Emerson VLS**435A, Mobrey VLS Series, VLSK*135A, VLSK*335A, VLSH**35A Operating Instructions Manual

...Page 1

Mobrey™ Series VLS

Vibrating Level Switch

Operating Instructions

IP4001, Rev CA

March 2018

Page 2

Mobrey Series VLS

March 2018

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

1.0 Introduction

1.1 Overview

Mobrey vibrating rod level switches are suitable for low and high level indication of granules and

powders with a minimum 0.05 kg/dm

Dust Ex versions are available for using the instrument in an explosion-proof environment.

The vibrating rod is a mechanical resonant system, excited and kept in resonance by an electronic unit.

The medium to be measured, when reaching the vibration rod end, will damp the vibration. The change

in vibration intensity is sensed by an electronic unit, which, upon the elapse of the delay time, actuates

the output circuit.

Operating Manual

IP4001, Rev CA

3

density such as cement, lime, sand, grain, feed, sugar, etc.

1.2 Accessories

User manual (IP4001)

2 off 3-pole terminal blocks

1½-in, sealing, for BSP only

2 off M20x1.5 cable glands

1.3 Order code

K Standard model with 1 x SPDT alarm relay

(1)

H

High temperature model with 1 x SPDT relay (not available with Extended Cable option)

B R 1½-in. BSPT mounting

N 1½-in. NPT mounting

1 Standard length rod, 207 mm insertion length

3 Extended rod, 300-3000 mm insertion length

4 Cable extended, 1000-20000 mm insertion length

1Z 20-255 Vac / Vdc, no hazardous area approval

3 Aluminum Alloy housing, powder coated

9 As code 3, but with Remote Electronics

5A 20-250 Vac / 20-50 Vdc, ATEX Dust Certification II 1/2 D

1. Only for standard and rod extended versions.

2

/**** State rod or cable extension length in mm

Page 3

Operating Instructions

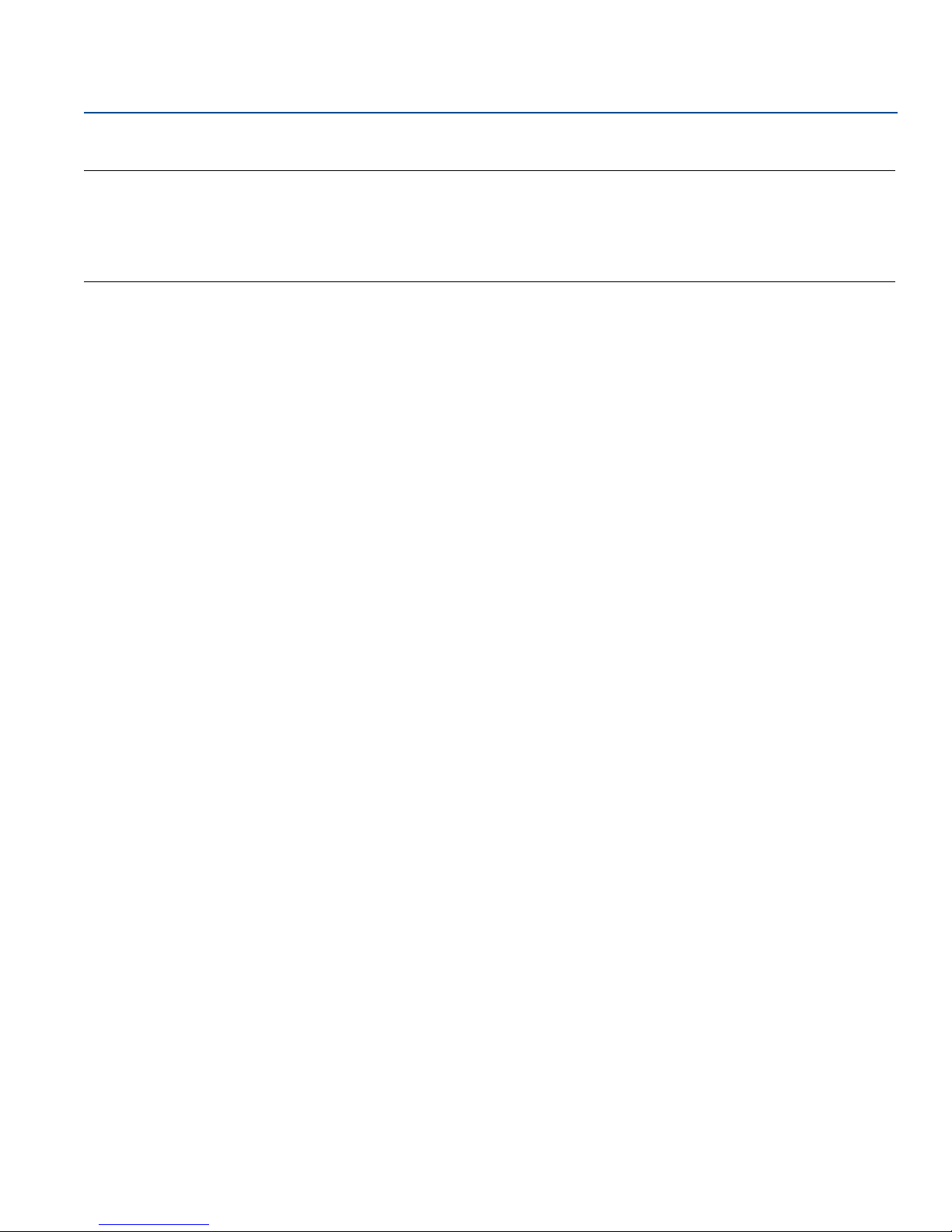

Standard version

Extended rod version

Cable extended version

~90

116

L=207

133

S=46

A

B

C

~90

A

B

C

S=46

116

133

L=300-3000

L=1000-2000

133

~90

A

B

C

S=46

116

IP4001, Rev CA

1.4 Dimensions

Figure 1-1. Mobrey Series VLS Dimensions

Mobrey Series VLS

March 2018

A. 2 off M20x1.5 conduit entries

B. 2 off NPT

C. 1

Dimensions are in mm.

1

1

/2-in. conduit entries

/2-in. BSP or NPT threaded process connection

2.0 Installation

When installed in a potentially explosive atmosphere, reference should be made to IP4001/SI.

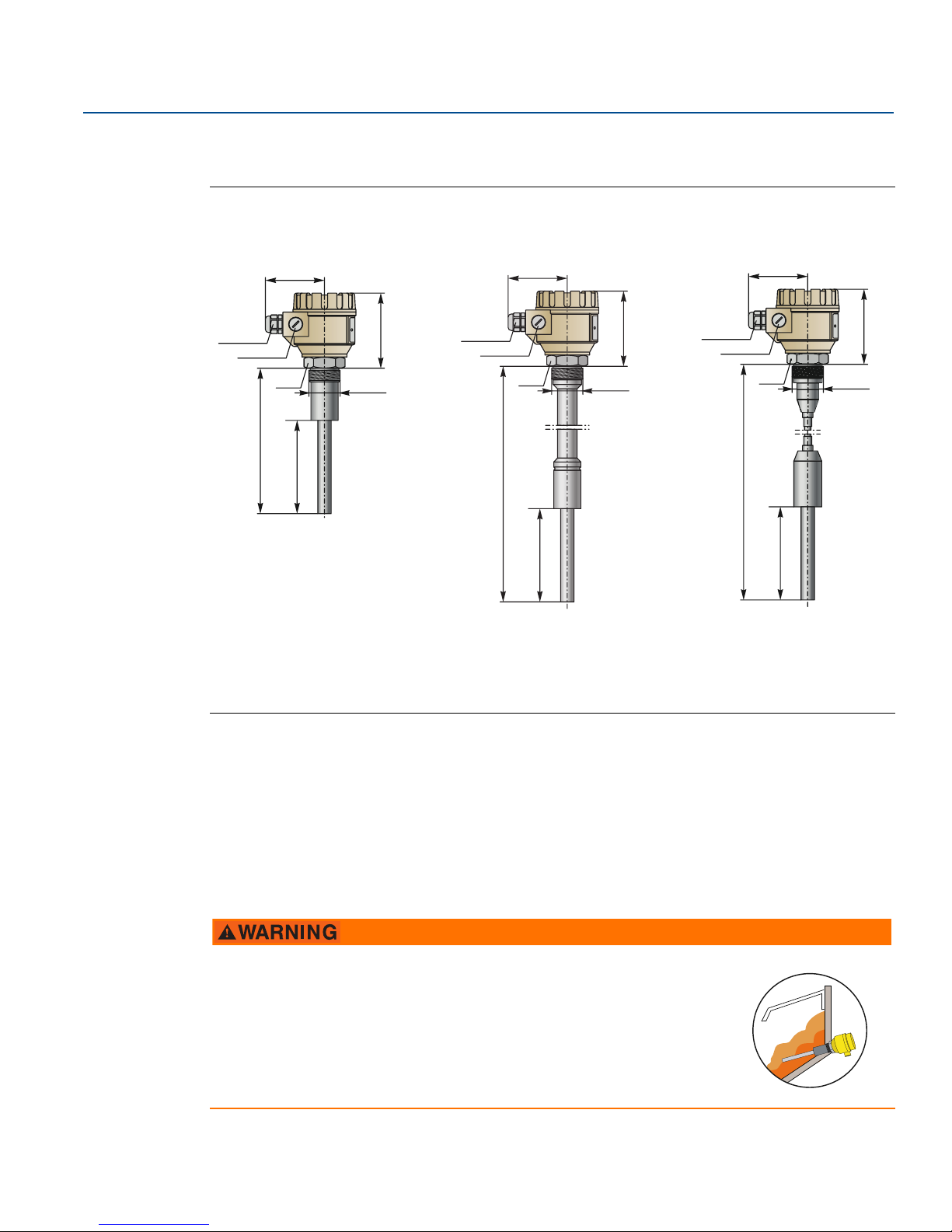

Prior to installation, it is advisable to check the switching function for proper adjustment on a sample

quantity of material (see “Adjustments” on page 6). The unit may not work with mediums that are within

the specified density range, but have very large granules or have too little friction.

Handle the device with great care, especially the sensing probe. Any impact on

the sensing probe may ruin its resonance system. A protective shield should be

installed (see inset, right) if the probe is exposed to falling material or an

excessive mechanical load.

3

Page 4

Mobrey Series VLS

Incorrect

Correct

Incorrect

Correct

March 2018

Operating Manual

IP4001, Rev CA

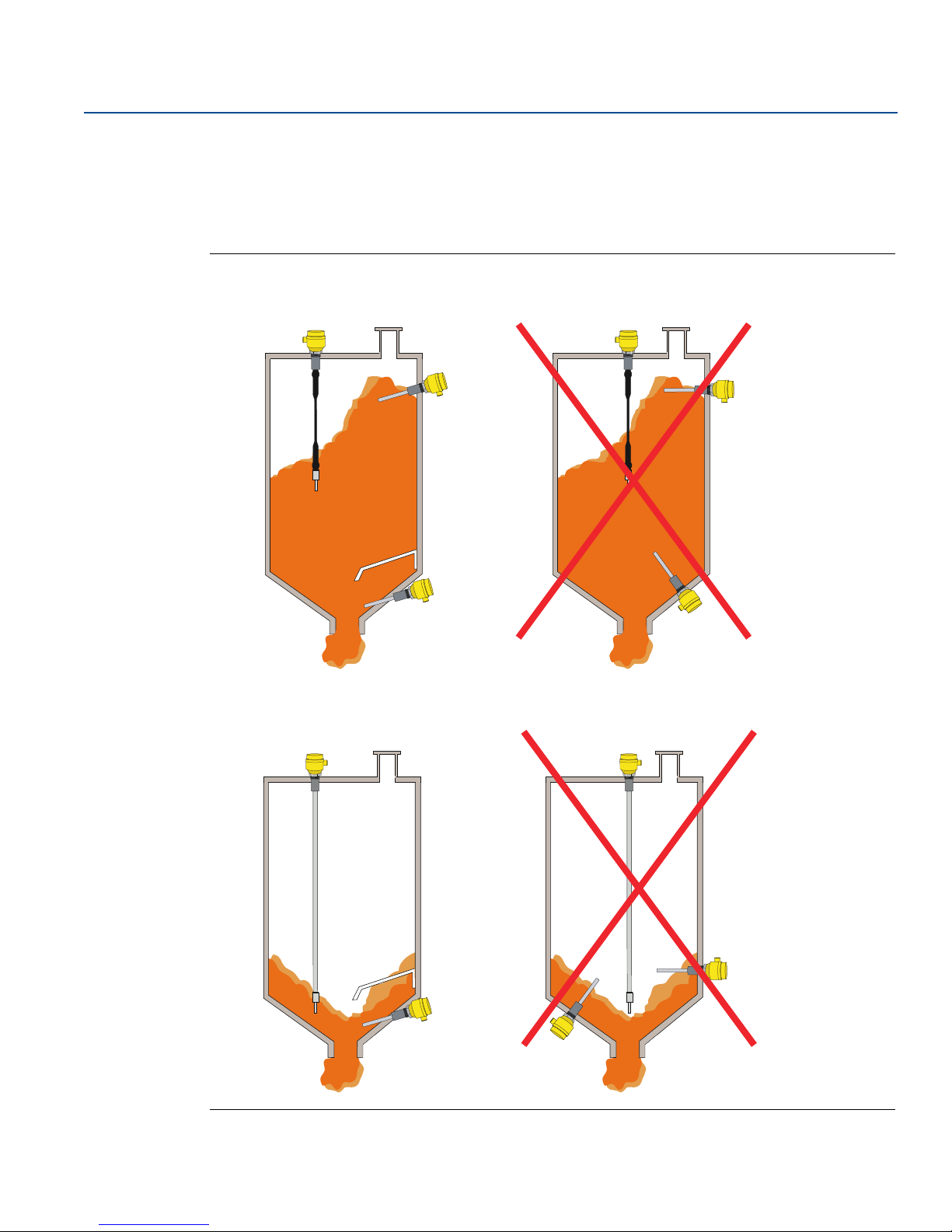

Screw in the device by its hexagon neck. After screwing tight the process connection, the housing can be

rotated (up to maximum of 300°), to adjust the cable gland to the required position.

It might be necessary to install the device at an offset level position relative to the switching level actually

required, taking into account caving or arching of the material in the silo (see Figure 1-2).

Figure 1-2. Examples of Correct and Incorrect Installations

4

Page 5

Operating Instructions

Incorrect

F = 500 N.

M = 100 Nm.

M = 100 Nm.

F = 45 kN.

Standard version

VLS**1

Extended rod version

VLS**3

Cable extended version

VLS**4

IP4001, Rev CA

With powder level detection, the device should be installed at an inclination exceeding the angle of

repose (or vertically in case of high level detection), to prevent powder deposition on the vibrating rod

that might substantially reduce the self-cleaning effect. Avoid mounting the rod in a recess (Figure 1-3)

Figure 1-3. Avoid Mounting Rod in Recess

Mobrey Series VLS

March 2018

In the case of tanks that are likely to be exposed to intense vibrations, necessary provisions shall be made

for damping the vibrations acting on the device (e.g. vibration damping inserts made of rubber have to

be applied).

Figure 1-4. Maximum Torque and Force

5

Page 6

Mobrey Series VLS

March 2018

3.0 Adjustments

The enclosure must not be opened when the equipment is electrically energized.

Remove the top cover of the housing to access the connection terminals and adjusting switches.

In case of Dust Ex instruments, the housing cover can only be opened after the removal of the cover

securing clamp.

Do not remove the wire from terminal pin 1 (Figure 1-5 on page 7) as it is an internal connection.

For grounding the unit, use the PE grounding screw terminal PE.

After correct installation, the electrical connections established, the housing cover fitted and secured,

the device is ready for operation. The switched-on state is indicated by the lighting of the LED.

The DENSITY setting (switch A) is to be set in accordance with the material density:

LOW position

– Recommended for loose and light materials with density below 0.1 kg/dm

– Represents small energy and amplitude of vibration as well as great sensitivity of detection.

Operating Manual

IP4001, Rev CA

3

.

HIGH position

3

– Recommended for (thick and heavy) materials with density over 0.1 kg/dm

.

– Represents vibration with great energy and amplitude, and small sensitivity of detection.

The instrument may not switch correctly in mediums with a density of less than 0.05 kg/dm

3

or with very

small internal friction.

To obtain FAIL SAFE alarm (switch C), use the de-energized state of the output as an alarm. A power

breakdown will then also be considered to be an alarm (see Table 1-1 on page 7).

The delay (switch B) is to be selected to comply with requirements of the process control technology the

unit is used for. Standard (switching delay is ~5 seconds) or fast response (switching delay is ~2 seconds)

can be selected.

Note

When operating the switches, standard electrostatic discharge precautions should be taken to avoid

damaging the instrument.

6

Page 7

Operating Instructions

C

N

N

L1

123

456

IP4001, Rev CA

Figure 1-5. Electrical Connections

Mobrey Series VLS

March 2018

L1

PE

PE

Table 1-1. Operation

Power Probe

A B CStatus LED

250VAC

8A/AC1

NO

NC

Not vibrating

(covered)

Fail-safe

mode

Low

LED Relay

Green

Energized

On

Fails

Vibrating

(free)

Low or

high

High

Low

High

Red

De-energized

Red

De-energized

Green

Energized

Not lit

De-energized

7

Page 8

Mobrey Series VLS

March 2018

4.0 Maintenance

Mobrey Series VLS devices do not require maintenance on a regular basis. In some instances, however,

the vibrating section may need a cleaning from deposited material. This must be carried out gently,

without harming the vibrating section of the vibrating rod.

Repairs during or after the guarantee period are affected by Emerson. Equipment sent back for repairs

must always be cleaned or neutralized (disinfected) by the user.

5.0 Specifications

Table 1-2. Specifications for Standard, Rod Extended, and Cable Extended Versions

Category Standard Rod extended Cable extended

Probe length 207 mm 0.3 to 3 m 1 to 20 m

Wetted-parts materials

Housing material Aluminum: Powder paint coated

Process connection 1½-in. BSP or 1½-in. NPT

Operating Manual

IP4001, Rev CA

1.4571 Probe: 1.4571

Cable: PE coated

Operating temperature ranges See Figure 1-6 and Table 1-3

Maximum pressure (absolute) 25 bar (2.5 MPa) 6 bar (0.6 MPa)

Minimum medium density

Response time (selectable)

Supply voltage (universal)

Power consumption 2.5 VA, 2 W

Electrical connections

Output SPDT (potential free), 250 Vac, 8 A, ac 1

Ingress protection IP67 (NEMA6) EN 60529:2001

Electrical protection Class I. (to be grounded)

Ex protection mark ATEX: II 1/2 D Ex ta/tb IIIC T90 °C… T170 °C Da/Db

Weight (with extension) 1.88 kg 1.88 kg (+1.4 kg/m) 1.88 kg (+ 0.6 kg/m)

Storage conditions

1. May depend on friction and granular size of the medium.

(1)

for normal types M20x1.5 plastic glands for cable Ø 6 to 12 mm,

2 pcs. plug-in type terminal blocks for 0.25 to 1.5 mm2 wire cross section

0.05 kg/dm (maximum granular size: 10 mm)

Not vibrating (covered): < 1.8 seconds or 5±1.5 seconds

Vibrating (free): < 2 seconds or 5±1.5 seconds

Normal type: 20…255 Vac/Vdc

Ex type: 20…250 Vac (50/60 Hz) or 20…50 Vdc

2 pcs. M20x1.5 cable glands with ta lIIC protection type or

internal thread for 2x ½-in NPT cable protection pipe

Ambient temperature range: -35°C to +60 °C

Relative humidity: 98% (maximum)

8

Page 9

Operating Instructions

TA (°C)

T

P

(°C)

60

20

35

-30

-30

50

75

110

160

IP4001, Rev CA

Figure 1-6. Ambient (TA) Versus Process (TP) Temperatures

Table 1-3. Thermal Data

Process temperature (Tp)

(EPL Da – category 1D)

Ambient air temperature (Ta)

(EPL Db – category 2D)

Maximum surface

temperature (process

connection)

Maximum surface

temperature (T)

T Class

1. The process temperature can reach +95 °C for a maximum period of one hour.

Mobrey Series VLS

March 2018

VLS**435A VLSK*(1/3)35A VLSH**35A

+60 °C +70 °C +80 °C...

+95 °C

+60 °C +50 °C +60 °C +60 °C +50 °C +60 °C +50 °C +35 °C

+85 °C +85 °C +95 °C +85 °C +85 °C +95 °C +95 °C +135 °C

+85 °C +85 °C +95 °C +85 °C +85 °C +95 °C +110 °C +160 °C

T90°C T100°C T90°C T100°C T115°C T170°C

+60 °C +70 °C +95°C +110 °C +160 °C

(1)

Minimum ambient air temperature (Ta) = –30 °C

Minimum process temperature (Tp) = –30 °C

9

Page 10

Mobrey Series VLS

March 2018

Operating Manual

IP4001, Rev CA

10

Page 11

Operating Instructions

IP4001, Rev CA

Mobrey Series VLS

March 2018

11

Page 12

Operating Instructions

IP4001, Rev CA

March 2018

Head Office

Emerson Automation Solutions

Rosemount Measurement Ltd.

158 Edinburgh Avenue

Slough, Berks., SL1 4UE, UK

+44 (0)1753 756600

+44 (0)1753 823589

Infocentral@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Emerson Terms and Conditions of Sale are available upon request

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Mobrey and Rosemount are marks of the Emerson family of companies.

All other marks are the property of their respective owners.

© 2018 Emerson. All rights reserved.

Loading...

Loading...