Emerson Mini Maestro DCD60x3/6, Mini Maestro DCD60x10/20, Mini Maestro DCD60x14/28, Mini Maestro DCD60x7/14 User Manual

Page 1

User Guide

Variable Speed Drive for

Permanent-magnet DC

Servo-motors

Part Number: 0470-0009-05

Issue: 5

www.controltechniques.com

Mini Maestro

Page 2

Safety Information

Persons supervising and performing the electrical installation or maintenance of a

Drive and/or its external Option Unit must be suitably qualified and competent in

these duties. They should be given the opportunity to study and if necessary to

discuss this User Guide before work is started.

The Drive is intended for operation from a nominal 60V DC supply. It is the installer’s

responsibility to ensure that this supply is safely isolated from dangerous mains

supply voltages, and correctly protected by fuses.

The Stop function of the Drive does not remove voltages from the terminals of the

Drive and external Option Unit. Mains supplies should be removed before any

servicing work is performed.

The installation instructions should be adhered to. Any questions or doubt should be

referred to the supplier of the equipment. It is the responsibility of the owner or user

to ensure that the installation of the Drive and external Option Unit, and the way in

which they are operated and maintained complies with the requirements of the

Health and Safety at Work Act in the United Kingdom and applicable legislation and

regulations and codes of practice in the UK or elsewhere.

The Drive may start automatically when power is applied. All necessary precautions

must be taken to avoid injury to personnel or damage to equipment as the result of

unexpected application of power.

The enable input of the Drive should not be relied upon to ensure safety of

personnel. If a safety hazard could exist from unexpected starting of the Drive, an

interlock should be installed to prevent the motor being inadvertently started.

General Information

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the optional

operating parameters of the equipment or from mismatching the Drive with the

motor.

The contents of this User Guide are believed to be correct at the time of printing. In

the interests of a commitment to a policy of continuous development and

improvement, the manufacturer reserves the right to change the specification of the

product or its performance, or the contents of the User Guide, without notice.

All rights reserved. No part of this User Guide may be reproduced or transmitted in

any form or by any means, electrical or mechanical including photocopying,

recording or by any information storage or retrieval system, without permission in

writing from the publisher.

Copyright © June 2007 Control Techniques Drives Ltd

Issue Code: 5

Page 3

Mini Maestro User Guide 3

Issue Number: 5 www.controltechniques.com

Contents

1 Data .................................................................................4

2 Mechanical Installation ..................................................6

2.1 Dimensions of the drive ...........................................................................6

2.2 Mounting location ....................................................................................6

2.3 Choke (optional) ......................................................................................9

3 Electrical Installation ...................................................11

3.1 Connections ..........................................................................................11

3.2 Grounding ..............................................................................................13

3.3 External power supply ...........................................................................13

3.4 Motor connections .................................................................................16

3.5 Signal connections ................................................................................17

4 Setting up the drive ......................................................18

4.1 Adjusting the potentiometers .................................................................18

4.2 Mounted components ............................................................................19

4.3 Making adjustments to the drive ............................................................20

4.4 Motor phasing ........................................................................................23

4.5 Dynamic calibration ...............................................................................23

5 Diagnostics ...................................................................27

5.1 LED indicators .......................................................................................27

5.2 Fault finding ...........................................................................................27

6 Accessories ..................................................................28

Page 4

4 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

1Data

Analog speed reference input ±10V (33kΩ input impedance)

Analog current reference input ±10V 22kΩ (TPRC)

Enable signal Minimum 10V

Maximum 30V

20kΩ input impedance

Error amplifier temperature drift ±25 µV / °C

Error amplifier offset Offset at 25°C ±100µV

Tachogenerator feedback control range 1 to 5000 RPM

Minimum tachogenerator signal at

maximum speed

5V

Armature feedback control range 150 ~ 3000 RPM

Ambient temperature Operating temperature range –10°C (50°F)

to +45°C (113°F)

D C s u p p l y : B a t t e r y

Nominal

Rectified AC supply

Minimum 24V

Maximum 72V

60V

Minimum 20V

Maximum 80V

Maximum ripple 2V peak to peak

Reference voltages ±10V 3mA maximum

Monitor motor current ±8V

Monitor motor requested current

(TPRC)

±10V

Power cables

2.5 mm

2

(AWG 14) for DCD60x10/20 and

DCD60x14/28 models

1.5 mm

2

(AWG 16) for DCD60x3/6 and

DCD60x7/14 models

Signal wiring

0.5mm

2

(AWG 20)

Current tolerance ±10%

Protection Overtemperature on heatsink 100°C

Undervoltage 20V

Overvoltage 80V

The supply terminals are not isolated from the control terminals.

The supply must either be isolated, or have its negative pole grounded.

WARNING

Page 5

Mini Maestro User Guide 5

Issue Number: 5 www.controltechniques.com

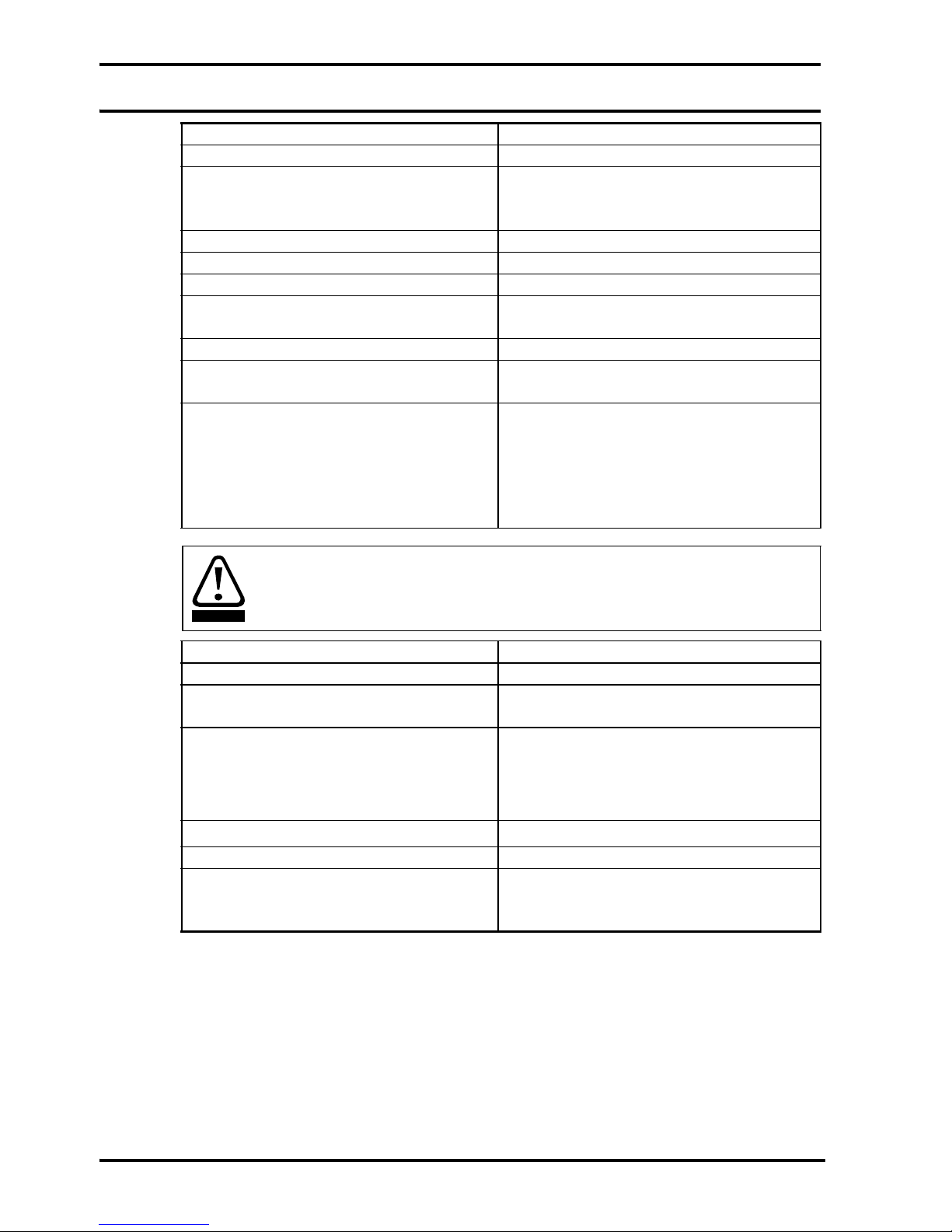

Output ratings

Model Nominal current Peak current

DCD60x3/6 1 to 3 A 6A for 2 sec.

DCD60x7/14 2 to 7 A 14A for 2 sec.

DCD60x10/20 3 to 10 A 20A for 2 sec.

DCD60x14/28 5 to 14 A 28A for 2 sec.

The peak current can be adjusted from 50% to 100% using the RIP resistor mounted on

SK1.

NOTE

The nominal current can be adjusted in the range shown using the RIN resistor mounted

on SK1.

NOTE

Page 6

6 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

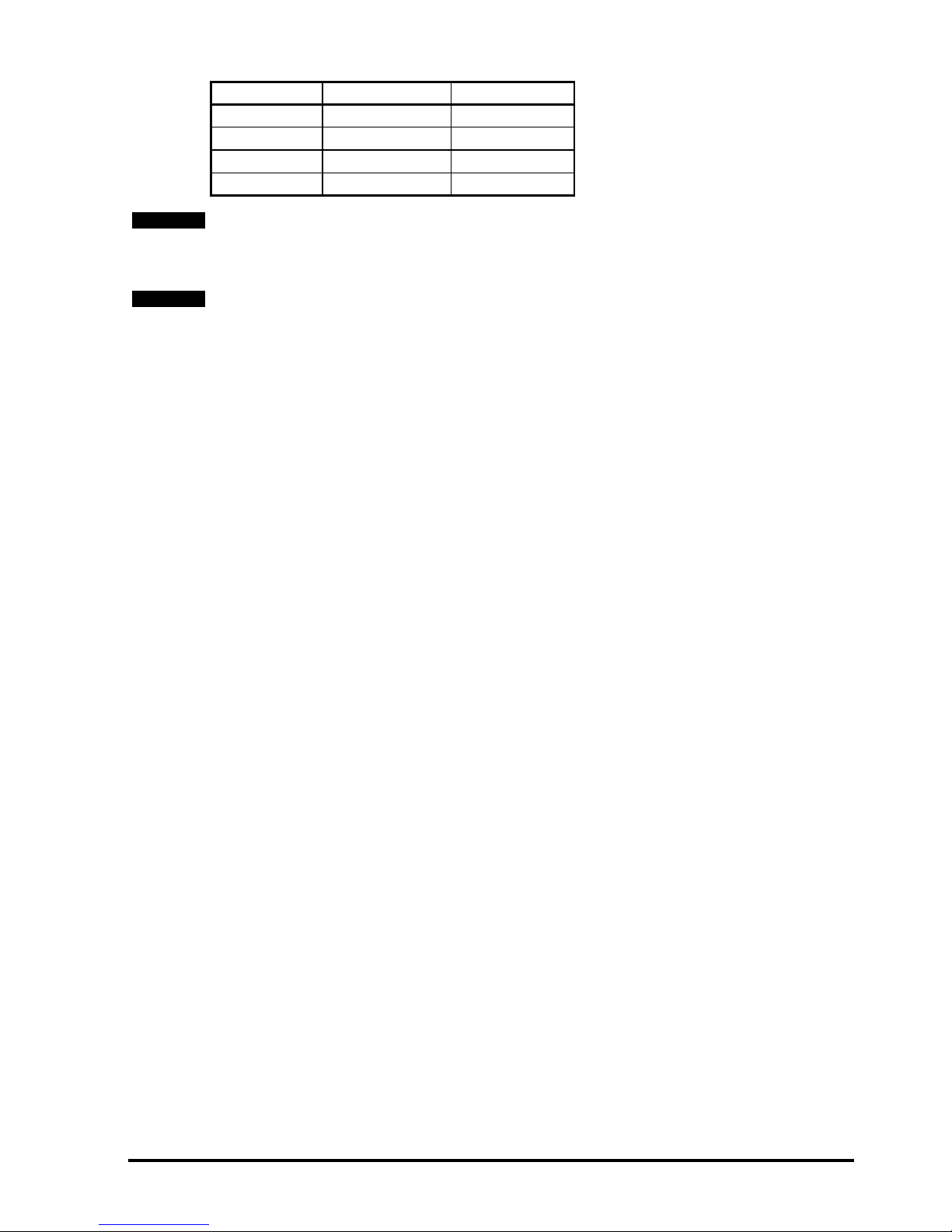

2 Mechanical Installation

2.1 Dimensions of the drive

Figure 2-1 Overall dimensions of the drive

2.2 Mounting location

The drive is contained on a Eurocard circuit board having a 64-pin DIN connector. Two

installation kits allow for installation as follows:

The ingress protection rating of the drive is IP00. When greater protection is required,

install the drive in a cabinet.

Choose a location that is free from excessive dust, corrosive vapours, gases and all

liquids, including condensation of atmospheric moisture.

Dimensions of the drive

A 100mm 3.937in

B 160mm 6.300in

C 8mm 0.315in

D 41mm 1.614in

Electric shock risk

The heatsink on the drive is LIVE. Switch off the supply and wait at least 10 seconds

before touching any part of the drive.

WARNING

Installation kit Part number Installation

3MB 7500 - 0009 Standard 19 inch rack

2MH 7500 - 0008 Panel mounting

Page 7

Mini Maestro User Guide 7

Issue Number: 5 www.controltechniques.com

If condensation is likely to occur when the drive is not in use, install an anticondensation heater. This heater must be switched off when the drive is in use;

automatic switching is recommended.

Install the drive so that the heatsink fins are vertical for best flow of cooling air.

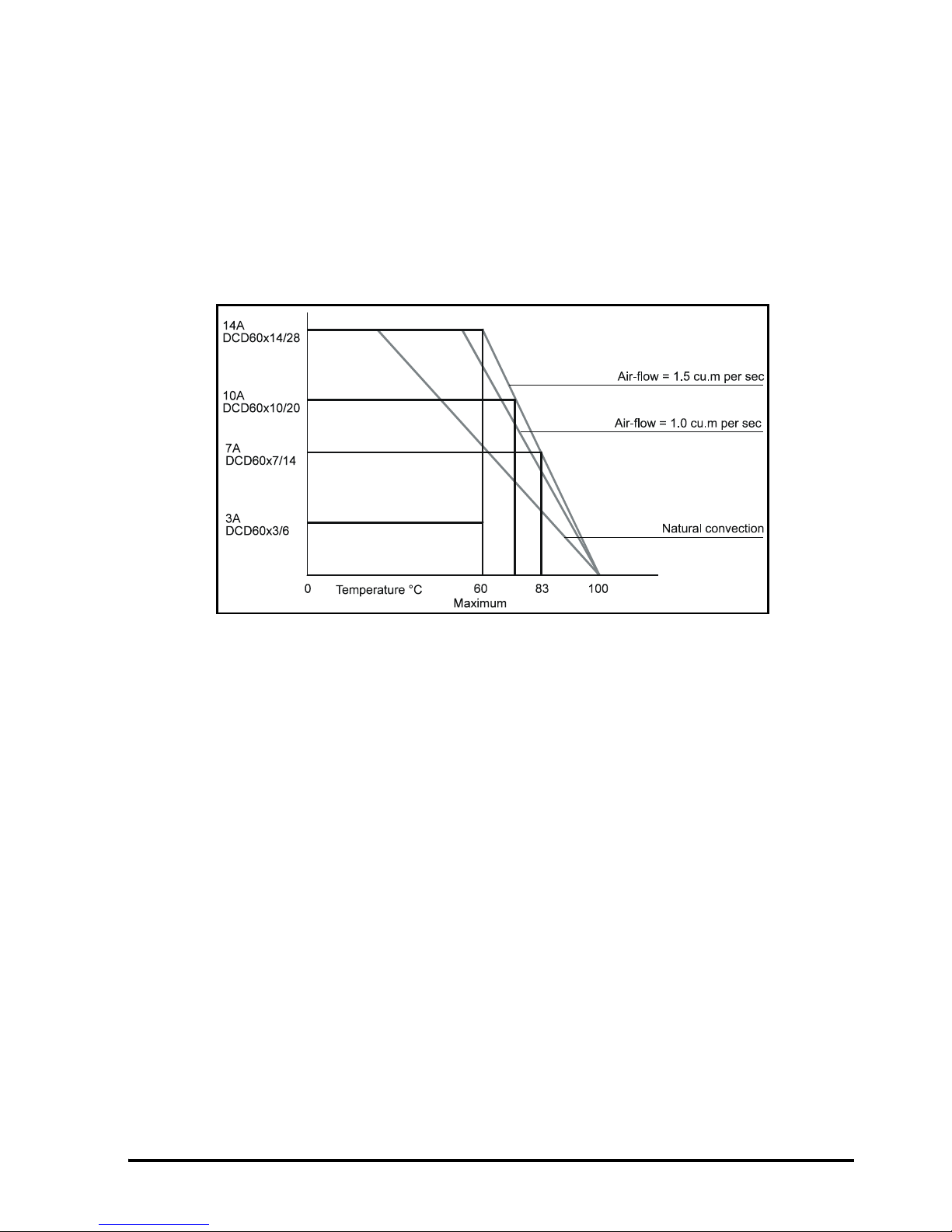

Observe the requirements for ambient temperature if the drive is to be mounted directly

above any heat generating equipment (such as another drive). When the ambient

temperature exceeds 50°C (120°F), the output power of the drive must be derated. The

drive has over-temperature protection which trips the drive when the heatsink reaches

100°C (212°F).

Figure 2-2 Derating the maximum output current with temperature

If the drive is to be installed directly beneath other equipment (such as another Variable

Speed drive), ensure the drive does not cause the ambient temperature requirements of

the equipment to be exceeded.

Leave adequate clearance around the drive to allow unimpeded airflow to the heatsink.

For model DCD60x14/28, apply forced cooling using a fan and cabinet of adequate

size.

The total power dissipated as heat from a drive, choke, transformer and heatsink is 10%

to 15% of the motor power.

Page 8

8 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

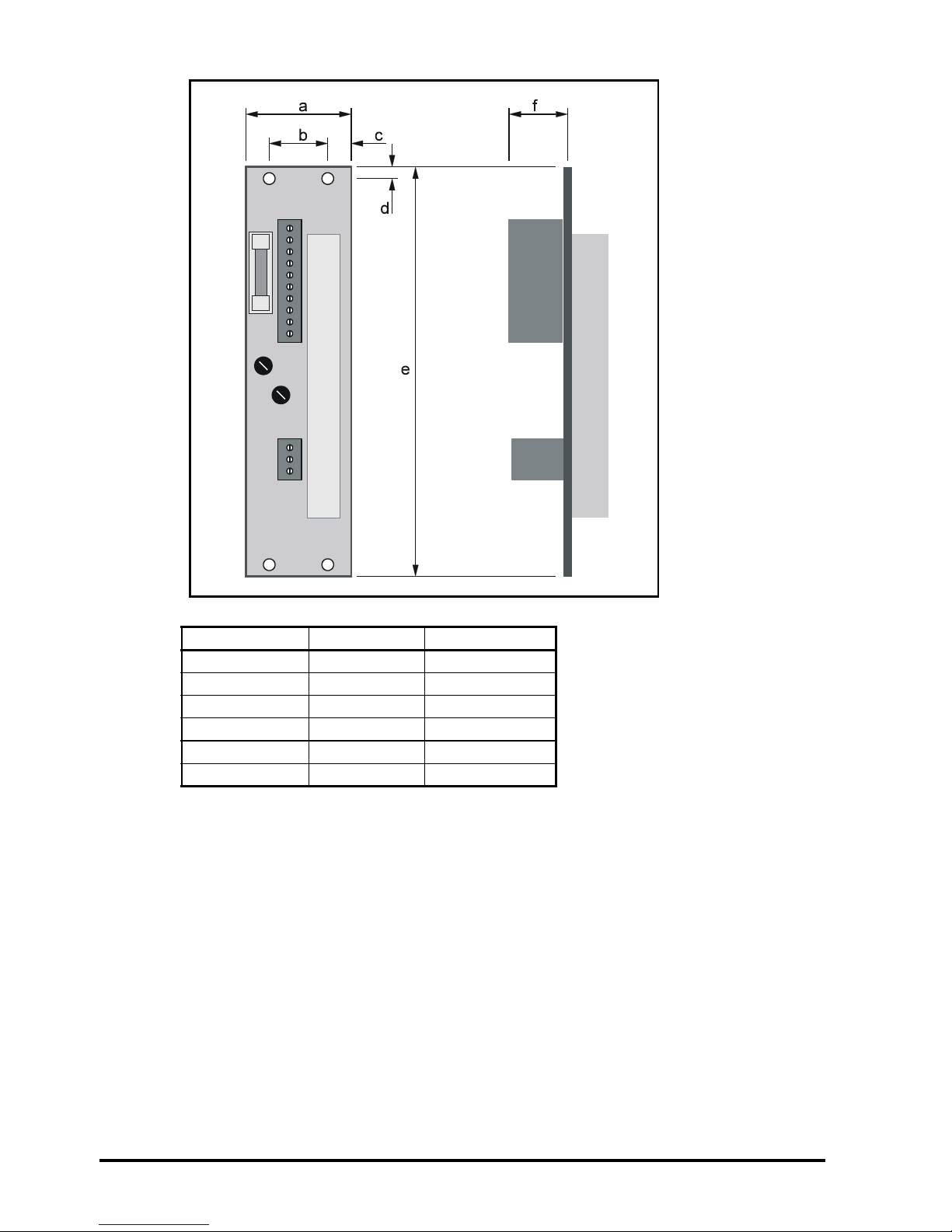

Figure 2-3 Dimensions of 3MB rack-mount installation kit

Dimension mm in

a 40 1.575

b 26 1.024

c 7 0.276

d 8 0.315

e 130 5.118

f 20 0.787

Page 9

Mini Maestro User Guide 9

Issue Number: 5 www.controltechniques.com

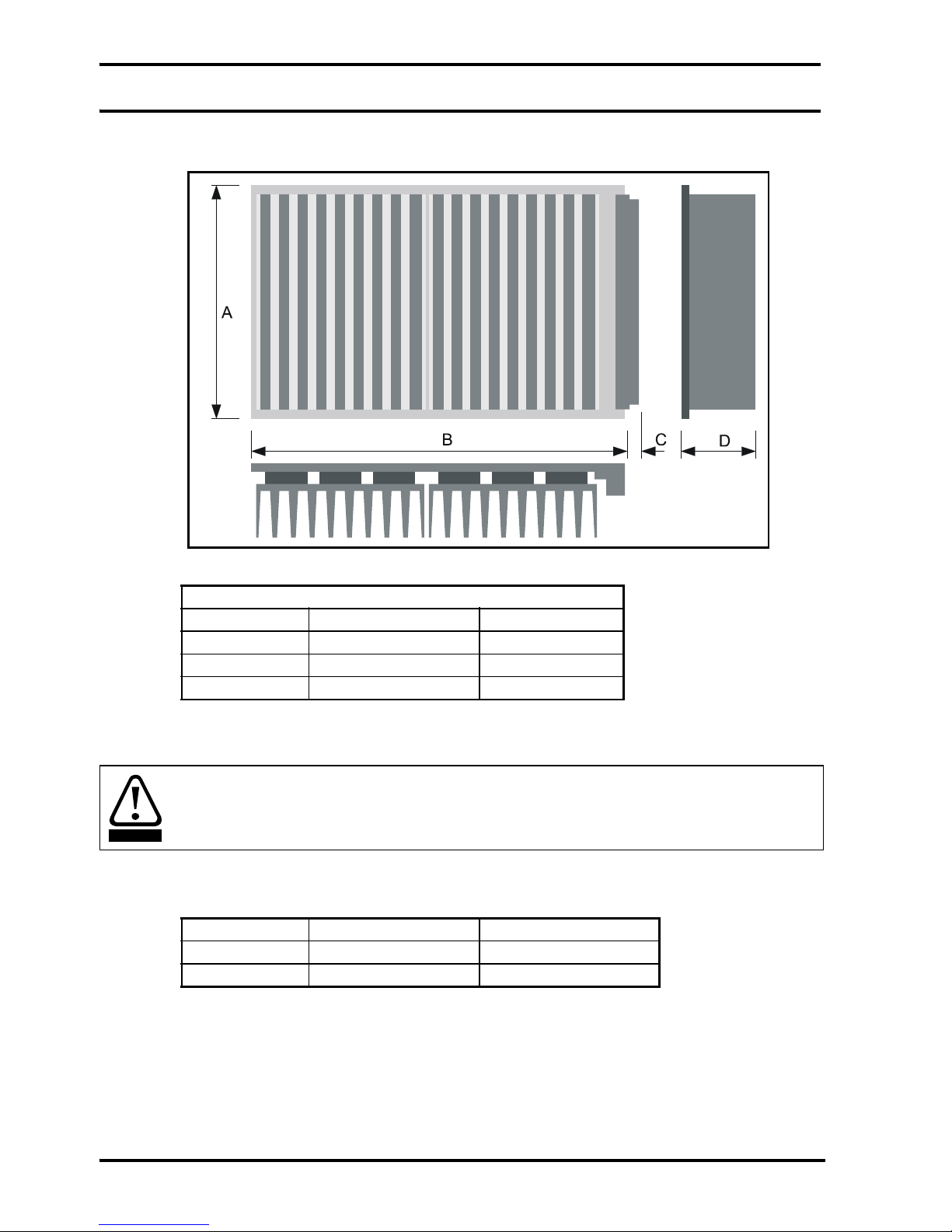

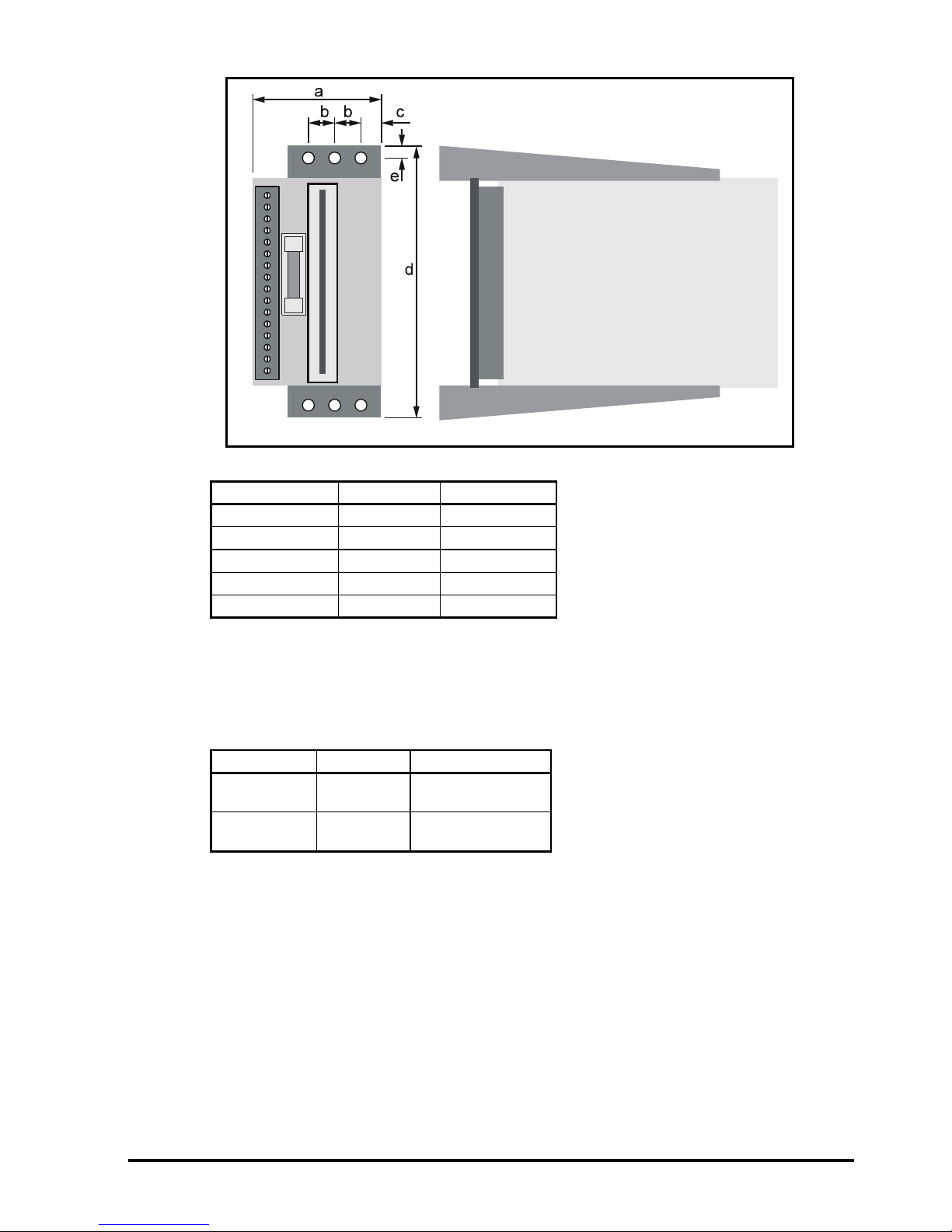

Figure 2-4 Dimensions of 2MH panel-mounting installation kit

2.3 Choke (optional)

When a motor has an inductance less than 1mH, a choke must be connected between

the motor and drive, and as close as possible to the drive. Refer to Figure 2-5 for

dimensions of the choke.

Dimension mm in

a 66 2.598

b 15 0.591

c 8 0.315

d 132 5.197

e 5 0.197

Model Choke Choke rating

DCD60x3/6

DCD60x7/14

L11 0.7mH, 8A

DCD60x10/20

DCD60x14/28

L12 1mH, 14A

Page 10

10 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

Figure 2-5 Dimensions of the L11 and L12 chokes

Dimension L11 L12

mm in mm in

a 56 2.205 75 2.953

b 12 0.472 87 3.425

c 64 2.520 7 0.276

d 56 2.205 75 2.953

e 64 2.520 100 3.937

f 6 0.236 8 0.315

g 52 2.047 44 1.732

h 40 1.575 44 1.732

j110.433

k 46 1.811 60 2.362

Hole diameter 4 0.157 4 0.157

Page 11

Mini Maestro User Guide 11

Issue Number: 5 www.controltechniques.com

3 Electrical Installation

3.1 Connections

Installation kits

Figure 3-1 Signal and power connections on the 3MB installation kit

Figure 3-2 Signal and power connections on the 2MH installation kit

Page 12

12 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

Figure 3-3 Locations of the signal and power connections on the installation kits

Edge connector of the drive

When an installation kit is used, the functions of the connections on the edge connector

do not need to be known. The connections are as follows:

ing

1

18

Pin number Function

1 Signal common

2 Protection enable

3TPRC

4 –10V, 3mA supply

5 +10V, 3mA supply

6 Speed reference input [non inverting]

7 Drive enable

8 Signal common

9 Tachogenerator input

10 Speed reference input [inverting]

11 I

mot

Analog signal proportional to the effective current in the motor

14, 15, 16, 17 +DC supply input

19, 20, 21, 22 –DC supply input

24, 25, 26, 27 Motor output + [M1]

29, 30, 31, 32 Motor output – [M2]

12, 13, 18, 23 Do not use

The signal common terminals are at the same potential as the -DC supply input terminals

CAUT ION

Page 13

Mini Maestro User Guide 13

Issue Number: 5 www.controltechniques.com

3.2 Grounding

To avoid intermittent tripping of the drive, use a single ground point for the supply and

signal circuits. A grounding bar of appropriate size can be used. This must be mounted

on insulated supports as close as possible to the drive and connected to the chassis

ground using cable of 10mm

2

to 20mm2. The shortest possible wiring should be used.

The connection to the chassis terminal of the enclosure must be adequately sized.

If in doubt, consult the supplier of the drive.

Figure 3-4 Ground connections

3.3 External power supply

A single external power supply may be used to supply a number of drives.

Peak motor current less than 15A

Use a single-phase or three-phase AC supply.

Peak motor current 15A or greater

Use a three-phase AC supply.

Signal cables and supply cables must be segregated and wired through different

trunking

NOTE

Page 14

14 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

Figure 3-5 Single-phase and three-phase power supply circuits

Transformer ratings

Power rating

Use the following equation:

Pt = {(Paz x 1.7) + 80} x 1.73 ÷ √(n + 2)

Where:

Paz = (Vm1 x Cm1) + (Vm2 x Cm2) + ...

Vm = Motor speed in radians per second (RPM ÷ 9.5)

Cm = Nominal torque in Nm

1.73 ÷ √(n + 2) Empirical conversion factor for drives connected in parallel

Secondary voltage

Select the required secondary voltage, as follows:

With no load: V2 ≅ V1 x 1.4

With full load: V2 ≅ V1 x 1.2

DC supply to the drive Secondary voltage VRMS

63 45

21 15

80 56

Page 15

Mini Maestro User Guide 15

Issue Number: 5 www.controltechniques.com

Reservoir capacitors

Use the following equation to calculate the total required value of reservoir capacitance:

C = (Pt ÷ V2) x 2000 µF

The factor 2000 allows for regeneration current during braking.

The factor can be reduced to 1000 when all of the following conditions apply:

V2 = 24V to 45V

Maximum motor speed = 1500 RPM

Three-phase AC supply is used

System inertia is less than the motor inertia

.Discharge resistor

The discharge resistor ensures the reservoir capacitors are discharged in 10 seconds

when the AC supply is disconnected from the drive.

Use the following equation to calculate the required value: R = 20 ÷ C

Use the following equation to calculate the power rating: P = [V2]

2

÷ R

AC supply fuses

Delayed action fuses should be connected in the primary and secondary circuits of the

transformer.

Use the following equations to calculate the ratings of the fuses:

DC supply fuses

A 12.5A fast-action fuse is fitted in the fuse holder on the panel of the installation kit.

This protects the DC supply to the drive. If necessary, replace this fuse with a 16A fastaction fuse. Refer to the following table:

If the green drive normal LED on the drive becomes unlit (even temporarily) when the

motor is being decelerated, this indicates overvoltage protection is occurring. To prevent

this occurrence, increase the value of reservoir capacitance

NOTE

Correct fuse protection must be used to avoid fire risk.

WARNING

Number of phases Primary fuses Secondary fuses

1 1.3 x Pt ÷ (VAC + 1) Frm 1.6 x Pt ÷ V1 Fsm

3 0.75 x Pt ÷ (VAC + 1) Frt Pt ÷ V1 Fst

DCD60x3/6 DCD60x7/14 DCD60x10/20 DCD60x14/28

12.5A 12.5A 16A 16A

Page 16

16 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

3.4 Motor connections

Normally the motor should be connected directly to the connector on the installation kit.

When any of the following conditions apply, a choke should be connected to each drive

output as shown in Figure 3-6.

• The motor inductance is less than 1mH

• During emergencies, the user short-circuits the motor connections

• High frequency switching noise is troublesome

• The motor overheats (irrespective of motor inductance)

Figure 3-6 Motor and choke connections

The two cables between the drive and the choke are a source of noise. The cables

should be kept as short as possible (300mm is recommended).

Terminal 3 of the choke should be connected to the + terminal of the motor.

Terminal 5 should be connected to the – terminal on the motor.

Terminal 4 should be connected to the grounding bar (only applies to L12).

Page 17

Mini Maestro User Guide 17

Issue Number: 5 www.controltechniques.com

3.5 Signal connections

Table 3.1 Signal connections common to both mounting kits

DC supply connections for 3MB

DC supply connections for 2MH

Motor connections for 3MB

Motor connections for 2MH

Signal cables and power cables must be segregated and wired through different

trunking.

Terminal

No.

Description I/O Notes

1

I

MOT

O

Analog signal proportional to the effective current in the motor.

Output signal ± 8V at maximum current.

2 Protection active O

NPN open-collector output 100mA, 47V. Use this to enable external

protection devices when the drive trips.

3 TPRC I/O

Analog signal proportional to the value of the requested current.

Signal range ±10V. When at ±10V the drive generates peak current.

When used as an input, and the same voltage range is applied, the drive

becomes a current amplifier using the applied voltage as current

reference.

40V

Signal common

5 -10V reference O 3mA max

6 +10V reference O 3mA max

7 Enable I

When a 10V DC to 30V DC signal is applied to this terminal, the drive is

enabled. When the signal is discontinued, the drive is disabled (0V).

Input impedance = 47kW

8

Speed reference

(non-inverting input)

I

When a differential signal from the external controller is not available,

connect terminal 10 to terminal 9.

90V

Signal common.

10

Speed reference

(inverting input)

I

The speed reference signal input is a differential input to minimize noise

problems.

11

Tac ho

(non-inverting input)

I Tachogenerator signal.

12

Tac ho

(inverting input)

I Tachogenerator signal.

NOTE

13 +DC I

14 -DC I

13 + 14 +DC I

15 + 16 -DC I

15 Motor M1 O Motor positive

16 Not used

17 Motor M2 O Motor negative

17 Motor M1 O Motor positive

18 Motor M2 O Motor negative

Page 18

18 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

4 Setting up the drive

Set up the drive by adjusting potentiometers and replacing specific capacitors and fixed

resistors. These components are fitted to socket SK1. If a drive is replaced, the socket

can be transferred to the replacement drive in order to keep the settings.

4.1 Adjusting the potentiometers

Five potentiometers are labelled as follows:

RAMP

DERIVATIVE

PROPORTIONAL

ZERO OFFSET

MAX SPEED

Figure 4-1 Locations of the potentiometers on the drive

RAMP potentiometer

Adjust the potentiometer to increase or decrease the time from 0 second to 2 seconds

for the motor to reach maximum speed (with a 10V speed reference signal). To disable

ramps set the potentiometer at the fully anti-clockwise position.

DERIVATIVE potentiometer

Turn the potentiometer clockwise to reduce the amount of overshoot in the system

response by increasing the derivative gain of the PID amplifier.

PROPORTIONAL potentiometer

Turn the potentiometer clockwise to increase the proportional gain of the PID amplifier.

ZERO REF potentiometer

Adjust this potentiometer to cancel any offset in the external speed reference signal.

MAX SPEED potentiometer

Turn the potentiometer anti-clockwise to reduce the maximum motor speed to 50%.

Turn the potentiometer clockwise to increase the maximum motor speed to 120%.

Drive status indicator LED

s

Te s t po i nt s

Potentiometers

0V

Page 19

Mini Maestro User Guide 19

Issue Number: 5 www.controltechniques.com

4.2 Mounted components

Figure 4-2 Locations of the mounted components on the drive

The following resistors and capacitors are mounted on socket SK1:

RIP resistor

Reduces the peak current to the required value.

RAI resistor

Compensates for the voltage drop due to internal resistance of the motor.

RIN resistor

Reduces the nominal current to the required value.

RKW.CRA resistor

Adjusts the drive for armature voltage speed feedback.

DER capacitor

Adjusts derivative gain.

INT capacitor

Adjusts integral gain.

JUMP.CRA jumper

Adjusts the response of the system when the drive is in armature feedback mode.

RT resistor

Normalizes the tachogenerator input signal and adapts the drive to the voltage

constant of the tachogenerator.

Most applications do not require DER or INT capacitors to be used. When an

application does require these capacitors, the recommended value is between 0.1mF

and 5mF.

NOTE

Page 20

20 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

4.3 Making adjustments to the drive

Zero speed offset

ZERO REF potentiometer

1. Connect the non-inverting input of the speed reference signal to terminal 9 and the

inverting input to terminal 10.

2. Set the speed reference signal for zero speed.

3. Apply +10V to +30V to terminal 7 Drive Enable.

4. Connect a digital multimeter to pins 11 and 12.

5. Enable the drive and adjust the ZERO REF potentiometer to reduce the multimeter

reading to not more than 1mV.

6. Restore the original wiring.

Maximum speed

RT resistor

Use the following equation to calculate the value of the RT resistor:

RT = 400 [(Vm x Ke

tacho

) - 5Ω]

Where:

Vm = Maximum speed of motor in RPM ÷

1000

Ke

tacho

= Tachogenerator voltage constant (voltage output at 1000 RPM) and in

general Ke

tacho

= V* 1000 / RPM

Resistor ratings:

Power: 0.25W

Tolerance: +20%.

Example

Max required speed = 3000 RPM ∴Vm = 3

Tachogenerator output = 7V at 1000 RPM ∴ Ke

tacho

= 7

Calculate:

RT = 400 [ (3 x 7) - 5Ω ] = 6.4kΩ

The nearest suitable value is 6.8kΩ.

A 10kΩ RT resistor is fitted as standard. This value is suitable for tachogenerator

voltage constant, Ke

tacho

= 10 and maximum motor speed = 3000 rpm.

NOTE

If the calculated value of RT is zero, fit a jumper instead of a resistor

If the calculated value is negative, the tachogenerator must be changed for one with a

greater value of Ke

tacho

in order for the motor to reach the required speed.

NOTE

Page 21

Mini Maestro User Guide 21

Issue Number: 5 www.controltechniques.com

Adjusting the nominal current

When the nominal current rating of the motor is less than the nominal current of the

drive, it is possible to reduce the maximum value of current produced by the drive by

fitting a RIN resistor. Refer to the following table:

The following equation is used to calculate the value of the RIN resistor:

Where:

I

NOM

= nominal desired current value

I

PEAK

= Drive peak current value

Adjusting speed for operation in armature feedback mode

JUMP.CRA jumper

RKW.CRA resistor

RAI resistor

Armature feedback mode can be used when a tachogenerator is not fitted to the motor.

Speed control is then less precise.

Speed is controlled using the motor voltage as feedback.

Voltage drop due to motor resistance can be compensated by adjusting the value of the

RAI resistor.

1. Connect jumper JUMP.CRA to enable operation with armature feedback.

2. Use the following equation to calculate the correct value of RKW resistor:

RKW = 0.260 x Vm x Ke

motor

Where:

Vm = Maximum speed in RPM

Ke

motor

= Motor voltage constant (voltage at 1000 RPM)

Calculating the value of the RAI resistor can be difficult since it is a function of the

following:

• Motor characteristics. (eg. armature resistance and temperature).

• Brush resistance (changing with wear).

Model Nominal current

3 / 6 3.0 2.8 2.6 2.4 2.2 1.9 1.7 1.5 1.2 1.1 0.9

7 / 14 7.0 6.5 6.0 5.5 5.0 4.4 4.0 3.4 2.8 2.5 2.2

10 / 20 10 9.3 8.6 7.8 7.0 6.3 5.7 4.9 4.0 3.5 3.1

14 / 28 14 13 12 11 9.9 8.8 8.1 6.8 5.6 4.9 4.3

Value KΩ

65 30 18 12 8.6 6.8 4.7 3.3 2.7 2.2

RIN

10000 I

NOM

×()Ω

I

PEAK

2I

NOM

×()–[]

----------------------------------------------- -------=

The correct setting of RIN resistor is necessary to prevent damage to motor and risk of

fire in the event of overload.

WARNING

Page 22

22 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

The following equation can be used to calculate a value for the RAI resistor:

Where:

Ip = Peak output current

Ratot = Ra + Rsp1 + Rsp2

Ra = Armature resistance (Ω)

Rsp = Brush resistance (Ω)

An approximate value may be found experimentally using a RAI resistor value of 400kΩ

to 600kΩ.

Adjusting the peak current

RIP resistor

When a RIN resistor is fitted, I

PEAK

may become excessively high in relation to I

NOM

. To

reduce the value of the peak current, use a RIP resistor.

Use the following equation to calculate the value of the RIP resistor:

Where:

I

LIM

= the new value required for I

PEAK

The following table may be used for finding an approximate value for I

PEAK

RAI 80 Vm×

Ke

motor

Ip

----------------------

× Ratot×=

Too low a value for the RAI resistor may modify the velocity loop response.

For guidance, contact Control Techniques.

NOTE

The new value for I

PEAK

must be ignored when the value of RIN is calculated.

NOTE

RIP

10 I

LIM

×()

I

PEAKILIM

–()

------------------------------------

kΩ=

When the peak current is reduced, the ratio between I

PEAK

and I

NOM

is altered. This

alteration increases the time before I

2

t protection takes place.

In this case, the peak current is supplied for more than 2 seconds

NOTE

Model Current

3 / 6 5.8 5.6 5.4 5.1 4.9 4.1

3.9 3.6 3.0

7 / 14 13.5 13.0 12.5 12.0 11.5 10.0 9.6 9.0 8.4 7.0

10 / 20 19.3 18.6 17.9 17.0 16.5 15.4 13.7 18.9 12.0 10.0

14 / 28 27 26 25 24 23 21 19 18 17 14

Value KΩ 270 130 83 56 47 33 22 18 15 10

Page 23

Mini Maestro User Guide 23

Issue Number: 5 www.controltechniques.com

4.4 Motor phasing

1. Ensure the speed reference signal is zero.

2. Ensure a drive enable signal is not applied.

3. Apply AC power.

4. Check that the green LED is lit.

5. Check the motor remains stationary or rotates slowly.

6. Increase the speed reference signal and check the motor rotates in the intended

direction and the speed increases.

7. If required, refer to Diagnostics.

4.5 Dynamic calibration

For modifying the settings, the following equipment is required:

Low frequency function generator

Frequency range: 0Hz to 10Hz

Output voltage: –3.5V to +3.5V

Twin-trace storage oscilloscope

1. Remove the speed reference signal from pins 9 and 10.

2. Connect the function generator output to pins 9 and 10.

3. Set the function generator at the following:

Squarewave output

Amplitude: ±2V

Frequency: 0.2Hz

4. Connect oscilloscope channel A to pin 11.

5. Connect oscilloscope channel B to pin 8.

6. Connect oscilloscope ground to pin 9.

7. Connect the oscilloscope external trigger input to the function generator output.

8. Set the oscilloscope as follows:

Sensitivity: 1mV per division

Timebase: 20ms per division

9. Apply power to the drive.

10. Enable the drive.

If the motor connections are not correct, the motor could rotate at a high speed in an

unspecified direction.

Before testing the motor, disconnect the motor from the machine and ensure the AC

supply can be quickly disconnected from the drive.

WARNING

When the motor load is a slide with limited travel, avoid the slide activating the limit

switches by increasing the reference signal frequency or decreasing the reference signal

amplitude in order to reduce the speed.

The minimum acceptable amplitude for the reference signal is 1V peak-to-peak.

CAUT ION

NOTE

Page 24

24 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

Figure 4-3 Waveform resulting from insufficient proportional gain

11. The waveform could be as shown in Figure 4-3. In this case, the system has

insufficient dynamic gain. Turn the PROPORTIONAL potentiometer clockwise to

obtain a waveform without oscillation.

12. When a waveform without oscillation has been obtained, in most cases the

response will have an overshoot as shown in Figure 4-4. In this case, the system

has insufficient derivative action. Turn the DERIVATIVE potentiometer clockwise to

eliminate the overshoot, as shown in Figure 4-5.

Figure 4-4 Waveform resulting from insufficient derivative gain

Page 25

Mini Maestro User Guide 25

Issue Number: 5 www.controltechniques.com

Figure 4-5 Ideal waveform

Figure 4-6 Waveform resulting from excessive derivative gain

If the derivative gain is set at an excessive value, current noise can occur. This causes

unnecessary heating of the drive and motor, and can induce I

2

t current limit trips.

It may be necessary to adjust repetitively the PROPORTIONAL and DERIVATIVE

potentiometers.

If the drive has instability problems after adjustment and when it is connected to a

position controller, re-adjust the proportional and derivative gains.

NOTE

Page 26

26 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

The maximum acceptable amplitude for the current noise is 15% of the amplitude of the

waveform.

Figure 4-7 Block diagram of the drive

Page 27

Mini Maestro User Guide 27

Issue Number: 5 www.controltechniques.com

5 Diagnostics

Two LEDs and one digital output are available on the drive to give the following:

Monitoring the status of the drive

Diagnostics

I

2

t protection

5.1 LED indicators

I2t protection indicator

The I2t LED is lit when I2t exceeds the programmed value set by the RIN resistor.

When the I

2

t LED is lit, the drive is limited to the value of nominal current set by the RIN

resistor.

I

2

t protection can be caused by:

A heavy working cycle with quick and frequent accelerations

Reversal of the drive

Drive rating inadequate.

When I

2

t limiting is not activated, the green LED will light and a Drive NORMAL output

signal will be produced.

DRIVE HEALTHY indicator

The DRIVE HEALTHY LED indicates that the drive is operating normally. When the LED

is unlit it indicates at least one of the drive protection functions is active.

5.2 Fault finding

Use the following procedures when the system is not working correctly after calibration.

Green LED off

Power supply voltage out of range

Check the DC supply voltage is within the acceptable range.

Drive protection is activated

Check for a short circuit between the power connector terminals.

Check the motor inductance is not too low.

Motor not in full control

Tachogenerator cables reversed

Reverse the tachogenerator cables.

Motor cables reversed

Reverse the motor cables.

No tachogenerator signal on pin 11

Check the tachogenerator and the tachogenerator cables.

RT resistor not installed

Calculate the correct value for the RT resistor see Setting up the drive to adjust

the components.

Speed reference signal

Reduce the speed reference signal to less than 1mV.

Motor turns in reverse direction

Speed reference signal connections reversed

Correct the speed reference signal connections.

Motor connections connections reversed

Correct the motor connections.

Tachogenerator connection pins reversed

Correct the tachogenerator connections.

Page 28

28 Mini Maestro User Guide

www.controltechniques.com Issue Number: 5

6 Accessories

DCD60x3/6

DCD60x7/14

Single-phase AC power supply

DCD60x3/6

DCD60x7/14

Three-phase AC power supply

DCD60x10/20

DCD60x14/28

Three-phase AC power supply

Code Description Part number

2MH

Panel mount installation kit including fuses and

connecting cable

7500-0008

3MB

Installation kit for 19 inch rack mounting including

screws and fuses

7500-0009

L11 0.7mH, 8A inductor 4371-1108

Bridge rectifier 25A 400V single - phase bridge rectifier

10,000µF 75V electrolytic capacitor 1664-1000

Code Description Part number

2MH

Panel mount installation kit including fuses and

connecting cable

7500-0008

3MB

Installation kit for 19 inch rack mounting including

screws and fuses

7500-0009

L11 0.7mH, 8A inductor 4371-1108

Bridge rectifier 25A 400V three - phase rectifier

10,000µF 75V electrolytic capacitor 1664-1000

Code Description Part number

2MH

Panel mount installation kit including fuses and

connecting cable

7500-0008

3MB

Installation kit for 19 inch rack mounting including

screws and fuses

7500-0009

L12 1mH, 14A inductor 4371-1214

Bridge rectifier 25A 400V three - phase rectifier

10,000µF 75V electrolytic capacitor 1664-1000

Page 29

Page 30

0470-0009-05

Loading...

Loading...