Emerson D Control Station Flameproof, DM Motor Starters, MS Motor Starters, EB Circuit Breakers Enclosures, GLOBAL PROTECTION Brochure

GLOBAL PROTECTION

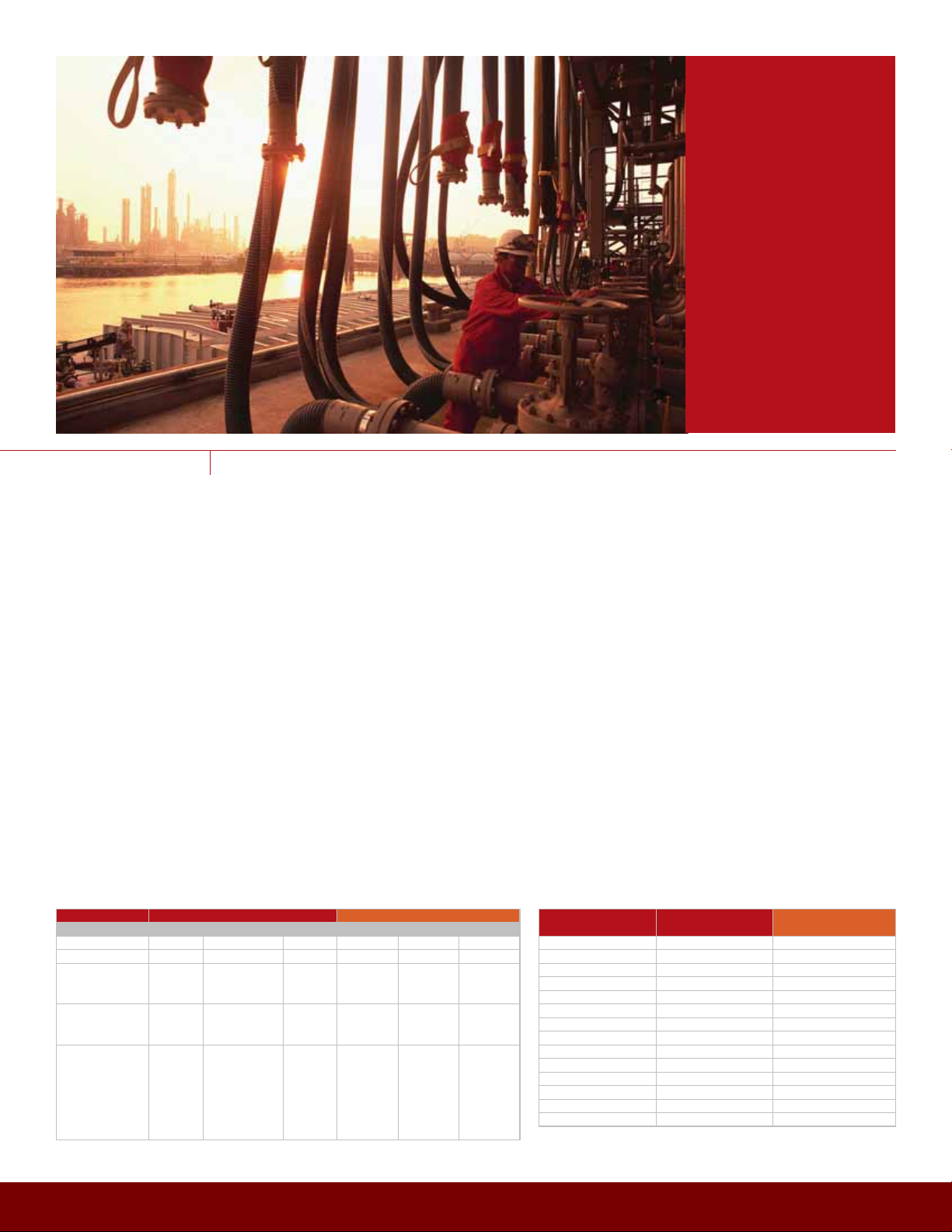

INTRODUCTION PROTECTING YOUR PEOPLE AND YOUR FACILITIES

Manufacturing and processing facilities, and the environments

they inhabit, continually challenge both man and machine.

With the presence of ammable gases and vapors, these

locations demand electrical products engineered to provide

proper protection from dangers like heat or spark-induced

ignition. ey must also endure nature’s toughest treatment

through corrosive ocean air on o shore rigs in the North Sea,

extreme heat at re neries in Saudi Arabia and frigid arctic

winds at mining facilities in the Canadian Oil Sands.

For over 100 years Appleton products have been helping to protect facilities, and their workers.

Whether your geography requires ATEX, IEC, NEC, or CEC certi cation, our product range,

regulatory involvement and technical expertise solve the challenges of out tting your facilities.

Our engineers have developed innovative advancements in lighting, electrical control devices

and instrumentation, making Appleton the leader in the production of hazardous location

electrical products.

At Appleton, we take the challenge of protecting hazardous environments seriously.

It is protection throughout your facility and around the globe.

INTRODUCTION IEC/ATEX VS. NEC/CEC HAZARDOUS LOCATIONS 4

LIGHTING INTRODUCTION 6

CONTROLS, ENCLOSURES

& PANELBOARDS

LED LIGHTING 8

FLUORESCENT LIGHTING 10

HID LIGHTING 12

STROBE & BEACON LIGHTING 14

INTRODUCTION 16

CONTROLS 18

ENCLOSURES 20

STARTERS 22

CIRCUIT BREAKERS 24

PANELBOARDS 26

PLUGS & RECEPTACLES

CABLE GLANDS,

CONNECTORS & FITTINGS

HEAT TRACING SYSTEMS

POWER QUALITY

SOLUTIONS

INTRODUCTION 28

PLUGS & RECEPTACLES 30

INTRODUCTION 32

CABLE GLANDS & CONNECTORS 34

CONDUIT FITTINGS 38

INTRODUCTION 40

HEAT TRACING SYSTEMS 42

INTRODUCTION 44

POWER QUALITY SOLUTIONS 43

1

GLOBAL UNDERSTANDING AND EXPERTISE

Appleton electrical products help protect re nery production in India, ensure pipeline ow in South Africa, and maintain deep sea drilling

operations in the Gulf of Mexico. Our worldwide presence demands mastery of the International Electrotechnical Commission (IEC), ATEX Directive

and the North American (NEC/CEC) rules and a full product line for every application throughout hazardous locations.

IEC, ATEX and NEC/CEC rules each identify the amount of exposure, destructive force and ignition temperature of the gas, vapor or dust.

However, the separate regulations differ in their nomenclature and sub-category tracking. To assist in out tting and application, the following

pages show the ratings and categories of each regulation body and reference points.

IEC STANDARDS and EN

STANDARDS

IEC STANDARDS

are identical.

have

become the universal

reference across Europe

and are adopted along

with other admissible

standards in much of the

rest of the world. IEC uses

three Zones to classify

hazardous environment

conditions based on the

duration and amount of

combustible exposed. IEC is

continuously reviewed by a

technical board for updates

and revisions.

INTERNATIONAL ELECTROTECHNICAL COMMISSION (IEC)

Founded in 1904, the IEC is now considered the world’s largest electrotechnology organization with over 130

countries as members and over 10,000 experts contributing to its standards. e IEC code de nes hazardous

locations as Zones. Zones de ne the amount of time rated equipment is exposed to hazardous atmospheres.

Zone 0 locations feature continuous or extended exposure to ammable gases or vapors. Zone 1 locations have an

intermittent presence of ammable gases or vapors, typically as a result of leakage. Zone 2 are locations in which

ammable gases or vapors are not likely to occur in normal operation, but may become present upon the failure

of equipment or through an accident. e exposure is unlikely and, if it does occur, it will do so infrequently and

for only a short period of time. Atmospheres of combustible dusts are rated as Zone 20, 21 or 22. Zones 20, 21

and 22 correspond with Zones 0, 1 and 2 in identifying the amount of exposure to the hazardous atmosphere.

IEC Groupings rate locations on whether the hazard is a mine (Group I) or an ignitable atmosphere above ground

(Group II). IEC Subdivisions label the ignitability of the atmosphere with “A” being the least ignitable and “C”

being the most.

ATEX DIRECTIVE

e ATEX Directive is the rst uniformed code which deals with the Essential Health and Safety Requirements

IEC/ATEX

(EHSR’s) enacted by the European Union for equipment that is either used within, or connected to equipment

located within, potentially hazardous environments. It includes safety devices, controllers, regulatory devices and

other equipment whose failure would provoke an explosion.

Area Classification - IEC vs NEC/CEC (Class/Division/Group)

In ammable Material IEC/CENELEC NEC/CEC

Gases And Vapors Zone Equipment Group Gas Group Class Division Group

Acetylene 0, 1 or 2 II C I 1 or 2 A 85 T6 T6

Hydrogen 0, 1 or 2 II B + H

Propylene Oxide

Ethyl Oxide 135 T4 T4

Butadiene 160 T3 T3C

Cyclopropane

Ethyl Ether 180 T3 T3A

Ethylene 200 T3 T3

Acetone

Benzene 230 T2 T2C

Butane 260 T2 T2B

Propane 280 T2 T2A

Hexane 300 T2 T2

Paint Solvents 450 T1 T1

Natural Gas

4

0, 1 or 2 II B I 1 or 2 B

0, 1 or 2 II B I 1 or 2 C

0, 1 or 2 II A I 1 or 2 D

“T” rating classifications list the ignition point of the hazardous atmosphere. For safe usage, fixture “T” ratings must be below that of the surrounding atmosphere.

I 1 or 2 B 100 T5 T5

2

IEC vs NEC “T” Ratings Temperature Classification Comparison

Temperatures in ºC IEC NEC/CEC

120 T4 T4A

165 T3 T3B

215 T2 T2D

NEC/CEC STANDARDS

operate across the U.S.,

Canada, the Middle East

and various locations across

the globe. NEC code is

reviewed and updated in

three year cycles. e CEC

code is updated regularly

through their 9,000

members and its active

involvement with the IEC.

NATIONAL ELECTRICAL CODE/CANADIAN ELECTRICAL CODE (NEC/CEC)

e NEC has been the standard for electrical wiring and equipment installations in the United States since 1897.

e CEC began in 1927 and provides the electrical product standards for Canada. NEC/CEC Code categorizes

hazardous locations into Classes, Divisions and Groups. Classes I, II and III de ne hazards into gases and vapors,

combustible dusts, and bers and yings, respectively. Divisions further break down the Classes by the amount of

the exposure to the combustible. Division 1 establishes locations where hazards are present during regular operations.

Division 2 locations are where hazards are encountered only during an abnormal situation, such as equipment

failure or a spill. Gas groups classify the explosive nature of the gas, vapor or dust when ignited.

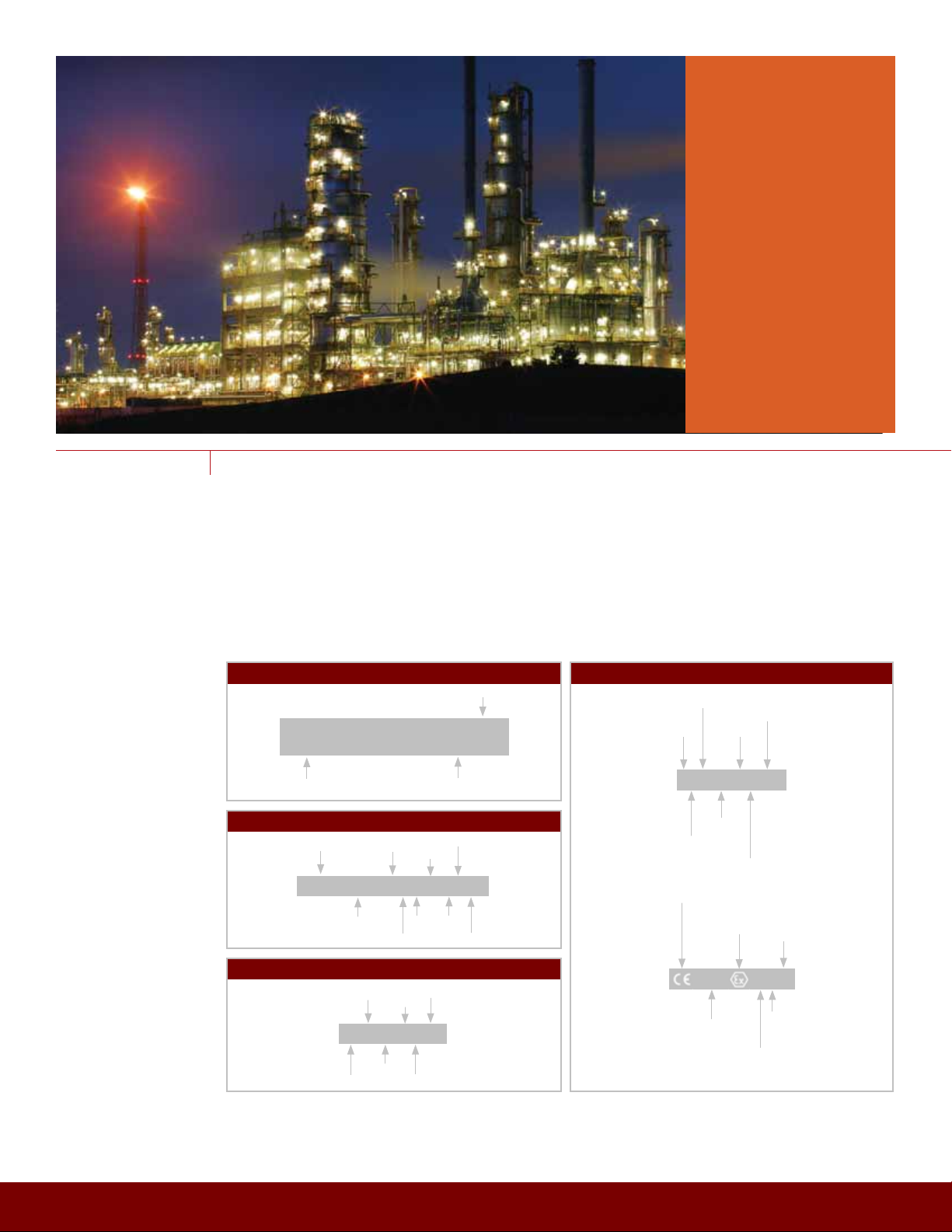

NEC/CEC

Certifications and performance

markings are displayed on all

electrical equipment to ensure

proper conformity to each

hazardous location’s requirements.

Appleton offers products approved

for ATEX, IEC, NEC and CEC

locations.

Product Marking Charts

US (NEC 500) and CA (CEC Annex J) EU (Directive 94/9/EC) - ATEX

Type of Protection

(optional except for I.S.)

Explosionproof with I.S. Outputs, Class I,

Division 1, Groups A, B, C, D, T5

Permitted Division

(optional except for Division 2)

Permitted Gas Group

US (NEC 505)

Permitted Class

National Standard

Class I, Zone 1, AEx d [ia] IIC T5

Permitted Zone

IEC and CA (CEC Section 18)

Type of Protection

Ex d [ia] IIC T5

Explosion-Protected

I.S. Output

American

Type of

Protection

Explosion-Protected

Temperature

Group

Gas Group

Temperature Class

I.S. Output

Class

Permitted Class

(T5 and T6 optional)

Gas Group

Group

Temperature Class

Type of Protection

European

Standard

Ex d [ia] IIC T5

I.S. Output

Explosion-Protected

CE Conformity Marking

Explosion-Protection

0081

Identifi cation Number of Notifi ed Body

Involved in Protection Control Stage

Temperature Class

Group

Gas Group

Marking

II 2 G

Category:

1 (for Zone 0 or 20)

2 (for Zone 1 or 21)

3 (for Zone 2 or 22)

Equipment Group:

I (for mines)

II (for other than mines)

Type of Explosive Atmosphere:

G (for gas, vapor and mist)

D (for dust)

Ambient temperature ranges other than standard -20 °C ≤ Ta ≤ +40 °C (-4 °F ≤ Ta ≤ +104 °F ) must be marked.

5

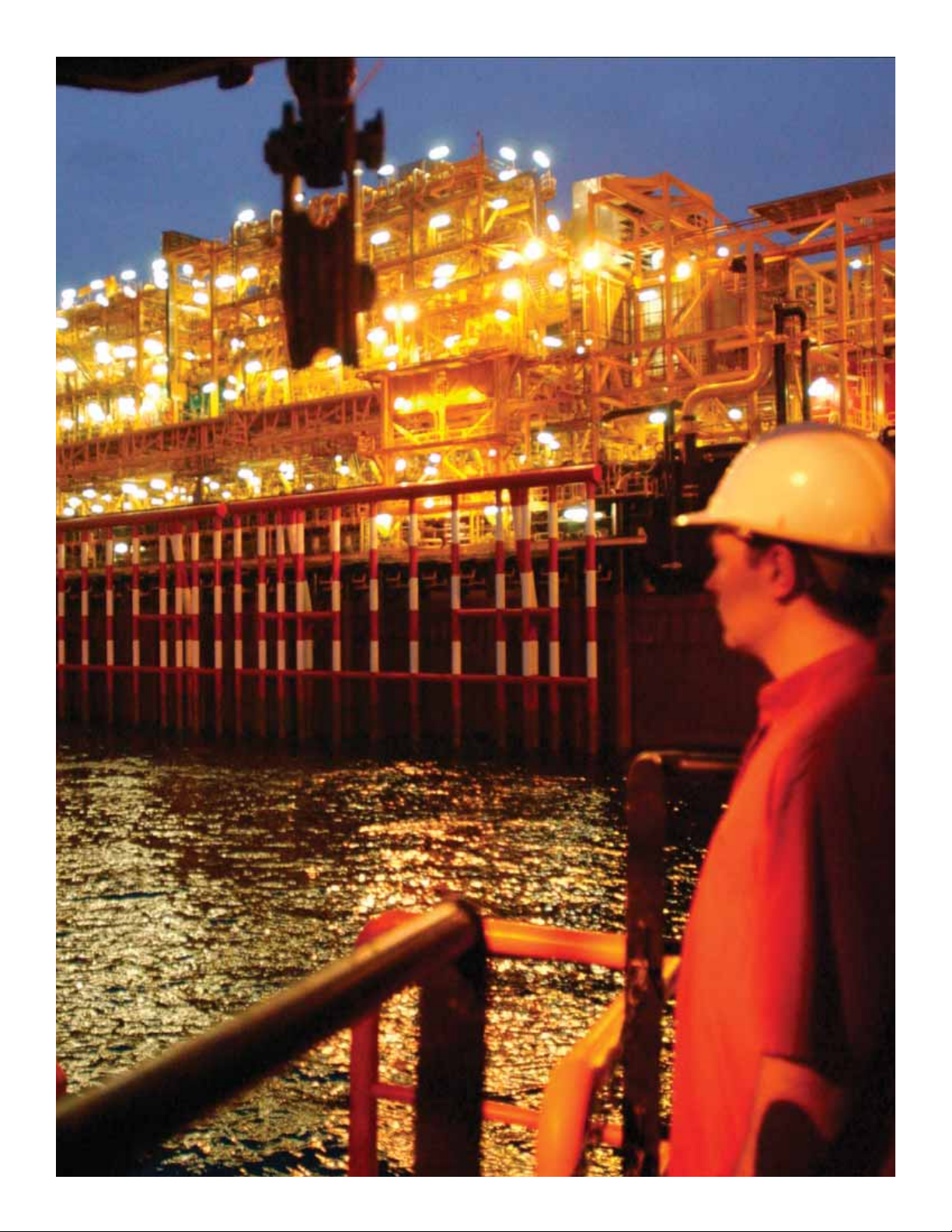

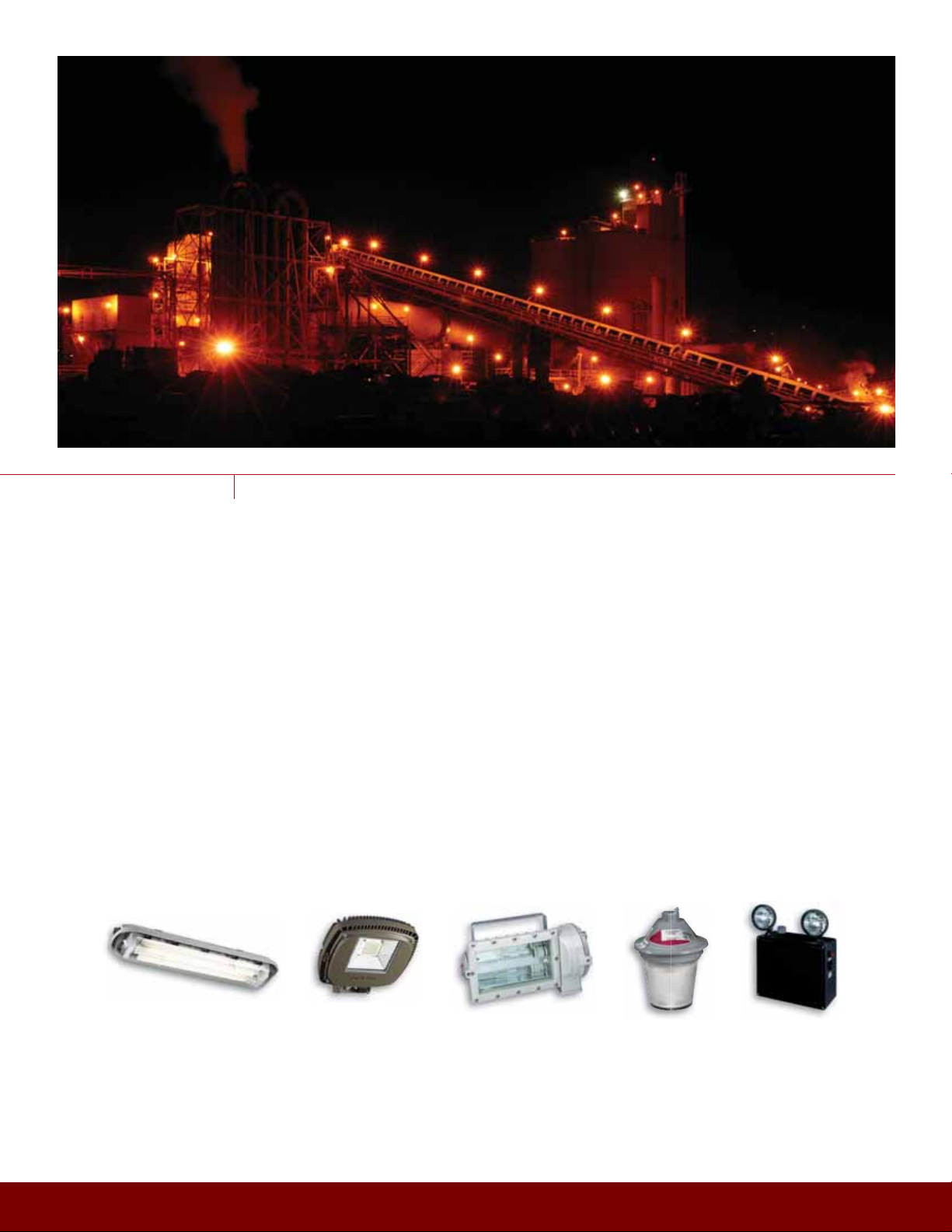

LIGHTING WHENEVER AND WHEREVER YOU NEED US

From the loading bays to the re ning rooms, facilities across the world

rely on lighting xtures to safely illuminate the narrow catwalks,

enclosed production oors and 24 hour docks that connect its four

corners. Besides providing light, these critical xtures must overcome

the inherent challenges and threats of hazardous environments.

6

Appleton’s line of enclosed and gasketed xtures are the perfect choice for use in Division

and Zone locations. Our vented re ectors result in cooler operation and increased lumen

output. Appleton’s restricted breathing xtures are secure from water, gases and vapors.

Our xtures are corrosion-resistant with stainless steel hardware and epoxy powder coated

copperfree aluminum. Even a feature like our “safety” high hinge provides additional

protection against accidental ballast housing disengagement while your maintenance team

is installing or servicing them.

Our line of ameproof and explosionproof xtures are available for use in Division and

Zone 1 and 2 locations. With intelligent engineering, they are manufactured to prevent

internal explosions from reaching the vapors surrounding the xture by cooling the hot

gases through precise amepaths. Appleton’s explosionproof xtures also address safety

outside of the lamp with innovative features like proprietary wireless mounting hoods that

allow for quicker and safer “hot” installation or servicing.

From our uorescent xtures to our high durability high pressure sodium luminaires

with long lamp life and low “T” ratings, Appleton’s entire line of lighting products deliver

unparalleled protection across your facility. Our proprietary coatings keep corrosion at

bay while our exclusive re ector technology and class leading photometrics deliver the

maximum amount of light possible. Appleton also boasts more xtures for use in high

ambient applications and the lowest “T” ratings in the industry for improved performance

and wider applications.

We relentlessly test our xtures to ensure they meet or exceed their rated capabilities even

in the most extreme conditions. at is why facility engineers around the world have

turned to Appleton for lighting products that improve e ciencies while protecting

their workers.

7

LIGHTING

ATEX/IECEx/NEC/CEC

LED LIGHTING MERCMASTER™ LED SERIES

LED lighting has come to hazardous locations, and Appleton’s Mercmaster LED is setting the

industry standard for safety, performance and e ciency. In day-to-day use, installation and

maintenance, the Mercmaster LED’s superior design simply shines. It is not just about e ciency.

LED lighting delivers real productivity bene ts.

• Compact lightweight low pro le design, well suited for low mounting heights

• Multiple mounting hoods accommodate any application requirement

• Fixture housing and mounting hoods are copperfree cast aluminum for better heat dissipation.

All exposed hardware is stainless steel

• Rounded edges throughout the heatsink reduce risk of injury during installation and

maintenance

• Hinge design increases safety during installation and servicing, assuring 360° compression on

ballast housing gasket

• Silicone rubber gasket seals out moisture, dirt and dust; stays exible and withstands high

temperatures

• Polycarbonate lens is threaded for easy removal and secure attachment

• Epoxy powder coat nish and stainless steel latch assembly are corrosion resistant

• Dark Sky Compliant: meets speci cations for low glare, focused beam and avoidance of

overlighting

LED LIGHTING AREAMASTER™ LED SERIES

ATEX/IECEx/NEC/CEC

Appleton’s Areamaster LED is versatile with a universal design for ood or high bay mounting,

making it ideal for replacing virtually any HID, uorescent or incandescent xture. Rated at 127

Watts, it delivers an optimal 13,000+ lumens of cool white light. Moreover, its highly directional

light does not require the use of external optics, resulting in system e ciencies as high as 80

percent.

• Compact in size, attractively styled contemporary design, rugged and dependable

• Easy to install and service

• One piece housing

• One piece lens hinged cover. Secured by four M6 captive stainless steel slotted hex head bolts

• ermal shock and impact resistant glass lens

• Heavy duty, high temperature, single piece, formed silicone rubber gasket

• Universal design for ood and high bay mounting; vibration rated in all con gurations

• Dark Sky Compliant: meets speci cations for low glare, focused beam and avoidance of

overlighting

8

ATEX/IECEx

LIGHTING

LED LIGHTING FDBAES SERIES

Appleton’s ATX FDBAES Series LED provides emergency lighting in hazardous locations. ese

units are entirely self-contained in a ameproof enclosure, and include a built in automatic selftest system. Switched, unswitched, addressable switched and addressable unswitched versions are

available

• Provides adequate lighting and/or visual indication of access on exit routes during an

evacuation in a hazardous environment

• Can be installed in hazardous areas designated as Zone 1-2 and 21-22

• Padlockable switch is available on switched models which individually cuts o power supply

and remote control

• All versions:

– Can be maintained in hazardous areas as an internal switch cuts o battery supply

automatically once the cover is unscrewed and opened

– Charge indicator with 4 nos yellow LEDs (lifetime over 10 years)

– Operates in any position

– Automatic built-in self-test system (SATI) with memorization of tests indicated by LEDs

LED LIGHTING FNES SERIES

ATEX/IECEx

Appleton’s ATX FNES Series LED provides emergency lighting in hazardous locations and can also

be equipped with a variety of labels to indicate exit routes. ese units are entirely self-contained,

and include a built in automatic self-test system.

• Provides adequate lighting and/or visual indication of access and exit routes during an

evacuation in a hazardous environment

• Can be installed in hazardous areas designated as Zone 2 and 21-22

• Non-maintained

• Operates in any position

• Charge indicator by green LED (lifetime over 10 years)

• Automatic built in self-test system (SATI) with memorization of tests indicated by LEDs

• Using a microprocessor and an internal clock, the unit will carry out automatic tests

• Remote control unit allows the xture to be controlled and checked without switching the

mains o

• e remote control unit installed in a safe area or inside a ameproof box allows manual

ignition of all the units (maximum 300 units) for visual inspection of their operation

9

LIGHTING

FLUORESCENT LIGHTING FE™ SERIES

ATEX/IECEx

FLUORESCENT LIGHTING FV™ SERIES

NEC/CEC

Appleton’s ATX increased safety FE Series of uorescent xtures go a step beyond with added

protection for everyday locations, as well as robust environments where corrosive atmospheres,

severe weather and detergents prevail. ese uorescent xtures are protected against the elements

with an elastomer gasket that ensures a consistent, durable seal that is hosedown ready. e

corrosion-resistant lens, body and hardware mean the FE Series uorescent luminaires will endure

the years. ese xtures o er a host of exclusive safety features that make servicing safe and easy.

• Hinged polycarbonate di user and multi-parabolic re ector for one handed maintenance

• Quick connector ballasts and IP 2X terminal shields

• Opening re ector activates power cut o switch to unit for safe access to internal controls

• If one tube fails, the other tubes remain lit

• Elastomer gasket and multiple cover fasteners

• Pre-impregnated berglass reinforced polyester body

• Optional dimmable switch alternates which tubes are lit for di erent lighting patterns and

brightness

e FV Series places cost e ective uorescent lighting in Class I, Division 2 marine and other

robust locations. O ering unprecedented safety and durability, the FV Series lens is rugged enough

to endure hose downs and o ers single handed lamp and internal control access. e internal

re ector is hinged for easy access to the control gear. e lens automatically engages a unit cut o

switch when opened. e FV Series stays cool with a T6 rating while operating with a remarkable

94% light producing e ciency.

• Nearly indestructible polycarbonate lens cover

• Automatic unit cut o switch

• Corrosion-resistant berglass reinforced polyester housing

• Single actuator enables one handed lens and re ector access

• Actuator can be removed for tamper-proof operation

• Multiple latch design and elastomer gasket provide a positive watertight seal

10

FLUORESCENT LIGHTING MERCMASTER™ III LOW PROFILE

e Mercmaster III Low Pro le enclosed and gasketed xture o ers superior lighting

in a small package for Class I, Division 2/Zone 2 locations. It is the perfect choice for low

NEC/CEC

clearance, low ceiling heights or where xture weights must be minimized. e PLT uorescent

lamps provide superior lighting e ciencies and economies. Its electronic ballast allows for icker

free, instant-on capabilities for zero blackout during momentary power dips. e Mercmaster

III Low Pro le is also suited for non-hazardous areas that are exposed to severe weather, excessive

moisture, dirt and dust.

• Maintains high output lighting in ambient temperatures ranging from -5°C to +54°C

(+23°F to +130°F)

• Excellent color rendering (82 CRI) for food processing and inspection facilities

• Compact pro le is perfect for low clearance locations

• Baked epoxy powder coat nish and stainless steel hardware for the ultimate corrosion

resistance

• Captive clamping bolt and high safety hinge provide for safe, easy maintenance

• Stainless steel threaded inserts prevent galling and freezing of re ectors, guards and other

bolt-on attachments

FLUORESCENT LIGHTING EFU FLUORESCENT SERIES

LIGHTING

NEC/CEC

ese factory sealed, explosionproof and dust-ignitionproof uorescent light xtures are suited

for any location where ignitable dust, fumes, gases, paint residue, paint powder or corrosive

atmospheres are present, including inside a paint spray booth. e EFU’s Class P ballasts feature

a thermally-activated protective device that guards against excessive voltage, internal ballast short

circuiting, inadequate lamp maintenance and improper xture applications.

• Non-sparking exterior surfaces for safer operation

• Instant Start and Rapid Start options

• Available cold weather ballasts for -18°C (0°F) starting

• Heat and impact resistant glass tubes

• Re ectors are easily removed for replacement or cleaning

• Explosionproof caps can easily be removed for quick wiring and relamping

11

LIGHTING

ATEX/IECEx/NEC/CEC

ATEX/IECEx

HID LIGHTING AREAMASTER™

Appleton’s rugged, enclosed and gasketed, Areamaster oodlights are rated for Class I, Division 2/

Zone 2 and severe non-hazardous environments. Areamasters resist corrosion with a one piece,

pressure cast, copperfree aluminum housing that features an architectural bronze polyester nish.

Its compound parabolic and double segment design, with an Alzak nished aluminum re ector,

provides optimum light distribution and e ciency.

• Compact size ts more locations

• Guard and re ector attached externally for quick and safe maintenance

• ermal shock and impact resistant glass

• Plug-in terminal block

• Available for use in conditions de ned as Class I, Zone 2 AEx nR IIC utilizing restricted

breathing as the method of protection

HID LIGHTING HBDC SERIES CYLINDRICAL BULKHEAD LIGHTS

Realize cost e ciencies and safety in Zone 1-2 and 21-22 locations with ameproof bulkhead

xtures. Appleton’s ATX HBDC Series produces industry leading photometrics for more light

in critical locations and feature high temperature internal wiring for extended durability. eir

housing design allows them to be mounted out of the way for safe lighting without added

obstacles.

ATEX/IECEx

• Hardened lamp glass

• Available with integrated lug mounts

• Corrosion-resistant housings, end caps and cover

• Guard and re ector attached externally for quick and safe maintenance

• readed access cover with O-ring seal

• Plug-in terminal block

HID LIGHTING PB SERIES FLOODLIGHTS

Keep large areas well lit and safe with Appleton’s ATX series of explosionproof and enclosed and

gasketed oodlight products. Our optional mounting, e cient light patterns and various wattages

enable you to put the light you need, wherever you need it. Floodlights are available for locations

as cold as -40°C (-40°F) and as high as +55°C (+131°F). We also use a ferromagnetic ballast for

optimal energy e ciency, reduced power loss, higher light output and increased lamp service life.

• Hinged mounts and pivoting lenses for easier mounting and repair

• Internal controls are insulated by Class H materials for maximum service life

• Corrosion-resistant, lightweight aluminum alloy housings conform to AFNOR

French codi cation

• Self tightening connection terminal blocks

• Operates at any angle

• Safety terminal box allows for safe and straightforward installation

• Adjustable beam angles

12

HID LIGHTING AND

COMPACT FLUORESCENT

IEC

HID LIGHTING MERCMASTER™ III

NEC/CEC

LIGHTING

NE850 SERIES

Appleton’s Nutsteel ameproof NE850 Series of wellglass xtures are rated Ex d, IIC for Zone 1

and 21 locations. Compact, e cient and lightweight, they o er an IP 66 and can be installed in

any harsh environment. eir size makes them perfect for low clearance locations or where xture

weight needs to be considered. Operating temperatures range from -20°C to +55°C (-4°F to

+131°F). An emergency version with battery back up is available.

• Shock resistant globe

• Corrosion-resistant fastenings

• REVESTEEL® anticorrosive coated aluminum body and guard

• AISI 304 stainless steel screws and lock washers

• Numerous lamping and mounting options

• 220 V, 60 Hz, 230/240 V, 50 Hz

e Mercmaster III’s modular construction allows it to t a vast range of applications and is

suitable for Class I, Division 2/Zone 2; Class II, Division 1 and 2; Class II and other robust

environments. Designed to dissipate heat from the ballast components out, Appleton’s thermal

performance with the Mercmaster III leads the industry. Appleton’s heat reducing internal

control design results in 18% cooler operation, which increases xture durability and enables the

Mercmaster III to be used in ambient temperatures up to +65°C (+149°F).

NEC/CEC

• Choice of heat-resistant prismatic glass refractors or globes

• Housing, hoods and guards are copperfree cast aluminum with baked epoxy powder coat nish

for superior corrosion-resistance

• “Safety” high hinge and swing away design eases servicing

• Capacitors are non-PCB type and thermally isolated from the ballast

• Mogul base porcelain socket features nickel plated contacts and +200°C (+392°F) welded leads

for trouble free operation in high ambient temperature locations

HID LIGHTING CODE•MASTER™ 2

e explosionproof Code•Master 2 xture features Appleton’s proprietary technology for

maximum safety and reliability in Class I and II locations. Internal components

are uniquely arranged for the greatest heat dissipation, which enables extended lamp life and

industry leading “T” ratings. Appleton’s exclusive wireless mounting hood enables power on xture

installation and removal in hazardous locations.

• Double lead Acme threading allows for ame-tight seals with fewer turns

• Lamp socket and glass globe designed for optimum light distribution and control

• Factory sealed — no external seals are required

• Fixture and mounting hood threads are pretreated with no gall, anti-seize coating

• Porcelain socket and nickel plated phosphor bronze screw shell assures long, trouble free

operation in high ambient areas

• Wide variety of mountings and light sources

13

LIGHTING

ATEX/IECEx

STROBE & BEACON IIC BEACONS & STATUS LAMPS

Appleton’s ATX series of ameproof lighting xtures o ers visual communication

in Zone 1-2 and 21-22 locations. Illuminated three stage indicator banks consist

of interchangeable colored modules that can be coupled with two other modules

for simultaneous lighting. Beacons are o ered up to 15 joules, which maintain a

remarkable 70% luminosity after eight million ashes. Various mountings, colors

and guards are available.

• High temperature internal wiring

• Polymethacrylate globes are available in red, green, orange and clear

• Corrosion-resistant exteriors

• Operating temperatures range from -40°C to +55°C (-40°F to +131°F)

• Mounting hardware available in either stainless steel or zinc plated steel

• All beacons and status lamps work in any position

14

Loading...

Loading...