Page 1

SPEC. NOS.

MODEL

584622100 (19” MAIN SHELF), 584622200 (19” EXPANSION SHELF)

584622300 (23” MAIN SHELF), 584622400 (23” EXPANSION SHELF)

DCS48375

NetSure™ +24VDC to -48VDC Converter System

Installation and User Instructions

UM584622100 (Issue AC, July 3, 2012)

Page 2

Business-Critical Continuity™, Emerson Network Power, and the Emerson Network

Power logo are trademarks and service marks of Emerson Electric Co.

NetSure™, NetSpan™, NetReach™, NetXtend™, and NetPerform™

are trademarks of Emerson Network Power, Energy Systems, North America, Inc.

All other trademarks are the property of their respective owners.

The products covered by this instruction manual are manufactured and/or

sold by Emerson Network Power, Energy Systems, North America, Inc.

The information contained in this document is subject to change without notice and may not be

suitable for all applications. While every precaution has been taken to ensure the accuracy and

completeness of this document, Emerson Network Power, Energy Systems, North America, Inc.

assumes no responsibility and disclaims all liability for damages resulting from use of this information

or for any errors or omissions. Refer to other local practices or building codes as applicable for the correct

methods, tools, and materials to be used in performing procedures not specifically described in this document.

This document is the property of Emerson Network Power, Energy Systems, North America, Inc.

and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use or disclosure of it without the written permission

of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Copyright © 2012, Emerson Network Power, Energy Systems, North America, Inc.

All rights reserved throughout the world.

Page 3

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

TABLE OF CONTENTS

CONTENTS PAGE

STATIC WARNING ................................................................................................................... iii

ADMONISHMENTS .................................................................................................................. iv

General Safety .................................................................................................................................................... iv

Voltages .............................................................................................................................................................. iv

Circuit Card Handling .......................................................................................................................................... iv

CHAPTER 1. DESCRIPTION AND INSTALLATION ACCEPTANCE CHECKLIST .................. 1

System Description .............................................................................................................................................. 1

Installation Acceptance Checklist ........................................................................................................................ 1

CHAPTER 2. INSTALLING THE SYSTEM ................................................................................ 3

General Requirements ......................................................................................................................................... 3

Mounting the Shelf(s) ........................................................................................................................................... 5

Securing the Main Shelf to a Relay Rack ...................................................................................................... 5

Securing the Expansion Shelf(s) to a Relay Rack and Installing the Expansion Wiring Cover on

the Main Shelf ................................................................................................................................................ 6

Installing Optional Lug Adapter Busbar Kits ........................................................................................................ 7

Installing Bullet Nose Circuit Breakers and/or Fuseholders (with TPS/TPL Fuses) ............................................ 8

Installing an Optional Bullet Nose GMT Fuse Block .......................................................................................... 10

CHAPTER 3. SETTING JUMPER AND SWITCH OPTIONS ................................................... 12

Jumper and Switch Settings on the System Interface Circuit Card ................................................................... 12

Switch S1 ..................................................................................................................................................... 12

Jumper P2 ................................................................................................................................................... 13

CHAPTER 4. MAKING ELECTRICAL CONNECTIONS .......................................................... 14

Admonishments ................................................................................................................................................. 14

Wiring Considerations ........................................................................................................................................ 14

Shelf(s) Grounding (Frame Ground) Connection ............................................................................................... 15

External Alarm, Reference, Monitoring, and Control Connections .................................................................... 16

Load Connections .............................................................................................................................................. 18

To Distribution Bus Row .............................................................................................................................. 18

To Optional Bullet Nose 6-Position GMT Fuse Block .................................................................................. 20

Expansion Shelf(s) Interconnections ................................................................................................................. 21

Installing Output Paralleling Leads .............................................................................................................. 21

FA/CBA and CAN Bus Interconnections ..................................................................................................... 22

DC Input Connections ........................................................................................................................................ 23

CHAPTER 5. INSTALLING THE CONVERTER MODULES AND INITIALLY STARTING THE

SYSTEM ................................................................................................................................... 25

Installing Converter Modules.............................................................................................................................. 25

Table of Contents Page i

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 4

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

Initially Starting and Checking System Operation .............................................................................................. 26

Initial Startup Preparation ............................................................................................................................ 26

Initially Starting the System ......................................................................................................................... 26

Checking System Status ............................................................................................................................. 26

CHAPTER 6. OPERATING PROCEDURES ............................................................................ 27

Converter Modules ............................................................................................................................................. 27

Using the Converter System with an ACU+ Controller ...................................................................................... 27

Local Indicators and Test Points ........................................................................................................................ 27

Local Indicators............................................................................................................................................ 27

Test Points ................................................................................................................................................... 28

CHAPTER 7. MAINTENANCE ................................................................................................. 29

Admonishments ................................................................................................................................................. 29

System Maintenance Procedures ...................................................................................................................... 29

CHAPTER 8. TROUBLESHOOTING AND REPAIR ................................................................ 30

Contact Information ............................................................................................................................................ 30

Admonishments ................................................................................................................................................. 30

Converter Modules ............................................................................................................................................. 30

System Troubleshooting Information ................................................................................................................. 30

Replacement Information ................................................................................................................................... 30

Replacement Procedures ................................................................................................................................... 31

Replacing a Converter Module .................................................................................................................... 31

Replacing a Distribution Device ................................................................................................................... 31

Replacing the System Interface Circuit Card .............................................................................................. 34

REVISION RECORD ................................................................................................................ 36

Page ii Table of Contents

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 5

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

STATIC WARNING

The printed circuit cards used in this equipment contain static sensitive components. The warnings listed below

must be observed to prevent damage to these components. Disregarding any of these warnings may result in

personal injury or damage to the equipment.

1. Strictly adhere to the procedures provided in this document.

2. Before touching any static sensitive component or printed circuit card containing such a component,

discharge all static electricity from yourself by wearing a wrist strap grounded through a one megohm

resistor. Some wrist straps, such as Emerson Network Power Part Number 631810600, have a built-in

one megohm resistor; no external resistor is necessary. Read and follow wrist strap manufacturer’s

instructions outlining use of a specific wrist strap.

3. Do not touch the traces or components on a printed circuit card containing static sensitive components.

Handle the printed circuit card only by the edges that do not have connector pads.

4. After removing a printed circuit card containing a static sensitive component, place the printed circuit card

only on conductive or anti-static material such as conductive foam, conductive plastic, or aluminum foil.

Do not use ordinary Styrofoam or ordinary plastic.

5. Store and ship static sensitive devices or printed circuit cards containing such components only in static

shielding containers.

6. If necessary to repair a printed circuit card containing a static sensitive component, wear an appropriately

grounded wrist strap, work on a conductive surface, use a grounded soldering iron, and use grounded

test equipment.

Static Warning Page iii

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 6

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

ADMONISHMENTS

GENERAL SAFETY

Danger: YOU MUST FOLLOW APPROVED SAFETY PROCEDURES.

Performing the following procedures may expose you to hazards. These

procedures should be performed by qualified technicians familiar with the

hazards associated with this type of equipment. These hazards may

include shock, energy, and/or burns. To avoid these hazards:

a) The tasks should be performed in the order indicated.

b) Remove watches, rings, and other jewelry.

c) Prior to contacting any uninsulated surface or termination, use a

voltmeter to verify that no voltage or the expected voltage is present.

d) Wear eye protection and use recommended tools.

e) Use double insulated tools appropriately rated for the work to be

performed.

VOLTAGES

Danger: This system operates from DC input power. All DC power sources must

be completely disconnected from the branch circuit wiring used to

provide power to this system before DC input connections are made.

Danger: This system produces DC power.

CIRCUIT CARD HANDLING

Warning: Installation or removal of the circuit cards requires careful handling.

Before handling any circuit card, read and follow the instructions

contained on the Static Warning Page.

Page iv Admonishments

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 7

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

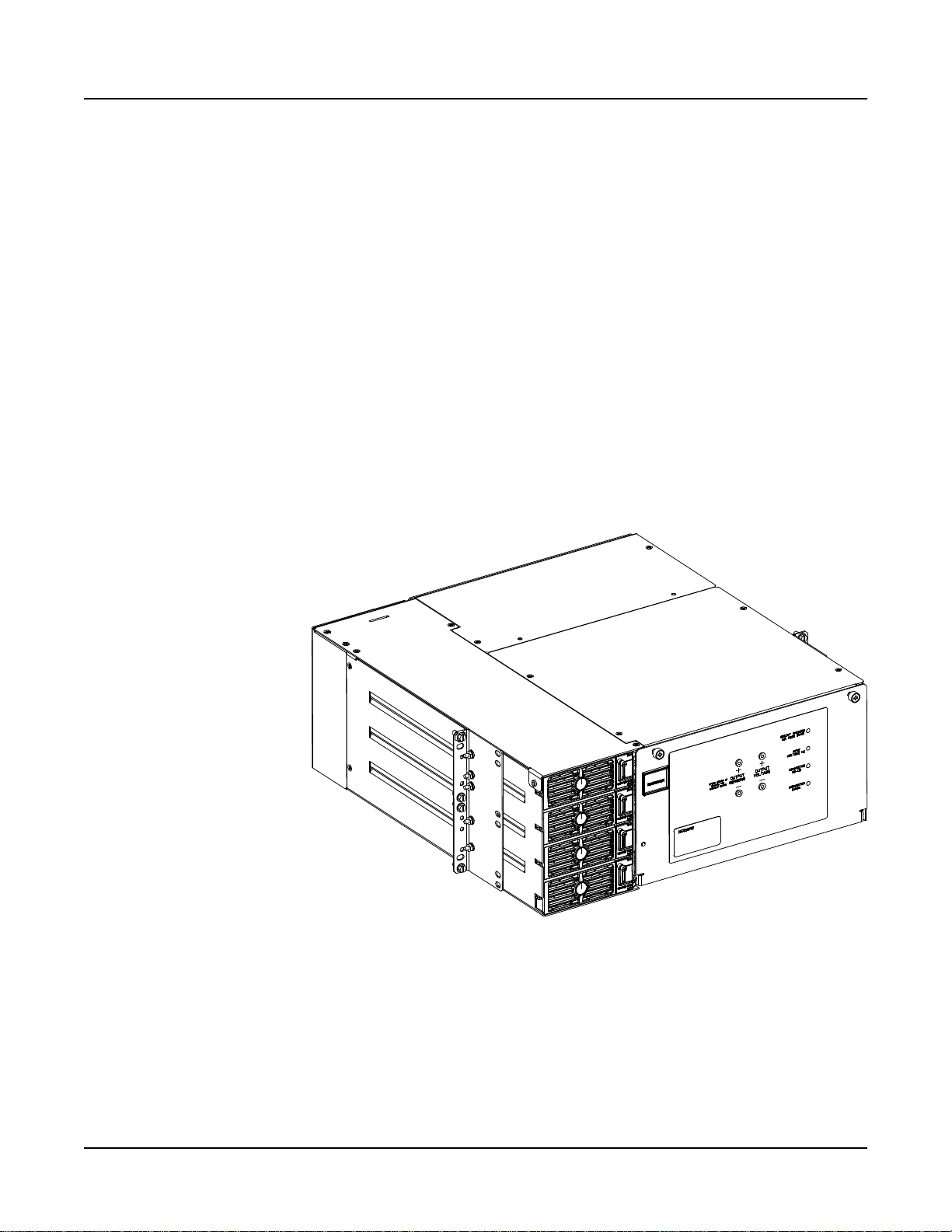

CHAPTER 1. DESCRIPTION AND INSTALLATION ACCEPTANCE CHECKLIST

SYSTEM DESCRIPTION

+24VDC to -48VDC @ up to 375A Converter System.

The NetSure™ DCS48375 Converter System is comprised of a main shelf and up to two

(2) expansion shelves. Each shelf provides mounting positions for up to four (4)

converter modules. Each shelf also provides a 15-position distribution row (19” version)

or 20-position distribution row (23” version) which accepts bullet nose circuit breakers

and TPS/TLS fuseholders. A GMT fuse block option is also available.

Note: Refer to SAG584622100 (System Application Guide) for additional system

information.

Note: Refer to UM1C24481500 (Converter Module User Instructions) for converter

module information.

INSTALLATION ACCEPTANCE CHECKLIST

Provided below is an Installation Acceptance Checklist. This checklist helps ensure

proper installation and initial operation of the system. As the procedures presented in

Chapters 2 through 5 of this document are completed, check the appropriate box on this

list. If the procedure is not required to be performed for your installation site, also check

the box in this list to indicate that the procedure was read. When installation is done,

ensure that each block in this list has been checked. Some of these procedures may

have been factory performed for you.

Chapter 1. Description and Installation Checklist Page 1

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 8

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

Note: The system is not powered up until the end of this checklist.

Note: Some of these procedures may have been factory performed.

Chapter 2. Installing the System

Optional Wiring Access Panel Installed on Top of Shelf(s), if desired

Main Shelf Secured to Relay Rack

Expansion Shelf(s) Secured to Relay Rack (if furnished)

and Expansion Wiring Cover installed on Main Shelf

Optional Lug Adapter Busbar Kits Installed

Bullet Nose Circuit Breakers Installed

Bullet Nose Fuseholders and TPS/TLS Fuses Installed

Optional Bullet Nose GMT Fuse Block Installed (if furnished)

Chapter 3. Setting Jumper and Switch Options

Jumper on System Interface Circuit Card Set

Switches on System Interface Circuit Card Set

Chapter 4. Making Electrical Connections

Shelf(s) Grounding (Frame Ground) Connection Made

External Alarm, Reference, Monitoring, and Control Connections Made

Load Connections Made

Expansion Shelf(s) Interconnections Made (if furnished)

DC Input Connections Made

Chapter 5. Installing the Converter Modules and Initially Starting the System

Converter Modules Installed

System Started and Checked

Page 2 Chapter 1. Description and Installation Checklist

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 9

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

CHAPTER 2. INSTALLING THE SYSTEM

GENERAL REQUIREMENTS

The shelf is designed for mounting in a 19-inch or 23-inch wide relay rack with 1-3/4

inch multiple drilling.

The installer should be familiar with the installation requirements and techniques to

be used in securing the shelf(s) to a relay rack.

This product is intended only for installation in a Restricted Access Location on or

above a non-combustible surface.

This product must be located in a Controlled Environment with access to

Craftspersons only.

This product is intended for installation in Network Telecommunication Facilities (CO,

vault, hut, or other environmentally controlled electronic equipment enclosure).

This product is intended to be connected to the common bonding network in a

Network Telecommunication Facility (CO, vault, hut, or other environmentally

controlled electronic equipment enclosure).

Typical industry standards recommend minimum aisle space clearance of 2'6" for the

front of the relay rack and 2' for the rear of the relay rack.

Converter module and mounting shelf ventilating openings must not be blocked and

temperature of air entering system must not exceed rated Operating Ambient

Temperature Range found in SAG584622100.

Chapter 2. Installing the System Page 3

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 10

UM584622100 Installation and User Instructions

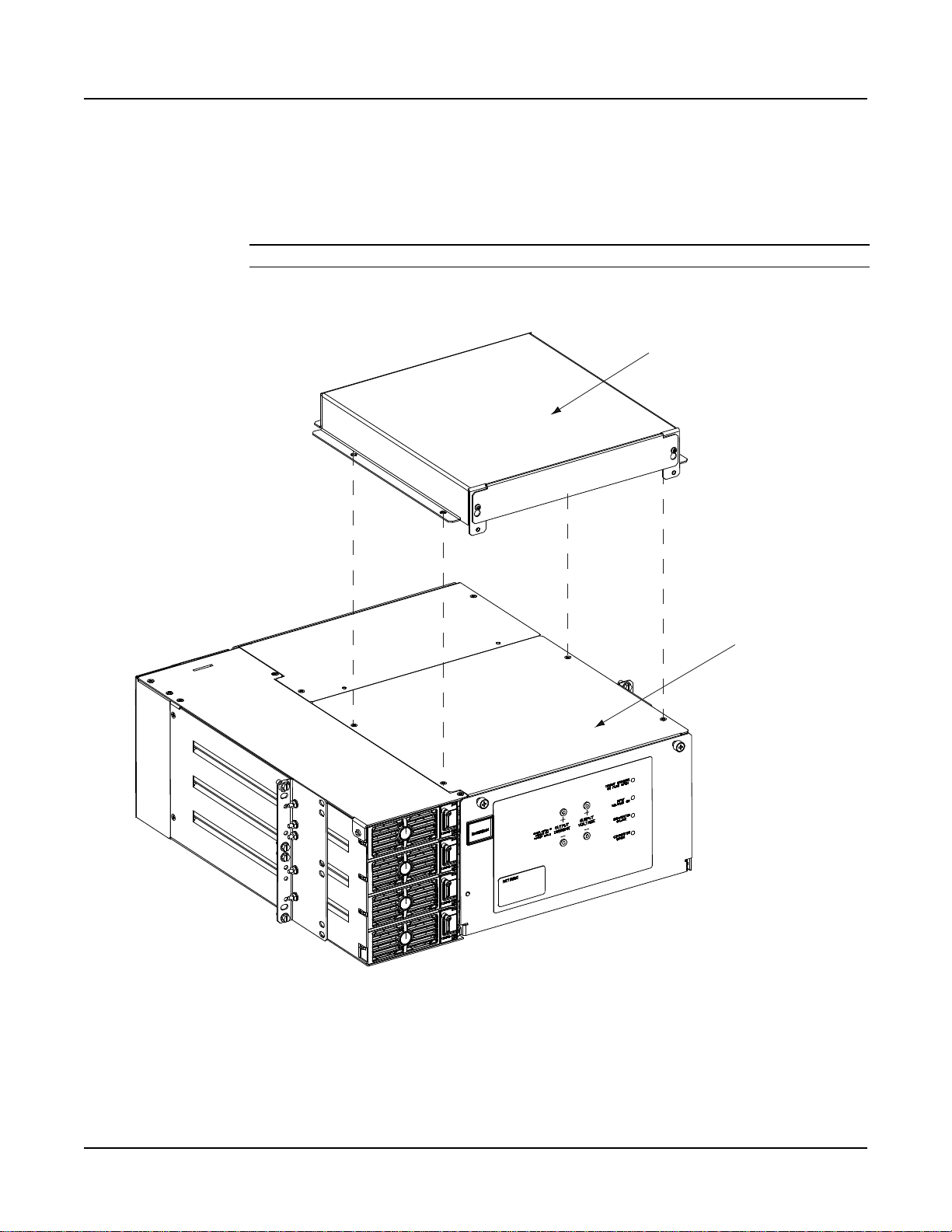

1. Open front door.

2. Remove top panel.

3. Install Wiring Access Cover

(use same hardware removed from top panel).

4. Close front door.

WiringAccess Cover

Top Panel

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

INSTALLING OPTIONAL WIRING ACCESS COVER ON TOP OF SHELF(S), IF DESIRED

The optional wiring access cover is a 1U high panel that is installed on top of the shelf(s)

to allow greater access to load distribution return connection points.

Procedure

1) To install the optional wiring access cover, perform the procedure in Figure 2-1.

Figure 2-1

Installing Optional Wiring Access Cover

Page 4 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 11

Installation and User Instructions UM584622100

584622100 and 584622200

Reversible MountingAngle

Torque mounting angle to

shelf connections to 20 in-lbs.

Torque mounting angle to

relay rack connections to 70 in-lbs.

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

MOUNTING THE SHELF(S)

The 584622100 and 584622200 shelves are equipped with reversible mounting angles

for mounting in a standard 19-inch or 23-inch wide relay rack having 1-3/4 inch multiple

drillings.

The 584622300 and 584622400 shelves mount in a standard 23-inch wide relay rack

having 1-3/4 inch multiple drillings.

Note: Refer to the “General Requirements” section at the beginning of this chapter.

Securing the Main Shelf to a Relay Rack

Procedure

1) 584622100 and 584622200: Reverse the mounting angles if required to fit your

relay rack. Refer to Figure 2-2.

2) Secure the shelf mounting angles to the relay rack at four (4) locations per side.

Use grounding washers at one (1) location per side. Refer to Figure 2-2. Ensure

the grounding washers are oriented properly to enable the teeth to dig into the

mounting angle surface for a secure ground connection.

Figure 2-2

Reversing the Mounting Angles (if required) and Securing the Shelf to a Relay Rack

Chapter 2. Installing the System Page 5

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 12

UM584622100 Installation and User Instructions

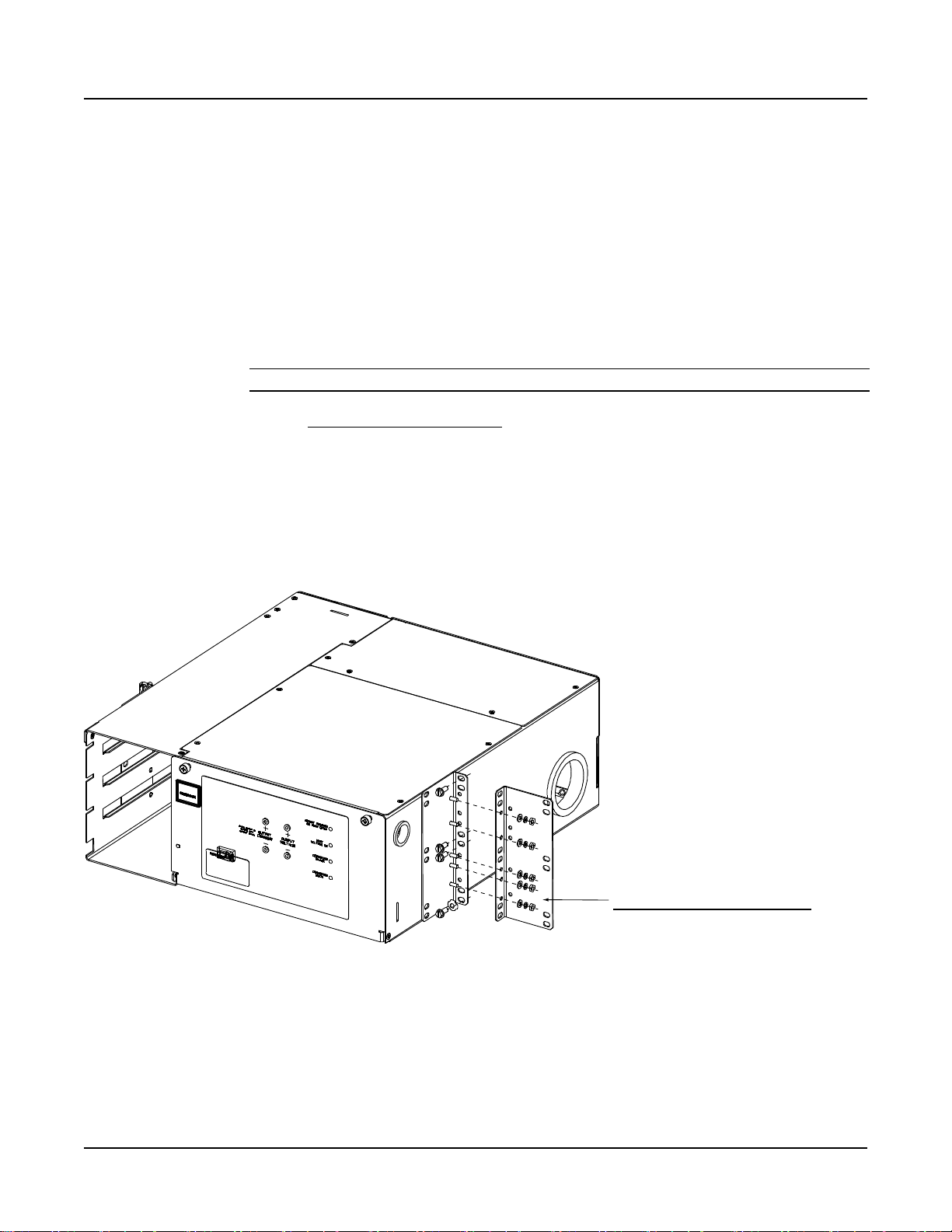

Expansion Wiring Cover

(supplied loose with Expansion

Shelf, attach to Main Shelf)

Replace this cover with the

Expansion Wiring Cover

Remove these tabs at the bottom of the top shelf and

at the top of the bottom shelf to allow wiring between

shelves.

Apply the provided material along the exposed edges

of the cutouts to provide protection to the wires as they

are passed between shelves.

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

Securing the Expansion Shelf(s) to a Relay Rack and Installing the Expansion Wiring Cover on the Main Shelf

SECURING AN EXPANSION SHELF TO A RELAY RACK

Secure an expansion shelf to a relay rack, directly below the shelf above it, per the

previous procedure. The optional 1U wiring access panel is recommended for expansion

shelves to facilitate load cable connections.

INSTALLING THE EXPANSION WIRING COVER ON THE MAIN SHELF

PERFORM THIS PROCEDURE AFTER PARALLELING THE OUTPUTS OF BOTH

SHELVES AS DESCRIBED IN THE “MAKING ELECTRICAL CONNECTIONS”

CHAPTER.

Procedure

1) Remove the cover shown in Figure 2-3 from the main shelf.

2) Remove the expansion wiring cover from the expansion shelf as shown in Figure

2-3.

3) On the expansion wiring cover for both the expansion shelf and the main shelf

(provided loose with the expansion shelf), remove the tabs shown in Figure 2-3

so wiring can pass between the shelves. Apply the provided material along the

exposed edges of the cutouts to provide protection to the wires as they are

passed between shelves.

4) Make the paralleling connections as described in the “Making Electrical

Connections” chapter.

5) Refer to Figure 2-3, and install the expansion wiring covers to both the main shelf

and the expansion shelf.

Installing the Expansion Wiring Cover on the Main Shelf

Page 6 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-3

Page 13

Installation and User Instructions UM584622100

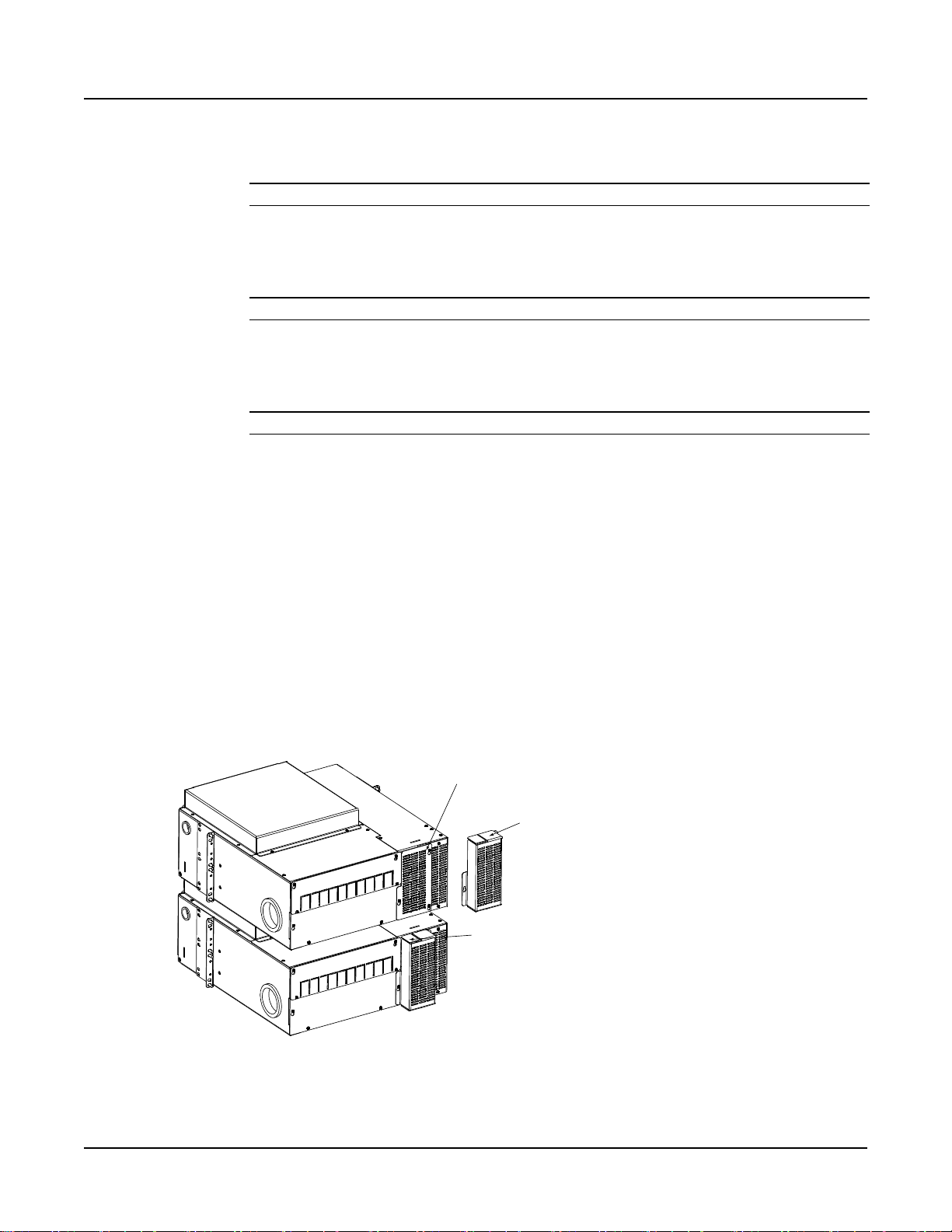

P/N 545405

P/N 545404

P/N 545571

1. Open the shelf’s front door.

2. Install the lug adapter busbar kits as shown.

Apply anti-oxidizing compound to busbar

mating surfaces before installing.

3. Torque connections to 58 in-lbs using the

supplied 1/4” hardware.

4. Close the front door after wiring is complete.

Top Cover Removed in

Illustration for Clarity Only

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

INSTALLING OPTIONAL LUG ADAPTER BUSBAR KITS

Procedure

1) Refer to Figure 2-4 to install the optional lug adapter busbar kits.

Figure 2-4

Installing Optional Lug Adapter Busbar Kits

Chapter 2. Installing the System Page 7

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 14

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

INSTALLING BULLET NOSE CIRCUIT BREAKERS AND/OR FUSEHOLDERS (WITH TPS/TPL FUSES)

Caution: For ambient temperatures at or below +40°C (+104°F), overcurrent

devices rated 100A or greater MUST HAVE an empty mounting position

between it and any other overcurrent protective device. Maximum size

circuit breakers that can be used are 100A single pole, 200A double pole,

and 250A triple pole. Maximum size fuse is 100A. The distribution row is

rated for a maximum of 250A.

For ambient temperatures between +40°C (+104°F) and +65°C (+149°F),

overcurrent devices rated 60A or greater MUST HAVE an empty

mounting position between it and any other overcurrent protective

device. Maximum size circuit breakers that can be used are 70A single

pole. No double pole or triple pole circuit breakers can be used.

Maximum size fuse 70A. The distribution row is rated for a maximum of

250A.

Note: Circuit breakers and/or fuses may have been factory installed for you. If so, verify

their positions and sizes.

Procedure

1) Open the shelf’s front door.

2) Circuit Breakers and Fuses: Ensure that a circuit breaker is in the OFF

position. Orient the distribution device as shown in Figure 2-5. Insert the

terminals on the rear of the distribution device into their corresponding sockets

on the distribution row. Ensure the alarm contact on the back of the distribution

device makes contact with the alarm terminal on the mounting circuit card. Push

distribution device in firmly until fully seated in the distribution row.

3) Fuses: When all fuseholders are installed, install an appropriately sized

TPS/TLS fuse in each. To do this, remove the fuse carrier from the mounted

fuseholder body by pulling it straight out. Slide the fuse in place between the

contacts of the fuse carrier. When done, push the fuse carrier back into the

fuseholder body. Note that a polarizing key on the bottom of the carrier prevents

the carrier from being inserted upside down. Verify that an 18/100 ampere alarm

fuse is present in each fuseholder and that a plastic safety cover is installed on

this fuse.

4) Record all circuit breaker and/or fuse sizes on the label provided.

5) Close the shelf's front door.

Page 8 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 15

Installation and User Instructions UM584622100

Fuseholder AssemblyCircuit Breaker

Insert these terminals

into corresponding sockets

on distribution row.

Insert these terminals

into corresponding sockets

on distribution row.

Longer Side

to the Bottom

Shorter Side

to the Top

Longer Side

to the Bottom

Shorter Side

to the Top

Fuse Carrier

Fuseholder Body

TPS/TLS Fuse

Alarm Fuse

(Replacement

P/N 248610301)

Safety Cover

(Replacement

P/N 248898700)

Polarizing Keyway

Matches Key on

Bottom of Fuse Carrier

Fuseholder Assembly

Exploded View

FuseholderAssembly (P/N 117201) includes

body & carrier,alarm fuse, and alarm fuse safety cover.

Lettering on

handle must be

right side up.

Turn off

before installing.

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

Figure 2-5

Installing Bullet Nose Circuit Breakers and/or Fuseholders (with TPS/TLS Fuse)

Chapter 2. Installing the System Page 9

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 16

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

INSTALLING AN OPTIONAL BULLET NOSE GMT FUSE BLOCK

Caution: At 40°C ambient, GMT fuses greater than 10A MUST HAVE an empty

mounting position between it and any other fuse. Maximum total current

is 35A. Maximum GMT fuse size is 15A.

At 65°C ambient, GMT fuses greater than 5A MUST HAVE an empty

mounting position between it and any other fuse. Maximum total current

is 21A. Maximum GMT fuse size is 10A.

Refer to Figure 2-6 while performing this procedure.

Procedure

1) Open the shelf’s front door.

2) Follow the steps in Figure 2-6.

3) Install an appropriately sized GMT fuse in each fuse mounting position on the

GMT distribution fuse block as required. If dummy fuses are installed, first

remove the dummy fuse.

a) Verify that dummy fuses are installed in all unused fuse positions on the

GMT distribution fuse block.

b) Verify that a plastic safety cover is installed on all GMT fuses on the GMT

distribution fuse block.

4) Record all fuse sizes (installed on the GMT distribution fuse block) on the label

provided.

5) Close the shelf's front door.

Page 10 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 17

Installation and User Instructions UM584622100

Remove two lug terminal busbars

for positions to be occupied

by GMT Fuse Block.

2.

Press in tabs to release

lug terminal busbars for

positions to be occupied

by GMT Fuse Block.

1.

Plug in GMT Fuse Block and secure

at one location on the RTN bar with

hardware provided. Torque to 58 in-lbs.

RTN Bar

3.

Top Cover Removed in

Illustration for Clarity Only

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

Installing an Optional Bullet Nose GMT Fuse Block

Figure 2-6

Chapter 2. Installing the System Page 11

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 18

UM584622100 Installation and User Instructions

S1

48V

50V

52V

54V

Switch 1

OFF

OFF

ON

ON

Switch 2

OFF

ON

OFF

ON

S1

1A / 1mV

400A / 50mV

Switch 3

OFF

ON

S1

Stand Alone Mode

ACU+ Controller Mode

Switch 4

OFF

ON

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

CHAPTER 3. SETTING JUMPER AND SWITCH OPTIONS

JUMPER AND SWITCH SETTINGS ON THE SYSTEM INTERFACE CIRCUIT CARD

Perform the following procedures to verify the factory settings and/or make the required

settings per your site requirements. These procedures can also be used to make

adjustments on a replacement circuit card.

Refer to Figure 3-1 for switch and jumper locations.

Switch S1

Switch Positions 1 and 2 of S1

Selects the converter system’s output voltage as shown in Table 3-1.

Table 3-1

Converter System Output Voltage Selection

Switch Position 3 of S1

Selects the current scale for the output current test points as shown in Table 3-2.

Table 3-2

Output Current Test Points “Current Scale” Selection

Switch Position 4 of S1

Selects whether converter system output voltage is controlled by the system interface

circuit card (stand alone mode) or by an ACU+ as shown in Table 3-3.

Table 3-3

Output Voltage Control Selection

Page 12 Chapter 3. Setting Jumper and Switch Options

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 19

Installation and User Instructions UM584622100

Inside View of Main Shelf’s Front Door

TB1

1 9 1 12

TB2P2

Jumper

P2

Switch

S1

S1

OFF

ON

4 3 2 1

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

Jumper P2

Jumper P2 is the CAN termination jumper.

a) When in stand alone mode, the jumper P2 must be in place to ensure reliable

communications.

b) When an ACU+ is on the CAN bus, jumper P2 should be removed.

Figure 3-1

System Interface Circuit Card Jumper and Switch Locations

Chapter 3. Setting Jumper and Switch Options Page 13

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 20

UM584622100 Installation and User Instructions

Crimp Lug Part No.

Crimp Tool Required1, T&B Model

TBM12 or TBM15 Hydraulic Heads

Color Key

Die Index/

Code No.

Die Cat.

Number

245393500

Burndy: YA25L-4TCG1

PINK

42H

15508

245393600

Burndy: YA26L-4TCG1

BLACK

45

15526

245393700

Burndy: YA27L-4TCG1

ORANGE

50

15530

245393800

Burndy: YA28L-4TCG1

PURPLE

54H

15511

514872

T & B: 256-30695-1879

YELLOW

62

15510

Burndy: YA29L-4TCG1

514873

T & B: 256-30695-1880

RED

71

15514

Burndy: YA31L-4TCG1

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

CHAPTER 4. MAKING ELECTRICAL CONNECTIONS

ADMONISHMENTS

Observe the admonishments located at the beginning of this document.

WIRING CONSIDERATIONS

All wiring should follow the current edition of the American National Standards Institute

(ANSI) approved National Fire Protection Association's (NFPA) National Electrical Code

(NEC), and applicable local codes. For operation in countries where the NEC is not

recognized, follow applicable codes.

For recommended wire sizes, crimp lugs, alarm relay contact ratings, and general wiring

information and restrictions; refer to System Application Guide SAG584622100.

Refer to drawing 031110100 for lug crimping information. Refer to drawings 031110200

and 031110300 for additional lug information.

Refer to Table 4-1 for supplemental lug crimping information when using the special

application crimp lug / strap combination.

1

The lugs should be crimped to the specifications given in the

manufacturer’s instructions furnished with the crimp tool or lug.

Table 4-1

Supplemental Lug Crimping Information when using the

Special Application Crimp Lug / Strap Combination

Page 14 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 21

Installation and User Instructions UM584622100

Frame Ground

Lead Enters Here

Frame Ground

* 1/4-20 x 0.5” studs on 5/8” center

for installation of lead with 2-hole lug.

* Torque to 84 in-lbs.

Rear panels removed in illustration.

Rear

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

SHELF(S) GROUNDING (FRAME GROUND) CONNECTION

For shelf grounding requirements, refer to the current edition of the American National

Standards Institute (ANSI) approved National Fire Protection Association's (NFPA)

National Electrical Code (NEC), applicable local codes, and your specific site

requirements.

Note: The DC return connection to this system can remain isolated from system frame

and chassis (DC-I).

Note: This system is suitable for installation as part of the Common Bonding Network

(CBN).

1/4-20 x 0.5” studs on 5/8” center are provided for installation of a customer provided

frame ground lead terminated in a 2-hole lug.

Procedure

1) For shelf(s) grounding (frame ground) connection, refer to Figure 4-1.

Chapter 4. Making Electrical Connections Page 15

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 4-1

Shelf(s) Grounding (Frame Ground) Connection

Page 22

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

EXTERNAL ALARM, REFERENCE, MONITORING, AND CONTROL CONNECTIONS

External alarm, reference, monitoring, and control connections are made to terminals of

TB1 and TB2 located on the system interface circuit card mounted on the inside of the

main shelf’s front door. Refer to Figure 4-2 for location.

External FA/CBA Alarm Input: An external FA/CBA alarm signal can be connected to the

system as described in the Expansion Shelf(s) Interconnections section.

External Alarm Relays

External alarm relays are extended to terminal block TB1 located on the system interface

circuit card. Relays are energized for normal operating conditions and de-energized for

an alarm condition.

Low Input Voltage Alarm: Alarms if a converter module reports a low input voltage

condition. A close loop circuit is provided between terminals 1 and 2 of TB1 and an

open loop circuit is provided between terminals 2 and 3 of TB1 during an alarm

condition.

Fuse / Circuit Breaker Alarm: Alarms if any distribution fuse or circuit breaker

opens. A close loop circuit is provided between terminals 4 and 5 of TB1 and an

open loop circuit is provided between terminals 5 and 6 of TB1 during an alarm

condition.

Converter Fail Major Alarm: Alarms if more than one converter module fails (or if

only one converter module is installed in the system and it fails). A close loop circuit

is provided between terminals 7 and 8 of TB1 and an open loop circuit is provided

between terminals 8 and 9 of TB1 during an alarm condition. Refer to the Operating

Procedures chapter for alarm conditions.

Converter Fail Minor Alarm: Alarms if one converter module fails. A close loop

circuit is provided between terminals 10 and 11 of TB1 and an open loop circuit is

provided between terminals 11 and 12 of TB1 during an alarm condition. Refer to the

Operating Procedures chapter for alarm conditions.

CAN Bus

An ACU+ can be connected to terminals 1 (CANL) and 2 (CANH) of TB2.

Output Current Signal Reference

The output current signal (also provided at the output current test points on the front door

of the main shelf) can be selected to be referenced to plus battery (input), referenced to

minus battery (input), or not referenced as detailed below. The output current signal can

be set at 1A/mV or 400A/50mV per CHAPTER 3. SETTING JUMPER AND SWITCH

OPTIONS.

Referenced to Plus Battery (input): Provide a jumper between terminals 4 (+BT)

and 5 (-IO) of TB2.

Page 16 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 23

Installation and User Instructions UM584622100

Inside View of Main Shelf’s Front Door

TB1

1 9 1 12

TB2P2

TB1

1 9

1 12

TB2

Conv

Minor

Conv

MajorFuse / CB

Low Input

Voltage

NC C NONC C NONC C NONC C NO

E

S

T

O

P+VO-VO+IO-IO+BT-BT

CANH

CANL

CAN

TERM

P2

Recommended Torqueis 5.0 in-lbs. Recommended Torque is 5.0 in-lbs.

Relays are energized for normal operating conditions

and de-energized for an alarm condition.

Relays are shown in the de-energized state.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

Referenced to Minus Battery (input): Provide a jumper between terminals 3 (-BT)

and 6 (+IO) of TB2.

Not Referenced: Do not provide a jumper.

Output Voltage Monitoring

An output voltage monitoring device can be connected to terminals 7 (-VO) and 8

(+VO) of TB2. These terminals are internally paralleled with the test points provided

on the front door of the main shelf.

Emergency Shutdown (Estop)

The converter modules can be inhibited by applying an external ground signal (24V

Return) to terminal 9 of TB2. Converter modules automatically restart upon removal

of the ground signal.

Chapter 4. Making Electrical Connections Page 17

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 4-2

External Alarm, Reference, Monitoring, and Control Connections

Page 24

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

LOAD CONNECTIONS

To Distribution Bus Row

1/4-20 x 0.625” studs on 5/8” centers are provided for installation of customer provided

load distribution leads terminated in 2-hole lugs. Refer to Figure 4-3.

Warning: Observe correct polarity when making connections. Otherwise

equipment damage may occur.

Procedure

1) For load connections to the distribution bus row, refer to Figure 4-3.

Page 18 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 25

Installation and User Instructions UM584622100

Load Distribution Connections

* 1/4-20 x 0.625” studs on 5/8” centers

for installation of leads with 2-hole lugs.

* Maximum lug width 0.625”.

* Torque to 58 in-lbs.

-48VDC

Return

Front

Front

Components removed in

illustration for clarity only.

Load

Distribution

Leads Enter

Here (break

tabs off shield

as required)

P/N 545405

P/N 545404

P/N 545571

Top Cover Removed in

Illustration for Clarity Only

Optional Busbar Adapters

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

Figure 4-3

Load Connections to Distribution Bus Row

Chapter 4. Making Electrical Connections Page 19

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 26

UM584622100 Installation and User Instructions

Load Leads

Load Return Leads

Wire Size Capacity: 26-14 AWG.

Recommended Torque: 4.5 in-lbs.

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

To Optional Bullet Nose 6-Position GMT Fuse Block

Warning: Observe correct polarity when making connections. Otherwise

equipment damage may occur.

Procedure

1) For load connections to an optional GMT fuse block, refer to Figure 4-4.

Figure 4-4

Load Connections to GMT Fuse Block

Page 20 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 27

Installation and User Instructions UM584622100

Cable, lugs (P/N 144511), and labels are

provided loose with the Expansion Shelf

to assemble a Return and a -48V

paralleling cable.

1. Cut the cables to the proper length.

2. Lug the cables

(use standard brown die for 2 ga. cable).

3. Connect cables between terminals

as indicated below. Torque to 58 in-lbs.

4. Re-Install Expansion Wiring Covers.

(refer to procedure in the

“Installing the System” chapter.)

Expansion

Wiring Covers

Hardware provided

on terminals.

RETURN

PARALLELING

CABLE

-48V

PARALLELING

CABLE

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

EXPANSION SHELF(S) INTERCONNECTIONS

Installing Output Paralleling Leads

Procedure

1) Perform the procedure in Figure 4-5 for each expansion shelf.

Figure 4-5

DC Output Paralleling Interconnections

Chapter 4. Making Electrical Connections Page 21

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 28

UM584622100 Installation and User Instructions

Connect these connectors

to mating connectors in

shelf above.

Connect these connectors

to mating connectors in

shelf above.

If there are expansion shelves,

move the termination plug

from connector in main shelf

to same connector in bottom

most expansion shelf.

If there are expansion shelves,

unplug the external FA/CBA

lead from this connector.

Move the termination plug

from connector in main shelf

to same connector in bottom

most expansion shelf.

Plug the external FA/CBA

lead from main shelf into

same connector in bottom

most expansion shelf.

Connect an external FA/CBA lead to

the butt splice located at the end of the

external FA/CBAplug assembly.

Supply a voltage signal within 1V of the

converter system output voltage to this

lead to activate the system’s fuse alarm

circuit.

Rear

External FA/CBA

connector in

bottom most

shelf.

External FA/CBA

plug terminated in

butt splice connector.

(12” long, 22 AWG,

yellow wire)

(Factory Supplied)

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

FA/CBA and CAN Bus Interconnections

Procedure

1) Perform the procedure in Figure 4-6 for each expansion shelf and to connect an

external FA/CBA alarm lead to this system.

Figure 4-6

FA/CBA and CAN Bus Interconnections

Page 22 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 29

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

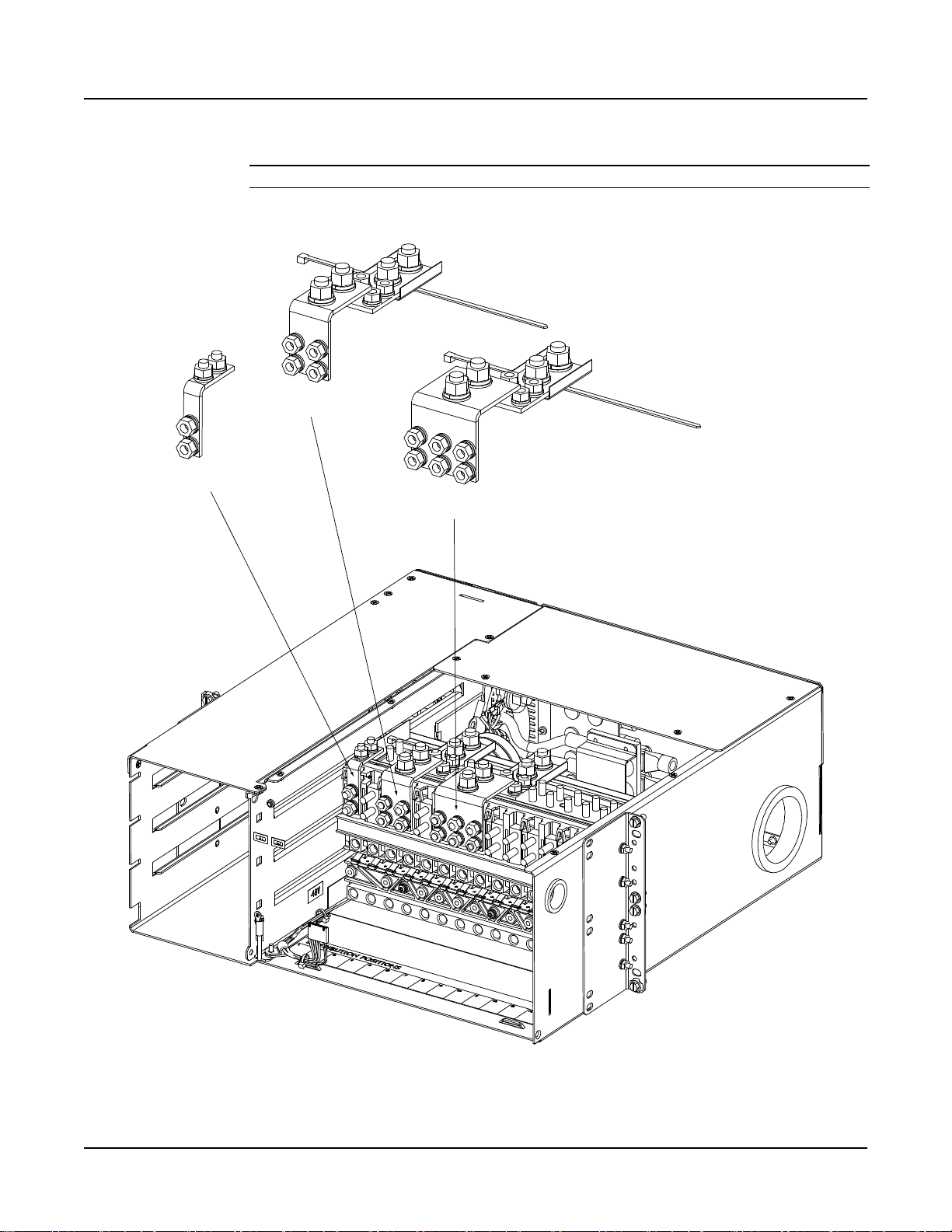

DC INPUT CONNECTIONS

3/8-16 x 0.875” studs on 1” centers are provided for installation of customer provided DC

input leads terminated in 2-hole lugs. Terminations are provided for each converter

module (individual feed). Adapter busbars are provided loose with each shelf which

allows two (2) converter modules to be fed by a single input. Refer to Figure 4-7.

Warning: Observe correct polarity when making connections. Otherwise

equipment damage will occur.

Note: The DC return connection to this system can remain isolated from system frame

and chassis (DC-I).

Note: This system is suitable for installation as part of the Common Bonding Network

(CBN).

Note: Recommended DC input protective device rating is 100A for individual converter

module feeds and 200A for dual converter module feeds. See SAG584622100 for

additional restrictions.

Procedure

1) For DC input connections, refer to Figure 4-7.

2) If using the dual converter module feed adapter busbars, install the busbars as

shown in Figure 4-7.

Chapter 4. Making Electrical Connections Page 23

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 30

UM584622100 Installation and User Instructions

DC Input Connections

* 3/8-16 x 0.875” studs on 1” centers

for installation of leads with 2-hole lugs.

* Provide separate inputs for each converter.

* Maximum lug width 0.812”.

* Torque to 240 in-lbs.

+24VDC

Converter #1 (top)

Converter #2

Converter #3

Converter #4 (bottom)

DC Input Leads

Enter Here

Return

Converter #1 (top)

Converter #2

Converter #3

Converter #4 (bottom)

Rear panels removed in illustration.

Rear

Dual Converter Module Feed

with Adapter Busbars

P/Ns 552506

Feed Two

Feed One

+24VDC

Converter #3

Converter #4

Return

Converter #3

Converter #4

+24VDC

Converter #1

Converter #2

Return

Converter #1

Converter #2

Rear

DC Input Connections

* 3/8-16 x 0.875” studs on 1” centers

for installation of leads with 2-hole lugs.

* Provide one input for two converters.

* Maximum lug width 1.156”.

* Torque to 240 in-lbs.

Discard Extra Hardware

Busbars

P/Ns 552506

584622100 / 584622200 shown.

584622300 / 584622400 similar.

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

Figure 4-7

DC Input Connections

Page 24 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 31

Installation and User Instructions UM584622100

Screw

Note: Handle must be

open when installing

or removing module.

Handle in

Closed Position

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

CHAPTER 5. INSTALLING THE CONVERTER MODULES AND INITIALLY STARTING THE SYSTEM

INSTALLING CONVERTER MODULES

The converter module is hot swappable. It can be installed with the system operating.

Warning: To prevent damage to the latching mechanism, ensure the handle is in

the open position when installing or removing a converter module.

NEVER hold the handle in the closed position when installing a

converter module into a shelf.

Procedure

1) Place the module into an unoccupied mounting slot without sliding it in

completely.

2) Loosen the captive screw on the module handle. Pull the handle to pivot it out of

the module front panel (this will also retract the latch mechanism located at the

right side of the module). Refer to Figure 5-1 for latch mechanism illustration.

3) Push the converter module completely into the shelf.

4) Push the handle into the front panel of the module. This will lock the module

securely to the shelf. Tighten the captive screw on the handle.

5) Repeat the above steps for each converter module being installed in the system.

6) After the converter modules are physically installed in the mounting shelf(s), they

are ready for operation immediately after power is supplied to them.

Figure 5-1

Converter Module Handle/Latch Mechanism

Chapter 5. Installing the Converter Modules and Initially Starting the System Page 25

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 32

UM584622100 Installation and User Instructions

Component

Indicator

Normal State

Main Shelf

Front Door

Circuit Breaker or

Fuse Open

(Red LED)

Off

Input Voltage OK

(Green LED)

On

Converter Major

(Red LED)

Off

Converter Minor

(Yellow LED)

Off

Converter

Modules

Power

(Green)

On

Protection

(Yellow)

Off

Fault

(Red)

Off

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

INITIALLY STARTING AND CHECKING SYSTEM OPERATION

Initial Startup Preparation

Ensure that all blocks for Chapters 2 through 4 in the Installation Acceptance

Checklist, located in Chapter 1, have been checked.

Ensure no objects block the ventilation openings on the system shelf(s).

Initially Starting the System

Procedure

1) Close the external disconnects or protective devices that supply input power to

the system. Converter modules automatically start.

2) Open each shelf’s front door.

3) Place each distribution circuit breaker (if furnished) to the ON position.

4) Close each shelf’s front door.

Checking System Status

Procedure

1) Observe the status of the indicators located on the main shelf’s front door and

the converter modules. If the system is operating normally, the status of these is

as shown in Table 5-1. Verify there are no external alarms.

Page 26 Chapter 5. Installing the Converter Modules and Initially Starting the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Table 5-1

Status and Alarm Indicators

Page 33

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

CHAPTER 6. OPERATING PROCEDURES

CONVERTER MODULES

Refer to UM1C24481500 (Converter Module User Instructions) for converter module

operation instructions.

USING THE CONVERTER SYSTEM WITH AN ACU+ CONTROLLER

The following outlines the steps to set-up the converter system to be used with an ACU+

controller. Refer to the ACU+ Controller User Instructions (UM1M820BNA) for ACU+

operation.

Set switch position 4 of S1 to the “ON” position. See Figure 3-1.

Remove (and store) Jumper P2. See Figure 3-1.

Connect terminal 1 (CANL) and 2 (CANH) of TB2 to the CAN bus the ACU+ resides

on. See Figure 4-2.

Note: The converter system must be the last device on the CAN bus to function

properly.

Note: If the converter system is used with control/monitoring via an ACU+ controller and

the converter input is powered through a distribution device in the host system,

the ACU+ controller should not be set up to calculate battery current. If battery

current measurement via the ACU+ is desired, the host system must measure

battery current with a battery shunt.

LOCAL INDICATORS AND TEST POINTS

Refer to the Converter Module User Instructions (UM1C24481500) for descriptions of the

local indicators located on the converter modules.

Refer to this section for descriptions of the local indicators and test points located on the

main shelf’s front door.

Local Indicators

The following local indicators are provided on the front door of the main shelf. Refer to

Figure 6-1.

a) Circuit Breaker or Fuse Open (Red LED): Illuminates red if any distribution

fuse or circuit breaker in the system opens.

b) Input Voltage OK (Green LED): Illuminates green when all converter modules

report input voltage is OK. This indicator is off if any converter module reports a

low input voltage condition.

Chapter 6. Operating Procedures Page 27

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 34

UM584622100 Installation and User Instructions

CHECKSWI TCH S1

SETTINGF OR

CURRENTSCALE

CIRCUIT BREAKER

OR FUSE OPEN

INPUT

VOLTAGEOK

CONVERTER

MAJOR

CONVERTER

MINOR

OUTPUT

CURRENT

OUTPUT

VOLTAGE

Front of Main Shelf

584622100 shown.

584622300 similar.

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

c) Converter Major (Red LED): Illuminates red if more than one converter module

fails (or if only one converter module is installed in the system and it fails).

Failure conditions are as stated in d) below.

d) Converter Minor (Yellow LED): Illuminates yellow if one converter module fails.

Failure conditions are as follows.

A converter module reports a high voltage shutdown condition (HVSD).

A converter module reports a fan failure.

A converter module reports an EEPROM failure.

A converter module reports a converter failure.

A converter module reports a low input voltage condition.

A converter module reports a high temperature condition.

A converter module reports a thermal derating condition.

Test Points

The following test points are provided on the front door of the main shelf. Refer to Figure

6-1.

a) Output Voltage (+, -): Provided for measuring system output voltage.

b) Output Current (+, -): Provided for measuring system output current. Scale is

User selectable for 400A/50mV or 1A/1mV. Current measurement is User

selectable to be referenced to plus battery, minus battery, or no reference. See

CHAPTER 3. SETTING JUMPER AND SWITCH OPTIONS.

Figure 6-1

Local Indicators and Test Points

Page 28 Chapter 6. Operating Procedures

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 35

Installation and User Instructions UM584622100

PROCEDURE

REFERENCED IN

COMPLETED (√)

Check ventilation openings for

obstructions such as dust,

papers, manuals, etc.

--

Inspect and tighten all

installer's connections.

Chapter 4.

Making Electrical

Connections.

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

CHAPTER 7. MAINTENANCE

ADMONISHMENTS

Observe the admonishments located at the beginning of this document.

SYSTEM MAINTENANCE PROCEDURES

It is recommended to perform and record the maintenance procedures listed in Table 7-1

every 6-months to ensure continual system operation.

The table references specific chapters in this document that help in performing these

procedures.

Note: This table may be reproduced as necessary to record and document

system performance.

Table 7-1

Maintenance Procedures to be Performed at 6-Month Intervals

Chapter 7. Maintenance Page 29

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 36

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

CHAPTER 8. TROUBLESHOOTING AND REPAIR

CONTACT INFORMATION

Support contact information is provided on the inside of the back cover of this document.

ADMONISHMENTS

Observe the admonishments located at the beginning of this document.

CONVERTER MODULES

Refer to UM1C24481500 (Converter Module User Instructions) for converter module

troubleshooting and repair instructions.

SYSTEM TROUBLESHOOTING INFORMATION

This system is designed for ease in troubleshooting and repair. The various indicators as

described in CHAPTER 6. OPERATING PROCEDURES and in the Converter Module

User Instructions (UM1C24481500) are designed to isolate failure to a specific element.

Once the faulty element has been identified, refer to “Replacement Information” and

"Replacement Procedures" in this chapter.

Clearing a Converter Fail Alarm after Removing a Converter Module

If a converter module is removed from the system, a converter fail alarm is generated. If

the converter module will not be replaced, the alarm should be cleared as described in

the following procedure.

Procedure

1) Momentarily push the “Update Converter Inventory” button located on the inside

of the main shelf’s front door. Refer to Figure 3-1 for location.

REPLACEMENT INFORMATION

When a trouble symptom is localized to a faulty converter module, the converter module

should be replaced in its entirety. Other than a converter module fan replacement, no

attempt should be made to troubleshoot or repair individual components on any converter

module.

Refer to SAG584622100 (System Application Guide) for replacement part numbers.

Page 30 Chapter 8. Troubleshooting and Repair

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 37

Installation and User Instructions UM584622100

Safety Cover

P/N 248898700

(GMT-X)

Safety Cover

P/N 102774

(GMT-Y)

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

REPLACEMENT PROCEDURES

Replacing a Converter Module

Refer to the Converter Module User Instructions (UM1C24481500) for a converter

module replacement procedure. Refer also to System Troubleshooting Information in this

chapter to clear a converter fail alarm after removing a converter module.

Replacing a Distribution Device

General

Replace distribution devices with the same type and rating, or equivalent. Refer to

SAG584622100 (System Application Guide) for part numbers.

Distribution Fuse “Alarm Fuse” Replacement

If a distribution fuse opens, the associated alarm fuse opens. Replace the distribution

fuse before replacing the alarm fuse.

Procedure

1) An alarm fuse is removed by pulling it straight out of the fuseholder. If the alarm

fuse is located in a modular fuse carrier, hold the fuse carrier in place with your

thumb while pulling on the alarm fuse to prevent the entire carrier from

inadvertently being pulled out.

2) Safety fuse covers are provided for all Bussmann GMT type fuses installed in the

system. These covers snap onto the fuses and provide protection from exposed

electrical terminations when a fuse opens. Insure that the safety fuse cover is

installed after replacing a fuse. Refer to Figure 8-1 for installation details.

Figure 8-1

Installation of Safety Fuse Covers

Chapter 8. Troubleshooting and Repair Page 31

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 38

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

Replacing a TPS/TLS Fuse

Note: Refer to Figure 2-5 as this procedure is performed.

Procedure

1) Open the shelf’s front door.

2) Remove the fuse carrier from the mounted fuseholder body by pulling it straight

out.

3) Remove the open fuse from the fuse carrier and replace it with the same type

and rating, or equivalent.

4) Replace the alarm fuse located in the front of the fuse carrier with the same type

and rating, or equivalent. Ensure that a plastic safety cover is installed on the

alarm fuse.

5) Push the fuse carrier securely back into the mounted fuseholder body. Note that

a polarizing key on the bottom of the carrier prevents the carrier from being

inserted upside down.

6) Verify there are no alarms active.

7) Close the shelf’s front door.

Page 32 Chapter 8. Troubleshooting and Repair

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 39

Installation and User Instructions UM584622100

Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375) Issue AC, July 3, 2012

Replacing a Bullet Nose Circuit Breaker or Fuseholder

Note: Refer to Figure 2-5 as this procedure is performed.

Procedure

1) Open the shelf’s front door.

2) Circuit Breaker: Operate a defective circuit breaker to the OFF position.

Fuseholder: Remove the fuse carrier from the mounted fuseholder body by

pulling it straight out.

3) Gently rock the defective circuit breaker or fuseholder up and down while pulling

firmly outward until the circuit breaker or fuseholder is free from the distribution

row.

4) Circuit Breaker: Ensure that the circuit breaker is in the OFF position, and is of

the correct rating.

5) Orient the distribution device as shown in Figure 2-5. Insert the terminals on the

rear of the distribution device into their corresponding sockets on the distribution

row. Ensure the alarm contact on the back of the distribution device makes

contact with the alarm terminal on the mounting circuit card. Push distribution

device in firmly until fully seated in the distribution row.

6) Circuit Breaker: Operate the replacement circuit breaker to the ON position.

Fuseholder: Push the fuse carrier securely back into the mounted fuseholder

body. Note that a polarizing key on the bottom of the carrier prevents the carrier

from being inserted upside down.

7) Verify there are no alarms active.

8) Close the shelf’s front door.

Chapter 8. Troubleshooting and Repair Page 33

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 40

UM584622100 Installation and User Instructions

Issue AC, July 3, 2012 Spec. Nos. 584622100, 584622200, 584622300, 584622400 (Model DCS48375)

Replacing the System Interface Circuit Card

Warning: The system interface circuit card contains static-sensitive devices.

Read the Static Warning at the front of this document before performing

the following procedure.

Caution: When performing any step in this procedure that requires removal or

installation of hardware, use caution to ensure no hardware is dropped

and left inside the cabinet; otherwise service interruption or equipment

damage may occur.

Note: When performing any step in this procedure that requires removal of existing

hardware, retain all hardware for use in subsequent steps.

Note: Refer to Figure 8-2 as this procedure is performed.

Procedure

1) Refer to the Static Warning and Admonishments at the beginning of this

document before performing this procedure.

2) Performing this procedure may activate external alarms. Do one of the following.