Page 1

Installation and Operation Manual

Dimension

Double-Acting Actuator

Product Data Sheet EHO

March 2015

EHO.01.05.EN, Page 2 of 2, Rev. 0

Part Number: VA001-507-32, Rev. 1

Release: August 2016

Bettis™ EHO (Electro-Hydraulic Operated)

Double-Acting Actuator

Page 2

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Table of Contents

Section 1: Introduction

1.1 Scope .......................................................................................................... 1

1.2 General Information ................................................................................... 1

1.3 Safety Information ...................................................................................... 2

1.4 Abbreviation Definitions ............................................................................. 2

Section 2: Installation

2.1 Preparation ................................................................................................. 4

2.2 Valve Preparation ........................................................................................5

2.3 Actuator Preparation .................................................................................. 5

2.4 Lifting the EHO Actuator ............................................................................. 6

2.5 Installing the EHO Actuator on the Valve ...................................................11

2.6 Setting the Stroke Limit Stops ....................................................................11

2.7 Hydraulic Fluid .......................................................................................... 12

2.8 Accumulator (Optional) ............................................................................ 12

Table of Contents

August 2016

Section 3: Electrical Connections

3.1 Remove Separate Terminal Chamber (STC) Cover ..................................... 17

3.2 Sealing Cable/Conduit Entries ................................................................... 18

3.3 Recommended Terminal Connections ...................................................... 18

3.4 Separate Terminal Chamber (STC) Connections ........................................ 19

3.5 Replace Terminal Chamber Cover ............................................................. 19

3.6 External Earth/Ground Connections .......................................................... 19

3.7 Discrete Controlled Inputs Connection ..................................................... 20

Section 4: Set-up/Start-up Procedure

4.1 Preparation ............................................................................................... 21

4.2 Initial Check of the Unit ............................................................................ 22

4.3 Initial Connections .................................................................................... 22

4.4 Hand Pump ............................................................................................... 22

4.5 Hydraulic Test ........................................................................................... 25

4.6 Check Rotation ......................................................................................... 26

4.7 Limit Switch Adjustment ........................................................................... 27

4.8 Function Test ............................................................................................ 30

4.9 Other Options ........................................................................................... 32

Section 5: Operation

5.1 Hydraulic Power System ........................................................................... 33

5.2 Reservoir ................................................................................................... 33

5.3 Main Components .................................................................................... 33

5.4 Functional Description .............................................................................. 37

Table of Contents

I

Page 3

Table of Contents

August 2016

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 6: Pushbutton Module (PBM)

6.1 Selector Knob and Control Pushbuttons ...................................................40

Section 7: Troubleshooting

Section 8: Hazardous Area Classification and SIL Certification

Section 9: Weights and Dimensions

9.1 EHO Standard Double Acting .................................................................... 43

Section 10: Sample Wiring Diagram

10.1 2-Way Electric Powered By an Electro-Hydraulic Power Unit ..................... 44

10.2 2-Way Electric With Emergency Shutdown Feature Powered By an Electro-

Hydraulic Power Unit ................................................................................ 45

II

Table of Contents

Page 4

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 1: Introduction

1.1 Scope

This manual is offered as a guide to be used along with locally approved and safe

practices to install, operate, service and maintain the Bettis EHO Actuator. Carefully

follow the instructions in this manual and make sure you install the actuator correctly

and according to your requirements.

1.2 General Information

1.2.1 Overview

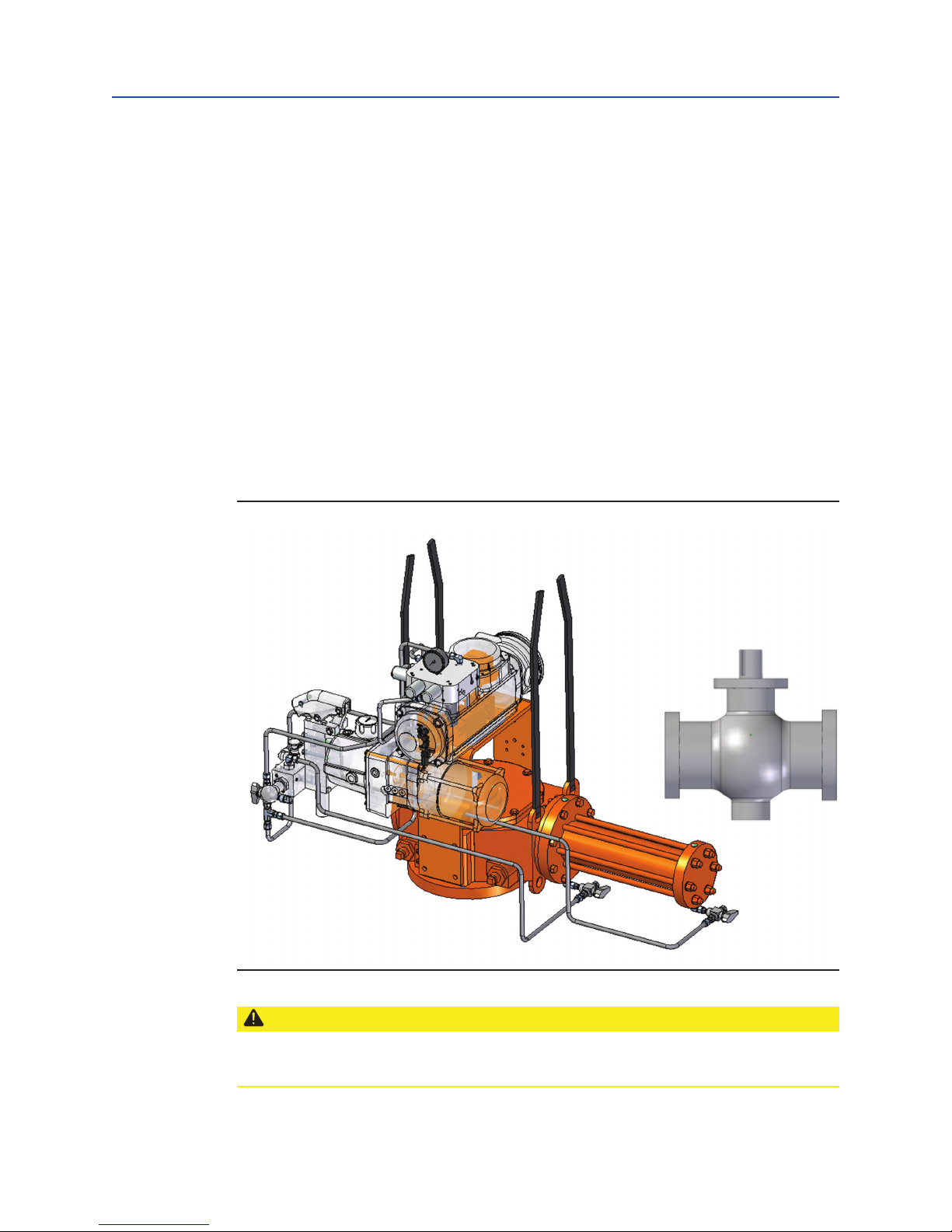

The Bettis EHO is a self-contained, quarter-turn, valve actuator that combines proven

technologies from Emerson’s Actuation Technologies. The actuator has been designed

for

critical shutdown applications where reliability is crucial. The EHO utilizes a dependable

spring-return actuator for the Fail-safe stroke combined with an integral hydraulic power

pack and electronic control module.

Section 1: Introduction

August 2016

The EHO accepts a wide range of single-phase, three-phase or DC power sources, also

solar panels are available for areas without electrical power. A hydraulic hand pump can

be used to stroke the actuator during commissioning or in the event of an emergency

power loss.

Electronic modules are contained within an explosion proof, IP68 enclosure and all

electronic components are isolated from the customer connection terminals.

The EHO provides a compact design with actuator and control components that have

been field proven for decades in critical service applications.

1.2.2 Product Attribute

• Easy installation – Bettis™ EHO actuator is a totally self-contained system and

designed for compactness and adaptable to new or existing valves.

• Bettis™ G-Series hydraulic double-acting or spring-return fail-safe actuator

• Shafer™ hydraulic control technology

• EIM™ electronics and communication technology

• Multiple input power options with either AC or DC

• Local lockable Remote/Local/Offline switch

• Local open/close/stop switch

• Partial stroke test

• Fast speed of operation to Fail-safe position if required

• Emergency shutdown – independent safety circuits and solenoid valve

• Dual sealed Separate Terminal Chamber, allows installation wiring to be

performed or fuses to be replaced without exposing control components to

hostile environmental conditions.

Introduction

1

Page 5

Section 1: Introduction

August 2016

• Control enclosure is made of low-copper aluminum alloy, powder-coated, salt

resistant also rated for IP68 ingress protection.

• Hydraulic hand pump manual override

• Accumulators (optional)

• Solar power (optional)

• Operating pressures up to 3000 psi with standard components

• Easy control over actuator stroking speeds – The stroking speed is controlled

through adjustable hydraulic flow control valves. This enables field personnel to

easily adjust actuator stroking speed to comply with field requirements.

1.3 Safety Information

Safety notices in this manual detail precautions the user must take to reduce the risk of

personal injury and damage to the equipment. The user must read these instructions in

their entirety. Failure to observe these safety notices could result in serious bodily injury,

damage to the equipment, void of the warranty. Take special notice of all tags, warning

labels and instructions presented on the actuator. These may provide more specific and

significant information regarding the actuator than this general manual.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

It is the responsibility of the user to ensure proper safety practices are utilized. Always

take necessary precautions and use proper protective equipment when dealing with

compressed gasses, compressed hydraulic fluid, pinch points and electricity.

Safety notices are presented in this manual in three forms (Warning, Caution and Note)

as follows:

WARNING:

Alerts user of potential danger; failure to follow the warning notice could result in

serious personal injury or death.

CAUTION:

Identifies precautions the user must take to avoid personal injury or equipment damage.

NOTE:

Highlights information critical to the user’s understanding of the Bettis EHO valve

actuator installation or operation.

2

Introduction

Page 6

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

1.4 Abbreviation Definitions

Abbreviations used in this manual and their definitions are listed in the table below:

Table 1. Abbreviation Definitions

Abbreviation Definition

IOM Installation Operation Manual

SCH Self-Contained Hydraulic

ESD Emergency Shutdown

FS Fail-safe

SR Spring-Return

DA Double-Acting

MAWP Maximum Allowable Working Pressure

MOP Maximum Operating Pressure

STC Separate Terminal Chamber

PBM Pushbutton Module

LDM Local Display Module

RDM Remote Display Module

CBM Circuit Breaker Module

PCB Printed Circuit Board

LS Limit Switch

PS Pressure Switch

NC Normally Closed

NO Normally Open

CCW Counterclockwise

CW Clockwise

OL Overload

PPE Personal Protective Equipment

GA General Arrangement Drawing

Section 1: Introduction

August 2016

Introduction

3

Page 7

Section 2: Installation

August 2016

Section 2: Installation

2.1 Preparation

2.1.1 Delayed Usage

If for any reason the actuator is not to be installed immediately, Bettis recommends the

following procedures. Failure to comply, with recommended procedures, could lead to

actuator malfunction and possibly void the warranty. For storage procedures exceeding

one year, consult Bettis for further recommendations.

As shipped from the factory, the Bettis EHO actuator is an inherently weatherproof unit,

providing that all compartment covers and cable entry plugs remain intact. The actuator

should be immediately stored in a clean, dry warehouse, free from vibration and rapid

temperature changes, until it can be installed and energized.

If the actuator must be stored outside, store it off of the ground at an elevation

sufficient to prevent it from being immersed in water or buried in snow. Check for any

unpainted or exposed metal surfaces and make sure they are protected with a coating

of grease to prevent any corrosion. Cover the actuator to prevent damage from site

debris.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

2.1.2 Tools and Materials Required

To complete these procedures, you will need the following documentation for the

Bettis EHO Actuator and items indicated in the table below:

• General Arrangement Drawing

• Bill of Material

• Hydraulic System Schematic

• System Wiring Diagram

Table 2. Tools and Material Requirements

Tools and Material Requirements

Primary Power Source for the EHO

(check the EHO System Electrical Diagram for requirements)

Supplemental quantity of hydraulic fluid, if needed

(See 2.7, Hydraulic Fluid and EHO specification, for required fluid type)

Nitrogen Source (if an Accumulator is supplied with the EHO)

Hand Tools: complete complement of open end (SAE and metric) wrenches, screw driv-

ers Philips and flat blade and a set of hex wrenches

Chains and lifting straps that are inspected and certified for the weight of the EHO

Actuator (check shipping weights)

Sealant for all cable and conduit entries (approvable by the National Electric Code or

your country standard and applicable local codes)

4

Installation

Page 8

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

2.2 Valve Preparation

2.2.1 Remove Valve Gearing if so equipped.

2.2.2 If valve is equipped with stops, remove valve stem extension housing. Examine

the valve stops to ensure no foreign material is present that would restrict

normal travel of the valve. Some valves are equipped with inspection ports in

the valve housing for ease in examining the stops.

2.2.3 Check alignment of stem key slot to the position of the valve. Normally

with the valve in the open position, the key slot is in line with the run of the

pipeline.

With the valve in the closed position, the key slot should be 90° to the run of

the valve.

2.2.4 The EHO Actuator may be mounted to the valve at any time regardless of

whether or not the valve is under pressure.

2.3 Actuator Preparation

Section 2: Installation

August 2016

2.3.1 Once the EHO Actuator is uncrated and cleaned for installation, check to ensure

there will be no interference with piping or other structure when the actuator is

properly mounted to the valve.

NOTE:

At this point, check to see that when the actuator is mounted to the valve and in its final

orientation, the outboard end of the power cylinder positioned below the Hydraulic

Reservoir Breather. If this is not possible, contact Bettis for further instructions on piping

to elevate the breather. See Vertical Mounted Actuator 2.4.4.

2.3.2 Check that all mounting materials such as fasteners, adapters, brackets etc. are

on hand and ready for use.

2.3.3 Check the actuator and valve to see that they are in the same relative position,

that is either open or closed. If the actuator has to be moved, use the hand

pump provided. For hand pump operation, remove the plug in the reservoir and

install the breather (refer to 4.4 Hand Pump Operation).

2.3.4 All spring-return EHO Actuators are supplied with a small accumulator for

protection from thermal-expansion of the hydraulic fluid. This accumulator is

pre charged at the factory and will not need service during installation or startup of the actuator.

CAUTION:

Be aware, while preparing to and lifting the actuator, the Thermal Compensating

Accumulator contains high-pressure nitrogen. Use care not to damage the accumulator

or its attachments.

Installation

5

Page 9

Section 2: Installation

August 2016

2.4 Lifting the EHO Actuator

NOTE:

All Bettis EHO G-Series Considerations

When handling any EHO G-Series, be aware of tubing, accessories, hand pump,

accumulators, Pushbutton module and control enclosures. Straps and chains can become

entangled and cause damage to these components. Never use chains on the spring

cartridge as it may warp and cause the actuator not to function correctly or may cause

personal injury.

NOTE:

Do not use hydraulic tubing and electrical cable for lifting.

CAUTION:

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Be sure to use appropriately rated crane/hoist and straps/chains to raise and lower

the actuator.

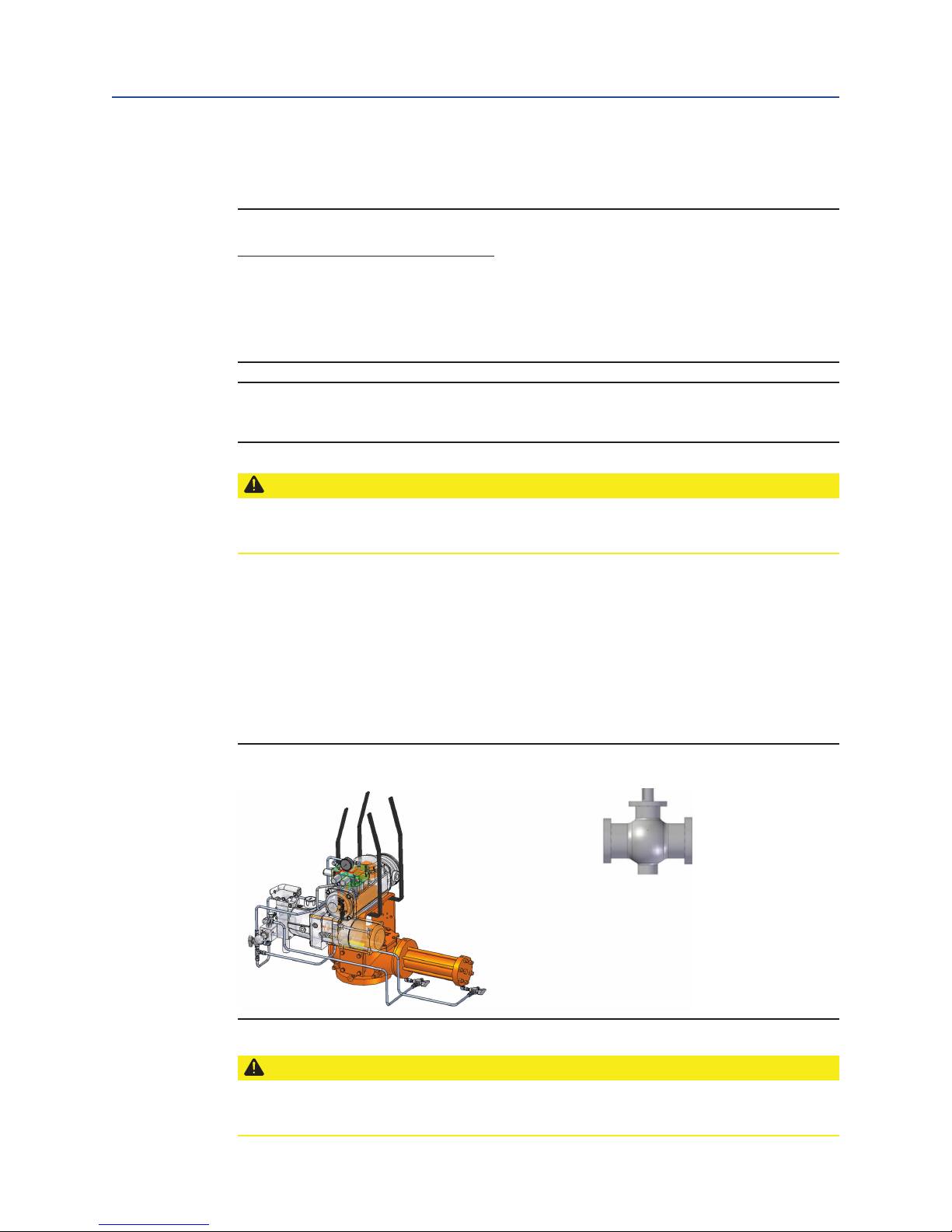

2.4.1 G01X – G2 and All E-Series Actuators

2.4.1.1

Figure 1 G01 – G2 and all E-Series Actuators with Horizontal Pipeline

and Vertical Stem

Horizontal Pipeline Vertical Stem

The small G-Series and all E-Series actuators mounting on a horizontal

pipeline with a vertical valve stem should be supported under the

“C” bracket and a two-point attachment for balance. A strap may be

attached to the stabilization tab on the spring module to balance the

unit while lifting. The weight of the actuator must be supported at the

“C” bracket, not the stabilization tab. See Figure 1.

CAUTION:

Never lift the actuator with a valve attached. Always handle actuator/valve assemblies

by attaching lifting equipment to the valve only.

6

Installation

Page 10

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 2: Installation

August 2016

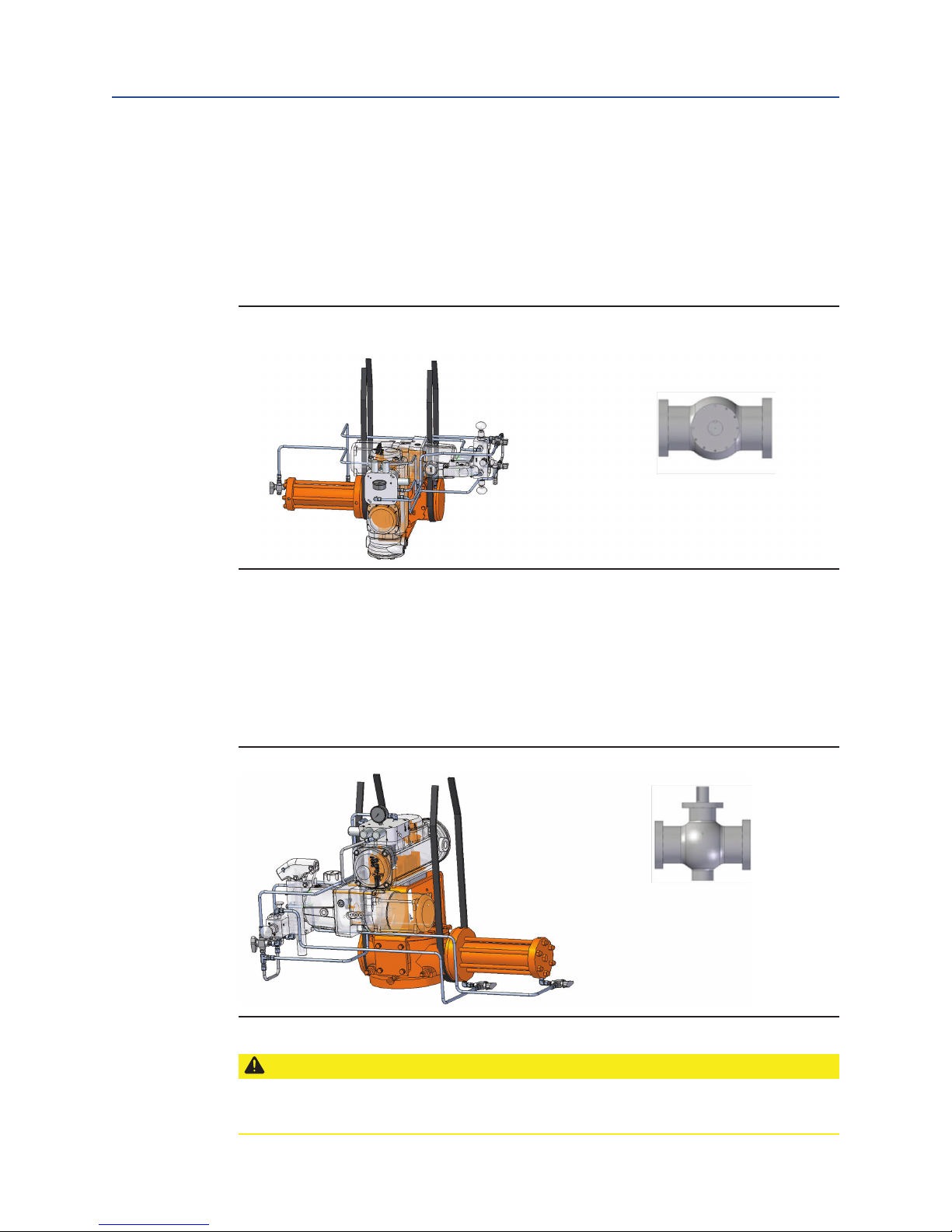

2.4.1.2

Horizontal Pipeline Horizontal Stem

The small G-Series and all E-Series actuators mounting on a horizontal

pipeline with a horizontal valve stem should be supported on

the ends of the drive module. A strap may be attached to the

stabilization tab on the spring module to balance the unit while

lifting. The weight of the actuator must be supported at the drive

module, not the stabilization tab. See Figure 2.

Figure 2 G01 – G3 and all E-Series Actuators with Horizontal

Pipeline and Horizontal Stem

2.4.2 G3-Series Actuators

2.4.2.1

Horizontal Pipeline Vertical Stem

The G3-Series actuator mounting on a horizontal pipeline with a

vertical valve stem should be supported at the ends of the drive

module. A strap may be attached to the stabilization tab on the spring

module to balance the unit while lifting. The weight of the actuator

must be supported at the drive module, not the stabilization tab. See

Figure 3.

Installation

Figure 3 G3 with a Horizontal Pipeline and Vertical Stem

CAUTION:

Never lift the actuator with a valve attached. Always handle actuator/valve assemblies

by attaching lifting equipment to the valve only.

7

Page 11

Section 2: Installation

August 2016

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

2.4.2.2

Horizontal Pipeline Vertical Stem

The G3-Series actuator mounting on a horizontal pipeline with a

horizontal valve stem should be supported on the ends of the drive

module. A strap may be attached to the stabilization tab on the

spring module to balance the unit while lifting. The weight of the

actuator must be supported at the drive module, not the stabilization

tab. Be sure to use appropriately rated crane/hoist and straps/chains

to raise and lower the actuator. See Figure 2 above.

2.4.3 G4 – G7 Series Actuators

2.4.3.1

Horizontal Pipeline Vertical Stem

The G4 – G7 Series actuators mounting on a horizontal pipeline with

a vertical valve stem should be supported using the lift lugs attached

to the drive module. A strap may be attached to the stabilization

tab on spring module to balance the unit while lifting. The weight of

the actuator must be supported by the lugs at drive module, not the

stabilization tab.

See Figure 4.

Figure 4 G4 – G7 with a Horizontal Pipeline and Vertical Stem

CAUTION:

Never lift the actuator with a valve attached. Always handle actuator/valve assemblies

by attaching lifting equipment to the valve only.

8

Installation

Page 12

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 2: Installation

August 2016

2.4.3.2

Horizontal Pipeline Horizontal Stem

The G4 – G7 Series actuators mounting on a horizontal pipeline with

a vertical valve stem should be supported using the lift lugs attached

to the drive module. A strap may be attached to the stabilization

tab on spring module to balance the unit while lifting. The weight of

the actuator must be supported by the lugs at drive module, not the

stabilization tab.

See Figure 5.

Figure 5 G4 – G7 with a Horizontal Pipeline and Horizontal Stem

CAUTION:

Never lift the actuator with a valve attached. Always handle actuator/valve assemblies

by attaching lifting equipment to the valve only.

Installation

9

Page 13

Section 2: Installation

August 2016

2.4.4 Mounting the Actuator in a Vertical Orientation on a Horizontal Stem

When mounting an Bettis EHO Actuator in a vertical orientation, the Spring Module

must be positioned up. The actuator may be supported by using two straps in the

configuration shown in Figure 6. A third strap or small chain may be attached to the

stabilization tab on spring module to balance the unit while lifting. The weight of the

actuator must be supported by the straps running over the spring module and under the

drive module flange.

Figure 6 Vertical Actuator Lift

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

CAUTION:

Never lift the actuator with a valve attached. Always handle actuator/valve assemblies

by attaching lifting equipment to the valve only.

NOTE:

When a vertical EHO Actuator is mounted to the valve, and in its final orientation, the

spring module must be up and outboard end of the power cylinder positioned below

the Hydraulic Reservoir Breather. If not possible, contact Bettis for further instructions

on piping to elevate the breather.

10

Installation

Page 14

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 2: Installation

2.5 Installing the EHO Actuator on the Valve

The actuator will be bolt-mounted directly to a bracket or adaptor that will be bolted

securely to the mounting flange top works of the valve.

2.5.1 Check to see that the dimensions of the bracket or adaptor are suitable for use

with the valve mounting flange and stem.

2.5.2 Check valve direction of rotation and the actuator direction of rotation to see

they match (for example: CW = close, CCW = open).

2.5.3 Check to see the actuator and valve are in the same relative position (see 2.3.3).

2.5.4 Check all mounting surfaces, they must be clean and free of debris to permit

proper fit up.

2.5.5 Prior to mounting, grease the coupling bore and the bore of the actuator.

NOTE:

Do not apply grease to the mounting flange surfaces on the valve or the adaptor.

August 2016

2.5.6 Install the stem key and grease it (keys may be held in place with tape).

2.5.7 Install the coupling onto the stem and stem key.

2.5.8 Install the coupling key and grease it.

2.5.9 Carefully align the coupling and key to the bore and keyway in the actuator

and slide the actuator onto the coupling until the adapter (bracket) bottoms

out on the valve bonnet.

NOTE:

Ensure the adapter seats out on the valve bonnet, without interference, before

installing fasteners.

2.5.10 Use the required fasteners to firmly attach the adapter to the valve bonnet.

Tighten the fasteners to their manufacturer’s recommended maximum torque

(dry or lubricated).

2.6 Setting the Stroke Limit Stops

2.6.1 The Bettis G-Series is provided with bi-directional travel stops allowing 80° to

100° total travel (+/- 5° adjustment at each end of the 90° stroke).

2.6.2 Actuators are shipped from the factory with the travel stops adjusted for

approximately 90° rotation. Generally, it is necessary to make slight travel

stop adjustments once the actuator is installed on the valve. Refer to the valve

manufacturer's recommendations for specific requirements.

2.6.3 When the valve has internal stops, the actuator stops must be set so that the

load is applied to them, not the valve stops.

2.6.4 If adjustment is required, use the hand pump to move the actuator off the stop

at the closed position before attempting to turn the adjusting screw (refer to

4.4, Hand Pump Operation).

Installation

11

Page 15

Section 2: Installation

August 2016

CAUTION:

Always use the hand pump to move the actuator off the stop before attempting to turn

the adjusting screw.

2.6.5 With the closed position stop set, use the hand pump to move the actuator

to the other end of the stroke and check the stop position. If adjustment is

required, slowly open Manual Bypass Valve (Lockable) (19) just enough to allow

the actuator to spring-return off the stop before adjusting.

2.7 Hydraulic Fluid

Bettis Electro-Hydraulic Operated actuators are shipped with the reservoir filled to

operation level. Before commissioning and periodically afterwards, check to see the

fluid level is correct. The oil fill cap is provided with a dipstick marked with a green and a

red mark. When the optional accumulator is drained of fluid and the actuator is at Failsafe Position, the oil should be at the green mark. The reservoir also has a sight gauge

for the purpose of seeing fluid is present. Should fluid need to be added or replaced, use

only factory approved hydraulic fluid.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

This specification covers hydraulic fluids which are approved by engineering for use in

Bettis Electro-Hydraulic Operated actuator in a temperature range from -40°F to 140°F

(-40°C to 60°C).

2.7.1 Approved Fluids

•

•

Although other brands of fluid matching the same specifications may be used, to

maintain the warranty and ensure trouble free operation, always check with the factory

before substituting any other fluid.

Standard Fluid [use with -20°F to 140°F (-29°C to 60°C) applications]

— ConocoPhillips Megaflow™ AW HVI Hydraulic Oil 22

— Shell Tellus S2 V 22

— Mobil DTE 10 Excel™ 22

Low Temperature Fluid [use with -40°F to 140°F (-40°C to 60°C) applications

— Mobil Univis™ HVI 13

12

Installation

Page 16

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

2.8 Accumulator (Optional)

2.8.1 Introduction

The Bettis EHO Actuator may be equipped with an accumulator to enable manual

operation of the actuator if there is a loss of electrical power. Accumulators always

have the nitrogen pressure drained for shipping (except for Thermal Compensating

Accumulator see 2.3.4).

NOTE:

When using this procedure, refer to the Bettis EHO Actuator General Arrangement

drawing and Hydraulic Schematic for the unit being worked on. (Schematic below is for

illustration only.)

WARNING:

Section 2: Installation

August 2016

This unit contains high-pressure hydraulic fluid and nitrogen gas. Exercise caution when

performing any type of maintenance. Wear proper safety attire and required personal

protective equipment, including safety glasses.

2.8.2 Accumulator Pre-charge

a. Locate Isolation Valve (F) (Nitrogen Blow Down and Fill) for the

Customer Nitrogen Fill Connection, called out on the General

Arrangement Drawing and Hydraulic Schematic (see illustration below).

b. Close the Isolation Valve (F) and remove the pipe plug from the adaptor.

NOTE:

The Adaptor is tapped with a 1/4-NPTF thread.

c. Ensure 3-way Isolation Valve (D) is turned fully counterclockwise.

d. Slowly open Isolation Valve (Accumulator drain) (E) and drain all the

fluid back to the reservoir.

e. Connect a nitrogen supply to the Customer Nitrogen Fill Connection at

Isolation Valve (F).

f. Open the Isolation Valve (F) (Nitrogen Blow Down and Fill) and

charge the Accumulator, to the pre-charge pressure as specified by

the Pressure versus Temperature Graph on the General Arrangement

Drawing.

NOTE:

For temperatures, which do not appear on the graph, the formula to calculate the

pre-charge pressure shown on the General Arrangement Picture Assembly should be

used.

Installation

13

Page 17

Section 2: Installation

August 2016

NOTE:

Recheck the pre-charge pressure after a time interval sufficient to insure the nitrogen

pressure is equal to the ambient temperature (a minimum of 4 hours). Adjust the

pre-charge pressure as required to conform to the Pressure versus Temperature graph.

NOTE:

The straight thread plug must be installed, after filling is complete, to prevent

accidental leakage of nitrogen from Isolation Valve (25).

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

g. After the nitrogen filling is complete, close the Isolation Valve (F)

(Nitrogen Blow Down and Fill).

h. Disconnect the nitrogen supply and remove the female pipe adaptor

from Isolation Valve (F).

i. Install the straight thread plug and O-ring, shipped as an accessory, into

Isolation Valve (F).

j. Close Isolation Valve (24).

Figure 7 Typical EHO Optional Accumulator System

G

H

C

F

B

D

I

E

14

A

Installation

Page 18

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Table 3. Typical EHO Optional Accumulator System

Part Number Part Name

A Reservoirs

B Accumulator

C Nitrogen Relief Valve

D 3-way Isolation Valve

E Isolation Valve (Accumulator Drain)

F Isolation Valve (Nitrogen Blow Down and Fill)

G Nitrogen Pressure Gauge

H Nitrogen Gauge Isolation Valve

I Speed Control

2.8.3 Pre-charge Verification

Check the nitrogen pre-charge in the accumulator periodically to ensure the accumulator is at full potential. Follow the steps below and record final readings for reference.

a. Shut off the hydraulic power supply to the accumulator.

b. Ensure 3-way Isolation Valve (D) is turned fully counterclockwise.

c. Slowly open Isolation Valve (Accumulator drain) (E) and drain all the

d. Read the pressure at the nitrogen pressure gauge (G) and compare it to

e. If the pre-charge is low, add nitrogen to increase the pressure to

f. Record Information below.

g. With bypass valve closed, reconnect the hydraulic power supply and

h. Check the entire nitrogen circuit for leaks using a liquid leak detector

Section 2: Installation

August 2016

fluid back to the reservoir.

the Oil/Temperature Chart shown on the General Assembly Drawing for

the job being checked.

the requirements listed on the GA Oil/Temperature Chart. See 2.8.2,

Accumulator Pre-charge, if the pre-charge is high relieve pressure to

equal the GA Oil/Temperature Chart.

bring the accumulator back up to full pressure.

such as Snoop (manufactured by Swagelok). As the unit is self-contained,

only a zero leak rate is acceptable. Corrective action must be taken for

any leaks found.

WARNING:

This unit contains high-pressure hydraulic fluid and nitrogen gas. Exercise caution when

performing any type of maintenance. Wear proper safety attire and required personal

protective equipment, including safety glasses. Ensure the accumulator has been

drained of all hydraulic and nitrogen pressure before attempting any repair.

Installation

15

Page 19

Section 2: Installation

August 2016

2.8.4 Nitrogen Pre-charge Maintenance Record

Serial Number: _____________________________

Tag Number: _______________________________

Date

Initial

Pre-charge

GA Chart

Requirement

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Final

Pre-charge

Nitrogen

Leak Test

Signed

16

Installation

Page 20

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 3: Electrical Connections

Section 3: Electrical Connections

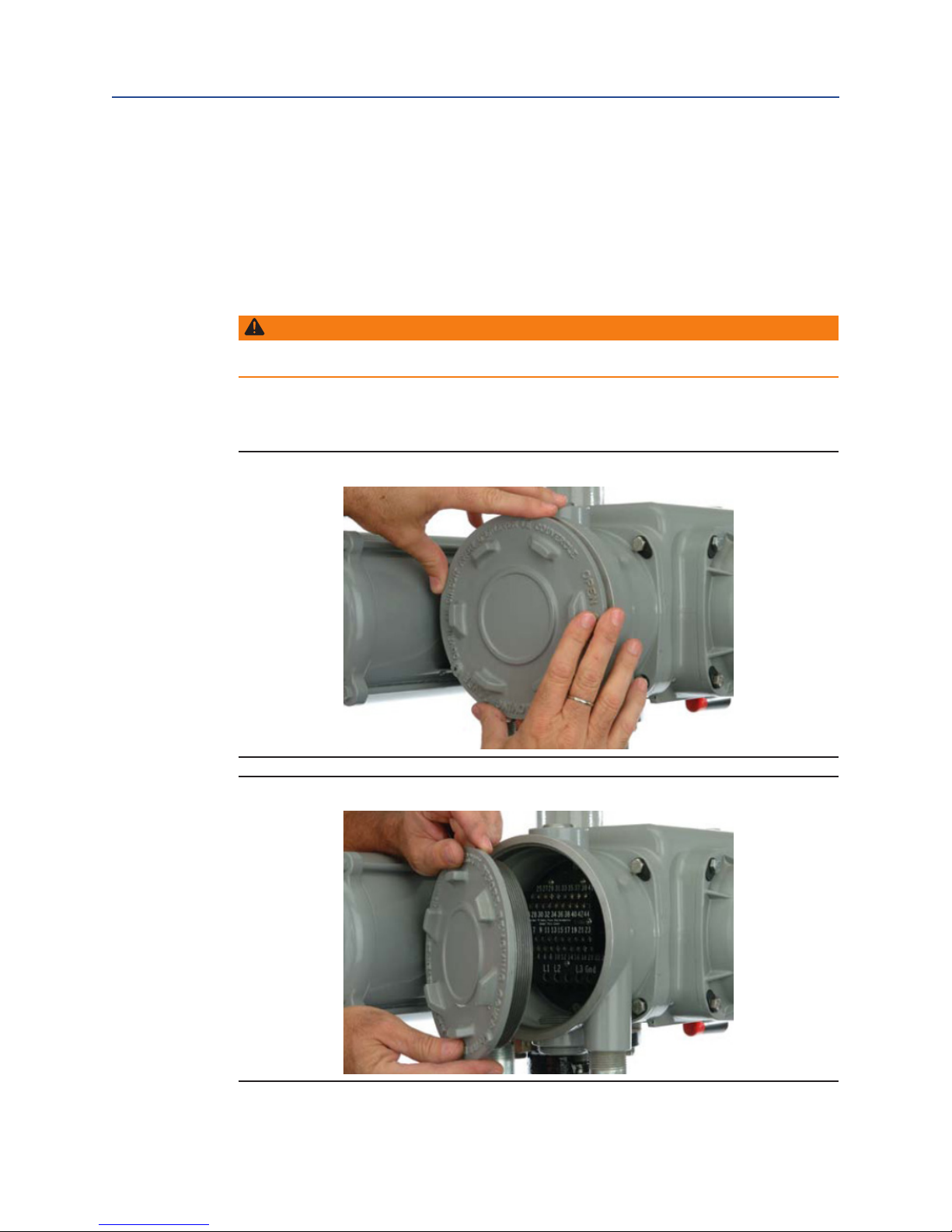

3.1 Remove Separate Terminal Chamber (STC)

Cover

WARNING:

Always verify electrical power is disconnected before removing the STC cover.

3.1.1 Remove cover with a strap wrench, drift, or pinch bar by rotating the

cover counterclockwise.

Figure 8 Remove STC Cover Turning Counterclockwise

May 2016

Figure 9 Lay Cover Aside

Electrical Connections

17

Page 21

Section 3: Electrical Connections

May 2016

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

3.2 Sealing Cable/Conduit Entries

Seal the cable and conduit entries in accordance with the National Electric Code or your

country standard and applicable local codes. All conduit entries should be sealed against

the site environment. All unused conduit entries must be sealed with threaded metal

plugs.

3.3 Recommended Terminal Connections

The Bettis Electro-Hydraulic actuator terminal block connectors are wire binding screw

connectors with rising captive plates. Connections can be made one of three ways:

• Strip and connect bare wire

• Strip and install wire ferrule

• Strip and install crimp-on insulated or non-insulated ring or fork-tongue connec-

tors for either M3 control signal terminal block screws or M4 power terminal

screws.

3.3.1 Loosen terminal block connectors L1, L2, L3 and GND screws with a common or

Phillips head screwdriver.

3.3.2 If bare wire is being used, strip insulation a maximum of 1/2 inch (12mm).

3.3.3 Insert wire or wire lug under terminal block connector screw clamps and

tighten.

Figure 10 Power Terminal Connection Length of Bare Wire Strip

Figure 11 Control Terminal Connection Length of Bare Wire Strip

18

Electrical Connections

Page 22

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 3: Electrical Connections

May 2016

3.4 Separate Terminal Chamber (STC) Connections

3.4.1 Connect the main power supply cables, including an Earth/Ground

(refer to the job specific Wiring Diagram).

3.4.2 Use the barrier strip clamp screws to connect the control wiring

(refer to the job specific Wiring Diagram).

3.4.3 Ensure all connections are hand tight, including any unused terminals.

NOTE:

The main power supply and ground wire connections are screw size M4.

The control connection screw size is M3.

3.5 Replace Terminal Chamber Cover

3.5.1 Clean electrical enclosure threads thoroughly and lightly grease with dielectric

grease before closing.

3.5.2 Replace the cover by reversing the order of the steps to remove the cover.

3.6 External Earth/Ground Connections

External connection points are provided on the operator for attaching earth/ground in

accordance with local electric codes for installation cables.

Connect the external earth/ground connection as follows.

3.6.1 Using a slotted tip screwdriver, back out the 5/16-inch set screw.

3.6.2 Connect 14 AWG or larger earth/ground wire, tighten setscrew.

Figure 12 External Earth/Ground Connection

Electrical Connections

19

Page 23

Section 3: Electrical Connections

May 2016

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

3.7 Discrete Controlled Inputs Connection

The actuator can be controlled by discrete inputs: two-wire control, three-wire

control, four-wire valve control. Connect the power for these discrete inputs as

detailed in

Figures 13 and 14. See Section 3.3, Electrical Connections, for general electrical

connection requirements.

Figure 13 Control Input Wiring – Internal Power Supply

Figure 14 Control Input Wiring – External Power Supply 24 VDC

20

Electrical Connections

Page 24

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 4: Set-up/Start-up Procedure

Section 4: Set-up/Start-up Procedure

In addition to this set-up/start-up procedure, the following documentation will be

necessary to fulfill all set-up and start-up requirements.

1. General Arrangement drawing

2. Bill of Material

3. Schematic drawing

4. Wiring Diagram drawing

When using these instructions, refer to the schematic diagram, wiring diagram, general

arrangement drawings for the Bettis EHO and the certified bills of material.

Numbers in [ ] correspond to components labeled on the wiring diagram. Numbers in

( ) correspond to components labeled on the schematic diagram. Information in (( )) is

descriptive.

When the Bettis EHO is delivered to the job site, it has been both pressure and function

tested. The oil reservoir was filled to operation level when it shipped from factory.

August 2016

4.1 Preparation

4.1.1 Safety First

Hydraulic Pressure

WARNING:

Ensure that test personnel and witnesses are properly informed of the hazards involved

with high pressures and the proper safety barriers are employed.

Never check for leakage using your fingers or hands. Fluid under high pressure can inject

into the skin and cause severe damage or death. Always use an implement such as a piece

of paper.

Safety Equipment

WARNING:

All personnel in the testing area must always wear safety glasses.

Set-up/Start-up Procedure

21

Page 25

Section 4: Set-up/Start-up Procedure

August 2016

4.1.2 Material and Equipment for Start-up and Set-up

To complete this procedure, you will also need the following materials and equipment:

Table 4. Required Material and Equipment

Required Material and Equipment

Miscellaneous fittings, adapters and Hand Tools: complete complement of open end

((SAE and metric)) wrenches, screw drivers Philips and flat blade and a set of hex

wrenches

Primary Power Source for the EHO

((check the EHO System Electrical Diagram for requirements))

Supplemental quantity of hydraulic fluid, if needed

((See 2.6, Hydraulic Fluid, and EHO specification for required fluid type))

Nitrogen Source ((if an Accumulator is supplied with the EHO))

4.2 Initial Check of the Unit

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

NOTE:

The components referenced below are referencing to schematic found in section 10.2.

and is for illustration purposes only. When using this procedure refer to the Bettis EHO

Actuator General Arrangement Drawing and Hydraulic Schematic for the unit being

worked on.

4.2.1 Check to ensure all hydraulic tube fittings are tight. Vibration during shipment

may have loosened connections.

4.2.2 Visually inspect the unit to make sure tubing, hand valves, gauges and other

equipment have not been damaged.

4.2.3 Using the Schematic drawing, verify that the Flow Control Valves (7) are fully

opened ((turn stem completely counterclockwise)).

4.2.4 Ensure Isolation Valve (Accumulator drain) (24) is closed ((if applicable)).

4.2.5 Ensure Isolation Valve (Nitrogen Blow Down and Fill) (25) is closed ((if

applicable)).

4.3 Initial Connections

Electrical connections should have been made to the STC (Separate Terminal Chamber).

If power is not connected, follow the instructions under Section 3, Electrical Connections,

before continuing. If an ((optional)) Circuit Breaker Module is provided, ensure it is turned to

OFF.

CAUTION:

Before the actuator is stroked, check to see it has been filled with fluid to the proper

level. ((See 2.7, Hydraulic Fluid.))

22

Set-up/Start-up Procedure

Page 26

Installation and Operation Manual

(M) Hand Pump Selection Valves

(L) Hand Pump

(J) Opening Solenoid

(K) Closing Solenoid

Part Number: VA001-507-32, Rev. 1

4.4 Hand Pump

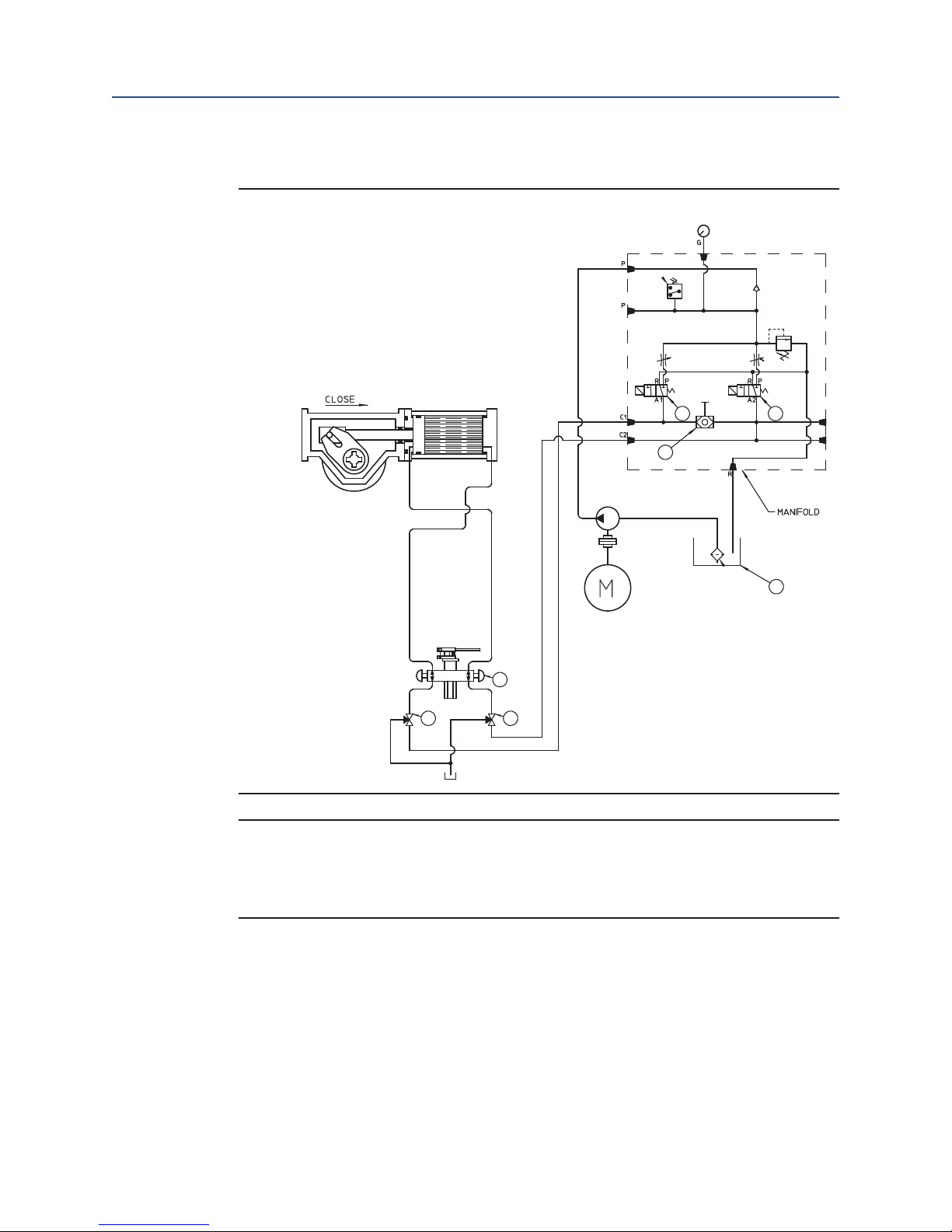

4.4.1 2-Way Remote Electric without ESD solenoid function

NOTE:

Hand Pump Isolation Valve (8)

The components referenced below are referencing Schematic 4.4.1. and is for

illustration purposes only. When using this procedure refer to the Bettis EHO Actuator

General Arrangement Drawing and Hydraulic Schematic for the unit being worked on.

4.4.1.1 Check the Reservoir (I) to see the hydraulic is at the proper level.

4.4.1.2 Rotate downward in the horizontal position both Hand Pump Selector

Valves (M).

4.4.1.3 Select and push inward the open or close knob located on the Hand

Pump Selector Manifold (L).

4.4.1.4 Use supplied Hand Pump Handle to discharge hydraulic fluid into the

open or close side of the actuator cylinder.

4.4.1.5 Continue hand pumping until the actuator completes the open or

close stroke and contacts the actuators adjustable end stops.

4.4.1.6 Once completion of the Hand Pumping operation, push the Pump ByPass Valve located on the top of the Hand Pump Selector Manifold (L)

and pull the pump handle downward retracting the pump ram into the

pump body.

4.4.1.7 Rotate both Hand Pump Selector Valves back into the upward vertical

position.

4.4.1.8 Check the Reservoir (I) to see the hydraulic fluid is at the proper level.

4.4.2 2-Way Remote Electric with an ESD solenoid function

Section 4: Set-up/Start-up Procedure

August 2016

Figure 15 2-Way Remote Electric Without an ESD Solenoid Function Schematic

Set-up/Start-up Procedure

J

L

M

M

K

I

23

Page 27

Section 4: Set-up/Start-up Procedure

August 2016

NOTE:

The components referenced below are referencing Schematic 4.4.2. and is for

illustration purposes only. When using this procedure refer to the Bettis EHO Actuator

General Arrangement Drawing and Hydraulic Schematic for the unit being worked on.

4.4.2.1 Check the Reservoir (I) to see the hydraulic is at the proper level.

4.4.2.2 Close Hand Pump Isolation Valve (O)

4.4.2.3 Rotate downward in the horizontal position both Hand Pump Selector

Valves (M).

4.4.2.4 Select and push inward the open or close knob located on the Hand

Pump Selectoranifold (L).

4.4.2.5 Use supplied Hand Pump Handle to discharge hydraulic fluid into the

open or close side of the actuator cylinder.

4.4.2.6 Continue hand pumping until the actuator completes the open or close

stroke and contacts the actuators adjustable end stops.

4.4.2.7 After completion of the Hand Pumping operation, push the Pump ByPass Valve located on the top of the Hand Pump Selector Manifold (L)

and pull the pump handle downward retracting the pump ram into the

pump body.

4.4.2.8 Rotate both Hand Pump Selector Valves (M) back into the upward

vertical position.

4.4.2.9 Check the Reservoir (I) to see the hydraulic fluid is at the proper level.

4.4.2.10 Once the ESD solenoid signal is re-established, slowly open Hand Pump

Isolation Valve (O).

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Figure 16 2-Way Remote Electric With an ESD Solenoid Function Schematic

N

H

J

Y

L

M M

K

(L) Hand Pump Selector

(M) Hand Pump Selection Valves

(H) Accumulator Isolation Valve(Optional)

(N) Accumulator Isolation Valve(Optional)

(J) Opening Solenoid

(K) Closing Solenoid

(O) Hand Pump Isolation Valve

(P) ESD Solenoid Valve(Optional)

O

P

24

Set-up/Start-up Procedure

Page 28

Installation and Operation Manual

(A) Pressure Gauge(Optional)

(B) Nitrogen Relief Valve(Optional)

(D) Isolation Valve(Optional)

(E) Hydraulic Accumulator With Nitrogen Blanket

Charge(Optional)

(H) Accumulator Isolation Valve(Optional)

(N) Accumulator Isolation Valve(Optional)

(R) Pressure Switch

(Q) Hydraulic Pressure Gauge

(S) Pressure Transmitter(Optional)

(T) Check Valve

(V) Adjustable Flow Controls

(U) Relief Valve

(O) Hand Pump Isolation Valve(Optional)

(W) Bettis G-series Double Acting Actuator

(AB) Pressure Transmitter(Optional)

(J) Opening Solenoid

(K) Closing Solenoid

(P) ESD Solenoid Valve(Optional)

(X) Shuttle Valve(Optional)

(AC) Shuttle Valve(Optional)

(Y) Hydraulic Pump

(AD) Accumulator override valve to open(Optional)

(AE) Accumulator override valve to close(Optional)

(Z) Electric Motor

(AA) Suction Strainer

(I) Fluid Reservoir

(L) Hand Pump

(M) Hand Pump Selection Valves

Part Number: VA001-507-32, Rev. 1

4.4.3 Manual Open or Close with Accumulator Override feature (Optional)

NOTE:

The components referenced below are referencing Schematic 4.4.2. and is for

illustration purposes only. When using this procedure refer to the Bettis EHO Actuator

General Arrangement Drawing and Hydraulic Schematic for the unit being worked on.

4.4.3.1 Select and slowly open the Accumulator override Isolation Valve

4.4.3.2 After completion of the Accumulator manual override stroke, return

Figure 17 2-Way Remote Electric With Emergency Shutdown Feature Powered

by an Electro-hydraulic power unit

Section 4: Set-up/Start-up Procedure

August 2016

(AD) for actuator open stroke and (AE) for actuator closing stroke.

The Isolation Valve is in the actuator stroking position when rotated

downward to the horizontal position.

the Isolation Valve (AD) or (AE) to the upward vertical position.

A

B

D

4.5 Hydraulic Test

Q

E

N

H

W

AD AE

L

M M

R

V

J

X

Y

AA

Z

S

T

U

O

K

I

P

AC

The system has been hydrostatic and function tested at the factory before shipping. This

test is to discover if any leaks have developed in the hydraulic fittings during shipping.

NOTE:

The components referenced below are referencing Schematic 4.4.2. and is for

illustration purposes only. When using this procedure refer to the Bettis EHO Actuator

General Arrangement Drawing and Hydraulic Schematic for the unit being worked on.

Set-up/Start-up Procedure

25

Page 29

Section 4: Set-up/Start-up Procedure

August 2016

4.5.1 Rotate both Hand Pump Isolation Valves (O) to the downward horizontal

position.

4.5.2 Select and push inward the open or close knob located on the Hand Pump

Selector Manifold (L).

4.5.3 Use supplied Hand Pump Handle to discharge hydraulic fluid into the open or

close side of the actuator cylinder.

4.5.4 Once the actuator is fully stroked and makes contact with the actuators

adjustable stops, observe if any leakage is detected at any tube fittings or port

connections from the Hand Pump to the Actuators operating ports.

4.5.5 Push the Pump By-Pass Valve located on the top of the Hand Pump Selector

Manifold (L) and pull the pump handle downward retracting the pump ram into

the pump body.

4.5.6 Select and push inward the opposite open or close knob located on the Hand

Pump Selector Manifold (L).

4.5.7 Repeat steps 4.5.3 thru 4.5.5

4.5.8 Rotate both Hand Pump Selector Valves (M) back into the upward vertical

position.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

4.6 Check Rotation

NOTE:

The components referenced below are referencing to schematic found in section 10.2.

and is for illustration purposes only. When using this procedure refer to the Bettis EHO

Actuator General Arrangement Drawing and Hydraulic Schematic for the unit being

worked on.

4.6.1 Turn on the electrical supply to the unit. If an ((optional)) Circuit Breaker Module

is supplied, turn the Circuit Breaker to ON.

4.6.2 Turn the LOCAL-OFF-REMOTE selector switch to LOCAL.

4.6.3 Ensure Flow Control Valves (V) are adjusted fully counterclockwise for maximum

flow.

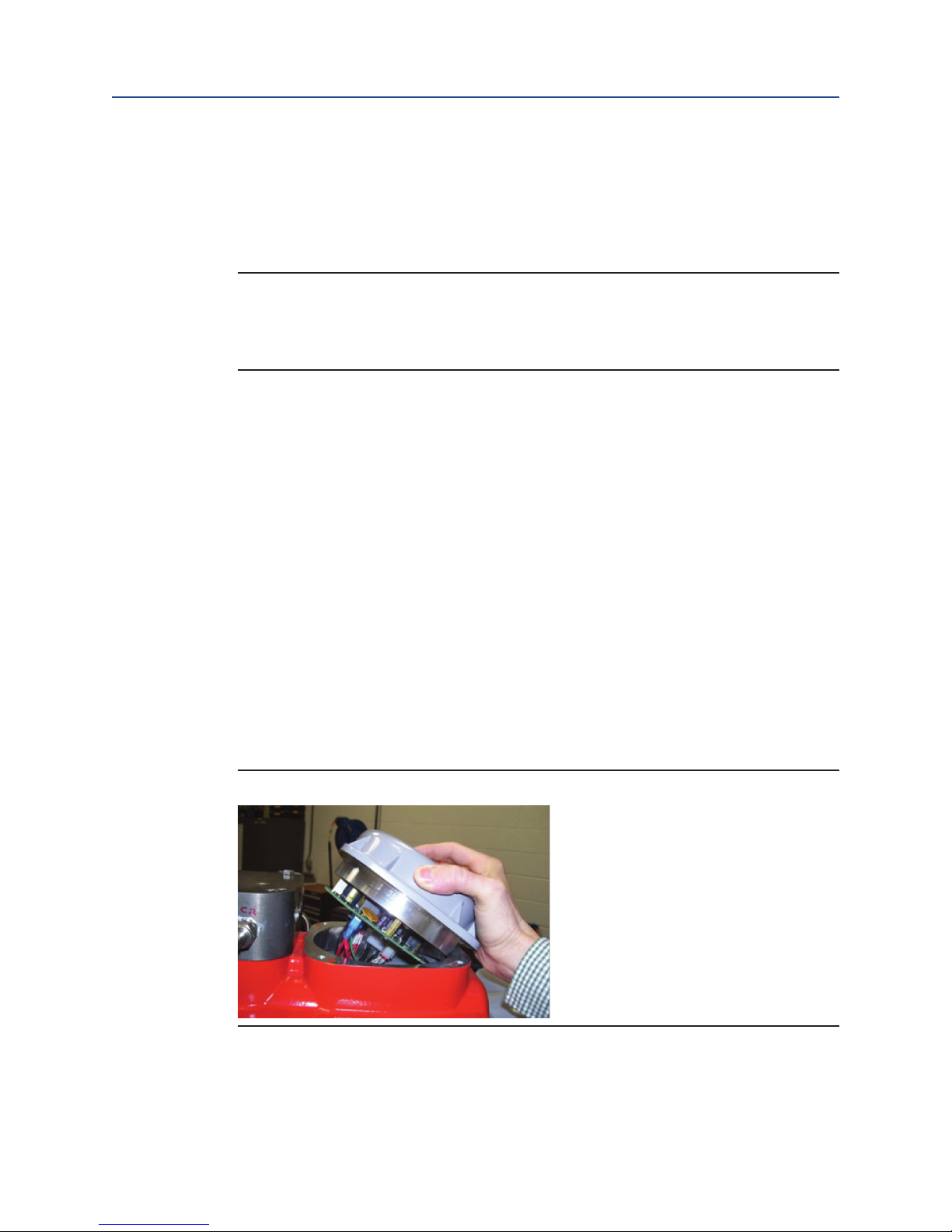

4.6.4 Open inspection port on side of unit to observe the rotation of the motor/pump

shaft.

Figure 18 Inspection Port for Motor Rotation

26

Set-up/Start-up Procedure

Page 30

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

4.6.5 While observing the inspection port, for motor rotation, push and release the

OPEN/CLOSE PUSHBUTTON to Power Stroke the actuator and immediately push

the STOP Pushbutton. Motor rotation should be counterclockwise when looking

at the back of the motor.

4.6.6 If needed, correct motor rotation.

NOTE:

If the EHO Actuator is supplied with optional ESD, before operating a motor-powered

stroke, a customer supplied ESD signal must be present and Solenoid Valve (P)

energized.

4.6.7 Push and release the OPEN/CLOSE PUSHBUTTON to Power Stroke the actuator.

The Electric Motor (Z) will start to run driving Hydraulic Pump (Y). The

Hydraulic Pump (Y) draws fluid from Reservoir (I) and pushes it into the Bettis

G-series hydraulic cylinder (W).

4.6.8 Shut off the electrical power going to the unit, if an (optional) Circuit Breaker

Module is supplied, turn the Circuit Breaker to OFF.

Section 4: Set-up/Start-up Procedure

August 2016

4.7 Limit Switch Adjustment

4.7.1 To complete limit switch adjustment, the actuator will need to be stroked from

a fully closed position to a fully open position etc. several times. In the following

instructions, the electric motor is used to Power Stroke the actuator. If it is not

safe or possible to use the electric motor at this time, use the Hand pump to

Power Stroke the actuator.

4.7.2 The limit switch adjustments are found in a covered compartment in line with

the valve stem and on the opposite side of the control box. Remove the limit

switch compartment cover by loosening the four corner bolts retaining it.

All covers have tapped holes for jackscrews to aid in removing the cover. Use

the retaining screws in these holes to lift the cover evenly at each corner. Use

caution to not allow the cover to bind during removal.

Figure 19 Remove Cover for Limit Switch Chamber

Set-up/Start-up Procedure

27

Page 31

Section 4: Set-up/Start-up Procedure

August 2016

WARNING:

If the actuator is being installed in a hazardous area, use extreme care. This procedure

requires the limit switch cover to be open while electrical power is connected to the unit.

Follow these steps only when the atmosphere is free of explosive gases.

4.7.3 Close Limit Switch Adjustment

4.7.3.1 The Open and Close Limit Switches, shown in Figure 20, are operated

by targets mounted in a plastic disk that rotates with the actuator

stroke. To adjust a Target, push down on it and slide it in a clockwise or

counterclockwise direction.

Figure 20 View of Limit Switch Targets

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Limit Switch #1 Target

NOTE:

The Switch Targets will be labeled to identify the switch they operate.

4.7.3.2 With the actuator in the Close Position, rotated fully clockwise, the

Target for CLOSE LS-2 will need to be adjusted.

4.7.3.3 Reconnect electrical power to the unit.

4.7.3.4 Push down on the Target for CLOSE LS-2 and move clockwise until it is

off of the switch in the clockwise direction. Both the OPEN and the

CLOSE lights on the PBM ((Pushbutton Module)) should be

illuminated

at this point.

4.7.3.5 Now, push down and slide the Target for CLOSE LS-2 counterclockwise

until the OPEN light just goes out. It is important to always adjust a

Target in the opposing direction of the valve travel to get an accurate

setting.

28

Set-up/Start-up Procedure

Page 32

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

4.7.3.6 With the LOCAL – OFF – REMOTE Switch set to LOCAL, push the OPEN

4.7.3.7 Push down and slide Target for OPEN LS-1 counterclockwise until it is

4.7.3.8 Now, push down and slide the Target for OPEN LS-1 clockwise until the

4.7.3.9 Push the CLOSE PUSHBUTTON and allow the actuator to rotate

4.7.4 Open Limit Switch Adjustment

4.7.4.1 With the actuator in the Open Position, rotated fully counterclockwise,

4.7.4.2 Reconnect electrical power to the unit.

4.7.4.3 Push down on the Target for OPEN LS-1 and move counterclockwise

4.7.4.4 Now, push down and slide the Target for OPEN LS-1 clockwise until the

4.7.4.5 With the LOCAL – OFF – REMOTE Switch set to LOCAL, push the CLOSE

4.7.4.6 Push down and slide Target for CLOSE LS-2 counterclockwise until it is

4.7.4.7 Now, push down and slide the Target for CLOSE LS-1 clockwise until the

4.7.4.8 Push the OPEN PUSHBUTTON and allow the actuator to rotate

4.7.5 Four Limit Switch Models

4.7.5.1 If your unit utilizes four switches LS-3 OPEN and LS-4 CLOSE, adjust

Section 4: Set-up/Start-up Procedure

August 2016

PUSHBUTTON and allow the Actuator to travel to the Open position,

rotated fully counterclockwise.

off the switch in the counterclockwise direction.

CLOSE light just goes out.

clockwise to the fully closed position and check to see CLOSE LS-2 is

operated; the OPEN light should go out. Cycle the actuator open and

closed a few times checking the setting of CLOSE LS-1 and OPEN LS-2.

the Target for OPEN LS-1 will need to be adjusted.

until it is off of the switch in the counterclockwise direction. Both the

OPEN and the CLOSE lights on the PBM (Pushbutton Module) should be

illuminated at this point.

CLOSE light just goes out. It is important to always adjust a Target in

the opposing direction of the valve travel to get an accurate setting.

PUSHBUTTON and allow the Actuator to travel to the Close position,

rotated fully clockwise.

off the switch in the clockwise direction.

OPEN light just goes out.

counterclockwise to the fully open position and check to see OPEN LS-2

is operated; the CLOSE light should go out. Cycle the actuator open

and closed a few times, checking the setting of CLOSE LS-1 and OPEN

LS-2.

in the same manner except you will need to use a continuity tester

on the terminal strip to detect switch operation. LS-3 is connected to

terminals A31, A32 and A33. LS-4 is connected to A35, A36 and A37.

Look at these switches on the wiring diagram for exact configuration.

Set-up/Start-up Procedure

29

Page 33

Section 4: Set-up/Start-up Procedure

August 2016

4.8 Function Test

4.8.1 Double Acting Actuator without an ESD Solenoid Valve

NOTE:

The components referenced below are referencing Schematic 4.8.1. and is for

illustration purposes only. When using this procedure refer to the Bettis EHO Actuator

General Arrangement Drawing and Hydraulic Schematic for the unit being worked on.

4.8.1.1 Ensure both Hand Pump Selector Valves (M) are in the automatic open

position.

4.8.1.2 Energize the desired solenoid valve (J) to open the actuator or (K) to

close the actuator.

4.8.1.3 Push and release the OPEN/CLOSE PUSHBUTTON to start the Electric

Motor. The Hydraulic Pump Draws Fluid from the Reservoir and

discharges fluid thru either the opening solenoid (J) or the closing

solenoid (K) which ever one is energized.

4.8.1.4 Upon completion of the open or close stroke, the Pressure Switch will

reach its set point and stop the Electric Motor.

4.8.1.5 Upon completion of the open or close stroke, the Limit Switch(s)

can be configured to de-energized the solenoid that is energized.

Some field installations can use the customer’s control room logic to

de-energize the solenoids after the actuator stroke open or close is

reached.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

30

Set-up/Start-up Procedure

Page 34

Installation and Operation Manual

(M) Hand Pump Selection Valves

(L) Hand Pump

(J) Opening Solenoid

(K) Closing Solenoid

Part Number: VA001-507-32, Rev. 1

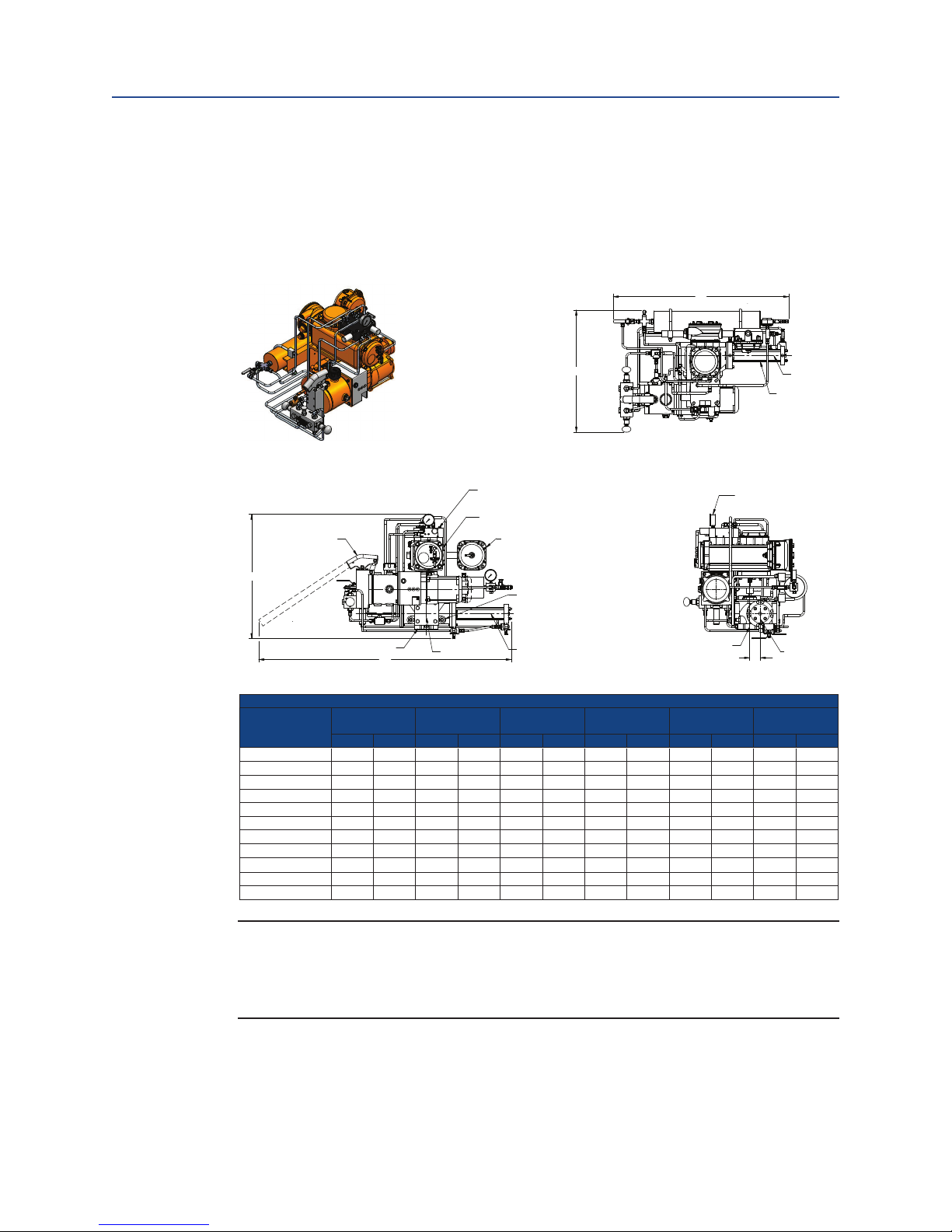

4.8.2 Double Acting Actuator with an (Optional) ESD Solenoid Valve and Accumulator

Figure 21 2-Way Remote Electric Without an ESD Solenoid Function Schematic

Section 4: Set-up/Start-up Procedure

August 2016

J

L

M

M

K

I

NOTE:

The components referenced below are referencing Schematic 4.8.2. and is for

illustration purposes only. When using this procedure refer to the Bettis EHO Actuator

General Arrangement Drawing and Hydraulic Schematic for the unit being worked on.

4.8.2.1 Ensure both Hand Pump Selection Valves (M) are in the automatic

4.8.2.2 ESD (Emergency Shut Down) Solenoid Valve (P)is constantly energized

4.8.2.3 Ensure Isolation Valve (H) is closed and Isolation Valves (N) and (O) are

4.8.2.4 Push and release the OPEN/CLOSE PUSHBUTTON to start the Electric

Set-up/Start-up Procedure

open position.

closed.

both open.

Motor. The Hydraulic Pump Draws Fluid from the Reservoir and

discharges fluid to the nitrogen pre-charged accumulator.

31

Page 35

Section 4: Set-up/Start-up Procedure

August 2016

4.8.2.5 Upon completion of the charging of the accumulator, the pressure

switch set point will be reached and it will stop the electric motor.

4.8.2.6 Energize the desired solenoid valve (J) to open the actuator or (K) to

close the actuator.

4.8.2.7 Upon completion of the open or close stroke, the Limit Switch(s)

can be configured to de-energized the solenoid that is energized.

Some field installations can use the customer’s control room logic to

de-energize the solenoids after the actuator stroke open or close is

reached.

Figure 22 2-Way Remote Electric With an ESD Solenoid Function Schematic

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

N

H

M M

4.9 Other Options

O

J

Y

L

K

(L) Hand Pump Selector

(M) Hand Pump Selection Valves

(H) Accumulator Isolation Valve(Optional)

(N) Accumulator Isolation Valve(Optional)

(J) Opening Solenoid

(K) Closing Solenoid

(O) Hand Pump Isolation Valve

(P) ESD Solenoid Valve(Optional)

P

Other options such as Partial Stroke Test may have been supplied with this order.

Refer to supplemental start-up procedures supplied with these options for start-up and

test.

The functional test of the Electro-Hydraulic Actuator is now complete.

The Bettis EHO Actuator is now operational and ready for service.

32

Set-up/Start-up Procedure

Page 36

Installation and Operation Manual

(Q) Hydraulic Pressure Gauge

(R) Pressure Switch

(S) Pressure Transmitter(Optional)

(T) Check Valve

(U) Relief Valve

(V) Adjustable Flow Controls

(W) Bettis G-series Double Acting Actuator

(J) Opening Solenoid

(K) Closing Solenoid

(X) Shuttle Valve(Optional)

(Y) Hydraulic Pump

(Z) Electric Motor

(AA) Suction Strainer

(I) Fluid Reservoir

(L) Hand Pump

(M) Hand Pump Selection Valves

Part Number: VA001-507-32, Rev. 1

Section 5: Operation

After initial start-up and commissioning procedures have been accomplished, the Bettis

EHO Actuator provides a simple self-contained means of operation for a quarter turn

valve. In case of a power failure the actuator can be operated by the use of the supplied

hand pump..

5.1 Hydraulic Power System

The Hydraulic System, powered by an electric motor, contains manifold based valves

and controls with minimal piping. The system will drive the actuator to the OPEN/CLOSE

position as selected by operation personnel.

5.2 Reservoir

The Bettis Self-contained Electro Hydraulic Actuator includes a fluid reservoir sized to

contain the hydraulic fluid required to operate the actuator cylinder and controls. The

standard unit has a sight gauge to ensure presence of fluid and a dipstick measure

attached to the fill/breather cap to more accurately gauge the quantity of fluid

contained.

Section 5: Operation

August 2016

5.3 Main Components

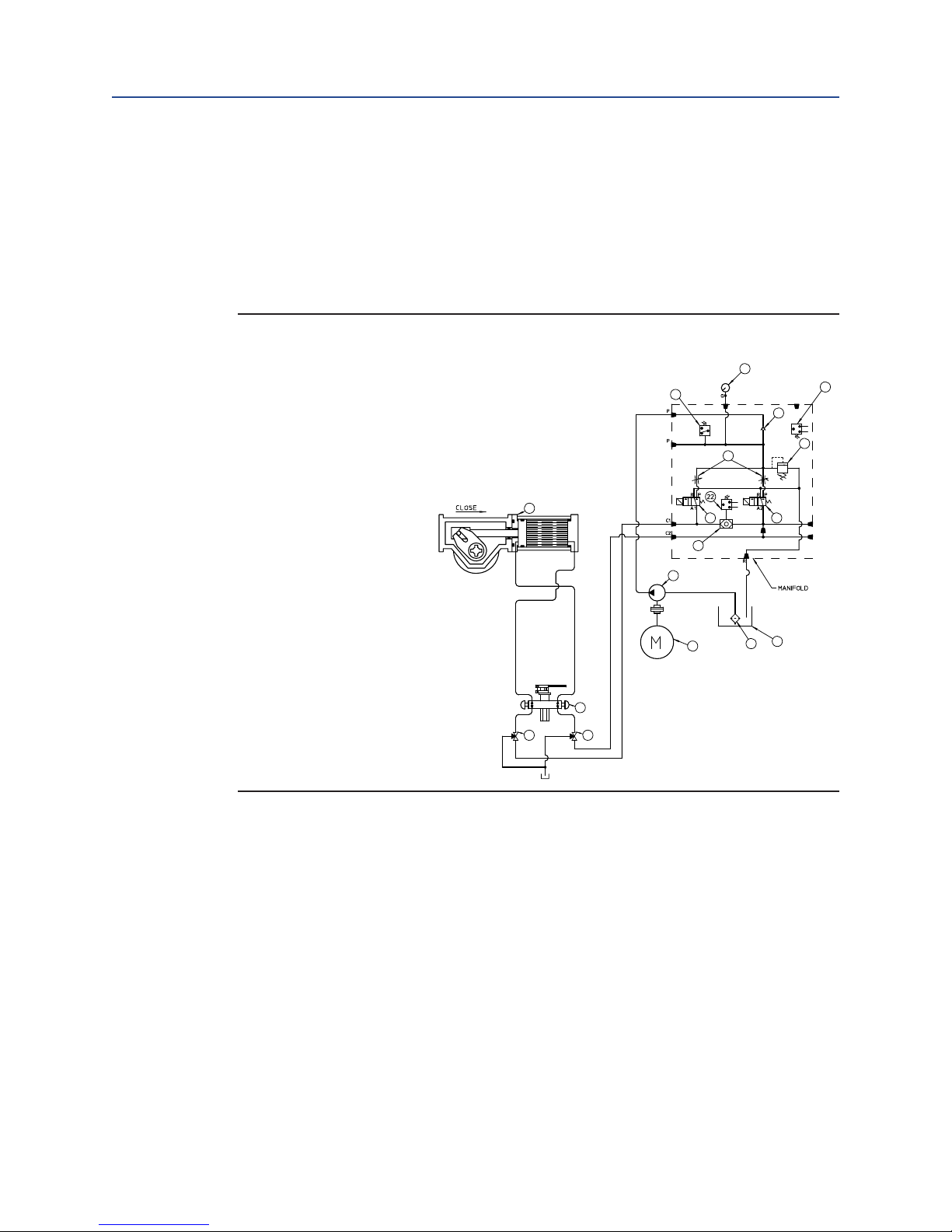

Figure 23 Basic Double Acting

W

M M

Q

R

V

J

X

Y

Z

L

AA

S

T

U

K

I

Operation

33

Page 37

Section 5: Operation

August 2016

NOTE:

Item numbers correspond to attached schematic drawing 11794-S

(W) Bettis G-series Double Acting Actuator

(Z) Electric Motor

(Y) Hydraulic Pump

(I) Fluid Reservoir

(K) 3-Way Normally Closed Solenoid Valve for closing the actuator

(J) 3-Way Normally Closed Solenoid Valve for opening the actuator

(V) Adjustable Flow Controls. There are two flow controls located upstream of the

open and close solenoid valve items (J) & (K).

(AA) Suction Strainer

(T) Check Valve

(U) Relief Valve: A pressure relief valve is provided to protect the actuator and control system from over-pressurization caused by the pump or thermal expansion of the

hydraulic fluid.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

(Q) Hydraulic Pressure Gauge

(R) Pressure Switch

(L) Hand Pump: Used to manually stroke the actuator open or closed.

(M) Hand Pump Selection Valves: These two valves are engaged to isolate the control

system before using the hand pump. Note: Both selection valves are engaged at the

same time when the hand pump is used to open or close the actuator.

(X) Shuttle Valve; (Optional) Used with an optional pressure transmitter.

(S) Pressure Transmitter(Optional)

34

Operation

Page 38

Installation and Operation Manual

(A) Pressure Gauge(Optional)

(B) Nitrogen Relief Valve(Optional)

(D) Isolation Valve(Optional)

(E) Hydraulic Accumulator With Nitrogen Blanket

Charge(Optional)

(H) Accumulator Isolation Valve(Optional)

(N) Accumulator Isolation Valve(Optional)

(R) Pressure Switch

(Q) Hydraulic Pressure Gauge

(S) Pressure Transmitter(Optional)

(T) Check Valve

(V) Adjustable Flow Controls

(U) Relief Valve

(O) Hand Pump Isolation Valve(Optional)

(W) Bettis G-series Double Acting Actuator

(AB) Pressure Transmitter(Optional)

(J) Opening Solenoid

(K) Closing Solenoid

(P) ESD Solenoid Valve(Optional)

(X) Shuttle Valve(Optional)

(AC) Shuttle Valve(Optional)

(Y) Hydraulic Pump

(AD) Accumulator override valve to open(Optional)

(AE) Accumulator override valve to close(Optional)

(Z) Electric Motor

(AA) Suction Strainer

(I) Fluid Reservoir

(L) Hand Pump

(M) Hand Pump Selection Valves

Part Number: VA001-507-32, Rev. 1

Figure 24 Main Components Double Acting with ESD Solenoid and Accumulator

Section 5: Operation

August 2016

A

B

E

H

D

Q

R

N

V

S

T

U

O

W

AD AE

M M

J

X

Y

Z

L

K

I

AA

(W) Bettis G Double Acting Actuator

(Z) Electric Motor

(Y) Hydraulic Pump

(I) Fluid Reservoir

(K) 3-Way Normally Closed Solenoid Valve for closing the actuator

(J) 3-Way Normally Closed Solenoid Valve for opening the actuator

(V) Adjustable Flow Controls. There are two flow controls located upstream of the

open and close solenoid valve items (J) & (K).

(AA) Suction Strainer

(T) Check Valve

(U) Relief Valve: A pressure relief valve is provided to protect the actuator and control system from over-pressurization caused by the pump or thermal expansion of the

hydraulic fluid.

Q) Hydraulic Pressure Gauge

(R) Pressure Switch

(L) Hand Pump: Used to manually stroke the actuator open or closed.

(AD) Optional accumulator override 3-way isolation valve to open the actuator

P

AC

(AE) Optional accumulator override 3-way isolation valve to close the actuator

Operation

35

Page 39

Section 5: Operation

August 2016

(M) Hand Pump Selection Valves: These two valves are engaged to isolate the control

system before using the hand pump. Note: Both selection valves are engaged at the

same time when the hand pump is used to open or close the actuator.

(X) Shuttle Valve; (Optional) Used with an optional pressure transmitter.

(P) (Optional) ESD 3-Way Normally Open Solenoid Valve

(E) (Optional) Hydraulic Accumulator w/nitrogen blanket charge: The accumulator is

used to stroke the actuator open or close with an additional override feature

(B) (Optional) Nitrogen Relief Valve: The relief valve is provided to prevent the nitrogen gas pressure to reach an over pressurization point caused by the pump or excessive

thermal expansion.

(N) (Optional) Accumulator Isolation Valve: Used to isolate the accumulator for repair

or maintenance.

(AB) (Optional) Pressure Transmitter: Used to transmit the pressure required to stroke

the valve over time as a diagnostic feature.

(H) (Optional) Accumulator Isolation Valve: This valve allows the hydraulic pressure to

by-pass back to the reservoir.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

(D) (Optional) Isolation Valve: Used to blow down or decay the nitrogen pressure from

the accumulator for repair or maintenance.

(A) (Optional) Pressure Gauge: Illustrates the accumulator nitrogen blanket pressure.

(O) (Optional) Hand Pump Isolation Valve: This valve isolates the ESD solenoid and

must be closed prior to using the hand pump for stroking the actuator open or closed.

(AC) (Optional) Shuttle Valve: This valve allows the actuator to close by either remote

electric by energizing the closing solenoid item (K) or by losing the electric signal thru

the ESD solenoid item (P).

(S) (Optional) Pressure Transmitter: Used to transmit the accumulator nitrogen blanket pressure.

36

Operation

Page 40

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

5.4 Functional Description

The following is a functional description of the Bettis Electro Hydraulic Actuator and a

brief explanation of the main components. Throughout this explanation, numbers which

appear in in [ ] correspond to components labeled on the wiring diagram. Numbers in

( ) correspond to components labeled on the schematic diagram. Information in (( )) is

descriptive.

5.4.1 Double Acting Without Accumulator and ESD Solenoid Valve

NOTE:

Refer to Section 10.1 for Hydraulic Schematic 11794-S, however the project specified

schematic may be slightly different in the numbering sequence and should be referred

to determine the actual options provided.

5.4.1.1 Power Stroke ((Open/Close))

Either one of the two closing or opening solenoids (J) or (K) are energized open

and the motor (Z) drives the hydraulic pump (Y) to supply the actuator open or

closing port thru the energized solenoid.

Section 5: Operation

August 2016

5.4.1.2 Manual Hand Pump Stroke

a. Open the hand pump selection isolation valve (M) to the pump posi-

tion. Note: both isolation valves (M) must be engaged whether hand

pumping open or close.

b. Select and push the open or close knob on the hand pump (L).

c. Stroke the hand pump (L) until the OPEN/CLOSE stroke is completed.

d. Push the manual relief valve located on the hand pump to retract the

pump ram back into the pump body and pull the pump handle down.

e. Upon completion of the OPEN/CLOSE hand pump stroke, return both

hand pump selection isolation valves back to the automatic position.

5.4.2 Double Acting with Optional Accumulator and ESD Solenoid Valve Functional

Description

NOTE:

Refer to Section 10.2. for Hydraulic schematic 11516-S, however the project specified

schematic may be slightly different in the numbering sequence and should be referred

to determine the actual options provided.

5.4.2.1 Accumulator Charge

The motor (Z) drives the hydraulic pump (Y) and discharges fluid to the nitrogen

blanket pre-charged accumulator (E).

5.4.2.2 Power Stroke ((Open/Close))

Upon completion of the accumulator charging, the pressure switch (R) set point

is reached and stops the motor. Either one of the two closing or opening solenoids (J) or (K) are energized open and the accumulator (E) provides hydraulic

pressure to flow thru the energized solenoid, either (J) or (K) and the actuator

strokes open or closed.

Operation

37

Page 41

Section 5: Operation

August 2016

NOTE:

Both Hand Pump Selection Isolation Valves (M) must be engaged whether hand

pumping open or close.

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

5.4.2.3 ESD Operation ((Optional))

In an ESD application the ESD Solenoid (P) is constantly energized closed. This

customer supplied signal is held as long as the signal is present. Upon loss of

the signal to the ESD solenoid, the solenoid will de-energize and open allowing

hydraulic supply fluid from the accumulator (E) to pass thru the ESD solenoid

and to the closing port of the actuator (W).

5.4.2.4 Manual Hand Pump Stroke

1. Open the Hand Pump Selection Isolation Valve (M) to the pump position.

2. Select and push the open or close knob on the Hand Pump (L).

3. Stroke the hand pump until the OPEN/CLOSE stroke is completed.

4. Push the manual relief valve located on the hand pump to retract the pump

ram back into the pump body and pull the pump handle down.

5. Upon completion of the OPEN/CLOSE hand pump stroke, return both hand

pump selection isolation valves back to the automatic position.

5.4.2.5 Accumulator override Feature ((Optional))

To stroke the actuator OPEN or CLOSED using the accumulator override isolation

valves , open valve (AD) to stroke the actuator open, or open (AE) to stroke the

actuator closed.

38

Operation

Page 42

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 6: Pushbutton Module (PBM)

Section 6: Pushbutton Module (PBM)

The Pushbutton Module consists of the following as shown in Figure 18:

• Two Pilot Lights: OPEN and CLOSE

• Three Pushbuttons: OPEN, CLOSE AND STOP

• Local – OFF – Remote Selector Knob

Figure 25 Pushbutton Module (PBM)

August 2016

The Pushbutton Module is the interface used to setup and operate the actuator and

display valve position.

To use the Local Control and Selector Knob, refer to the following tables.

Pushbutton Module (PBM)

39

Page 43

Section 6: Pushbutton Module (PBM)

August 2016

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

6.1 Selector Knob and Control Pushbuttons

The selector knob provides the choice of Local/Off/Remote operation.

The control pushbuttons perform normal Open/Stop/Close function in the local control

mode.

Table 5. Selector Knob

Selector Knob Rotate Local Control Mode Function

OFF (Stop) Return position Stop movement: Prevents motor operation

REMOTE (Auto) Clockwise

LOCAL (Hand) Counterclockwise

Table 6. Pushbuttons

Remote control: Allows control from remote

location

Local operation: Allows control from the local

control knob

Pushbutton Local Control Mode Function

STOP Stop movement: Prevents motor operation

CLOSE Actuator moves to close position

OPEN Actuator moves to open position

Table 7. Pilot Lights

Pilot Lights Valve Position

Valve Closed Valve Mid-Stroke Valve Open

CLOSE Illuminated Illuminated Off

OPEN Off Illuminated Illuminated

40

Pushbutton Module (PBM)

Page 44

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 7: Troubleshooting

WARNING:

To prevent personal injury, the actuator must be in spring-return, Fail-safe Position and all

hydraulic pressure drained, including an optional accumulator, before opening any tube

lines or attempting replacement operations below.

Of all the system components, the actuator itself is least likely to malfunction and require

the most time and effort to service.

Table 8. Troubleshooting

Symptoms Possible Reason

1. Ensure voltage is adequate to the unit.

EHO does not turn on.

EHO is on, but motor does

not run.

EHO motor runs, but

fails to develop sufficient

pressure to open the valve.

EHO will not return to the

Fail-safe Position.

2. Check to see that the electrical power is connected to

the correct terminals.

3. Branch circuit fuse blown out.

1. Ensure the Local/Off/Auto switch is in the proper position.

2. Ensure the field power wiring is an adequate size.

3. Power supply is insufficient.

4. Check to see if thermal overload is tripped.

1. Low fluid level in reservoir.

2. Wrong motor shaft rotation.

3. Hand pump isolation valve (O) is closed

(if optional accumulator is provided).

4. ESD solenoid is not energized because signal power

is insufficient.

5. The Relief valve is cracking open.

Check to ensure setting set to factory setting.

1. Ensure the Local/Off/Auto switch is in the proper position when initiating the open/close command.

2. Hand pump isolation valve (O) is closed; preventing

ability to stroke to the Fail-safe Position.

Section 7: Troubleshooting

August 2016

Should any issue be experienced besides the symptoms noted above, please consult factory.

Important check points for automatic operation of the EHO:

1. Ensure oil level is at the proper level.

2. Ensure hand pump isolation valve (O) is open.

3. Check to see that the ESD (optional) signal power is on.

Troubleshooting

41

Page 45

Section 8: Hazardous Area Classification and SIL Certification

August 2016

Installation and Operation Manual

Part Number: VA001-507-32, Rev. 1

Section 8: Hazardous Area Classification and

SIL Certification

— CSA, Canadian Standard Association Certification Class I, Division I,

Groups, C and D Group B configuration upon request

— FM, Factory Mutual Certification Class I, II, and III, Groups C, D, E, F, G,

Division I, T4 Group B configuration upon request

— ATEX Directive EExd IIB T4

— RoHS Directive

This product is only intended for use in large-scale fixed installation

excluded from the scope of Directive 2011/65/EU on the restriction of

the use of certain hazardous substances in electrical and electronic

equipment (RoHS 2).

— IECEx Certificate of Conformity Ex d IIB T4

— SIL II Certification

42

Hazardous Area Classification and SIL Certification

Page 46

Installation and Operation Manual

Dimension

Double-Acting Actuator

Product Data Sheet EHO

March 2015

EHO.01.05.EN, Page 2 of 2, Rev. 0

Section 9: Weights and Dimensions

Part Number: VA001-507-32, Rev. 1

Section 9: Weights and Dimensions

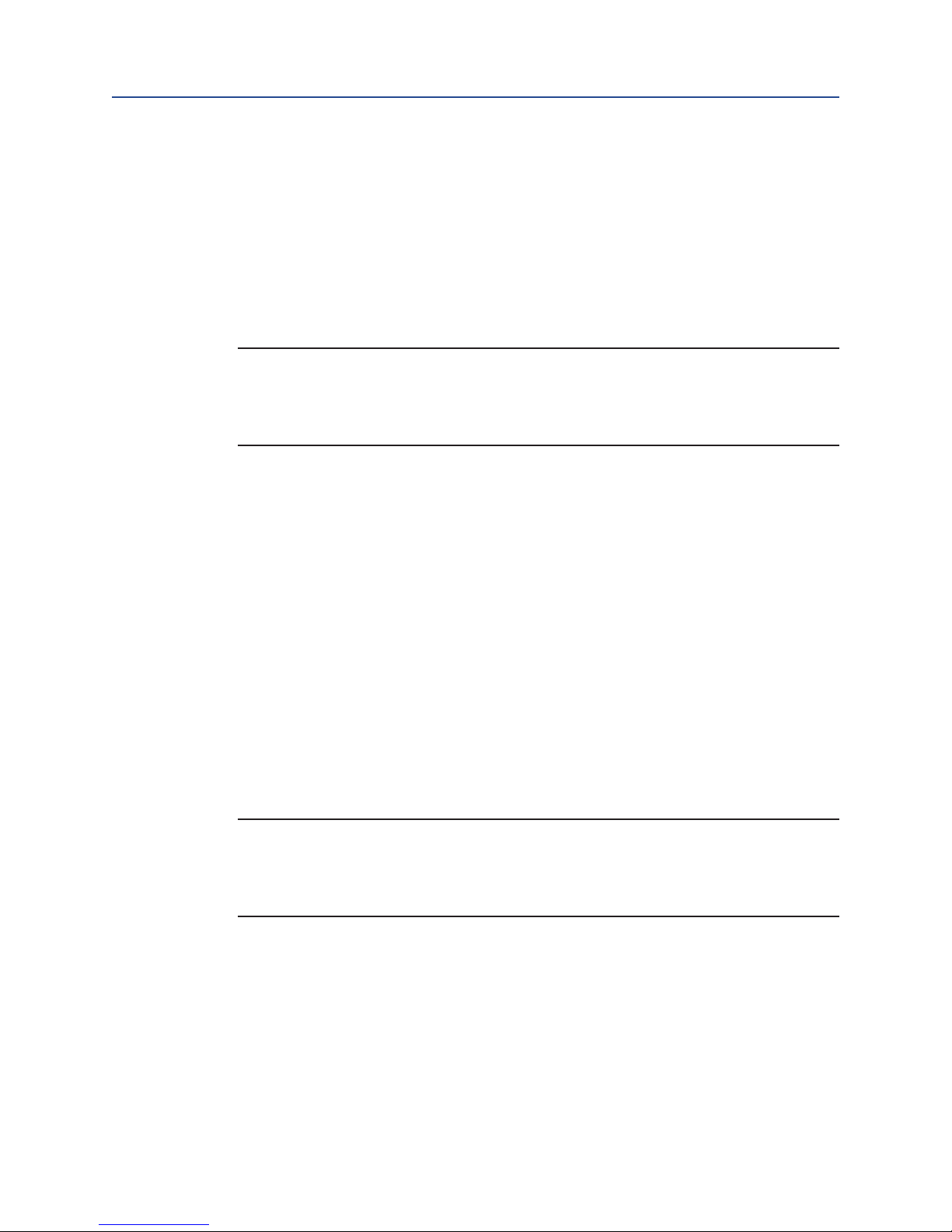

9.1 EHO Standard Double Acting

August 2016

Actuator

G01001.5 39.8 1010.9 27.7 703.6 28.3 718.8 57.9 1470.7 2.4 61.0 513 233

G2002.0 40.6 1031.2 28.7 729.0 29.0 736.6 58.3 1480.8 2.9 73.7 546 248

G3004.0 46.8 1188.7 30.1 764.5 32.5 825.5 61.5 1562.1 3.5 88.9 626 284

G4003.0 52.0 1320.8 34.5 876.3 31.9 810.3 66.8 1696.7 4.3 109.2 770 349

G4004.0 53.0 1346.2 35.5 901.7 32.9 835.7 67.8 1722.1 5.3 134.6 783 355

G5004.0 58.3 1480.8 37.4 950.0 34.8 883.9 73.2 1859.3 5.5 139.7 1141 518

G5005.0 59.3 1506.2 38.4 975.4 35.8 909.3 74.2 1884.7 6.5 165.1 1300 590

G7005.0 64.3 1633.2 40.4 1026.2 39.7 1008.4 81.6 2072.6 6.8 172.7 1786 810

G7008.0 65.3 1658.6 41.4 1051.6 40.7 1033.8 82.6 2098.0 7.8 198.1 1829 830

G8008.0 76.5 1943.1 427.0 1085.8 39.5 1003.3 87.5 2222.5 8.0 203.2 2461 1116