||

|

|

|

|

|

|

||||

R632A-CFF |

950,000 |

10.7 |

3/4 FNPT |

|

|

|

|||

|

|

|

|

|

|

||||

R632A-CFFXA(2) |

|

9 to 13 |

22 to 32 |

|

|

|

|||

|

|

|

|

|

|

|

|||

R632A-HCF |

850,000 |

9.6 |

|

1/2 FNPT |

|

|

|

||

|

|

|

|

|

|

||||

R632A-HCFXA(2) |

FPOL |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||

R632A-JFF |

850,000 |

9.6 |

3/4 FNPT |

|

|

|

|

|

|

|

|

|

|

|

|

||||

R632A-JFFXA(2) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

1.Based on 30 psig / 2.1 bar inlet pressure and 2 inches w.c. / 5 mbar droop.

2.First and Second-Stage spring case vents opposite gauge taps.

27

Loading...

Loading...