Page 1

Software for Gas Chromatographs

MON2020

Applies to all Emerson XA Series Gas Chromatographs

3-9000-745, Rev F

April 2014

Page 2

NOTICE

ROSEMOUNT ANALYTICAL, INC. (“SELLER”) SHALL NOT BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS IN THIS MANUAL OR

OMISSIONS FROM THIS MANUAL. SELLER MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT, SHALL

SELLER BE LIABLE FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION,

LOSS OF PROFITS, ETC.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY AND MAY BE TRADEMARKS/

REGISTERED TRADEMARKS OF THESE COMPANIES.

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE EVERY EFFORT HAS

BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR

IMPLIED, REGARDING THE PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. WE RESERVE THE RIGHT

TO MODIFY OR IMPROVE THE DESIGNS OR SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

SELLER DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF ANY PRODUCT. RESPONSIBILITY FOR

PROPER SELECTION, USE AND MAINTENANCE OF ANY SELLER PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

ROSEMOUNT AND THE ROSEMOUNT ANALYTICAL LOGO ARE REGISTERED TRADEMARKS OF ROSEMOUNT ANALYTICAL. THE

EMERSON LOGO IS A TRADEMARK AND SERVICE MARK OF EMERSON ELECTRIC CO.

©

2014

ROSEMOUNT ANALYTICAL INC.

HOUSTON, TX

USA

All rights reserved. No part of this work may be reproduced or copied in any form or by any means—graphic, electronic, or

mechanical—without first receiving the written permission of Rosemount Analytical Inc., Houston, Texas, U.S.A.

Page 3

Warranty

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein and except as otherwise expressly provided

herein, Rosemount Analytical, Inc. (“Seller”) warrants that the firmware will execute the programming instructions provided

by Seller, and that the Goods manufactured or Services provided by Seller will be free from defects in materials or

workmanship under normal use and care until the expiration of the applicable warranty period. Goods are warranted for

twelve (12) months from the date of initial installation or eighteen (18) months from the date of shipment by Seller,

whichever period expires first. Consumables and Services are warranted for a period of 90 days from the date of shipment or

completion of the Services. Products purchased by Seller from a third party for resale to Buyer (“Resale Products”) shall carry

only the warranty extended by the original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond

making a reasonable commercial effort to arrange for procurement and shipping of the Resale Products. If Buyer discovers

any warranty defects and notifies Seller thereof in writing during the applicable warranty period, Seller shall, at its option,

promptly correct any errors that are found by Seller in the firmware or Services, or repair or replace F.O.B. point of

manufacture that portion of the Goods or firmware found by Seller to be defective, or refund the purchase price of the

defective portion of the Goods/Services. All replacements or repairs necessitated by inadequate maintenance, normal wear

and usage, unsuitable power sources, unsuitable environmental conditions, accident, misuse, improper installation,

modification, repair, storage or handling, or any other cause not the fault of Seller are not covered by this limited warranty,

and shall be at Buyer's expense. Seller shall not be obligated to pay any costs or charges incurred by Buyer or any other party

except as may be agreed upon in writing in advance by an authorized Seller representative. All costs of dismantling,

reinstallation and freight and the time and expenses of Seller's personnel for site travel and diagnosis under this warranty

clause shall be borne by Buyer unless accepted in writing by Seller. Goods repaired and parts replaced during the warranty

period shall be in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This

limited warranty is the only warranty made by Seller and can be amended only in a writing signed by an authorized

representative of Seller. Except as otherwise expressly provided in the Agreement, THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESSED OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR

ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. It is understood that corrosion or erosion of

materials is not covered by our guarantee.

2. LIMITATION OF REMEDY AND LIABILITY: SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE.

THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF WARRANTY HEREUNDER SHALL BE LIMITED TO REPAIR, CORRECTION,

REPLACEMENT OR REFUND OF PURCHASE PRICE UNDER THE LIMITED WARRANTY CLAUSE IN SECTION 1 HEREIN. IN NO

EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT,

NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL SELLER'S LIABILITY TO BUYER AND/OR ITS

CUSTOMERS EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR SERVICES PROVIDED BY SELLER

GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO EVENT SHALL SELLER'S LIABILITY TO BUYER

AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM

“CONSEQUENTIAL DAMAGES” SHALL INCLUDE, BUT NOT BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, LOSS OF USE,

LOSS OF REVENUE AND COST OF CAPITAL.

Page 4

Page 5

Contents

Contents

Chapter 1 Getting started .................................................................................................................1

1.1 MON2000 and MON2020 ...............................................................................................................2

1.2 Getting started with MON2020 ...................................................................................................... 3

1.2.1 System requirements ...................................................................................................... 4

1.2.2 Install MON2020 ..............................................................................................................4

1.2.3 Start MON2020 ............................................................................................................... 4

1.2.4 Register MON2020 ..........................................................................................................4

1.2.5 Set up the data folder ...................................................................................................... 5

1.2.6 Set up MON2020 to connect to a gas chromatograph ..................................................... 5

1.2.7 Export a GC directory .......................................................................................................7

1.2.8 Import a GC Directory file ................................................................................................ 7

1.2.9 Launch MON2020 from the SNAP-ON for DeltaV ............................................................. 8

1.2.10 Launch MON2020 from the AMS Device Manager ........................................................... 8

1.2.11 The MON2020 user interface ...........................................................................................9

1.2.12 Connect to a gas chromatograph .................................................................................. 12

1.2.13 Disconnect from a gas chromatograph ..........................................................................13

1.3 Keyboard commands ................................................................................................................... 13

1.4 Procedures guide ......................................................................................................................... 14

1.5 Configuration files ........................................................................................................................17

1.5.1 Edit a configuration file ..................................................................................................17

1.5.2 Save the current configuration ...................................................................................... 17

1.5.3 Import a configuration file ............................................................................................. 18

1.5.4 Restore the GC's factory settings ................................................................................... 18

1.6 Configure your printer ..................................................................................................................19

1.7 Online help ...................................................................................................................................19

1.8 Operating modes for MON2020 ...................................................................................................19

1.9 The Physical Name column ...........................................................................................................20

1.10 Select the GC’s networking protocol ............................................................................................ 20

1.11 The context-sensitive variable selector .........................................................................................20

Chapter 2 Chromatograph ............................................................................................................. 23

2.1 The Chromatogram Viewer .......................................................................................................... 24

2.1.1 Data displayed in the chromatogram window ................................................................25

2.1.2 Display a live chromatogram ......................................................................................... 26

2.1.3 Display an archived chromatogram ............................................................................... 26

2.1.4 Protected chromatograms ............................................................................................ 28

2.1.5 Display a saved chromatogram ......................................................................................29

2.2 Options for displaying chromatograms ........................................................................................ 29

2.3 Configure the appearance of the chromatograph .........................................................................30

2.3.1 The Graph bar ................................................................................................................30

2.3.2 Additional plot commands ............................................................................................ 32

2.4 Change how a chromatogram displays .........................................................................................33

2.4.1 Edit a chromatogram .....................................................................................................33

2.4.2 Display chromatogram results .......................................................................................34

2.4.3 Save a chromatogram ....................................................................................................34

2.4.4 Remove a chromatogram from the Chromatogram Viewer ...........................................34

2.4.5 Initiate a forced calibration ............................................................................................ 35

i

Page 6

Contents

2.4.6 Chromatogram Viewer tables ........................................................................................35

2.4.7 Open a comparison file ..................................................................................................37

2.4.8 Save a comparison file ................................................................................................... 37

2.5 Miscellaneous commands ............................................................................................................ 37

2.5.1 The Chromatogram Viewer's Timed Events table ...........................................................38

2.5.2 Launch the Timed Events table from the Chromatogram Viewer ................................... 39

2.5.3 Edit Timed Events from the Chromatogram Viewer ....................................................... 39

2.5.4 Use the Chromatogram Viewer’s cursor to update a Timed Event ..................................40

2.5.5 The Chromatogram Viewer's Component Data table .....................................................41

2.5.6 Edit retention times from the Chromatogram Viewer ....................................................42

2.5.7 Display raw data from the Chromatogram Viewer ......................................................... 42

2.6 Set the gas chromatograph’s date and time .................................................................................43

2.6.1 Set daylight savings ....................................................................................................... 43

Chapter 3 Hardware .......................................................................................................................47

3.1 Heater configuration ....................................................................................................................47

3.1.1 Set the temperature of the gas chromatograph’s heaters ..............................................47

3.1.2 Rename a heater ............................................................................................................47

3.1.3 Set a heater’s voltage type .............................................................................................48

3.1.4 Monitor the temperature of a heater ............................................................................. 48

3.1.5 Monitor the operational status of a heater .....................................................................48

3.1.6 Set the desired temperature ..........................................................................................48

3.1.7 Set PWM Output ............................................................................................................49

3.1.8 Take a heater out of service ........................................................................................... 50

3.2 Valve configuration ...................................................................................................................... 50

3.2.1 Rename a valve ..............................................................................................................51

3.2.2 Set a valve’s operational mode ...................................................................................... 51

3.2.3 Monitor the operational status of a valve ....................................................................... 52

3.2.4 Invert the polarity of a valve ...........................................................................................52

3.2.5 Set the usage mode for a valve ...................................................................................... 52

3.3 Managing the gas chromatograph's pressure ............................................................................... 53

3.3.1 Change the carrier pressure set point ............................................................................ 53

3.3.2 Check the status of the EPC ........................................................................................... 54

3.3.3 Switch to a different EPC mode ......................................................................................54

3.4 Detectors ..................................................................................................................................... 55

3.4.1 Offset the baseline .........................................................................................................56

3.4.2 Ignite the FID flame ....................................................................................................... 56

3.4.3 Reset the preamp value ................................................................................................. 57

3.4.4 Balance the preamp .......................................................................................................57

3.5 Discrete inputs ............................................................................................................................. 58

3.5.1 Rename a discrete input ................................................................................................ 58

3.5.2 Set a discrete input’s operational mode .........................................................................58

3.5.3 Monitor the operational status of a discrete input ..........................................................59

3.5.4 Invert the polarity of a discrete input ............................................................................. 59

3.6 Discrete outputs .......................................................................................................................... 59

3.6.1 Rename a discrete output ..............................................................................................59

3.6.2 Set a discrete output’s operational mode ...................................................................... 60

3.6.3 Monitor the operational status of a discrete output .......................................................60

3.6.4 Set the usage mode for a discrete output ...................................................................... 61

3.7 Manage your gas chromatograph’s analog inputs ........................................................................ 62

3.7.1 Rename an analog input ................................................................................................62

3.7.2 Set an analog input’s operational mode .........................................................................62

ii

Page 7

Contents

3.7.3 Set the scale values for an analog input device ...............................................................63

3.7.4 Set the type of analog input signal .................................................................................63

3.7.5 Monitor the status of an analog input ............................................................................ 64

3.7.6 Calibrate an analog input ...............................................................................................64

3.8 Analog outputs ............................................................................................................................ 65

3.8.1 Rename an analog output ..............................................................................................65

3.8.2 Set an analog output’s operational mode ...................................................................... 65

3.8.3 Set the scale values for an analog output device ............................................................ 66

3.8.4 Map a system variable to an analog output ....................................................................66

3.8.5 Monitor the status of an analog output ..........................................................................66

3.8.6 Calibrate an analog output ............................................................................................ 67

3.9 The Hardware Inventory List .........................................................................................................67

Chapter 4 Application .................................................................................................................... 69

4.1 Configure the system ................................................................................................................... 69

4.2 The Component Data Tables ........................................................................................................ 72

4.2.1 Edit a Component Data Table ........................................................................................ 73

4.2.2 Add a component to a Component Data Table .............................................................. 76

4.2.3 Remove a component from a Component Data Table ................................................... 77

4.2.4 View the standard values for a component .................................................................... 77

4.2.5 Display raw data from the Component Data table ......................................................... 78

4.2.6 Change the default C6+ mixture ratio ........................................................................ 79

4.3 The Timed Events tables ...............................................................................................................80

4.3.1 Configure valve events .................................................................................................. 81

4.3.2 Configure integration events ......................................................................................... 82

4.3.3 Configure spectrum gain events .................................................................................... 85

4.3.4 Set the cycle and analysis time .......................................................................................86

4.3.5 Remove an event from the Timed Event Table ............................................................... 86

4.3.6 Add an event to the Timed Event Table .......................................................................... 87

4.4 The Validation Data Tables ...........................................................................................................88

4.5 Calculations ................................................................................................................................. 89

4.5.1 Set standard calculations by stream ...............................................................................89

4.5.2 Edit average calculations ............................................................................................... 90

4.5.3 View an archive of averages for a given variable ............................................................. 91

4.5.4 Copy an average calculation configuration .................................................................... 92

4.5.5 Copy component settings ..............................................................................................93

4.6 Set the calculation method to GPA or ISO .....................................................................................93

4.7 Set alarm limits ............................................................................................................................ 95

4.8 System alarms ..............................................................................................................................97

4.9 Streams ........................................................................................................................................97

4.9.1 Designate how a stream will be used ............................................................................. 98

4.9.2 Link a valve with a stream .............................................................................................. 98

4.9.3 Assign a data table to a particular stream .......................................................................99

4.9.4 Change the base pressure for a stream .......................................................................... 99

4.10 Create a stream sequence for a detector .................................................................................... 100

4.11 Communications ........................................................................................................................100

4.11.1 Create or edit registers ................................................................................................ 101

4.11.2 Create a MAP file ..........................................................................................................103

4.11.3 Assign a variable to a register .......................................................................................106

4.11.4 View or edit scales ....................................................................................................... 106

4.12 Configure an Ethernet port .........................................................................................................107

iii

Page 8

Contents

4.13 Local Operator Interface variables .............................................................................................. 107

4.14 Map a FOUNDATION fieldbus variable ........................................................................................ 108

Chapter 5 Logs and reports ...........................................................................................................111

5.1 Alarms ........................................................................................................................................111

5.1.1 View unacknowledged and active alarms .....................................................................111

5.1.2 Acknowledge and clear alarms .................................................................................... 112

5.1.3 View the alarm log ....................................................................................................... 112

5.2 The maintenance log ..................................................................................................................113

5.2.1 Add an Entry to the Maintenance Log .......................................................................... 114

5.2.2 Delete an entry from the maintenance log ...................................................................114

5.3 The parameter list ...................................................................................................................... 114

5.3.1 View and edit the parameter list .................................................................................. 115

5.3.2 Import the Parameter List ............................................................................................ 115

5.4 Drawings and documents ...........................................................................................................116

5.4.1 View drawings or documents .......................................................................................116

5.4.2 Add files to the GC ....................................................................................................... 117

5.4.3 Delete files from the GC ...............................................................................................117

5.5 The event log ............................................................................................................................. 117

5.6 Reports ...................................................................................................................................... 118

5.6.1 Report types ................................................................................................................ 118

5.6.2 View reports from live data .......................................................................................... 127

5.6.3 View a saved report ..................................................................................................... 128

5.7 Generate reports from archived data ..........................................................................................129

5.7.1 Generate analysis and calibration reports from archived data ...................................... 129

5.7.2 Generate an Average report from archived data .......................................................... 130

5.7.3 Schedule the generation of reports ..............................................................................131

5.8 Trend data ..................................................................................................................................132

5.8.1 View live trend data ..................................................................................................... 132

5.8.2 View saved trend data ................................................................................................. 133

5.9 Trend Graph options .................................................................................................................. 133

5.10 Properties of the trend graph ..................................................................................................... 135

5.10.1 The trend graph bar .....................................................................................................135

5.11 The Trend bar .............................................................................................................................137

5.11.1 Edit a trend graph ........................................................................................................ 137

5.11.2 Enter a description for a trend graph ............................................................................137

5.11.3 Save a trend .................................................................................................................138

5.11.4 View associated trend data ..........................................................................................138

5.11.5 Remove a trend graph from view .................................................................................138

5.11.6 Refresh a trend graph .................................................................................................. 139

5.11.7 Display trend data ....................................................................................................... 139

5.12 Generate a repeatability certificate ............................................................................................ 140

5.13 Generate a GC Configuration report ........................................................................................... 142

5.14 Delete archived data from the gas chromatograph .................................................................... 144

5.15 The molecular weight vs. response factor graph .........................................................................145

Chapter 6 Analysis ........................................................................................................................147

6.1 Auto sequencing ........................................................................................................................ 147

6.2 Analyze a single stream .............................................................................................................. 147

6.3 Calibrate the gas chromatograph ...............................................................................................148

6.4 Validate the gas chromatograph ................................................................................................ 149

6.5 Configure the valve timing ......................................................................................................... 150

6.6 Auto valve timing alarms ............................................................................................................151

iv

Page 9

Contents

6.7 Halt an analysis ...........................................................................................................................151

6.8 Stop an analysis ..........................................................................................................................152

Chapter 7 Tools ............................................................................................................................ 155

7.1 The Modbus Test program ......................................................................................................... 155

7.1.1 Modbus protocol comparison ...................................................................................... 155

7.1.2 Set communication parameters .................................................................................. 156

7.1.3 Obtain Modbus Data ................................................................................................... 157

7.1.4 Transmit a single data type .......................................................................................... 158

7.1.5 Transmit data using a template ................................................................................... 160

7.1.6 Set the log parameters ................................................................................................ 162

7.1.7 Save Modbus data ....................................................................................................... 163

7.1.8 Print Modbus data ....................................................................................................... 163

7.1.9 Assign scale ranges to User_Modbus registers ............................................................. 163

7.2 Communication errors ............................................................................................................... 164

7.3 Users ..........................................................................................................................................164

7.3.1 Create a user ................................................................................................................166

7.3.2 Export a list of user profiles .......................................................................................... 167

7.3.3 Import a list of user profiles ......................................................................................... 167

7.3.4 Edit a user profile ......................................................................................................... 167

7.3.5 Remove a user ............................................................................................................. 168

7.3.6 Change a user’s password ............................................................................................168

7.3.7 Reset the administrator password ............................................................................... 168

7.3.8 Find out who is connected to the gas chromatograph ................................................. 169

7.4 Upgrade the firmware ................................................................................................................ 169

7.5 Cold booting .............................................................................................................................. 170

7.6 View diagnostics ........................................................................................................................ 170

7.7 Adjust the sensitivity of the LOI Keys .......................................................................................... 171

7.8 Set the I/O card type ...................................................................................................................171

Appendices and reference

Appendix A Custom calculations ..................................................................................................... 173

A.1 Insert a comment ....................................................................................................................... 178

A.2 Insert a conditional statement ....................................................................................................178

A.3 Insert an expression ....................................................................................................................180

A.4 Create a constant ....................................................................................................................... 181

A.5 Create a temporary variable ....................................................................................................... 182

A.6 Insert a system variable .............................................................................................................. 182

v

Page 10

Contents

vi

Page 11

Getting started

1 Getting started

Welcome to MON2020—a menu-driven, Windows-based software program designed to

remotely operate and monitor the Daniel® Danalyzer™ XA series and the Rosemount

Analytical XA series of gas chromatographs.

MON2020 operates on an IBM-compatible personal computer (PC) running the Windows

XP operating system or later.

MON2020 can initiate or control the following gas chromatograph (GC) functions:

• Alarm parameters

• Alarm and event processing

• Analog scale adjustments

• Analyses

• Baseline runs

• Calculation assignments and configurations

• Calibrations

• Component assignments and configurations

• Diagnostics

• Event sequences

• Halt operations

• Stream assignments and sequences

• Valve activations

• Timing adjustments

Getting started

1

®

MON2020 can generate the following reports:

• 24-Hour Averages

• Analysis (GPA)

• Analysis (ISO)

• Calibration

• Final Calibration

• Validation

• Final Validation

• Hourly Averages

• Monthly Averages

• GC Configuration

• Raw Data

• Variable Averages

• Weekly Averages

1

Page 12

Getting started

• Dew Temperature Calculation (optional)

MON2020 can access and display the following GC-generated logs:

• Alarm Log

• Event Log

• Parameter List

• Maintenance Log

1.1 MON2000 and MON2020

Users familiar with MON2000 or MON2000 Plus will find a few changes when using

MON2020:

• Login security is at the gas chromatograph level instead of at the software level. This

means that you no longer have to log in after starting MON2020—but you do have

to log in to the gas chromatograph to which you are trying to connect. For more

information, see Section 1.2.12.

• An “administrator” role has been added to the list of user roles. This new role has the

highest level of authority and is the only role that can create or delete all other roles.

For more information, see Section 7.3.

• Multiple users can connect to the same gas chromatograph simultaneously. By

default, the first user to log in to the GC with “supervisor” authority will have read/

write access; all other users, including other supervisor-level users, will have read

access only. This configuration can be changed so that all supervisor-level users have

read/write access regardless of who logs in first. For more information, see

Section 4.1.

• Users can display multiple windows within MON2020.

• Automatic re-connection. If MON2020 loses its connection with the GC, it

automatically attempts to reconnect.

• Users can view multiple instances of certain windows. To aid in data processing or

troubleshooting, MON2020 is capable of displaying more than one instance of

certain data-heavy windows such as the Chromatogram Viewer and the Trend Data

window.

• Enhanced Chromatogram Viewer. The following enhancements have been made to

the Chromatogram Viewer:

- Users can view an unlimited number of chromatograms, in any configuration. For

example, a user can view an archived chromatogram and a live chromatogram.

For more information, see Section 2.1.

- The “Keep Last CGM” option. Upon starting a new run, MON2020 can keep the

most recently completed chromatogram on the graph for reference.

- Overview window. When zoomed in to a smaller section of a chromatogram, the

user can open a miniature ‘overview’ window that displays the entire

chromatogram, for reference. For more information, see Section 2.3.2.

2

Page 13

Getting started

- Older chromatograms available. MON2020 has access to archived

chromatograms as old as four or five days. For more information, see

Section 2.1.3.

- Full screen mode. For more information, see Section 2.2.

- Protected chromatograms. Chromatograms that you designate as “protected”

will not be deleted. For more information, see Section 2.1.4.

• The “Invert Polarity “option. This feature reverses a device’s effect. For more

information, see Section 3.2.4 and Section 3.5.4.

• Streamlined variables-picking menu. The method for selecting variables for

calculations and other purposes is contained within one simple, self-contained

menu. For more information, see Section 1.11.

• GC Time. The GC Status Bar displays the date and time based on the GC’s physical

location, which may be different than the PC’s location. For more information, see

Section 2.6.

• Daylight savings time. You have option of enabling a GC’s daylight savings time

feature. Also, there are two options for setting the start and end times for daylight

savings time on the GC. For more information, see Section 2.6.1.

• Baseline offsetting. In some situations that involve TCD detectors the baseline may

be displayed either too high on the graph, in which case the tops of the peaks are

cut off, or too low on the graph, so that the bases of the peaks are cut off. If this

occurs it is possible to offset the baseline either up or down so that the entire peak

can be displayed on the graph. This offset will be applied to all traces—live, archived

and saved—that are displayed thereafter. For more information, see Section 2.5.7.

• Microsoft Excel-based Parameter List. The Parameter List has been expanded to offer

seven pages of information, and is Microsoft® Excel-based to allow for access

outside of MON2020. The document can be imported to and exported from GCs.

For more information, see Section 5.3.

• Optional FOUNDATION fieldbus variables. If your GC is installed with a Foundation

fieldbus, you can map up to 64 GC variables to monitor using the AMS Suite. For

more information, see Section 4.14.

• Optional local operator interface (LOI) variables. If your GC is installed with an LOI,

you can configure up to 25 GC parameters to monitor using the LOI’s Display mode.

For more information, see Section 4.13.

• Access to GC-related drawings such as flow diagrams, assembly drawings, and

electrical diagrams.

• Validation runs. During a validation run, the GC performs a test analysis to verify that

it is working properly. For more information, see Section 4.4 and Section 6.4.

Getting started

1

1.2 Getting started with MON2020

This section covers such issues as installing, registering and setting up the software, as well

as configuring MON2020 to meet your specific needs.

3

Page 14

Getting started

1.2.1 System requirements

To achieve maximum performance when running MON2020, ensure your PC meets the

following specifications:

Compatible

operating systems

Compatible

browser

Minimum

hardware

specifications

Windows® XP (Service Pack 2 or later), Windows® Vista, or

Windows® 7.

Internet Explorer® 6.0 or later.

A PC with a 400 MHz Pentium or higher processor.

At least 256 MB of RAM.

At least 100 MB of available hard disk space. On Windows XP, if NET

2.0 is not installed, an additional 280 MB of hard disk space will be

needed.

A Super VGA monitor with at least 1024 x 768 resolution.

One Ethernet port for connecting remotely or locally to the gas

chromatograph.

1.2.2 Install MON2020

You must install MON2020 from the CD-ROM onto your hard drive; you cannot run the

program from the CD-ROM.

Double-click the Setup file and follow the on-screen installation instructions.

Upon successful installation, MON2020 creates a shortcut icon on the computer’s

desktop.

Note

MON2020 is not an upgrade to MON2000; therefore, MON2020 should be installed to its own

directory, separate from the MON2000 directory.

Note

You must be logged onto the computer as an administrator to install MON2020. Windows® Vista

and Windows® 7 users, even with administrator privileges, will be prompted by the operating

system’s User Account Control feature to allow or cancel the installation.

1.2.3 Start MON2020

To launch MON2020, double-click its desktop icon or click the Start button and select

Emerson Process Management → MON2020.

1.2.4 Register MON2020

Each time you start MON2020 it will prompt you to register if you have not already done

so. You can also register by selecting Register MON2020... from the Help menu.

4

Page 15

Getting started

Registering your copy of MON2020 allows you to receive information about free updates

and related products.

1. Complete the appropriate fields on the Register MON2020 window.

Note

The software's serial number is located on the back of its CD case.

2. Click Next to continue.

3. Choose the desired registration method by clicking the corresponding checkbox.

4. Click Finish.

1.2.5 Set up the data folder

The data folder stores GC-specific files such as reports and chromatograms. The default

location for the data folder is C:\Users\user_account_name\Documents\GCXA Data. If

you want MON2020 to store its data in a different location—on a network drive, for

instance—do the following:

1. Move the data folder to its new location.

2. Select Program Settings... from the File menu.

3. The current location of the data folder displays in the Data Folder field.

Getting started

1

To change the data folder’s location, click on the Browse button that is located to

the right of the Data Folder field.

4. Use the Browse for Folder window to navigate to the GCXP Data folder’s new location

and click OK.

Note

Another method for changing the folder location is to type the folder’s location into the Data

Folder field and press ENTER. When the “Create the folder?” message appears, click Yes.

5. The Data Folder field updates to display the new location.

1.2.6 Set up MON2020 to connect to a gas chromatograph

To configure MON2020 to connect to a GC, do the following:

1. Select GC Directory... from the File menu.

If this is the first time that this option was selected, you will get the following error

message:

5

Page 16

Getting started

“GC directory file not found” messageFigure 1-1:

If you get the “GC directory file not found” message, click OK. The GC Directory

window appears and displays a table containing an inventory of the GCs to which

MON2020 can connect.

2. If you are configuring the first GC connection for MON2020, there will be only one

generic GC record listed in the window. To add another record, select Add from the

GC Directory window’s File menu. A new row will be added to the bottom of the

table.

3. Click in the GC Name field and enter the name for the GC to which you want to

connect.

4. Optionally, you can click in the Short Desc field and enter pertinent information

about the GC to which you want to connect, such as its location. You can enter up to

100 characters in this field.

5. Click Ethernet. The Ethernet Connection Properties for New GC window appears.

6. In the IP address field, enter the IP address of the GC to which you want to connect.

Note

The default address for the GC's RJ-45 port in DHCP mode is 192.168.135.100.

Note

If you type in an invalid IP address, you will get an error message when MON2020 attempts to

connect to the GC.

7. Click OK. When the Save changes? message appears, click Yes.

8. Repeat steps 2 through 7 for any other GCs to which you want to connect.

9. To delete a GC from the table, select the GC and then select Delete from the File

menu.

10. To copy a GC's configuration information into a new row, select the row to be copied

and then select Insert Duplicate from the File menu.

11. To insert a row below a GC, select the GC and then select Insert from the File menu.

12. To sort the table alphabetically, select Sort from the Table menu or click Sort from

the GC Directory window.

13. To copy the list of GCs to the clipboard to be pasted into another application, select

Copy Table to Clipboard from the Table menu.

6

Page 17

Getting started

14. To print the list of GCs, select Print Table... from the Table menu.

15. To save the changes and keep the window open click Save from the GC Directory

window. To save the changes and close the window, click OK. When the Save

changes? message appears, click Yes.

For more details about configuring MON2020 connections, see Section 4.12.

1.2.7 Export a GC directory

The GC Directory, which contains the list of networked GCs that are currently configured for

your copy of MON2020, can be saved as a DAT file to a PC or other storage media such as a

compact disk or flash drive.

To save the GC Directory to the PC, do the following:

1. Click Export.

The Export GC Directory window displays.

2. Select the checkbox for each gas chromatograph whose information you want to

save.

Note

If you want to save the entire list, click Select All.

Getting started

1

3. Click OK.

The Export GC Directory File save as dialog displays.

4. Choose a save location.

The default location is C:\Users\user_account_name\Documents\GCXA Data.

Note

The file is automatically given the name of GC_DIRECTORY_EXPORT.DAT. If you prefer a

different name, type it into the File name field.

5. Click Save.

1.2.8 Import a GC Directory file

A GC Directory file can be used to restore GC directory information to your copy of

MON2020, or it can be used to quickly and easily supply other copies of MON2020 that are

installed on other computers with the profiles of the GCs that are in your network.

To import a GC Directory file, do the following:

1. Select GC Directory... from the File menu.

If this is the first time that this option was selected, you will get the following error

message:

7

Page 18

Getting started

“GC directory file not found” messageFigure 1-2:

If you get the “GC directory file not found” message, click OK. The GC Directory

window appears

2. Click Import.

The Import GC Directory File dialog displays.

3. Locate the GC directory file and select it.

4. Click Open.

The newly configured GC Directory window reappears with the list of networked GCs

displayed in the GC Directory table.

1.2.9 Launch MON2020 from the SNAP-ON for DeltaV

This section assumes that DeltaV is installed on the PC along with MON2020.

Note

To successfully use MON2020 SNAP-ON for DeltaV, you must be familiar with using the DeltaV

digital automation system.

To start MON2020, do the following:

1. Start the DeltaV Explorer by clicking on its desktop icon or by clicking the Start

button and selecting DeltaV → Engineering → DeltaV Explorer.

2. In the Device Connection View, open device icons by clicking once on each icon.

Follow the path of connections until you locate the desired gas chromatograph icon.

3. Right-click on a connected gas chromatograph icon to display the context menu.

4. Select SNAP-ON/Linked Apps → Launch MON2020.

MON2020 starts and connects automatically to the GC.

1.2.10 Launch MON2020 from the AMS Device Manager

This section assumes that DeltaV and AMS are installed on the PC along with MON2020.

To start MON2020, do the following:

8

Page 19

Getting started

1. Start the AMS Device Manager by clicking on its desktop icon or by clicking the Start

button and selecting AMS Device Manager → AMS Device Manager.

2. In the Device Connection View, open device icons by clicking once on each icon.

Follow the path of connections until you locate the desired gas chromatograph icon.

3. Right-click on a connected gas chromatograph icon to display the context menu.

4. Select SNAP-ON/Linked Apps → Launch MON2020.

MON2020 starts and connects automatically to the GC.

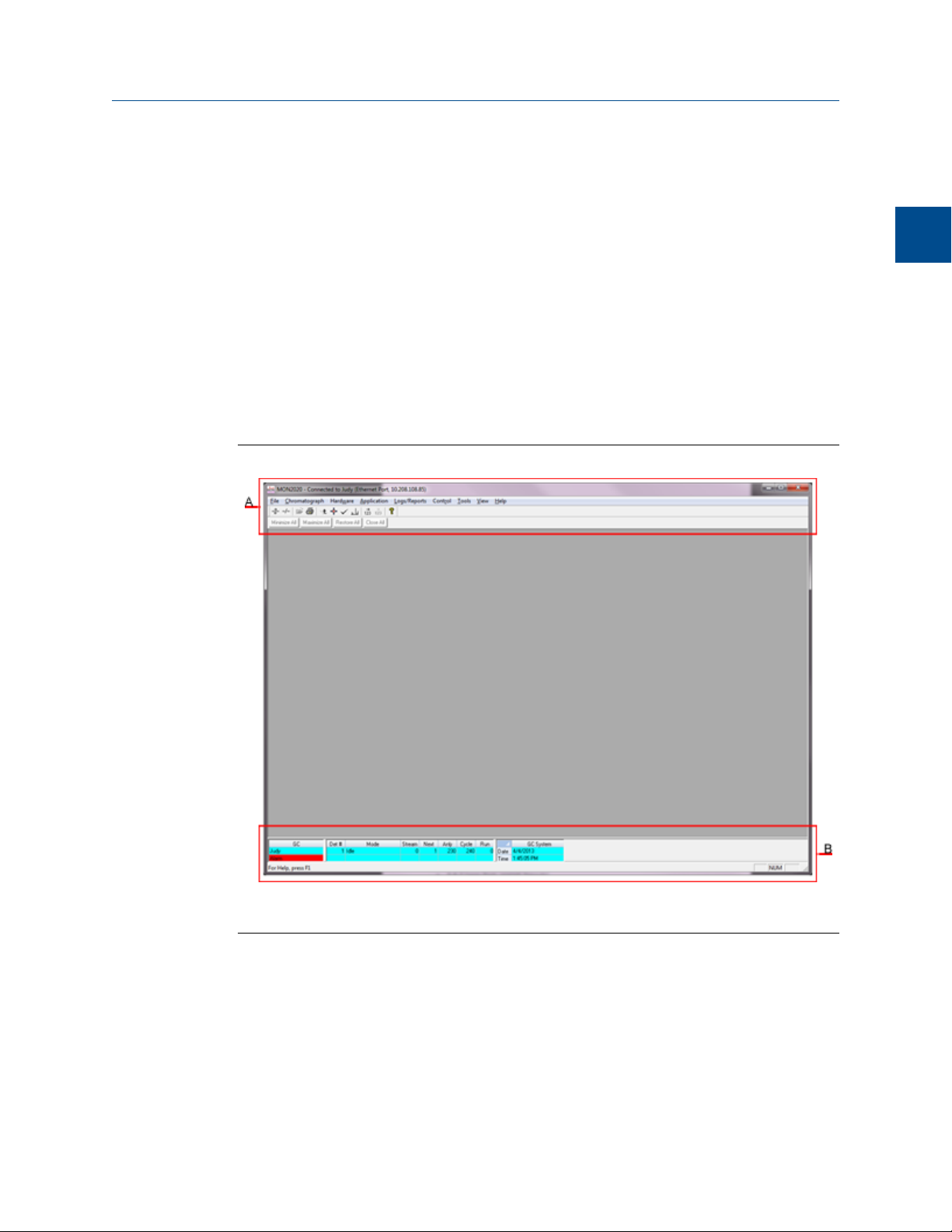

1.2.11 The MON2020 user interface

MON2020 has two areas of interaction: the Control Area, at the top of the program’s main

window, and the GC Status Bar, located at the bottom of the program’s main window.

The MON2020 windowFigure 1-3:

Getting started

1

A. Control Area

B. GC Status Bar

The main user interface

The main user interface of the main window contains the menus and icons that allow you

to control MON2020 and the GC to which MON2020 is connected.

9

Page 20

Getting started

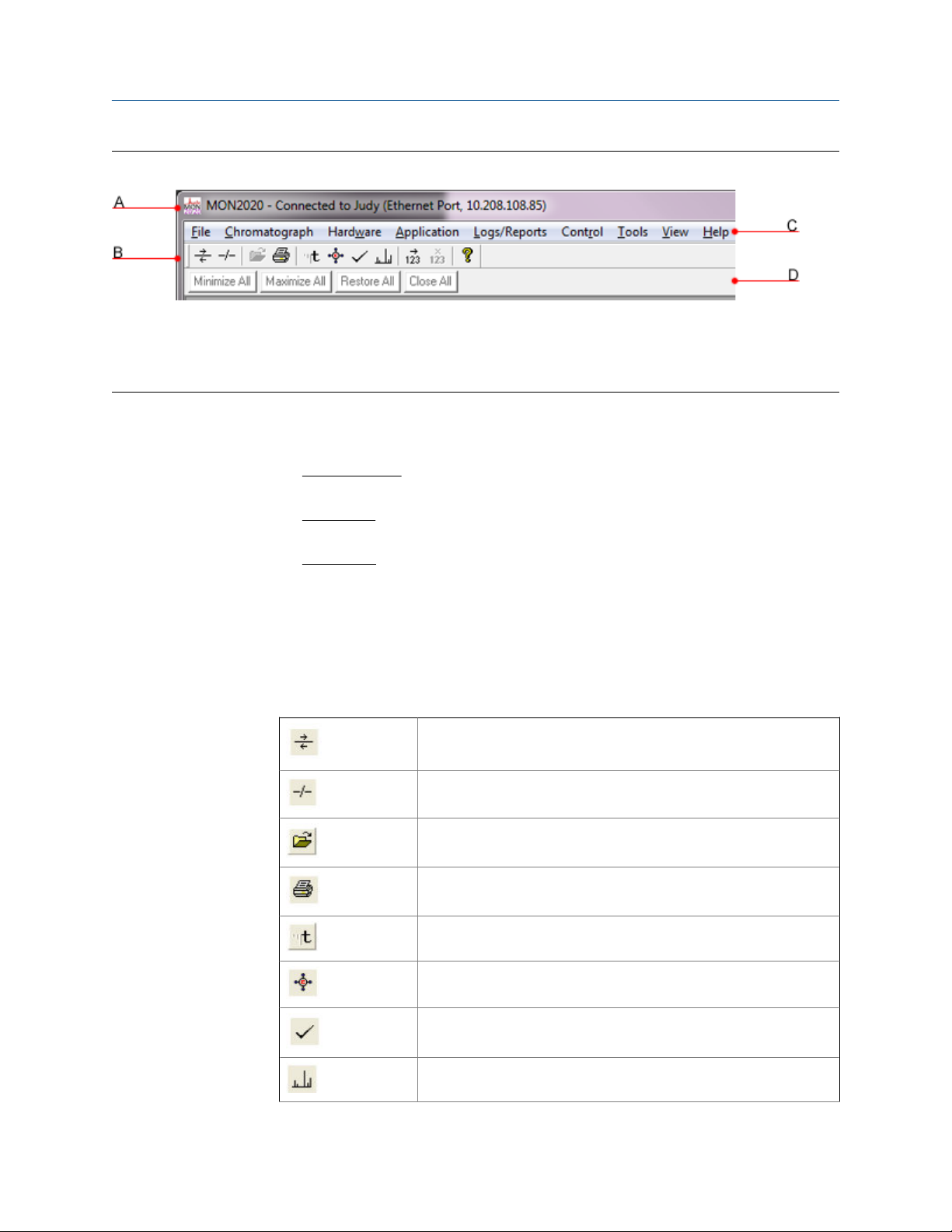

The Control AreaFigure 1-4:

A. Title bar

B. Toolbar

C. Menu bar

D. Dialog Control Tabs

• Title bar - The Title bar displays the name of the program, as well as the program’s

• Menu bar - The Menu bar contains the commands that allow you to control and

• Toolbar - The Toolbar contains shortcut icons for the most important and/or most

connection status. MON2020 has the following three overall status modes:

- Not connected - If MON2020 is not connected to a GC, then “MON2020”

displays in the Title bar.

- Connected - If MON2020 is connected to a GC, then “MON2020 - Connected to”

and the name of the GC and the connection type displays in the Title bar.

- Offline Edit - If MON2020 is in offline edit mode, then “MON2020 - Offline Edit

<filename>” displays in the Title bar.

monitor gas chromatographs.

often used MON2020 commands. From the Toolbar you can do such things as

connect to and disconnect from a GC, view chromatographs, and view help files.

10

Connect to a gas chromatograph.

Disconnect from a gas chromatograph.

Open a configuration file.

Print a GC configuration report.

View the Timed Events window.

View the Component Data window.

Clear or acknowledge alarms.

Open the CGM Viewer window.

Page 21

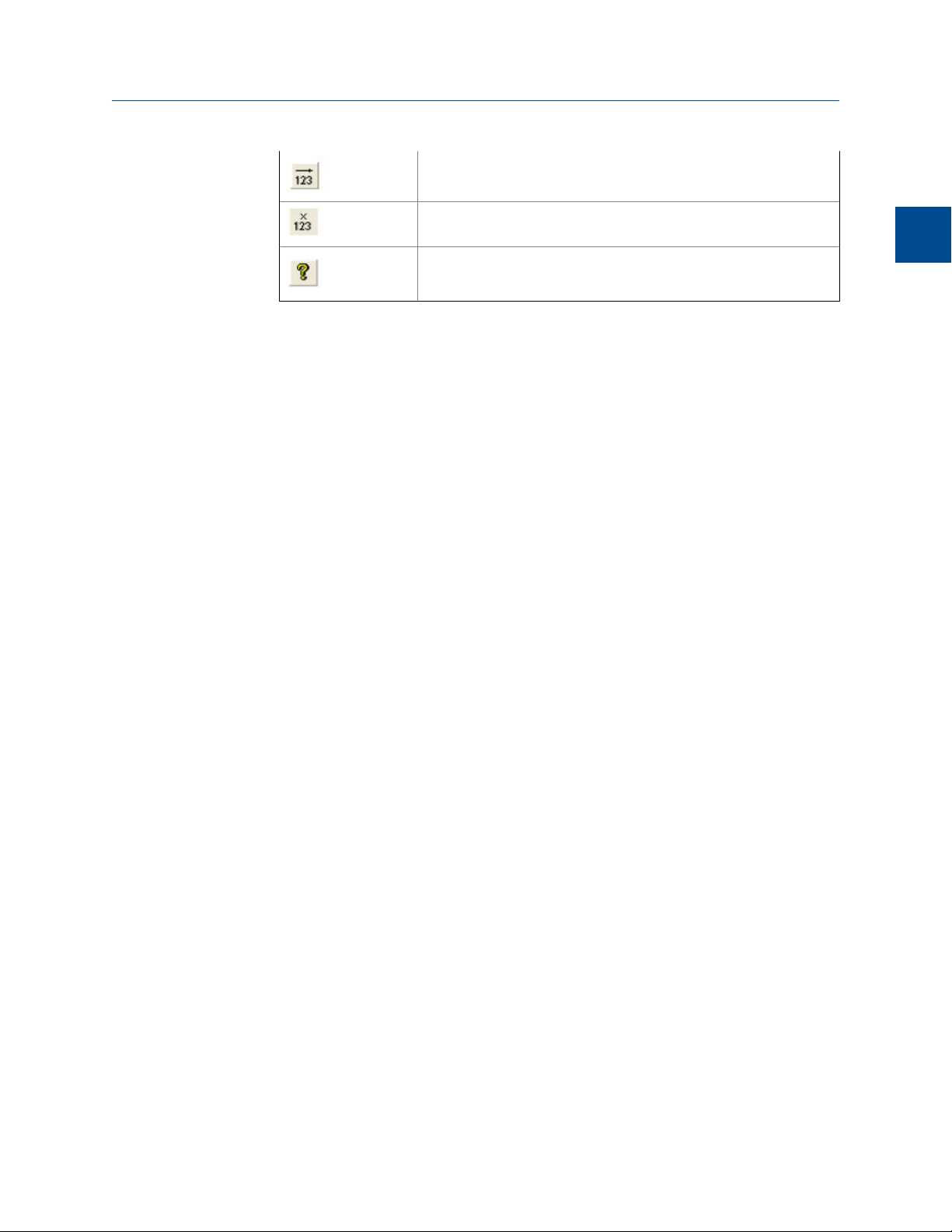

Getting started

Begin auto sequencing.

Halt auto sequencing.

Open the About MON2020 window.

• Dialog Control Tabs bar - The Dialog Control Tabs bar contains four buttons that

allow you to manage the behavior of all windows that are open in the main window.

The four buttons are Minimize All, Maximize All, Restore All, and Close All. The

bar also displays a button for each open window that allows you to select or deselect

that window.

You can hide or display the Toolbar and the Dialog Control Tabs bar by clicking the

appropriate option from the View menu.

The GC Status Bar

The GC Status Bar of the main window displays useful information about the status and

functioning of the gas chromatograph to which MON2020 is connected.

The GC Status Bar contains the following sections:

Getting started

1

GC The first row displays the name of the GC to which MON2020 is connected.

If MON2020 is not connected to a GC, “Not Connected” displays in this

row. If MON2020 loses its connection to the GC, “Comm Fail” displays in

this row, and the program will automatically try to reconnect. The second

row displays status flags such as active alarms (with red background),

unacknowledged alarms (with yellow background), or File Edit modes.

Det # A GC can have a maximum of two detectors.

Mode Potential modes are: Idle, Warmstart Mode, Manual Anly, Manual Cal,

Manual Validation, Auto Anly, Auto Cal, Auto Validation, Auto Valve

Timing, Module Validation, CV Check, Manual Purge, Auto Purge, and

Actuation Purge.

Stream The current stream being analyzed.

Next The next stream to be analyzed.

Anly The analysis time.

Cycle The total cycle time, in seconds, between successive analyses.

Run The amount of time, in seconds, that has elapsed since the current cycle

began.

GC System Displays the date and time according to the GC to which MON2020 is

connected. The date and time displayed may be different from the user’s

date and time, depending on the physical location of the GC.

11

Page 22

Getting started

FID Flame

Status

Displays the status of the FID flame. Options are OFF with red background,

ON with green background, and OVER TEMP with red background. The FID

Flame Status indicator only displays on the GC Status Bar when the GC to

which MON2020 is connected has an FID detector.

You can hide or display the GC Status Bar by clicking GC Status Bar from the View menu.

1.2.12 Connect to a gas chromatograph

Before connecting to a GC you must create a profile for the it on MON2020. See

Section 1.2.6 to learn how to do this.

Also, to connect to a gas chromatograph you must log on to it first. Most of MON2020’s

menus and options are inactive until you have logged on to a GC.

To connect to a GC, do the following:

1. There are two ways to start the process:

a.

On the Toolbar, click .

b. Select Connect... from the Chromatograph menu.

The Connect to GC dialog, which displays a list of all the GCs to which you can

connect, appears.

Note

If you want to edit the connection parameters for one or all GCs listed in the Connect to GC

window, click Edit Directory. The GC Directory window will appear. See Section 1.2.6 for more

information.

2. Click the Ethernet button beside the GC to which you want to connect.

The Login dialog appears.

3. Enter a user name and user PIN and click OK.

Once connected, the name of the GC appears under the GC column in the GC Status

Bar.

Note

All GCs are shipped with a default user name: emerson. A user password is not required when

using this administrator-level user name. To add a user password to either of these user

names or for information about creating and edit user names in general, see Section 7.3.

Note

If you enter an invalid user name or password, the Login dialog will close without connecting

to the GC.

12

Page 23

Getting started

1.2.13 Disconnect from a gas chromatograph

Disconnecting from a GC will automatically log you off of the GC.

To disconnect from a gas chromatograph, do one of the following:

•

On the Toolbar, click .

• Select Disconnect from the Chromatograph menu.

Note

If you are connected to a GC and want to connect to a different GC, it is not necessary to disconnect

first; simply connect to the second GC, and in the process MON2020 will disconnect from the first

GC.

1.3 Keyboard commands

You can use the following keyboard keystrokes throughout the program:

Arrow

keys

Moves cursor:

• Left or right in a data field.

• Up or down in a menu or combo box.

• Up or down (column), left or right (row) through displayed data

entries.

Getting started

1

Delete

Enter Activates the default control element (e.g., the OK button) in current

Esc Exits application or active window without saving data.

F1 Accesses context-sensitive help topics.

Insert

Tab Moves to the next control element (e.g., button) in the window; to use Tab

Shift+Tab Moves to previous control element (e.g., button) or data field in window;

Space Toggles settings (via radio buttons or check boxes).

You can use the following function keys from the main window:

F2 Starts the Auto-Sequencing function. See Section 6.1 for more information.

• Deletes the character after cursor.

• Deletes selected rows from a table or return row values to the default

settings.

window.

• Toggles between insert and type-over mode in selected cell.

• Inserts a new row above the highlighted row.

key to move to next data field, select Program Settings... from the File

menu and clear the Tab from spreadsheet to next control check box.

see Tab description.

13

Page 24

Getting started

F3 Halts the GC (e.g., an analysis run) at the end of the current cycle. See Section 6.1 for

more information.

F5 Displays the Timed Events table per specified stream. See Section 4.3 for more

information.

F6 Displays the Component Data table per specified stream. See Section 4.2 for more

information.

F7 Displays the chromatogram for the sample stream being analyzed. See Section 2.1.2

for more information.

F8 Displays any chromatogram stored in the GC Controller. See Section 2.1.3 for more

information.

1.4 Procedures guide

Use the following table to look up the related manual section, menu path and, if

appropriate, the keystroke for a given procedure.

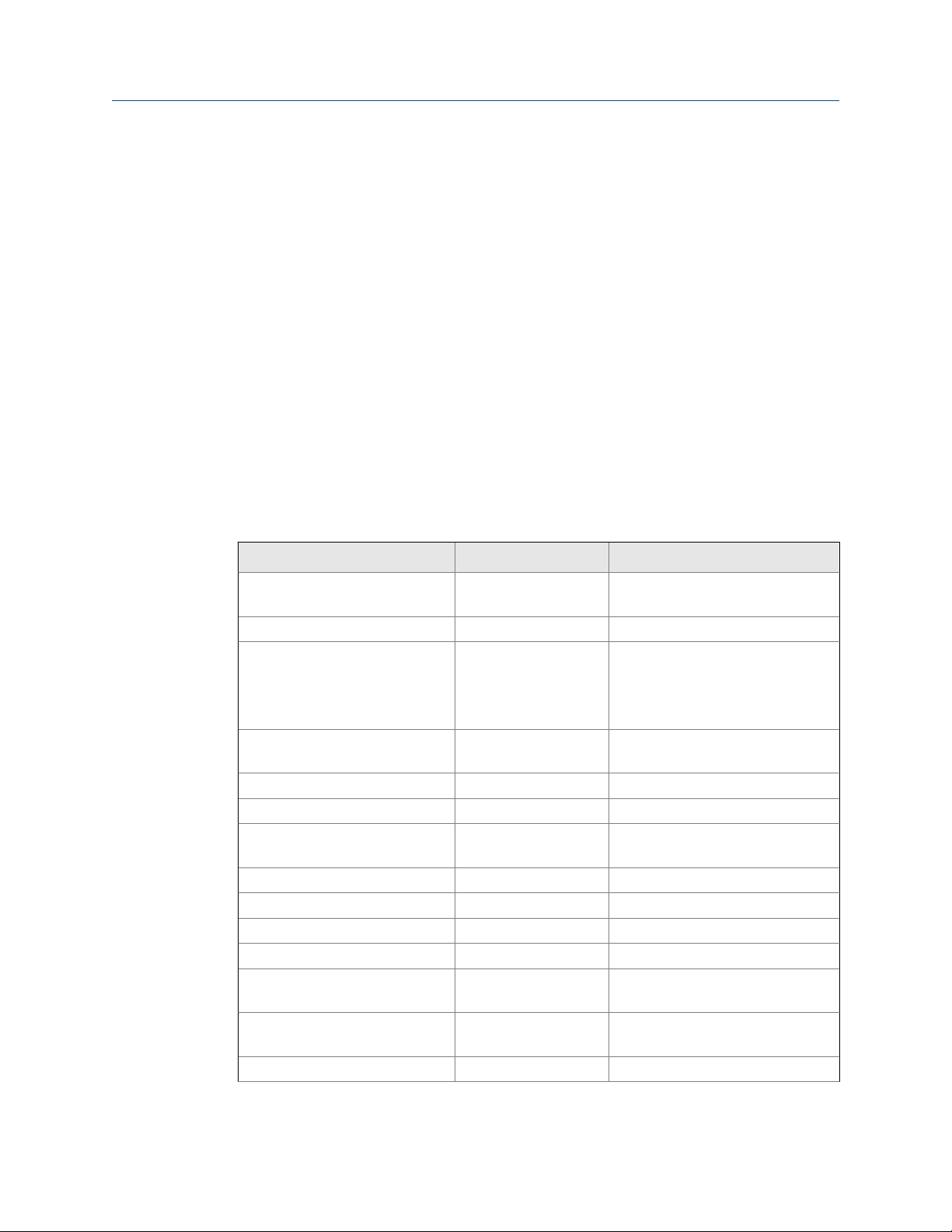

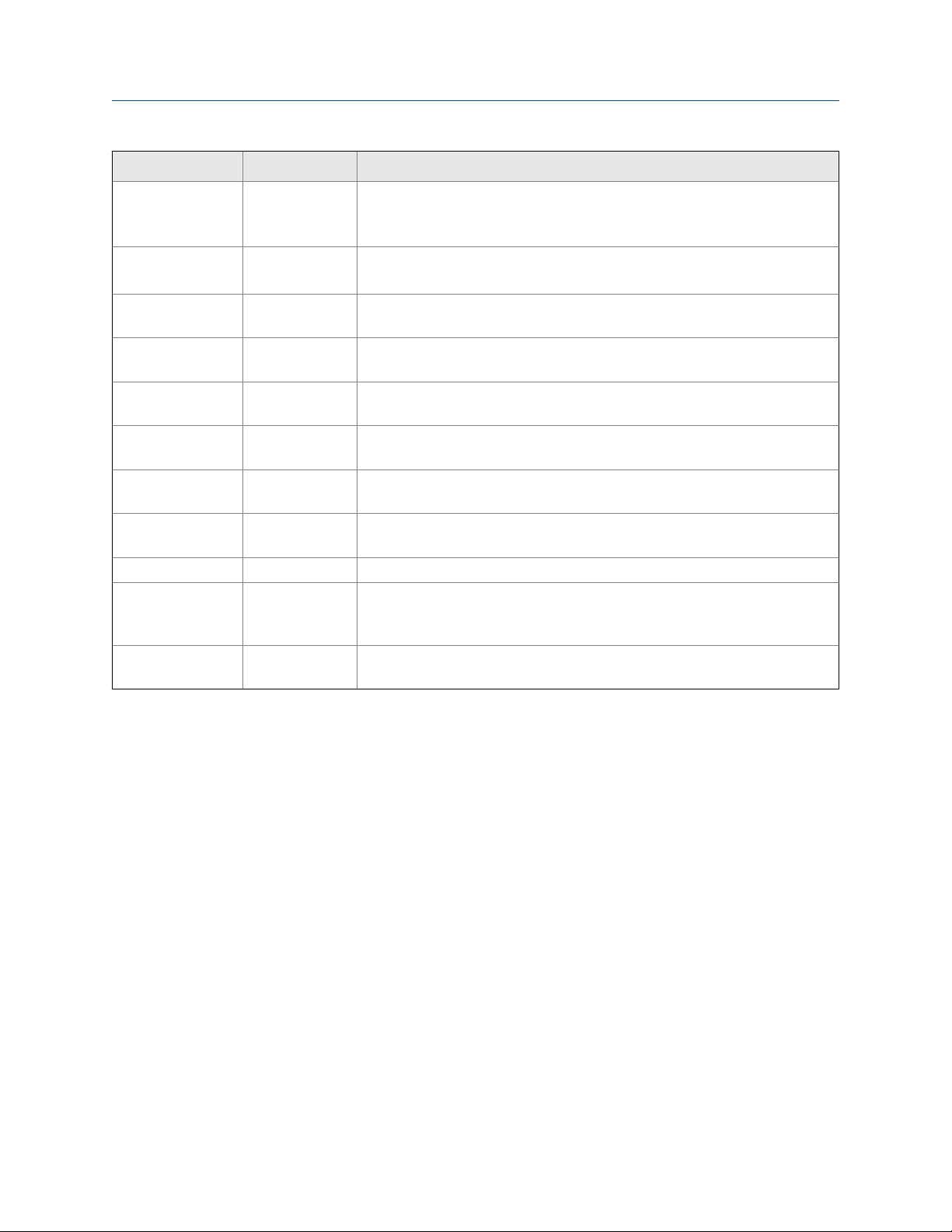

MON2020 Task ListTable 1-1:

Task or Data Item Section(s) Menu Path [Keystroke]

24-hour average, component(s)

measured

Add a gas chromatograph Section 1.2.6 File → GC Directory

Alarms, related components Section 4.2

Alarms, stream number(s) programmed

Analysis Report (on/off) Section 5.7.3 Logs/Reports → Printer Control...

Analysis time Section 4.3.4 Application → Timed Events... [F5]

Starting or ending auto-calibration

Auto-calibration interval Section 4.9 Application → Streams...

Auto-calibration start time Section 4.9 Application → Streams...

Autocal time Section 4.9 Application → Streams...

Baseline Section 4.9 Application → Streams...

Base pressure used for calculations

Calibration concentration Section 4.2 Application → Component Data...

Calibration cycle time Section 4.3.4 Application → Timed Events... [F5]

Section 4.5.2 Application → Calculations → Aver-

ages...

Application → Component Data...

Section 4.7

Section 3.5

Section 4.7 Application → Limit Alarms → User...

Section 4.9 Application → Streams...

Section 4.9 Application → Streams...

[F6]

Application → Limit Alarms → User...

Hardware → Discrete Outputs...

[F6]

14

Page 25

Getting started

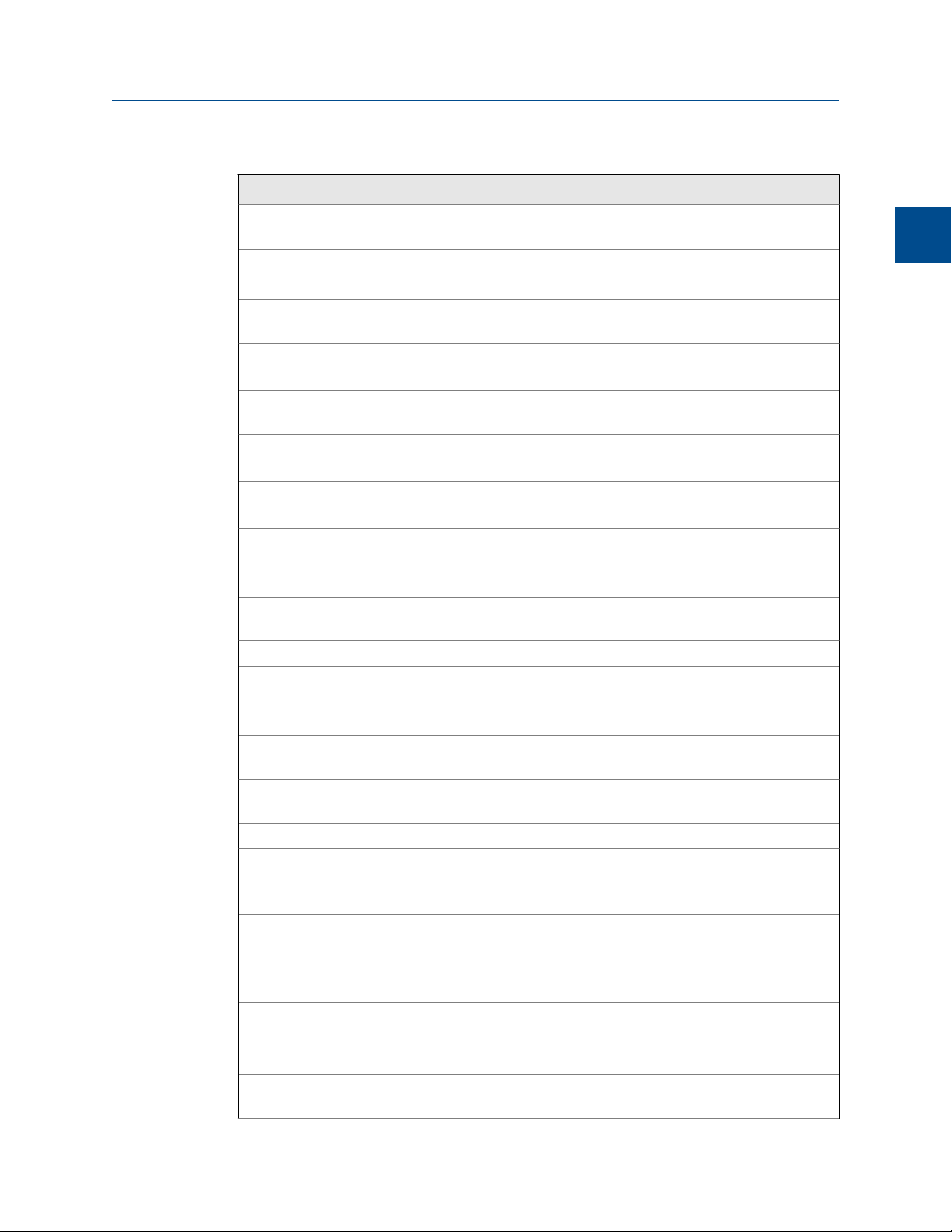

MON2020 Task List (continued)Table 1-1:

Task or Data Item Section(s) Menu Path [Keystroke]

Calibration runs, number averaged

Calibration runs, number of Section 4.9 Application → Streams...

Calibration stream number Section 4.9 Application → Streams...

Change the default C6+ mixture

ratio

Communications Section 4.11 Application → Communication...

Component code and name Section 4.2 Application → Component Data...

Component full scale (for output) Section 4.1

Component(s) programmed for

input

Component(s) programmed for

output

Component, retention time Section 4.2 Application → Component Data...

Component zero (for output) Section 3.7 Hardware → Analog Outputs...

Compressibility (on/off) Section 4.5.1 Application → Calculations → Con-

Configure the valve timing Section 6.5 Control → Auto Valve Timing...

Current date Section 2.6 Chromatograph → View/Set GC

Current time Section 2.6 Chromatograph → View/Set GC

Cycle time Section 4.3.4 Application → Timed Events... [F5]

Delete alarms Section 4.7

Delete component from component list

Delete inhibit, integration, peak

width

Delete output(s) Section 3.7

Enable or disable multi-user write Section 4.1 Application → System...

Existing alarm(s) Section 5.1 Logs/Reports → Alarms → Alarm

Section 4.9 Application → Streams...

Section 4.2.6 Application → Compnent Data Ta-

ble...

Application → Ethernet Ports...

[F6]

Application → System...

Section 3.7

Section 3.6

Section 3.4

Section 4.7

Section 3.7

Section 3.5

Section 5.1

Section 4.2 Application → Component Data...

Section 4.2 Application → Timed Events... [F5]

Section 3.5

Hardware → Analog Outputs...

Application → Analog Inputs...

Application → Discrete Inputs...

Application → Limit Alarms → User...

Hardware → Analog Outputs...

Hardware → Discrete Outputs...

[F6]

trol...

Time...

Time...

Application → Limit Alarms...

Logs/Reports → Alarms → Alarm

Log...

[F6]

Hardware → Analog Outputs...

Hardware → Discrete Outputs...

Log...

Getting started

1

15

Page 26

Getting started

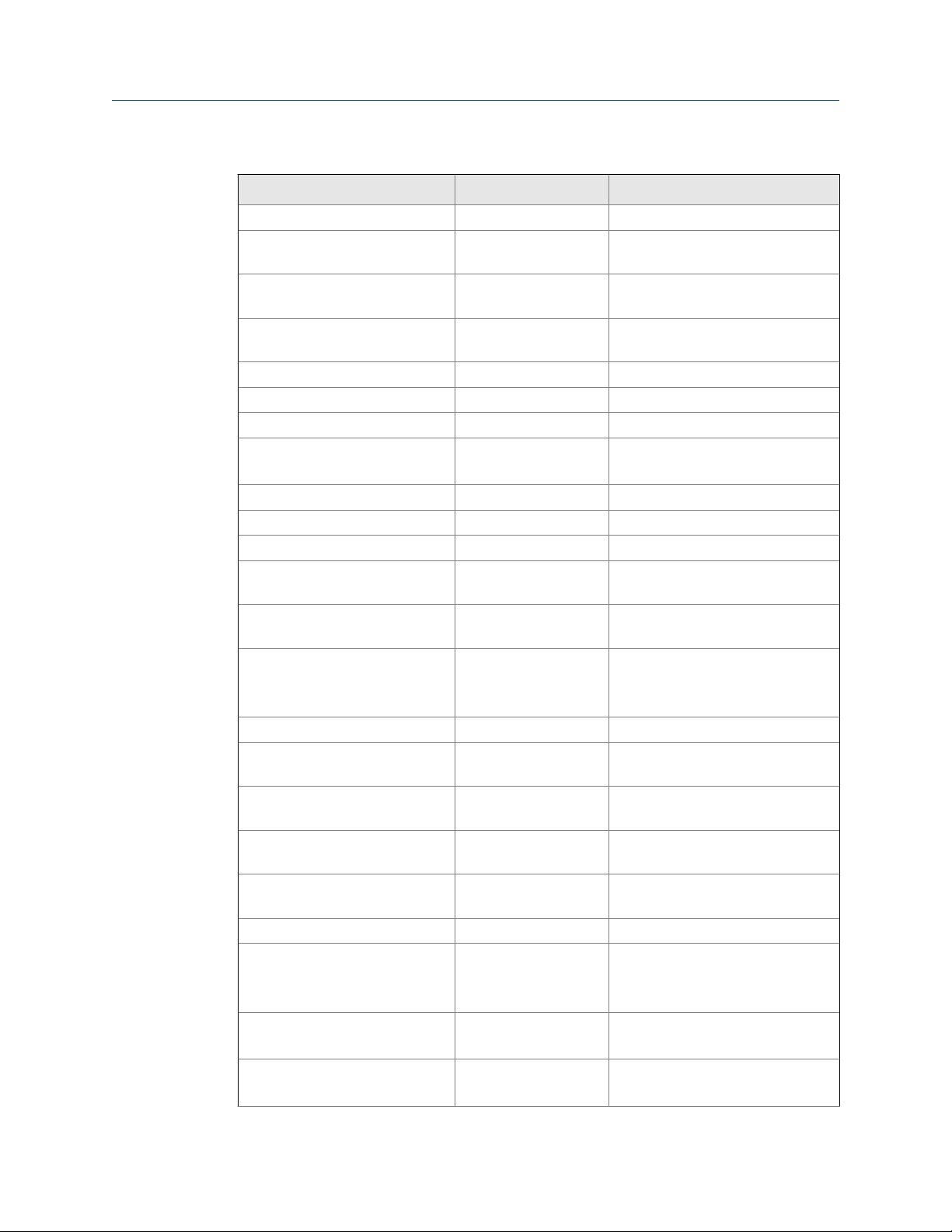

MON2020 Task List (continued)Table 1-1:

Task or Data Item Section(s) Menu Path [Keystroke]

Full-scale value (for input) Section 3.6 Hardware → Analog Inputs...

Generate a repeatability certificate

GPM liquid equivalent (on/off) Section 4.5.1 Application → Calculations → Con-

Height or area measurement

method

High alarm Section 4.7 Application → Limit Alarms → User...

(Analyzer) I.D. Section 4.1 Application → System...

Inhibit on-off times Section 4.3.4 Application → Timed Events... [F5]

Input(s) being used Section 3.6

Integration on-off times Section 4.3.4 Application → Timed Events... [F5]

Low alarm Section 4.7 Application → Limit Alarms → User...

Manage the GC's pressure Section 3.3 Hardware → EPC...

Mole percent (on/off) Section 4.5.1 Application → Calculations → Con-

Normalization (on/off) Section 4.5.1 Application → Calculations → Con-

Outputs being used Section 4.7

Peak width, on time Section 4.3.4 Application → Timed Events... [F5]

Relative density (on/off) Section 4.5.1 Application → Calculations → Con-

Response factor Section 4.2 Application → Component Data...

Response factor, percent deviation

Retention time, percent deviation Section 4.2 Application → Component Data...

Spectrum gain Section 4.3.3 Application → Timed Events... [F5]

Stream number(s) (for output) Section 4.7

Stream sequences skipped, number

Streams analyzed, number Section 4.1

Section 5.12 Logs/Reports → Repeatability Certif-

icate...

trol...

Section 4.2 Application → Component Data...

[F6]

Hardware → Analog Inputs...

Section 3.4

Section 3.7

Section 3.5

Section 4.2 Application → Component Data...

Section 3.7

Section 3.5

Section 4.1

Section 4.9

Section 4.9

Hardware → Discrete Inputs...

trol...

trol...

Application → Limit Alarms → User...

Hardware → Analog Outputs...

Hardware → Discrete Outputs...

trol...

[F6]

[F6]

[F6]

Application → Limit Alarms → User...

Hardware → Analog Outputs...

Hardware → Discrete Outputs...

Application → System...

Application → Streams...

Application → System...

Application → Streams...

16

Page 27

Getting started

MON2020 Task List (continued)Table 1-1:

Task or Data Item Section(s) Menu Path [Keystroke]

Streams analyzed, sequence Section 4.1

Section 4.9

Valve on/off times Section 4.3.1 Application → Timed Events... [F5]

Weight percent (on/off) Section 4.5.1 Application → Calculations → Con-

Wobbe value (on/off) Section 4.5.1 Application → Calculations → Con-

Zero value (for input) Section 3.6 Hardware → Analog Inputs...

1.5 Configuration files

Use the File menu to edit, save, and restore configuration files.

1.5.1 Edit a configuration file

To edit a configuration file, do the following:

Application → System...

Application → Streams...

trol...

trol...

Getting started

1

1. Disconnect from the GC.

2. Select Open Configuration File... from the File menu.

The Open dialog displays. Configuration files are saved with the .xcfg extension.

3. Locate and select the configuration file that you want to edit and click Open.

MON2020 opens the file in offline edit mode.

4. Use the Application and Hardware menu commands to edit the configuration file.

For more information on these commands, see Chapter 3 and Chapter 4.

5.

When finished editing the configuration file, click

configuration file and to leave offline edit mode.

1.5.2 Save the current configuration

Configuration files are saved with the .xcfg extension. To save a GC’s current configuration

to a PC, do the following:

1. Select Save Configuration (to PC)... from the File menu.

The Save as dialog displays.

to save the changes to the

2. Give the file a descriptive name or use the pre-generated file name and navigate to

the folder to which you want to save the file.

17

Page 28

Getting started

3. Click Save.

1.5.3 Import a configuration file

CAUTION!

The current configuration will be overwritten, so be sure to save it before importing a new or

previous configuration. See Section 1.5.2 to learn how to save a configuration.

CAUTION!

The GC must be in Idle mode while performing this task.

To import a configuration into a GC, do the following:

1. Select Restore Configuration (to GC)... from the File menu.

The Open dialog displays. Configuration files are saved with the .xcfg extension.

2. Locate and select the configuration file that you want to import and click Open.

The file’s data is loaded into the GC.

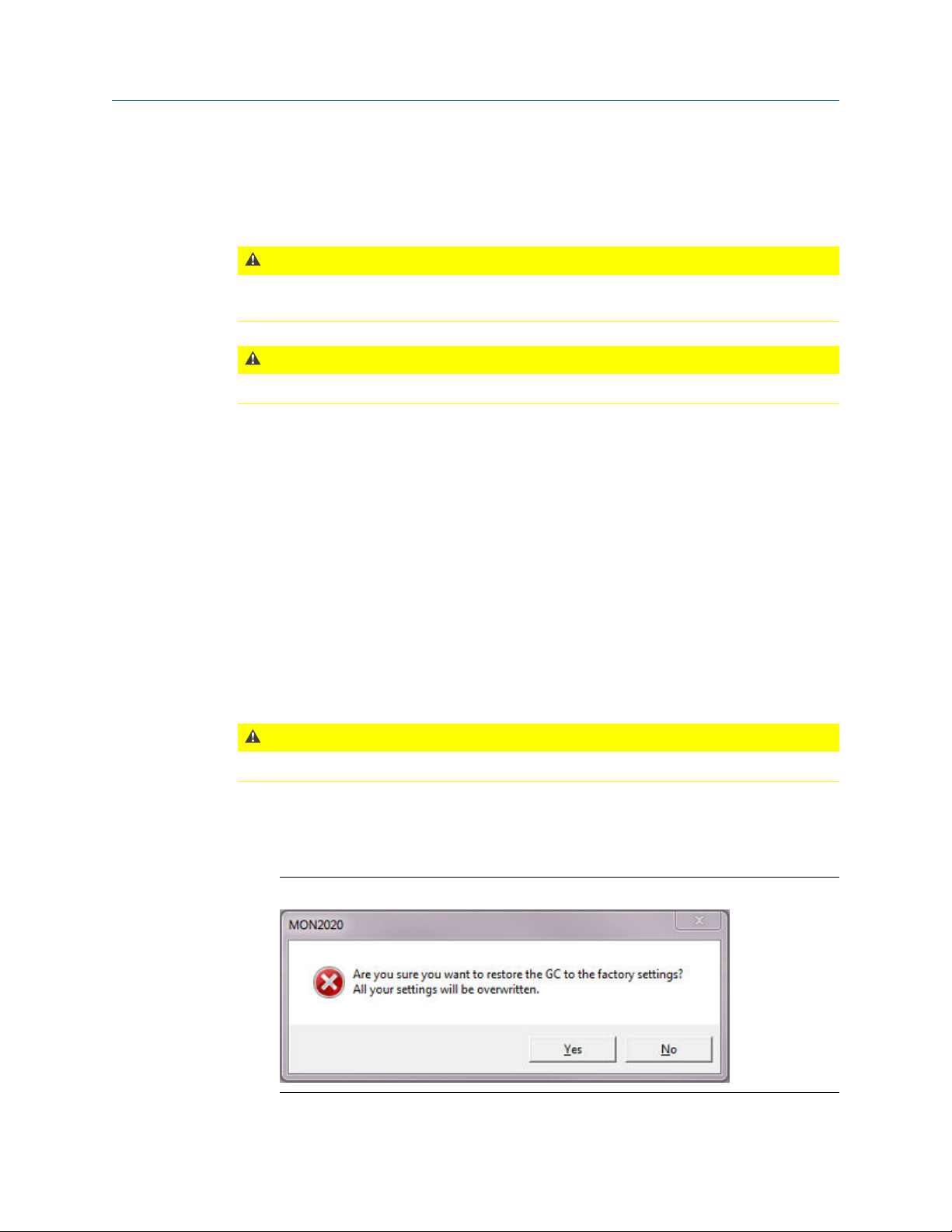

1.5.4 Restore the GC's factory settings

The GC’s default timed event, component data and validation data tables are created at

the factory and are not accessible by users. To restore these tables to their default values,

do the following:

CAUTION!

The GC must be in Idle mode while performing this task.

1. Select Restore to Factory Settings... from the File menu.

The following warning message displays:

Restore to Factory Settings warning messageFigure 1-5:

18

Page 29

Getting started

2. Click Yes.

MON2020 restores the default values to the GC’s data tables. When the process is

completed, a confirmation message displays.

3. Click OK.

1.6 Configure your printer

Select Print Setup... from the File menu to configure the settings for the printer

connected to your PC. These settings will apply to any print job queued from MON2020,

such as the reports that are configured by the Printer Control. See Section 5.7.3 for

information.

The settings available depend on the printer model. Refer to the printer manufacture’s

user manual for more information.

Note

Your new configuration will be cleared, i.e., the settings will return to the default values, when you

exit MON2020.

Getting started

1

1.7 Online help

Currently, the online help feature contains all user information and instructions for each

MON2020 function as well as the MON2020 system.

To access the online help, do one of the following:

• Press F1 to view help topics related to the currently active dialog or function.

• Select Help Topics from the Help menu to view the help contents dialog.

1.8 Operating modes for MON2020

The GC supports two different operating modes. Each mode allows the GC to analyze data

from a given number of detectors, streams, and methods, as detailed in below.

Operating Modes for MON2020Table 1-2:

Mode ID Number Detectors Supported Streams Supported Methods Supported

0 1 1 1

1 2 1 1

19

Page 30

Getting started

1.9 The Physical Name column

Most MON2020 hardware windows, such as the analog inputs or the valves, contain a

hidden column called Physical Name that lists the default name of the associated GC

device. It might be useful to know a device’s physical name while troubleshooting.

To view the hidden column, do the following:

1. Select Program Settings... from the File menu.

The Program Settings window displays.

2. Select the Show Physical Names checkbox.

3. Click OK.

The Physical Name column now will be visible on all windows that have the column,

such as the Heater window or the Valves window.

1.10 Select the GC’s networking protocol

MON2020 can connect to the GC using one of two networking protocols: PPP or SLIP. If the

version level of the GC’s firmware is 1.2 or lower, MON2020 should be configured to use

the SLIP protocol; otherwise, the PPP protocol should be used.

To select the GC’s networking protocol, do the following:

1. Select Program Settings... from the File menu.

The Program Settings window displays.

2. To use the PPP protocol, make sure the Use PPP protocol for serial connection (use SLIP

if unchecked) checkbox is selected; to use the SLIP protocol, make sure the Use PPP

protocol for serial connection (use SLIP if unchecked) checkbox is not selected.

3. Click OK.

1.11 The context-sensitive variable selector

The MON2020 method for selecting variables for calculations and other purposes is based

on a simple, self-contained system.

20

Page 31

Getting started

Example of a context-sensitive variable selectorFigure 1-6:

The context-sensitive variable selector consists of a first-level element, called the context

element, that is followed by a series of tiered, drop-down lists. The options available from

the drop-down lists depend upon the context element.

The following example explains how to use the context-sensitive variable selector to select

a user alarm variable:

1. Click on the second-level drop-down list.

The full list of available streams displays.

2. Select the stream you want to use for the alarm.

3. Click the third-level drop-down list.

Getting started

1

The full list of available user alarm variables displays.

4. Select the variable you want to use for the alarm.

If there are components associated with the variable, the fourth-level drop-down

list will display.

5. If displayed, click the fourth-level drop-down list.

The full list of available components displays.

6. Select the component you want to use for the alarm.

7. Click [Done].

The context-sensitive variable selector closes and the variable displays in the Variable

field.

21

Page 32

Getting started

22

Page 33

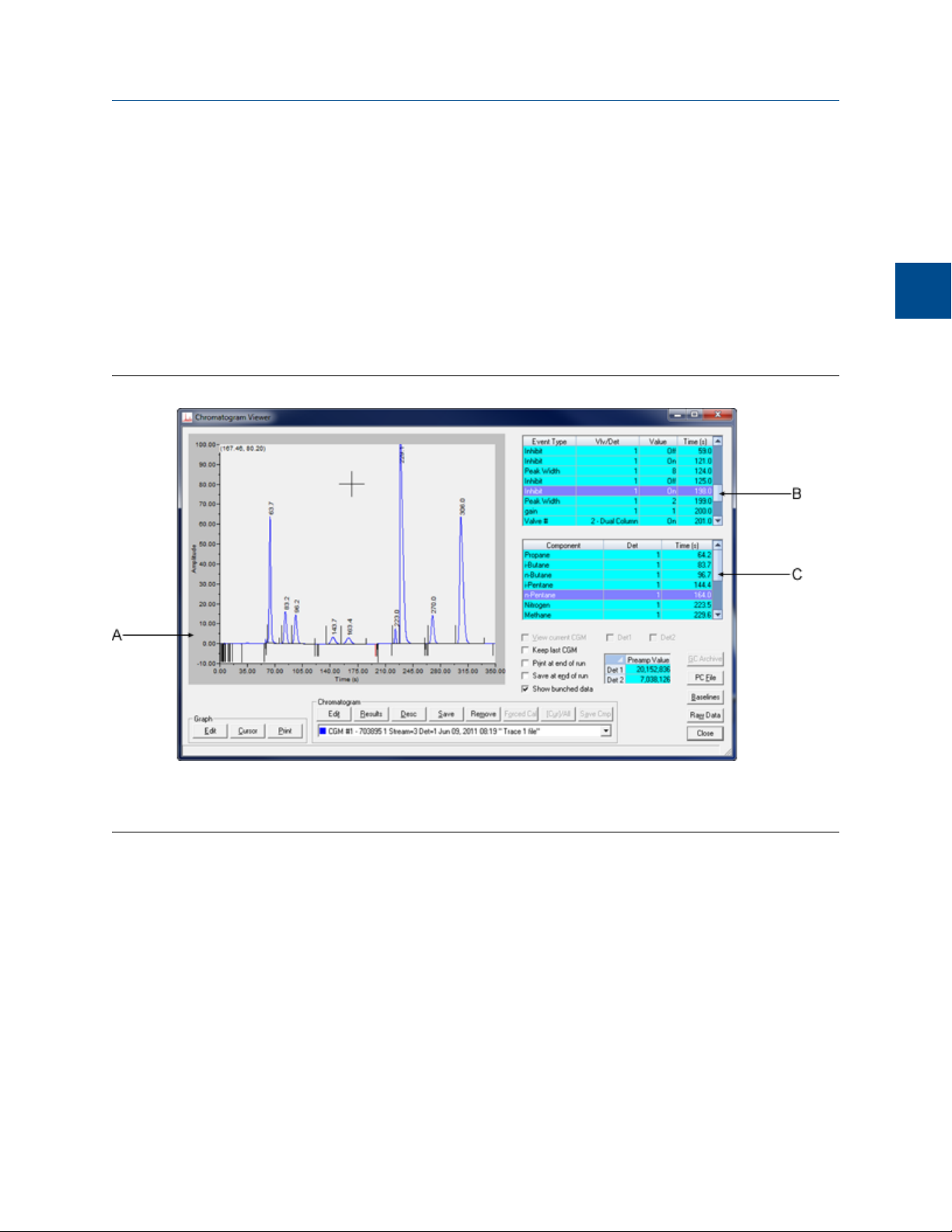

2 Chromatograph

When it comes to viewing and managing chromatograms, MON2020 is flexible and

straightforward. This chapter shows you how to access the Chromatogram Viewer, as well

as how to use the viewer to display, print, and manipulate live, archived, or saved

chromatograms. There is no limit to the number of archived and saved chromatograms

that can be displayed at once. The Chromatogram Viewer can display all three types of

chromatograms together, alone, or in any combination.

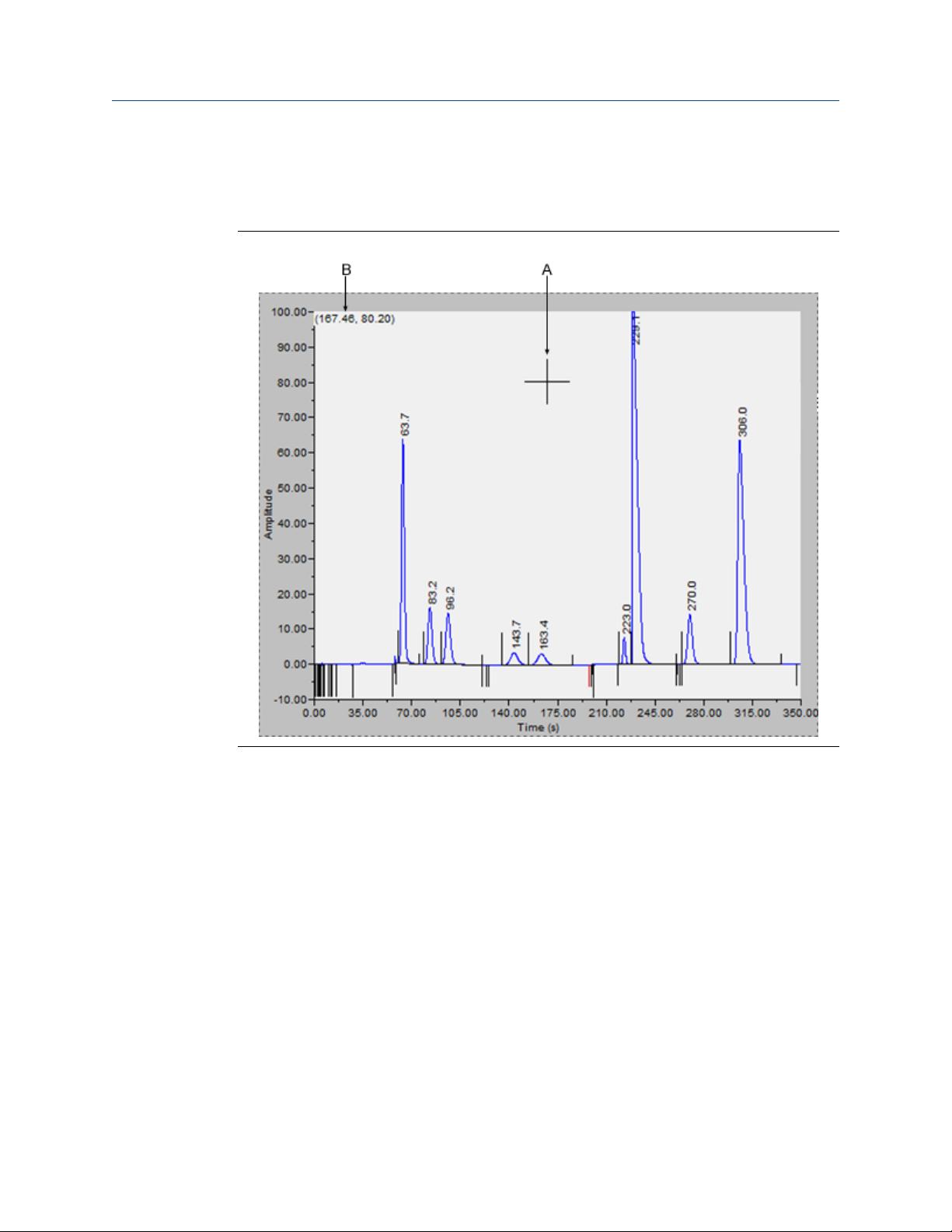

The Chromatogram ViewerFigure 2-1:

Chromatograph

Chromatograph

2

A. Chromatogram window

B. Time events table

C. Component data table

A chromatogram displays in the chromatogram window. If the chromatogram contains one

trace, the Det1 checkbox is automatically checked; if the chromatogram contains two

traces, the Det1 and Det2 checkboxes are automatically checked. To remove a trace,

uncheck its detector checkbox.

Each trace that displays is color-coded; use the Chromatogram pull-down menu to select a

specific trace.

23

Page 34

Chromatograph

Chromatogram pull-down menuFigure 2-2:

The list of GC events associated with the production of the chromatogram, along with

each event’s status and time, displays in the Timed Events table to the right of the

chromatogram display window. The Component Data table, to the lower right of the

chromatogram display window, lists the components measured during the analysis. These

tables are updated in real-time, just as the chromatogram is.

Note

By default, the timed events and component data tables are configured to scroll to and highlight the

next occurring event in the analysis cycle. To disable this feature, right-click on one of the tables and

uncheck the Auto Scroll option on the pop-up menu.

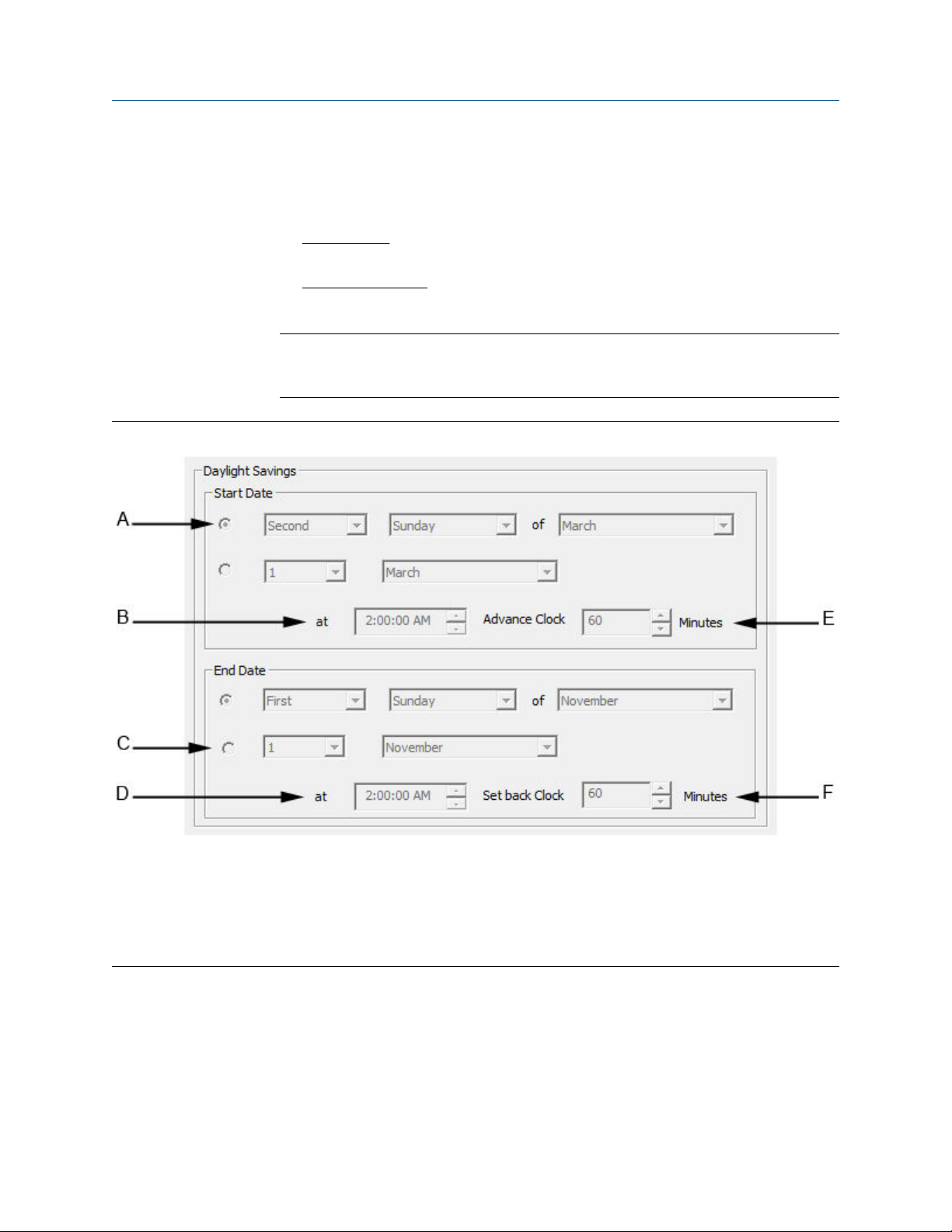

2.1 The Chromatogram Viewer