Page 1

Application Guidelines

PeC Solution Overview for

Commercial Comfort Applications

Page 2

AGL_Sol_PEC_02_E_Rev01

About these guidelines ................................................................................................ 1

1 Safety instructions ............................................................................................ 1

1.1 Icon explanation ................................................................................................................. 1

1.2 Safety statements .............................................................................................................. 1

1.3 General warnings ............................................................................................................... 2

1.4 Use with flammable refrigerants ........................................................................................ 2

1.5 General recommendations................................................................................................. 2

1.6 Communication with Application Engineering and Development teams ........................... 3

2 Product description .......................................................................................... 4

2.1 General information about the Emerson PeC controller .................................................... 4

2.2 Refrigerants ....................................................................................................................... 4

2.3 Available PeC configurations ............................................................................................. 5

2.4 Main components and parts .............................................................................................. 5

2.4.1 Supported compressor range ................................................................................. 5

2.4.2 Supported variable speed drive ............................................................................. 6

2.4.3 PeC accessories .................................................................................................... 6

2.4.4 Supported electronic expansion valve range ......................................................... 6

2.4.5 Supported pressure transmitters ............................................................................ 6

2.4.6 Supported temperature sensors ............................................................................. 6

2.5 PeC system functionalities ................................................................................................. 7

2.6 System configuration ......................................................................................................... 7

3 Hardware configuration .................................................................................... 8

3.1 PeC Hardware configuration options ................................................................................. 8

3.2 Examples of application ..................................................................................................... 9

3.2.1 Monoblock air-to-water chiller system scheme with variable-speed & fixed-speed

compressors and 1 electronic expansion valve .................................................................. 9

3.2.2 Monoblock air-to-water reversible heat pump system scheme with variable-

speed & fixed-speed compressors and 1 electronic expansion valve .............................. 11

3.3 DLT sensor installation .................................................................................................... 12

4 OEM control strategy on PeC ......................................................................... 13

4.1 System controller with Modbus communication............................................................... 13

4.2 OEM capacity demand strategy ....................................................................................... 14

4.3 System controller with analog 0-10 V demand signal + 1 digital signal........................... 14

5 PeC functionalities .......................................................................................... 15

5.1 State machine matrix ....................................................................................................... 15

5.2 Functionalities .................................................................................................................. 16

5.2.1 Smart compressor operating map management .................................................. 16

5.2.2 DLT limitation control function with wet suction control ....................................... 17

5.2.3 Main superheat control ......................................................................................... 17

5.2.4 External capacity request via Modbus ................................................................. 17

Page 3

AGL_Sol_PEC_02_E_Rev01

5.2.5 Start-up configuration function ............................................................................. 17

5.2.6 Compressor shutdown ......................................................................................... 17

5.2.7 Oil return function ................................................................................................. 17

5.2.8 Maximum speed during heating ........................................................................... 17

5.2.9 Speed control ....................................................................................................... 17

5.2.10 Envelope limitations ............................................................................................. 18

5.2.11 Variable-speed Scroll smart crankcase heater function ....................................... 18

5.2.12 FREMAR band protection (FREquency Management to Avoid Resonances) ..... 18

5.3 Alarm management .......................................................................................................... 18

5.3.1 "Alarm State" during compressor operation ......................................................... 18

5.3.2 Hardware alarms .................................................................................................. 19

5.3.3 Software alarms ................................................................................................... 19

5.3.4 Machine alarms summary .................................................................................... 20

5.4 Energy metering ............................................................................................................... 20

5.5 Modbus protocol specifications ........................................................................................ 21

6 Laboratory testing ........................................................................................... 22

6.1 Semi-manual mode .......................................................................................................... 22

6.2 Manual mode ................................................................................................................... 22

6.3 Starting lab testing with Modmonitoring software ............................................................ 22

6.4 Software update on the PeC ............................................................................................ 22

7 Electrical connection ...................................................................................... 23

7.1 General recommendations............................................................................................... 23

7.1.1 EMC ...................................................................................................................... 24

7.1.2 Ferrites ................................................................................................................. 24

7.1.3 Digital inputs and outputs wiring .......................................................................... 25

8 Items list for electronic solution package ..................................................... 26

9 Certification & approval .................................................................................. 27

10 Dismantling & disposal ................................................................................... 27

DISCLAIMER ............................................................................................................... 27

Page 4

AGL_Sol_PEC_02_E_Rev01 1

About these guidelines

The purpose of these guidelines is to provide guidance in the application of the Emerson PeC

controller in users’ systems. They are intended to answer the questions raised while designing,

assembling, starting and operating a system with this product.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the system. The performance and reliability of the system may be impacted if

the product is not used according to these guidelines or is misused.

These guidelines cover stationary applications only. For mobile applications, please contact the

Application Engineering department at Emerson as other considerations may apply.

1 Safety instructions

Emerson PeC controllers are manufactured according to the latest European safety standards.

Particular emphasis has been placed on the user’s safety.

The PeC controllers are intended for installation in systems in accordance with the European

Machinery Directive MD 2006/42/EC, the Low Voltage Directive LVD 2014/35/EU and the

Electromagnetic Compatibility Directive EMC 2014/30/EU. They may be put to service only if they

have been installed in these systems according to instructions and conform to the corresponding

provisions of legislation. For relevant standards please refer to the Manufacturer’s Declaration,

available on request or at www.climate.emerson.com/en-gb.

These guidelines form part of the product and must always be kept near the controller for easy and

quick reference. They should be retained throughout the lifetime of the controller.

You are strongly advised to follow these safety instructions.

1.1 Icon explanation

WARNING

This icon alerts the user of important

instructions to avoid personal injury and

material damage.

CAUTION

This icon alerts the user of instructions

to avoid property damage and possible

personal injury.

WARNING

High voltage!

This icon alerts the user of non-insulated

"dangerous voltage" within the product

area that is sufficiently high to constitute a

risk of electric shock to persons.

IMPORTANT

This icon alerts the user of important

operating and maintenance or

assistance instructions.

Danger of explosive atmosphere

This icon indicates a risk of explosive

atmosphere.

NOTE

This word indicates a recommendation

for easier operation.

1.2 Safety statements

▪ This product can only be used for purposes specified by the manufacturer.

▪ This product is designed to be used in HVAC/R systems and can only be installed,

operated or maintained by qualified electrical personnel with additional system-related

expertise. Please immediately contact the manufacturer for support if the user is

uncertain with any safety-related issue.

▪ Electrical connections must be made by qualified electrical personnel with additional

system-related expertise.

▪ All valid standards and local electrical regulations for connecting electrical and

refrigeration equipment must be observed.

▪ The national legislation and regulations regarding personnel protection must be

observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn

where necessary.

Page 5

2 AGL_Sol_PEC_02_E_Rev01

1.3 General warnings

WARNING

Conductor cables! Electrical shock hazard! This product operates at

hazardous voltages which can cause severe personal injury or equipment

damage. Extreme care and precautions must be taken when handling the

product. Electrical connections must be made by qualified electrical

personnel.

Use a grounded system only. Moulded electrical plugs must be used in all

applications. Refer to original equipment wiring diagrams.

Do not operate system before all cable connections are completed.

Disconnect all voltages from system before installation or service. Allow drive

components to electrically discharge for a minimum of two minutes before

servicing.

WARNING

Conductor cables! Electrical shock hazard! The controller must always be

inserted inside an electrical panel that can only be accessed by authorised

personnel. The keyboard must be the only part that can be reached. The

device must never be hand-held while being used.

CAUTION

The controller cannot be used as a safety device. Verify the limits of

application before using the device.

IMPORTANT

Transit damage! Controller disfunction! Use original packaging.

1.4 Use with flammable refrigerants

WARNING

The PeC controller is not designed or qualified based on the ATEX directive!

The PeC controller fulfils the requirements of the mentioned system standard

with the usage of flammable refrigerants.

Usage with flammable refrigerants is limited to systems which are based on the IEC 60335-2-40

standard. For systems using flammable refrigerants A2L and A3 the following points must be

considered:

▪ The controller mounting area must be in Zone 2 or outside any ATEX zone and in line with

"Pollution Degree 2" classification.

▪ No airstream guided over the electronics.

▪ No condensation under normal operation.

▪ The IP class of the controller mounting area must be in line with the system standard.

1.5 General recommendations

The customer shall bear full responsibility and risk for product configuration in order to achieve the

results pertaining to installation and/or final equipment/system. Upon customer's request and

following a specific agreement, Emerson. may be present during the start-up of the final

machine/application, as a consultant. However, under no circumstances can Emerson be held

responsible for the correct operation of the final equipment/system.

Since Emerson products form part of a very high level of technology, a qualification/configuration/

programming/commissioning stage is required to use them as best as possible. Otherwise, these

products may malfunction, and Emerson cannot be held responsible.

It is good practice to bear the following in mind for all Emerson products:

▪ Prevent the electronic circuits from getting wet as contact made with water, humidity or any

other type of liquid can damage them. Comply with the temperature and humidity limits

specified in the guidelines in order to store the product correctly.

▪ The device must not be installed in particularly hot environments as high temperatures can

cause damage, eg, to electronic circuits and/or plastic components forming part of the casing.

Page 6

AGL_Sol_PEC_02_E_Rev01 3

Comply with the temperature and humidity limits specified in the guidelines in order to store the

product correctly.

▪ Under no circumstances is the device to be opened – the user does not require the internal

components. Please contact qualified service personnel for any assistance.

▪ Prevent the device from being dropped, knocked or shaken as either can cause irreparable

damage.

▪ Do not clean the device with corrosive chemical products, solvents or aggressive detergents.

▪ The device must not be used in applications that differ from those specified in these guidelines.

1.6 Communication with Application Engineering and Development teams

When communicating with Application Engineering and/or development teams at Emerson during

the development and testing phases of programs using the PeC, please include:

1. log file

2. description file

3. configuration file

These will help them give you more precise and complete answers to your questions.

Page 7

4 AGL_Sol_PEC_02_E_Rev01

2 Product description

2.1 General information about the Emerson PeC controller

The PeC (Performance Controller) controller has been specifically developed for Copeland™ scroll

compressors using R410A and R32 refrigerants in heating and cooling applications such as

reversible heat pumps, in both air-to-water and brine-to-water configurations.

PeC was developed to run and protect the refrigerant cycle with low control effort for the system

controller but also to provide detailed information around the refrigerant cycle.

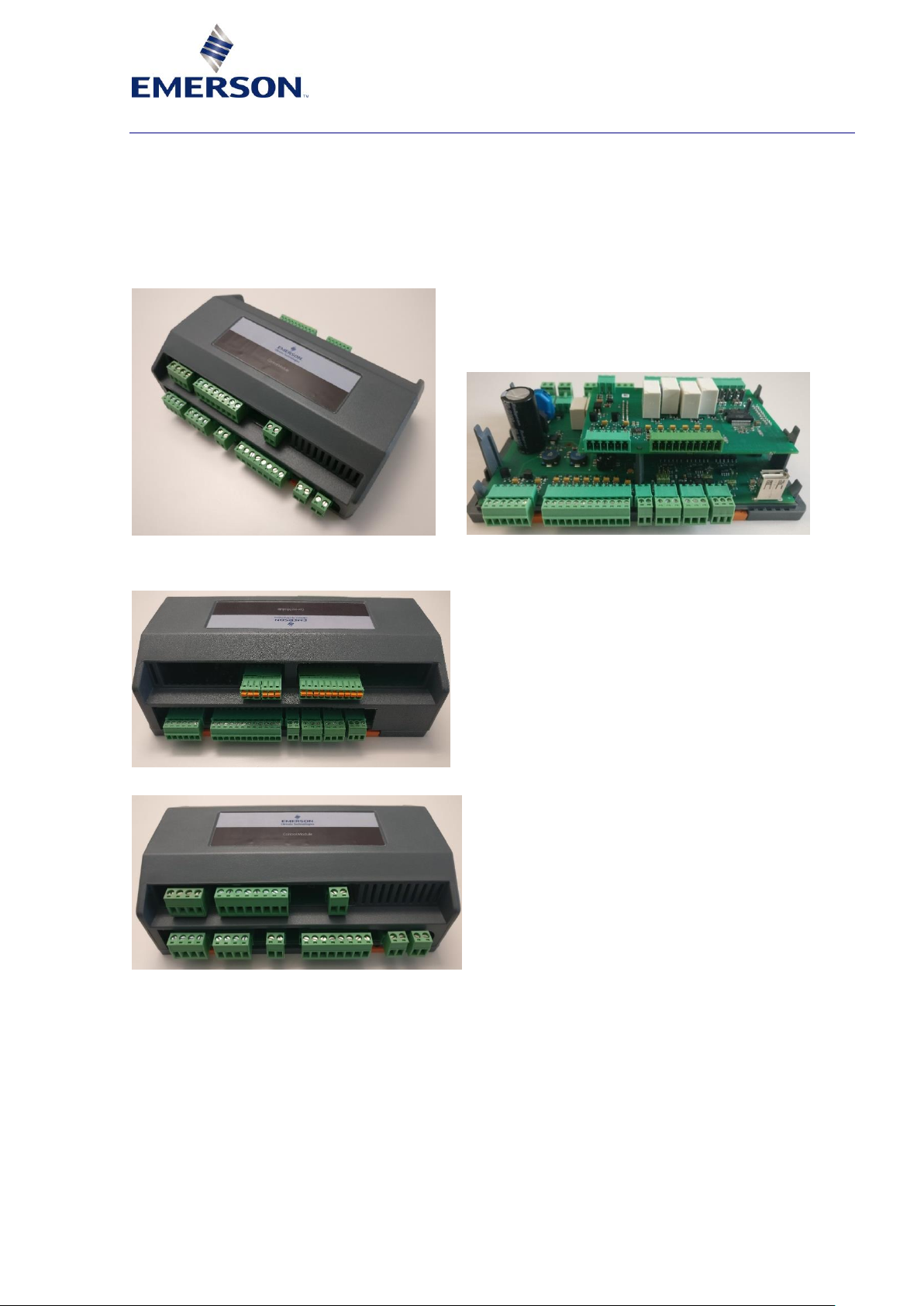

Figure 1: PeC external view Figure 2: Internal view

The external dimensions of the PeC controller are 185 x 130 x 60 mm.

Figure 3: Top side view

Figure 4: Bottom side view

2.2 Refrigerants

The PeC controller operates with refrigerant systems using:

▪ R410A

▪ R32

Page 8

AGL_Sol_PEC_02_E_Rev01 5

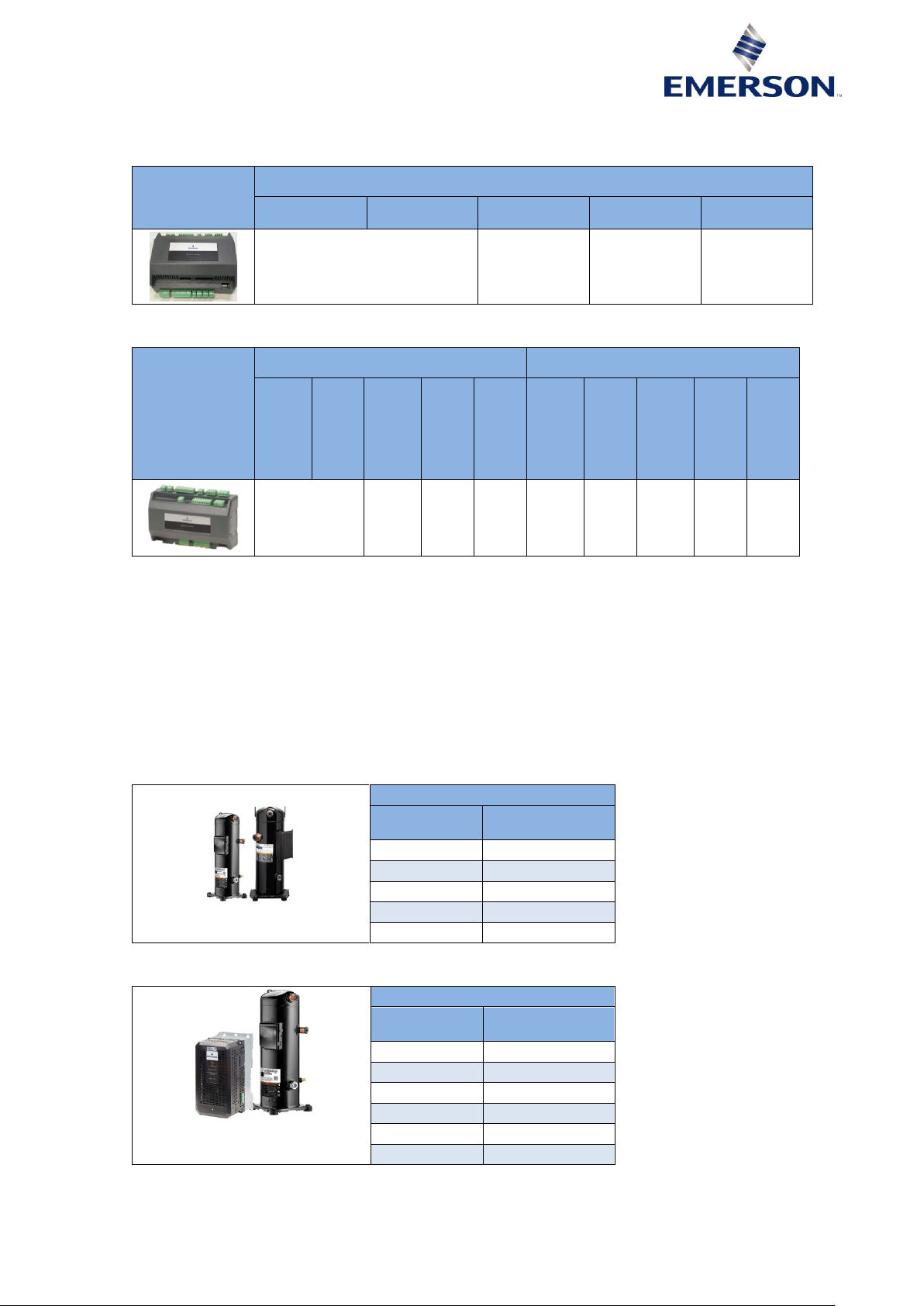

2.3 Available PeC configurations

The following tables show the hardware and software capabilities with PeC C100 and C200.

PeC C100

Circuit 1

VS compressor

+ EV3 drive

Fixed speed

Temperature

probe min-max

Pressure

EXV

(bipolar)

1-3

(1 can be a variable speed)

5-7 2 1

Table 1

PeC C200

Circuit 1

Circuit 2

VS

compressor

+ EV3 drive

Fixed speed

Temperature

.probe

min-max

Pressure

EXV

(bipolar)

VS

compressor

+ EV3 drive

Fixed speed

Temperature

. Probe

min-max

Pressure

EXV

(bipolar)

1-3

(1 can be a

variable speed)

5-7 2 1 0 0-3

4-6 2 1

Table 2

NOTE: The PeC factory default is unconfigured (-1) so configuration is needed. Invalid or

unconfigured compressor package selection will cause an alarm.

2.4 Main components and parts

For components and parts ordering please contact the Application Engineering or Sales

Department at Emerson.

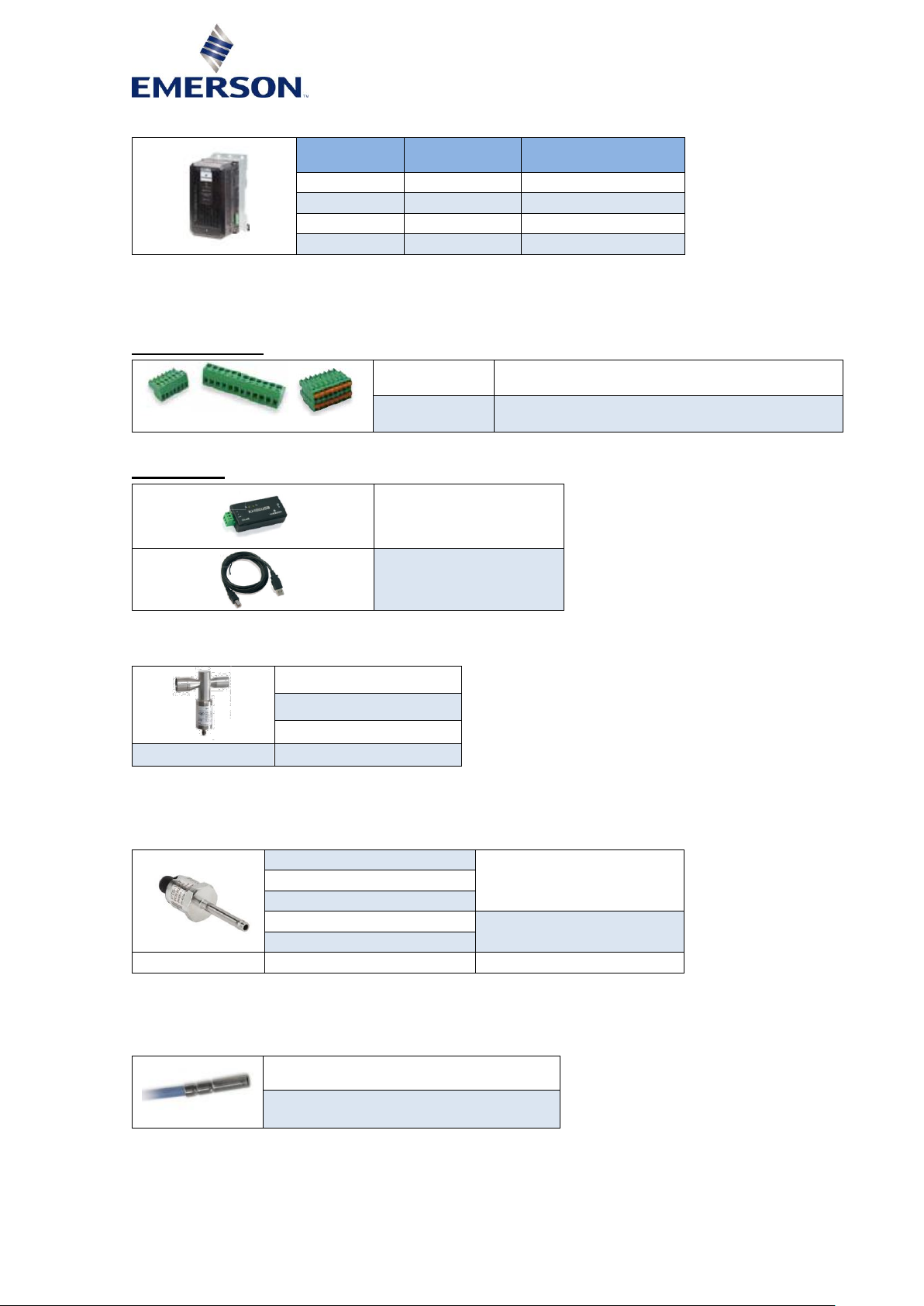

2.4.1 Supported compressor range

The PeC controller has been specifically developed for Copeland Scroll variable-speed

compressors using R410A and R32 refrigerants. It is currently qualified for the following ranges:

R32

Fixed-speed

compressor

Variable-speed

compressor

YP137

YPV066

YP154

YPV096

YP182

YP232

YP292

Table 3: Qualified compressors for use with R32

R410A

Fixed-speed

compressor

Variable-speed

compressor

ZP104

ZPV066

ZP122

ZPV096

ZP154

ZP182

ZP232

ZP292

Table 4: Qualified compressors for use with R410A

NOTE: Additional fixed-speed compressors may be supported based on customer request.

Page 9

6 AGL_Sol_PEC_02_E_Rev01

2.4.2 Supported variable speed drive

EV3150

EV3185

Compatible

compressor model

1 YPV066

1 ZPV066

1 YPV096

1 ZPV096

Table 5: Compatible compressor models

NOTE: The Emerson EV3 inverter drive is compliant with CAT 3 of EMC homologations.

2.4.3 PeC accessories

Plug-in connector

PeC C100

Screw terminals and/or cage clamp female

connectors

PeC C200

Screw terminals and/or cage clamp female

connectors

Table 6

USB adapter

XJ485-USB converter

Cable XJ485-USB

converter

Table 7

2.4.4 Supported electronic expansion valve range

Alco EX4

Alco EX5

Alco EX6

EXV-M30 (wires)

3.0 m

Table 8: Qualified expansion valves

NOTE: Additional expansion valves may be supported based on customer request.

2.4.5 Supported pressure transmitters

Alco PT5N-7 (7 bar max)

Low side

Alco PT5N-10 (10 bar max)

Alco PT5N-18 (18 bar max)

Alco PT5N-30 (30 bar max)

High side

Alco PT5N-50 (50 bar max)

Cable for PT5N

PT4-M30

3.0 m

Table 9: Qualified pressure transmitters

NOTE: Additional pressure transducers may be supported based on customer request.

2.4.6 Supported temperature sensors

TP1 series

100K (high temperature)

(for future use)

Table 10: Qualified temperature sensors

NOTE: Additional temperature sensors may be supported based on customer request.

Page 10

AGL_Sol_PEC_02_E_Rev01 7

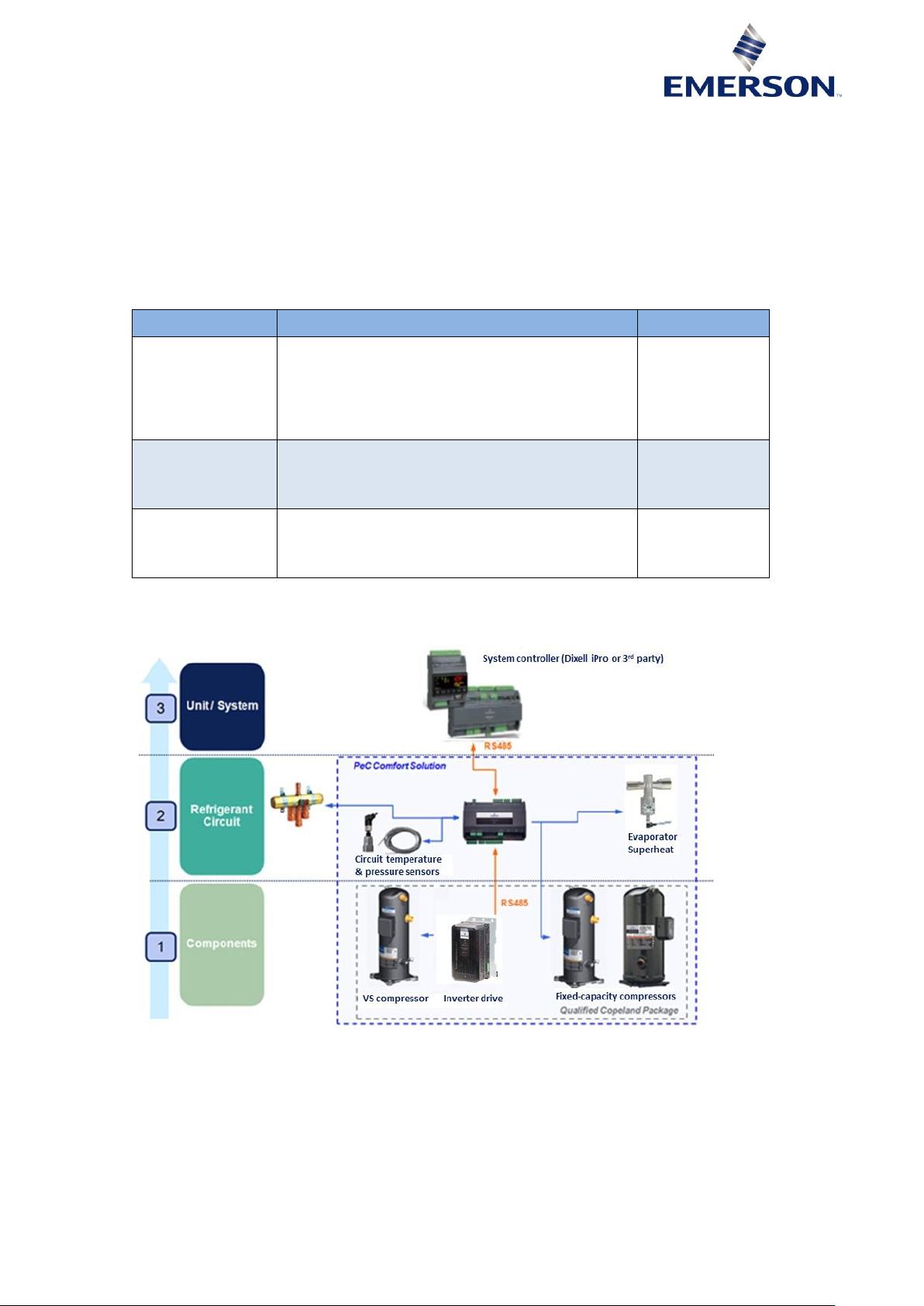

2.5 PeC system functionalities

The PeC controller controls and manages the refrigerant system comprising the Copeland Scroll

variable-speed compressor (ZPV066 or ZPV096 & YPV066 or YPV096), the drive, the electronic

expansion valves (EX range) and the 2- or 4-way valve. It is not a main system controller: it does

not control or manage the full unit (chiller / heat pump / others).

The OEM system controller and the PeC communicate via Modbus serial communication, in order

to exchange the fundamental parameters and information to provide an optimised combined control

of compressor and expansion devices for maximum performance and reliability.

Table 11 below gives an overview of the PeC features and benefits.

PeC

Features

Benefits

Smart

refrigerant circuit

management

▪ Variable speed & fixed speed

▪ Tandem/Trio capacity management

▪ Smart superheat control & EXV management

▪ Dynamic compressor operating maps

management

▪ Reverse cycle management

High efficiency &

reduced time-tomarket

Protection &

diagnostics

▪ Active compressor envelope protection

▪ Active floodback protection

▪ Oil recovery management

▪ Performance monitoring

Improved

protection &

increased

reliability

Communication

▪ RS485 Modbus OR analog interface

communication with system controller

▪ Pre-programmed Modbus communication with

CSD100 and alarms/parameters transfer

Modularity

Table 11

2.6 System configuration

Figure 5

Page 11

8 AGL_Sol_PEC_02_E_Rev01

3 Hardware configuration

3.1 PeC Hardware configuration options

The controller board owns digital inputs and outputs that can provide customized use to the OEM.

Configuration can be set via Modbus using "Configuration Parameters".

Factory default

of digital inputs

& outputs

Description

Type

DI1

Input for high-pressure switch signal

Fixed function

DI2

Input for demand On/Off selection

Future use

DI3

Input for heating or cooling mode selection

Future use

DO1

Relay for switching 2 or 4-way valve

Fixed function

DO2

Relay for fixed-speed compressor start/stop

Fixed function

DO3

Relay for fixed-speed compressor start/stop

Fixed function

DO4

Relay for fixed-speed compressor start/stop

See below

Table 12

Configuration parameter options on DO1:

Register [94] if Defrost is enabled

0 = Cooling open circuit, heating closed circuit

1 = Cooling closed circuit, heating open circuit

Configuration parameter options on DO4:

Register [150] if compressors 1,3 installed (refer to index 86 bit 3) then relay can be used

to indicate PeC status

0 = Alarm negative logic (Alarm = Relay contact open)

1 = Alarm positive logic (Alarm = Relay contact closed)

2 = Drive active positive logic (speed <> = 0 relay closed)

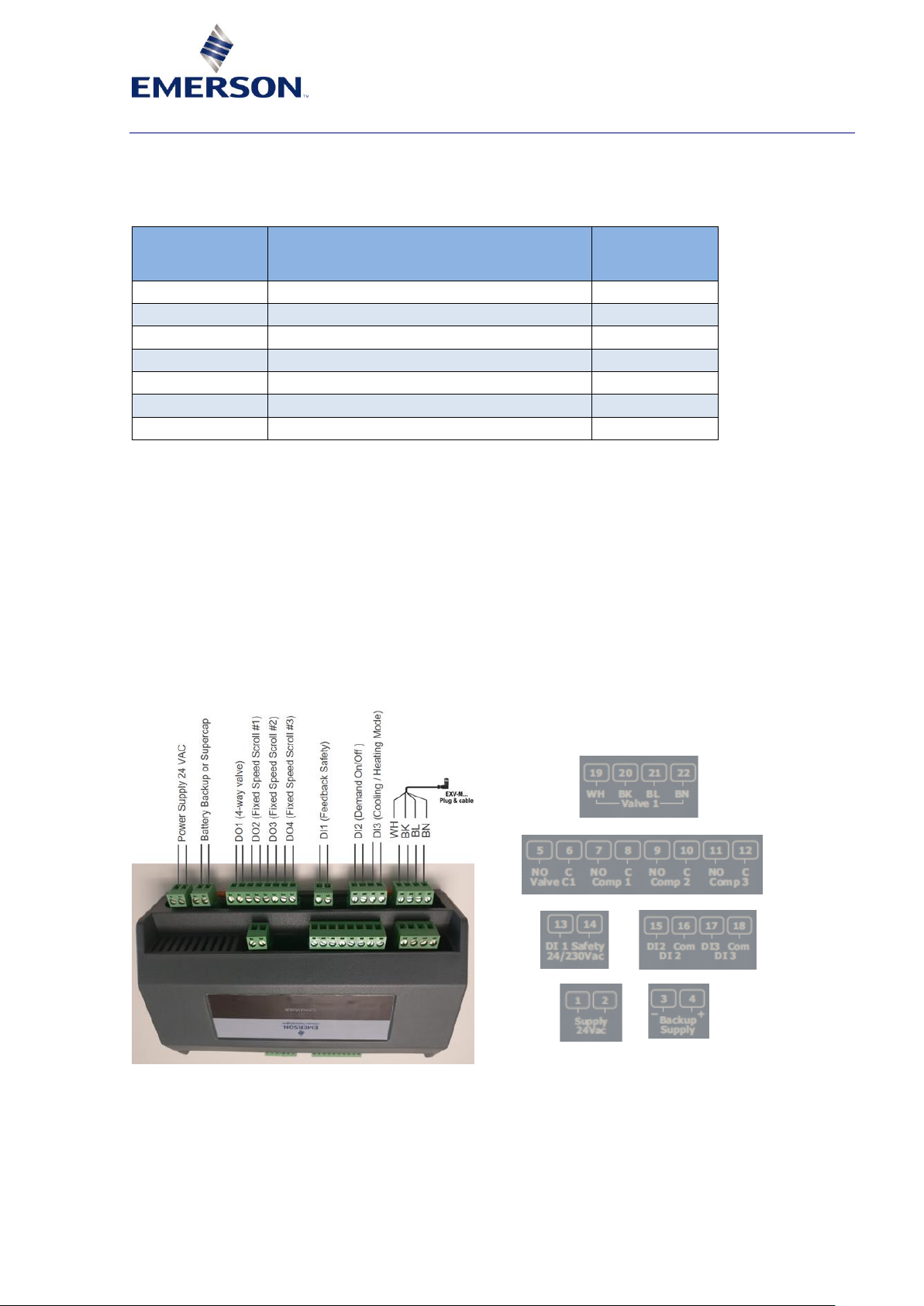

Figure 6: PeC controller top side – Power supply, digital outputs & inputs & EXV connections

NOTE: For more information please refer to Application Guidelines AGL_Sol_PEC_01 "PeC

Solution Controllers for commercial Comfort Applications – PeC C100 & PeC C200" or

contact your local Application Engineering representative at Emerson.

Page 12

AGL_Sol_PEC_02_E_Rev01 9

3.2 Examples of application

3.2.1 Monoblock air-to-water chiller system scheme with variable-speed & fixed-speed

compressors and 1 electronic expansion valve

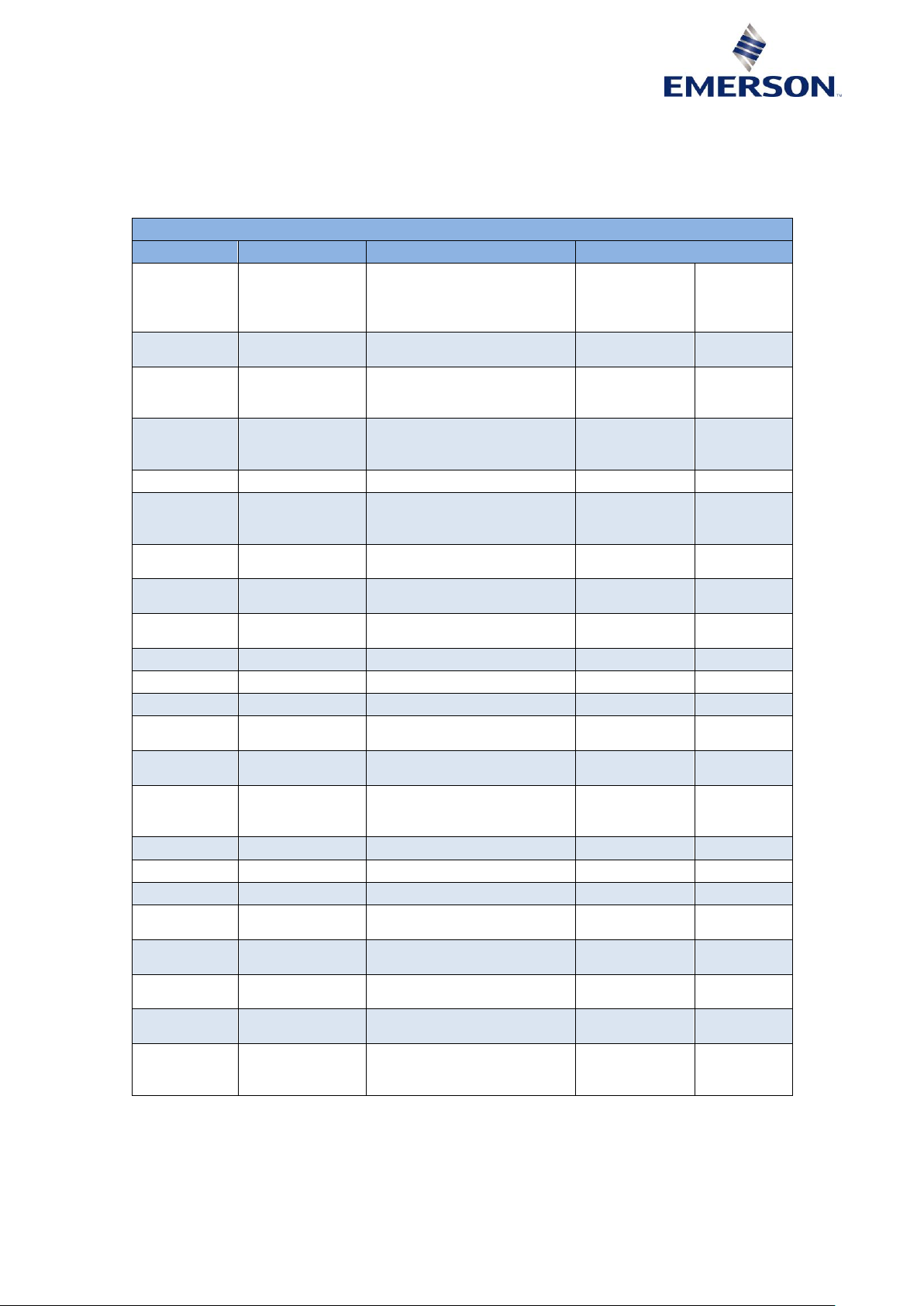

The schematic in Figure 7 shows an air-to-water chiller designed for cooling applications.

PeC controller

I/O

Type

Function

Comments

P1

PT5N-7-10-18

Suction pressure for

superheat (SH) control, high

SH protection and envelope

management

Configurable

Mandatory

P2

PT5N -30-50

Discharge pressure for

envelope management

Configurable

Mandatory

T1

TP1

Evaporator outlet gas

temperature for SH control

and high SH protection

Configurable

Optional

T2

TP1

Compressor suction gas

temperature for SH control

and high SH protection

Configurable

Mandatory

T3

TP1

Ambient temperature

Configurable

Mandatory

T4

TP1

Liquid temperature before

main EXV for energy counter

function & EXV management

Configurable

Mandatory

T5

TP1

Variable-speed compressor

discharge temperature

Configurable

Mandatory

T6

TP1

Fixed-speed compressor

discharge temperature

Configurable

Mandatory

T7

TP1

Fixed-speed compressor

discharge temperature

Configurable

Mandatory

24 VAC

Power supply

Fixed

24 VDC

Supercap XEC mono valve

Optional DO1

Relay

4-way

Fixed

Not needed

DO2

Relay

Fixed-speed compressor

command #1

Configurable

DO3

Relay

Fixed-speed compressor

command #2

Configurable

DO4

Relay

Fixed-speed compressor

command #3 ➔ indicates if

the drive is running or not

Configurable

DI1

Digital input

Feedback safety

Fixed

DI2

Digital input

Not used

State readable

by Modbus

Optional

DI3

Digital input

Not used

State readable

by Modbus

Optional

EXV/BIP

Stepper out -

bipolar

EXV control

Fixed An.In.

0-10 V analog

input

Not used

State readable

by Modbus

Optional

Bus Inverter

Modbus RS485

Communication with EV3

inverter

Fixed Bus Ctrl

Modbus RS485

Communication with system

controller

Fixed

Bus Slave

Modbus RS485

Modbus slave (may be used

for monitoring and/or

flashing)

Fixed

Table 13

Page 13

10 AGL_Sol_PEC_02_E_Rev01

Figure 7: Air-to-water chiller for cooling application

Figure 8: PeC C100 bottom side – Digital inputs, Modbus communication, pressure and temperature inputs

NOTE: For more information please refer to Application Guidelines AGL_Sol_PEC_01 "PeC

Solution Controllers for commercial Comfort Applications – PeC C100 & PeC C200" or

contact your local Application Engineering representative at Emerson.

Page 14

AGL_Sol_PEC_02_E_Rev01 11

3.2.2 Monoblock air-to-water reversible heat pump system scheme with variable-speed &

fixed-speed compressors and 1 electronic expansion valve

The schematic in Figure 9 shows an air-to-water reversible chiller/heat pump with the ability for

reverse cycling for defrost and heating modes. The main expansion valve, 4-way valve and

compressors are controlled by PeC.

PeC controller

I/O

Type

Function

Comments

P1

PT5N-7-1018

Suction pressure for

superheat (SH) control, high

SH protection and envelope

management

Configurable

Mandatory

P2

PT5N -30-50

Discharge pressure for

envelope management

Configurable

Mandatory

T1

TP1

Evaporator outlet gas

temperature for SH control

and high SH protection

Configurable

Optional

T2

TP1

Compressor suction gas

temperature for SH control

and high SH protection

Configurable

Mandatory

T3

TP1

Ambient temperature

Configurable

Mandatory

T4

TP1

Liquid temperature before

main EXV for energy counter

function & EXV management

Configurable

Mandatory

T5

TP1

Variable-speed compressor

discharge temperature

Configurable

Mandatory

T6

TP1

Fixed-speed compressor

discharge temperature

Configurable

Mandatory

T7

TP1

Fixed-speed compressor

discharge temperature

Configurable

Mandatory

P1

24 VAC

Power supply

Fixed P2

24 VDC

Supercap XEC mono valve

Optional DO1

Relay

4-way

Configurable

Not needed

DO2

Relay

Fixed-speed compressor

command #1

Fixed DO3

Relay

Fixed-speed compressor

command #2

Fixed

DO4

Relay

Fixed-speed compressor

command #3 ➔ indicates if

the drive is running or not

Configurable

DI1

Digital Input

Feedback safety

Fixed DI2

Digital Input

Not used

Fixed

Optional

DI3

Digital Input

Not used

Fixed

Optional

EXV/BIP

Stepper out -

bipolar

EXV control

Fixed An.In.

0-10 V analog

input

Not used

Fixed

Optional

Bus Inverter

Modbus RS485

Communication with EV3

inverter

Fixed Bus Ctrl

Modbus RS485

Communication with system

controller

Fixed

Bus Slave

Modbus RS485

Modbus slave (may be used

for monitoring and/or

flashing)

Fixed

Table 14

Page 15

12 AGL_Sol_PEC_02_E_Rev01

Figure 9: Air-to-water reversible chiller/heat pump

3.3 DLT sensor installation

The DLT sensor assembly improves the accuracy and response time of the temperature

management.

The high-pressure safety input was designed to fulfill the requirements of standard EN 378.

Please follow the recommendations below for sensor assembly:

▪ The temperature sensor has to be installed along the straight or bended pipe at a distance of

120 mm from the compressor shell.

▪ The discharge pipe including the sensor must be insulated to reduce the impact of ambient

temperature.

▪ Use thermal compound to improve heat transfer to the sensor. The thermal compound must be

approved for maximum system operating temperatures (usually 150 °C for R32).

▪ Protect the sensor from being moved or removed from its position by transport, vibration or any

other incident.

▪ The sensor must be installed in a copper sleeve to improve response time and to reduce setoff.

The copper sleeve must be brazed on the surface of the discharge pipe. Use thermal compound

to improve the heat transfer from the sleeve to the sensor.

Figure 10: Discharge temperature sensor mounting

Page 16

AGL_Sol_PEC_02_E_Rev01 13

4 OEM control strategy on PeC

4.1 System controller with Modbus communication

OEM system controller with Modbus RS485 RTU

System

controller

or separate

hardware

Bus

Digital I/O

↓ ↓ ↓

↑……↑

↑……↑

↓……↓

↓↑↑↑

Operating

mode

Heating/Cooling

Standby/Off

Capacity

Defrost

Start/Stop

Refrigerant cycle

info

Measured &

calculated values

Alarms and

warnings

Hardware &

software

Manual control

3 EXV’s & speed

& 2 relays

4/2-way valve

Digital

Switches/Input

↓ ↓ ↓

↑……↑

↑……↑

↓……↓

↓↑↑↑

Bus

Digital I/O

PeC

Table 15

The PeC was developed to run and protect the refrigerant cycle with low control effort for the

system controller but also to provide detailed information around the refrigerant cycle.

The system controller has to provide operating mode and capacity request to run the system.

▪ PeC operating modes can be Off, Heating, Cooling, Standby or Manual.

▪ Modbus communication also gives the possibility of enhanced use of all PeC functions shown

above.

▪ Accessories (pumps, fan, etc.) have to be controlled directly by the OEM controller to ensure

problem-free conditions for running the refrigerant cycle, eg, water flow on condenser around

compressor activity.

The OEM is responsible for developing a mitigation strategy in response to the occurrence of

alarms and warnings on the PeC.

There are different alarm conditions: "Alarm", "W arning" and "Alarm State".

Alarms and warnings may not lead to direct system shutdown. The system controller can monitor

these and take preventive action with the capacity request in order to avoid system shutdown by an

"Alarm State". The occurrence of an "Alarm State" will force immediate system shutdown.

When not acting on the PeC during an "Alarm State" phase, the PeC will recover, if possible, after

a recommended waiting phase (Alarm Pause).

The OEM has to consider the best response to specified alarms, eg, continue to activate the

system or let the system run, lock the system to protect it against damage, etc.

An advantage of Modbus communication is that it provides the full PeC functionality such as:

1) Operation control

▪ Gives precise control on operating mode and capacity request given %.

2) Monitoring all sensor values and system status

▪ Gives opportunity to use these data for OEM processing the system by the system

controller and for data logging. This provides valuable information to analyse the system

operation.

3) Explicit warning and alarm information

▪ The OEM controller can get explicit fault and warning information for preventive actions on

the system, as well for service and maintenance.

4) Manual control options

▪ For customized individual control strategy, the OEM controller can take control on the

compressor speed, the EXV’s and the 4-way valve instead of PeC internal control function.

5) Additional hardware functionality

▪ 1 Digital input + 2 potential free relays can be used by the system controller via Modbus or

internal pre-defined function.

Page 17

14 AGL_Sol_PEC_02_E_Rev01

4.2 OEM capacity demand strategy

The OEM controller should adapt the capacity demand signal to variable speed operation.

Common P, PI or PID control strategy should be used to avoid strong setpoint exceeding. This will

enhance the system efficiency and reduce useless high speeds, temperatures and sound on the

system. An optimal strategy has to be figured out via OEM system qualification process.

Figure 11

4.3 System controller with analog 0-10 V demand signal + 1 digital signal

Currently unused –Option available in future.

Page 18

AGL_Sol_PEC_02_E_Rev01 15

5 PeC functionalities

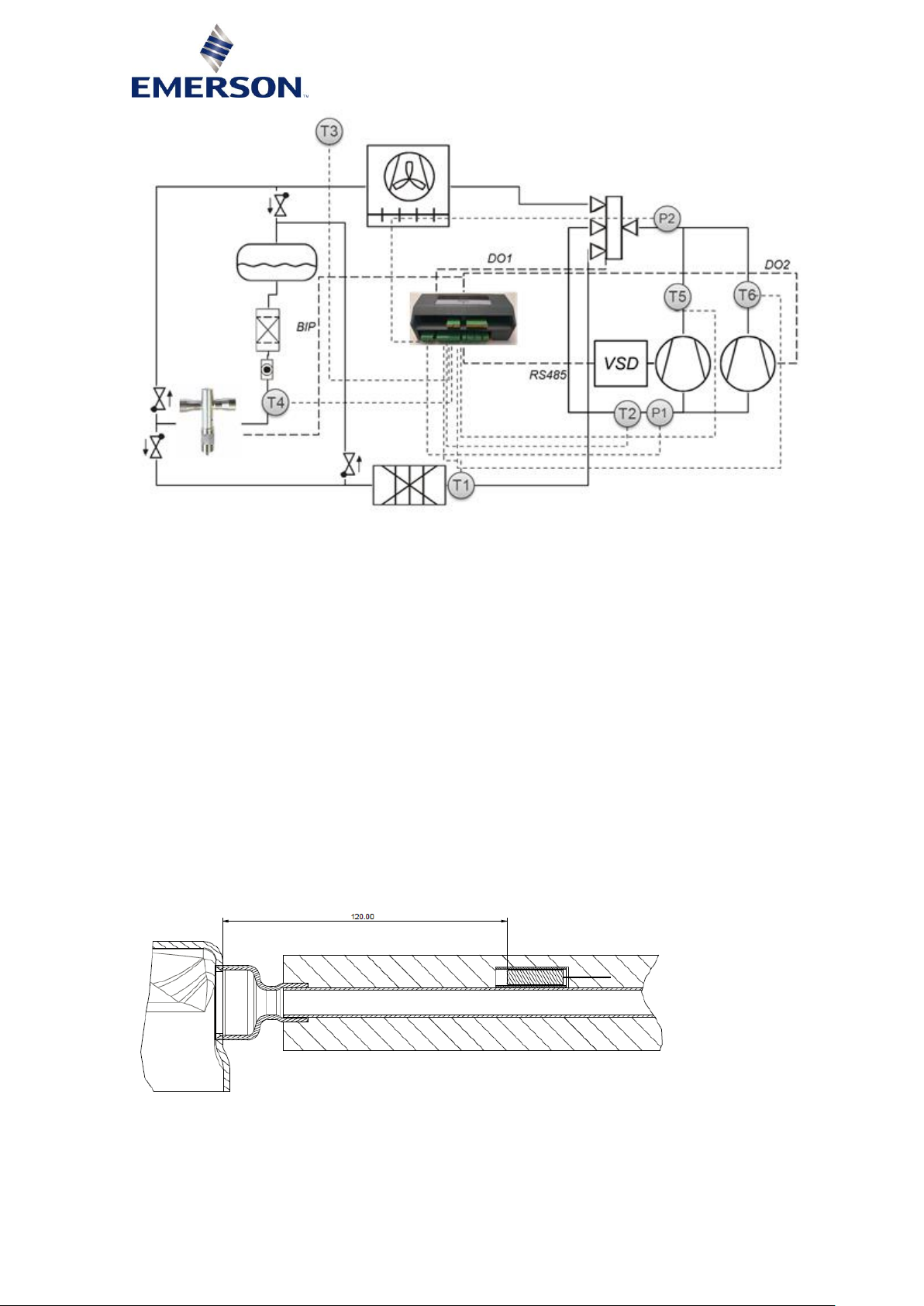

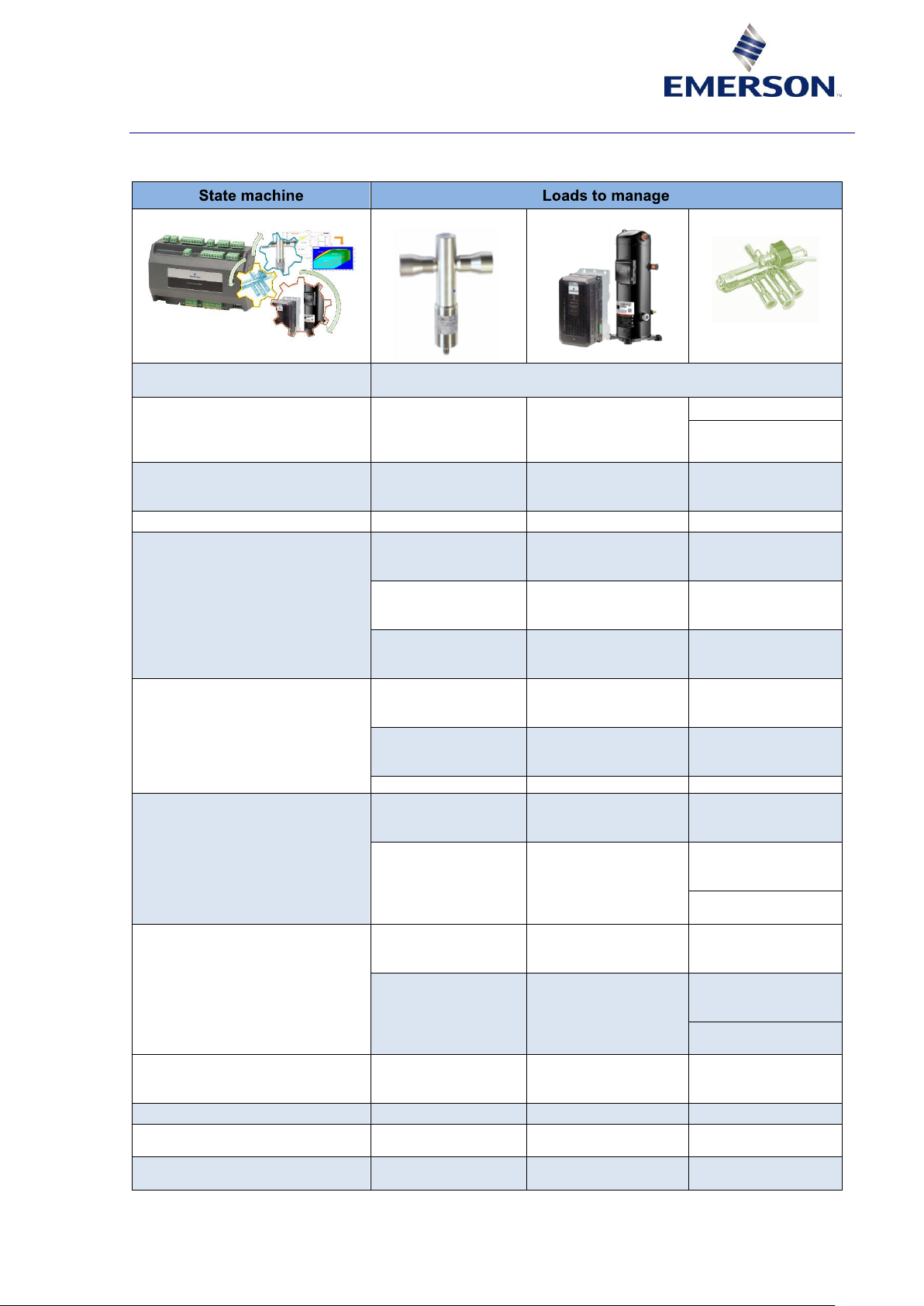

5.1 State machine matrix

EXV

Compressor pack

4-way valve

Off

After shutdown all valves are closed, the 4-way valve switches to cooling

position

Start-up

Normal start-up with

predefined opening

(function of ambient

temperature)

Normal start-up with

predefined speed and

duration

Swappable

Heating or cooling

active

Shutdown

Combination of

suction pressure and

compressor speed

The compressor speed

is reduced and the

valve is closing.

Standby

Stator heater

Cooling

Normal operation

(dynamic setpoint

graph)

Normal capacity

matching

Low superheat

operation (IPsensitive)

Exceptions

(protections,

prevention)

Floodback operation

Exceptions

(protections,

prevention)

Heating

Normal operation

(dynamic setpoint

graph)

Normal capacity

matching

Discharge

temperature

protection

Floodback operation

Transition to cooling / defrost

With unit stop: close

valves in relation with

capacity

With unit stop: shut

down all compressors

regularly

With unit stop: wait

for pressure band to

swap

Without unit stop:

proceed to cooling

start-up opening

Without unit stop: ramp

down to defined

capacity on each circuit

Without unit stop:

wait for defined

capacity to swap

Low delta pressure

protection

Transition to heating

With unit stop: close

valves in relation with

capacity

With unit stop: shut

down all compressors

regularly

With unit stop: wait

for pressure band to

swap

Without unit stop:

proceed to cooling

start-up opening

Without unit stop: ramp

down to defined

capacity on each circuit

Without unit stop:

wait for defined

capacity to swap

Low delta pressure

protection

Defrost

Suction pressure

regulation

Suction pressure

regulated capacity

band

Manual

Full manual mode

Full manual mode

Full manual mode

Emergency shutdown

Valve closing by

capacity

Fast capacity

shutdown

No action

Alarm

Valve closing by

capacity

Fast capacity

shutdown

No action

Table 16

Page 19

16 AGL_Sol_PEC_02_E_Rev01

The application is governed by a state machine of which the various states can be described as

follows:

▪ Off: The compressor shutdown procedure is executed. After shutdown, all valves are closed,

the 4-way valve switches to cooling position.

The stator heater function is active for both variable and fixed-speed scrolls.

▪ Shutdown: The compressor speed is reduced and the valve is closing.

▪ Standby: The compressor shutdown procedure is executed. After shutdown all valves are

closed and the 4-way valve switches to cooling position.

The stator heater function is active.

▪ Cooling: The compressor is running, the expansion valve is active and the 4-way valve is in

cooling position.

▪ Heating: The compressor is running, the expansion valve is active and the 4-way valve is in

heating position.

▪ Alarm: The unit has encountered a problem and stopped. When the PeC enters this state, it

shadows and clears the alarms. To avoid immediate restart, the unit is moved into waiting state

for a configurable amount of time.

▪ Transit cooling: The normal shutdown procedure is applied to switch off the compressors then

restart the system to cooling mode.

▪ Transit heating: The normal shutdown procedure is applied to switch off the compressors then

restart the system to heating mode.

▪ Defrost: The compressor is running, the expansion valve is active, the 4-way valve is in cooling

position.

▪ Waiting: The unit is in delayed restart after an alarm occurred during operating mode.

▪ Manual: The user takes control of every component individually.

▪ Compressor start: The unit has a heating request but the 4-way valve is in cooling mode, so

the unit starts in cooling mode to build up the necessary pressure to switch the 4-way valve.

Duration: 10 seconds at 2700 rpm.

5.2 Functionalities

5.2.1 Smart compressor operating map management

The operating envelopes of the variable-speed Scroll (VSS) are stored in the controller.

Based on measurements of suction and discharge pressures the possible speed range is

calculated for every operating point. Protection algorithms prevent the operating point to leave the

operating map by acting on compressor speed and expansion valve opening. Envelope alarm limits

are defined in order to avoid operation out of the envelope.

Additional fallback protection is implemented as safety software function in the drive. Torque and

discharge temperature limitation are the major protective features.

Figure 12

Page 20

AGL_Sol_PEC_02_E_Rev01 17

5.2.2 DLT limitation control function with wet suction control

The PeC will monitor the discharge line temperature. In case the high DLT area is entered,

superheat control will change into Discharge Temperature Protection control. The smart logic on

the EXV control ensures that the portion of liquid refrigerant droplets at the inlet of the compressor

is sufficient to keep the discharge line gas temperature below the allowed limit, while COP is kept

as good as possible, following the strategy "As much as needed and as little as possible".

The discharge gas temperature limitation is compressor-type dependent.

5.2.3 Main superheat control

One bipolar expansion valve per circuit can be controlled by PeC for heating and cooling mode.

The superheat control is based on pressure/temperature control strategy involving a self-adapting

PID control algorithm in order to adapt to different operating conditions. The main superheat

setpoint is being adapted in a pre-defined range in order to achieve stable and optimal operating

conditions.

NOTE: To test the control behaviour at special conditions, fixed and non-adaptive PID

parameters can be used in the "Manual Control mode". Please contact the Application

Engineering department at Emerson in case this functionality needs to be configured.

5.2.4 External capacity request via Modbus

The capacity request for heating and cooling modes can be sent by the system controller via

Modbus communication. In addition to the capacity, the operating mode has to be set separately.

The capacity input request, sent via Modbus communication, is an absolute value expressed in %.

The maximum available capacity for the current operating conditions is accessible by the system

controller via Modbus communication.

5.2.5 Start-up configuration function

During variable-speed compressor start-up, the compressor will run to the start-up speed with a

given ramp-up rate. When the 4-way valve position is correctly set, the compressor will go to the

mode-based start-up speed. The compressor speed is stabilized at the start-up speed for a given

time (start-up duration). After that, the controller will modulate the speed to meet the capacity

requirement of the system.

5.2.6 Compressor shutdown

If the controller receives a compressor shutdown command, it will switch off the fixed-speed

compressor(s) first if it is (they are) running. Then the variable-speed compressor will shut down

according to a pre-determined procedure.

5.2.7 Oil return function

To ensure sufficient oil level in the compressor at all times, the system has to be properly designed

and qualified by the OEM. To qualify oil return performance of the system, Emerson can provide

compressors with sight tubes.

All the parameters associated to the oil return function are configurable. If the compressor speed

goes below a threshold value for a certain amount of time, the oil return function triggers. This

function forces the compressor to an "oil return" speed for a brief period.

5.2.8 Maximum speed during heating

Maximum speed during heating restricts the speed of the compressor, to limit the load on it and the

heating capacity of the system.

5.2.9 Speed control

The speed regulation algorithm is used in heating and cooling modes. The PeC calculates the

speed that has to be applied to the compressor in order to match the requested capacity.

However, if the operating point reaches the lower limit of evaporating temperature, the compressor

speed is decreased in order to stay inside the envelope.

When the condensing temperature reaches the upper limit of the envelope, the speed is also

decreased.

Page 21

18 AGL_Sol_PEC_02_E_Rev01

5.2.10 Envelope limitations

To avoid overload of the compressor motor, the MOP function of the PeC limits the evaporating

pressure to a pre-determined value, defined according to the safe operating envelope of the

compressor(s). The evaporating temperature is limited by decreasing the main expansion valve

opening causing higher superheat values.

The speed request has to respect the allowed envelopes according to the unit’s operating point.

This means that for the evaporating and condensing temperatures of the unit, the controller runs

through all the envelopes of the compressor to find the lowest and highest envelopes containing

the point.

The calculated envelope gives the minimum and maximum speeds allowed for the operating point.

Note that for each limit, the controller progresses to refine the envelope (up to a precision of

50 rpm).

If the evaporating temperature of the unit goes around the left side of the largest envelope allowed

(equivalent to 4500 rpm) or if the condensing temperature goes around the top side of the largest

envelope, a smart control algorithm is implemented to attempt to bring back the unit’s operating

point inside the allowed envelopes. The resulting speed is not filtered but it is still bound according

to the allowed envelopes.

5.2.11 Variable-speed Scroll smart crankcase heater function

The PeC controller uses a smart crankcase heating function to prevent the risk of liquid migration.

It keeps the scroll temperature in a temperature band of 5-10 K above the evaporating

temperature. The heater function is only active in "Standby" mode of the PeC. By using "Standby"

and "Off" modes, the heater can be switched on and off by the OEM system controller.

This function is available only when there is one variable-speed compressor on the circuit.

5.2.12 FREMAR band protection (FREquency Management to Avoid Resonances)

Due to system design and the wide speed range of the compressor, harmful or disturbing

resonance vibrations can occur in the mechanical system. If such resonances are measured during

the OEM system qualification process and cannot be avoided, the Fremar band protection can be

used to cut out the critical speed range(s) by defining the Fremar bandwidth and up to 3 separate

frequencies.

5.3 Alarm management

5.3.1 "Alarm State" during compressor operation

Exceeding hard-programmed or configured operating limits leads to an alarm or warning to the

alarm registers. Depending on the delay time and the different alarms and warnings, the system

may continue to run.

The PeC will react, on a delayed warning or alarm, by changing the speed and valve opening to

avoid getting into an "Alarm State". The OEM system controller can also trigger preventive actions

by, eg, reducing demanded capacity, increasing pump speed, fan speed, etc.

If there is no delay time on an alarm or if the delay time has expired, the PeC goes into "Alarm"

state. "Alarm" state means:

1. Compressor is shut down as fast as possible and valves will close accordingly.

a. Alarm registers are copied as a snapshot into shadow alarm registers and cleared.

b. Hardware and software alarm words are written to the alarm history.

c. The alarm relay is activated (the relay status can be monitored via Modbus communication,

"Read parameter").

2. After the alarm cause has disappeared, the application state goes into "Waiting" state (alarm

pause) before a restart is attempted.

3. When the alarm pause time has expired, all the alarms, alarm shadows and relay/bit are

cleared and the PeC goes back to normal operating mode.

NOTE: For more information please refer to Technical Information TI_Sol_PEC_01

"Performance Controller PeC – Modbus Interface Description" or contact your local

Application Engineering representative at Emerson.

Page 22

AGL_Sol_PEC_02_E_Rev01 19

5.3.2 Hardware alarms

On occurrence of any hardware alarm, the system will shut down immediately. If not mentioned

specifically, all hardware alarms are self-resetting and the system will restart when the alarm

disappears and the forced waiting time (Alarm Pause) has expired.

▪ Valve alarms: A complete valve check is performed at start-up. This test is repeated on a valve

if it has been detected as faulty. Upon regular operation, at the end of each valve movement,

the energized coils are checked.

▪ Sensor failures: These alarms are evaluated permanently regardless of application state.

▪ VSS & bipolar drive communication: Every second the PeC reads the variables available

from the bipolar drive unit and the VSS drive. After 5 successive failed attempts, the associated

alarm will be raised and the associated data will be invalidated. Note that during the first four

failures, the old values are kept.

During HP alarm or EVU lock, the VSS communication alarm is disabled (drive is unpowered).

▪ High-pressure switch alarm: This alarm is raised whenever the digital input 2 is released.

During HP alarm, the VSS communication alarm is disabled (drive is unpowered).

▪ Compressor alarm: This alarm is raised if there are major or minor faults on the VSS drive.

The details of the compressor alarm cause are reported in the VSS fault structures.

▪ EEPROM failure: The EEPROM memory holding configuration parameters and energy counter

values are checked at reset. This alarm is resettable only by power off – power on.

▪ COM timeout: When the analog input is not used on the controller, the communication to the

system controller has a timeout of 60 sec. When this timeout expires, the compressor shuts

down. When communication resumes, the system restarts in the state present on the write

variables.

5.3.3 Software alarms

Delay counter triggers an "Alarm State" when configured delay time is exceeded

Delay counter increases

Over limits

↓

Limit value

Delay counter stopped

Inside limits

Dead band

Limit value - Bandwidth

Delay counter cleared

Inside limits

↑

Table 17: Dead band function on alarms

▪ Low pressure alarm: This alarm works in a dual fashion. If the pressure is above the threshold,

the alarm is cleared.

▪ Low superheat: This alarm works in a dead band fashion with an incremental counter.

▪ High superheat alarm: This alarm works in a dead band fashion with an incremental counter

and can indicate low refrigerant charge in the system.

▪ Valve large opening: Raised only as warning. This alarm works in a dead band fashion with an

incremental counter and can indicate low refrigerant charge in the system.

▪ High condensing pressure: This pressure alarm is one of the system protection functions:

when the maximum condensing pressure (adjustable) after a time delay (adjustable) is

exceeded, the high condensing pressure alarm is triggered and the compressor is shut down to

protect the system before the mandatory high-pressure switch triggers.

This does not replace the high-pressure switch limiter imposed by EN 378.

▪ Freeze alarm: This alarm is currently inactive. It will be implemented in future in order to protect

the heat exchanger in cooling mode.

▪ Envelope Tc low: Raised only as warning. This flag is raised if the condensing temperature is

below the minimum allowed value. No preventive action is performed and the allowed time

outside the envelope is 30 minutes.

▪ Envelope Tc high: Raised only as warning. This flag is raised if the condensing temperature is

above the maximum allowed value. Compressor speed is decreased in order to stay inside the

allowed application envelope.

▪ Envelope Te low: Raised only as warning. This flag is raised if the evaporating temperature is

below the minimum allowed value. Compressor speed is decreased in order to stay inside the

allowed application envelope.

Page 23

20 AGL_Sol_PEC_02_E_Rev01

▪ Envelope Te high: Raised only as warning. This flag is raised if the evaporating temperature is

above the maximum allowed value. Valve opening is decreased in order to stay inside the

allowed application envelope (MOP protection).

▪ Envelope alarm: The envelope alarm is triggered if one of Tc low, Tc high, Te low or Te high

flags are raised for the respective durations. This alarm stops the system.

▪ High discharge temperature: This alarm is triggered immediately if the discharge temperature

exceeds 130 ºC.

5.3.4 Machine alarms summary

Alarm description

Alarm

Status

Inverter

speed

Circuit 1

fixed-

speed

comp.

Circuit 2

fixed-

speed

comp.

Valve 1

Valve 2

System

controller

action

Any sensor failure

Inverter communication

Oil sensing controller

communication

Inverter alarms

Circuit safety 1, 2

Power loss

Valve 1, 2

High discharge temp. 1,

2, 3, 4, 5, 6

Low pressure 1, 2

Low superheat 1, 2

High superheat 1, 2

High pressure 1, 2

Envelope 1, 2

Freeze protection 1,2

Alarm

Shutdown

Switch

off

Switch

off

Closing

Closing

Force

immediate

system

shutdown

Supervisor

communication

Alarm

OFF

OFF

OFF

OFF

OFF

Force graceful

system

shutdown

Valve large opening 1,2

Warning

Normal

control

Normal

control

Normal

control

Normal

control

Normal

control

Envelope Tc low 1, 2

Warning

(for 30

min.)

Normal

control

Normal

control

Normal

control

Normal

control

Normal

control

Envelope Te high 1,2

Warning

(for 10 s)

Normal

control

Normal

control

Normal

control

MOP

control

MOP

control

Envelope Tc high 1,2

Warning

(for 10 s)

Speed

reduction

OFF

(after 5 s)

OFF

(after 5 s)

Normal

control

Normal

control

Can monitor

these and take

preventive

action

(increase fan

or pump

speed)

Envelope Te low 1,2

Warning

(for 10 s)

Speed

reduction

OFF

(after 5 s)

OFF

(after 5 s)

LOP

Control

LOP

Control

Table 18

5.4 Energy metering

PeC provides information on system performance: power, COP, SCOP, SEER, heating and cooling

capacity and minimum / maximum capacity.

PeC calculates the energy from compressors performance maps and values measured from the

refrigerant cycle:

▪ Heating energy + electrical energy in heating mode

▪ Cooling energy + electrical energy in cooling mode

These values can be read once per second in Wh (2 X 16 bit).

Page 24

AGL_Sol_PEC_02_E_Rev01 21

Accumulated values for SCOP and SEER calculation are stored once every 24 hours in read-only

registers. Resetting the PeC or a "power off" cycle will lead to a loss of non-stored information.

All these values can be accessed via Modbus communication.

For SCOP and SEER calculation, accessory power for fan, pump, etc. is included in the

calculation (constant 150 W by default). Static accessory power can be pre-set, from 0 to 3000 W,

on configuration parameter.

For greater accuracy, it is possible to give the actual accessory power consumption, eg, for

variable fan, pump, etc. via Bus communication to the PeC, to be considered for SCOP and SEER

calculation.

Variable accessory power has to be written to the "Accessory Power value" write register.

On PeC power up, the "Accessory Power" write register is initialized by the "Accessory Power"

configuration parameter value.

5.5 Modbus protocol specifications

NOTE: Please read carefully Technical Information TI_Sol_PEC_01 "Performance Controller

PeC – Modbus Interface Description" to avoid system-controller communication problems

and to be able to use the latest PeC features. If further information is needed, please contact

your local Application Engineering representative at Emerson.

Page 25

22 AGL_Sol_PEC_02_E_Rev01

6 Laboratory testing

6.1 Semi-manual mode

For lab testing purposes and/or to achieve special running parameters or conditions, it is possible

to activate the semi-manual mode in heating or cooling mode. It is possible to change the control

mode from automatic to manual on the compressor speed or the expansion valves, to get manual

control over the device(s).

Heating/cooling capacity, compressor speed or valve openings are set as absolute values of kW,

RPM or % valve opening.

Defrost can be activated and deactivated via push button registers.

NOTE: The semi-manual mode is only available via Modbus communication and for

experienced users.

6.2 Manual mode

To test the system components attached to the PeC, it is possible to handle all active components

manually.

No automatic function and no safety or alarm functions are active in this mode.

All components must be controlled manually, eg, for component function test.

To go into the manual mode, the "Analog command" must be deactivated ("Analog command

inhibits" configuration parameter).

NOTE: The manual mode is only available via Modbus communication and for experienced

users.

6.3 Starting lab testing with Modmonitoring software

To quick-start lab testing, Emerson provides a Modbus communication-based PC software with

which all the PeC functionalities are available and the testing on the prototype can be performed.

NOTE: For more information please contact your local Application Engineering

representative at Emerson.

6.4 Software update on the PeC

For lab testing purposes or during the qualification process, an update of the PeC firmware may be

needed. To this end, Emerson can supply a programming tool and an instruction sheet about how

to flash the new firmware on the PeC controller.

The PeC software may be updated via a Modbus cable through the "Modbus Slave" port.

NOTE: For more information or to get the programming tool or instruction sheet, please

contact your local Application Engineering representative at Emerson.

Page 26

AGL_Sol_PEC_02_E_Rev01 23

7 Electrical connection

7.1 General recommendations

WARNING

Conductor cables! Electrical shock hazard! The controller operates at

hazardous voltages which can cause severe personal injury or equipment

damage. Extreme care and precautions must be taken when handling the

product.

The controller must always be inserted inside an electrical panel that can

only be accessed by authorised personnel. The keyboard must be the only

part that can be reached. Insert the probe where it cannot be reached by the

end-user.

Disconnect all the electric connections before performing any maintenance

or servicing work.

The device must never be hand-held while being used.

CAUTION

Wrong supply voltage! Material damage! Verify that the power supply

voltage is correct before connecting the controller.

Consider the maximum current that can be applied to each relay.

IMPORTANT

Make sure that the wires for the probes, the loads and the electrical power

supply are separated and sufficiently distant from each other, without crossing

or intertwining with each other.

Separate the power of the controller from the rest of the electrical devices

connected inside the electrical panel. The secondary of the transformer must

never be connected to the earth.

In the case of applications in industrial environments, it may be useful to use

the main filters in parallel to the inductive loads.

During the installation process, follow the recommendations below to prevent the device from

malfunctioning:

▪ Separate the cables of the analog inputs from those of the digital inputs, and the serial line

cables from the power cables, to avoid malfunction due to electromagnetic interference.

▪ Separate the power of the device from that of other electrical components.

▪ Never connect the secondary of the supply transformer to the earth.

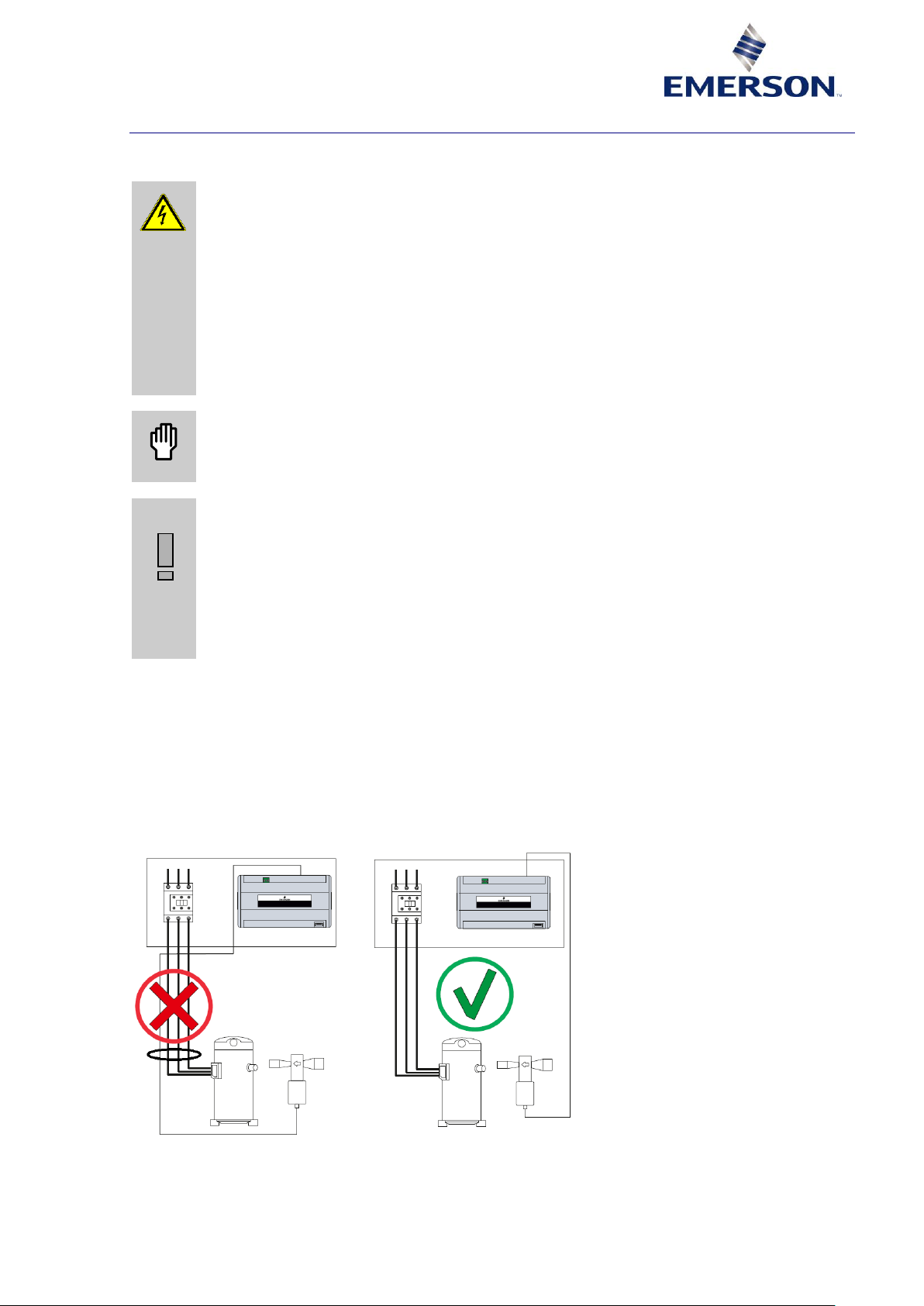

▪ Separate the signal cables from the power cables. It is recommended to follow the diagram in

Figure 13 below as far as possible.

Figure 13: Example of wrong connection

The example in above diagram shows how improper connection can generate a wrong signal to the

EXV valve and the possibility to lose steps.

Page 27

24 AGL_Sol_PEC_02_E_Rev01

7.1.1 EMC

▪ Separate drive-to-compressor supply from controls, sensor lines and communication lines.

▪ Keep a distance of 10 cm between clean and dirty lines and components if possible.

▪ Do not disable EMC measures by:

o wrong mounting of components (position & orientation);

o crossing or bringing together clean and dirty cables or components;

o putting components too close together;

o not keeping enough clearance distance.

Figure 14

7.1.2 Ferrites

▪ Ferrites should be positioned close to input and output of the drive.

▪ Do not pass input and output wires which would make the ferrite useless.

Figure 15: Example of good practice 4 turns with one ferrite

NOTE: For more information, please refer to Application Guidelines AGL_Sol_EV3 "EV3

Inverter Drive for ZPV* Variable Speed Compressors" and AGL_AC_VS_YPV "Copeland

Scroll Variable Speed Compressors for R32 Applications – YPV066* & YPV096*" or contact

your local Application Engineering representative at Emerson.

EV3

VSS

Drive supply

EMC measures,

eg, filter, Ferrites, etc.

VSS supply

screened cable

1 DC choke internal

RCD

type B/B+

Page 28

AGL_Sol_PEC_02_E_Rev01 25

7.1.3 Digital inputs and outputs wiring

Figure 16: Digital inputs and outputs wiring for variable-speed circuit 1 (proposal)

Figure 17: Digital inputs and outputs wiring for fixed-speed circuit 2

PeC

DO8 (FS Scroll #6)

DO7 (FS Scroll #5)

DO6 (FS Scroll #4)

DI4 (Feedback safety)

PeC

Modbus master

DO3 (FS Scroll #6)

DO2 (FS Scroll #5)

DI1 (Feedback safety)

Page 29

26 AGL_Sol_PEC_02_E_Rev01

8 Items list for electronic solution package

Description

Type

Item number

PeC series

PeC C100 (single circuit)

PeC C200 (double circuit)

8418438

8418449

Electronic expansion

valves

EX4 – 7 Bipolar stepper

motor valves, uniflow

EX4-I21

EX5-U21

EX6-M21

800615

800618

800621

Cable connector

assembly

EXV-M60 (6-m cable)

804665

Pressure transmitter

Suction pressure 18 bar

Discharge gas pressure

50 bar

PT5N-18M

PT5N-18T

PT5N-50M

PT5N-50T

(Type: xxM = screwed,

xxT = brazed)

805351

805381

805353

805383

Plugged cable assembly

for pressure sensor

PT4-M15 (1.5-m cable)

PT4-M30 (3-m cable)

PT4-M60 (6-m cable)

804803

804804

804805

Temperature sensor with

TP1 NP3 (3-m cable)

TP1 NP6 (6-m cable)

TP1 NP12 (12-m cable)

804489

804490

804491

Accessories

Connectors kit

PeC C100

PeC C200

807983

807984

PeC – EV3 Drive

Modbus connection

XJ485-USB converter

3185902

PeC Firmware flash

cable

Cable XJ485-USB

converter

8416512

Table 19

Page 30

AGL_Sol_PEC_02_E_Rev01 27

9 Certification & approval

▪ The controllers PeC C100 and C200 comply with the Low Voltage Directive LVD 2014/35/EU.

The applied harmonised standards are:

− EN 60335-1:2012/A11:2014: Household and similar electrical appliances - Safety - Part 1:

Part 1: General requirements;

− EN 60335-2-40:2003/A13:2012: Household and similar electrical appliances - Safety - Part

2-40: Particular requirements for electrical heat pumps, air conditioners and dehumidifiers.

Other applied standards:

− DIN IEC 60335-2-40:2018-05: Household and similar electrical appliances - Safety - Part 240: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers;

− EN 60079-15:2010: Explosive atmospheres - Part 15: Equipment protection by type of

protection "n".

▪ The controllers PeC C100 and C200 comply with the Electromagnetic Compatibility Directive

EMC 2014/30/EU. The applied harmonised standards are:

− EN 55014-1:2006/A2:2011: Electromagnetic compatibility - Requirements for household

appliances, electric tools and similar apparatus Part 1: Emission;

− EN 55014-2: 1997/A2:2008: Electromagnetic compatibility - Requirements for household

appliances, electric tools and similar apparatus Part 2: Immunity - Product family standard.

Other applied standards:

− DIN EN 55014-1:2018-08: Electromagnetic compatibility - Requirements for household

appliances, electric tools and similar apparatus Part 1: Emission;

− DIN EN 55014-2:2016-01: Electromagnetic compatibility - Requirements for household

appliances, electric tools and similar apparatus Part 2: Immunity - Product family standard.

▪ The controllers PeC C100 and C200 comply with RoHS 2011/65/EU, (EU) 2015/863.

10 Dismantling & disposal

With reference to the Waste Electrical and Electronic Equipment (WEEE)

Directive 2012/19/EU and to the relative national legislation, please note that:

▪ There lies the obligation not to dispose of electrical and electronic

waste as municipal waste but to separate the waste.

▪ Public or private collection points must be used to dispose of the goods in accordance

with local laws. Furthermore, at the end of the product's life, it is also possible to return

this to the retailer when a new purchase is made.

▪ This equipment may contain hazardous substances. Improper use or incorrect disposal

can have adverse effects on human health and the environment.

▪ The symbol shown on the product or the package indicates that the product has been

placed on the market after 13 August 2005 and must be disposed of as separated waste.

▪ Should the product be disposed of incorrectly, sanctions may be applied as stipulated in

applicable local regulations regarding waste disposal.

DISCLAIMER

1. The contents of this publication are presented for informational purposes only and are not to be

construed as warranties or guarantees, express or implied, regarding the products or services

described herein or their use or applicability.

2. Emerson Climate Technologies GmbH and/or its affiliates (collectively "Emerson"), as

applicable, reserve the right to modify the design or specifications of such products at any time

without notice.

3. Emerson does not assume responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use and maintenance of any Emerson product remains

solely with the purchaser or end user.

4. Emerson does not assume responsibility for possible typographic errors contained in this

publication.

Page 31

28 AGL_Sol_PEC_02_E_Rev01

Page 32

BENELUX

Josephinastraat 19

NL-6462 EL Kerkrade

Tel: +31 45 535 06 73

Fax: +31 45 535 06 71

benelux.sales@emerson.com

UK & IRELAND

Unit 17, Theale Lakes Business Park

Reading, Berkshire RG7 4GB

Tel: +44 1189 83 80 00

Fax: +44 1189 83 80 01

uk.sales@emerson.com

GERMANY, AUSTRIA & SWITZERLAND

Theo-Mack Str. 3

DE-63477 Maintal

Tel: +49 6109 605 90

Fax: +49 6109 60 59 40

ECTGermany.sales@emerson.com

FRANCE, GREECE & MAGHREB

8, Allée du Moulin Berger

FR-69134 Ecully Cédex, Technoparc - CS 90220

Tel: +33 4 78 66 85 70

Fax: +33 4 78 66 85 71

mediterranean.sales@emerson.com

ITALY

Via Ramazzotti, 26

IT-21047 Saronno (VA)

Tel: +39 02 96 17 81

Fax: +39 02 96 17 88 88

italy.sales@emerson.com

SPAIN & PORTUGAL

C/ Pujades, 51-55 Box 53

ES-08005 Barcelona

Tel: +34 93 412 37 52

iberica.sales@emerson.com

CZECH REPUBLIC

Hajkova 22

CZ - 133 00 Prague

Tel: +420 733 161 651

Fax: +420 271 035 655

Pavel.Sudek@emerson.com

ROMANIA & BULGARIA

Parcul Industrial Tetarom 2

Emerson Nr. 4 400641 Cluj-Napoca

Tel: +40 374 13 23 50

Fax: +40 374 13 28 11

ro-bg.sales@emerson.com

ASIA PACIFIC

Suite 2503-8, 25/F., Exchange Tower

33 Wang Chiu Road, Kowloon Bay

Kowloon , Hong Kong

Tel: +852 2866 3108

Fax: +852 2520 6227

SWEDEN, DENMARK, NORWAY & FINLAND

Pascalstr. 65

DE-52076 Aachen

Tel: +49 2408 929 0

Fax: +49 2408 929 525

nordic.sales@emerson.com

EASTERN EUROPE & TURKEY

Pascalstr. 65

DE-52076 Aachen

Tel: +49 2408 929 0

Fax: +49 2408 929 525

easterneurope.sales@emerson.com

POLAND

Szturmowa 2

PL-02678 Warsaw

Tel: +48 22 458 92 05

Fax: +48 22 458 92 55

poland.sales@emerson.com

RUSSIA & CIS

Dubininskaya 53, bld. 5

RU-115054, Moscow

Tel: +7 - 495 - 995 95 59

Fax: +7 - 495 - 424 88 50

ECT.Holod@emerson.com

BALKAN

Selska cesta 93

HR-10 000 Zagreb

Tel: +385 1 560 38 75

Fax: +385 1 560 38 79

balkan.sales@emerson.com

MIDDLE EAST & AFRICA

PO Box 26382

Jebel Ali Free Zone - South, Dubai - UAE

Tel: +971 4 811 81 00

Fax: +971 4 886 54 65

mea.sales@emerson.com

For more details, see www.climate.emerson.com/en-gb

Connect with us: facebook.com/EmersonCommercialResidentialSolutions

AGL_Sol_PEC_02_E_Rev01

Emerson Commercial & Residential Solutions

Emerson Climate Technologies GmbH - Pascalstrasse 65 - 52076 Aachen, Germany

Tel. +49 (0) 2408 929 0 - Fax: +49 (0) 2408 929 570 - Internet: www.climate.emerson.com/en-gb

The Emerson logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Technologies Inc. is a subsidiary of Emerson Electric Co.

Copeland is a registered trademark and Copeland Scroll is a trademark of Emerson Climate Technologies Inc.. All other trademarks are property of their respective owners.

Emerson Climate Technologies GmbH shall not be liable for errors in the stated capacities, dimensions, etc., as well as typographic errors. Products, specications, designs and

technical data contained in this document are subject to modication by us without prior notice. Illustrations are not binding.

© 2019 Emerson Climate Technologies, Inc.

Loading...

Loading...