Page 1

Installation Manual

MMI-20040393, Rev AD

Micro Motion® TA-Series Flow and Density

Meters

April 2019

Page 2

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The EU declaration

of conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available

on the internet at www.emerson.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 704 136

Mexico +41 (0) 41 7686

111

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Europe and Middle East Asia Pacific

666

France 0800 917 901 India 800 440 1468

Central & Eastern +41 (0) 41 7686

111

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

New Zealand 099 128 804

Japan +81 3 5769 6803

2

Page 3

Installation Manual Contents

MMI-20040393 April 2019

Contents

Chapter 1 Planning........................................................................................................................ 5

1.1 About this document........................................................................................................................5

1.2 Related documentation....................................................................................................................5

1.3 Installation checklist.........................................................................................................................6

1.4 Best practices................................................................................................................................... 7

1.5 Temperature limits...........................................................................................................................7

Chapter 2 Mounting.......................................................................................................................9

2.1 Mount the meter.............................................................................................................................. 9

Chapter 3 Wiring......................................................................................................................... 11

3.1 Tantalum wiring............................................................................................................................. 11

Chapter 4 Grounding....................................................................................................................13

Chapter 5 Purge the sensor case ..................................................................................................15

Installation Manual 3

Page 4

Contents Installation Manual

April 2019 MMI-20040393

4 Micro Motion TA Series

Page 5

Installation Manual

MMI-20040393 April 2019

Planning

1 Planning

1.1 About this document

This manual provides information on planning, mounting, and grounding the meter. For

information on full configuration, maintenance, troubleshooting, or service of the

transmitter, see the configuration and use manual.

The information in this document assumes that users understand:

• Basic transmitter and sensor installation, configuration, and maintenance concepts

and procedures

• All corporate, local government, and national government safety standards and

requirements that guard against injuries and death

1.2 Related documentation

You can find all product documentation on the product documentation DVD shipped with

the product or at www.emerson.com.

For more information, see any of the following documents:

Product Data Sheets

• Micro Motion TA-Series Flow and Density Meters Product Data Sheet

• Micro Motion Model 5700 Product Data Sheet

Other installation manuals

• Micro Motion Model 5700 Transmitters with Configurable Outputs: Installation Manual

• Micro Motion Model 5700 with Ethernet Transmitters: Installation Manual

• Micro Motion Model 5700 Transmitters for FOUNDATION™ Fieldbus: Installation Manual

• Micro Motion Model 5700 Transmitters with Intrinsically Safe Outputs: Installation Manual

Configuration and use manuals

• Micro Motion Model 5700 Transmitters with Configurable Outputs: Configuration and Use

Manual

• Micro Motion Model 5700 with Ethernet Transmitters: Configuration and Use Manual

• Micro Motion Model 5700 Transmitters for FOUNDATION™ Fieldbus: Configuration and Use

Manual

• Micro Motion Model 5700 Transmitters with Intrinsically Safe Outputs: Configuration and

Use Manual

Other documents

• Modbus Interface Tool

• For hazardous area installations, see the approval documentation shipped with the

transmitter, or download the appropriate documentation at www.emerson.com.

Installation Manual 5

Page 6

Planning Installation Manual

April 2019 MMI-20040393

1.3 Installation checklist

□ Safety messages are provided throughout this content to protect personnel and

equipment. Read each safety message carefully before proceeding to the next step.

□ If possible, install the meter in a location that will prevent direct exposure to sunlight.

The environmental limits for the meter may be further restricted by hazardous area

approvals.

□ If you plan to mount the meter in a hazardous area:

— Verify that the meter has the appropriate hazardous area approval. Each meter has

a hazardous area approval tag attached to the meter housing.

— For ATEX/IECEx installations, strictly adhere to the safety instructions documented

in the ATEX/IECEx approvals documentation available on the Product

Documentation DVD shipped with the product or at www.emerson.com. Be sure to

reference this documentation in addition to the information shown in this guide.

□ Verify that the local ambient and process temperatures are within the limits of the

meter.

1.3.1

□ Follow the wiring instructions in the Model 5700 installation manual for signal and

power wiring.

□ Mount the meter in a location and orientation that allows sufficient clearance to open

the housing cover. Allow 8 in (203 mm) to 10 in (254 mm) clearance at the wiring

access points.

□ Install the meter so that the flow direction arrow on the sensor case matches the actual

forward flow of the process. Flow direction is also software-selectable.

Orientation options

You can mount the meter in any orientation as long as the conduit openings or display do

not point upward. Keep the sensor tubes full of process fluid to achieve best performance.

CAUTION

Installing the meter with the conduit openings or display facing upward risks moisture

entering the housing, which could damage the meter.

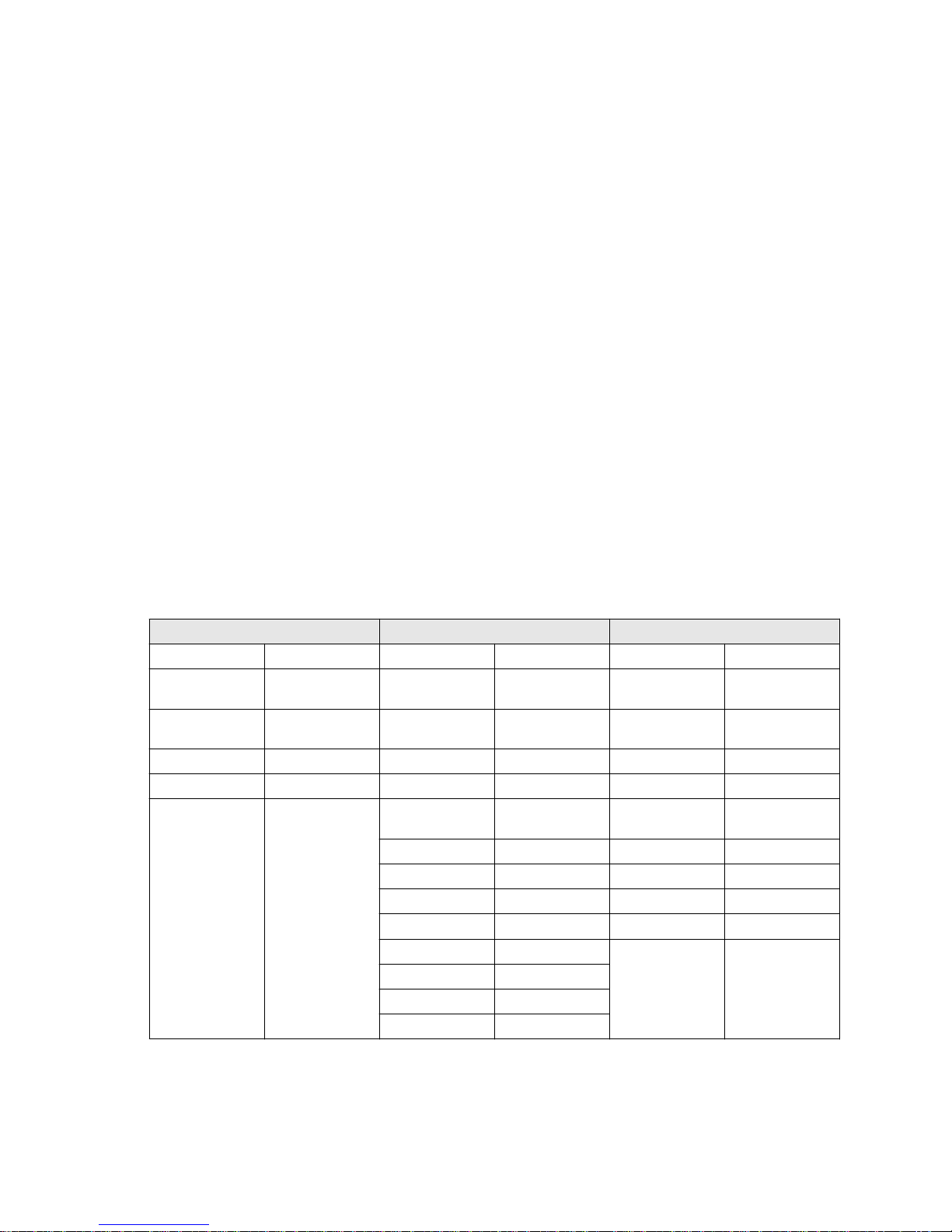

Table 1-1: Preferred sensor orientation

Liquids

6 Micro Motion TA Series

Page 7

Installation Manual

MMI-20040393 April 2019

Table 1-1: Preferred sensor orientation (continued)

Gases

Slurries

Planning

1.4 Best practices

• There are no pipe run requirements for Emerson meters. Straight runs of pipe

upstream or downstream are unnecessary.

• If the meter is installed in a vertical pipeline, liquids and slurries should flow upward

through the meters. Gases should flow downward.

• Keep the meter tubes full of process fluid.

• For halting flow through the meter with a single valve, install the valve downstream

from the meter.

• Minimize bending and torsional stress on the meter. Do not use the meter to align

misaligned piping.

• The meter does not require external supports. The flanges will support the sensor in

any orientation.

• Do not use the junction box to pick up the meter.

• Do not use the junction box as a step.

• Do not unscrew and rotate the junction box as this will break the wires.

• Do not install the meter in suspended pipes.

• Do not adjust the meter position by pulling or grasping the meter.

1.5 Temperature limits

Temperature type Min Max

Process temperature -40 °F (-40.0 °C) 356 °F (180.0 °C)

Ambient temperature -40 °F (-40.0 °C) 176 °F (80.0 °C)

Use the extended mount junction box (electronic interface code H) for process

temperatures above 176 °F (80.0 °C).

Installation Manual 7

Page 8

Planning Installation Manual

April 2019 MMI-20040393

8 Micro Motion TA Series

Page 9

Installation Manual Mounting

MMI-20040393 April 2019

2 Mounting

2.1 Mount the meter

Use your common practices to minimize torque and bending load on process connections.

Prerequisites

Read the installation checklist and best practices if you have not yet done so already. See

Installation checklist and Best practices.

Procedure

Mount the meter using the following illustration.

Installation Manual 9

Page 10

Mounting Installation Manual

April 2019 MMI-20040393

10 Micro Motion TA Series

Page 11

Installation Manual Wiring

MMI-20040393 April 2019

3 Wiring

3.1 Tantalum wiring

• A 9-wire cable is limited to 1,000 ft (304.80 m) between the sensor and the

transmitter.

• If you are using the Smart Meter Verification (SMV) application, the 9-wire cable is

limited to 60 ft (18.29 m) maximum.

• Use Teflon™ jacketed cable for SMV applications.

DANGER

Make sure the hazardous area specified on the sensor approval tag is suitable for the

environment in which the sensor will be installed. Failure to comply with the

requirements for intrinsic safety in a hazardous area could result in an explosion.

CAUTION

Fully close and tighten all housing covers and conduit openings. Improperly sealed

housings can expose electronics to moisture, which can cause measurement error or

flowmeter failure. Inspect and grease all gaskets and O-rings.

3.1.1

Connect the 9-wire cable

Procedure

1. Prepare and install the cable according to the instructions in the Micro Motion 9-Wire

Flowmeter Cable Preparation and Installation Guide.

2. Insert the stripped ends of the individual wires into the terminal blocks of the

junction box. Ensure that no bare wires remain exposed.

Terminal block number

1 Blue

Wire color

Installation Manual 11

Page 12

Wiring Installation Manual

April 2019 MMI-20040393

Terminal block number Wire color

2 Gray

3 Green

4 White

5 Orange

6 Yellow

7 Purple

8 Red

9 Brown

shield

3. Match the wires color for color. For wiring at the transmitter or remote core

processor, refer to the transmitter documentation.

4. Tighten the screws to hold the wires in place.

5. Ensure integrity of gaskets, then tightly close and seal the junction box cover and all

housing covers.

6. Refer to the transmitter installation manual for signal and power wiring

instructions.

12 Micro Motion TA Series

Page 13

Installation Manual Grounding

MMI-20040393 April 2019

4 Grounding

The meter must be grounded according to the standards that are applicable at the site.

The customer is responsible for knowing and complying with all applicable standards.

Prerequisites

Use the following guides for grounding practices:

• In Europe, IEC 60079-14 is applicable to most installations, in particular Sections

16.2.2.3 and 16.2.2.4.

• In the U.S.A. and Canada, ISA 12.06.01 Part 1 provides examples with associated

applications and requirements.

If no external standards are applicable, follow these guidelines to ground the sensor:

• Use copper wire, 14 AWG (2.08 mm²) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

CAUTION

Ground the flowmeter to earth, or follow ground network requirements for the facility.

Improper grounding can cause measurement error.

Procedure

• Check the joints in the pipeline.

• If the joints in the pipeline are ground-bonded, the sensor is automatically

grounded and no further action is necessary (unless required by local code).

• If the joints in the pipeline are not grounded, connect a ground wire to the

grounding screw located on the sensor electronics.

Tip

The sensor electronics may be a transmitter, core processor, or junction box. The

grounding screw may be internal or external.

Installation Manual 13

Page 14

Grounding Installation Manual

April 2019 MMI-20040393

14 Micro Motion TA Series

Page 15

Installation Manual Purge the sensor case

MMI-20040393 April 2019

5 Purge the sensor case

Prerequisites

Make sure the following are available before beginning the purge procedure:

• Teflon™ tape

• Argon or nitrogen gas sufficient to purge the sensor case

Whenever a purge plug is removed from the sensor case, you must repurge the case.

Procedure

1. Shut down the process, or set control devices for manual operation. Before

performing the case purging procedure, shut down the process or set the control

devices for manual operation. Performing the purge procedure while the flowmeter

is operating could affect measurement accuracy, resulting in inaccurate flow

signals.

2. Remove both purge plugs from the sensor case. If purge lines are being used, open

the valve in the purge lines.

DANGER

• Stay clear of the rupture disk pressure relief area. High-pressure fluid escaping

from the sensor can cause severe injury or death. The sensor must be oriented

so that personnel and equipment will not be exposed to any discharge along

the pressure relief path.

• Take all necessary precautions when removing purge plugs. Removing a purge

plug compromises the secondary containment of the sensor and could expose

the user to process fluid.

• Improper pressurization of the sensor case could result in personal injury.

CAUTION

Be sure to use thread protectors when removing the purge fitting so as not to

damage the disk membrane surrounding the rupture disk.

3. Prepare the purge plugs for reinstallation by wrapping them with 2–3 turns of

Teflon tape.

4. Connect the supply of nitrogen or argon gas to the inlet purge connection or open

inlet purge line. Leave the outlet connection open.

• Exercise caution to avoid introducing dirt, moisture, rust, or other contaminants

into the sensor case.

• If the purge gas is heavier than air (such as argon), locate the inlet lower than the

outlet, so that the purge gas will displace air from bottom to top.

• If the purge gas is lighter than air (such as nitrogen), locate the inlet higher than

the outlet, so that the purge gas will displace air from top to bottom.

Installation Manual 15

Page 16

Purge the sensor case Installation Manual

April 2019 MMI-20040393

5. Make sure that there is a tight seal between the inlet connection and sensor case, so

that air cannot be drawn by suction into the case or purge line during the purging

process.

6. Run purge gas through the sensor.

The purge time is the amount of time required for full exchange of atmosphere to

inert gas. The larger the line size, the greater amount of time is required to purge

the case. If purge lines are being used, increase the purge time to fill the additional

volume of the purge line.

Note

Keep the purge gas pressure below 7.25 psi (0.5 bar).

7. At the appropriate time, shut off the gas supply, then immediately seal the purge

outlet and inlet connections with the purge plugs.

Avoid pressurizing the sensor case. If pressure inside the case elevates above

atmospheric pressure during operation, the flowmeter density calibration will be

inaccurate.

8. Make sure that the purge fitting seals are tight so that air cannot be drawn by

suction into the sensor case.

16 Micro Motion TA Series

Page 17

Installation Manual

MMI-20040393 April 2019

Installation Manual 17

Page 18

*MMI-20040393*

MMI-20040393

Rev. AD

2019

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado USA 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.emerson.com

Micro Motion Asia

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6363-7766

F +65 6770-8003

©

2019 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE,

ProLink, MVD and MVD Direct Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of their respective owners.

Micro Motion Europe

Emerson Automation Solutions

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.micromotion.nl

Micro Motion United Kingdom

Emerson Automation Solutions

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Loading...

Loading...