Page 1

Instruction Manual

P/N MMI-20011276, Rev. A

March 2008

Micro Motion

®

Series 3000 MVD Transmitters

Net Oil Computer Supplement

Page 2

©2008, Micro Motion, Inc. All rights reserved. ELITE and ProLink are registered trademarks, and MVD and MVD Direct Connect

are trademarks of Micro Motion, Inc., Boulder, Colorado. Micro Motion is a registered trade name of Micro Motion, Inc., Boulder,

Colorado. The Micro Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. All other trademarks

are property of their respective owners.

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Communication tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Manuals and manual use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 NOC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Introduction to the NOC system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.1 NOC system components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Installation architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.3 Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.4 Required well data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.5 Water cut determination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 NOC application features and options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.1 Temperature correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.2 Pressure compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.3 Shrinkage factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.4 Gas carry-under – Transient Bubble Remediation (TBR) . . . . . . . . . . . . 11

2.3.5 Gas measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.6 Gas measurement with liquid carry-over – Transient Mist

Remediation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.7 Recalculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Planning the configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 NOC measurement terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3 Using the Display and Menu System . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Startup and Well Performance Measurement screen . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Menu systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.1 Accessing management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3.2 Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Using the function buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Using the cursor control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5.1 Selecting from a list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5.2 Changing a variable value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5.3 Cursor control example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6 Scientific notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Net Oil Computer Supplement i

Page 4

Contents

Chapter 4 Configuring the NOC Application . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Well Performance Measurement menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Basic configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4 Setting up a water cut monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.5 Setting up pressure compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.5.1 Obtaining the external pressure value . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.5.2 Setting up pressure compensation for oil density and water density . . . . 30

4.5.3 Setting up pressure compensation for pressure effect . . . . . . . . . . . . . . 30

4.6 Setting up Transient Bubble Remediation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7 Setting up gas measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.8 Setting up Transient Mist Remediation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.9 Performing density determination procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.9.1 Performing a density determination for water . . . . . . . . . . . . . . . . . . . . . 32

4.9.2 Performing a density determination for oil . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 5 Operation Mode – NOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2 Well testing overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.1 Running a well test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.2 Viewing well test data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.3 Time periods for average, minimum, maximum, and total values . . . . . . 47

5.2.4 Other activity during a well test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.5 Recalculating well test data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3 Continuous mode measurement overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.1 Viewing Continuous mode measurement data . . . . . . . . . . . . . . . . . . . . 51

5.3.2 Pausing and resuming Continuous mode measurement. . . . . . . . . . . . . 52

5.3.3 Resetting, saving, and managing Continuous mode time periods. . . . . . 53

5.3.4 Other activity during Continuous mode measurement . . . . . . . . . . . . . . 54

5.3.5 Viewing archive records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.6 Recalculating Continuous mode data . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.4 Changing modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 6 Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2 NOC status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Appendix A Series 3000 Menu Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.2 Startup display and menu access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3 View menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.4 Management menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

ii Micro Motion® Series 3000 MVD Transmitters

Page 5

Chapter 1

Before You Begin

1.1 About this manual

This manual explains how to configure and use the Net Oil Computer application on the

Micro Motion

This manual does not provide information on basic installation, configuration, and use of the

Model 3500 or Model 3700 transmitter. For basic platform information and instructions, see the

manual entitled Micro Motion

Use Manual.

1.2 Communication tools

You can communicate with a Series 3000 device using any of the following communication tools:

• The local display

®

Series 3000 MVD platform (a Model 3500 or Model 3700 MVD transmitter).

®

Series 3000 MVD Transmitters and Controllers: Configuration and

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

• ProLink II v2.5 and higher (ProLink II v2.7 recommended)

• 375 Field Communicator with the appropriate DD:

To configure or use the NOC application, you must use either the local display or ProLink II v2.7.

This manual focuses on the use of the local display. Detailed menu flowcharts for the local display are

provided throughout this manual and in Appendix A.

For general information on installing ProLink II and connecting to the Series 3000 platform, see the

manual entitled Micro Motion

Use Manual.

1.3 Manuals and manual use

Table 1-1 lists the basic steps required to install, set up, configure, and use the Series 3000 device with

the NOC application. Table 1-1 also identifies the manual in which the associated information is

provided. Note that for some tasks you will need to use both manuals.

Micro Motion 3000 Mass flo v7 DD v2

®

Series 3000 MVD Transmitters and Controllers: Configuration and

Net Oil Computer Supplement 1

Page 6

Before You Begin

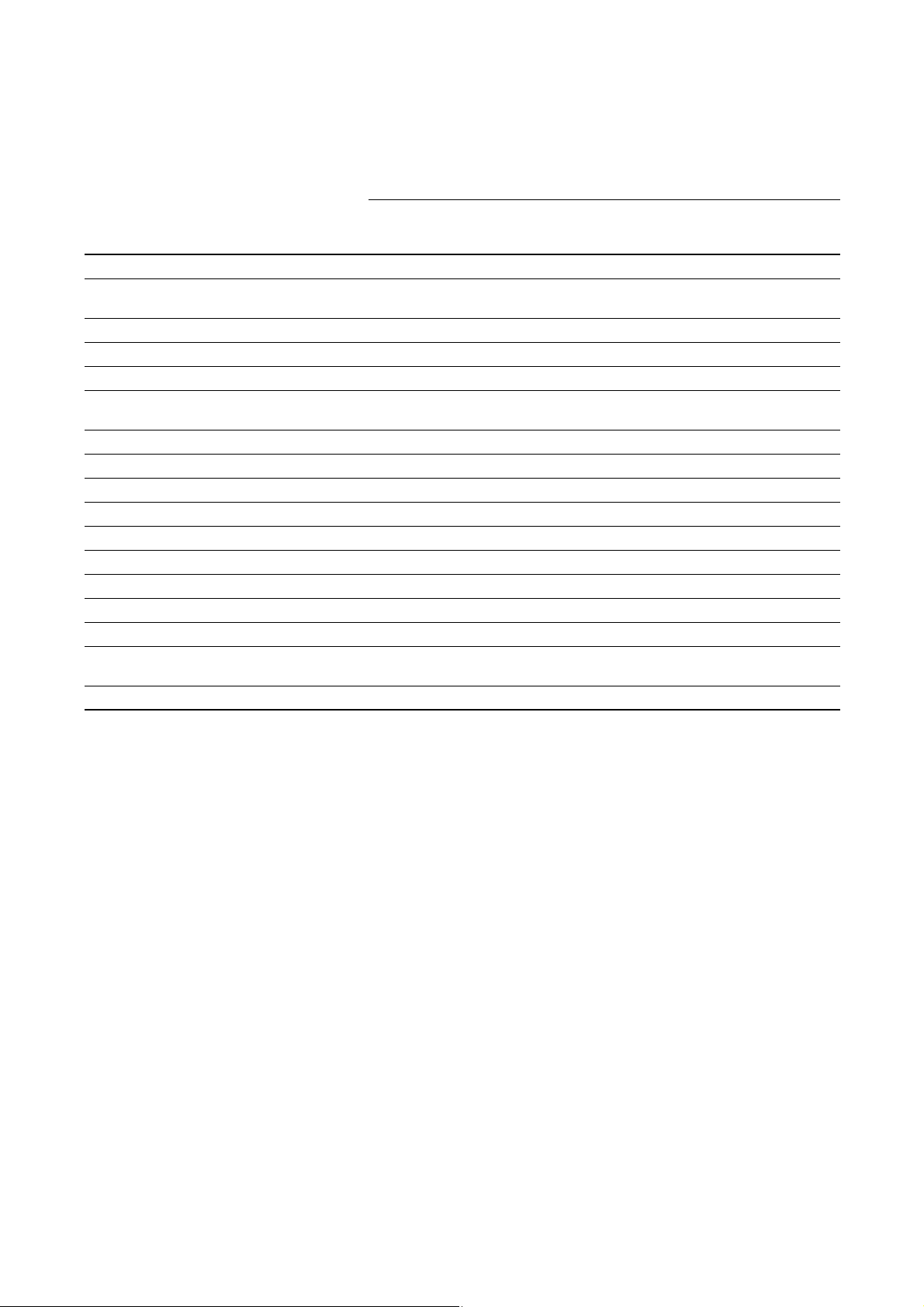

Table 1-1 Tasks and manual location

Manual

Series 3000 MVD Transmitters:

Step

1 Install the Series 3000 device ✓

2 Wire the Series 3000 device to the

sensor

3Wire I/O ✓

4 Set up digital communications ✓

5 Start up the system ✓

6 Learn to use the display and menu

system

7 Configure security and language ✓

8 Configure system data ✓

9 Configure inputs ✓

10 Configure digital communications ✓

11 Configure the NOC application ✓

12 Configure outputs ✓✓

13 Configure NOC status alarm severity ✓✓

14 Perform optional configuration ✓

15 Operate the NOC application ✓

16 Perform calibrations and meter

verification

17 Troubleshoot ✓✓

Net Oil Computer Supplement

(this manual)

✓

Series 3000 MVD Transmitters and

Controllers:

Configuration and Use Manual

✓

✓

1.4 Micro Motion customer service

For customer service, phone the support center nearest you:

• In the U.S.A., phone

800-522-MASS (800-522-6277) (toll-free)

• In Canada and Latin America, phone +1 303-527-5200

•In Asia:

- In Japan, phone 3 5769-6803

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

Customers outside the U.S.A. can also email Micro Motion customer service at

International.MMISupport@EmersonProcess.com.

2 Micro Motion® Series 3000 MVD Transmitters

Page 7

Chapter 2

NOC Overview

2.1 Overview

This chapter discusses various topics that should be reviewed and considered before beginning

configuration of the Series 3000 platform with the NOC application. Topics include:

• Introduction to the NOC system – see Section 2.2

- NOC system components – see Section 2.2.1

- Installation architecture – see Section 2.2.2

- Operation modes – see Section 2.2.3

- Water cut determination and required well data – see Section 2.2.5

• NOC application features and options – see Section 2.3

- Temperature correction – see Section 2.3.1

- Pressure compensation – see Section 2.3.2

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

- Shrinkage factors – see Section 2.3.3

- Transient Bubble Remediation – see Section 2.3.4

- Gas measurement – see Section 2.3.5

- Transient Mist Remediation – see Section 2.3.6

- Recalculation – see Section 2.3.7

This chapter also includes:

• A list of questions that should be answered before beginning configuration – see Section 2.4.

• A list of NOC measurement terms and definitions – see Section 2.5.

2.2 Introduction to the NOC system

“NOC” is an abbreviation of “Net Oil Computer.” In the present context, NOC is a software option

that can be purchased for three members of the Series 3000 family: the Model 3500 panel-mount

transmitter, the Model 3500 rack-mount transmitter, and the Model 3700 field-mount transmitter.

When paired with a Micro Motion sensor installed on the oil/water leg of a two-phase separator or the

oil leg of a three-phase separator, the NOC application can provide real-time measurements of water

cut. Alternatively, the NOC application can receive water cut data from an external water cut monitor

(see Section 2.2.5 for information on water cut options). When the water cut value is known, net oil

volume flow and net water volume flow can be calculated.

If desired, real-time gas measurement may be implemented by installing a meter on the gas leg. The

Series 3000 platform then receives gas flow data via its frequency input.

Net Oil Computer Supplement 3

Page 8

NOC Overview

2.2.1 NOC system components

The Series 3000 MVD NOC system requires:

Optional components include:

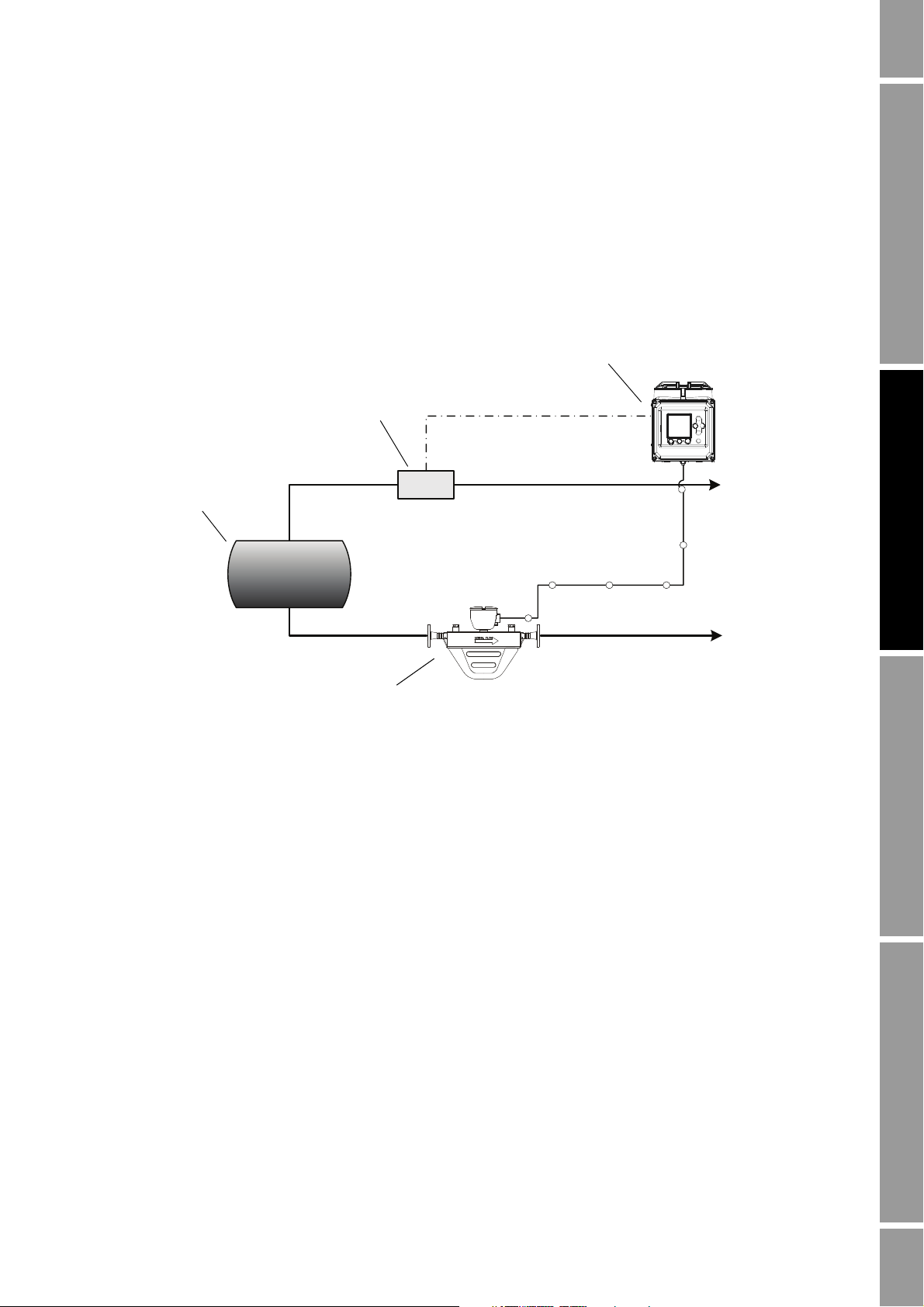

2.2.2 Installation architecture

The Series 3000 MVD NOC system is designed for installation with a three-phase separator, a

two-phase separator, or a variety of compact separators. See Figures 2-1 through 2-3.

• One Series 3000 MVD transmitter with the Net Oil Computer software option

• One Micro Motion sensor installed on the oil/water or oil leg

• A meter on the gas leg. This meter can be used for gas measurement with or without Transient

Mist Remediation:

- If only gas measurement will be implemented, either a third-party meter or a

Micro Motion meter may be used. Gas measurement must be based on mass flow.

- If Transient Mist Remediation will be implemented, a Micro Motion meter must be used.

• A water cut monitor on the oil/water or oil leg.

• A pressure sensor on the oil/water or oil leg. Data from the pressure sensor enables pressure

compensation (see Section 2.3.2).

Note: These figures do not illustrate all possible combinations.

4 Micro Motion® Series 3000 MVD Transmitters

Page 9

NOC Overview

F

Separator

Series 3000 platform

Flowmeter (gas)

Micro Motion sensor

Oil/water leg

Gas leg

Gas flow rate (Frequency input)

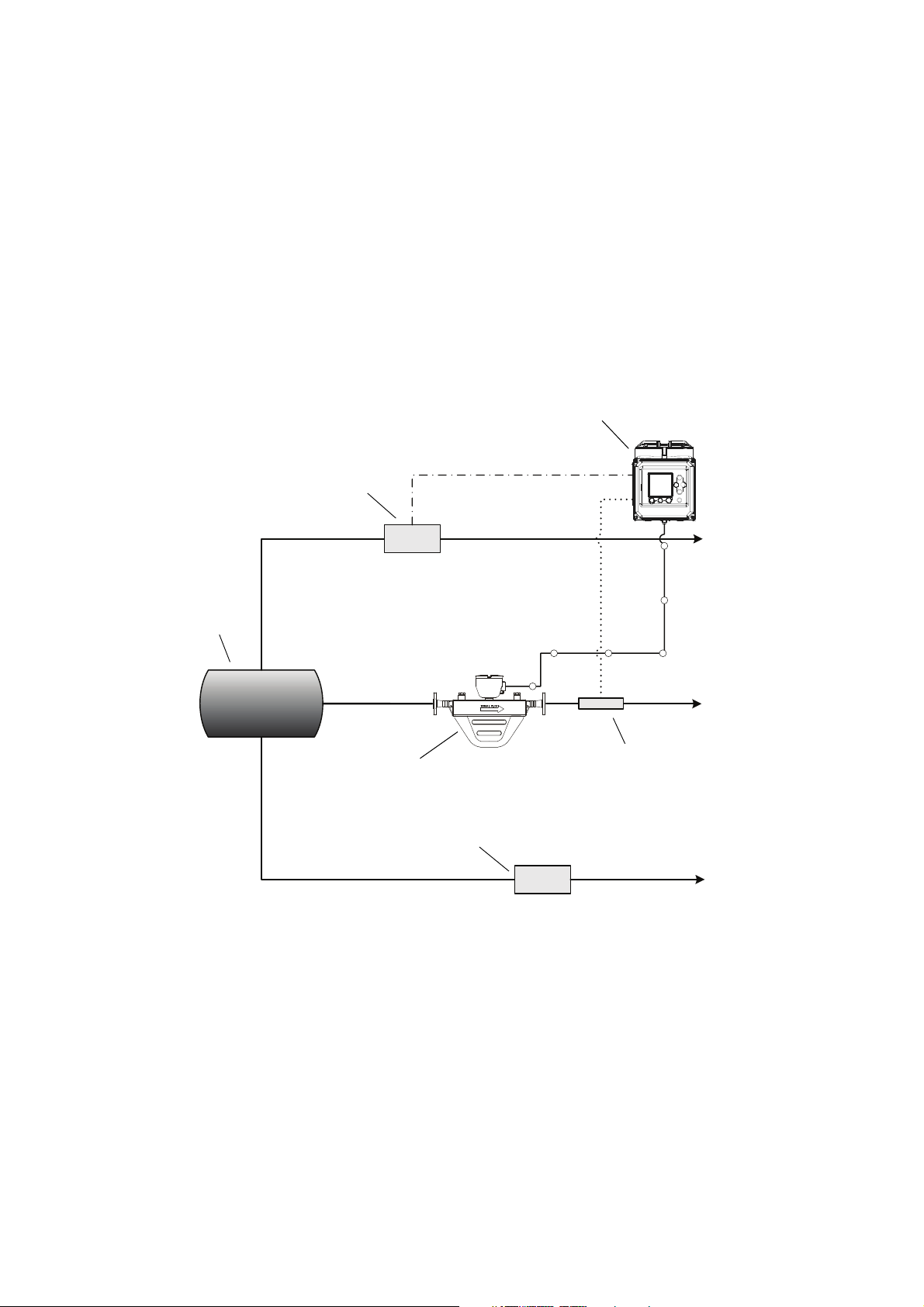

In Figure 2-1:

Figure 2-1 NOC system with two-phase separator

• The NOC system is implemented with a two-phase separator.

• An optional gas meter is installed, and gas data is sent to the Series 3000 device via the

frequency input.

• Density-based water cut data is used.

• Because there is no pressure sensor, pressure compensation is not applied.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

Net Oil Computer Supplement 5

Page 10

NOC Overview

F

F

Series 3000 platform

Separator

Micro Motion sensor

Oil leg

Gas leg

Water leg

Gas flow rate (Frequency input)

Flowmeter (water)

Water cut monitor

Flowmeter (gas)

Water cut data

(HART)

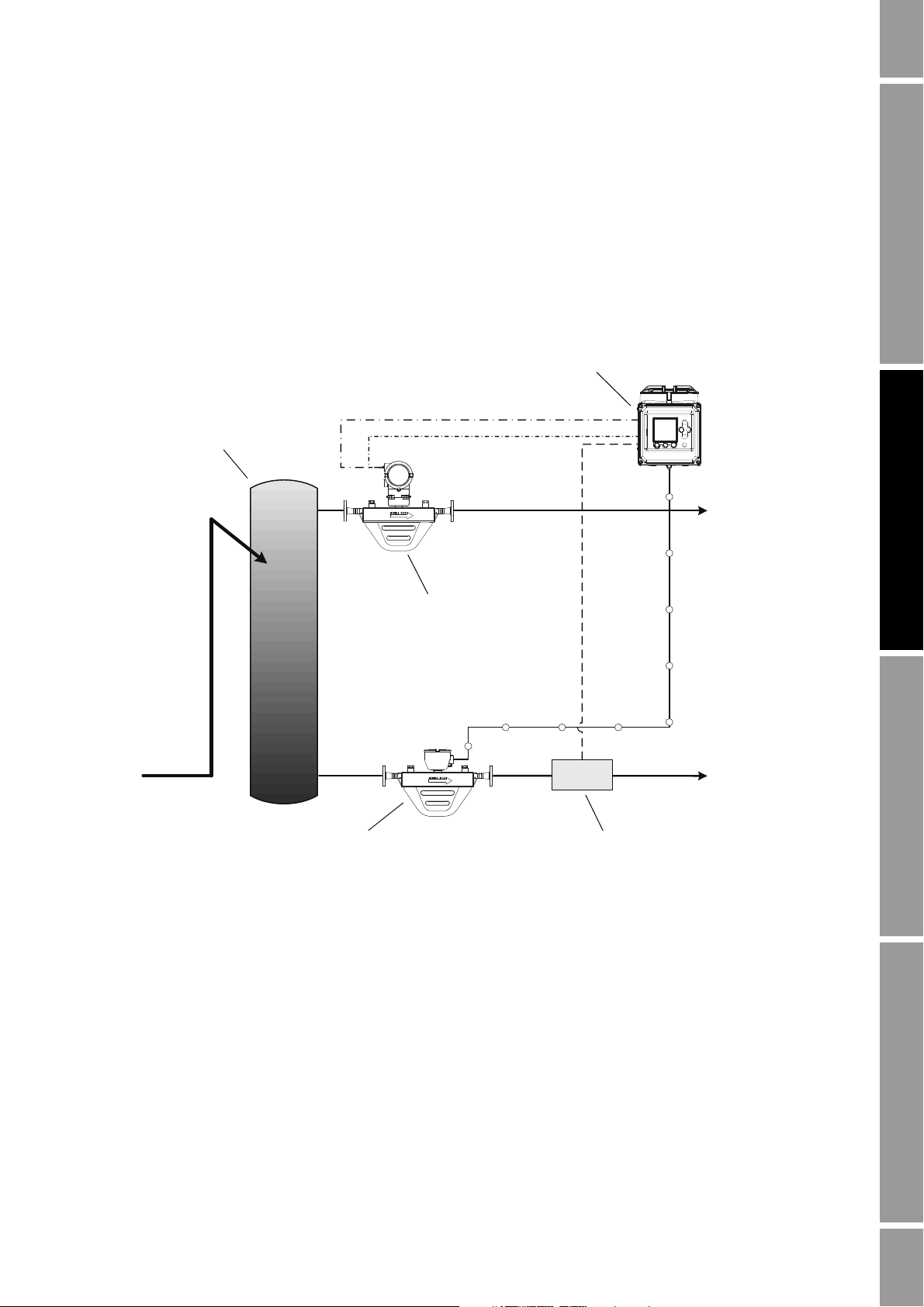

In Figure 2-2:

Figure 2-2 NOC system with three-phase separator

• The NOC system is implemented with a three-phase separator.

• An optional gas meter is installed, and gas flow rate data is sent to the Series 3000 device via

the frequency input.

• A meter is installed on the water leg, but the Series 3000 device does not monitor or record

flow data from this source.

• A water cut monitor is installed on the oil leg. The NOC system can be configured to use either

density-based water cut data or data from the water cut monitor.

• Because there is no pressure sensor, pressure compensation is not applied.

6 Micro Motion® Series 3000 MVD Transmitters

Page 11

NOC Overview

P

GLCC

Micro Motion sensor

Gas leg

Oil/water leg

Micro Motion

TMR gas meter

Pressure sensor

Series 3000 platform

Pressure data

(HART)

Gas flow rate data (Frequency input)

TMR drive gain data (HART)

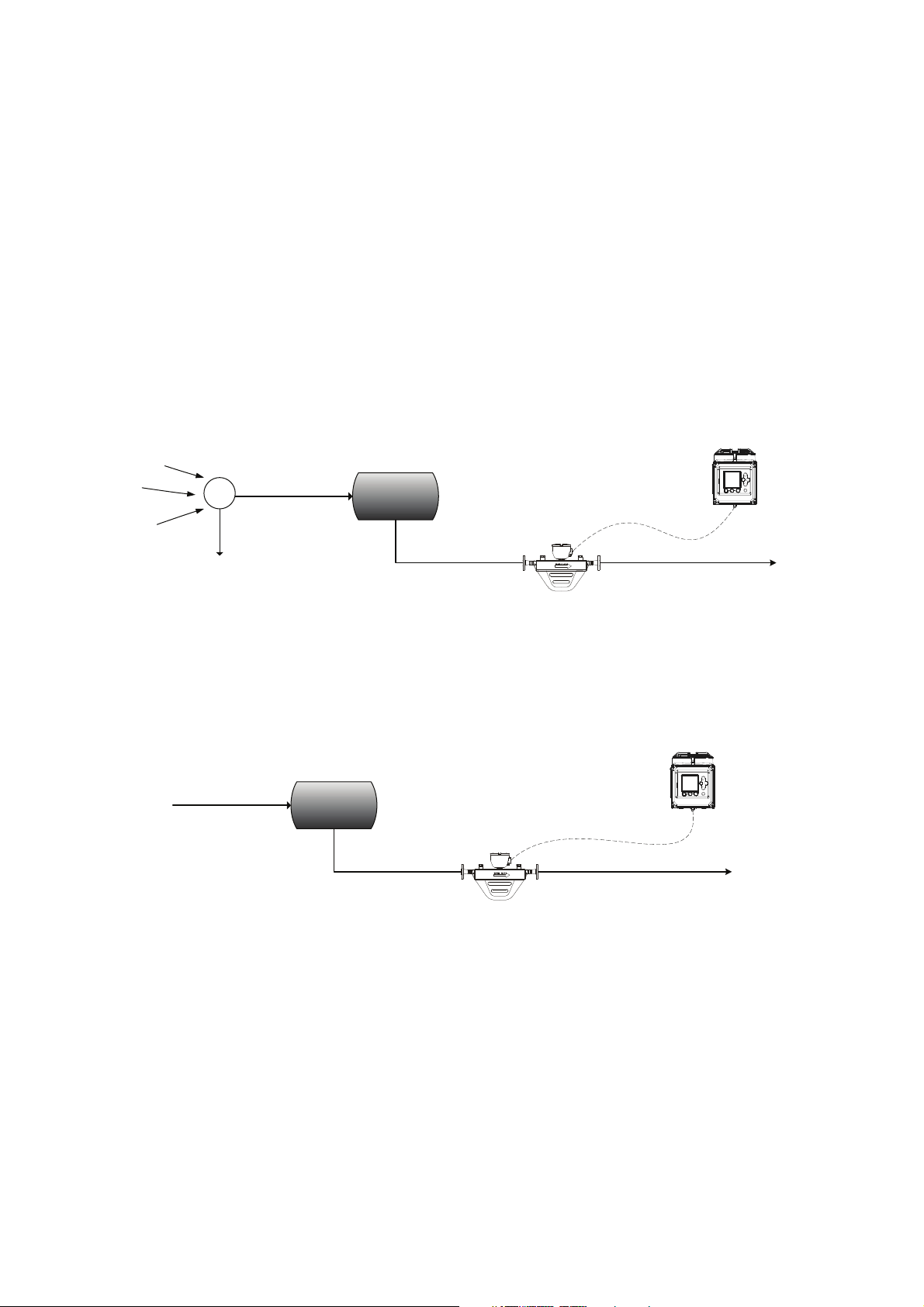

In Figure 2-3:

Figure 2-3 NOC system with GLCC

• The NOC system is implemented with a Gas-Liquid Cylindrical Cyclone™ (GLCC).

• A gas meter is installed on the gas leg. In this example, a Micro Motion meter is used, and it

provides gas flow rate data for gas measurement, and drive gain data for Transient Mist

Remediation via a HART connection.

• Density-based water cut data is used.

• A pressure sensor is installed on the oil/water leg. This enables pressure compensation.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

Net Oil Computer Supplement 7

Page 12

NOC Overview

From production wells

One well to

test separator

Other wells to

production separator

Micro Motion sensor

Series 3000 platform

To production separatorLiquid leg

Micro Motion sensor

Series 3000 platform

To production separatorLiquid leg

From single well

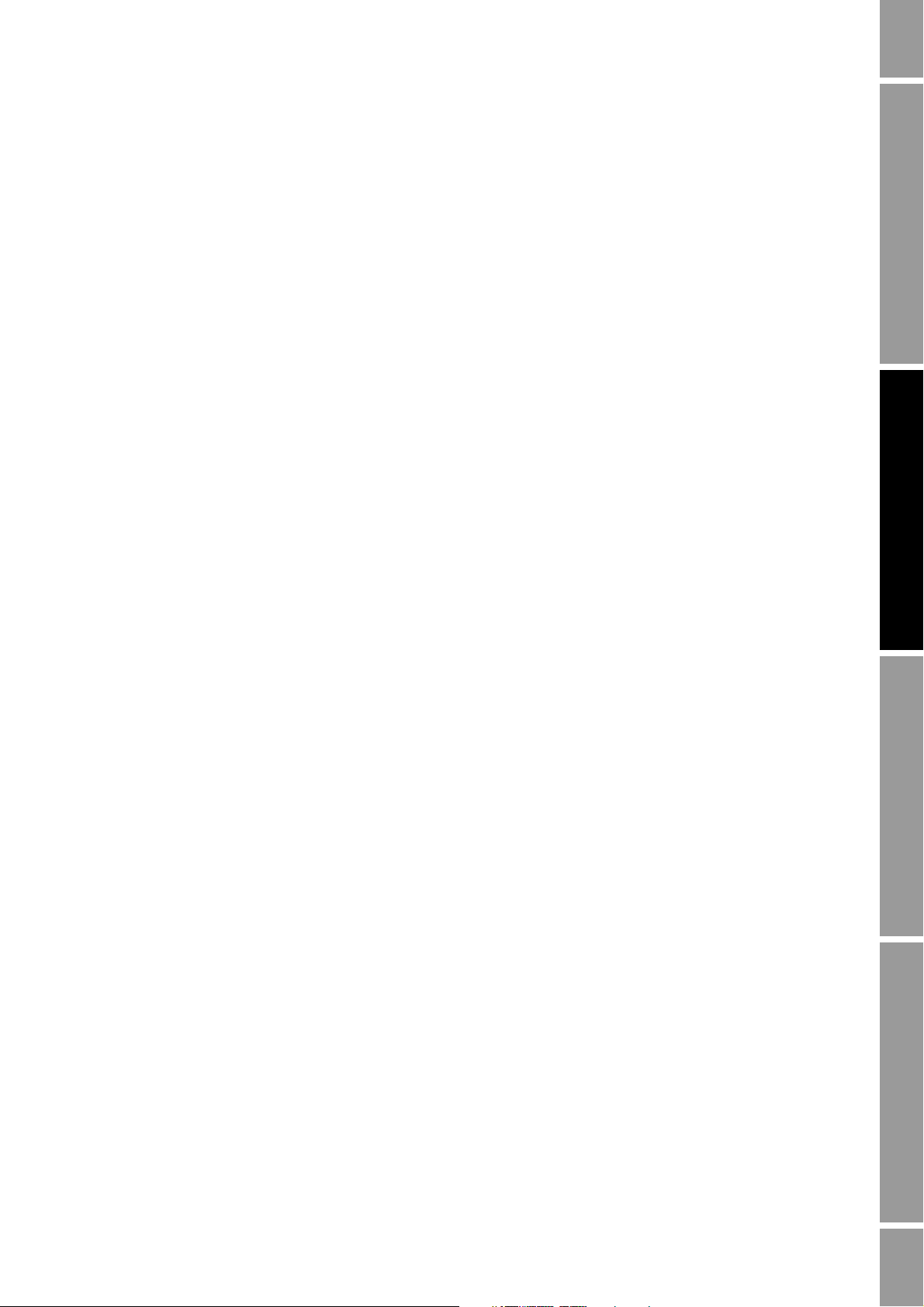

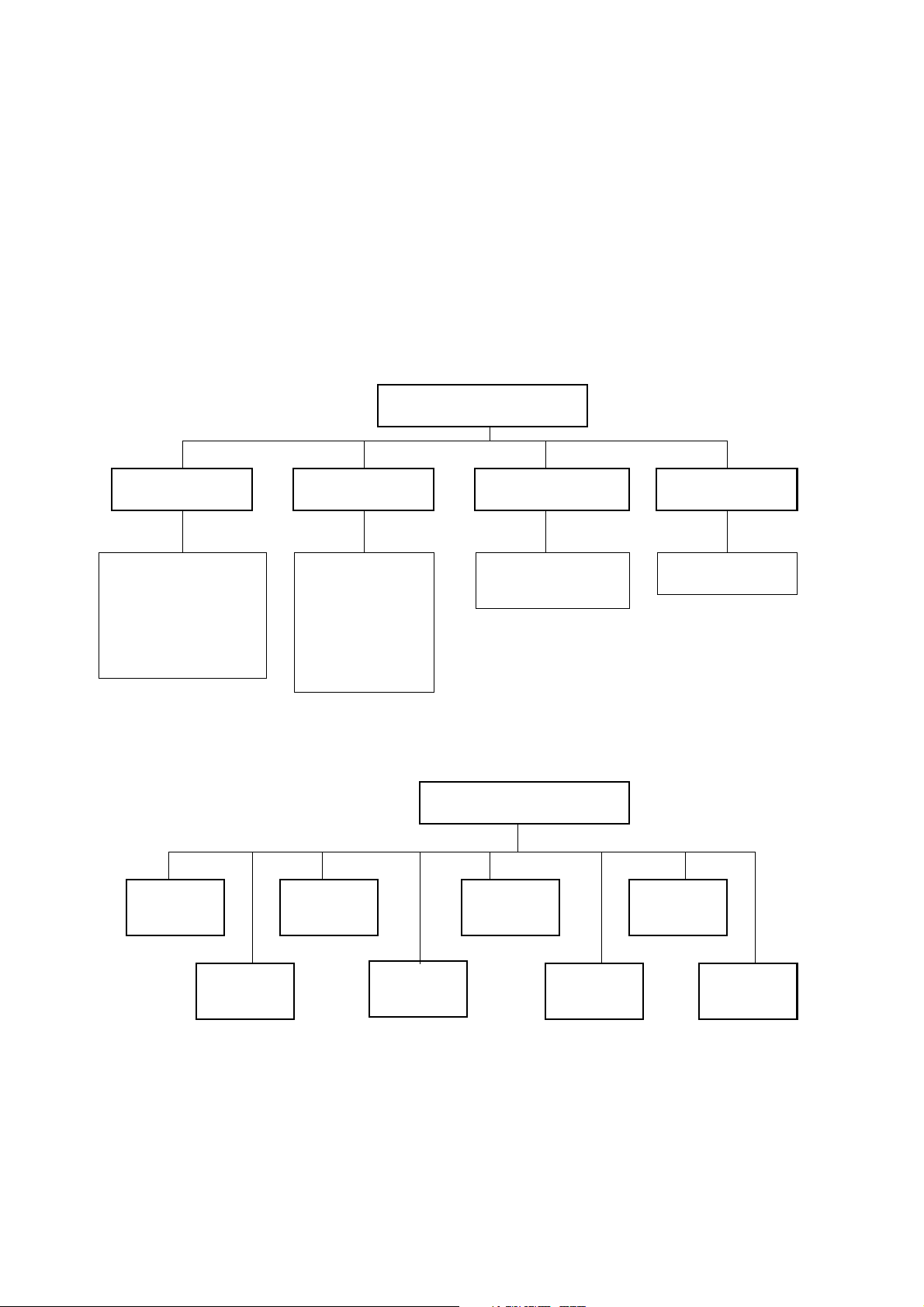

2.2.3 Operation modes

The NOC system operates in either Well Test mode or Continuous mode:

• In Well Test mode, well tests can be performed on up to 48 wells. A manifold system is used to

ensure that output from a single well is routed through the test separator and the NOC system.

See Figure 2-4. The system can save data for three tests per well. If more than three tests are

run on a specific well, older tests are overwritten as required.

• In Continuous mode, one well is measured continuously. See Figure 2-5. The NOC system

supplies current flow data plus running averages and totals.

After initial configuration, you can change the operation mode. However, changing modes affects

current measurement and data collection. Before changing modes, see Section 5.4.

Figure 2-4 Well Test mode

Figure 2-5 Continuous mode

8 Micro Motion® Series 3000 MVD Transmitters

Page 13

NOC Overview

Water cut

D

LDO

–

D

WDO

–

-----------------------=

2.2.4 Required well data

The following information is required for each well that will be tested or measured by the

NOC system:

If the density values are not known:

• Density of dry oil from this well, at reference temperature and reference pressure. To ensure

the most accurate net oil data, the density should be based on live oil rather than dead oil.

“Live oil” refers to crude oil at line pressure.

• Density of the water from this well, at reference temperature and reference pressure.

• You can take samples of produced oil and produced water, perform laboratory analysis, and

enter the results into the well configuration.

• You can perform an in-line density determination for oil, water, or both (see Section 4.9).

During in-line density determination, the appropriate process fluid (water or live oil) is routed

through the sensor, density values are averaged over a user-specified time period, and these

values are converted to reference temperature. The water cut calculation uses these average

values for D

and DW.

O

• You can enter approximate values at initial configuration, begin measurement, and recalculate

NOC data at a later time when well-specific density values are known (see Section 2.3.7).

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

2.2.5 Water cut determination

There are two options for determining water cut:

• Density-based – The NOC application derives the water cut by applying the following

equation:

where:

- D

= Density of the liquid (oil/gas mixture), as measured by the Micro Motion sensor

L

- D

- D

= Density of produced oil (user-supplied value)

O

= Density of produced water (user-supplied value)

W

• Water cut monitor (external water cut) – A water cut monitor is used to measure the process

stream directly, and the Series 3000 transmitter retrieves the water cut data via a HART

connection. Accordingly, a HART connection between the primary mA output on the NOC

platform and the water cut monitor is required.

Net Oil Computer Supplement 9

Page 14

NOC Overview

RefDensity

Applied

RefDensity

Configured

Pressure

Operating

Pressure

Reference

–()× CompensationFactor×=

2.3 NOC application features and options

This section describes several features and options of the NOC application.

2.3.1 Temperature correction

Temperature correction refers to the conversion of data collected at the observed process temperature

to the equivalent values at reference temperature. The NOC application automatically applies

temperature correction to NOC data, using the temperature data from the RTD built into the

Micro Motion sensor.

2.3.2 Pressure compensation

The Series 3000 MVD NOC application can perform two types of pressure compensation:

• Pressure compensation for pressure effect

• Pressure compensation for oil density and water density

Pressure compensation for pressure effect

Pressure effect is defined as the change in sensor flow tube sensitivity due to the change of process

pressure away from calibration pressure. The Series 3000 transmitter can adjust the sensor’s raw mass

or density measurements to compensate for this pressure effect.

To implement pressure compensation for pressure effect, the following information is required:

• Flow factor – the percent change in the flow rate per psi. To obtain this value, see the sensor’s

product data sheet and reverse the sign.

• Density factor – the change in fluid density, in g/cm3/psi. To obtain this value, see the sensor’s

product data sheet and reverse the sign.

• Calibration pressure – the pressure at which the flowmeter was calibrated (which therefore

defines the pressure at which there will be no pressure effect). Refer to the calibration

document shipped with your sensor. If the data is unavailable, use 20 psi.

Note: For many sensors, the pressure effect is so small that pressure compensation is not required. See

the sensor’s product data sheet.

Pressure compensation for oil density and water density

Due to the presence of gas bubbles, the density of produced oil and water can be affected by pressure.

If pressure compensation for oil density and water density is enabled, the configured reference

densities of oil and water are adjusted as shown in the equation below.

where:

• The compensation factor for oil is the value configured for Pressure Compensation for Oil

Density, entered as the density change per unit of pressure change.

• The compensation factor for water is 3.0E

–6

g/cm3/psi.

10 Micro Motion® Series 3000 MVD Transmitters

Page 15

NOC Overview

Drive gain (%)

Density (measured)

Drive gain (actual)

2.3.3 Shrinkage factors

“Shrinkage” is a decrease in volume caused by the evaporation of solution gas, by the flashing of

volatile natural gas, or by lowered temperature during the crude oil stabilization process. By

estimating the shrinkage during oil storage or transport, you can estimate sellable oil based on

upstream volume measurement.

The NOC application includes two shrinkage factors: one for oil and one for water. The net oil flow

rate and net water flow rate measured by the NOC application are automatically multiplied by the

corresponding shrinkage factor. By default, the shrinkage factors are set to 1.0, resulting in no

compensation for shrinkage.

Use your standard methods to determine the appropriate shrinkage factors, taking into consideration

the location of the Micro Motion sensor in your process.

2.3.4 Gas carry-under – Transient Bubble Remediation (TBR)

Transient Bubble Remediation (TBR) is a standard feature of the NOC application. It is used to

provide more accurate process data during intermittent gas carry-under – gas entrainment in the liquid

stream. TBR is applicable only when the density-based water cut is used.

Note: If a water cut monitor is used to measure water cut directly, see the vendor documentation for

suggestions on maintaining accuracy through transient bubble conditions.

When the density-based water cut is used to calculate net oil, transient bubbles have a negative effect

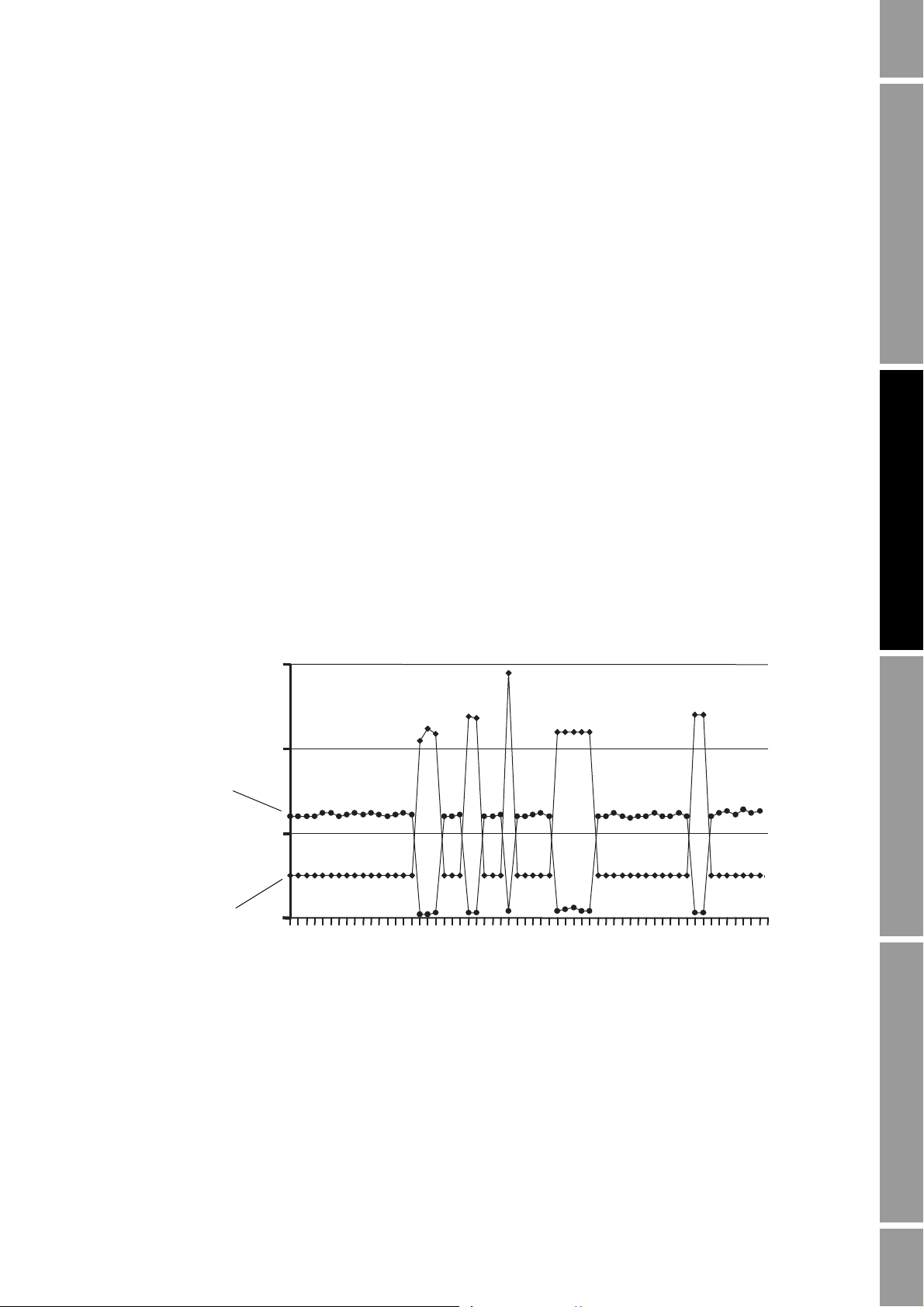

on NOC measurement accuracy. Figure 2-6 shows the effect of transient bubbles on density.

Figure 2-6 Effect of transient bubbles on density

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

Net Oil Computer Supplement 11

A “transient bubble condition” is defined in terms of the sensor’s drive gain: if the drive gain exceeds

the configured threshold for more than three seconds, the configured TBR actions are performed. The

transient bubble interval persists until drive gain is below the configured threshold for three seconds.

Page 16

NOC Overview

Density (measured)

Drive gain (actual)

Drive gain setpoint

Time Period

(seconds)

Density values

(retrieved and averaged)

To determine the value to use for the drive gain threshold, observe drive gain values for this system

during various flow conditions.

The NOC application can perform several different actions if transient bubbles are detected:

Additionally, you can configure a discrete output to report TBR status (see Section 5.3).

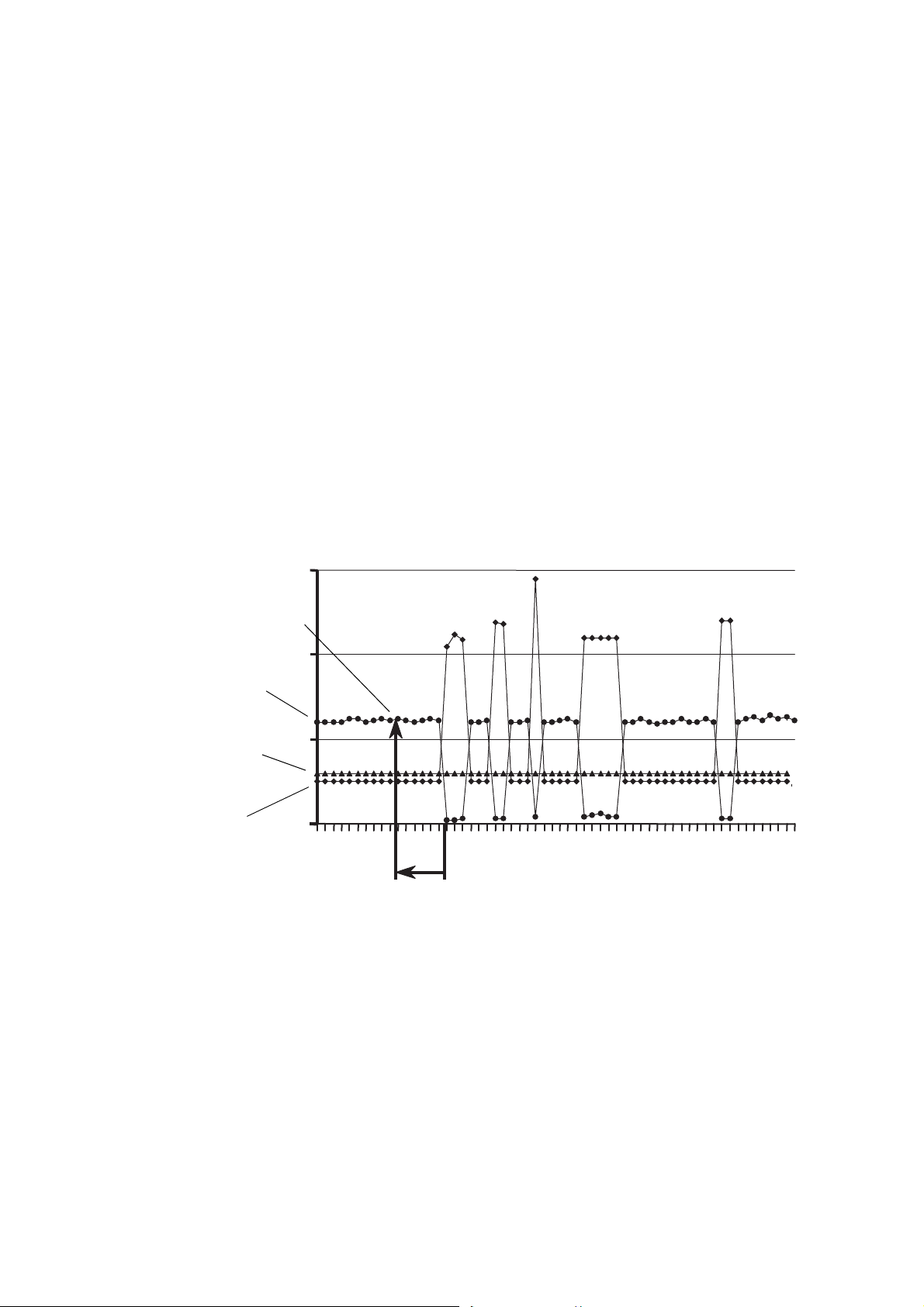

The Hold Last Value option directs the NOC application to retrieve the measured density value from

an earlier point in the process. The earlier point is identified by the configured Time Period (see

Figure 2-7). The density values from a three-second period around this point are averaged, and this

retrieved density average is then used in NOC calculations. Figure 2-8 shows how the Hold Last Value

action affects the density measurement.

Note: If the Time Period happens to fall into a previous transient bubble interval, the NOC

application automatically extends the lookback interval as required to retrieve an averaged value

from measured density values rather than substituted density values.

• Substituting a previously measured density value for the measured density value in NOC

calculations (the Hold Last Value option)

• Stopping the well test (if a well test is in progress)

• Posting an alarm

Figure 2-7 Hold Last Value option

12 Micro Motion® Series 3000 MVD Transmitters

Page 17

NOC Overview

Density

(used in NOC calculations)

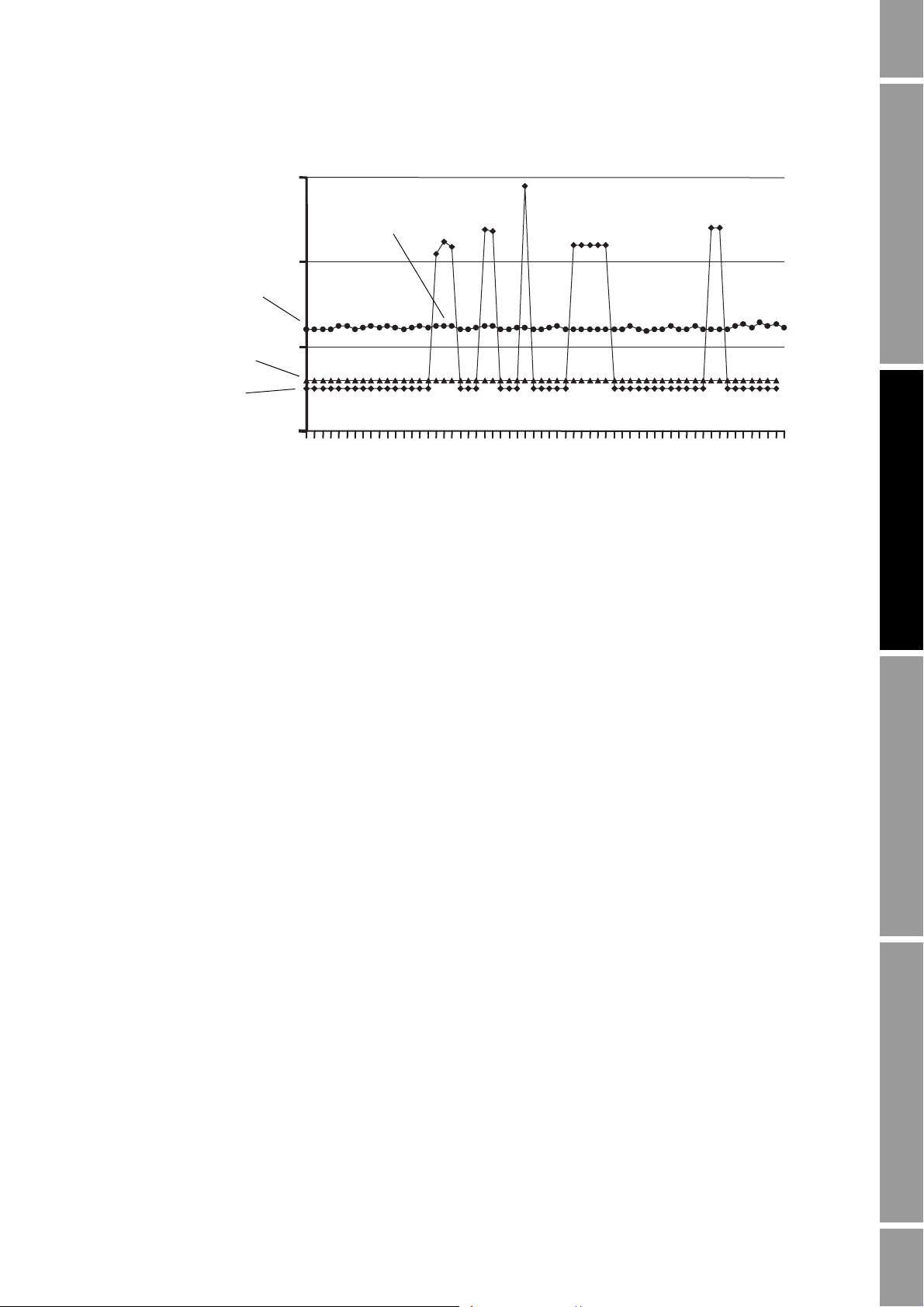

Drive gain (actual)

Averaged retrieved

density value

Drive gain setpoint

Figure 2-8 Hold Last Value effect on density measurement

2.3.5 Gas measurement

If you want the NOC application to report gas flow data:

• A mass flow gas meter must be installed on the gas leg

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

• The gas meter must be connected to the Series 3000 platform via the frequency input

• The density of produced gas at reference temperature and reference pressure must be

configured in the NOC application

The Transient Mist Remediation option may be implemented to provide more accurate gas flow data

during conditions of liquid carry-over. See the following section for more information on TMR.

If gas measurement without TMR will be implemented, the gas meter may or may not be a Micro

Motion product. If gas measurement with TMR will be implemented, the gas meter must be a Micro

Motion product.

2.3.6 Gas measurement with liquid carry-over – Transient Mist Remediation

Transient Mist Remediation (TMR) is an optional feature of the NOC application. It is used to

provide more accurate gas flow data during intermittent liquid carry-over – liquid entrained in the gas

stream. Additionally, because the liquid is assumed to be a mixture of oil and water in the same

proportions as in the liquid stream, the NOC application provides the option of adding the estimated

quantities back to the net oil and net water values from the liquid stream. This “addback” option

provides a more accurate measurement of total oil and water production from the well.

In addition to the gas measurement requirements described in the previous section, TMR requires

drive gain data from the TMR gas meter. Accordingly, a HART connection must be set up between

the primary mA output on the NOC platform and the TMR gas meter.

Variations in the drive gain from the TMR gas meter are used to detect liquid carry-over. When the

drive gain exceeds a user-specified threshold, liquid is assumed to be present in the gas stream. The

transient mist interval persists until drive gain is below the configured threshold.

To determine the value to use for the drive gain threshold, observe drive gain values for the TMR gas

meter during various flow conditions.

Net Oil Computer Supplement 13

Page 18

NOC Overview

Drive gain (actual)

Drive gain setpoint

Mass flow rate

M1

(averaged mass flow rate)

M3

(average of M1 and M2)

M2

(averaged mass flow rate)

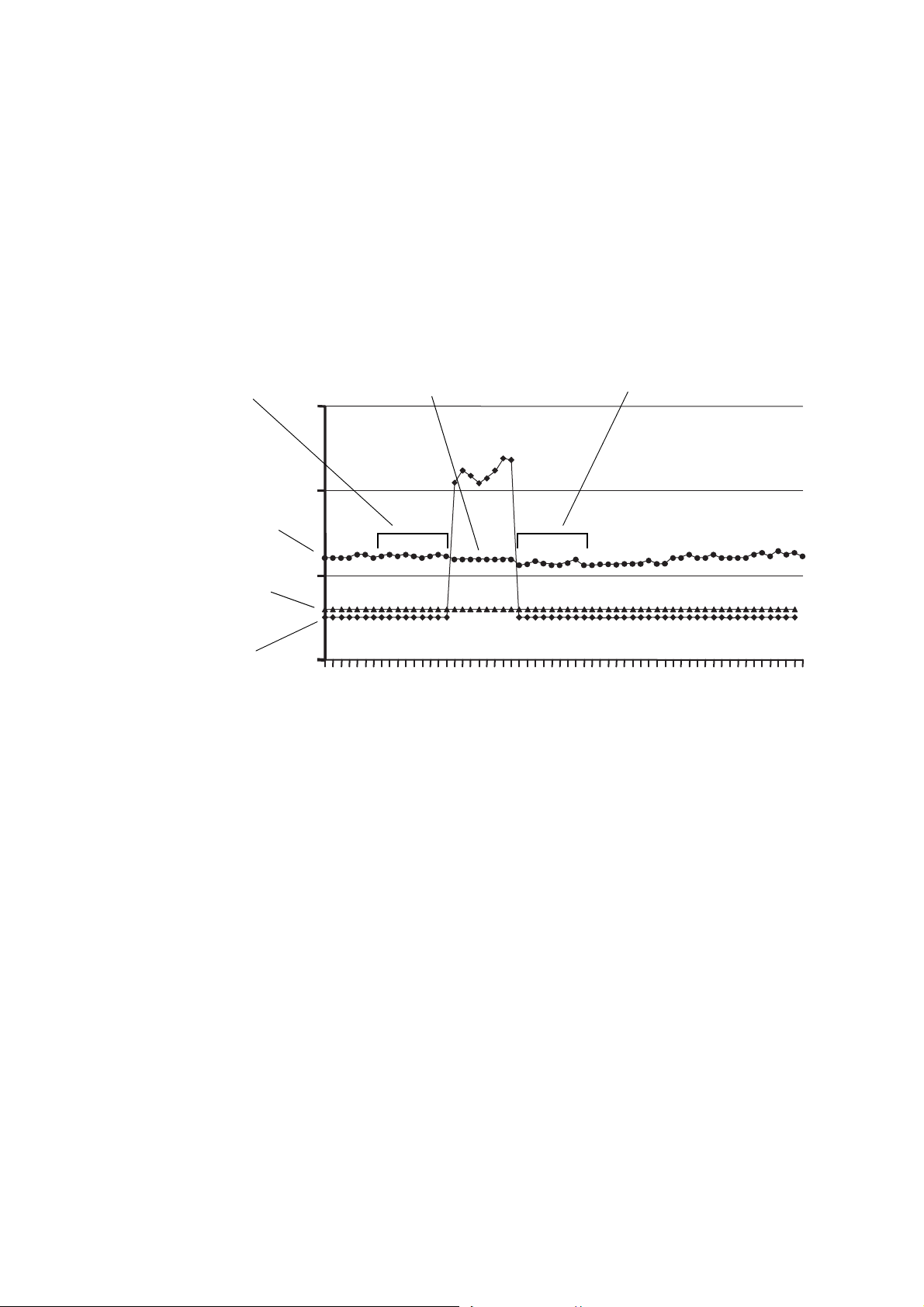

When a transient mist interval is detected:

• The mass flow rate over the previous n seconds is averaged and stored as the TMR M1 value,

where n is the value configured for Time Period.

• When the drive gain drops below the configured threshold for more than three seconds, the

mass flow rate over the next n seconds is averaged and stored as the TMR M2 value.

The M1 and M2 values are then averaged, and the resulting value M3 is used as the mass flow rate for

the TMR interval. See Figure 2-9 for an illustration of TMR.

Figure 2-9 TMR implementation

2.3.7 Recalculation

The Recalculation feature is used to convert existing NOC data to:

• A different reference temperature

• A different oil density at reference temperature

• A different water density at reference temperature

• A different reference density of gas

• A different reference pressure

• A different pressure compensation factor for oil

• Different shrinkage factors

For example, recalculation allows you to begin NOC measurement before precise reference values are

known, and then adjust the NOC data when the reference values are available.

During recalculation, you can change any or all of the values listed above. You can recalculate well

test results for any of the stored well tests, and you can recalculate the Continuous mode measurement

data for saved archive records.

When a well test or archive record is recalculated, the recalculated results can be saved if desired. The

original data is not overwritten.

14 Micro Motion® Series 3000 MVD Transmitters

Page 19

NOC Overview

Note the following:

• Only the most recent 24 hours of data can be recalculated.

• Recalculation is based on 15-minute “snapshot” average values. As a result, recalculated data

will typically be less accurate than the original data, which is based on continuous

measurement.

2.4 Planning the configuration

This section contains a set of questions that you should answer before beginning basic configuration

of the Net Oil Computer Software and the NOC system.

Note: These questions are specific to implementation of the NOC system. They do not address basic

system configuration (e.g., configuring the clock, passwords, events, communications, etc.).

1. Will this system be used to test multiple wells or to perform continuous measurement of a

single well?

2. If it will be used for well testing, what wells will be tested? in what order?

3. Will you use density-based water cut data or a water cut monitor? If you are using a water cut

monitor, what is its range?

4. For all wells that will be measured:

a. What is the oil density at reference temperature? If not known, will you perform a density

determination?

b. What is the water density at reference temperature? If not known, will you perform a

density determination?

c. (Well Test mode only) What is the well’s purge time?

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

5. Will you use HART communications for any of the following: water cut data, pressure data, or

TMR data? If yes:

a. What is (are) the HART tag(s) of the external device(s)?

b. Is the primary mA output wired to support HART communications with the external

device(s)?

6. Does the system include gas measurement? If yes:

a. Is the frequency input wired to the gas meter?

b. What is the reference density of the gas (density at reference temperature and pressure)?

7. Will TBR be configured? If yes, what drive gain will be used as the TBR threshold?

8. Will TMR be configured? If yes, what drive gain will be used as the TMR threshold?

9. If you will configure pressure compensation for oil density, what is the value to use?

10. If you will configure shrinkage factors, what are the values to use?

Net Oil Computer Supplement 15

Page 20

NOC Overview

2.5 NOC measurement terminology

The terms used in NOC measurement are listed and defined in Table 2-1. These terms are used in a

variety of process variables and locations throughout the NOC application.

Table 2-1 NOC measurement terms and definitions

NOC term Definition

Gross The sum of the oil volume and the water volume, as measured by the NOC application.

Net oil Oil only, measured by volume, corrected to reference temperature, with the oil

Water cut Percentage of water in production stream, corrected to reference temperature, with the

Uncorrected water cut Percentage of water in production stream at operating conditions.

Net water Water only, corrected to reference temperature, with the water shrinkage factor applied.

Back flow Uncorrected volume flow moving backward through the sensor.

Uncorrected oil Oil only, through the oil or oil/water leg, measured by volume, with no corrections

Uncorrected water Water only, through the oil or oil/water leg, measured by volume, with no corrections

Uncorrected gross Raw volume flow measurement from the oil or oil/water leg.

Density Density of the mixture, with no corrections applied.

Carry-over Oil and water entrained in the gas stream and added back to the net oil and net water

Carry-under Gas entrained in the liquid stream

Gas volume Volume of gas in the gas stream, calculated by the NOC application from mass flow

Actual Flow rate as measured at the time of viewing

Average Rolling average, calculated from the beginning of the applicable time period.

Total Rolling total, calculated from the beginning of the applicable time period.

If TMR carry-over is implemented, this value includes oil and water from the gas leg.

shrinkage factor applied. If TMR carry-over is implemented, this value includes oil from

the gas leg.

water shrinkage factor applied.

If TMR carryover is implemented, this value includes water from the gas leg.

applied. Any configured pressure compensations are applied. Temperature correction

and shrinkage factors are not applied.

applied. Any configured pressure compensations are applied. Temperature correction

and shrinkage factors are not applied.

measurements

data from the gas meter

16 Micro Motion® Series 3000 MVD Transmitters

Page 21

Chapter 3

Well Performance Meas

View Production Meas

Quick View

Pause / Resume

Reset

Save

SEL HELP EXIT

Well Performance Meas

Start Well Test

View Well Tests

Recalculate Well Test

SEL HELP EXIT

Continuous mode Well Test mode

Using the Display and Menu System

3.1 About this chapter

This chapter explains how to use the Series 3000 display and menu system. Using the display, you can

move through the menus, configure the application, monitor and control the application, and perform

maintenance and diagnostic tasks:

All NOC operations are accessed from the Well Performance Measurement screen.

All configuration, maintenance, and other functions are accessed via the Management menu.

3.2 Startup and Well Performance Measurement screen

When the Series 3000 device is powered on, it automatically tests its display. During display testing,

the screen darkens for approximately five seconds. After the display test is completed:

1. The Micro Motion logo is displayed for two to three seconds.

2. An application list is displayed for two to three seconds.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

3. The device enters operation mode and the Well Performance Measurement screen is displayed,

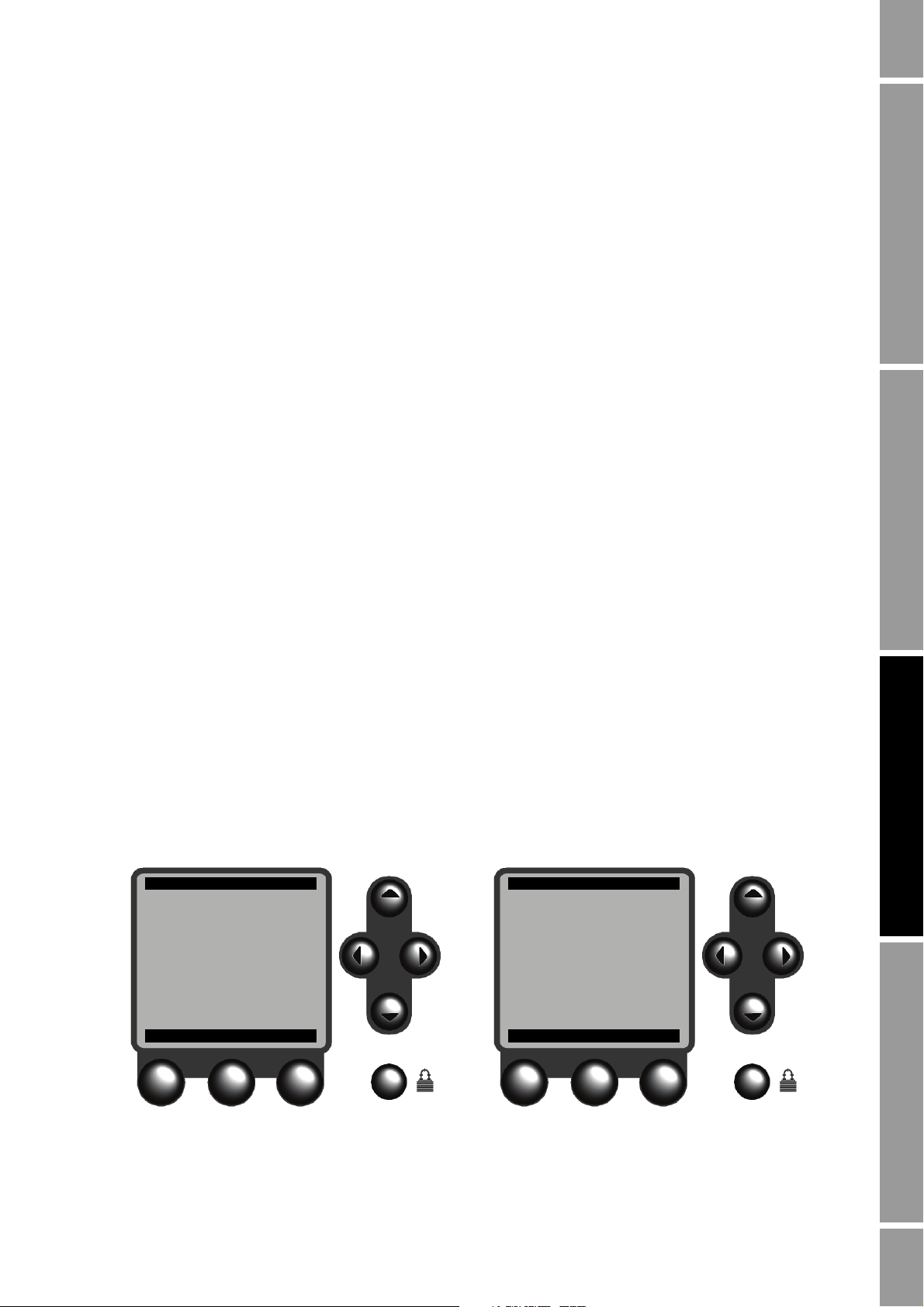

as shown in Figure 3-1. There are two versions of this screen, depending on whether the NOC

application is in Continuous mode or Well Test mode. All NOC operations are accessed from

this screen.

4. If there are any active alarms, the alarm category will be displayed in the alarm bar. To view,

acknowledge, or respond to the alarms, see Chapter 6.

Figure 3-1 Well Performance Measurement screen

Net Oil Computer Supplement 17

Page 22

Using the Display and Menu System

Management

System

Inputs

Well Performance Meas

Measurements

Outputs

Monitoring

Digital Communication

Maintenance Security Language

Security

Passwords

Language

Configuration

Active alarm log

Alarm history

Alarm event log

Process inventory

Meter fingerprinting

(1)

Calibration

Diagnostics

Meter verification

(2)

(1) Available only on systems with the standard core processor.

(2) Available only on systems with the enhanced core processor,

and only if the meter verification option was purchased.

View

Well

performance

measurement

Process

totalizers

LCD

options

Active alarm

log

Power outageProcess

monitoring

Diagnostic

monitor

Applications

list

3.3 Menu systems

Most Series 3000 display functions are organized into two menu systems:

• The Management menu allows you to perform configuration and maintenance tasks.

• The View menu allows you to monitor and control the process. The Well Performance

Measurement screens shown in Figure 3-1 are part of the View menu.

Figures 3-2 and 3-3 show high-level views of these menu systems. More detailed menus for the NOC

application are provided in Chapters 4 and 5, and menu flowcharts for the Series 3000 device with the

NOC application are provided in Appendix A.

Figure 3-2 Management menu

Figure 3-3 View menu

18 Micro Motion® Series 3000 MVD Transmitters

Page 23

Using the Display and Menu System

To enter the menus:

• To enter the Management menu system, press the

the lower right corner of the display, marked with a padlock icon (see Figure 3-1). You may or

may not be required to enter a password (see the following section).

• To move from the Well Performance Measurement screen to the top-level View menu, press

the

EXIT button (see Figure 3-1).

3.3.1 Accessing management functions

Security button. The Security button is in

You can use the

menus. When the

Security button to access management functions from any point in the Series 3000

Security button is pressed:

• If security is disabled, the Management menu will be displayed immediately. By default,

security is disabled.

• If security has been enabled, you will be prompted to enter a password. There are two

passwords:

- The configuration password enables access to all functions. When it is entered, the

Management menu is displayed.

- The maintenance password enables access to the maintenance functions. When it is

entered, the Maintenance menu is displayed.

Both passwords consist of a sequence of four cursor control button presses. To enter a password:

1. Press the four cursor control buttons in the correct sequence.

2. Press

SEL.

To configure and enable security, see Chapter 6.

3.3.2 Shortcuts

From any point in the menu system, you can:

• Return to the Management menu (if security is disabled) or the password entry screen (if

security is enabled) by pressing the

• Return to the operating screen by pressing the

Security button, as described in the previous section.

Security button, then pressing the EXIT button.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

3.4 Using the function buttons

The buttons at the bottom of the display are the function buttons. The functions performed by the

buttons vary, depending on the screen and the current state of the application. The function currently

assigned to the button is always displayed on the screen, above the button. The buttons are sometimes

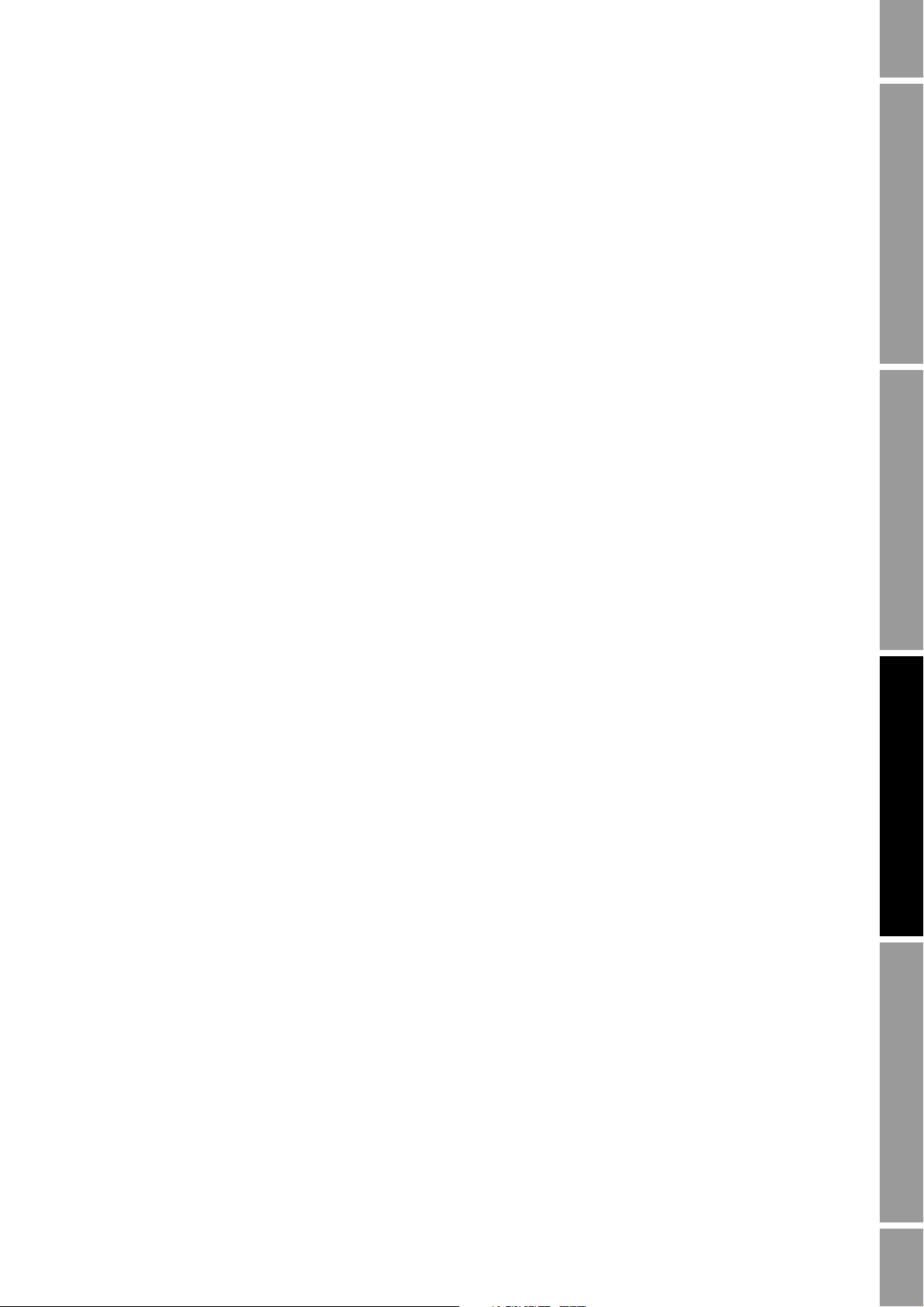

referred to as F1, F2, and F3. Figure 3-4 lists the functions supported by the NOC application.

Note: The left and right cursor control buttons may also be used as function buttons. See Figure 3-4.

If a cursor is shown on the display, the action performed by the function button applies to the item

where the cursor is located. Before pressing a function button, be sure the cursor is located correctly.

See Section 3.5.

Net Oil Computer Supplement 19

Page 24

Using the Display and Menu System

ALARMS

DEVICE 1

Configuration

Maintenance

Security

Language

SEL HELP EXIT

F3 function button

VIEW Access the View menu

EXIT Exit to previous menu or cancel a change

NO Cancel action

PREV Return to the previous screen

ABORT • Abort sensor zero

• Abort calibration

F2 function button

HELP Show a help screen

RESET Reset total

START Start a well test

VIEW View net oil data

PRINT Print a ticket

NEXT Advance to the next screen

ACKALL Acknowledge all alarms

F1 function button

SEL Select the highlighted menu item

CHG Make a change to the highlighted menu item

SAVE Save a change

YES Proceed with action

ACK Acknowledge an alarm message

START Start well test or density determination

STOP Stop well test or density determination

RESET Measurement group or all measurements

PAUSE (Continuous mode) Pause NOC measurement

RESUME (Continuous mode) Resume NOC measurement

NEXT Test next well

RETURN Exit to Well Test screen

CLEAR Clear power outage events

OK Acknowledge

F3 function button

F1 function button

Figure 3-4 Function buttons

20 Micro Motion® Series 3000 MVD Transmitters

Page 25

Using the Display and Menu System

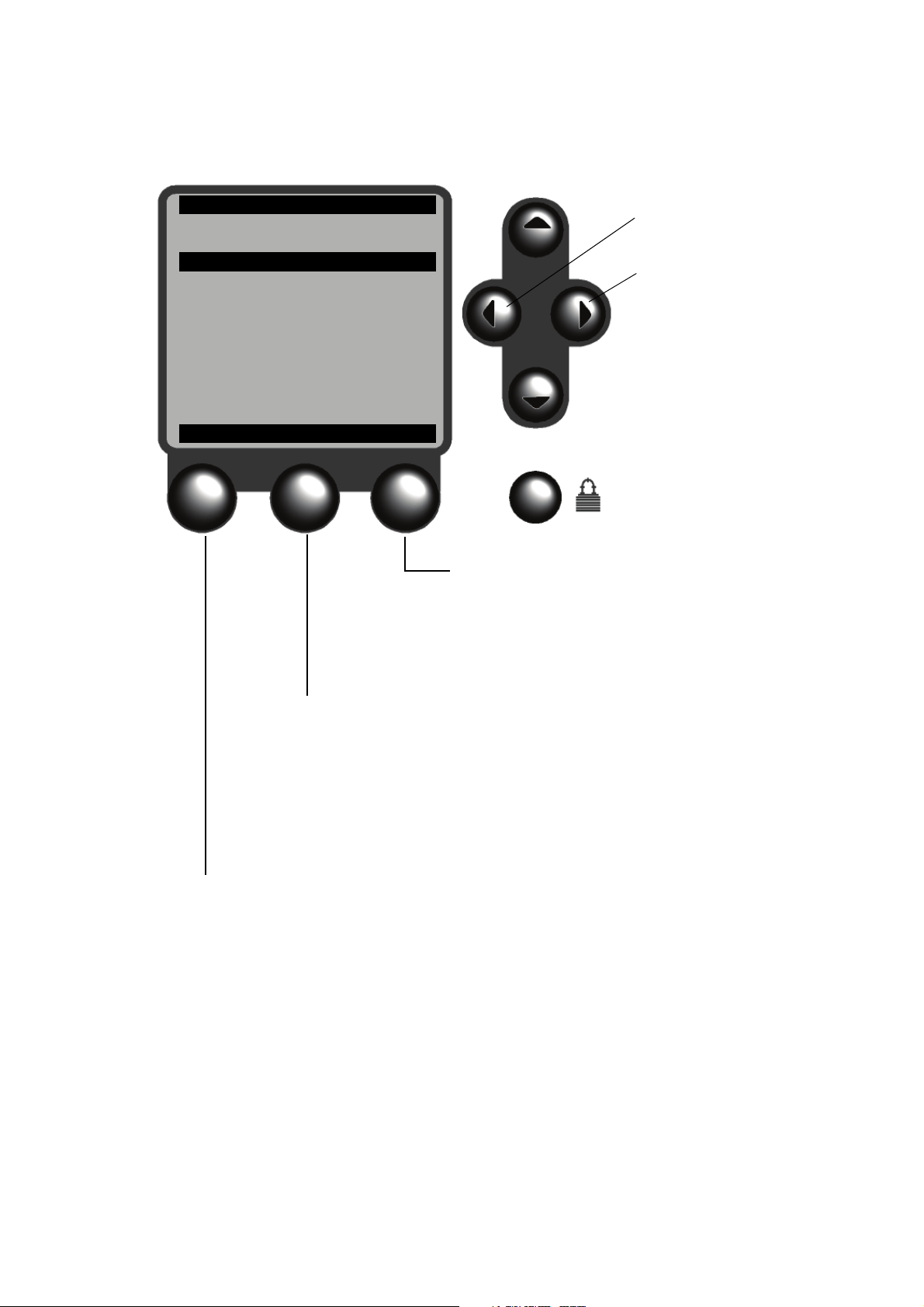

3.5 Using the cursor control buttons

The cursor control buttons move the cursor around the display menus. In menus, the cursor is a

reverse-video highlight bar.

•Use the

Up and Down buttons to locate the cursor at the menu item you want to select or

change.

• After locating the cursor at the desired menu item, press

select or change the item.

3.5.1 Selecting from a list

For enumerated lists, pressing

CHG will display a separate screen from which you can choose the

desired option. From that screen:

• Press

• Press

SAVE to save the change and return to the previous screen, or

EXIT or the Left button to return to the previous screen without saving.

3.5.2 Changing a variable value

If you need to change the value of a variable, the cursor appears as a line under a character in the

current value.

• If the variable has a value of Yes or No, all cursor control buttons toggle between the two

choices.

• If the variable has a numeric or character value, press the

to increase or decrease the value of the character at the cursor.

• If the variable has more than one digit or character, press the

buttons to move the cursor to the next or previous character.

When the value is correct, press

SEL or CHG, or the Right button, to

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

Up and Down cursor control buttons

Left and Right cursor control

SAVE.

Press

EXIT to return to the previous screen without saving.

3.5.3 Cursor control example

Figure 3-5 shows a typical configuration sequence involving both a menu item and a variable.

Pressing

HELP produces a screen that has help for the item at the cursor.

3.6 Scientific notation

Scientific notation is used on some screens for displaying values that contain more digits than the

display can show, or that exceed the precision of the floating point data type. For example, the value

1234000.000 would be displayed as 1.234E6 or 1.234+6.

Net Oil Computer Supplement 21

Page 26

Using the Display and Menu System

Density

↓

Density Units

g/cm3

Density Damping

1.7 sec

Density Cutoff

0.005

000 g/cm3

Slug Low Limit

0.005000 g/cm3

SAVE HELP EXIT

Density

↓

Density Units

g/cm3

Density Damping

1.7 sec

Density Cutoff

0.005000 g/cm3

Slug Low Limit

0.005000 g/cm3

CHG HELP EXIT

Move cursor up/Scroll up

Move cursor down/Scroll down

EXIT

Current

selection is

highlighted

Increase value at cursor

or toggle YES/NO

Decrease value at

cursor or toggle YES/NO

Var iabl e

Indicates items

available to scroll

Current

selection is

underscored

Menu item

Move cursor to left

Move cursor to right

SELECT

Figure 3-5 Cursor control buttons

22 Micro Motion® Series 3000 MVD Transmitters

Page 27

Chapter 4

Configuring the NOC Application

4.1 About this chapter

This chapter explains how to configure the NOC application and perform density determination

procedures.

The following topics are discussed:

• Basic configuration procedure – see Section 4.3

• Setting up a water cut monitor – see Section 4.4

• Setting up pressure compensation – see Section 4.5

• Setting up Transient Bubble Remediation – see Section 4.6

• Setting up gas measurement – see Section 4.7

• Setting up Transient Mist Remediation – see Section 4.8

• Performing density determination procedures – see Section 4.9

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

- Density determination for water – see Section 4.9.1

- Density determination for oil – see Section 4.9.2

Failure to perform configuration tasks in the proper sequence could result in an incomplete

configuration. See Section 1.3 for the recommended configuration sequence.

Do not change configuration during data collection. Changes made to the NOC configuration will affect

NOC measurement. Changes made to other configuration parameters may affect NOC measurement.

To ensure accurate NOC data, follow the instructions in Section 5.2.4 (Well Test mode) or Section 5.3.4

(Continuous mode) to change configuration.

4.2 Well Performance Measurement menu

Use the Well Performance Measurement menu, shown in Figure 4-1, to access and configure NOC

parameters. The Well Performance Measurement menu is accessed through the Configuration option

of the Management menu. To access the Management menu, see Chapter 3.

Net Oil Computer Supplement 23

Page 28

Configuring the NOC Application

Continuous Mode

Well Test Mode

Well Performance Meas

60 degF

15 degC

20 degC

Transient Bubble Remd

•Drive Gain Level

• Action Taken

• Time Period

Transient Mist Remed

(2)

•Drive Gain Level

• Time Period

• Add Carry-Over Totals

• Gas Meter HART Tag

Press Comp Oil Dens

Shrinkage Factors

•Factor for Oil

• Factor for Water

Mode of operation Reference Temperature Well Data-Densities

Compensations

Wells 1 to 12

(1)

Wells 13 to 24

(1)

Wells 25 to 36

(1)

Wells 37 to 48

(1)

Well Name

(1)

Oil Density

Water Density

Gas Reference Density

Press Comp Oil Density

Reference Pressure

Purge Time

(1)

Oil Deviation

Water Devi ation

Oil Duration Ave

Water Duration Ave

Well #: Well Name

(1)

Well #: Well Name

(1)

.

.

.

Well #: Well Name

(1)

Gas Meter

Gas Volume Units

Water Cut Monitor

Ext Water Cut Limit

External inputs

(1) Displayed only in Well Test mode.

(2) Displayed only if the Transient Mist Remediation option was purchased.

Figure 4-1 Well Performance Measurement menu

4.3 Basic configuration procedure

24 Micro Motion® Series 3000 MVD Transmitters

To configure the NOC application, the following general steps are required:

1. Set

2. Set

3. If you are using Continuous mode, use the Well Data-Densities menu to set the well

Mode of Operation to Continuous or Well Test.

• In Continuous mode, one well, separator, or pipeline is monitored continuously. A reset

• In Well Test mode, a well test may be performed on any of the wells on a manifold, up to

parameters for the well to be measured. See Table 4-1 for definitions of these parameters.

function is used to define the starting point for totals, averages, and maximum/minimum

values.

48 wells. Each well is configured independently and well test data is stored separately.

Reference Temperature to the reference temperature to be used by the NOC application.

Page 29

Configuring the NOC Application

4. If you are using Well Test mode:

a. Use the Well Data-Densities menu to specify the well to configure.

b. Assign a name to the well.

c. Use the Well Data-Densities menu to set the well parameters for the well to be measured.

See Table 4-1 for definitions of these parameters.

d. Repeat for all wells in the system.

Note: Micro Motion recommends configuring wells in the order in which they will be tested. For

example, the first well to be tested should be Well 1; the second well should be Well 2, and so on. If

you do this, you can use the NEXT function to move to the next well automatically.

Table 4-1 Well parameters

Parameter Default Description

Well name None (Well Test mode only) Enter a name to identify this well.

Oil density 0.8000

Water density 1.0000

Gas reference

density

Pressure

compensated oil

density

Reference

pressure

Purge time 0 sec (Well Test mode only) The measurement delay period after a well test has been

Oil deviation 0.5000

Water deviation 0.5000

Oil duration ave 30 sec The sample time, in seconds, for an oil density determination procedure. See

Water duration ave 30 sec The sample time, in seconds, for an in-line water density determination procedure.

3

g/cm

3

g/cm

0.001205

3

g/cm

0.0000

g/cm3/PSI

0.0 PSI The reference pressure value used to correct line density values to standard density

3

kg/m

3

kg/m

The name may contain a maximum of 16 characters, including spaces.

The density of oil from this well, at reference pressure and reference temperature.

Required only if density-based water cut will be used. See Section 2.2.5.

The density of water from this well, at reference pressure and reference temperature.

Required only if density-based water cut will be used. See Section 2.2.5.

(Used only if gas measurement is implemented) The density of gas from this well at

reference pressure and reference temperature.

The factor used to compensate the configured reference density of oil for the effect of

pressure. See Section 2.3.2.

values.

started. Used to allow the separator to empty any contents from the previous test.

The maximum acceptable difference between two consecutive density readings

during a density determination for oil. If the difference is greater than the configured

oil deviation, the density averaging is restarted. See Section 4.9.2.

The maximum acceptable difference between two consecutive density readings

during a density determination for water. If the difference is greater than the

configured oil deviation, the density averaging is restarted. See Section 4.9.1.

Section 4.9.2.

See Section 4.9.1.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

5. Use the External Inputs menu shown in Figure 4-1 to enable or disable use of a water cut

monitor. If

Water Cut Monitor is enabled, additional setup is required. See Section 4.4.

6. Use the External Inputs menu shown in Figure 4-1 to enable or disable gas measurement. If

Gas Meter is enabled, additional setup is required. See Section 4.7.

Net Oil Computer Supplement 25

Page 30

Configuring the NOC Application

7. Set the parameters in the Compensations menu as desired.

•For

Transient Bubble Remediation, see Section 2.3.4 for a discussion of this feature, and

see Section 4.6 for additional setup instructions.

•For

Transient Mist Remediation, see Section 2.3.6 for a discussion of this feature, and

see Section 4.8 for additional setup instructions.

•For

Pressure Compensated Density, see Section 2.3.2 for a discussion of this feature,

and see Section 4.5 for additional setup instructions.

•For

Shrinkage Factors, see Section 2.3.3 for a discussion of this feature. To “disable”

shrinkage factors, set them to 1.0.

8. If desired, configure discrete outputs, milliamp outputs, or the frequency output to report NOC

data. To do this, refer to the manual entitled Series 3000 MVD Transmitters and Controllers:

Configuration and Use Manual and:

a. Assign the desired process variable to the output. Available NOC process variables are

listed in Table 4-2.

b. Configure other output parameters as desired.

Table 4-2 Assigning NOC process variables to outputs

Can be assigned to

NOC process variable

TBR event

External water cut ✓

Uncorrected oil volume rate ✓✓

Uncorrected water cut ✓

Uncorrected water volume rate ✓✓

Back flow rate

Net oil flow rate

Net water cut

Gross volume rate

Net water flow rate

Average uncorrected oil rate

Average uncorrected water cut

Average uncorrected gross rate

Average uncorrected water rate

Average back flow rate

Average net oil flow rate

Average net water cut

Average gross volume rate

Average net water rate

Average gas volume flow rate

(1)

Discrete outputs Milliamp outputs Frequency output

✓

✓✓

✓✓

✓

✓✓

✓✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

(1) ON = TBR active; OFF = TBR inactive.

26 Micro Motion® Series 3000 MVD Transmitters

Page 31

Configuring the NOC Application

9. If desired, configure the severity level of the NOC status alarms. The status alarms listed in

Table 4-3 indicate specific states of the NOC application. Like all other status alarms on the

Series 3000 platform, they can be configured for three different severity levels – Ignore, Info,

and Fault. To configure the NOC status alarms, see the instructions in the manual entitled

Series 3000 MVD Transmitters and Controllers: Configuration and Use Manual.

Table 4-3 NOC status alarms

Alarm severity

Alarm

Category

Electronics A136 Power Outage The power was off for

Process A138 TBR Active The drive gain has

Configuration A137 Measurements

number

A139 Water Cut

A140 TMR Active The drive gain has

Maintenance

menu listing Description

at least 30 seconds.

exceeded the

configured TBR

threshold.

The water cut

Overrange

Paused

measured by the

water cut monitor is

above the configured

External Water Cut

Limit.

exceeded the

configured TMR

threshold.

Continuous mode

measurements have

been paused for

more than 15

minutes.

User

config?

Info Yes No

Info Yes No

Info Yes No

Info Yes No

Info Yes No

Affected by fault

timeoutDefault

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

Net Oil Computer Supplement 27

Page 32

Configuring the NOC Application

10. If desired, configure the process monitor to display NOC process variables. Instructions for

configuring the process monitor are in the manual entitled Series 3000 MVD Transmitters and

Controllers: Configuration and Use Manual. The following NOC process variables can be

assigned to the process monitor:

•External Water Cut

• Uncorrected Water Cut

•Net Water Cut

• Uncorrected Oil Volume Rate

• Uncorrected Oil Total

• Uncorrected Oil Inventory

• Uncorrected Water Volume Rate

• Uncorrected Water Total

• Uncorrected Water Inventory

• Back Flow Rate

• Back Flow Total

• Back Flow Inventory

• Net Oil Flow Rate

• Net Oil Total

• Net Oil Inventory

•Net Water Flow Rate

•Net Water Total

•Net Water Inventory

• Gross Volume Rate

• Gross Volume Total

• Gross Volume Inventory

• Gas Volume Flow Rate

•Gas Volume Total

•Gas Volume Inventory

Note: The process monitor may also be used to display other variables such as external pressure,

external temperature, etc. This may be useful to verify setup and configuration.

28 Micro Motion® Series 3000 MVD Transmitters

Page 33

Configuring the NOC Application

4.4 Setting up a water cut monitor

If you will use a water cut monitor:

1. Ensure that the water cut monitor is correctly installed and tested, and configured to report

water cut data in %.

2. Enable the water cut monitor as an external input, as described in Section 4.3, Step 5.

3. If desired, specify a value for

value, an alarm will be posted. Micro Motion recommends setting this parameter to the highest

value in your water cut monitor’s range. To disable the alarm, set the value to 100%.

4. Set up a HART polling connection between the Series 3000 device and the water cut monitor

as follows:

a. Ensure that the primary mA output has been wired to support HART protocol, and that it

has a HART connection to the water cut monitor.

b. From the Configuration menu shown in Figure 3-2, select

c. Select

d. Set

e. Set

Polling Variable 1 or Polling Variable 2.

Polling Control to Poll as Primary or Poll as Secondary.

Polled Variable to External Water Cut.

f. Specify the tag of the device to be polled.

5. To verify that water cut data is being received, view the current water cut value as shown in

Figure 5-2 (Well Test mode) or Figure 5-3 (Continuous mode). Ensure that the displayed value

matches the value sent by the water cut monitor.

4.5 Setting up pressure compensation

To set up pressure compensation:

1. Obtain the external pressure value, as described in Section 4.5.1

2. Enable and configure pressure compensation for oil density and water density and/or pressure

compensation for pressure effect, as described in Sections 4.5.2 and 4.5.3.

The same external pressure value is used for both types of pressure compensation.

Ext Water Cut Limit. When the measured water cut exceeds this

Inputs>External Inputs.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

4.5.1 Obtaining the external pressure value

To obtain the external pressure value, you must set up a HART polling connection between the Series

3000 device and the external pressure device, as follows;

1. Ensure that the primary mA output has been wired to support HART protocol, and that it has a

HART connection to the external pressure device.

2. See Figure 3-2. Select

a. Select

b. Set

c. Set

Polling Variable 1 or Polling Variable 2.

Polling Control to Poll as Primary or Poll as Secondary.

Polled Variable to Pressure.

Configuration>Inputs>External Inputs, and:

d. Specify the tag of the device to be polled.

e. Set

Pressure Units to the units used by the external pressure device.

3. To verify, configure the process monitor to display the external pressure value and observe the

pressure data.

Net Oil Computer Supplement 29

Page 34

Configuring the NOC Application

4.5.2 Setting up pressure compensation for oil density and water density

To set up pressure compensation for oil density and water density:

1. See Figure 4-1. In the Well Data-Densities menu, set

be used to compensate for the effect of pressure on oil density.

2. In the Compensations menu, set

4.5.3 Setting up pressure compensation for pressure effect

To set up pressure compensation for pressure effect:

Press Comp Oil Density to the factor to

Press Comp Density to Enable.

1. See Figure 3-2. Select

a. Select the

b. Set

c. Set

Polling Variable that you have defined for pressure.

Pressure Compensation to Enable.

Flow Factor, Density Factor, and Cal Pressure to the appropriate values for your

Configuration>Inputs>External Inputs, and:

sensor. See Section 2.3.2.

4.6 Setting up Transient Bubble Remediation

To se t up T B R:

1. See Figure 4-1. In the Compensations menu, select

a. Set

Drive Gain Level to the drive gain value (in percent) that represents a transient bubble

condition in this process stream. To determine the best value, you may find it useful to

observe drive gain values for this system using the View>Well Performance

Measurements>View Production Measurements menu.

b. Set

c. Set

Action Taken to the desired action.

Time Period to the number of seconds that the transmitter will look back to retrieve a

density value.

2. If desired, configure a discrete output to report TBR status. See Section 4.3, Step 8.

Transient Bubble Remd, and:

4.7 Setting up gas measurement

To set up and enable gas measurement:

1. Ensure that the external gas measurement device is correctly installed and tested, and

configured to report gas data in the units that will be used in the NOC application.

2. Ensure that the external gas measurement device has been wired to the frequency input of the

Series 3000 platform.

3. At the Series 3000 platform, configure the frequency input and perform a loop test, as

described in the manual entitled Series 3000 MVD Transmitters and Controllers:

Configuration and Use Manual.

4. See Figure 4-1. In the External Inputs menu:

a. Set

b. Set

30 Micro Motion® Series 3000 MVD Transmitters

Gas Meter to Enable (see Section 4.3, Step 6).

Gas Volume Units to the units to be used for gas measurement.

Page 35

Configuring the NOC Application

5. In the Well Data–Densities menu, set Gas Reference Density to the reference density of the

gas from this well.

• In Continuous mode – set for the well to be measured

• In Well Test mode – set for each well to be measured

6. To verify that gas data is being received, view the current gas volume as shown in Figure 5-1

(Well Test mode) or Figure 5-3 (Continuous mode). Ensure that the displayed value matches

the value sent by the gas measurement device.

4.8 Setting up Transient Mist Remediation

To se t up T M R:

1. Ensure that a Micro Motion meter has been installed on the gas leg, and that it is operating

correctly.

2. Follow the instructions in Section 4.7 to set up and enable gas measurement.

3. At the TMR gas meter:

a. Set the primary variable (the variable reported over the primary mA output) to drive gain.

b. Define a HART tag (software tag) for the device.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

4. Ensure that the primary mA output of the Series 3000 platform has been wired to support

HART protocol, and establish a HART connection to the TMR gas meter.

5. Refer to Figure 4-1. In the Compensations menu, select

a. Set

Drive Gain Level to the drive gain value (in percent) that represents a transient mist

condition in this process stream. To determine the best value, you may find it useful to

observe drive gain values for the TMR gas meter.

b. Set

Time Period to the number of seconds over which the transmitter will average mass

flow data.

c. Set

Add Carry-Over Totals as desired. If set to Yes, the estimated oil and water quantities

from the gas leg will be added to the net oil and net water data from the oil/water leg.

d. Set

Gas Meter HART Tag to the HART tag of the TMR gas meter.

6. To verify that drive gain data is received, view the current drive gain value as shown in

Figure 5-1 (Well Test mode) or Figure 5-3 (Continuous mode).

4.9 Performing density determination procedures

All density determination procedures are accessed from Management>Maintenance>Calibration (see

Section 3-2). When you select Density Determination from the Calibration menu:

• In Continuous mode, the Last Dates screen shown in Figure 4-2 is displayed.

• In Well Test mode, the well selection screens are shown first. After a well has been selected,

the Last Dates screen shown in Figure 4-2 is displayed.

The Last Dates screen shows the date and time of the most recent oil and density determination

procedures performed to completion on this device.

If you choose to continue, the Procedure Selection screen shown in Figure 4-3 is displayed.

If you are performing both a density determination for oil and a density determination for water, it is

typically more convenient to perform the density determination for water first.

Transient Mist Remed, and:

Net Oil Computer Supplement 31

Page 36

Configuring the NOC Application

Density Determination

Last Water Density

xxxx

Last Oil Density

xxxx

Continue?

YES NO

Density Determination

Water Density

Oil Density

Enter Water Cut

SEL HELP EXIT

Figure 4-2 Density determination – Last Dates screen

Figure 4-3 Density determination – Procedure Selection screen

4.9.1 Performing a density determination for water

There are two density determination methods for water: in-line and manual. The in-line method

requires enough water in the separator to supply a stable flowing density for the density determination

period. If there is not enough water, you must use the manual method. This section provides

instructions for both methods.

32 Micro Motion® Series 3000 MVD Transmitters

Page 37

Configuring the NOC Application

Measure & Save

Actual Rate

xxxx.x bbl/day

Water Deviation

x.xxxx g/cm3

Water Duration Ave

xx sec

START RESET EXIT

Measure & Save

Actual Water Density

x.xxxx g/cm3

Actual Temperature

xxx.x deg F

Actual Pressure

xx.xxxx PSI

Volume

xxxx.x bbl/day

START RESET EXIT

Top of screen Bottom of screen

In-line density determination for water

To perform a in-line density determination for water:

1. Ensure that the correct fluid (water) is flowing through the sensor. You may need to close the

outlet valve from the separator and wait for the phases to settle, then open the outlet valve.

2. From the Calibration menu, select

the Procedure Selection screen (see Figure 4-3) is displayed. In Well Test mode, you will be

required to select the well for which the procedure will be performed.

3. From the Procedure Selection screen, select

Density Determination and work through the screens until

Water Density.

4. From the next screen, select

Measure and Save.

5. The display now shows the current values for water density, water temperature, volume,

flowrate, and pressure (if pressure compensation for water density is enabled), plus the

configured Water Deviation and Water Duration Ave values (see Figure 4-4). Monitor the

density and temperature values, watching for the density and temperature readings to stabilize.

Note: The Water Deviation and Water Duration Ave values shown here are read-only. If you need to

change them, you must reconfigure the well data. See Section 4.3.

6. (Optional) Press

RESET to reset the volume total to 0. This enables you to monitor the amount

of fluid that remains in the separator (if the separator volume is known).

Figure 4-4 Density determination for water – Preparing to start

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

7. When the density and temperature readings have stabilized, press

application will now average the density and temperature of the process fluid until a good

sample is achieved.

Net Oil Computer Supplement 33

Note: If the averaging procedure does not end automatically, you may need to verify your process

fluid or increase the Water Deviation value.

A “good sample” means that, for the configured Water Duration Ave, no two consecutive

density readings differed by more than the configured Water Deviation limit. If the water

deviation limit is exceeded, averaging is restarted.

START. The NOC

Page 38

Configuring the NOC Application

--AVERAGING--

Actual Water Density

x.xxxx g/cm3

Actual Temperature

xxx.x deg F

Actual Pressure

xx.xxxx PSI

STOP

Measure and Save

Av Watr Density @ Ref

x.xxxx g/cm3

Av Water Density at

dd-mm-yy hh:mm

Current Dens @ Ref

x.xxxxx g/cm3

Current Dens Saved

dd-mm-yy hh:mm

SAVE HELP EXIT

During this period, the screen shown in Figure 4-5 is displayed. (The current pressure value

may or may not be displayed.) You can press

to the previous screen.

Figure 4-5 Density determination for water – In process

STOP to stop the averaging. You will be returned

8. When the good sample is achieved, the results are shown on a screen similar to Figure 4-6.

This screen also displays the stored value for water density at reference temperature, and the

date and time and which this value was stored.

• To discard the data from this procedure, press

EXIT. You will be returned to the Procedure

Selection screen. From this point you can repeat the density determination procedure or

EXIT to move up the menu and return to other functions.

press

• To replace the stored value with the new value, press

SAVE.

Figure 4-6 Density determination for water – In-line procedure results

34 Micro Motion® Series 3000 MVD Transmitters

Page 39

Configuring the NOC Application

Water Density

Water Density

1.0000 g/cm3

Water Temperature

60.0 deg F

Calculate at Ref

CHG EXIT

9. If pressure compensation for oil density and water density is enabled, pressure data from the

beginning of the density determination procedure is displayed, along with the stored reference

pressure.

• Press

SAVE to save the current pressure value as the new reference pressure.

• Press

EXIT to retain the existing reference pressure.

Manual density determination for water

To perform a manual density determination for water:

1. Fill the separator with production fluid from the well to be tested, and let the phases settle.

2. Take a water sample from the bottom of the water layer or from the water trap.

3. Cover the sample container and allow the sample to cool to near-ambient temperature.

4. Measure the density and temperature of the sample, using a hygrometer and a thermometer.

5. From the Calibration menu, select

Density Determination and work through the screens until

the Procedure Selection screen (see Figure 4-3) is displayed. In Well Test mode, you will be

required to select the well for which the procedure will be performed.

6. From the Procedure Selection screen, select

7. From the next screen, select

Manually Enter.

Water Density.

8. The transmitter displays a screen similar to Figure 4-7, showing the configured reference

temperature and the stored value for water density at reference temperature. In this screen:

a. Enter the density of the water sample, in the units shown on screen.

b. Enter the temperature of the water sample, in the units shown on screen.

c. Select

Calculate at Ref, then press CHG.

NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin NOC Overview NOC ConfigurationUsing the DisplayBefore You Begin

Figure 4-7 Density determination for water – Manual procedure

Net Oil Computer Supplement 35

Page 40

Configuring the NOC Application

Manually Enter

Water Density @ Ref

x.xxxx g/cm3

Water Density at

dd-mm-yy hh:mm

Current Dens @ Ref

x.xxxxx g/cm3