Page 1

Instruction Manual

P/N 20001909, Rev. DA

August 2009

ProLink® II Software

for Micro Motion®

Transmitters

Installation and Use Manual

Page 2

© 2009 Micro Motion, Inc. All rights reserved.

The Micro

ProLink, MVD Direct Connect, and PlantWeb are marks of one of the Emerson Process Management family of companies. All

other trademarks are property of their respective owners.

Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. Micro Motion, ELITE, MVD,

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 About ProLink II software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.1 Supported transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.2 Uses of ProLink II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 ProLink II requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 PC requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Installation kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Determining your transmitter type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Required privileges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Install the ProLink II software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Generate a temporary license. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Connect the PC to the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.1 Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Configure ProLink II connection parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 Obtain and configure a site key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.8 Troubleshooting the ProLink II installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.8.1 Insufficient privileges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.8.2 Missing or corrupt Registry entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.9 Troubleshooting the ProLink II connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.9.1 OPC server or OPC client issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.9.2 Other issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3 Using ProLink II Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Connecting to a transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.2 Disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3 Using the Commissioning Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.1 Disabling write-protect mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.2 Saving transmitter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.3 Starting the Commissioning Wizard automatically. . . . . . . . . . . . . . . . . . 29

3.4 ProLink II help system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.5 Viewing installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6 Viewing process data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.7 Viewing and resetting totalizers and inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.8 Viewing meter status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.9 Viewing and acknowledging alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.9.1 Viewing alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.9.2 Acknowledging alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation and Use Manual i

Page 4

Contents

3.10 Managing the ProLink II license . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.10.1 Transferring to same PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.10.2 Transferring to different PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 4 Initial Transmitter Startup Procedures. . . . . . . . . . . . . . . . . . . . . . 37

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 Loop tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3 Trimming the milliamp (mA) output(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4 Zeroing the meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 5 Transmitter Configuration, Characterization,

and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Using configuration files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.1 Saving a configuration file to a PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.2 Loading a configuration file to a transmitter. . . . . . . . . . . . . . . . . . . . . . . 44

5.3 Configuring a transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3.1 Using the Gas Unit Configurator tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.4 Characterizing the meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4.1 When to characterize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4.2 Characterization parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4.3 How to characterize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5 Calibrating the meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5.1 When to calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.2 Density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5.3 Temperature calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.6 Compensating for pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6.1 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6.2 Pressure correction factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6.3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.7 Compensating for temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.8 Configuring polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 6 Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 7 Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.2 Using Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.2.1 Defining the log file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.2.2 Specifying log contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.2.3 Starting and stopping the logging function . . . . . . . . . . . . . . . . . . . . . . . 63

7.2.4 Data Logger tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix A Transmitter Terminal Reference . . . . . . . . . . . . . . . . . . . . . . . . . . 65

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

A.2 Transmitter terminal diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

ii ProLink® II Software for Micro Motion® Transmitters

Page 5

Contents

Appendix B Configuring the Discrete Batch Application . . . . . . . . . . . . . . . . . . 73

B.1 About this appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

B.2 About discrete batching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

B.3 Discrete batch configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

B.3.1 Flow source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

B.3.2 Control options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

B.3.3 Configure presets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

B.3.4 Batch control methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

B.4 Running a batch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

B.5 Performing Batch AOC calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Installation and Use Manual iii

Page 6

iv ProLink® II Software for Micro Motion® Transmitters

Page 7

Chapter 1

Before You Begin

1.1 About this manual

This manual explains how to install the Micro Motion

on your personal computer (PC).

This manual also provides an overview of using ProLink II with Micro Motion transmitters. Before

using this instruction manual, the reader should be familiar with the Microsoft Windows operating

system.

There are a number of transmitter and application features that may appear in your ProLink II

installation: for example, the enhanced density application, the petroleum measurement application,

the custody transfer application, event configuration, or display configuration. This manual contains

information on configuring and using the discrete batch application (see Appendix B). For detailed

information on configuring and using other transmitter-specific or application-specific features, see

the appropriate transmitter or application manual. If you still have questions, contact the Micro

Motion Customer Service Department. Telephone numbers are listed in Section 1.5.

®

ProLink®II software program, v2.9 and later,

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

1.2 About ProLink II software

This section provides an overview of ProLink II software.

1.2.1 Supported transmitters

The ProLink II program supports the following Micro Motion transmitters and devices:

• Model 1700/2700

• Model 1500/2500

• Model 2400S

• Model 2200S

• Model 7826 and Model 7828 (advanced electronics)

• Core processor and enhanced core processor

•MVD

• Series 3000 with 4-wire sensor interface (MVD™)

• RFT9739

• RFT9712

• IFT9701/9703

Note: MVD Direct Connect is a direct host meter that does not include a transmitter. However,

ProLink II can be used to communicate with the core processor component in MVD Direct Connect

installations.

™

Direct Connect

™

Installation and Use Manual 1

Page 8

Before You Begin

1.2.2 Uses of ProLink II

Using ProLink II, you can:

• Perform initial transmitter startup procedures

• Read process variables

• Manage totalizers and inventories

• Configure the transmitter

• Perform verification and calibration procedures

• Read meter status information and alarm conditions

• Troubleshoot the meter

1.3 ProLink II requirements

Before starting the ProLink II installation, review the requirements in this section.

1.3.1 PC requirements

To install and run ProLink II, your PC must meet or exceed the following requirements:

• 200 MHz Pentium processor

• One of the following:

- Windows 2000 with Service Pack 3 and 128 MB RAM

- Windows XP with Service Pack 1 and 128 MB RAM

• 80 MB of available hard disk space

• Video with support for 256 or more colors

•CD-ROM drive

• An available serial port or USB port

1.3.2 Installation kits

Micro Motion provides ProLink II installation kits for RS-485 connections and for Bell 202

connections. There are four different kit options:

• RS-232 to Bell 202 HART converter with tester and cables

• RS-232 to RS-485 Modbus/HART converter with tester and cables

• USB to Bell 202 HART converter with tester and cables

• USB to Bell 202 HART converter with tester and cables

Note: A Windows driver is required for correct operation of USB converters and adapters. Drivers are

provided with the installation kit. Install the driver before connecting the converter or adapter. Failure

to install the driver first will result in Windows not recognizing the device when it is plugged in.

2 ProLink® II Software for Micro Motion® Transmitters

Page 9

Before You Begin

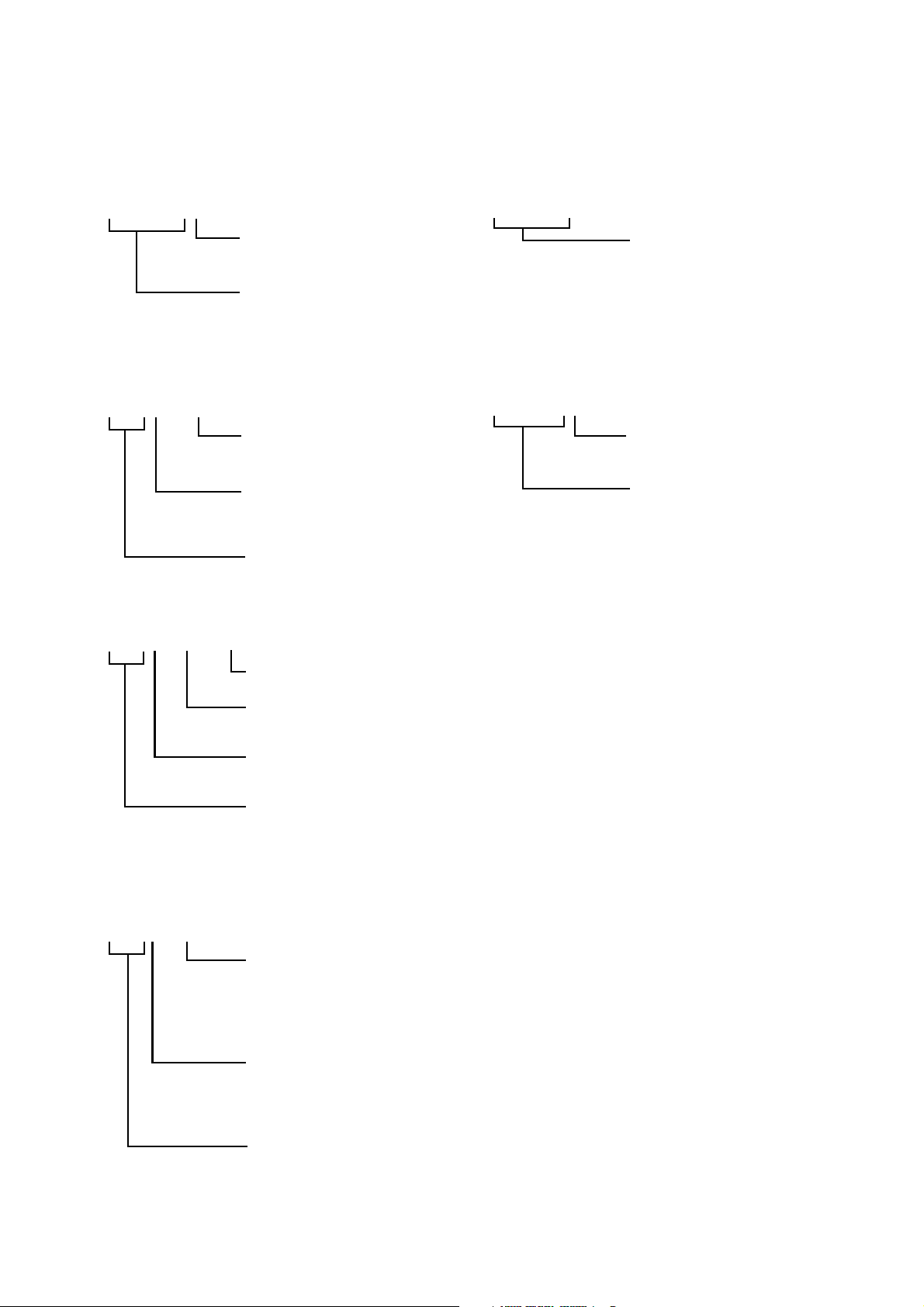

1.4 Determining your transmitter type

To configure, use, and troubleshoot the transmitter, you must know your transmitter type,

installation/mounting type, and outputs option board type (Series 1000/2000 transmitters only). The

transmitter’s model number, which is provided on a tag attached to the transmitter, provides this

information. See Figure 1-1 for assistance in interpreting the model number.

If you are using MVD Direct Connect, refer to the model number on the sensor.

1.5 Micro Motion customer service

For customer service, phone the support center nearest you:

• In the U.S.A., phone

800-522-MASS (800-522-6277) (toll-free)

• In Canada and Latin America, phone +1 303-527-5200

•In Asia:

- In Japan, phone 3 5769-6803

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Customers outside the U.S.A. can also email Micro Motion customer service at

flow.support@emerson.com.

Installation and Use Manual 3

Page 10

Before You Begin

R F T 9 7 3 9 x x x x x x x

Mounting:

• R = rack-mount or panel-mount

• D, E = field-mount

Transmitter model

x 7 0 0 x x x x x x x x x x

Outputs option board:

• A = analog outputs option board

• B, C = configurable input/outputs option board

• D = intrinsically safe outputs option board

•E = F

OUNDATION fieldbus outputs option board

• G = PROFIBUS PA outputs option board

Mounting/installation type:

• R = remote (4-wire remote installation)

• I = integral (transmitter mounted on sensor)

• C = transmitter/core processor assembly (9-wire remote installation)

• B = remote core processor with remote transmitter

Transmitter model

3 x x 0 x x x x x x x x x x x x

Sensor interface:

• 0 = none (MVD)

• 5, 6 = 4-wire (MVD)

Mounting:

• R = rack-mount

• P = panel-mount

• A = field-mount

Transmitter model

I F T 9 7 0 x x x x x x x x

Mounting:

•I, M = integral

• R, L, J, S, A = remote

Transmitter model

x 5 0 0 x x x x x x x x x x x x

Software option 1:

• B = Filling and Dosing application

(1)

Outputs option board:

• A = analog outputs option board

• B, C = configurable input/outputs option board

Mounting/installation type:

• D = 4-wire to sensor with integral core processor

• B = remote core processor with remote transmitter

Transmitter model

IFT9701/9703

RFT9739

Model 1700/2700

Model 1500/2500

Series 3000

R F T 9 7 1 2 x x x x x x x

Transmitter model

RFT9712

(1) Model 1500 transmitter with filling and dosing application only.

Requires Outputs option board C.

Figure 1-1 Transmitter model numbers and codes

4 ProLink® II Software for Micro Motion® Transmitters

Page 11

Before You Begin

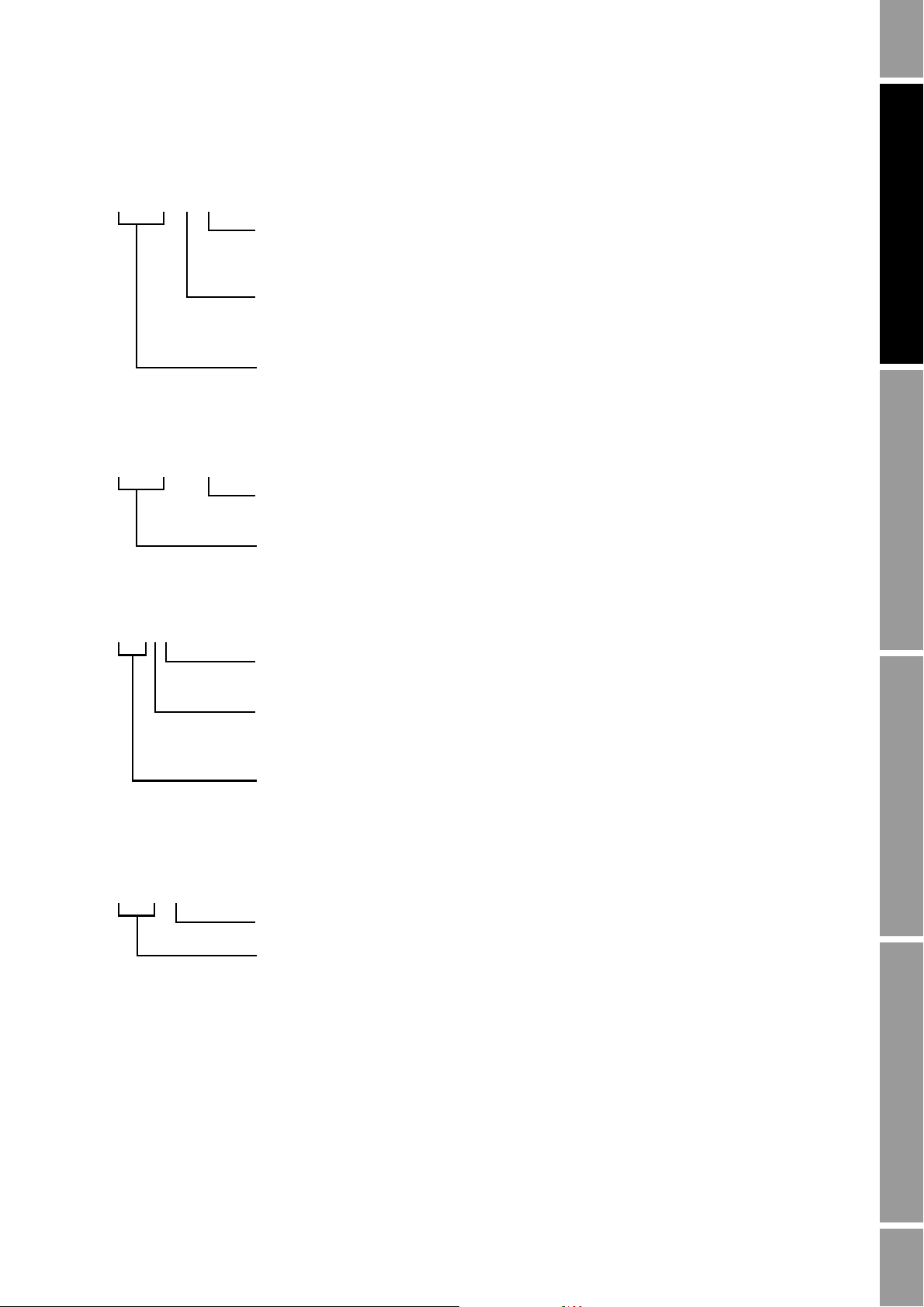

2 4 0 0 S x x x x x x x x x

User interface option:

• 1 = display/LCD with glass lens

• 2 = no display/LCD

• 3 = display/LCD with non-glass lens

Outputs option board:

• A = analog outputs option board

• C = DeviceNet I/O option board

• D = PROFIBUS DP I/O option board

Transmitter model

Model 2400S

2 2 0 0 S x x x x x x x x x

User interface option:

• 1 = display/LCD with glass lens

• 4 = display/LCD with non-glass lens

Transmitter model

Model 2200S

L F T x x x x x x x x

Display

• 1,2 = display

• 3 = no display

Mounting and output option:

• 1,3,4 = analog outputs, field mount transmitter

• 2,5,8 = analog outputs, RS-485, DIN rail transmitter

•6 = F

OUNDATION fieldbus outputs, field mount transmitter

Transmitter model

LF-Series

7 8 2 x x x x x x x x x x x

Amplifier system

• C, D, W, K, L = Advanced electronics

Transmitter model

7826/7828

Figure 1-1 Transmitter model numbers and codes continued

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 5

Page 12

6 ProLink® II Software for Micro Motion® Transmitters

Page 13

Chapter 2

Installation and Setup

2.1 Overview

This chapter provides information on installing ProLink II software, connecting to the transmitter, and

troubleshooting the installation or connection.

To install and set up ProLink II, the following steps are required:

1. Ensure required privileges (see Section 2.2)

2. Install the ProLink II software onto your PC (see Section 2.3)

3. Generate the temporary license (see Section 2.4)

4. Connect the wires between the PC and the transmitter (see Section 2.5)

5. Configure the connection and connect to the transmitter (see Section 2.6)

6. Obtain and configure a site key (see Section 2.7)

For troubleshooting information, see Sections 2.8 and 2.9.

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

2.2 Required privileges

Installation of ProLink II requires Administrator privileges. After ProLink II is installed, it can be run

by non-Administrator users.

2.3 Install the ProLink II software

To install ProLink II software:

1. Insert the ProLink II CD-ROM into the CD-ROM drive.

2. If the setup program does not start automatically, locate and run the SETUP.EXE file. The file

is located in the root directory on the CD-ROM (e.g., D:\setup.exe, where “D” is your

CD-ROM drive letter).

3. Follow the on-screen instructions to complete the installation. If you have a previous version

of ProLink II installed on your PC, you may be prompted to remove it before installing the

new version.

Notes:

(1) The ProLink II site key is associated with a disk drive and specific folder on your PC. If you

decide to move ProLink II after installation, you will have to transfer the license and reinstall

ProLink II. To avoid this step, be sure to install ProLink II into a location that you can use

permanently.

Installation and Use Manual 7

Page 14

Installation and Setup

WARNING

WARNING

(2) If the user who installs ProLink II does not have Administrator rights, the installation wizard may

display a message warning that the installation may not be successful. If this occurs, the

installation wizard will run to completion but the Windows Registry may not be updated correctly.

If you are subsequently unable to connect to a transmitter, reinstall the software with

Administrator privileges.

(3) If you have a Model 2700 transmitter with transmitter software earlier than v3.4, and you have

the concentration measurement application installed, you cannot access the concentration

measurement functions with ProLink II v2.1 or later. Contact Micro Motion for alternative

solutions.

2.4 Generate a temporary license

The first time you run ProLink II, you will be prompted to generate a temporary license. This license

will allow you to run ProLink II with full functionality for seven days, starting from the current date

and time. Follow the on-screen instructions to generate the temporary license.

Note: If you attempt to use ProLink II after the temporary license has expired, ProLink II will no

longer allow you to connect to a transmitter.

2.5 Connect the PC to the transmitter

To connect the PC to the transmitter:

1. Connect the appropriate signal converter to your PC’s serial or USB port, using adapters as

required. (See Section 1.3.2 for a list of the available installation kits and signal converters.)

• For connections using the Bell 202 physical layer, use the Bell 202–RS-232 signal

converter.

• For connections using the RS-485 physical layer, use the RS-485–RS-232 signal

converter.

2. Connect the two leads of the signal converter to the appropriate terminals on your transmitter

using the terminal reference in Table 2-1 and the connection diagrams in Section 2.5.1.

On Model 1700/2700 and LF-Series field-mount transmitters, opening the

power supply compartment in explosive atmospheres while the power is on

can cause an explosion.

Before using the service port to communicate with the transmitter in a hazardous

area, make sure the atmosphere is free of explosive gases.

On Model 1700/2700 and LF-Series field-mount transmitters, opening the

power supply compartment can expose the operator to electric shock.

To avoid the risk of electric shock, do not touch the power supply wires or terminals

while using the service port.

8 ProLink® II Software for Micro Motion® Transmitters

Page 15

Installation and Setup

WARNING

WARNING

WARNING

CAUTION

On Model 3350/3700 transmitters, opening the wiring compartment in

explosive atmospheres can cause an explosion.

Do not remove the compartment covers in an explosive atmosphere within three

minutes after power is disconnected.

On Model 2400S and Model 2200S transmitters, removing the transmitter

housing cover in a hazardous area can cause an explosion.

Because the housing cover must be removed to connect to this transmitter using

the service port clips or HART clips, these connections should be used only for

temporary connections, for example, for configuration or troubleshooting purposes.

When the transmitter is in an explosive atmosphere, use a different method to

connect to your transmitter.

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Removing the core processor lid can expose the operator to electric shock.

To avoid the risk of electric shock, do not touch the power supply wires or terminals

while removing or replacing the core processor lid, or while using the RS-485

terminals.

Connecting a HART device to the transmitter’s primary mA output could

cause transmitter output error. If the primary mA output is being used for

flow control, connecting the HART Interface to the output loop, via either the

mA terminals or the HART clips, could cause the transmitter’s 4–20 mA

output to change, which would affect flow control devices.

Set control devices for manual operation before connecting the HART Interface to

the transmitter’s primary mA output loop.

Installation and Use Manual 9

Page 16

Installation and Setup

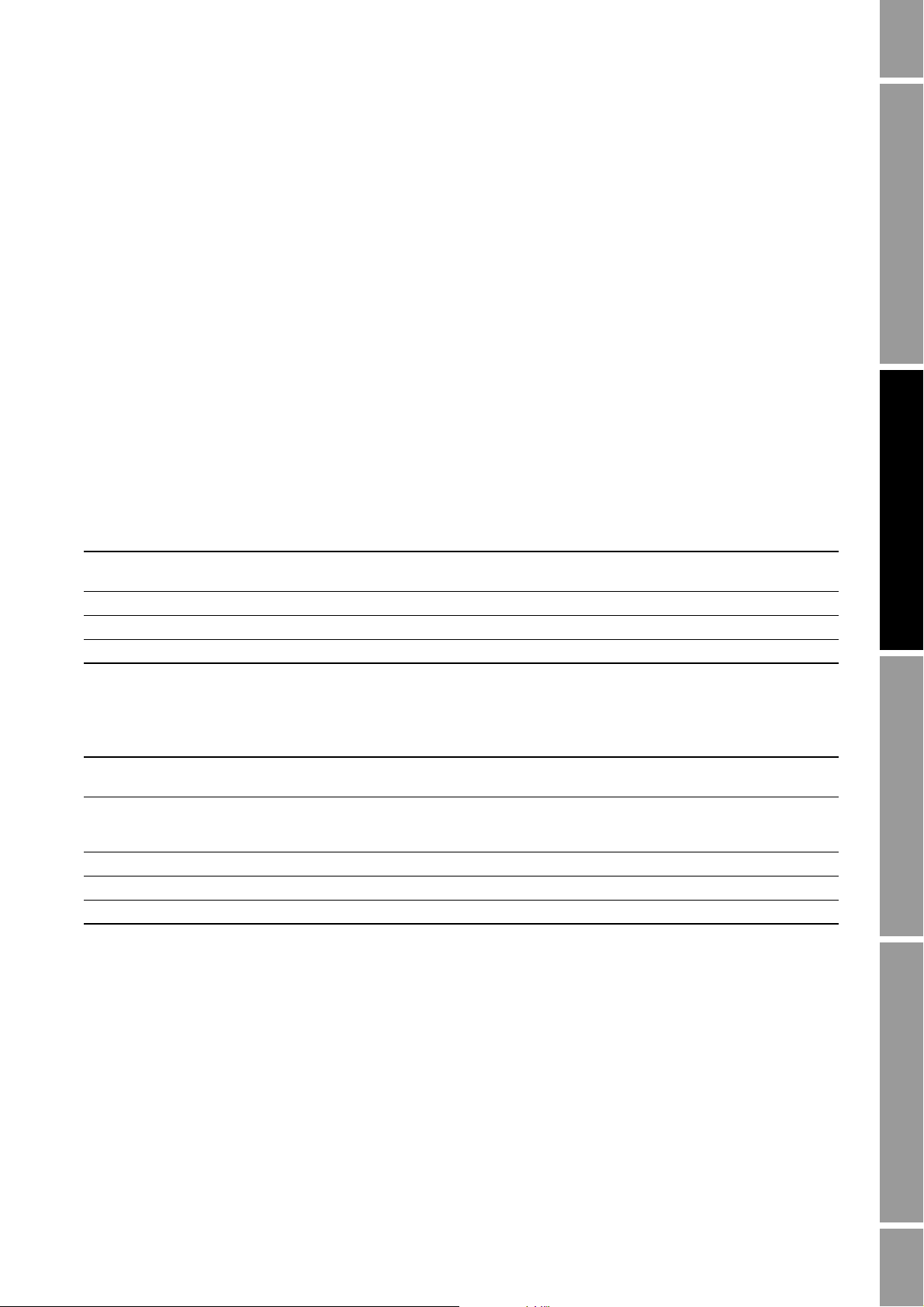

Table 2-1 Transmitter terminals for ProLink II connections

Terminals for connection type

HART/Bell 202 HART/RS-485 Modbus/RS-485 Service port

Transm itter

PV+ PV– A B A B A B

IFT9701/9703 4–20+ 4–20–

RFR9712 17 16 21 22

RFT9739

• Rack-mount Z30 D30 Z22 D22 Z22 D22

• Field-mount 17 18 27 26 27 26

Model 1700/2700 with

12565687

analog outputs

LF-Series field-mount

12565687

with output code 1 or 3

Model 1700/2700 with

I.S. outputs

(1)

Model 2700 with

12 87

12 87

configurable I/O

LF-Series field-mount

12 87

with output code 4

Model 2700 with

F

OUNDATION

™

fieldbus

LF-Series field-mount

87

87

with output code 6

Model 2700 with

87

PROFIBUS-PA

Model 2200S HART clips

Model 2400S with

analog outputs

1 2 Service port clips

or

HART clips

Model 2400S with

Service port clips

DeviceNet

Model 2400S with

Service port clips

PROFIBUS-DP

Series 3000

• Panel-mount with

c2 a2 c32 a32 c32 a32 c32 a32

solder-tail or screw

connectors

• Panel-mount with

14 15 24 25 24 25 24 25

I/O cables

• Rack-mount c2 a2 c32 a32 c32 a32 c32 a32

• Field-mount 2 1 11 12 11 12 11 12

Model 1500/2500 21 22 33 34 33 34

LF-Series DIN rail with

21 22 33 34 33 34

output code 2, 5, or 8

Model 7826/7828

Model 7829

Model 7835, 7845,

7846, or 7847

(2)

(2)

(2)

34

34

11 12

10 ProLink® II Software for Micro Motion® Transmitters

Page 17

Installation and Setup

VIATOR

VIATOR

or

DCS or

PLC

R1

R3

R2

Primary mA output terminals

Tr an s m it t er

USB plug

Bell 202 signal

converter

Notes:

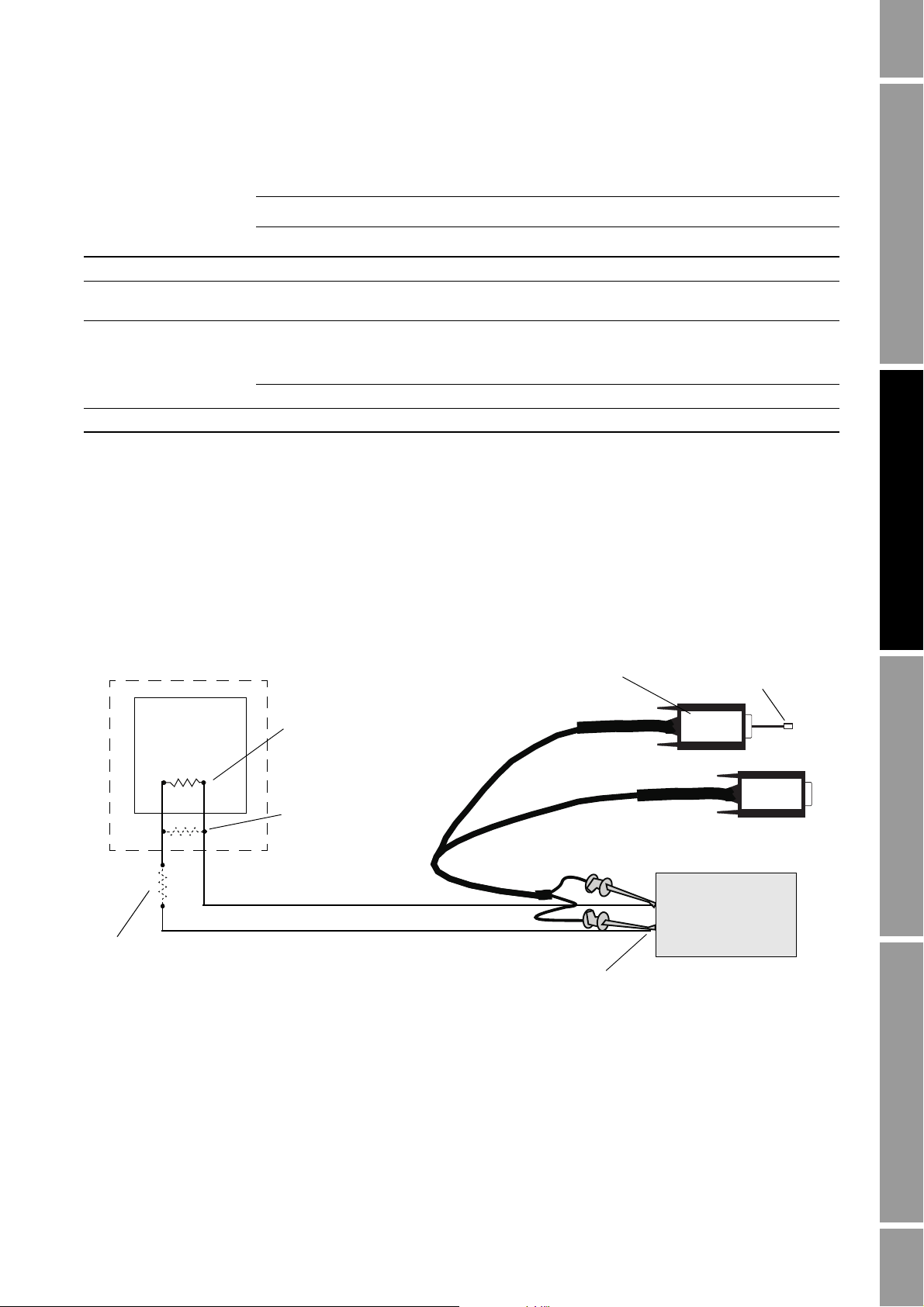

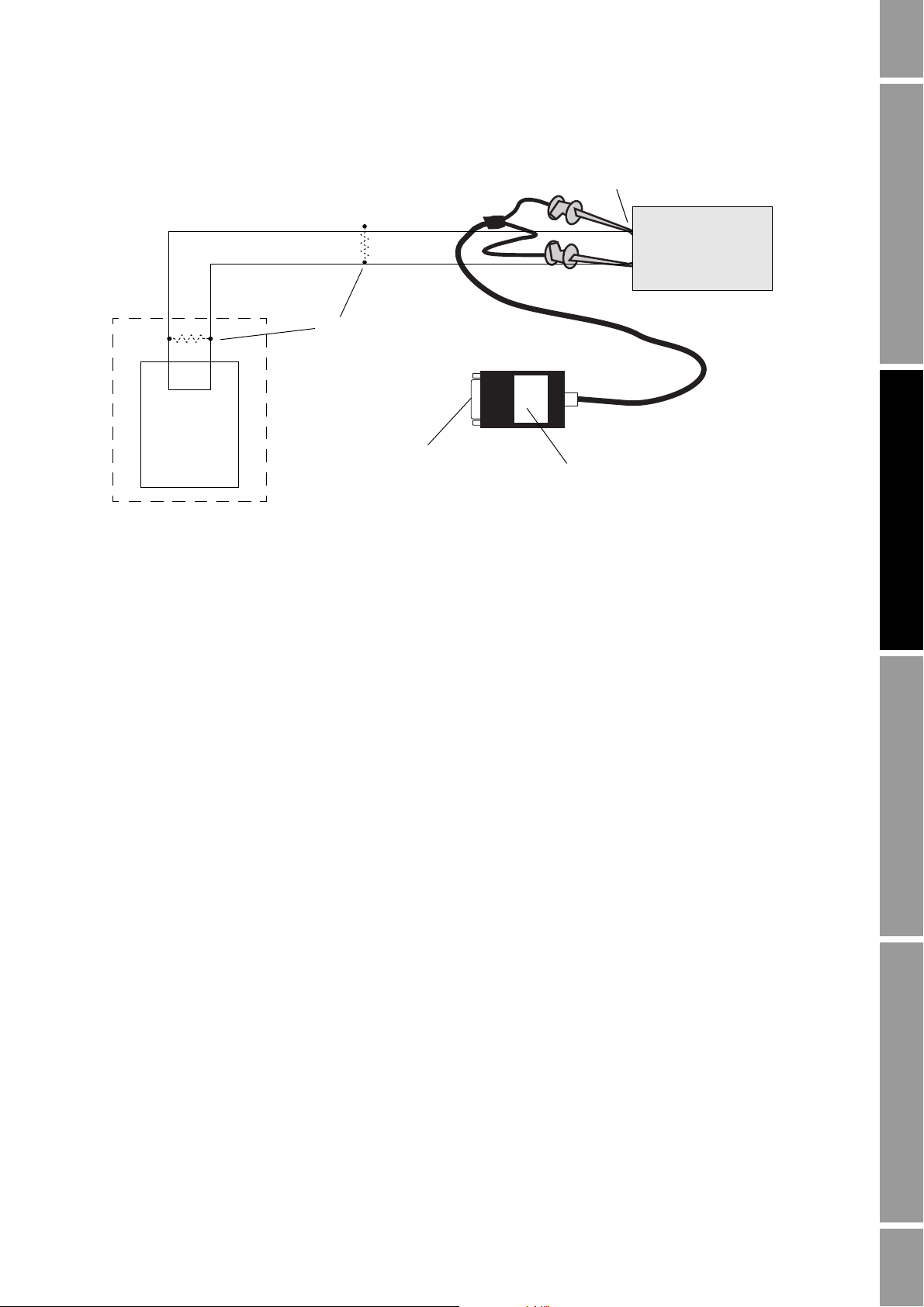

• Connect the HART interface leads to the primary mA output of the transmitter, or to any point on the network.

• If necessary, use any combination of R1, R2, and R3 to bring the total resistance within 250–600 Ω.

(250–1000 Ω for RFT9712 and RFT9739).

• If no other device is connected to the primary mA output, add R1.

• If the primary mA is connected to a DCS or PLC with R2:

• Where R2 is insufficient, add R1 to bring R1+R2 into range.

• Where R2 is absent, add R3.

Table 2-1 Transmitter terminals for ProLink II connections continued

Terminals for connection type

HART/Bell 202 HART/RS-485 Modbus/RS-485 Service port

Transm itter

Model 7835 EXD

MVD™ Direct Connect™

with no barrier

(2)

(3)

PV+ PV– A B A B A B

34

34

MVD Direct Connect with

I.S. barrier

• To barrier

• To core processor

(4)

(3)

13 14

34

Core processor 3 4

(1) If connecting to terminals 1 and 2, terminals must be externally powered, with a minimum of 250

Ω

not apply to service port.

(2) Transmitter version with advanced electronics option only.

(3) Connection is not intrinsically safe.

(4) Intrinsically safe connection.

2.5.1 Connection diagrams

Use the following diagrams to make the connection between your PC and the transmitter.

Figure 2-1 Typical HART/Bell 202 connection to transmitter or multidrop network

and 17.5 volts. Requirement does

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 11

Page 18

Installation and Setup

VIATOR

VIATOR

R1

Prongs

Transmitter

or

USB plug

Notes:

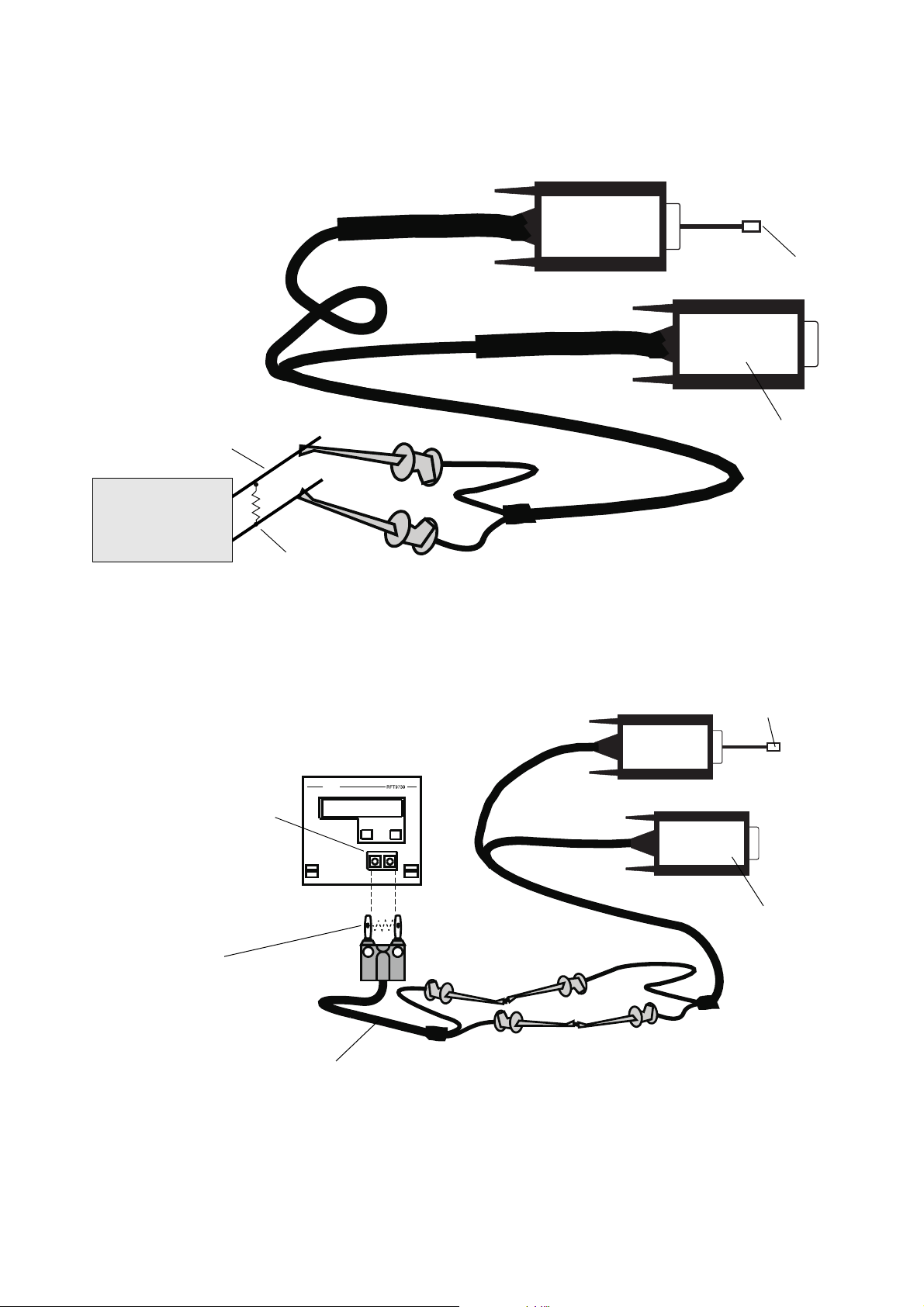

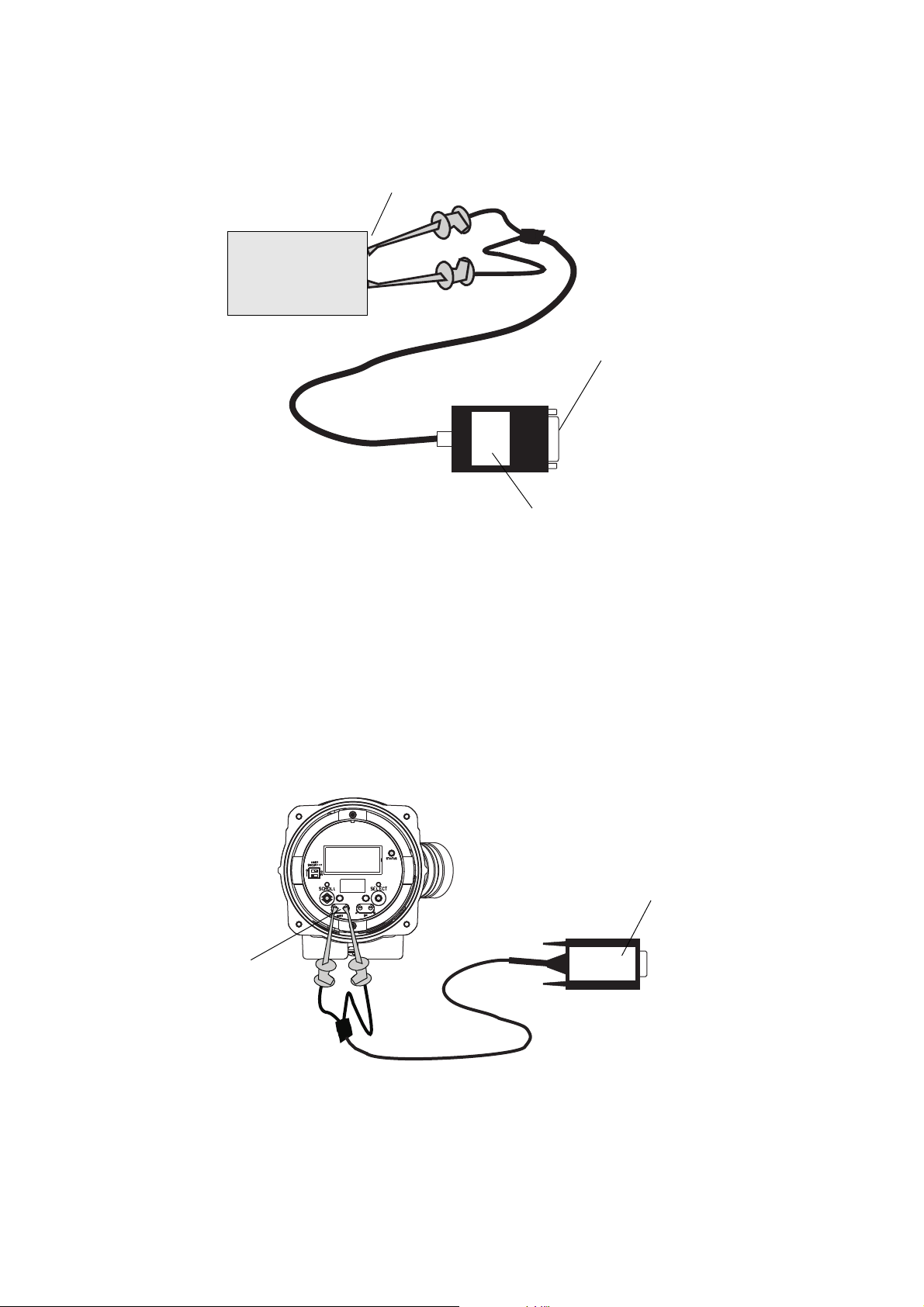

• Add R1 if necessary to bring the total resistance within 250–1000 Ω.

Bell 202 signal

converter

VIA

VIA

TOR

TOR

R1

HART jack

Bell 202 cable (not included)

or

USB plug

Bell 202 signal

converter

Notes:

• Add R1 if necessary to bring the total resistance within 250–1000 Ω.

Figure 2-2 HART/Bell 202 temporary connection to RFT9739 field-mount and RFT9712 transmitters

Figure 2-3 HART/Bell 202 temporary connection to RFT9739 rack-mount transmitters

12 ProLink® II Software for Micro Motion® Transmitters

Page 19

Installation and Setup

–

+

VIATOR

VIATOR

or

+

–

DCS or

PLC

R2

R3

R1

Primary mA output terminals

Transmitter

External power supply

USB plug

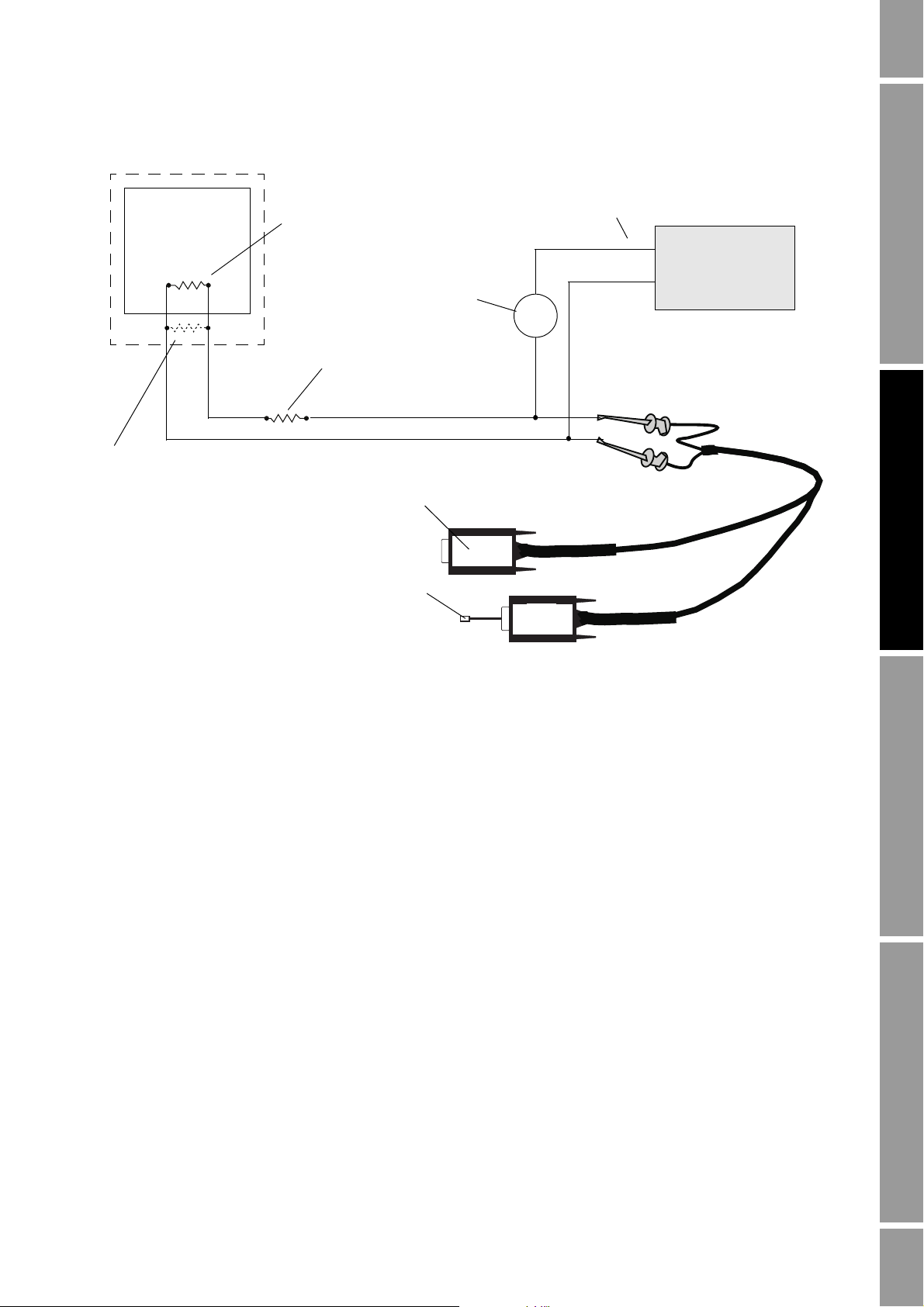

Notes:

• Connect the HART interface leads to the primary mA output of the transmitter, or to any point on the network.

• If necessary, use any combination of R1, R2, and R3 to bring the total resistance within 250–600 Ω.

• If no other device is connected to the primary mA output, add R1.

• If the primary mA is connected to a DCS or PLC with R2:

• Where R2 is insufficient, add R1 to bring R1+R2 into range.

• Where R2 is absent, add R3.

Bell 202 signal

converter

Figure 2-4 HART/Bell 202 connection to Model 1700/2700 I.S. transmitters

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 13

Page 20

Installation and Setup

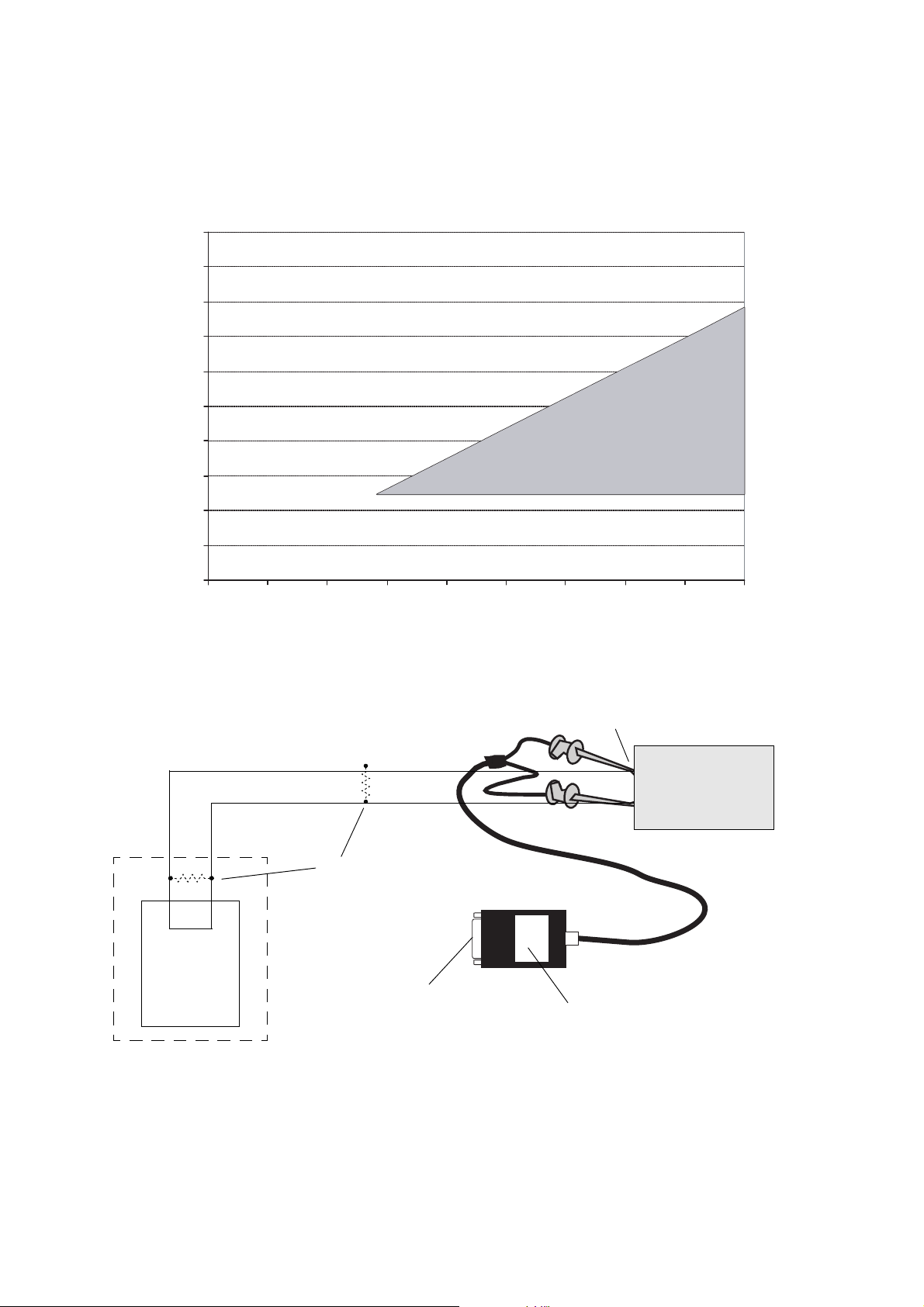

R

max

= (V

supply

– 12)/0.023

A minimum of 250 ohms and 17.5 volts is required

Supply voltage VDC (Volts)

External resistance (Ohms)

Operating range

12 3014 16 18 20 22 24 26 28

0

1000

900

800

700

600

500

400

300

200

100

DCS or

PLC

R1

Attach serial port or USB

adapter if necessary (not

shown)

RS-485 terminals

Transmitter

RS-232 <-> 2-wire RS-485

interface converter

Notes:

• Connect the interface leads to the RS-485 terminals on the transmitter, or to any point on the network.

• Ensure that your transmitter’s RS-485 terminals are configured for HART protocol.

• For RFT9712 transmitters, set the jumper for RS-485 communications.

• For long-distance communication, or if noise from an external source interferes with the signal, add two 120-Ω

terminating resistors (R1) at each end of the RS-485 network.

Figure 2-5 Model 1700/2700 I.S. transmitters: Resistance and voltage requirements for

HART/Bell 202 connections

Figure 2-6 HART/RS-485 connection to transmitter or multidrop network

14 ProLink® II Software for Micro Motion® Transmitters

Page 21

Installation and Setup

DCS or

PLC

R1

Attach serial port or USB

adapter if necessary (not

shown)

RS-485 terminals

Transmitter

RS-232 <-> 2-wire RS-485

interface converter

Notes:

• Connect the interface leads to the RS-485 terminals on the transmitter, or to any point on the network.

• Ensure that no other Modbus master devices are currently active on the network.

• For RFT9712 transmitters, set the jumper for RS-485 communications.

• For long-distance communication, or if noise from an external source interferes with the signal, add two 120-Ω

terminating resistors (R1) at each end of the RS-485 network.

Figure 2-7 Modbus/RS-485 connection to transmitter or multidrop network

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 15

Page 22

Installation and Setup

Attach serial port or USB adapter

if necessary (not shown)

Service port terminals

Transmitter

RS-232 <-> 2-wire RS-485

Interface Converter

Notes:

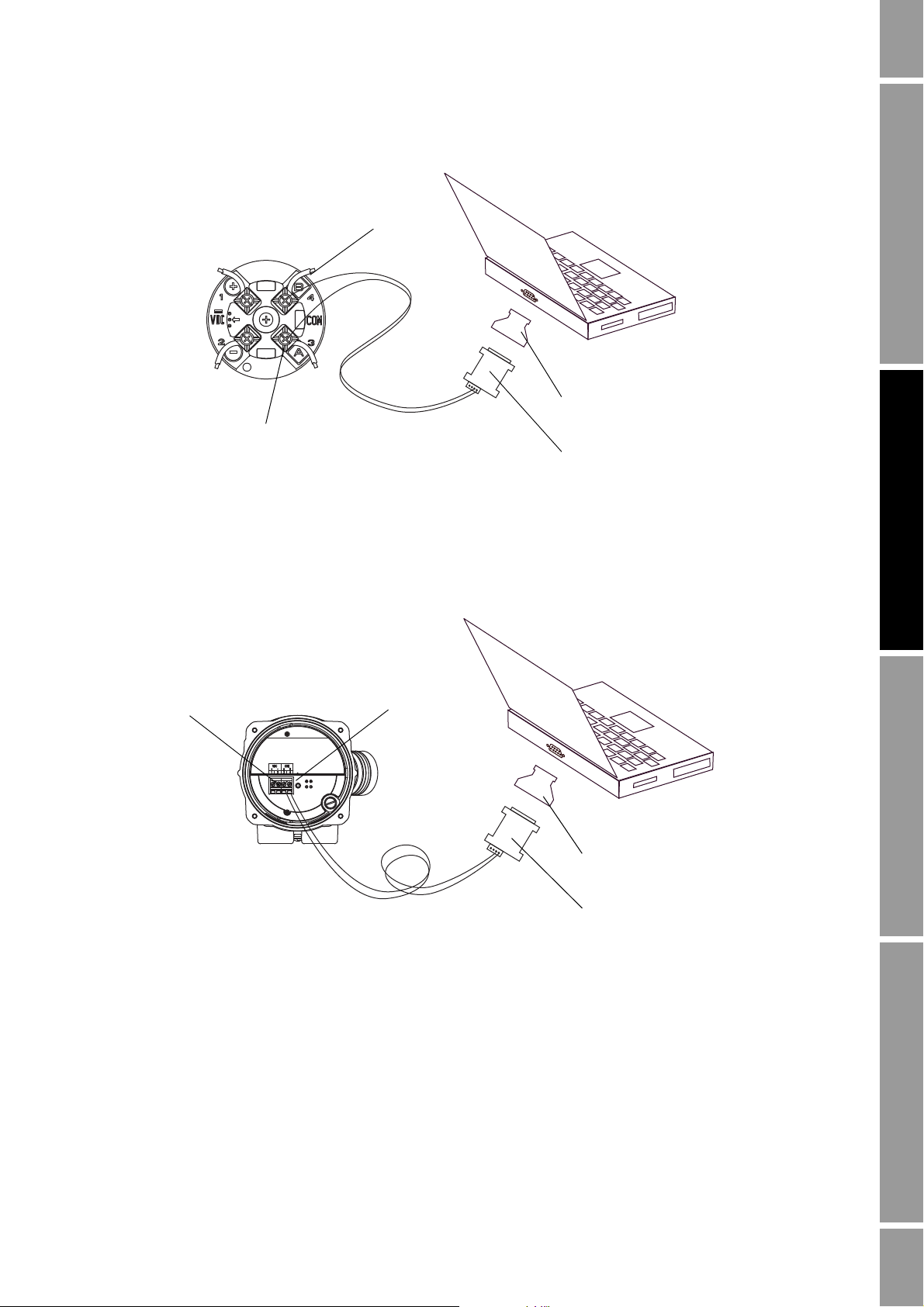

• For Model 1700/2700, Model 2400S, and LF-Series field-mount transmitters, the service port is available at any

time.

• For Model 1500/2500, Series 3000, and LF-Series DIN rail transmitters, the service port is available during a

10-second interval after power-up. If a service port connection is made during this time, the ports will remain in

service port mode.

• Ensure that no other Modbus master devices are currently active on the network.

• All service ports are accessed using the default address of 111. If you are connecting over a multidrop network

with multiple service ports, it is not possible to specify which device to connect to.

VIATOR

HART clips

Bell 202 signal

converter

Notes:

• If necessary, add resistance across the HART clips to bring the total resistance within 250–600 Ω.

Figure 2-8 Modbus/RS-485 temporary connection to the service port

Figure 2-9 HART/Bell 202 temporary connection to HART clips

16 ProLink® II Software for Micro Motion® Transmitters

Page 23

Installation and Setup

Core processor

RS-485 to RS-232

signal converter

Attach serial port or USB

adapter if necessary

RS-485/B

RS-485/A

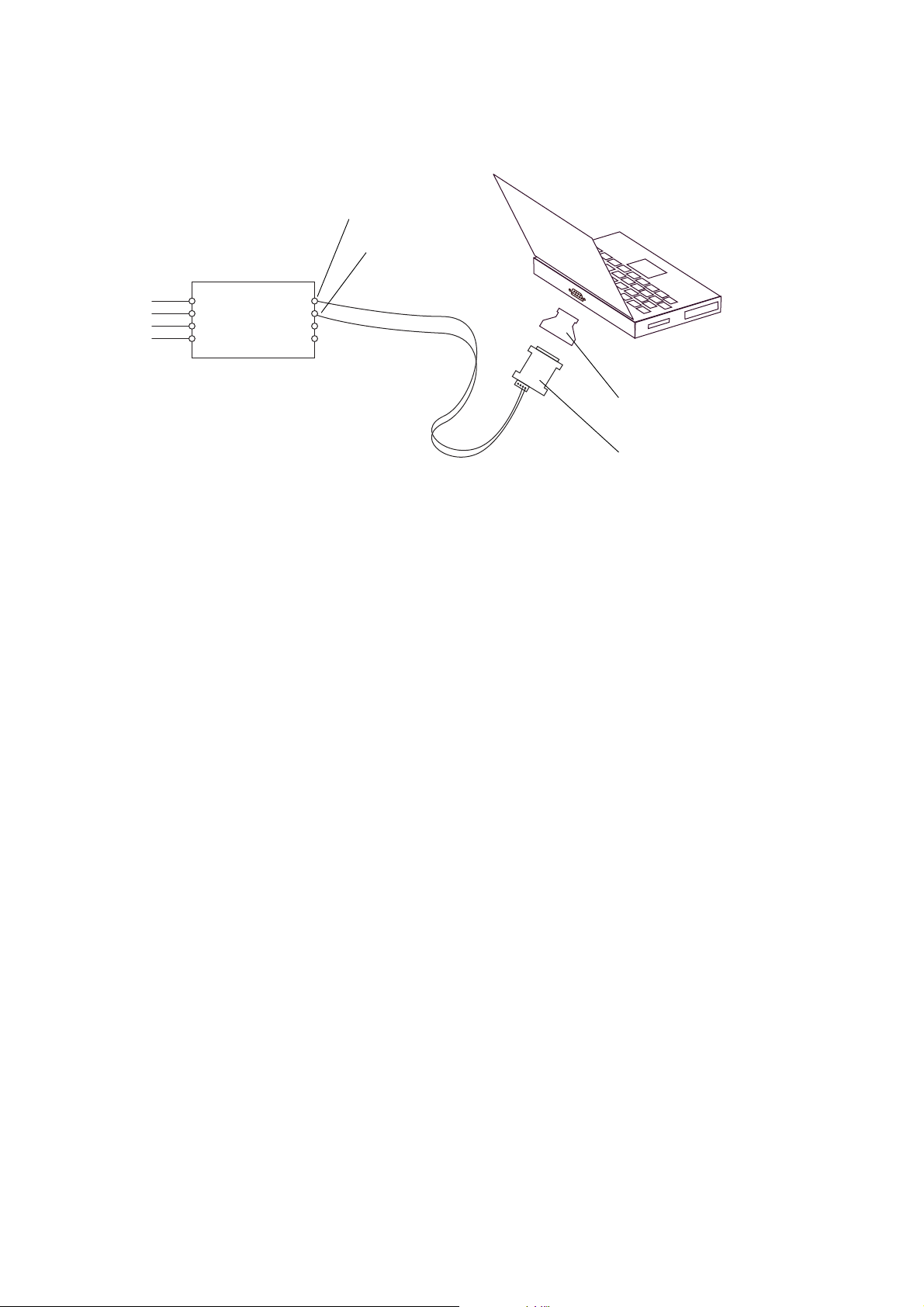

Notes:

• Ensure that no other Modbus master devices are currently active on the network.

• Before using ProLink II to communicate with the core processor, disconnect any wiring to a remote PLC.

Core processor

RS-485 to RS-232

signal converter

Attach serial port or USB

adapter if necessary

RS-485/B

RS-485/A

Notes:

• Ensure that no other Modbus master devices are currently active on the network.

• Before using ProLink II to communicate with the core processor, disconnect any wiring to a remote PLC.

Figure 2-10 Modbus/RS-485 connection to RS-485 terminals on standard core processor

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Figure 2-11 Modbus/RS-485 connection to RS-485 terminals on enhanced core processor

Installation and Use Manual 17

Page 24

Installation and Setup

RS-485 to RS-232

signal converter

Attach serial port or USB

adapter if necessary

RS-485/B

RS-485/A

I.S. barrier

Non-I.S. terminals

Notes:

• Ensure that no other Modbus master devices are currently active on the network.

• Before using ProLink II to communicate with the core processor, disconnect any wiring to a remote PLC.

Figure 2-12 Modbus/RS-485 connection to RS-485 terminals on MVD Direct Connect I.S. barrier

2.6 Configure ProLink II connection parameters

To connect to the transmitter, ProLink II must use connection parameters appropriate to the

transmitter.

• If you are connecting to an MVD Direct Connect system, ProLink II can use any of the

supported communication settings listed in Table 2-2. The core processor auto-detects

incoming communications parameters and switches to match.

• If you are connecting to a Model 2400S transmitter using the service port:

- For point-to-point connections, you can use a service port connection type.

- For multidrop network connections, you can use any Modbus/RS-485 connection type and

specify the transmitter’s Modbus address. The transmitter auto-detects incoming

communications parameters and switches to match. The service port auto-detection limits

are described in Table 2-3.

• If you use a service port or HART/Bell 202 connection type, the connection parameters are

standard: when one of these connection types is specified, ProLink II automatically uses the

appropriate parameters.

18 ProLink® II Software for Micro Motion® Transmitters

Page 25

Installation and Setup

• If you use any other connection type, you must configure ProLink II connection parameters to

match the transmitter’s configuration. If you do not know the transmitter’s configuration, you

can use a Communicator or the transmitter’s display to view or change its configuration.

- For all transmitters, if you are using HART protocol, you can specify the transmitter’s

HART tag (software tag) instead of the HART address, if a HART tag has been configured

in the transmitter.

- For all Series 1000/2000/3000 transmitters, see Table 2-4 for default values for each

connection type.

- For LF-Series transmitters, see Table 2-5 for default values for each connection type.

- For IFT97xx transmitters, communication parameters are not configurable. Settings are

listed in Table 2-6. Configure ProLink II connection parameters to match these settings.

- For RFT97xx transmitters, communication is configured using switches and jumpers on

the transmitter. Check your transmitter and refer to the transmitter manual to determine

your transmitter’s configuration, then configure ProLink II connection parameters to

match these settings. Factory default settings for these transmitters are listed in Table 2-6.

Table 2-2 MVD Direct Connect auto-detection limits

Parameter Option

Protocol Modbus RTU (8-bit)

Modbus ASCII (7-bit)

Baud rate Standard rates between 1200 and 38,400

Parity Even, odd, none

Stop bits 1, 2

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Table 2-3 Model 2400S service port auto-detection limits

Parameter Option

Protocol Modbus RTU (8-bit)

Address Responds to both:

Baud rate Standard rates from 1200 to 38,400

Stop bits 1, 2

Parity Even, odd, none

Modbus ASCII (7-bit)

• Service port address (111)

• Configured Modbus address (default=1)

Installation and Use Manual 19

Page 26

Installation and Setup

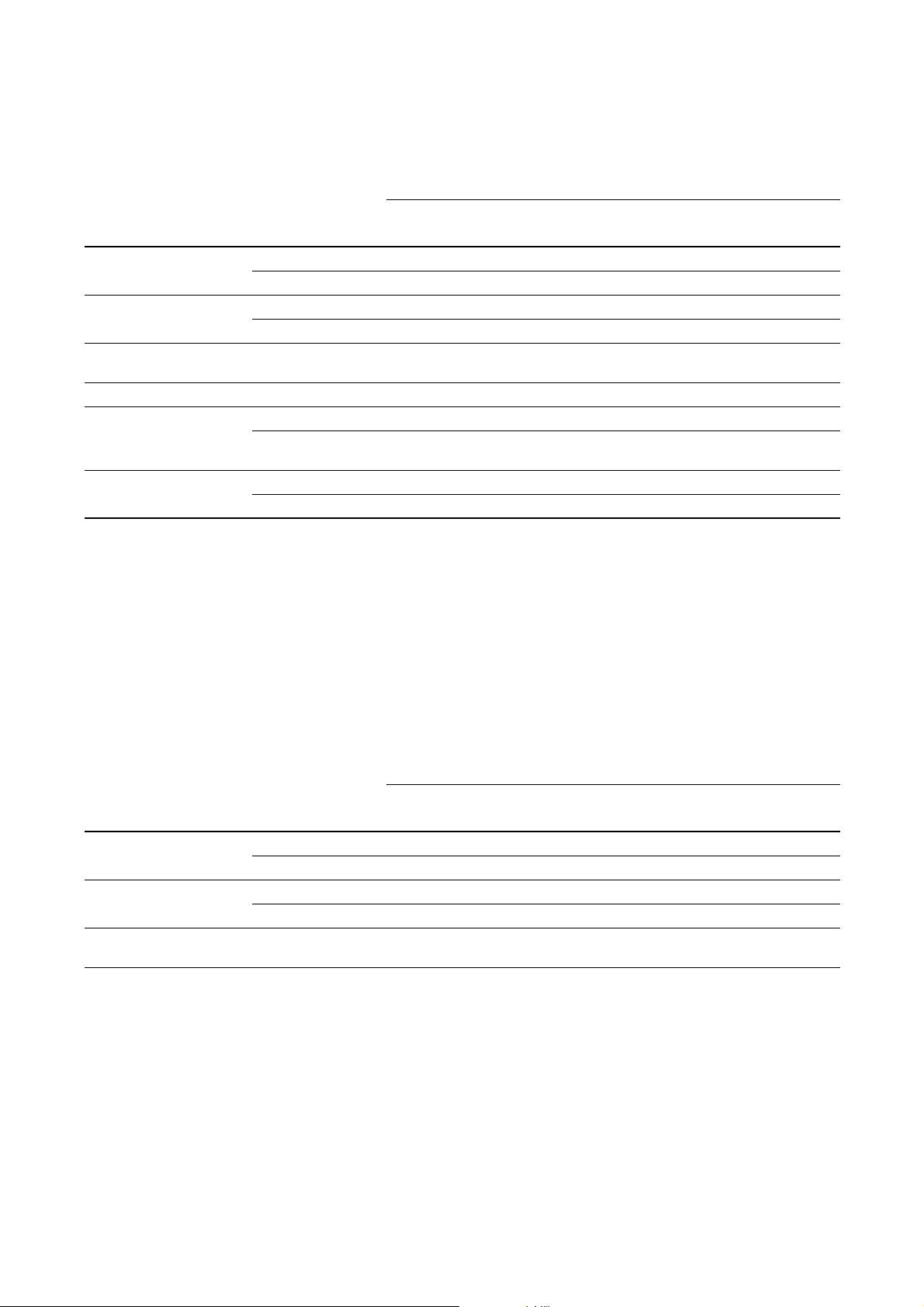

Table 2-4 Default communication parameters for Series 1000/2000/3000 transmitters

Default values

Stop

(1)

bits Parity Address

Transmitter Physical layer Protocol Baud

Model 1500/2500 Bell 202

RS-485

Model 1700/2700

Analog

Model 1700/2700 I.S.,

Bell 202

RS-485

Bell 202

(2)(3)

(5)

(2)

(5)(6)

(2)

(4)

HART

1200 8 1 odd 0

Modbus RTU 9600 8 1 odd 1

(4)

HART

1200 8 1 odd 0

HART 1200 8 1 odd 0

(4)

HART

1200 8 1 odd 0

Data

bits

Model 2700 Config. I/O

Model 2200S Bell 202

Model 2400S Analog Bell 202

RS-485 Modbus

Series 3000 Bell 202

RS-485

(2)

(2)

(2)

(5)

(4)

HART

(4)

HART

(RTU or ASCII)

(4)

HART

1200 8 1 odd 0

1200 8 1 odd 0

Autodetect

Autodetect

Autodetect

Autodetect

1200 8 1 odd 0

Modbus RTU 9600 8 1 odd 1

1

(1) ProLink II automatically sets data bits appropriately for the configured protocol. Even though a data bits parameter may be

configured in the transmitter, you do not need to configure it in ProLink II. HART protocol is always 8 data bits. If your transmitter

is configured for Modbus with 7 data bits, specify Modbus ASCII; if your transmitter is configured for Modbus with 8 data bits, specify

Modbus RTU.

(2) Connection to primary mA output, or to HART clips (Model 2400S and Model 2200S transmitters only).

(3) Except Model 1500 transmitter with the Filling and Dosing application. The Model 1500 transmitter with the Filling and Dosing

application does not support Bell 202 / HART communication.

(4) HART/Bell 202 parameters are not configurable. The settings shown here are always in effect.

(5) Connection to RS-485 terminals.

(6) Available only on Model 1700/2700 transmitters with analog outputs.

Table 2-5 Default communication parameters for LF-Series transmitters

Default values

Data

Transmitter Physical layer Protocol Baud

DIN rail Bell 202

RS-485

Field-mount with output

option 1 or 3

Field-mount with output

Bell 202

RS-485

Bell 202

(2)(3)

(5)

(2)

(5)

(2)

option 4

(1) ProLink II automatically sets data bits appropriately for the configured protocol. Even though a data bits parameter may be

configured in the transmitter, you do not need to configure it in ProLink II. HART protocol is always 8 data bits. If your transmitter

is configured for Modbus with 7 data bits, specify Modbus ASCII; if your transmitter is configured for Modbus with 8 data bits, specify

Modbus RTU.

(2) Connection to primary mA output.

(3) Except transmitters with the Filling and Dosing application. Transmitters with the Filling and Dosing application do not support

Bell 202 / HART communication.

(4) HART/Bell 202 parameters are not configurable. The settings shown here are always in effect.

(5) Connection to RS-485 terminals.

(4)

HART

1200 8 1 odd 0

Modbus RTU 9600 8 1 odd 1

(4)

HART

1200 8 1 odd 0

HART 1200 8 1 odd 0

(4)

HART

1200 8 1 odd 0

bits

Stop

(1)

bits Parity Address

20 ProLink® II Software for Micro Motion® Transmitters

Page 27

Installation and Setup

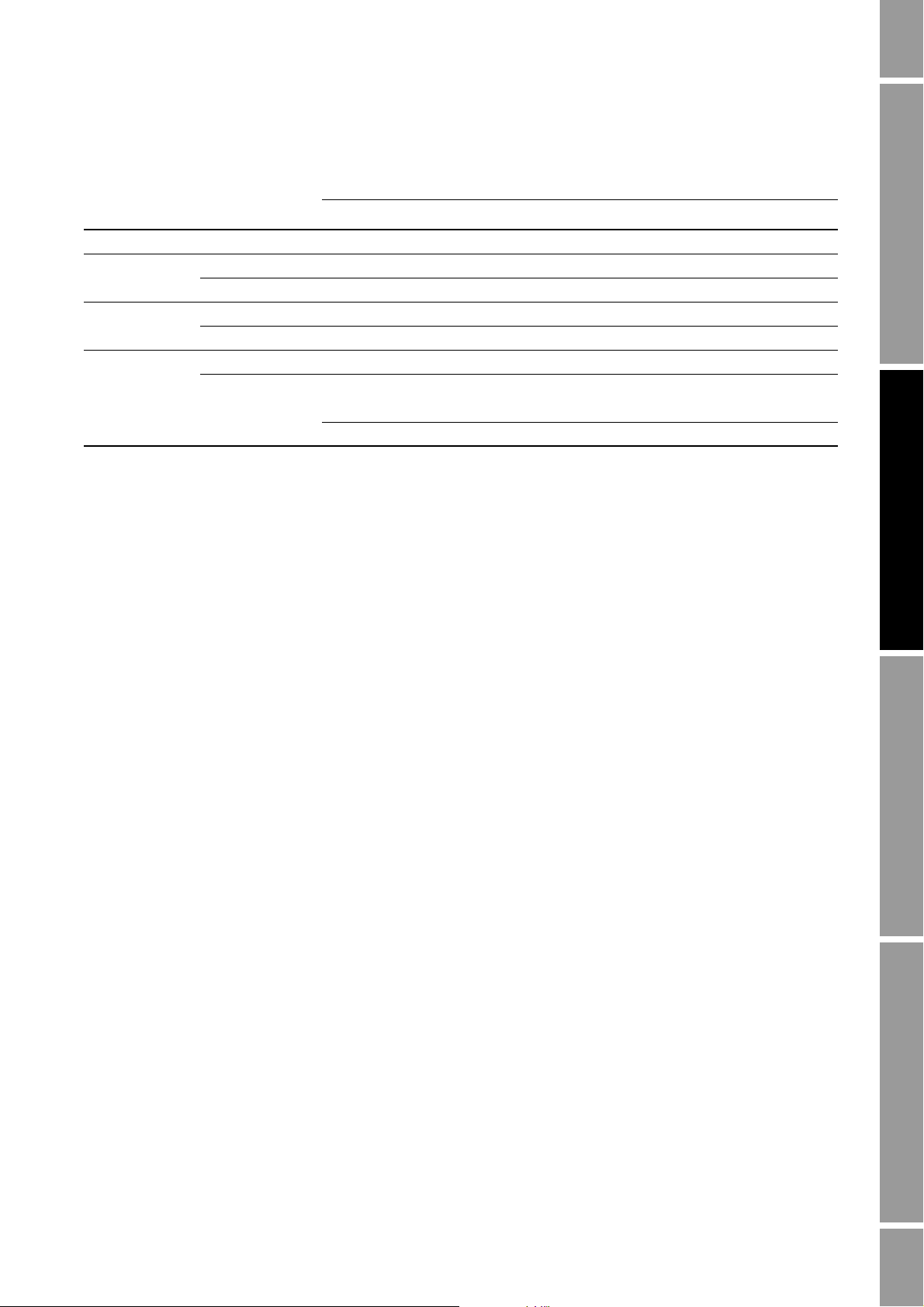

Table 2-6 Default communication parameters for RFT97xx and IFT97xx transmitters

Default values

(1)

Transmitter Physical layer Protocol Baud Data bits

IFT9701/9703

RFT9712 Bell 202

RFT9739 v2 Bell 202

RFT9739 v3 Bell 202

(1) ProLink II automatically sets data bits appropriately for the configured protocol. Even though a data bits parameter may be

configured in the transmitter, you do not need to configure it in ProLink II.

(2) IFT9701/9703 communication parameters are not configurable. The settings shown here are always in effect.

(3) Connection to primary mA output.

(4) Connection to RS-485 terminals.

(5) Dip switch settings on the transmitter are used to select either Std. comm or User defined.

(2)

Bell 202

RS-485

RS-485

RS-485

• Std. comm Modbus RTU 9600 8 1 odd 1

• User defined HART 1200 8 1 odd 0

(3)

(3)

(4)

(3)

(4)

(3)

(4)(5)

HART 1200 8 1 odd 0

HART 1200 8 1 odd 0

HART 1200 8 1 odd 0

HART 1200 8 1 odd 0

HART 1200 8 1 odd 0

HART 1200 8 1 odd 0

Stop bits Parity Address

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

2.7 Obtain and configure a site key

To obtain and configure a site key:

1. Open the License Request file as follows:

Start > Programs > MMI > ProLink II v2.9 > ProLink II License Request Form

2. Edit the file, supplying all requested information including the site code.

To find the site code, choose

3. Save the edited file.

4. Contact Micro Motion in one of the following ways:

• Send an email to:

Flow.Support@Emerson.com

Attach the edited file to the email. The file is named LicenseRequest.txt, and in typical

installations is located in

Note: This is the default location. If the ProLink II installation program found an existing license file,

the program and License Request file were installed in the location of the license file.

• Telephone 800-522-6277 (toll-free in the U.S.), or 303-530-8250 (worldwide), and request

a site key. Have the edited registration text file available for reference.

Note: To minimize the possibility of error, Micro Motion recommends using the email method.

5. When the site key is provided:

a. Start ProLink II.

b. Choose

File > License. See Figure 2-13.

File > License (see Figure 2-13).

Program Files > MMI > ProLink II v2.9.

Installation and Use Manual 21

Page 28

Installation and Setup

Figure 2-13 License window

c. Enter the site key into the

Site Key textbox, then click Validate.

2.8 Troubleshooting the ProLink II installation

If you have problems with the ProLink II installation, review the information in this section and

follow the suggestions. If you cannot resolve the problem, contact Micro Motion customer support.

2.8.1 Insufficient privileges

If you are unable to install ProLink II, verify that you have the required privileges (see Section 2.2).

2.8.2 Missing or corrupt Registry entries

During a successful ProLink II installation, information is written to the Windows Registry. If, for any

reason, ProLink II information in the Registry is corrupted or missing, you can replace or update the

required information as follows:

1. Choose

Start > Programs > MMI > ProLink II v2.9 > ProLink II Registrar.

2. A batch file that updates the Windows Registry will be executed. Click

pop-up messages.

3. Close the command window.

Note: You must have sufficient privileges to write to the Registry.

OK as required by the

22 ProLink® II Software for Micro Motion® Transmitters

Page 29

Installation and Setup

2.9 Troubleshooting the ProLink II connection

If you cannot connect to the transmitter, review the information in this section and follow the

suggestions. If you cannot resolve the problem, contact Micro Motion customer support.

2.9.1 OPC server or OPC client issues

If the Context message displays either of the following:

The OPC server could not be started.

The OPC client database could not be opened.

reinstall ProLink II, ensuring that you have the required privileges (see Section 2.2).

2.9.2 Other issues

If the Context message displays either of the following:

The serial port could not be opened, or the device did not respond. Port availability and

connection wiring should be checked.

An unexpected error code was returned.

try the following:

1. Check all the wiring between the PC and the transmitter, and ensure that all components are

powered up. See the setup information for your connection type in Section 2.5, or refer to the

transmitter manual.

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

2. Check all the connection parameters – baud rate, parity, stop bits, protocol, address, and COM

port – and ensure they are correct for both ProLink II and the transmitter.

3. Choose

Start > Programs > MMI > ProLink II v2.9 > ProLink II Registrar. This program

updates Registry entries.

4. Ensure that ProLink II is configured for the correct COM port. To do this, install the LED

indicator/tester. (If you purchased the ProLink II installation kit from Micro Motion, this

device was included.) Attempt a connection.

• The indicators for the TD, RD, DTR, and RTS lines should be ON. Usually they are red,

but if another program has used the COM port the RTS indicator may be green. If no

indicators are ON, you are not connected to the COM port, ProLink II is configured for the

wrong COM port, or there is a wiring problem.

• When you try to connect, verify that the RTS LED changes color or flashes. If no LED

change is detected, you are connected to the wrong COM port or the COM port isn’t

assigned correctly. Check the device manager on your PC for the proper COM port

configuration.

5. Make sure that you don’t have interference over the COM port. Other programs or devices

may be trying to use the COM port. If the TD light is flashing while you are not using

ProLink II, the COM port is in use by another program. Terminate the other program and try

again.

6. If you use the configured COM port for any other program, verify that the other program is not

currently running. Personal digital assistants (PDAs) often have automatic update programs

that use the COM ports continually.

7. For HART connections to Model 1700/2700 transmitters with the intrinsically safe outputs

option board, ensure that the terminals are externally powered.

Installation and Use Manual 23

Page 30

Installation and Setup

8. Try adding resistance to the connection.

• For HART connections, refer to the installation instructions earlier in this chapter. Verify

• For HART connections to Model 1700/2700 transmitters with the intrinsically safe outputs

• RS-485 connections may require added resistance if the connection is long-distance or if

9. For RS-485 connections, swap the leads between the two terminals and try again.

10. For Modbus network connections, ensure that ProLink II is the only Modbus master active on

the network.

11. For RS-485 connections, try connecting through the service port, if available on your

transmitter.

12. For HART/Bell 202 connections:

a. If burst mode in enabled, try disabling it.

b. Ensure that polling for external pressure/temperature is disabled.

c. Ensure that ProLink II is the only master on the network.

that there is a 250–600 Ω resistor in parallel in the communications circuit.

option board, ensure that the resistor is in series. Attach the modem across the resistor.

there is external noise that interferes with the signal. Add two 120-Ω resistors in parallel

with the output, one at each end of the communication segment.

13. For HART connections using the USB HART Interface:

a. Ensure that you have selected

Converter Toggles RTS in the ProLink II Connect

window.

b. Ensure that the required Windows driver is installed on your PC. If this driver is not

installed, Windows will not recognize the USB converter when it is plugged into the USB

port.

14. For connections to the Model 2400S transmitter, if you are using Modbus ASCII protocol with

an RS-485 connection rather than a service port connection, ensure that Modbus ASCII

support is enabled on your transmitter.

24 ProLink® II Software for Micro Motion® Transmitters

Page 31

Chapter 3

Using ProLink II Software

3.1 Overview

This chapter provides information on the ProLink II user interface, including:

• Starting ProLink II and connecting to a transmitter (see Section 3.2)

• Using the Commissioning Wizard (Section 3.3)

• The ProLink II help system (see Section 3.4)

• Viewing installed options (see Section 3.5)

• Viewing process data (see Section 3.6)

• Viewing and resetting totalizers and inventories (see Section 3.7)

• Viewing status and alarms (see Section 3.8)

• Managing the ProLink II license (see Section 3.10)

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

3.2 Startup

When ProLink II first starts up, the ProLink II main screen and

(see Figure 3-2). Until you connect to a transmitter, most of the menu options are disabled.

3.2.1 Connecting to a transmitter

Depending on your transmitter, you may have several different options for making the connection

from ProLink II to the transmitter. Review the following connection guidelines when selecting your

connection method. Instructions for making the connection are provided following the guidelines.

Connection guidelines

• You must have the appropriate signal converter for the connection type you choose. See

• Modbus connections are faster than HART connections.

• Using a HART connection from ProLink II, you cannot have more than one client window

Connect dialog box are displayed

Section 2.5.

open at a time.

Installation and Use Manual 25

Page 32

Using ProLink II Software

• Service port connections:

- Service ports use standard connection parameters, so you do not have to know the

transmitter’s configuration.

- ProLink II uses Modbus protocol for service port connections, which is the fastest protocol

available.

- On Model 1700/2700 transmitters, LF-Series field-mount transmitters, and Model 2400S

transmitters, the service port is always available.

- On Model 1500/2500 transmitters, LF-Series DIN-rail transmitters, and Series 3000

transmitters, the service port is available only for ten seconds after power-up. For service

port access, you will have to power down the transmitter, which may not be acceptable in

your installation.

- On Series 1700/2700 and LFT field-mount transmitters, you must open the wiring

compartment to access the service port. On Model 2400S transmitters, you must remove

the housing cover. Therefore, on these transmitters the service port is appropriate only for

temporary connections.

• HART/Bell 202 connections:

- HART/Bell 202 connections use standard connection parameters, so you don’t have to

know the transmitter’s configuration.

- Because the HART/Bell 202 connection is made over the primary mA output terminals,

the communication signal can interfere with certain procedures such as loop testing, and

may cause the output to change. Depending on how the primary mA output is being used,

this may have significant consequences for process control.

- Depending on the transmitter and wiring method, HART/Bell 202 connections may be

appropriate for both temporary and permanent connections.

• RS-485 connections:

- To use an RS-485 connection, you must know the transmitter’s configuration.

- RS-485 connections are appropriate for both temporary and permanent connections.

Making the connection – Model 7826 and 7828

1. Ensure that your PC is connected to a transmitter, using one of the methods described in

Chapter 2.

2. Choose

3. Set

Connection > Connect to Densitometer/Viscometer. See Figure 3-1.

Serial Port to the PC COM port you are using to connect to the device.

4. If you know the address of the device and you want to communicate with this product only,

enter the device address in both the

From Address and To Address fields.

5. If you do not know the address, or if you want to communicate with multiple devices, enter a

range of device addresses using the

6. Click

Connect.

ProLink II will poll all addresses in the specified range, and populate the

From Address and To Address fields.

Found list with all

Model 7826/7828 that it finds in that range. When polling is complete, select the desired address from

the

Found list. To switch to a different device, return to the connection window and select a different

address from the

Found list.

26 ProLink® II Software for Micro Motion® Transmitters

Page 33

Using ProLink II Software

Figure 3-1 Connect to Densitometer/Viscometer window

Making the connection – all other transmitters

1. Ensure that your PC is connected to a transmitter, using one of the methods described in

Chapter 2.

2. Choose

3. Select the protocol to use. Depending on the

Connection > Connect to Device. See Figure 3-2.

Protocol option that you choose, different

communications options will be available for configuration.

4. Specify

Baud Rate, Parity, Stop Bits, COM Port, and Address/Tag as appropriate for your

connection and transmitter. See Section 2.6 for more information on these parameters.

5. If you are using the USB HART Interface, select

6. Click

Connect.

Converter Toggles RTS.

Alternately, if you do not know the address of your transmitter:

1. Click

Poll. ProLink II will poll the network for all Micro Motion transmitters, and display a

list of all transmitters found.

2. Select the transmitter to connect to, and click

OK.

Figure 3-2 Connection window (all other transmitters)

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 27

Page 34

Using ProLink II Software

Notes:

• Due to the design of HART protocol, connections made using HART protocol are slower than

connections that use Modbus protocol. If you use HART protocol, you cannot open more than one

ProLink II window at a time.

• If you are using HART protocol and a HART tag (software tag) has been configured for your

transmitter, you can specify the HART tag instead of the HART address.

• ProLink II can connect to only one transmitter at a time. To connect to another transmitter, you

must first disconnect from the current connection.

3.2.2 Disconnecting

To disconnect from the currently connected transmitter, choose

3.3 Using the Commissioning Wizard

When ProLink II first connects to a transmitter, the Commissioning Wizard appears (see Figure 3-3).

The Commissioning Wizard is a tool that guides you through the most common transmitter

configuration tasks.

Notes:

• If you have configured the Commissioning Wizard not to appear, you must choose

Commissioning Wizard

to start the wizard.

• ProLink II does not preserve the task status of the wizard between sessions.

Figure 3-3 Commissioning Wizard

Connection > Disconnect.

Tools >

28 ProLink® II Software for Micro Motion® Transmitters

Page 35

Using ProLink II Software

To start configuring your transmitter, click Next and follow the on-screen instructions provided. When

each task set is finished, the Task Status will change from Not Started to Completed, allowing you to

see what configuration steps you have already performed.

3.3.1 Disabling write-protect mode

To assist with configuration, write-protect mode can be automatically disabled while using the

Commissioning Wizard. To allow ProLink II to disable write-protect mode, select

to remove device write-protection if necessary

If write-protect mode was enabled before you started the Commissioning Wizard, it will be re-enabled

as soon as you exit the wizard.

3.3.2 Saving transmitter configuration

Allow the wizard

.

The Commissioning Wizard allows you to save your transmitter’s configuration to a file on the PC.

See Section 5.2 for more information about working with configuration files.

To save your transmitter’s configuration, click

3.3.3 Starting the Commissioning Wizard automatically

You can control whether the Commissioning Wizard starts automatically whenever you connect to a

transmitter by enabling or disabling the

to a transmitter

checkbox.

Note: If you disable the checkbox, you will need to choose

to start the wizard.

3.4 ProLink II help system

ProLink II provides context-sensitive help for most windows and dialog boxes.

• To access the complete help system, choose

• To access help for a specific window or dialog box, make the object active, then press F1.

3.5 Viewing installed options

Many transmitters can be purchased with application options. To view the list of installed options,

choose

View > Installed Options. See Figure 3-4. Installed options are selected.

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Save Transmitter Configuration.

Always start the Commissioning Wizard after connecting

Tools > Commissioning Wizard in order

Help > Help Topics.

Installation and Use Manual 29

Page 36

Using ProLink II Software

Figure 3-4 Installed Options window

3.6 Viewing process data

ProLink II provides the following windows for viewing process data and related information:

•

Process Variables window

•

Output Levels window

Tota liz er Control window

•

The following windows are available if the associated option has been installed on the transmitter:

•

API Process Variables window

CM Process Variables window

•

All of these windows are opened from the

ProLink menu. For information on the data displayed in

these windows, see the transmitter manual, the application manual, or the ProLink II help system (see

Section 3.4).

3.7 Viewing and resetting totalizers and inventories

The

Totalizer Control window is used to:

• View current values of the totalizers and inventories

• Start, stop, and reset totalizers

• Reset inventories

• Reset frequency input total (Series 3000 transmitters only)

If the concentration measurement application is available and enabled in the transmitter, the

Totalizer Control

window is used to view and control totalizers and inventories related to the

concentration measurement application.

CM

Inventories can be reset only if this function is enabled in the

30 ProLink® II Software for Micro Motion® Transmitters

Preferences menu.

Page 37

Using ProLink II Software

To enable inventory reset:

1. Choose

2. Select

View > Preferences.

Enable Inventory Totals Reset.

3. Click

Apply (if necessary).

To manage totalizers and inventories:

1. Choose

ProLink > Totalizer Control or ProLink > CM Totalizer Control (if the concentration

measurement application is enabled in the transmitter). See Figure 3-5.

2. Use the buttons in this window to start, stop, or reset the totalizers and/or inventories.

Note: The

Start, Stop, and Reset buttons displayed under All Totals affect the mass totalizer, the

volume totalizer, and all API-related totalizers.

3. The

Reset Inventories button under All Totals is displayed only if this function is enabled

(see above). Use this button to reset all inventories, including API-related inventories.

Note: ProLink II does not support separate resetting of the API volume totalizer and API volume

inventory. To reset these, you must reset all totalizers or all inventories.

Figure 3-5 Totalizer Control window

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 31

Page 38

Using ProLink II Software

3.8 Viewing meter status

ProLink II allows you to view a variety of status information:

•

Connection LED – located in the lower right corner of the main window (see Figure 3-2).

This LED indicates the status of the connection between ProLink II and the transmitter:

- Green – Good connection

- Red – Connection fault

- Gray – No connection

•

Device Fault Status LED – located in the lower right corner of the main window (see

Figure 3-2). This LED indicates whether or not alarms are active:

- Green – No active alarms

- Red – One or more active alarms

- Gray – Unknown

See Section 3.9 for more information about alarms.

•

Diagnostic Information window – displays sensor diagnostic data

•

Output Levels window – displays current data for the transmitter’s mA, frequency, and

discrete outputs, and also displays discrete event status

•

Status window – displays alarm status. See Section 3.9 for more information about alarms.

Alarm Log window – displays alarm status and alarm acknowledgment status. See Section 3.9

•

for more information about alarms.

•

Core Processor Diagnostics window – displays detailed diagnostic data for the core

processor component

Note: The Core Processor Diagnostics window is read-only. If changes are required, contact

Micro Motion.

•

FingerPrint window – displays detailed information for both process variable data and sensor

diagnostic data

32 ProLink® II Software for Micro Motion® Transmitters

Page 39

Using ProLink II Software

3.9 Viewing and acknowledging alarms

The transmitter sets alarms whenever a process variable exceeds its defined limits or when the

transmitter detects a fault condition.

3.9.1 Viewing alarms

There are two ways to view alarms:

•Using the

tabs:

Status window (see Figure 3-6). In this window, alarms are organized into three

Critical, Informational, and Operational. If an alarm is active, the associated tab is

highlighted. In each panel, active alarms are indicated with red lights; inactive alarms are

indicated with green lights. This window displays only current alarm data and does not display

alarm history.

Alarms in the

Status window are independent of user-programmed alarm severity. That is,

alarms will still appear in the

•Using the

panels:

Alarm Log window (see Figure 3-7). In this window, alarms are organized into two

High Priority and Low Priority. These panels list all active alarms and all alarms that

are no longer active but have not been acknowledged:

- A red light indicates a currently active alarm.

- A green light indicates an alarm that is no longer active but has not been acknowledged.

Status window even when their severity is configured to Ignore.

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Unlike the

Alarms that are configured to Ignore will not appear in the

Status window, alarms in the Alarm Log do respond to user-configured severity.

Alarm Log.

Notes:

• The organization of alarms in the Status and Alarm Log windows is predefined and is not

configurable. For example, an alarm on the Critical tab cannot be moved to the Informational tab.

• For information about a specific alarm condition, see your transmitter manual.

Figure 3-6 Status window

Installation and Use Manual 33

Page 40

Using ProLink II Software

Figure 3-7 Alarm Log window

3.9.2 Acknowledging alarms

To acknowledge an alarm using ProLink II, you must use the

To acknowledge an alarm:

1. Choose

2. Select

ProLink > Alarm Log.

Ack for each alarm you want to acknowledge.

- If the alarm is no longer active (green light), the alarm will be cleared from the list, and the

Alarm Log window will be updated as soon as new data is received from the transmitter.

- If the alarm is still active (red light), the red light will remain, but the name of the alarm

will be grayed out. The alarm will be cleared from the list as soon as it is no longer active.

3.10 Managing the ProLink II license

Both the ProLink II temporary license and permanent license are keyed to a specific disk and a

specific folder or directory on a specific PC. If you want to move the ProLink II installation, you must

use the appropriate license transfer function:

•

To Di recto ry is used to transfer ProLink II to another location on the same PC.

•

Out of Computer and Into Computer are used to transfer ProLink II to another PC.

Alarm Log window.

34 ProLink® II Software for Micro Motion® Transmitters

Page 41

Using ProLink II Software

3.10.1 Transferring to same PC

To transfer ProLink II to another location on the same PC:

1. Choose

File > License.

2. Click

To Directory.

3. Specify the directory to which ProLink II will be transferred.

4. Install ProLink II in the new directory, following the instructions in Section 2.3. As part of this

procedure, you will be required to de-install the current installation.

3.10.2 Transferring to different PC

1. At the target PC (the PC to which you are transferring):

a. Install ProLink II, following the instructions in Section 2.3.

b. In the new installation, choose

c. Click

Into Computer and supply a diskette when requested. ProLink II will write license

File > License.

transfer data to the diskette.

2. At the source PC (the PC where ProLink II is currently installed):

a. Start ProLink II and choose

b. Click

Out of Computer and insert the transfer diskette. ProLink II will copy the license to

File > License.

the transfer diskette. At this point, the license is no longer valid on the source PC.

3. At the target PC:

a. In the

License window, click Into Computer.

b. Insert the transfer diskette. ProLink II will copy the license to the new installation, and you

can begin using the program in the new location.

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

Installation and Use Manual 35

Page 42

36 ProLink® II Software for Micro Motion® Transmitters

Page 43

Chapter 4

Initial Transmitter Startup Procedures

4.1 Overview

The first time you start up your transmitter, it may be useful to perform one or more of the following

tasks:

• Perform a loop test on transmitter outputs (and inputs, if your transmitter has a discrete input

or frequency input)

• Trim the mA outputs

• Zero the meter

Not all transmitters or all meters require these steps. Refer to the transmitter manual shipped with

your device.

4.2 Loop tests

A loop test is a means to:

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

• Verify that outputs are being sent by the transmitter and received accurately by the receiving

devices

• Determine whether or not you need to trim the mA outputs

• Verify that the discrete input or frequency input sent by an external device is being received

correctly by the transmitter (if the transmitter has a discrete input or frequency input)

The general procedure for performing a loop test is shown in Figure 4-1. You can also perform a loop

test from the Commissioning Wizard:

1. Choose

2. Click

3. Click

Tools > Commissioning Wizard.

Task 5: Perform loop tests.

Next.

Installation and Use Manual 37

Page 44

Initial Transmitter Startup Procedures

Fix Milliamp 1

Fix Milliamp 2

Fix Freq Out Read Discrete InputFix Discrete Out 1

Fix Discrete Out 2

Enter pulses/second

(Hz) value

Toggle remote input

device

Read output at

receiving device

Read output at

receiving device

Loop test successful

UnFix

Check output wiring

Troubleshoot output

Correct?

Read output at

receiving device

ON or OFF

Verify reading at

transmitter

Enter mA value

Ye s No output

Correct?

Fix FrequencyFix mA

Fix Discrete Output

Correct? Correct?

Loop test successful Check input wiring

Troubleshoot remote

device

Ye s No input

Read Freq Input

Read frequency at

remote device

Verify reading at

transmitter

Correct?

ProLink > Test

Figure 4-1 Loop test procedure

4.3 Trimming the milliamp (mA) output(s)

Trimming the mA output creates a common measurement range between the transmitter and the device

that receives the mA output. For example, a transmitter might send a 4 mA signal that the receiving

device reports incorrectly as 3.8 mA. If the transmitter output is trimmed correctly, it will send a

signal appropriately compensated to ensure that the receiving device actually indicates a 4 mA signal.

38 ProLink® II Software for Micro Motion® Transmitters

Page 45

Initial Transmitter Startup Procedures

Note the following:

• If you have two mA outputs, you should trim both.

• You must trim the output at both the 4 mA and 20 mA points to ensure appropriate

compensation across the entire output range.

• If you are trimming the primary mA output, and you are connected to the transmitter via the

primary mA output (HART/Bell 202), the communication signal to ProLink II will affect the

reading. Disconnect ProLink II before reading the output, then reconnect and resume the trim,

after taking the reading. If you are using any other protocol, this is not required.

• Any trimming performed on the output should not exceed ±200 microamps. If more trimming

is required, contact Micro Motion customer support.

To trim mA outputs, choose

Milliamp 1 Trim

1. Choose

2. Click

3. Click

. You can also initiate mA trim from the Commissioning Wizard:

Tools > Commissioning Wizard.

Task 6: Trim mA outputs.

Next.

Figure 4-2 Milliamp trim wizard – Screen 1

ProLink > Calibration > Milliamp 1 Trim or ProLink > Calibration >

ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin ProLink II Setup Transmitter StartupUsing ProLink IIBefore You Begin

This screen allows you to compare the transmitter output (the

Present Output value) to the

output level being received at an external device.

4. Read the mA output level at the receiving device.

5. Type the value that you read at the receiving device in the

6. Click

Next. At this point, the transmitter trims the milliamp output and displays the adjusted

Enter Meas box.

output in the following screen:

Installation and Use Manual 39

Page 46

Initial Transmitter Startup Procedures

Figure 4-3 Milliamp trim wizard – Screen 2

If the adjusted output is not 4.0:

a. Click

Back.

b. Read the output level at the receiving device and enter the new value in the

box.

c. Click

Next.

Enter Meas

d. Repeat until the adjusted output is 4.0 (or close enough for your application).

If the adjusted output is 4.0, click

7. Click

Next to repeat this procedure to trim the 20 mA output.

Once you have completed the 20 mA trim, the procedure is complete. Click

4.4 Zeroing the meter

Zeroing the meter establishes the meter’s point of reference when there is no flow. Zeroing is not

universally required for proper flowmeter operation. If you are unsure about whether you need to

zero, contact Micro Motion.

When you zero the meter, you may need to adjust the zero time parameter. Zero time is the amount of

time the transmitter takes to determine its zero-flow reference point. The default zero time is

20 seconds, which is appropriate for most applications.

•A long zero time may produce a more accurate zero reference but is more likely to result in a

zero failure. This is due to the increased possibility of noisy flow, which causes incorrect

calibration.

•A short zero time is less likely to result in a zero failure but may produce a less accurate zero

reference.

Do not zero the meter if a high severity alarm is active. Correct the problem, then zero the meter. You

may zero the meter if a low severity alarm is active. See Section 3.8 for information on viewing

transmitter status and alarms.

Next.

Finish.

Note: In some menus, a convergence limit parameter is displayed. This parameter applies only to the

RFT9739 transmitter. Micro Motion recommends that you use the default value for convergence limit.

40 ProLink® II Software for Micro Motion® Transmitters

Page 47

Initial Transmitter Startup Procedures