Page 1

Installation Manual

20002273, Rev. AA

Micro Motion® MVD™ Direct Connect™

Meters

July 2014

Page 2

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EC declaration of conformity for directives that apply to this product. The EC declaration of

conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available on

the internet at www.micromotion.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive can be found on the internet at

www.micromotion.com/documentation.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the transmitter

configuration manual. Product data sheets and manuals are available from the Micro Motion web site at www.micromotion.com/

documentation.

Return policy

Micro Motion procedures must be followed when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Failure to follow Micro Motion

procedures will result in your equipment being refused delivery.

Information on return procedures and forms is available on our web support system at www.micromotion.com, or by phoning the

Micro Motion Customer Service department.

Micro Motion customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 318 495 555 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800917901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudia Arabia 800 844 9564

UAE 800 0444 0684

Page 3

Contents

Chapter 1 Before you begin .......................................................................................................... 5

1.1 Safety .................................................................................................................................... 5

Chapter 2 Product overview and architecture .............................................................................. 7

2.1 Installation options ................................................................................................................ 7

2.2 Multidrop installation............................................................................................................. 10

Chapter 3 Installation................................................................................................................... 11

3.1 Supplying power .................................................................................................................... 11

3.1.1 MVD Direct Connect installations without the MVD Direct Connect I.S. barrier ....... 11

3.1.2 MVD Direct Connect installations with the MVD Direct Connect I.S. barrier ............. 12

3.2 Locating the components ......................................................................................................13

3.3 Installing the core processor .................................................................................................. 14

3.4 Wiring the core processor to the sensor ................................................................................. 18

3.5 4-wire cable preparation and core processor wiring ............................................................... 18

3.6 Installing the MVD Direct Connect I.S. barrier......................................................................... 21

3.7 Wiring at the MVD Direct Connect I.S. barrier ........................................................................ 22

3.8 Wiring to the remote host...................................................................................................... 23

3.9 Wiring to the power supply .................................................................................................... 24

3.10 Grounding ............................................................................................................................. 24

Chapter 4 MVD Direct Connect communications .......................................................................... 27

4.1 Addresses .............................................................................................................................. 27

4.2 Response time ....................................................................................................................... 27

4.3 Byte order in floating-point values ......................................................................................... 27

4.4 Additional information........................................................................................................... 28

Installation Manual 3

Page 4

4 Direct Connect Meters

Page 5

Before you begin

1 Before you begin

This manual provides installation information for Micro Motion®MVD™ Direct Connect

meters. MVD Direct Connect meters may or may not include the MVD Direct Connect I.S.

barrier. Both installation types are discussed here.

Additionally, this manual provides basic information for establishing communication

between the MVD Direct Connect meter and the remote host system.

1.1 Safety

For information on I.S. applications, refer to Micro Motion ATEX, UL, or CSA installation

instructions.

WARNING!

Improper installation in a hazardous area can cause an explosion. For information about

hazardous applications, refer to the appropriate Micro Motion approval documentation,

shipped with the meter or available from the Micro Motion web site.

CAUTION!

Excess voltage can damage the core processor. To avoid damaging the core processor, use only

low-voltage DC power.

Installation Manual 5

Page 6

Before you begin

6 Direct Connect Meters

Page 7

Product overview and architecture

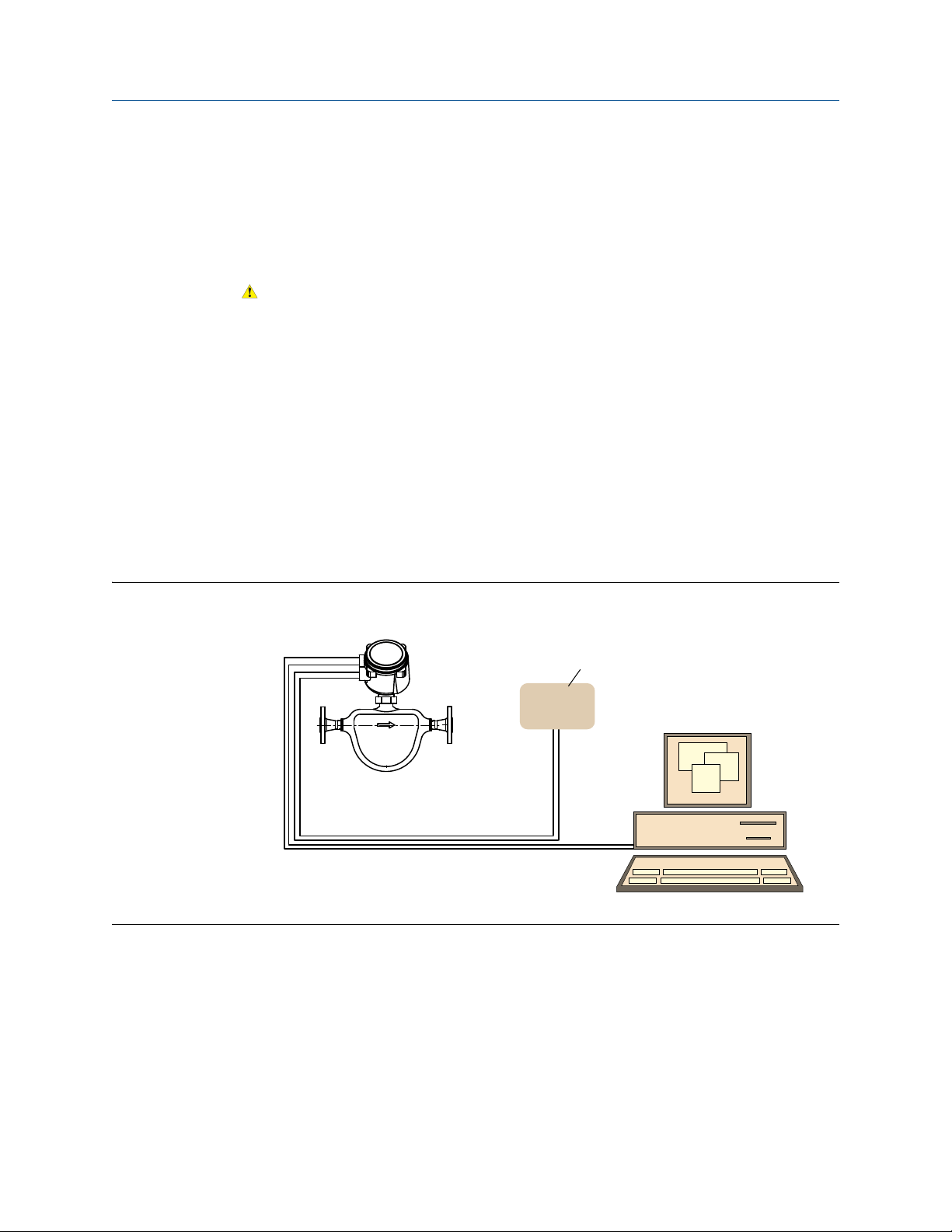

Core processor

Remote host

User-supplied power cable

User-supplied RS-485 cable

DC power supply

Sensor

2 Product overview and architecture

MVD Direct Connect meters are used to supply Micro Motion sensor data directly to a

remote Modbus-capable host, rather than to a Micro Motion transmitter. Because there is

no transmitter component, MVD Direct Connect systems are not intrinsically safe unless

the MVD Direct Connect I.S. barrier is included in the installation.

WARNING!

MVD Direct Connect systems without the MVD Direct Connect I.S. barrier are not intrinsically

safe.

2.1 Installation options

All MVD Direct Connect systems include a sensor and a core processor. Either the standard

core processor or the enhanced core processor may be installed. The core processor

(standard or enhanced) can be mounted integrally with the sensor or remotely.

If the MVD Direct Connect I.S. barrier is installed, a separate barrier is required for each

core processor.

See Figure 2-1 and Figure 2-2 for illustrations of MVD Direct Connect installations without

the MVD Direct Connect I.S. barrier. See Figure 2-3 and Figure 2-4 for illustrations of

MVD Direct Connect installations with the MVD Direct Connect I.S. barrier.

Figure 2-1 MVD Direct Connect installations – Integral core processor, no I.S. barrier

Installation Manual 7

Page 8

Product overview and architecture

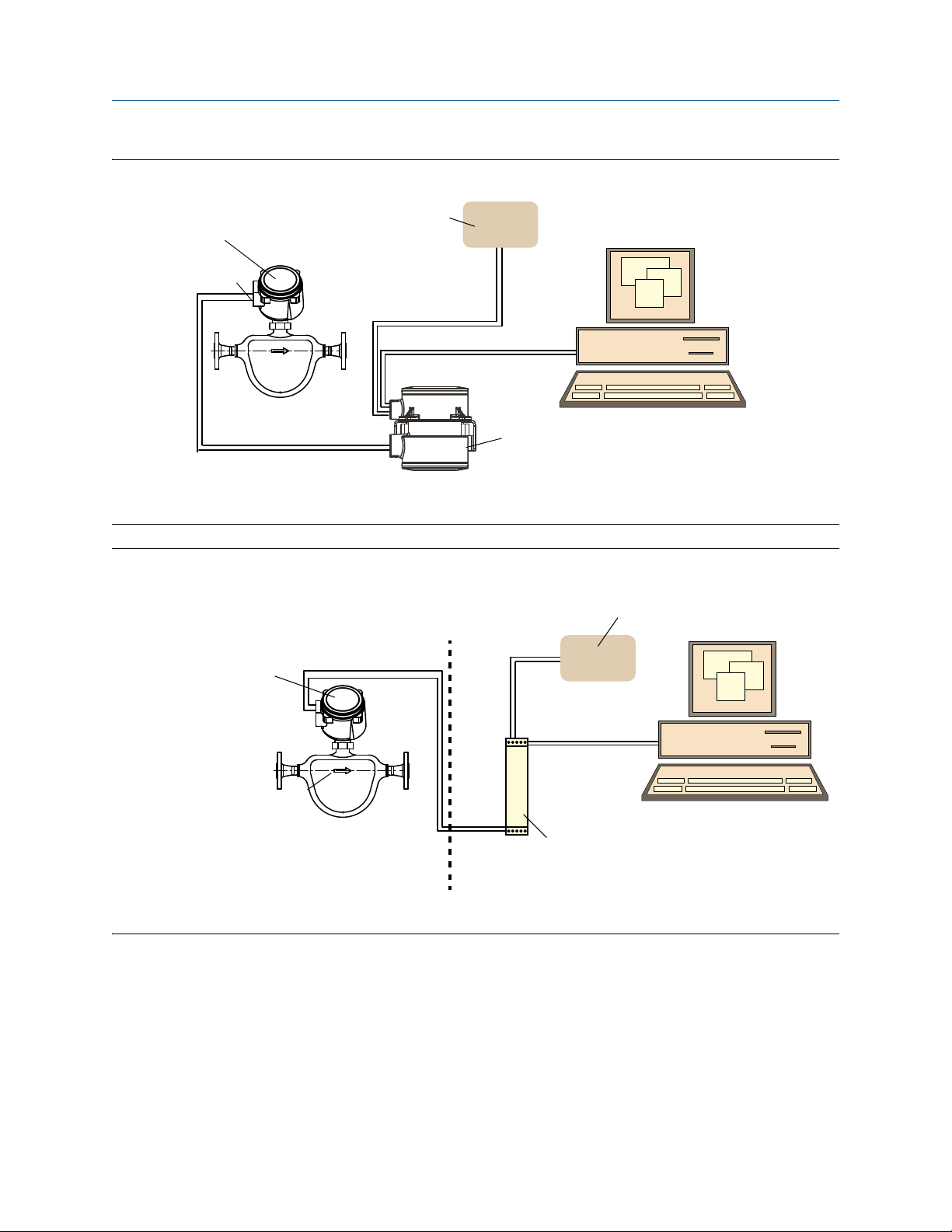

User-supplied

power cable

User-supplied RS-485 cable

Sensor

Core processor

Junction box

Micro Motion 9-wire cable

Remote host

DC power supply

Remote host

User-supplied power

cable

User-supplied

RS-485 cable

4-wire cable

Core processor

Sensor

DC power supply

Safe areaHazardous area

Barrier

Figure 2-2 MVD Direct Connect installations – Remote core processor, no I.S. barrier

Figure 2-3 MVD Direct Connect installations – Integral core processor, I.S. barrier

8 Direct Connect Meters

Page 9

Product overview and architecture

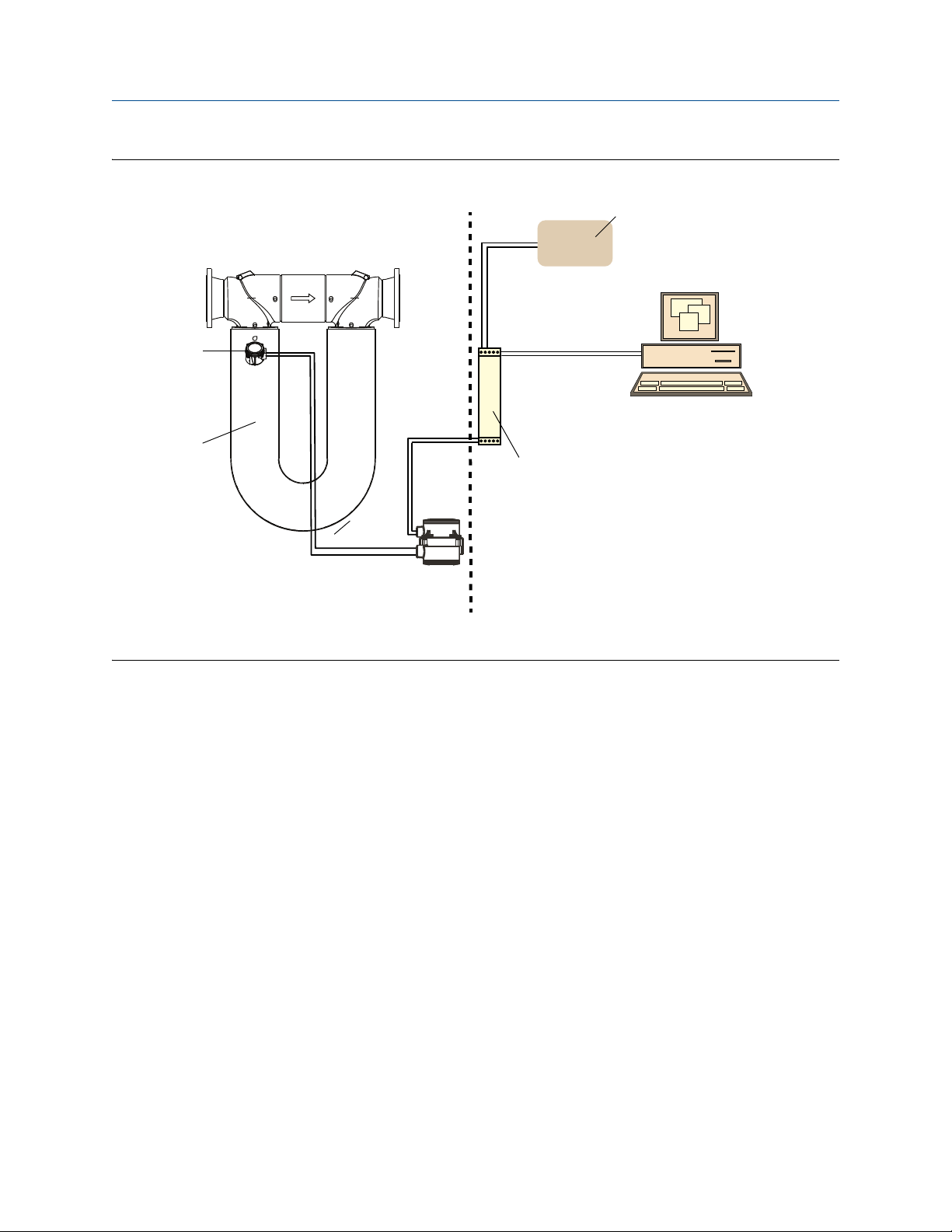

4-wire cable

User-supplied power

cable

User-supplied

RS-485 cable

Sensor

Micro Motion

9-wire cable

DC power supply

Remote host

Safe areaHazardous area

Barrier

Core processor

Junction box

Figure 2-4 MVD Direct Connect installations – Remote core processor, I.S. barrier

Installation Manual 9

Page 10

2.2 Multidrop installation

Safe area

Hazardous area

Up to fifteen MVD Direct Connect installations can be networked to a single remote host. If

I.S. barriers are used, one barrier is required for each core processor. Figure 2-5 shows the

four options for a multidrop installation.

Figure 2-5 Multidrop installation options

Product overview and architecture

10 Direct Connect Meters

Page 11

Installation

MinimumSupplyVoltage 15V CableResistance CableLength 0.15A+=

3 Installation

3.1 Supplying power

Power supply requirements depend on your installation type:

• MVD Direct Connect without the MVD Direct Connect I.S. barrier (see Figure 2-1 and

Figure 2-2)

• MVD Direct Connect with the MVD Direct Connect I.S. barrier (see Figure 2-3 and Figure

2-4)

3.1.1 MVD Direct Connect installations without the

MVD Direct Connect I.S. barrier

In MVD Direct Connect installations without the I.S. barrier, power is supplied directly to

the core processor. The core processor supplies power to the sensor. The power supply

must meet the following requirements:

• Power must be supplied from a common floating regulated power supply with the

correct voltage.

• The voltage requirement for a single core processor is 15–26 VDC. The maximum

power consumption of a single core processor is approximately 3 W.

• The power supply may be used to power any number of core processors, but must not

be used to power other devices.

• Use shielded wiring.

• The power supply must not allow power surges or conducted radio frequency

interference (RFI) to propagate through to its output.

• The power supply must not be grounded.

CAUTION!

Grounding the power supply to the core processor can cause damage to the core processor or

the remote host. To avoid damaging the core processor or the remote host, ensure that the

power supply to the core processor is not grounded.

• In EU countries, the power supply must meet the requirements of the EMC directive.

• The power supply cable must comply with the size and length requirements listed in

Table 3-2. A minimum DC input of 15 V is required for each core processor. At startup,

the power source must provide a minimum of 0.2 A of short-term current per core

processor. The maximum steady state current is 0.15 A. For assistance in sizing the

power supply cable, refer to Table 3-1 and use the equation below:

Installation Manual 11

Page 12

Installation

MinimumSupplyVoltage 15V 0.0128 ohms/ft 350 ft 0.15A+=

MinimumSupplyVoltage 15V CableResistance CableLength 0.15 A+=

MinimumSupplyVoltage 15.7V=

MinimumSupplyVoltage 19.2V CableResistance CableLength 0.15A+=

Example

The core processor is mounted 350 feet from a DC power supply. If you want to use 18 AWG cable,

calculate the required voltage at the DC power supply as follows:

Table 3-1 Typical power cable resistances at 68 °F (20 °C)

Gauge Resistance

14 AWG 0.0050 /foot

16 AWG 0.0080 /foot

18 AWG 0.0128 /foot

20 AWG 0.0204 /foot

22 AWG 0.0328 /foot

2,5 mm

1,5 mm

1 mm

0,75 mm

0,5 mm

2

2

2

2

2

0,0136 /meter

0,0228 /meter

0,0340 /meter

0,0460 /meter

0,0680 /meter

Note

These values include the resistance of both high and low conductors in a cable.

3.1.2 MVD Direct Connect installations with the

MVD Direct Connect I.S. barrier

In MVD Direct Connect installations with the I.S. barrier, power is supplied to the barrier.

The barrier supplies power to the core processor, and the core processor supplies power to

the sensor. The power supply must meet the following requirements:

• The power supply can be either floating or grounded.

• The voltage requirement for a single barrier is 24 VDC ±20%. The maximum power

consumption of a single barrier plus core processor is approximately 3.5 W.

• The power supply cable must comply with the size and length requirements listed in

Table 3-3. A minimum DC input of 19.2 V is required at the barrier terminals. At

startup, the power source must provide a minimum of 0.2 A of short-term current per

core processor. The maximum steady state current is 0.15 A. For assistance in sizing

the power supply cable, refer to Table 3-1 and use the equation below:

12 Direct Connect Meters

Page 13

Installation

MinimumSupplyVoltage 19.9V=

MinimumSupplyVoltage 19.2V CableResistance CableLength 0.15A+=

MinimumSupplyVoltage 19.2V 0.0128 ohms/ft 350 ft 0.15A+=

Example

A single MVD Direct Connect I.S. barrier is mounted 350 feet from a DC power supply. If you want to

use 18 AWG cable, calculate the required voltage at the DC power supply as follows:

3.2 Locating the components

See the sensor installation manual for information on locating the sensor or the sensor/

core processor assembly. If the core processor is installed remotely from the sensor, see

the sensor installation manual for information on the maximum distance between these

two components.

Maximum distance between the core processor, the power supply, the remote host, and

the I.S. barrier (if your installation includes the barrier) depends on the wire size and type.

Ensure that your installation complies with these requirements.

• Table 3-2 lists the wire size and length requirements for MVD Direct Connect

installations without the I.S. barrier.

• Table 3-3 lists the wire size and length requirements for MVD Direct Connect

installations with the I.S. barrier.

Table 3-2 Wire sizes and lengths – MVD Direct Connect installations without I.S.

barrier

Span Cable type Wire size Max length

Core processor to

remote host

Core processor to

power supply

Note

Power wires must be sized to provide a minimum of 15 V at the core processor. See the discussion in

the preceding section.

RS-485 22 AWG (0,35 mm2) or

Power 22 AWG (0,35 mm

larger

20 AWG (0,5 mm

18 AWG (0,8 mm

2

) 300 feet (90 meters)

2

) 500 feet (150 meters)

2

) 500 feet (150 meters)

500 feet (150 meters)

Installation Manual 13

Page 14

Installation

Mounting bracket

(wall mount)

Mounting bracket

(pipe mount)

Table 3-3 Wire sizes and lengths – MVD Direct Connect installations with I.S. barrier

Span Cable type Wire size Max length

Core processor

to barrier

Barrier to host RS-485 22 – 18 AWG

Barrier to power

supply

Notes

• Core processor to barrier wire must be sized to provide a minimum of 15 V at the core processor.

See the discussion in the preceding section.

• Barrier to power supply wiring must be sized to provide a minimum of 19.2 V at the barrier. See

the discussion in the preceding section

RS-485 22 AWG (0,35 mm2) or larger 500 feet (150 meters)

Power 22 AWG (0,35 mm

2

) 300 feet (90 meters)

20 AWG (0,5 mm2) 500 feet (150 meters)

18 AWG (0,8 mm

(0,35 – 0,8 mm

2

) 500 feet (150 meters)

2)

1000 ft (300 meters)

Power 22 AWG (0,35 mm2) 300 feet (90 meters)

20 AWG (0,5 mm

18 AWG (0,8 mm

2

) 500 feet (150 meters)

2

) 500 feet (150 meters)

3.3 Installing the core processor

Note

This step is required only if the core processor is mounted separately from the sensor. Refer to Figure

2-2 and Figure 2-4.

See Figure 3-1 for a diagram of the mounting bracket supplied with the core processor.

Both pipe mounting and wall mounting are shown.

Figure 3-1 Remote core processor – Wall mount or pipe mount

14 Direct Connect Meters

Page 15

Installation

End-cap (to 9-wire ground screw)

Mounting bracket

Core processor cover

Core processor housing

Conduit opening

for 4-wire cable

Conduit opening

for 9-wire cable

4 X Cap screws (4 mm)

To mount the core processor:

1. Identify the components shown in Figure 3-2. For dimensions, see Figure 3-3.

2. If desired, reorient the core processor housing on the bracket.

a. Loosen each of the four cap screws (4 mm).

b. Rotate the bracket so that the core processor is oriented as desired.

c. Tighten the cap screws, torquing to 30 to 38 in-lbs (3 to 4 N-m).

3. Attach the mounting bracket to an instrument pole or wall. For pipe mount, two

user-supplied U-bolts are required. Contact Micro Motion to obtain a pipe-mount

installation kit if required.

Figure 3-2 Remote core processor components

Installation Manual 15

Page 16

Figure 3-3 Dimensions – Remote core processor

1/2˝–14 NPT

or

M20 X 1.5

2 13/16

(71)

2 1/4 (57)

4 1/2

(114)

3 5/16 (84)

1 11/16 (43)

To centerline

of 2˝ pipe

5 1/2

(140)

Pipe mount

2 1/2

(64)

2X 3 (76)

2 5/8 (67)

4X Ø3/8

(10)

4 9/16

(116)

Wall mount

2 13/16 (71)

5 11/16 (144)

3/4˝–14 NPT

2 3/8

(61)

Ø4 3/8

(111)

Dimensions in

inches

(mm)

6 3/16

(158)

Installation

16 Direct Connect Meters

Page 17

Installation

1/2˝–14 NPT

or

M20 X 1.5

2 13/16

(71)

3 13/16

(97)

4 1/2

(114)

2 5/16

(58)

4 9/16

(116)

To centerline

of 2˝ pipe

5 1/2

(140)

Pipe mount

2 1/2

(64)

2X 3

(76)

5 7/16

(67)

4X Ø3/8

(10)

4 9/16

(116)

Wall mount

2 13/16

(71)

5 11/16

(144)

3/4˝–14 NPT

3 7/8

(99)

Ø4 3/8

(111)

Dimensions in

inches

(mm)

6 3/16

(158)

Figure 3-4 Dimensions – Remote enhanced core processor

Installation Manual 17

Page 18

Installation

3.4 Wiring the core processor to the sensor

Note

This step is required only if the core processor is mounted separately from the sensor. Refer to Figure

2-2 and Figure 2-4.

Wire the core processor to the sensor using a Micro Motion 9-wire cable. See the sensor

installation manual for instructions.

3.5 4-wire cable preparation and core processor wiring

Note

This step is required for all MVD Direct Connect installations

1. Ensure that the cables meet the following requirements:

- Twisted-pair construction

- The size and length requirements described in the preceding sections

2. Use one of the following methods to shield the wiring from the core processor:

- If you are installing unshielded cable, the cable must be installed in continuous metallic

conduit that provides 360° termination shielding for the enclosed wiring. Go to Step 7.

- If you are installing shielded or armored cable with a user-supplied cable gland, terminate

the shield or braid and drain wires in the cable gland. Never connect the drain wires to the

internal ground screw of the core processor. Go to Step 7.

- If you are installing shielded or armored cable with a Micro Motion-supplied cable gland:

• With shielded cable (where the shield consists of foil), prepare the cable and apply

shielded heat shrink as described in Steps 3 through 6. The shielded heat shrink provides a

shield termination suitable for use in the gland.

• With armored cable (where the shield consists of braid), prepare the cable as described

as described in Steps 3 through 6. Do not apply heat shrink (omit Steps 5d through 5g).

3. Remove the cover from the core processor.

4. Slide the gland nut and the clamping insert over the cable.

18 Direct Connect Meters

Page 19

Installation

4 1/2 in

(114 mm)

3/4 in

(19 mm)

7/8 in

(22 mm)

7/8 in

(22 mm)

Shielded

heat shrink

Gland body

Gland nut

Gland clamping

insert

Shield drain wire(s) wrapped twice around exposed shield foil

Figure 3-5 Micro Motion cable gland and heat shrink

5. For connection at the core processor housing, prepare cable as follows (for armored

cable, omit Steps 5d through 5g):

a. Strip 4 1/2 inches (114 mm) of cable jacket.

b. Remove the clear wrap that is inside the cable jacket, and remove the filler material

between the wires.

c. Remove the foil shield that is around the insulated wires, leaving 3/4 inch (19 mm)

of foil or braid and drain wires exposed, and separate the wires.

d. Wrap the shield drain wire(s) around the exposed foil twice. Cut off the excess wire.

Figure 3-6 Wrapping the shield drain wires

e. Place the shielded heat shrink over the exposed shield drain wire(s). The tubing

should completely cover the drain wires.

f. Without burning the cable, apply heat (250 °F or 120 °C) to shrink the tubing.

Installation Manual 19

Page 20

Figure 3-7 Applying the heat shrink

Shielded heat shrink completely covers exposed drain wires

g. Position gland clamping insert so the interior end is flush with the heat shrink.

h. Fold the cloth shield or braid and drain wires over the clamping insert and

approximately 1/8 inch (3 mm) past the O-ring.

Figure 3-8 Folding the cloth shield

Installation

i. Install the gland body into the core processor housing conduit opening.

Figure 3-9 Gland body and core processor housing

6. Insert the wires through the gland body and assemble the gland by tightening the

gland nut.

7. Connect signal wires to the RS-485 terminals on the core processor (see Figure 3-10). If

you are using Micro Motion 4-wire cable, use the green and white wires.

20 Direct Connect Meters

Page 21

Installation

RS-485/B

(Green)

4-wire ground screw

(do not use)

VDC –

(Black)

VDC +

(Red)

RS-485/A

(White)

RS-485/B (Green)

RS-485/A (White)

VDC+ (Red)

VDC– (Black)

Standard core processor Enhanced core processor

Figure 3-10 Connecting the wires at the core processor

8. Connect power supply wires to the VDC terminals on the core processor (see Figure

3-10). If you are using Micro Motion 4-wire cable, use the red and black wires.

9. Reattach the core processor cover.

CAUTION!

If the core processor is mounted integrally with the sensor, twisting the core processor will

damage the sensor. To avoid damaging the sensor, do not twist the core processor.

CAUTION!

Damaging the RS-485 wires can cause measurement error or meter failure. Damaging the

power supply wires can cause meter failure. When replacing the core processor cover, make

sure that the wires are not caught or pinched.

Installation Manual 21

Page 22

Installation

1.39

(35)

for mounting on

35 mm DIN rail

4.095

(104)

0.925

(23,5)

Dimensions in

inches

(mm)

4.291

(109)

3.6 Installing the MVD Direct Connect I.S. barrier

Note

This step is required only for installations that include the MVD Direct Connect I.S. barrier. Refer to

Figure 2-3 and Figure 2-4.

The barrier is designed to snap onto a 35 mm DIN rail. Dimensions are shown in Figure 3-11.

To remove the barrier from the rail, lift the bottom lock.

Figure 3-11 Barrier dimensions

22 Direct Connect Meters

Page 23

Installation

44 (RS-485 B)

43 (RS-485 A)

41 (VDC –)

42 (VDC +)

14 (RS-485 B)

13 (RS-485 A)

11 (VDC –)

12 (VDC +)

I.S. terminals

for connection to core processor

Non-I.S. terminals

for connection to remote host and power supply

3.7 Wiring at the MVD Direct Connect I.S. barrier

Note

This step applies only to installations that include the MVD Direct Connect I.S. barrier. Refer to Figure

2-3 and Figure 2-4.

1. Connect the core processor to the barrier:

a. Connect the RS-485 wires from the core processor to the I.S. RS-485 terminals at

the barrier (terminals 43 and 44), matching A and B. See Table 3-4 and Figure 3-12. If

you are using Micro Motion 4-wire cable, you can identify the wires by color.

b. Connect the power supply wires from the core processor to the I.S. VDC terminals

at the barrier (terminals 42 and 41), matching positive and negative (+ and –). See

Table 3-4 and Figure 3-12. Do not terminate the shields at the barrier.

Table 3-4 Core processor terminals and barrier I.S. terminals

Function

RS-485 A White 3 43

RS-485 B Green 4 44

VDC + Red 1 42

VDC – Black 2 41

Wire color (Micro Motion 4-wire

cable)

Core processor

terminals

Barrier I.S.

terminals

2. Connect RS-485 wires to the non-I.S. RS-485 terminals at the barrier (terminals 13 and

14). See Figure 3-12. These wires will be used in the next step to connect the barrier to

the remote host. Do not terminate the shields at the barrier.

3. Connect power supply wires to the non-I.S. VDC terminals at the barrier (terminals 11

and 12). See Figure 3-12. These wires will be used in the next step to connect the barrier

to the power supply.

Figure 3-12 Barrier terminals

Installation Manual 23

Page 24

3.8 Wiring to the remote host

Note

This step is required for all MVD Direct Connect installations.

1. At the remote host, open the wiring compartment and identify the RS-485 terminals.

Refer to the vendor documentation if required.

2. If you are connecting the RS-485 wires directly from the core processor (see Figures

2-1 and 2-2):

a. Connect the RS-485 wires from the core processor (see Figure 3-10) to the RS-485

terminals at the remote host.

b. Do not terminate the shield, braid, or drain wire(s) at the remote host.

c. Do not terminate the RS-485 lines using the standard 60-ohm termination resistor.

If possible, do not terminate the RS-485 lines at all. If the RS-485 cable is 1000 feet

(300 meters) long or longer, and termination is required, the total termination

must be 175 ohm or above.

3. If you are connecting the RS-485 wires from the I.S. barrier (see Figures 2-3 and 2-4):

a. Connect the RS-485 wires from the barrier (see Figure 3-12) to the RS-485 terminals

at the remote host.

Installation

b. Terminate the shields at the remote host.

c. The barrier contains internal pull-up/pull-down and termination resistors. Do not

add external resistors.

4. Close the wiring compartment.

3.9 Wiring to the power supply

Note

This step is required for all MVD Direct Connect installations.

1. You may connect multiple MVD Direct Connect installations to a single power supply,

as long as each installation receives sufficient power.

2. If you are connecting the power supply wires directly from the core processor (see

Figures 2-1 and 2-2):

a. Do not connect any other equipment to the power supply used for

MVD Direct Connect installations.

b. Connect the power supply wires from the core processor (see Figure 3-10),

matching positive and negative (+ and –).

If you are connecting the power supply wires from the I.S. barrier (see Figure 2-3 and

Figure 2-4):

a. The power supply may be used to power other equipment.

b. Connect the power supply wires from the barrier (see Figure 3-12), matching

positive and negative (+ and –).

24 Direct Connect Meters

Page 25

Installation

9-wire ground screw

3.10 Grounding

Note

This step is required for all MVD Direct Connect installations.

CAUTION!

Improper grounding could cause measurement error. To reduce the risk of measurement

error:

• Ground the meter to earth, or follow ground network requirements for the facility.

• For installation in an area that requires intrinsic safety, refer to the appropriate Micro

Motion approval documentation.

• For hazardous area installations in Europe, refer to standard EN 60079-14 if national

standards do not apply.

The sensor/core processor assembly (see Figure 2-1 and Figure 2-3) or the sensor alone (see

Figure 2-2 and Figure 2-4) must be grounded. To ground these components, see the sensor

installation manual.

If your installation includes a remote core processor (see Figure 2-2 and Figure 2-4), it must

be grounded. To ground the remote core processor:

• The core processor has two internal ground screws: one 4-wire ground screw and one

9-wire ground screw. Do not use the 4-wire ground screw. The 9-wire ground screw

may be used (see Figure 3-13). To access the 9-wire ground screw, remove the core

processor end-cap (see Figure 3-2).

• Use copper wire, 14 AWG (2,0 mm

• Keep all ground leads as short as possible, less than 1 ohm impedance.

• Connect ground leads directly to earth, or follow plant standards.

If your installation includes the MVD Direct Connect I.S. barrier (see Figure 2-3 and Figure

2-4), the barrier is not grounded. Do not ground the barrier.

2

) or larger, for grounding.

Figure 3-13 Core processor 9-wire ground screw

Installation Manual 25

Page 26

Installation

26 Direct Connect Meters

Page 27

MVD Direct Connect communications

4 MVD Direct Connect

communications

For communication with the remote host, the core processor uses an industry-standard

RS-485 half-duplex communication line driver. Supported communication settings are

described in Table 4-1. The remote host can use any supported setting and the core

processor will automatically detect and switch.

Table 4-1 Supported communication settings

Parameter Option

Protocol Modbus RTU (8-bit)

Modbus ASCII (7-bit)

Baud rate Standard rates between 1200 and 38,400

Parity Even, odd, none

Stop bits 1, 2

4.1 Addresses

When addressing specific registers in the core processor, certain remote hosts require the

program to subtract 1 from the address. For more information, see the manual entitled

Modbus Mapping Assignments for Micro Motion Transmitters.

4.2 Response time

The core processor’s default response time to a valid query is 1.2 milliseconds. If required,

a delay may be programmed into the core processor (see the manual entitled Modbus

Mapping Assignments for Micro Motion Transmitters).

The core processor may be queried as often as once every 10 milliseconds. If you are

sending queries at this rate at 38,400 baud, a maximum of three floating-point values can

be returned per query.

Core processors may be multidropped, with a maximum of 15 per segment.

Communication throughput is improved with fewer units per segment.

4.3 Byte order in floating-point values

Four bytes are used to transmit floating-point values. When the core processor leaves the

Micro Motion factory, its default byte order is either 1–2–3–4 (typical) or 3–4–1–2. For

contents of bytes, see Table 4-2.

Installation Manual 27

Page 28

MVD Direct Connect communications

Table 4-2 Byte contents in Modbus commands and responses

Byte Bits Definitions

1 S E E E E E E E S = Sign

E = Exponent

2 E M M M M M M M E = Exponent

M = Mantissa

3 M M M M M M M M M = Mantissa

4 M M M M M M M M M = Mantissa

If the core processor is attached to a transmitter for any reason (for example, for field

testing), the byte order is automatically set to 1–2–3–4. It may be necessary to reset the

byte order before resuming MVD Direct Connect operation. Byte order is controlled by the

value in register 521. The byte order codes and associated byte orders are listed in Table

4-3.

Table 4-3 Byte order codes and byte orders

Byte order code Byte order

01

13–4–1–2

22

34

–2–3–4

–1–4–3

–3–2–1

4.4 Additional information

For more information on programming a remote host for use with MVD Direct Connect

systems, see the manual entitled Modbus Mapping Assignments for Micro Motion

Transmitters.

28 Direct Connect Meters

Page 29

MVD Direct Connect communications

Installation Manual 29

Page 30

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.micromotion.com

Micro Motion Europe

Emerson Process Management

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 318 495 555

F +31 (0) 318 495 556

www.micromotion.nl

*20002273*

20002273

Rev. AA

2014

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Micro Motion Japan

Emerson Process Management

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

©2014 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Process

Management family of companies. All other marks are property of

their respective owners.

Loading...

Loading...