Page 1

TI_Stream_NGCS_01_E_Rev02 1/18

Date of last update: Jun-20

Ref: TI_Stream_NGCS_01_E_Rev02

Application Engineering Europe

NEXT GENERATION CORESENSE™

FOR COPELAND STREAM™ COMPRESSORS

1 Introduction ............................................................................................................................................................ 3

2 Specifications ........................................................................................................................................................ 3

3 Next Generation CoreSense features ................................................................................................................... 4

4 Warnings, trips and lockouts ................................................................................................................................. 4

5 Protection features ................................................................................................................................................ 5

5.1 Oil protection ................................................................................................................................................. 5

5.1.1 Insufficient oil pressure protection ............................................................................................................ 5

5.1.2 Oil level protection (optional) .................................................................................................................... 5

5.2 Motor overheat protection ............................................................................................................................. 6

5.2.1 Static overheat protection ......................................................................................................................... 6

5.2.2 Dynamic overheat protection .................................................................................................................... 6

5.3 High discharge temperature protection......................................................................................................... 6

5.4 Current protection ......................................................................................................................................... 7

5.4.1 Locked rotor protection ............................................................................................................................. 7

5.4.2 MOC protection ......................................................................................................................................... 7

5.4.3 Switching frequency overstepping protection ........................................................................................... 7

5.4.4 MOC detection at first start ....................................................................................................................... 7

5.5 Phase / voltage monitoring ........................................................................................................................... 8

5.5.1 Missing phase protection / Phase failure protection ................................................................................. 8

5.5.2 Undervoltage protection ............................................................................................................................ 8

5.5.3 Overvoltage protection .............................................................................................................................. 8

5.5.4 Voltage imbalance protection ................................................................................................................... 8

5.5.5 Welded contactor protection ..................................................................................................................... 8

5.5.6 Part-winding protection ............................................................................................................................. 9

6 Variable frequency drive mode .............................................................................................................................. 9

7 Emergency mode .................................................................................................................................................. 9

8 LEDs on the terminal box cover .......................................................................................................................... 10

8.1 Compressor status codes ........................................................................................................................... 10

8.2 Failure alarms displayed by LEDs .............................................................................................................. 11

9 Alarm history ........................................................................................................................................................ 11

10 Reset button ........................................................................................................................................................ 12

11 Crankcase heater control .................................................................................................................................... 12

12 Power consumption measurement ...................................................................................................................... 12

13 Data port for communication with Next Gen CoreSense module app ................................................................ 12

Page 2

TI_Stream_NGCS_01_E_Rev02 2/18

13.1 Connectivity ................................................................................................................................................ 13

14 Modbus module (optional) ................................................................................................................................... 13

15 Next Gen CoreSense module app ...................................................................................................................... 13

16 Electrical connections .......................................................................................................................................... 14

16.1 Basic connections ....................................................................................................................................... 14

16.2 Wiring diagrams .......................................................................................................................................... 14

17 List of tables and figures ...................................................................................................................................... 18

Page 3

TI_Stream_NGCS_01_E_Rev02 3/18

1 Introduction

CoreSense™ is an ingredient brand name for compressor electronics associated with Copeland™ branded

compressors. The CoreSense technology uses the compressor as a sensor to unlock information from within the

compressor, providing value-added features such as advanced motor protection, diagnostics, power consumption

measurement and communication.

With active protection, advanced algorithms, and features like fault history and LED indicators, the Next Generation

CoreSense (or Next Gen CoreSense) for Copeland brand compressors enables technicians to diagnose the past

and recent state of the system, allowing for quicker, more accurate diagnostics and less downtime. Next Gen

CoreSense is available as standard with the 4- and 6-cylinder Stream compressors.

The advantages of the Next Gen CoreSense module versus other protection modules are the response speed and

the overall protection scheme. All protection features are functional right after compressor start and the module will

stop the compressor in less than a second if a harming situation is detected.

Figure 1: Next Generation CoreSense module

2 Specifications

The Next Gen CoreSense module is located and prewired in the terminal box. All required parameters are flashed

during the production of the compressor.

The power supply for the control module can be 115V AC or 230V AC.

Operating ambient temperature

-30 °C to 70 °C

Storage temperature

-30 °C to 80 °C

Voltage requirements

115-230 VAC - 50/60Hz

Protection class

IP00

Table 1: Next Gen CoreSense specifications

Figure 2: Next Gen CoreSense inside the terminal box

Page 4

TI_Stream_NGCS_01_E_Rev02 4/18

3 Next Generation CoreSense features

Next Gen CoreSense is a modular system. This modular design gives the customers the flexibility to choose individual

protection and/or control levels. It is possible to extend the compressor protection from just basic functions to a high

tier protection to enlarge the lifetime of the compressor.

Figure 3: Inside view of the Next Gen CoreSense module, with the modular boards

Basic features

Motor overheat protection

High discharge temperature protection

Insufficient oil pressure protection

Oil level protection (in combination with Emerson TraxOil)

Current protection

Phase failure protection

Voltage imbalance protection

Undervoltage and overvoltage protection

Power consumption measurement

Part-winding protection

Crankcase heater control

Welded contactor protection

Switching frequency overstepping protection

Connection with computer, Android or iOS device

LEDs on the terminal box cover

Reset button for manual reset

Table 2: List of basic features

4 Warnings, trips and lockouts

Next Gen CoreSense provides 3 different protection levels. Each of them has its own LED colour.

▪ Warning alarms: Compressor will continue to run.

▪ Trip alarms: Compressor turns off for defined time with automatic reset.

The compressor was stopped due to a fault condition. The compressor will restart when the fault condition is

cleared and the defined off time has elapsed.

▪ Lockout alarms: Compressor turns off, manual reset is necessary.

The compressor was stopped due to a fault condition. The compressor will restart when the fault condition is

cleared and a manual reset using the reset button has been done. If a Modbus extension module is mounted,

the reset can be done via Modbus.

Page 5

TI_Stream_NGCS_01_E_Rev02 5/18

5 Protection features

5.1 Oil protection

5.1.1 Insufficient oil pressure protection

The Next Gen CoreSense module receives an input from the oil pressure differential sensor (OPS3) located in the

oil pump.

The module replaces the mechanical oil pressure switch. Furthermore, it provides the added value of communication

for insufficient oil pressure warning and lockout via LED flash codes and/or a supervisory pack controller. Total

insufficient oil pressure time for the compressor is stored and accumulated in the module memory.

The module will issue a warning when the oil pressure differential falls below 0.95 bar for 4 seconds. Once the oil

pressure differential falls below 0.95 bar for 2 minutes, the module will trip the compressor and a "low oil pressure

lockout" will be reported. Before using the reset button, troubleshooting needs to be done to understand the failure.

The compressor will switch back on once the reset has been manually activated.

NOTE: This feature is not applicable to Stream CO2 compressors that do not have an oil pump fitted and are

"splash" lubricated.

OPS3 Oil Pressure Switch sensor technical data:

▪ Permitted ambient temperature: -30 °C to 90 °C

▪ Protection Class: IP45

Figure 4: OPS3 Oil Pressure Switch and electronic

part (delivered connected)

5.1.2 Oil level protection (optional)

The oil protection is achieved with an OW4/5 TraxOil watch device and OM3/4/5 TraxOil level monitoring device.

The TraxOil uses a hall sensor to measure the oil level. A magnetic float (unaffected by foaming oil) changes its

position according to the oil level. The hall sensor converts the magnetic field changes into an equivalent signal,

which is used by the integrated electronic controller to monitor and display the actual oil level with LEDs.

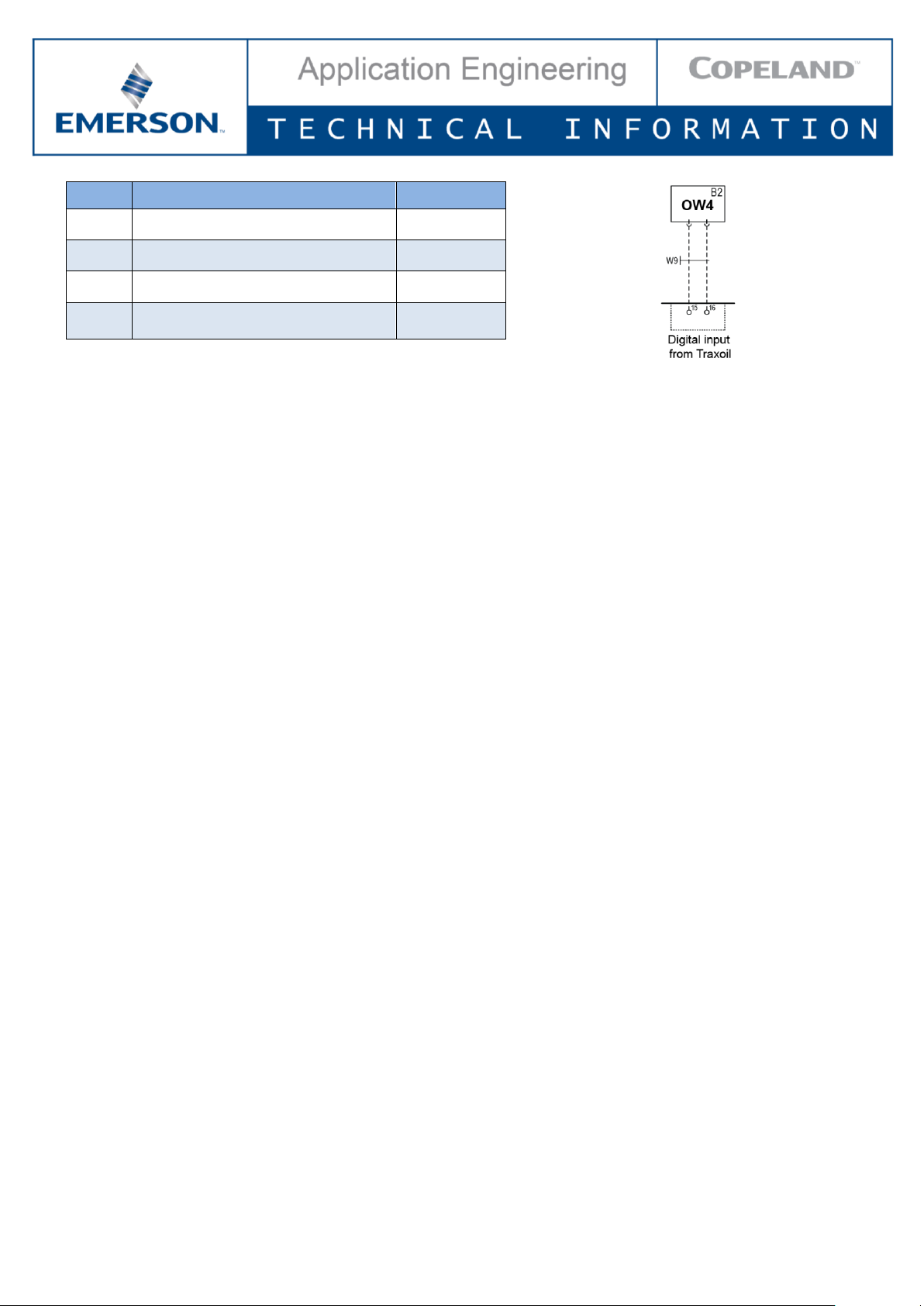

Figure 5: TraxOil OW5 Oil watch device Figure 6: Sight glass level control zones

Page 6

TI_Stream_NGCS_01_E_Rev02 6/18

LEDs

Status

Function

•

Oil level in green zone (60 – 40 %)

OK

• •

Oil level in green zone (60 – 40 %)

OK

•

Oil level in yellow zone (40 – 25 %)

OK

•

Oil level in red zone (25 – 0 %)

Warning or

trip

Table 3: LED code legend

The oil watch device is not part of the standard compressor delivery; it will have to be connected to the Next Gen

CoreSense module via terminals 15 and 16.

Two connection possibilities can be chosen in the Next Gen CoreSense module app:

▪ Closed when OK:

o Default setting after activation

o Connect Blue (BU) and Black (BK) wires

▪ Open when OK:

o Connect Brown (BN) and Black (BK) wires

The user has the possibility to select between a warning or trip condition if the oil level is below 25 %.

5.2 Motor overheat protection

By using Positive Temperature Coefficient (PTC) thermistors on 4M* and 6M* Stream compressor models, Next Gen

CoreSense provides motor overheating protection.

Two chains of three thermistors each connected in series are embedded in the motor windings in such a manner that

the temperature of the thermistors can follow with little inertia.

5.2.1 Static overheat protection

The Next Gen CoreSense module will trip the compressor if the motor windings are getting too hot.

Standard condition:

▪ Total resistance of the thermistor chains @ 25 °C ≤ 1.8 kΩ

Alarm condition:

▪ Trip condition: PTC resistance > 4.5 kΩ;

▪ Reset condition: PTC resistance < 2.75 kΩ; 5 min time delay.

Trip due to sensor failure:

▪ Short circuit: PTC resistance < 20 Ω;

▪ Open circuit: PTC resistance > 20 kΩ.

5.2.2 Dynamic overheat protection

If the motor winding temperature increases in a short period (>240ohm/400ms), the module will trip the compressor.

The compressor will restart after 5 minutes.

5.3 High discharge temperature protection

Discharge temperature protection is provided using a PT1000 sensor in the compressor cylinder head.

The sensor is pre-installed at the factory and connected to the Next Gen CoreSense module. The module will protect

the compressor from high discharge temperature conditions. If the temperature sensor detects a discharge

temperature higher than 154 °C, the module will shut off the compressor until the temperature cools down to an

acceptable level (20 K below setpoint).

The configurable range of trip settings is 108 °C to 154 °C and the reset value is 83 °C to 134 °C.

▪ Trip value ≥ 154 °C for 0.5 sec

▪ Trip alarm: automatic reset after 2 minutes; discharge temp < 130 °C

Page 7

TI_Stream_NGCS_01_E_Rev02 7/18

PT1000 sensor technical data:

▪ Measuring range: -40°C to 155°C, 170°C for 30 minutes max

▪ Tightening torque: 15 Nm

▪ Protection class: IP65

Figure 7: Discharge temperature sensor

5.4 Current protection

A current sensor is located in the terminal box.

One power supply wire (2 from the same phase in case of part-winding) is going through

this sensor – see T1 in Chapter 16.2 Wiring diagrams.

The direction of the leads has to be respected.

Figure 8: Current sensor

5.4.1 Locked rotor protection

If, 2.5 seconds after compressor start, the current is 150% of the MOC value, an alarm is triggered and the

compressor trips. The alarm is reset after 5 minutes.

After 10 trips a lockout is activated and the Next Gen CoreSense module must be reset manually using the reset

button (no automatic reset).

5.4.2 MOC protection

The MOC value of a compressor is stored into the Next Gen CoreSense module. The compressor trips if the

measured current is higher than the MOC for more than 2 seconds.

This function starts 4.5 seconds after compressor start and resets automatically 5 minutes after tripping.

5.4.3 Switching frequency overstepping protection

The number of compressor starts is monitored over a defined period of time. If the compressor reaches the maximum

number of starts in a time shorter than the defined one, an alarm is triggered.

▪ Default setting is 10 starts in 1 hour and trip generation.

▪ The reset time is calculated as the difference between the defined time period (1 hour) and the actual time it

took for the defined maximum number of starts (10) to occur.

▪ Example:

o 10 starts occurred in 35 minutes

o the alarm is triggered at 35 minutes

o automatic reset will be done after 25 minutes

It is possible to choose between a warning or compressor trip.

5.4.4 MOC detection at first start

Most compressors have two sets of nominal voltages and frequencies:

▪ 50 Hz or 60 Hz value for part-winding motors (AW…)

▪ different voltages for Δ/Y start motors (EW...)

At first start and at every power reset, the Next Gen CoreSense module automatically detects the compressor power

supply (voltage and frequency) and will automatically select the corresponding MOC and undervoltage/overvoltage

protection setpoints.

If the measured voltage and/or frequency is different from the one defined on the nameplate, the module will generate

a warning.

For example, if an AWM/D (400 V / 50 Hz or 460 V / 60 Hz) motor is connected to a 230 V power line, the green LED

will flash.

Page 8

TI_Stream_NGCS_01_E_Rev02 8/18

5.5 Phase / voltage monitoring

There are 6 voltage sensor circuits to measure the 3 phases. Thanks to the 6 sensors the part-winding motors can

also be protected.

The status of each phase in direct on-line and part-winding is monitored for undervoltage, overvoltage and phase

asymmetry.

5.5.1 Missing phase protection / Phase failure protection

A comparison is made between the voltage of each phase and their average. If any of the 3 power phases is missing

after compressor start, a single-phasing condition exists.

Any voltage imbalance above 60 % is a condition for phase-loss trip.

Alarm conditions: occurs in case of missing phase conditions.

▪ Trip time: 5 minutes with automatic reset.

A missing phase can be detected during start-up and when the compressor is running.

5.5.2 Undervoltage protection

Occurs when the compressor voltage is lower than the nominal supply voltage.

Low voltage warning condition: voltage < 85 % of the nominal line voltage for 2 seconds.

Low voltage trip conditions: voltage < 75 % of the nominal line voltage 2 seconds.

▪ Trip time: 2 minutes.

5.5.3 Overvoltage protection

Occurs when the compressor voltage is higher than the nominal supply voltage.

High voltage warning condition: voltage > 115 % of the nominal line voltage for 2 seconds.

High voltage trip conditions: voltage > 125 % of the nominal line voltage for 2 seconds.

▪ Trip time: 2 minutes.

5.5.4 Voltage imbalance protection

The purpose of this feature is to protect the compressor against a voltage imbalance that could lead to motor

overheating.

A configurable setting (default = 5 %) for voltage imbalance is used to determine the operating limit of the compressor.

The voltage imbalance setting is configurable in the range of 2 to 8 % using the Next Gen CoreSense module app.

Alarm conditions:

▪ Warning: when the voltage imbalance > 3 % (configurable).

▪ Trip: when the voltage imbalance > 5 % (configurable).

▪ Reset: automatic reset after 5 min; voltage imbalance < 5 %.

5.5.5 Welded contactor protection

This protection verifies 3 independent run signals:

▪ voltage available on all terminals;

▪ current detected on 1 phase;

▪ demand signal – signal from controller to contactor.

If the three run signals are not identical, the Next Gen CoreSense module will generate an alert.

Protection is disabled in default setting. If the Next Gen CoreSense module is connected to the main controller

(terminals 17 and 18) and a demand signal is detected the feature is enabled.

The user has the possibility to select between a warning or trip condition. After a trip, the compressor will restart

after 2 minutes. Default setting is warning.

After 10 trips a lockout is activated and the module must be reset manually using the reset button (no automatic

reset).

Page 9

TI_Stream_NGCS_01_E_Rev02 9/18

5.5.6 Part-winding protection

The two winding supply cables should go through the current sensor in the same direction.

At first start or at power reset of the Next Gen CoreSense module, the voltage is measured on both windings.

▪ If the voltages are identical:

o the compressor is connected in full winding;

o the protection is disabled.

▪ If the voltages are different, the voltages are compared again after 1 second:

o if the voltage on the second winding is the same as on the first winding:

- the compressor is connected in part-winding;

- the protection is enabled;

o if the voltage on the second winding is not the same as on the first winding, the second winding is improperly

connected and the compressor trips.

The user has the possibility to select between a warning or trip condition. After a trip, the compressor will restart

after 2 minutes. Default setting is trip.

6 Variable frequency drive mode

When operating with a variable frequency drive, all electrical alarms are disabled.

The variable frequency drive (VFD) mode can be activated through the following procedure:

▪ disconnect the Next Gen CoreSense Module from the power supply;

▪ disconnect the current sensor terminals 9 and 10;

▪ connect a bridge between the current sensor terminals on the module (short circuit);

▪ energize the module:

o a short-circuit alarm (orange flashing LED) of the current sensor will appear;

▪ press and hold the reset button for more than 10 sec (can only be done during the first 5 minutes after power

reset):

o green/red quick flash code of LED;

o after 10 sec, flashing becomes slow;

▪ once the reset button is released, the VFD mode is activated.

If the current sensor is connected again, the VFD mode can be activated by pressing the reset button for more than

10 seconds.

7 Emergency mode

The emergency mode can exceptionally be used to bypass the advanced protection and operate only with basic

protection (oil pressure and motor temperature).

To activate the emergency mode:

▪ disconnect the discharge line temperature sensor from the Next Gen CoreSense module, terminals 7 and 8;

▪ connect a bridge between the discharge line temperature sensor terminals (short circuit);

▪ press and hold the reset button for more than 10 seconds.

Page 10

TI_Stream_NGCS_01_E_Rev02 10/18

8 LEDs on the terminal box cover

Status LEDs in 3 colours (green, orange and red) are visible on the top of the T-box.

Figure 9: Next Gen CoreSense module terminal box

8.1 Compressor status codes

▪ Steady green: An indication of normal operation. There are no faults or issues with the compressor.

▪ Flashing green: An indication that there is a warning condition. The compressor keeps running.

▪ Steady orange: An indication that the compressor is in emergency mode.

▪ Flashing orange: An indication that the compressor has tripped and will automatically restart after a defined

time (auto reset).

▪ Steady red: An indication that CoreSense is in parametrization mode.

▪ Flashing red: An indication that the compressor is locked out. Manual reset is needed for restart.

Reset button

Page 11

TI_Stream_NGCS_01_E_Rev02 11/18

8.2 Failure alarms displayed by LEDs

Alarms are displayed via coloured LEDs and flashing sequences. Every flash sequence is interrupted by a 2-second

pause.

Standard settings

Chap.

Flash

code

Protection feature

Standard

delivery

Compressor

keeps running

Automatic reset

Manual reset

required

Automatic reset

after trip

Warning

Trip

Lockout

5.1.1

1

Low oil pressure

(oil pump)

X

< 0.95 bar

after 4 sec

< 0.95 bar

after 2 min

5.1.2

Oil level protection

(OM)

X

Selection

possible

Oil level below

25 %

Correct oil level

5.2.1

2

Static motor overheat

protection

X

PTC resistance

> 4.5 kΩ

5 minutes and PTC

resistance < 2.75 kΩ

5.2.2

Dynamic motor

overheat protection

X

> 240 Ω/400 ms

5 minutes

5.3

3

High discharge

temperature (DLT)

X 154 °C

2 minutes and

< 130 °C

5.4.1

4

Locked rotor

protection

X 150 % of MOC

10 X Trip

5 minutes

5.4.2

Maximum Operating

Current (MOC)

X MOC

5 minutes

5.4.3

Switching frequency

protection

X

Selection

possible

10 starts/hour

When number of

starts/set time period

is lower than set value

5.4.4

MOC detection at first

start

X

Voltage different

from nameplate

5.5.1

5

Missing phase

protection

X

60 % of voltage

imbalance

5 minutes

5.5.2

Undervoltage

protection

X

< 85 % of nominal

voltage for 2 sec

< 75 % of nominal

voltage for 2 sec

2 minutes

5.5.3

Overvoltage

protection

X

> 115 % of

nominal voltage

for 2 sec

> 125 % of

nominal voltage

for 2 sec

2 minutes

5.5.4

Voltage imbalance

protection

X

Imbalance > 3 %

Imbalance > 5 %

5 minutes and min

2 % below setpoint

5.5.5

Welded contactor

protection

X

No demand

signal/current on

one phase

Selection

possible

10 X Trip

5.5.6

Part-winding

protection

X

Selection

possible

Voltage difference

after 1 sec

Table 4: Flashing explanation X = Disabled in standard delivery

9 Alarm history

The 20 most recent alarms are stored in the module memory and can be downloaded with the Next Gen CoreSense

module app.

Page 12

TI_Stream_NGCS_01_E_Rev02 12/18

10 Reset button

Pressing the reset button is needed after a compressor lockout. In addition, it can be used for an immediate trip

reset (no compressor waiting time to restart).

▪ If the tripping condition is cleared, all tripping counters are set to zero, the compressor can restart.

▪ If the tripping condition is not cleared, the reset signal is ignored.

11 Crankcase heater control

The Next Gen CoreSense module controls the crankcase heater directly, so only a crankcase heater with the same

power supply as the CoreSense module (115 VAC or 230 VAC) can be applied and connected to terminals 3 and 4.

Figure 10: Wiring diagram – Crankcase heater connections

12 Power consumption measurement

The power is calculated from the measured voltage, current and power factor.

Accuracy for each measurement:

▪ voltage ± 5 %

▪ current ± 5 %

▪ power factor ± 10 %

Power consumption in kWh is provided in the Next Gen CoreSense module app.

13 Data port for communication with Next Gen CoreSense module app

The data port can be used for communication with the Next Gen CoreSense module app to parameter or download

data (running history and alarms).

Figure 11: Data port on the Next Gen CoreSense module

Page 13

TI_Stream_NGCS_01_E_Rev02 13/18

13.1 Connectivity

There are two possibilities for communication over the data port, USB or Bluetooth gateway.

USB gateway can be used with any computer USB type-A. Adapters USB type-A to USB micro-B and USB-C are

delivered to enable connection with Android devices. The connection with iOS devices is not possible over USB

gateway.

Bluetooth gateway can be used with any device with Bluetooth adapter. It is also the only connection possibility for

iOS devices.

Figure 12: USB gateway Figure 13: Bluetooth gateway

14 Modbus module (optional)

The Next Gen CoreSense module can be equipped with a Modbus extension module for communication via RS485.

The diagnosis data can be read into system controllers using the standard Modbus RTU Protocol.

Figure 14: Modbus extension module

NOTE: More information about the Modbus interface can be found in the dedicated Technical Information

TI_Stream_NGCS_02 "Next Generation CoreSense™ – Modbus Interface Description".

15 Next Gen CoreSense module app

An application can be downloaded from Google Play Store for Android, Microsoft Store for Windows or Apple Store

for iOS devices. It provides access to the error memory/counter, so the current status of the system can be assessed,

and the operating data can be reviewed.

This application also allows to analyse the measurements done by the Next Gen CoreSense module various sensors

and to give information about compressor operation such as:

▪ operating time in normal / warning / tripping conditions;

▪ number of starts & stops;

▪ power consumption;

▪ compressor running time;

▪ crankcase heater running hours counter.

The Next Gen CoreSense module app can be connected to the Next Gen CoreSense using DP-USB gateway (not

applicable for Apple devices) or Bluetooth gateway.

Page 14

TI_Stream_NGCS_01_E_Rev02 14/18

16 Electrical connections

16.1 Basic connections

The Next Gen CoreSense module is originally delivered with the basic modules preconnected.

Figure 15: Next Gen CoreSense basic protections

16.2 Wiring diagrams

IMPORTANT

For Stream CO2 small and medium compressor models (4MTL-05 to 4MTL-30 &

4MSL-03 to 4MSL-15), the blue positions 1U, 2V, 3W, 7Z, 8X, 9Y in diagrams

below must be considered. The position of the terminals in all the other Stream

compressor models corresponds to the black positions. The factory delivery is

correct, DO NOT reverse the connections.

Legend

B1 .......... Discharge gas sensor DGT ....... Discharge gas temperature monitoring

B2 .......... Oil level watch (TraxOil) OW ........ Digital oil level watch

B3 .......... Oil differential pressure switch (OPS) OPS ....... Oil differential pressure protection

B11 ........ High-pressure switch AR ......... Alarm relay

B12 ........ Low-pressure switch DS ......... Demand signal

CTR2 ..... DP Gateway

E1 .......... Heater CH ......... Control oil heater

F1,F2,F3 Compressor fuses PTC ....... Motor thermal protection

F4, F5 .... Fan fuses PM ......... Phase monitoring

F6 .......... CoreSense and heater fuse PS .......... Power supply

F7 .......... Control circuit fuse

H1 ......... Diagnosis LED

K11 ........ Time relay for part-winding (if used)

M2 ......... Fan motor

Q11 ....... Compressor contactor Q15 ........ Fan contactor

Q12 ....... Compressor contactor Y (if Y/Δ start) Q13 ........ Compressor contactor Δ (if Y/Δ start)

Q14 ....... Compressor contactor 2nd part-winding (if used)

SB1 ....... Reset button

Y21 ........ Solenoid valve capacity control 1

Y22 ........ Solenoid valve capacity control 2

T1 .......... Current sensor CM ......... Current monitoring

Page 15

TI_Stream_NGCS_01_E_Rev02 15/18

Figure 16: Wiring diagram for part-winding motors (AW…)

Page 16

TI_Stream_NGCS_01_E_Rev02 16/18

Figure 17: Wiring diagram for Star / Delta motors (EW…)

Page 17

TI_Stream_NGCS_01_E_Rev02 17/18

Figure 18: Wiring diagram (2nd part) for part-winding and Star / Delta motors (AW… and EW…)

Page 18

TI_Stream_NGCS_01_E_Rev02 18/18

17 List of tables and figures

Tables

Table 1: Next Gen CoreSense specifications ............................................................................................................... 3

Table 2: List of basic features ....................................................................................................................................... 4

Table 3: LED code legend ............................................................................................................................................ 6

Table 4: Flashing explanation X = Disabled in standard delivery ........................................................................... 11

Figures

Figure 1: Next Generation CoreSense module ............................................................................................................ 3

Figure 2: Next Gen CoreSense inside the terminal box ............................................................................................... 3

Figure 3: Inside view of the Next Gen CoreSense module, with the modular boards .................................................. 4

Figure 4: OPS3 Oil Pressure Switch and electronic part (delivered connected) .......................................................... 5

Figure 5: TraxOil OW5 Oil watch device

Figure 6: Sight glass level control zones .................................................................................................................. 5

Figure 7: Discharge temperature sensor ...................................................................................................................... 7

Figure 8: Current sensor ............................................................................................................................................... 7

Figure 9: Next Gen CoreSense module terminal box ................................................................................................. 10

Figure 10: Wiring diagram – Crankcase heater connections ..................................................................................... 12

Figure 11: Data port on the Next Gen CoreSense module ........................................................................................ 12

Figure 12: USB gateway

Figure 13: Bluetooth gateway ..................................................................................................................................... 13

Figure 14: Modbus extension module ........................................................................................................................ 13

Figure 15: Next Gen CoreSense basic protections .................................................................................................... 14

Figure 16: Wiring diagram for part-winding motors (AW…) ....................................................................................... 15

Figure 17: Wiring diagram for Star / Delta motors (EW…) ......................................................................................... 16

Figure 18: Wiring diagram (2nd part) for part-winding and Star / Delta motors (AW… and EW…) ............................ 17

Loading...

Loading...