Page 1

A technical manual from the experts

in Business-Critical Continuity

™

NetSure™ RDB Series

Installation and User Manual — Plug-n-Play 48V Rack Distribution

Section 6041 (Issue AG, January 21, 2013)

Page 2

Business-Critical Continuity™, Emerson Network Power, and the Emerso n Net wo rk

Power logo are trademarks and service marks of Emerson Electric Co.

NetSure™, NetSpan™, NetReach™, NetXtend™, and NetPerform™

are trademarks of Emerson Network Power, Energy Systems, North America, Inc.

All other trademarks are the property of their respective owners.

The products covered by this instruction manual are manufactured and/or

sold by Emerson Network Power, Energy Systems, North America, Inc.

The information contained in this document is subject to change without notice and may not be

suitable for all applications. While every precaution has been taken to ensure the accuracy and

completeness of this document, Emerson Network Power, Energy Systems, North America, Inc.

assumes no responsibility and disclaims all liability for damages resulting from use of this information

or for any errors or omissions. Refer to other local practices or building codes as applicable for the correct

methods, tools, and materials to be used in performing procedures not specifically described in this document.

This document is the property of Emerson Network Power, Energy Systems, North America, Inc.

and contains confidential and proprieta r y information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use or disclosure of it without the written permission

of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Copyright

©

2013, Emerson Network Power, Energy Systems, North America, Inc.

All rights reserved throughout the world.

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.0 INSTALLATION

1.1 Shipment Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Installing the Rack PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Installing the Rack PDU Directly to a Rack Frame or Existing Mounting Bracket . . . . . . . . 2

1.2.2 Installing Rack PDUs to a Rack Frame using the Optional Mounting Bracket . . . . . . . . . . . . 2

2.0 ELECTRICAL CONNECTIONS

2.1 Connecting the Rack PDU DC Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Connecting the Rack PDU’s DC Output to Customer Equipment . . . . . . . . . . . . . . . . . . . . . 4

2.3 Connecting External Circuit Breaker Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 SPECIFICATIONS AND TECHNICAL DATA

3.1 Conformity and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.1 NetSure™ RDB L6, P/Ns 547692, 547693, 547499 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.2 NetSure

3.4.3 NetSure

3.4.4 NetSure

3.4.5 NetSure

3.4.6 NetSure

™

RDB L15, P/Ns 547694, 547695, 547615 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

™

RDB M6, P/Ns 547696, 547697, 547503 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

™

RDB H2, P/N 547500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

™

RDB H3, P/Ns 547698, 547699, 547501 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

™

RDB Mounting Bracket, P/N 547665. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Input Quick Connect Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6 Output Cable Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6.1 P/N 547595, P/N 547613 and P/N 555654 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6.2 Output Connector Kits (P/N 554878 and P/N 554944). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7 Replacement Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.0 OPERATION

4.1 Connecting Power to the Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Removing Power from the Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.1 Local Alarm Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.2 External Circuit Breaker Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

REVISION RECORD

i

Page 4

This Page Intentionally Left Blank

ii

Page 5

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WARNING

!

Please read and follow all safety information!

Failure to observe the safety information listed below may result in electric shock, fire

hazards, or serious injury.

Please safeguard this Installation and User Manual.

Intended Use

The NetSure™ RDB Rack PDU (Power Distribution Unit) is designed to deliver power to

information technology and telecommunication equipment.

Operate the Rack PDU in an indoor environment only within an ambient temperature range and a

relative humidity range as listed in 3.2 - Environmental Characteristics. Install the Rack PDU in

a clean environment, free of conductive contaminants, moisture, flammable liquids, gases and corrosive substances.

• Do not use the Rack PDU in moist environments. If the Rack PDU is exposed to moisture, immediately disconnect the Rack PDU from DC input power by opening the circuit breaker or removing

the fuse or breaker supplying DC input to the Rack PDU. Send the Rack PDU to the manufacturer for inspection.

• Do not use the Rack PDU for household applications.

Installation and Operation

Improper installation and operation may cause overheating and lead to increased fire hazard. It may also destroy the device and damage other connected systems.

• Installation and start-up must be performed by a qualified service engineer.

• Make sure that the total input current of the connected systems does not exceed the current rating specified on the rating plate of the Rack PDU.

Electrical Safety

Damaged Rack PDUs or connected cables increase the risk of electric shock or smoldering

fire.

• Check the unit for external signs of damage prior to start-up operation! Do not operate the device

if you detect any damage or other deficiencies.

• Only use the supplied DC input power cable.

Personal Safety

Careless handling increases the risk of electric shock.

• Never touch the outlets or the Rack PDU with wet or moist hands.

Service

Repairs should only be performed by qualified service technicians.

Unauthorized changes, modifications, or repairs of the device are performed at the owner’s risk and

will void all warranty claims.

• Do not open the Rack PDU.

• Please contact the nearest customer service center in case of malfunction! Damage and defects

must be repaired immediately.

• Always disconnect the unit from power before troubleshooting.

1

Page 6

1.0 INSTALLATION

The NetSure™ RDB Rack PDUs (Power Distribution Units) are designed to be installed on the left

and/or right rear frames of IT racks. They can be mounted directly to the rack or use Rack PDU

Mounting Kit P/N 547665. See 3.4 - Dimensions for hole dimensions.

1.1 Shipment Inspection

Unpack the shipping container, inspect all items for damage and verify that the shipment is complete

and undamaged. Report any damage to your local Emerson representative and the carrier.

1.2 Installing the Rack PDU

WARNING

!

Ensure proper grounding.

The Rack PDU’s "Ground Lead Bracket" must be ground bonded to the mounting bracket (if

used) or rack frame. The mounting bracket (if used) must be ground bonded to the rack frame.

The rack frame must be ground bonded to your site ground. This is typically accomplished

through the use of paint free areas and/or grounding washers used when mounting the

components.

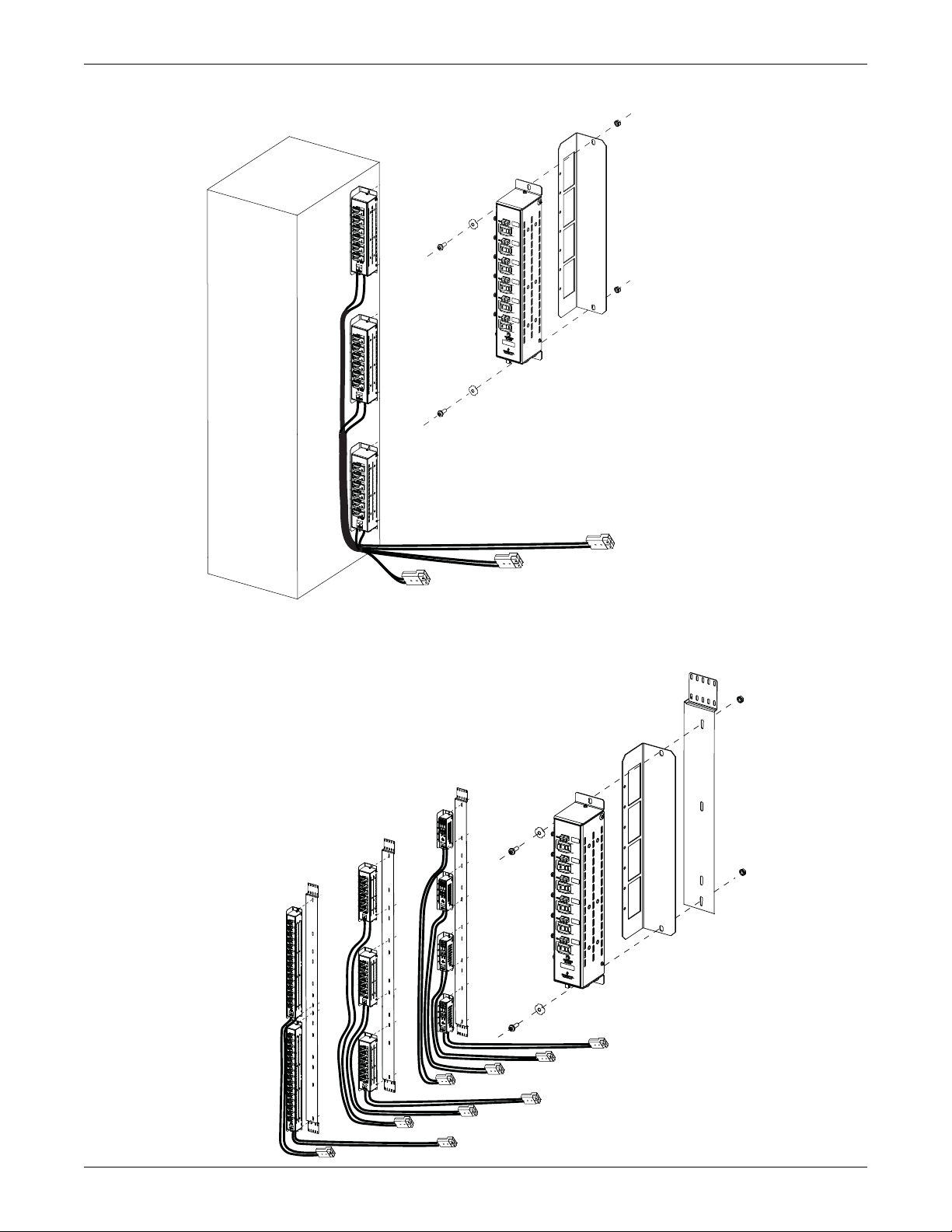

1.2.1 Installing the Rack PDU Directly to a Rack Frame or Existing Mounting Bracket

Installation

Install the Rack PDU directly to the rack frame or existing mounting bracket as shown in Figure 1.

Note that the supplied "Ground Lead Bracket" is to be placed between the PDU and the rack frame or

existing mounting bracket as shown in Figure 1. Use the supplied 1/4-20 screws and 1/4-20 KEPS

nuts.

1.2.2 Installing Rack PDUs to a Rack Frame using the Optional Mounting Bracket

If using the Rack PDU Mounting Kit, install the Rack PDU mounting bracket to the left and/or right

rear frame of the rack using the appropriate hardware that fits to the cabinet that will be used.

Install the Rack PDUs to the Rack PDU mounting bracket that was previously installed on the frame

as shown in Figure 2. Note that the supplied "Ground Lead Bracket" is to be placed between the

PDU and the mounting bracket as shown in Figure 2.

2

Page 7

Figure 1 Mounting Rack PDUs Directly to Rack Frame

Rack PDUs can be mounted on either side.

Rack PDUs and Ground Lead Bracket can be

rotated 180 degrees (cables can exit at top or bottom).

PDU

Ground wires not shown

in illustration for clarity.

Ground

Lead

Bracket

Rear

Screw

Ground

Washer

Keps

Nut

Rack PDUs and Ground Lead Bracket

can be rotated 180 degrees (cables can

exit at top or bottom).

PDU

Ground wires not shown

in illustration for clarity.

Ground Lead

Bracket

Mtg

Bracket

Screw

Ground

Washer

Keps

Nut

Installation

Figure 2 Mounting Rack PDUs using Optional Mounting Bracket Kit

3

Page 8

2.0 ELECTRICAL CONNECTIONS

+

-

DC Input Cable Assembly

(factory supplied and connected)

(6’ Cable)

Customer provided cables

to output circuit breaker or fuse

of a NetSure ITM DC UPS

or other DC source.

from DC Source or

NetSure ITM DC UPS

(field cut)

Input Quick

Connect Kit*

(separately ordered)

(includes Red

housing and

contacts)

350A Red

Connector

350A Red

Connector

Typical

Rack PDU

Bottom View

OBSERVE CORRECT POLARITY

(+): Ground Return

(-): -48Vdc

*547668 (Red housing plus 1/0 contacts)

*547669 (Red housing plus 2/0 contacts)

*547670 (Red housing plus 3/0 contacts)

*547671 (Red housing plus 4/0 contacts)

DC Output Cable Assembly

(separately ordered)*

(ground wires shipped loose w/ PDU’s)

Typical PDU

Side View

Red/Black

Connector

(P/O Cable Assy.)

Red/Black

Connector

(P/O PDU)

Ground Lead

Bracket

to

Customer

Equipment

-

+

GND

-

+

GND

-

+

GND

-

+

GND

-

+

GND

-

+

GND

OBSERVE CORRECT POLARITY

Red Connector To Red Connector

Black Connector To Black Connector

Red (-): -48Vdc

Black (+): Ground Return

PDU Model DC Output Cable P/N* Wire Size/Length Connector Rating

L6 547595 10 AWG / 6’ 45A

M6 547595 10 AWG / 6’ 45A

L15 547595 10 AWG / 6’ 45A

H2 547613 6 AWG / 4’ 75A

H3 547613 6 AWG / 4’ 75A

L6 555654 10 AWG / 10’ 45A

M6 555654 10 AWG / 10’ 45A

L15 555654 10 AWG / 10’ 45A

Factory

Connected to

Ground Wire Bracket

Ground

Leads

Output

Leads

2.1 Connecting the Rack PDU DC Input

The Rack PDU’s input is designed to be fed from a 200A (max) breaker or fuse using the factory supplied and connected DC input cable assembly and the customer connected input quick connect kits.

See Figure 3.

Figure 3 DC Input Connections

Electrical Connections

2.2 Connecting the Rack PDU’s DC Output to Customer Equipment

Figure 4 DC Output Connections

The Rack PDU’s output circuit breakers are connected to customer equipment via the separately

ordered output cable assemblies. A ground lead is also supplied with each output cable. Each ground

lead is terminated with a connector on one end (which mates with a connector on a ground wire factory connected to the "Ground Lead Bracket") and left unterminated on the other end. See Figure 4.

4

Page 9

2.3 Connecting External Circuit Breaker Alarms

Typical

Rack PDU

Bottom View

Circuit Breaker Alarm Connector

(mating screw-type connector supplied,

wire size range 16-24 AWG,

recommended torque 1.8 in-lbs)

-48Vdc signal provided

to both terminals when

any circuit breaker is

in the OFF position.

Typical interconnections when

“daisy-chaining” multiple Rack PDUs.

-48Vdc alarm signal (out)

(to ACU+ Controller in a NetSure ITM DC UPS

or Customer Monitoring Equipment)

When used with other monitoring equipment, refer to the

instructions supplied with this equipment.

When used with a NetSure ITM DC UPS, refer to Section 6040

(NetSure ITM Installation Instructions) for circuit breaker alarm

connections to the ACU+ Controller.

™

Negative 48Vdc is provided to a set of alarm terminals if any circuit breaker is in the OFF position.

See Figure 5.

Figure 5 Alarm Connections

Electrical Connections

5

Page 10

3.0 SPECIFICATIONS AND TECHNICAL DATA

3.1 Conformity and Standards

The NetSure RDB Rack PDU (Power Distribution Unit) has the following agency approval ratings:

• UL 60 950-1 + UL 1801 - Recognized (cURus)

3.2 Environmental Characteristics

The NetSure RDB Rack PDU (Power Distribution Unit) is designed to operate under the following

environmental conditions without damage or degradation in electrical operating characteristics:

Specifications and Technical Data

Operating Temperature

Storage Temperature -40°F to +176°F (-40°C to +80°C).

Relative Humidity 0 to 95%, non-condensing.

Operating Elevation 6562 ft (2000m) at full power.

3.3 Specifications

Model

RDB - Basic Rack PDUs

L6

L15

Part

Number

547692

547693 630 15 3.8 90

547499 840 20 5.0 120

547694

547695 630 15 8.4

547615 840 20 8.4

547696

Number

of

Outlets

6

15

-40°F to +104°F (-40°C to +40°C) (Models L6 and L15).

-40°F to +113°F (-40°C to +45°C) (Models H2, H3, and M6).

Power Rating per Outlet Power Rating per PDU Input/Output

Voltage

Max Watts Max Amps

1

Max kW Max Amps

1

(nominal)

420 10 2.5 60

420 10 6.3 150

2

2

1050 25 6.3 150

200

200

2

2

-48Vdc

M6

547697 1260 30 7.6 180

547503 1470 35 8.4

6

2

H2 547500 2 3360 80 6.7 160

547698

H3

547699 2520 60 7.6 180

3

547501 2940 70 8.4

1

Max Amps rated at end of battery discharge (42V).

2

PDU power rating limited to 200A, 8.4kW each.

2100 50 6.3 150

2

6

200

200

2

2

Page 11

3.4 Dimensions

3.4.1 NetSure™ RDB L6, P/Ns 547692, 547693, 547499

Factory Connected to

Ground Lead Bracket

Jumper Length: 3 (76)

10 AWG Cable

Tyco Electronics

Mate-N-Lok Connector, 350866-1

with 350922-3 male pin

Detail A, Ground Lead Jumper

3.10

(78.74)

0.28 (7.11) x 0.50 (12.70)

slot

Top View

3.00

(76.20)

Specifications and Technical Data

Notes:

1. Dimensions are in inches (millimeters),

unless otherwise specified.

2. Includes hardware to mount PDU

to IT rack or bracket P/N 547604.

3. Rack PDU and/or Ground Lead Bracket

can be mounted either as shown or

180 degree rotate.

4. Six outlets.

0.40

(10.16)

Left Side View

DC Output

Cable Assembly

P/N 547595 or P/N 555654

(separately ordered,

see 3.6.1)

Ground wires

factory connected to

Ground Lead Bracket.

(ground wires not shown)

See Detail A.

Local Circuit Breaker

Open Alarm Indicator

0.28 (7.11) dia.

Circuit Breaker Alarm Connector

(mating screw-type connector supplied,

wire size range 16-24 AWG,

recommended torque 1.8 in-lbs)

1.25

(31.75)

Front View

15.06

(383.03)

15.88

(403.35)

Right Side View

DC Input Cable Assembly

(factory supplied and connected)

See Detail B.

1/0 AWG Cables

Bottom View

72

(1828.80)

Detail B, DC Input Cable Assembly

7

350A Anderson, PP350

Powerpole Connector,

Red

Page 12

3.4.2 NetSure™ RDB L15, P/Ns 547694, 547695, 547615

Detail B, DC Input Cable Assembly

1/0 AWG Cables

72

(1828.80)

350A Anderson, PP350

Powerpole Connector,

Red

DC Input Cable Assembly

(factory supplied and connected)

See Detail B.

Front View

Top View

Bottom View

Right Side View

0.28 (7.11) x 0.50 (12.70)

slot

0.28 (7.11) dia.

Left Side View

3.10

(78.74)

3.00

(76.20)

0.40

(10.16)

30.83

(783.08)

31.63

(803.40)

1.25

(31.75)

Notes:

1. Dimensions are in inches (millimeters),

unless otherwise specified.

2. Includes hardware to mount PDU

to IT rack or bracket P/N 547604.

3. Rack PDU and/or Ground Lead Bracket

can be mounted either as shown or

180 degree rotate.

4. Fifteen outlets.

DC Output

Cable Assembly

P/N 547595 or P/N 555654

(separately ordered,

see 3.6.1)

Circuit Breaker Alarm Connector

(mating screw-type connector supplied,

wire size range 16-24 AWG,

recommended torque 1.8 in-lbs)

Ground wires

factory connected to

Ground Lead Bracket.

(ground wires not shown)

See Detail A.

Local Circuit Breaker

Open Alarm Indicator

Detail A, Ground Lead Jumper

Tyco Electronics

Mate-N-Lok Connector, 350866-1

with 350922-3 male pin

Factory Connected to

Ground Lead Bracket

Jumper Length: 3 (76)

10 AWG Cable

Specifications and Technical Data

8

Page 13

3.4.3 NetSure™ RDB M6, P/Ns 547696, 547697, 547503

Specifications and Technical Data

Factory Connected to

Ground Lead Bracket

Jumper Length: 3 (76)

10 AWG Cable

Tyco Electronics

Mate-N-Lok Connector, 350866-1

with 350922-3 male pin

Detail A, Ground Lead Jumper

3.10

(78.74)

0.28 (7.11) x 0.50 (12.70)

factory connected to

Ground Lead Bracket.

(ground wires not shown)

P/N 547595 or P/N 555654

(separately ordered,

Ground wires

See Detail A.

DC Output

Cable Assembly

see 3.6.1)

slot

Top View

3.83

(97.28)

Notes:

1. Dimensions are in inches (millimeters),

unless otherwise specified.

2. Includes hardware to mount PDU

to IT rack or bracket P/N 547604.

3. Rack PDU and/or Ground Lead Bracket

can be mounted either as shown or

180 degree rotate.

4. Six outlets.

0.40

(10.16)

15.08

(383.03)

15.88

(403.35)

Left Side View

Local Circuit Breaker

Open Alarm Indicator

0.28 (7.11) dia.

Circuit Breaker Alarm Connector

(mating screw-type connector supplied,

wire size range 16-24 AWG,

recommended torque 1.8 in-lbs)

1/0 AWG Cables

1.70

(43.18)

Front View

Bottom View

72

(1828.80)

Right Side View

DC Input Cable Assembly

(factory supplied and connected)

See Detail B.

350A Anderson, PP350

Powerpole Connector,

Red

Detail B, DC Input Cable Assembly

9

Page 14

3.4.4 NetSure™ RDB H2, P/N 547500

Detail B, DC Input Cable Assembly

350A Anderson, PP350

Powerpole Connector,

Red

1/0 AWG Cables

72

(1828.80)

DC Input Cable Assembly

(factory supplied and connected)

See Detail B.

Circuit Breaker Alarm Connector

(mating screw-type connector supplied,

wire size range 16-24 AWG,

recommended torque 1.8 in-lbs)

Front View

Top View

Bottom View

Right Side View

Left Side View

0.28 (7.11) x 0.38 (9.65)

slot

0.28 (7.11) dia.

3.39

(86.12)

3.31

(84.07)

0.35

(8.89)

9.83

(249.68)

10.56

(268.22)

1.13

(28.70)

Notes:

1. Dimensions are in inches (millimeters),

unless otherwise specified.

2. Includes hardware to mount PDU

to IT rack or bracket P/N 547604.

3. Rack PDU and/or Ground Lead Bracket

can be mounted either as shown or

180 degree rotate.

4. Two outlets.

DC Output

Cable Assembly

P/N 547613

(separately ordered,

see 3.6.1)

Ground wires

factory connected to

Ground Lead Bracket.

(ground wires not shown)

See Detail A.

Local Circuit Breaker

Open Alarm Indicator

Anderson, PP75

Powerpole Connectors

Factory Connected to

Ground Lead Bracket

Jumper Length: 3.25 (83)

8 AWG Cable

Detail A, Ground Lead Jumper

Specifications and Technical Data

10

Page 15

3.4.5 NetSure™ RDB H3, P/Ns 547698, 547699, 547501

Detail B, DC Input Cable Assembly

350A Anderson, PP350

Powerpole Connector,

Red

1/0 AWG Cables

72

(1828.80)

DC Input Cable Assembly

(factory supplied and connected)

See Detail B.

Front View

Top View

Bottom View

Right Side View

Left Side View

0.28 (7.11) x 0.38 (9.65)

slot

0.28 (7.11) dia.

3.39

(86.12)

3.31

(84.07)

0.34

(8.64)

9.87

(250.70)

10.56

(268.22)

1.73

(43.94)

Notes:

1. Dimensions are in inches (millimeters),

unless otherwise specified.

2. Includes hardware to mount PDU

to IT rack or bracket P/N 547604.

3. Rack PDU and/or Ground Lead Bracket

can be mounted either as shown or

180 degree rotate.

4. Three outlets.

DC Output

Cable Assembly

P/N 547613

(separately ordered,

see 3.6.1)

Circuit Breaker Alarm Connector

(mating screw-type connector supplied,

wire size range 16-24 AWG,

recommended torque 1.8 in-lbs)

Ground wires

factory connected to

Ground Lead Bracket.

(ground wires not shown)

See Detail A.

Local Circuit Breaker

Open Alarm Indicator

Anderson, PP75

Powerpole Connectors

Factory Connected to

Ground Lead Bracket

Detail A, Ground Lead Jumper

Jumper Length: 3.25 (83)

8 AWG Cable

Specifications and Technical Data

11

Page 16

3.4.6 NetSure™ RDB Mounting Bracket, P/N 547665

6.81

2.68

6.000 (TYP)

1.375

1.75 (TYP)

0.218 X 0.562 SLOT (II)

0.218 X 0.375 SLOT (4)

0.281 X 1.000 SLOT (14)

0.218 X 0.562 SLOT (20)

0.25

o

0.147+0.002 (40 PLCS)

2.56

R 0.062 REF

3.69

0.25 X 45 (TYP)

o

73.63

0.000

0.75

2.250

3.25

0.64

1.33

2.02

2.70

3.39

0.000

0.845

3.032

4.785

14.656

19.867

22.847

29.277

32.718

35.617

38.012

40.909

44.357

50.780

53.761

58.971

68.842

70.595

72.782

71.937

1.687

Specifications and Technical Data

12

Page 17

3.5 Input Quick Connect Kit

SB350

10 AWG Cables

72

(1829)

45A Anderson, PP45

Powerpole Connector,

Red/Black

6 AWG Cables

48

(1219)

75A Anderson, PP75

Powerpole Connector,

Red/Black

unterminated ends

unterminated ends

DC Output Cable Assembly, P/N 547595

GND

+

-

GND

+

-

DC Output Cable Assembly, P/N 547613

10 AWG Cables

69

(1753)

Tyco Electronics

Mate-N-Lok Connector, 350865-1

with 350923-3 female socket

unterminated end

8 AWG Cables

45

(1143)

Anderson, PP75

Powerpole Connectors

unterminated end

+

-

Tyco Electronics

Mate-N-Lok Connector, 350865-1

with 350923-3 Female Socket

45A Anderson, PP45

PowerPole Connector,

Red/Black

10 AWG Cables

unterminated Ends

10 AWG Cables

unterminated Ends

GND

117

(2972)

120

(3048)

DC Output Cable Assembly, P/N 555654

Notes:

1. Dimensions are in inches (millimeters),

unless otherwise specified.

Provides the mating connector and contacts for the DC Input Cable Assembly factory supplied and

connected to the Rack PDU.

P/N

547668 1/0

Contact Size

(AWG)

Specifications and Technical Data

Mating

Anderson

Powerpole

Connector

547669 2/0

547670 3/0

547671 4/0

3.6 Output Cable Assemblies

3.6.1 P/N 547595, P/N 547613 and P/N 555654

350A, Red

(SB350)

13

Page 18

3.6.2 Output Connector Kits (P/N 554878 and P/N 554944)

554878

For use with L6, L15 and M6 RDB

Includes red and black connector

housings and contacts for 10-14 AWG,

and 12-16 AWG wire sizes.

P/N 142992 for

14 - 10 AWG

P/N 145369 for

16 - 12 AWG

554944

For use with H2 and H3 RDB

Includes red and black connector

housings and contacts for 6 AWG,

8 AWG and 10-12 AWG wire sizes.

P/N 101621 for

12 - 10 AWG

P/N 247109602

for 8 AWG

P/N 111691 for

6 AWG

3.7 Replacement Circuit Breakers

Specifications and Technical Data

NetSure

Rack PDU

P/N

547692

547694

547693

547695

547499

547615

Replacement

Circuit Breakers

P/N

142907 (10A)

142908 (15A)

141801 (20A)

547696 143041 (25A)

547697 143042 (30A)

547503 141802 (35A)

547698 142951 (50A)

547699 142952 (60A)

547501 142953 (70A)

547500 142955 (80A)

14

Page 19

4.0 OPERATION

WARNING

!

Improper operation may cause overheating and lead to increased fire hazard.

Improper operation may also destroy the device and damage other connected

systems.

Make sure that the total input current of the connected systems does not exceed the current

rating specified on the rating plate of the Rack PDU. Please refer to the operating instructions

or the rating plates of the connected systems or the circuit breaker for power specifications.

4.1 Connecting Power to the Loads

To connect DC power to the load(s), operate the respective circuit breaker on the Rack PDU to the ON

position.

4.2 Removing Power from the Loads

To disconnect DC power from the load(s), operate the respective circuit breaker on the Rack PDU to

the OFF position.

4.3 Alarms

Operation

4.3.1 Local Alarm Indicator

Each Rack PDU contains a circuit breaker alarm indicator. This indicator illuminates Red if any circuit breaker on the Rack PDU is in the OFF position.

4.3.2 External Circuit Breaker Alarm

Negative 48Vdc is supplied to a set of terminals when any circuit breaker on the Rack PDU is in the

OFF position. These terminals may be connected to customer external alarm circuits.

15

Page 20

5.0 REVISION RECORD

Change

Issue

AA LLP214446 New

AB LLP214895 Table in 3.3 revised. Manufacturer P/Ns added to 3.5 and 3.6.

Number

(ECO)

Description of Change

Revision Record

AC LLP215438

AD LLP215960

AE LLP217560

AF LLP217939

AG LLP218160 UPdated DC output connector color.

Updated circuit breaker part number on the DC power strips and changed

hardware stack-up on the PDU.

Updated orientation of Snap-Pak breakers and it’s connections to the following

assembly: 547499, 547692, 547693, 547615, 547694 and 547695. Added

insulator for wire connection for assembly: 547500 547501 54 7698 and 547699.

Updated reference about rack PDU mounting kit, rack PDU mounting bracket and

rack PDU mounting bracket dimensions. Updated RDB ground connections for

547499, 547503, 547615 and 547595.

Update the size of ground lead jumper used for 547500,547698,547699, 547501

and update the length of ground lead jump er. Update the size of ground wire used

for 547613. Add connector kit information for 554878 and 554944.

Add part number 555654 DC output cable assembly. Add labels to output

connector kits.

16

Page 21

NetPerform™ Optimization Services

At Emerson Network Power, we understand the importance of reliable equipment – it’s critical to both

your business and your bottom line. That is why we offer a wide array of services to meet all of your

network infrastructure needs.

Technical Support

Email

Phone

Services - Design, Deployment & Optimization

Email

Phone

FreedomCare

Spare Parts

Email

Phone

DCpower.TAC@Emerson.com

OSP.TAC@Emerson.com

1.800.800.5260

ES.Services@Emerson.com Provides quotes and bid responses, order

1.800.800.1280, option 7

Secure.EmersonNetworkPower.com

DCpower.Spares@Emerson.com

OSP.Spares@Emerson.com

1.800.800.1280, option 5

Answers technical product and system

questions; determines status of warranties and

contractual agreements for repair.

placement and scheduling for design, and

deployment and optimization services.

Download service & maintenance reports

online.

Pricing and PO processing of spare parts,

including but not limited to breakers, cables,

fuses, rectifier fans, misc. breaker and fuse

panels, enclosure fans, doors & switches, etc.

DC Power Depot Repair

Email

Phone

DCpower.Repair@Emerson.com Creates and processes RMAs, determines lead

1.800.800.1280, option 6

times and pricing, provides repair shipping

information and status.

DC Power Product Training

Email

Phone

DCpower.Training@Emerson.com Requests for quotes, order placement and

1.800.800.1280, option 8

scheduling.

For More Information

To learn more about service offerings from Emerson Network Power, please contact your sales

representative, call 1-800-800-1280 option 7, email ES.Services@Emerson.com

www.EmersonNetworkPower.com/EnergySystems

.

or visit

Page 22

Emerson Network Power.

The global leader in enabling Business-Critical Continuity

™

.

AC Power

Connectivity

Embedded Computing

Embedded Power

Infrastructure Management & Monitoring

Outside Plant Racks & Integrated Cabinets

ServicesPower Switching & Controls

Surge Protection

Emerson Network Power

Energy Systems, North America

4350 Weaver Parkway, Warrenville, IL 60555

Toll Free: 800-800-1280 (USA and Canada)

Telephone: 440-246-6999 Fax: 4 40- 246-4876

Web: EmersonNetworkPower.com/EnergySystems

EnergyNet: Secure.EmersonNetworkPower.com

.

DC Power Precision Cooling

EmersonNetworkPower.com

Emerson (NYSE: EMR), based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering

together to provide innovative solutions for customers in industrial, commercial, and consumer markets through its

network power, process management, industrial automation, climate technologies, and tools and storage businesses.

For more information, visit: Emerson.com.

Emerson Network Power, a business of Emerson (NYSE:EMR), is the global leader in enabling Business-Critical Continuity

™

from grid to chip for telecommunication networks, data centers, health care and industrial facilities. Emerson Network

Power provides innovative solutions and expertise in areas including AC and DC power, precision cooling, embedded

computing and power, integrated racks and enclosures, power switching and controls, infrastructure management, and

connectivity. All solutions are supported globally by local Emerson Network Power service technicians. For more

information on Emerson Network Power’s full suite of solutions specifically supporting the communications network

infrastructure, including NetSpan

™

, NetReach™ and NetXtend™ outside plant enclosures and equipment, NetSure™ DC

power systems, and NetPerform

™

Optimization, Design & Deployment services, visit:

EmersonNetworkPower.com/EnergySystems.

Learn more about Emerson Network Power products and services at: EmersonNetworkPower.com.

Loading...

Loading...