Page 1

D4 Valve

D103039X012

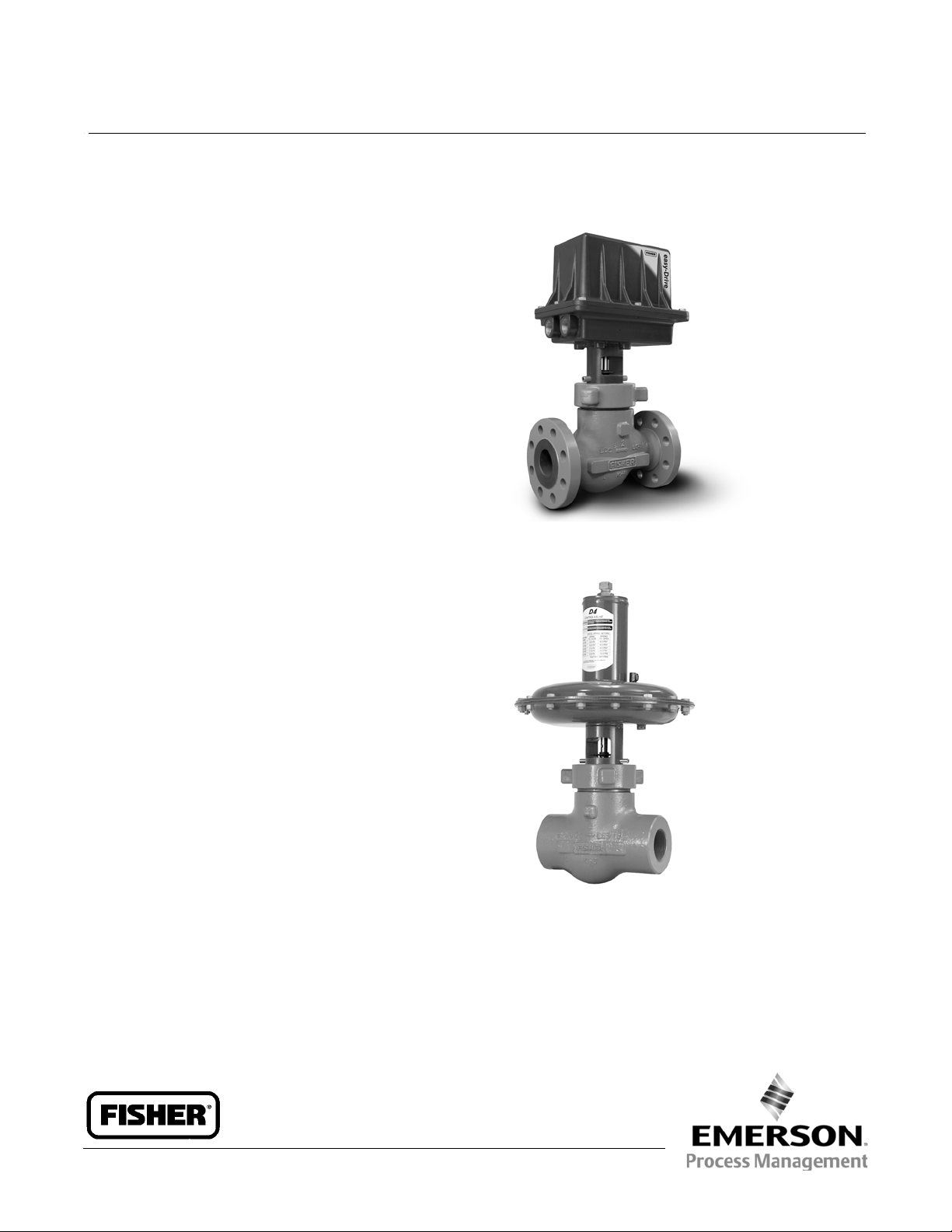

Fisherr D4 Control Valve Assembly

The Fisher D4 control valve is a compact, rugged globe

valve designed primarily for high-pressure throttling

applications using either pneumatic or electric control.

This valve is ideal for use on pressure and flow control

applications within the oil and gas production industry.

The D4 is an excellent control valve for high-pressure

separators, scrubbers, and other processing

equipment. These valves are especially useful for

either throttling or on/off control of liquids or gases

which are gritty, sticky, or which have a tendency to

builduponinternalvalveparts.

If the control valve requires maintenance, the trim and

packing can be maintained by removing the deep-bore

hammer nut and lifting the actuator/bonnet assembly

off the valve without disassembling the actuator.

W9933-1

Product Bulletin

51.2:D4

November 2013

Features

Electric and Pneumatic

Safer Bonnet / Valve Body Connection– Unique

design provides additional protection if disassembly

of bonnet/valve body connection is inadvertently

started while there is still pressure in the valve body.

Pins mounted in the valve bonnet help ensure the

bonnet disengages from the valve body as the

hammer nut is removed, while the threads are still

engaged.

Heavy-Duty Guiding–Massive guiding (figures 1 and

2) positively aligns the valve plug in the seat ring for

reliable service. The screwed-in seat ring completely

encloses the seat ring gasket.

Live-loaded Packing System–The packing system

provides an improved stem seal to help prevent the

loss of valuable or hazardous process fluids or gases.

It features Fisher ENVIRO-SEALt packing

technology to provide reduced packing

maintenance.

FISHER D4 CONTROL VALVE WITH easy-Drive™ ELECTRIC

ACTUATOR (NPS 2 RF FLANGED END CONNECTION)

W8531

FISHER D4 CONTROL VALVE

(NPS 2 NPT END CONNECTION)

www.Fisher.com

Page 2

Product Bulletin

51.2:D4

November 2013

D4 Valve

D103039X012

Features (continued)

Electric and Pneumatic

NACE Constructions–NACE compatible trim is

available with the D4 control valve. These

constructions meet the metallurgical requirements

of NACE MR0175 / ISO 15156.

Quick-Change Valve Plug–Removable groove pin

allows quick, easy valve plug replacement.

Severe Service Capability with Tungsten Carbide

Trim–D4 valves are available with tungsten carbide

trim for erosive service. This trim is designed

specifically for severe service applications in the oil

and gas industry. Durable tungsten carbide trim

may benefit your application by wearing better and

lasting longer.

Easy Installation–Compact design allows

installation where space is a premium. Screwed

valve bodies feature compact face-to-face

dimensions while flanged valve bodies conform to

ISA-75 standards for maximum versatility.

Electric

Low Power Consumption-- The Fisher easy-Drive

electric actuator operates with 12 or 24VDC and

less than 0.1 watt hours per operation, using

Modbus,4-20mA,1-5VDC,ordrycontactcontrol

signals.

Low Temperature-- Theeasy-Driveelectricactuator

design allows use in ambient temperatures as low

as -20C(-4F) without use of a heater.

Easy Installation--The compact design allows

installation where space is a premium. Fisher

easy-Drive calibrates by simply opening and closing

the valve.

Remote Monitoring and Configuration-- Loss of

signal position is programmable over Modbus.

Pneumatic

Easy Maintenance–Hammer nut bonnet/body joint

allows repair or maintenance with a minimum of

tools, without removing the valve body from the

piping system. Seat ring can be removed with the

same service tools used with a Fisher D valve.

Integral Bonnet Flange– Bonnet has an integral

flange that accepts hammer nut force when making

the bonnet-to-body connection. There are no snap

rings subject to possible failure in sour service or in

atmospheric corrosion.

Standard Trim for Throttling or On-Off Service–

Micro-Form trim is standard for throttling or on-off

service at no extra cost.

Application Flexibility–Choices of port diameters up

to 31.8 mm (1.25 inches), end connections, and

trim materials suit these valves to many

applications, including sour service.

Low Temperature Materials--Valve construction

materialsallowuseinapplicationsaslowas-40C

(-40F) for the pneumatic actuator.

Installation

D4 control valves may be installed in any position, but

normally the actuator is vertical and above the valve.

Install the control valve so the flow direction arrow on

thesideofthevalvebodyindicatesthedirectionofthe

process flow.

Dimensions are shown in tables 12 and 13 and

figures 1 and 2.

2

Page 3

D4 Valve

D103039X012

Valve Specifications

Product Bulletin

51.2:D4

November 2013

Available Actuation Configurations

Spring-To-Close Pneumatic

Flow Coefficients

See Fisher Catalog 12

Spring-To-Open Pneumatic

Electric

Valve Sizes and End Connection Styles

(1)

See table 3

Dimensions

See tables 12 and 13 and figures 1 and 2.

Face-to-face dimensions for flanged valves conform

to ISA-75.03 (CL150-600) and ANSI/ISA-75.16 Short

(CL900/1500)

Maximum Inlet Pressures and Temperatures

(1)

Flanged connections are consistent with the ASME

B16.34 pressure-temperature class, subject to

Material Temperature Capabilities for the Valve Body

Assembly (see following specification). For NPT end

connections, the valve body rating is 4250 psig.

Maximum Pressure Drops

(1)

Seetables7,8,9,10,and11

Shutoff Classification per ANSI/FCI 70-2

and IEC 60534-4

Class IV

Flow Characteristic

Equal percentage

Flow Direction

Flow up only

1. The pressure or temperature limits in the referenced tables andany applicable ASME code limitations should not be exceeded.

Port Diameters

See table 3

Construction Materials

Valve Body and Bonnet: ASME SA 352 LCC

Valve Plug and Seat: See table 5

Valve Stem: S20910

Actuator O-Rings: (HNBR) Hydrogenated Nitrile

Bonnet O-Ring:

Standard: HNBR

Optional: Fluorocarbon

Packing: PTFE/Carbon PTFE

Packing Springs: N07718

Packing Retainer: S17400

Actuator Diaphragm: Chloroprene

Actuator Spring: Painted steel

Seat Ring Gasket: S31600 (316 SST)

Spring Cover (Fail Up): PVC

Valve Plug Travel

19 mm (0.75 inch)

Valve Plug Style

Micro-Form valve plug

Material Temperature Capabilities

Valve Body Assembly:

Standard Bonnet O

(-40 to 275F)

Optional Bonnet Fluorocarbon O

-23 to 204C(-10to400F)

-

Ring: -40 to 135C

-

Ring:

3

Page 4

Product Bulletin

51.2:D4

November 2013

Actuator Specifications

D4 Valve

D103039X012

ELECTRIC ACTUATOR

Material Temperature Capabilities

Electric Actuator Assembly:

-20 to 70C(-4to158F) ambient

(1)

Electromagnetic Compatibility

Meets EN 61326-1 (First Edition)

Immunity: Industrial locations per table 2 of EN

61326-1 Standard. Performance is shown in table 2

Emmissions: Class A

ISM Equipment Rating: Group 1, Class A

Available Electric Actuator Configurations

easy-Drive Electric On/Off

easy-Drive Electric Positioning

Power Requirements

12 or 24VDC, minimum 4 amp power supply required

(fuse to 5 amps)

Maximum Current Draw

4amps

Conduit Connections

Two 3/4 NPT connections

PNEUMATIC

Input Signal to Actuator

Seetables7,8,9,and10

Material Temperature Capabilities

Actuator Assembly:

Fail-Down, Spring-to-Close: -40 to 93C

(-40 to 200F)

Fail-Up, Spring-to-Open: -40 to 93C

(-40 to 200F)

Control Signals

On/Off: Dry contact, Modbus RTU

Positioning: 1-5VDC, 4-20 mA, Modbus RTU

Available Pneumatic Actuator Configurations

Spring-to-Open

Electrical Classification

Spring-to-Close

Hazardous Area:

CSA (C/US) – Explosion proof

FM– Explosion proof (pending)

ATEX– Flameproof (pending)

Maximum Actuator Casing Pressure

3.4 bar (50 psig)

IECEx– Flameproof (pending)

Refer to table 1 for specific approval information

Electrical Housing:

Actuator Diaphragm Effective Area

452 cm

2

CSA -- Type 4X

FM -- NEMA 4X (pending)

ATEX -- IP66 (pending)

IECEx -- IP66 (pending)

1. The pressure or temperature limits in the referenced tables andany applicable ASME code limitations should not be exceeded.

Actuator Pressure Connections

1/4 NPT internal

ACTUATOR

(1)

(1)

(69 square inches)

4

Page 5

D4 Valve

D103039X012

Table 1. Hazardous Area Classifications - CSA (Canada and United States)

CERTIFICATION BODY

CSA Class I,Division 1, GP C, D T6 ---

Table 2. EMC Summary Results - Immunity

PORT PHENOMENON BASIC STANDARD TEST LEVEL

Electrostatic discharge (ESD) IEC 61000-4-2

CERTIFICATION

OBTAINED

ENTITY RATING TEMPERATURE CODE ENCLOSURE RATING

T6 (Tamb ≤ 70_C)

4kV Contact

8kV Air

Product Bulletin

51.2:D4

November 2013

CSA Type 4X Enclosure

PERFORMANCE

CRITERIA

(1)

A

Enclosure

I/O signal/ control

Performance criteria is +/- 5% stem position

1. A= No degradation during testing. B = Temporary degradation during testing, but is self recovering.

2. Criteria A with conduit on DC and I/O cables, CriteriaB without conduit

Radiated EM field IEC 61000-4-3

Rated powerfrequency

magnetic field

Burst IEC 61000-4-4 1kV A

Surge IEC 61000-4-5 1kV cable shield, and line to ground A

Conducted RF IEC 61000-4-6 3V 150 kHz to 80 MHz at 3 Vrms A

IEC 61000-4-8 30 A/m@ 50 and 60 Hz A

Ordering Information

When ordering, specify:

Application Information

1. Type of application

a. Throttling or on-off

b. Reducing or relief (back pressure)

2. Controlled fluid

80 to1000 MHz @ 10V/m 1kHz AM at 80%

1400 to2000 MHz @ 3V/m 1kHz AM at 80%

2000 to2700 MHz @ 1V/m 1kHz AM at 80%

a. Range of flowing pressure drops

b. Maximum drop at shutoff

5. Flow rates

a. Minimum controlled flow

b. Normal flow

c. Maximum flow

(2)

A

/B

a. Type (include chemical analysis, if available)

b. Temperature (normal and maximum

anticipated)

c. Specific gravity

3. Range of flowing inlet pressures

4. Pressure drops

6. Input signal range to actuator

Control Valve Assembly Information

Refer to the Specifications and review the information

under each specification.

5

Page 6

Product Bulletin

51.2:D4

November 2013

Table 3. Valve Sizes and Connection Styles

VALVE

SIZE,

NPS

1

2

X = Available construction.

PORT

DIAMETER,

(INCHES)

0.25, 0.375,

0.5, 0.75

0.25, 0.375,

0.5, 0.75, 1,

1.25

Table 4. Fisher D4 Control Valves Approximate Weights, Kg (Pounds)

Valve Body Size, NPS

Screwed 32 (71) 39 (87) 22 (49) 29 (64)

CL150 34 (74) 39 (86) 24 (52) 29 (63)

CL300 and 600 37 (81) 48 (106) 27 (59) 33 (73)

CL900 and 1500 50 (110) 66 (146) 40 (88) 51 (113)

SCREWED RAISED FACE (RF) FLANGED

4250 psi CL150 CL300 CL600

X X X X X X X

X X X X X X X

Pneumatic Electric

1 2 1 2

CL900 and

1500

CL600

D4 Valve

D103039X012

RING TYPE JOINT

(RTJ) FLANGE D

CL900 and

1500

Table 5. Typical Combinations of Metal Trim Parts

DESIGNATION VALVE PLUG SEAT RING

Standard S41600 hardenedto 38 HRC minimum S17400

Sour S17400 (NACE MR0175/ISO 15156) S17400 (NACE MR0175/ISO 15156)

Tungsten Carbide Tungsten carbide / S17400(NACE MR0175/ISO15156) Tungsten carbide / S17400 (NACE MR0175/ISO15156)

Table 6. Fisher D4 Environmental Limits for NACE MR0175/ISO 15156 with Sour Trim

MAXIMUM TEMPERATURE MAXIMUM H2S PARTIAL PRESSURE

_C _F MPa psia

204 400 1.4 200 No

199 390 2.3 330 No

191 375 2.5 360 No

149 300 2.8 400 No

135 275 No Limit Yes

Table 7. Maximum Shutoff Pressure Drops

When Used with Typical Control Instrumentation

INPUT SIGNAL TO

ACTUATOR

SPRING Light Rate Heavy Rate

INITIAL SPRING

SETTING

PORT DIAMETER Maximum PressureDrop

mm Inches Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi

6.4

9.5

12.7

19.1

25.4

31.8

1. The pressure or temperature limits in the referenced tables and any applicable ASMEcode limitations shouldnot be exceeded.

2. For example, use the column marked 0-1.4 bar (0-20 psig) for a 0.21-1.0 bar (3-15 psig) pneumatic controller with1.4 bar (20 psig) supply pressure.

3. For applications with downstream pressure in excess of 196 bar (2845 psig), use 196 bar (2845 psig) forMaximum Shutoff Pressure.

0.25

0.375

0.5

0.75

1

1.25

0to1.2Bar

(0 to 18 Psig)

0.77 Bar

(11.2 Psig)

(3)

293

(3)

293

191

80

42

25

4250

4250

2765

1160

610

365

(3)

(3)

(1)

0to1.4Bar

(0 to 20 Psig)

0.77 Bar

(11.2 Psig)

(3)

293

(3)

293

191

80

42

25

for Fisher D4 Control Valves with Pneumatic Actuator (Spring-to-Close)

(2)

4250

4250

2765

1160

610

365

(3)

(3)

0to2.0Bar

(0 to 30 Psig)

0.85 Bar

(12.4 Psig)

293

293

219

92

49

30

4250

4250

3180

1340

715

430

0to2.3Bar

(0 to 33 Psig)

1.05 Bar

(15.3 Psig)

293

293

288

123

67

41

4250

4250

4180

1785

965

590

0to2.4Bar

(0 to 35 Psig)

1.18 Bar

(17.1 Psig)

293

293

293

143

78

48

COMPATIBLE WITH

ELEMENTAL SULFUR?

0to3.4Bar

(0 to 50 Psig)

1.18 Bar

(17.1 Psig)

4250

4250

4250

2080

1130

700

293

293

293

143

78

48

4250

4250

4250

2080

1130

700

6

Page 7

D4 Valve

D103039X012

Product Bulletin

51.2:D4

November 2013

Table 8. Maximum Shutoff Pressure Drops

When Used with Instrumentation with Restricted Output Range

INPUT SIGNAL TO ACTUATOR

SPRING Heavy Rate Heavy Rate

INITIAL SPRING SETTING

PORT DIAMETER Maximum Pressure Drop

mm Inches Bar Psi Bar Psi

6.4

9.5

12.7

19.1

25.4

31.8

1. The pressure or temperature limits in the referenced tables and any applicable ASMEcode limitations shouldnot be exceeded.

2. For example, an Electro-PneumaticTransducer calibrated for 0.4-2.0bar (6-30 psig) outputpressure.

3. For applications with downstream pressure in excess of 118 bar (1715 psig), use 118 bar (1715 psig) forMaximum Shutoff Pressure.

0.25

0.375

0.5

0.75

1

1.25

Table 9. Maximum Shutoff Pressure Drops

When Used with Typical Control Instrumentation

INPUT SIGNAL TO

ACTUATOR

SPRING Light Rate Heavy Rate

INITIAL SPRING

SETTING

PORT DIAMETER Maximum PressureDrop

mm Inches Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi

6.4

9.5

12.7

19.1

25.4

31.8

1. The pressure or temperature limits in the referenced tables and any applicable ASMEcode limitations shouldnot be exceeded.

2. For example, use the column marked 0-1.4 bar (0-20 psig) for a 0.21-1.0 bar (3-15 psig) pneumatic controller with1.4 bar (20 psig) supply pressure.

3. For applications with downstream pressure in excess of 190 bar (2760 psig), use 190 bar (2760 psig) forMaximum Shutoff Pressure.

0.25

0.375

0.5

0.75

1

1.25

0to1.2Bar

(0 to 18 Psig)

0.23 Bar

(3.4 Psig)

(3)

293

(3)

293

187

78

41

24

4250

4250

2715

1135

600

355

(3)

(3)

(1)

(1)

0to1.4Bar

(0 to 20 Psig)

0.23 Bar

(3.4 Psig)

(3)

293

293

233

99

53

32

for Fisher D4 Control Valves with Pneumatic Actuator (Spring-to-Close)

(2)

293

210

113

(3)

(3)

45

23

13

0.4 to 2.0 Bar

(6 to 30 Psig)

0.97 Bar

(14.0 Psig)

4250

3045

1635

655

330

185

(3)

(3)

293

293

282

120

65

39

0.14 to 2.3 Bar

(2 to 33 Psig)

1.17 Bar

(17.0 Psig)

4250

4250

4095

1750

945

580

for Fisher D4 Control Valves with Pneumatic Actuator (Spring-to-Open)

(2)

4250

4250

3380

1430

765

465

(3)

(3)

0to2.0Bar

(0 to 30 Psig)

0.28 Bar

(4.0 Psig)

293

293

293

147

80

49

4250

4250

4250

2130

1160

715

0to2.3Bar

(0 to 33 Psig)

0.28 Bar

(4.0 Psig)

293

293

293

178

97

60

4250

4250

4250

2575

1410

875

0to2.4Bar

(0 to 35 Psig)

0.28 Bar

(4.0 Psig)

293

293

293

198

109

68

4250

4250

4250

2875

1575

985

0to3.4Bar

(0 to 50 Psig)

0.28 Bar

(4.0 Psig)

293

293

293

293

195

123

4250

4250

4250

4250

2830

1785

Table10.MaximumShutoffPressureDrops

(1)

for Fisher D4 Control Valves with Pneumatic Actuator

(Spring-to-Open) When Used with Instrumentation with Restricted Output Range

(3)

(3)

196

82

43

26

0.4 to 2.0 Bar

(6 to 30 Psig)

0.69 Bar

(10.0 Psig)

4250

4250

2845

1195

630

380

(3)

(3)

INPUT SIGNAL TO ACTUATOR

SPRING Heavy Rate Heavy Rate

INITIAL SPRING SETTING

PORT DIAMETER Maximum Pressure Drop

mm Inches Bar Psi Bar Psi

6.4

9.5

12.7

19.1

25.4

31.8

1. The pressure or temperature limits in the referenced tables and any applicable ASMEcode limitations shouldnot be exceeded.

2. For example, an Electro-PneumaticTransducer calibrated for 0.4-2.0bar (6-30 psig) outputpressure.

3. For applications with downstream pressure in excess of 202 bar (2925 psig), use 202 bar (2925 psig) forMaximum Shutoff Pressure.

0.25

0.375

0.5

0.75

1

1.25

293

293

(2)

293

293

293

156

85

52

0.14 to 2.3 Bar

(2 to 33 Psig)

0.42 Bar

(6.1 Psig)

4250

4250

4250

2265

1235

765

7

Page 8

Product Bulletin

51.2:D4

November 2013

D4 Valve

D103039X012

Table 11. Fisher D4 easy-Drive Maximum Pressure Drop

PORT DIAMETER MAXIMUM PRESSURE DROP

mm Inch Bar psi

6.4

9.5

12.7

19.1

25.4

31.8

1. Downstream pressure, P2, is limited to 2250 psig.

Table 12. Dimensions - Pneumatic Actuator

END

CONNECTION

STYLE

Screwed

CL150 RFFlg

CL300 RFFlg

CL600 RFFlg

CL600 RTJFlg

CL900/1500 RFFlg

CL900/1500 RTJ Flg

1. Also seefigures 1 and 2.

A D G A D G

mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches

155

184

197

210

210

273

273

6.12

7.25

7.75

8.25

8.25

10.75

10.75

Table 13. Dimensions - Pneumatic Actuator

FAIL ACTION

0.25

0.375

0.5

0.75

1

1.25

293

293

247

105

56

34

(1)

NPS 1 VALVE BODY NPS 2 VALVE BODY

209

209

209

209

209

209

209

8.24

8.24

8.24

8.24

8.24

8.24

8.24

46

46

46

46

46

46

46

1.81

1.81

1.81

1.81

1.81

1.81

1.81

230

254

267

286

289

340

343

9.00

10.00

10.50

11.25

11.38

13.38

13.50

215

215

215

215

215

215

215

(1)

C E F

mm Inches mm Inches mm Inches

Fail Down,Spring-To-Close 333 13.12 312 12.30 241 9.47

Fail Up, Spring-To-Open 333 13.12 324 12.74 --- ---

1. Also seefigures 1 and 2.

(1)

4250

4250

3576

1518

814

495

8.47

8.47

8.47

8.47

8.47

8.47

8.47

70

70

70

70

70

70

70

2.75

2.75

2.75

2.75

2.75

2.75

2.75

Table 14. Dimensions - Electric Actuator

END

CONNECTION

STYLE

Screwed

CL150 RF Flg

CL300 RF Flg

CL600 RF Flg

CL600 RTJFlg

CL900/1500 RF Flg

CL900/1500 RTJFlg

1. Also seefigure 3.

A B C A B C D

mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches

155

184

197

210

210

273

10.75

273

10.75

NPS 1 VALVE BODY NPS 2 VALVE BODY

6.12

7.25

7.75

8.25

8.25

46

1.81

46

1.81

46

1.81

46

1.81

46

1.81

46

1.81

46

1.81

(1)

414

414

414

414

414

414

414

16.29

16.29

16.29

16.29

16.29

16.29

16.29

230

254

267

286

289

340

343

9.00

10.00

10.50

11.25

11.38

13.38

13.50

NPS 1 AND 2

VALVE BODY

70

2.75

70

2.75

70

2.75

70

2.75

70

2.75

70

2.75

70

2.75

438

438

438

438

438

438

438

17.24

17.24

17.24

17.24

17.24

17.24

17.24

275

275

275

275

275

275

275

10.83

10.83

10.83

10.83

10.83

10.83

10.83

8

Page 9

D4 Valve

D103039X012

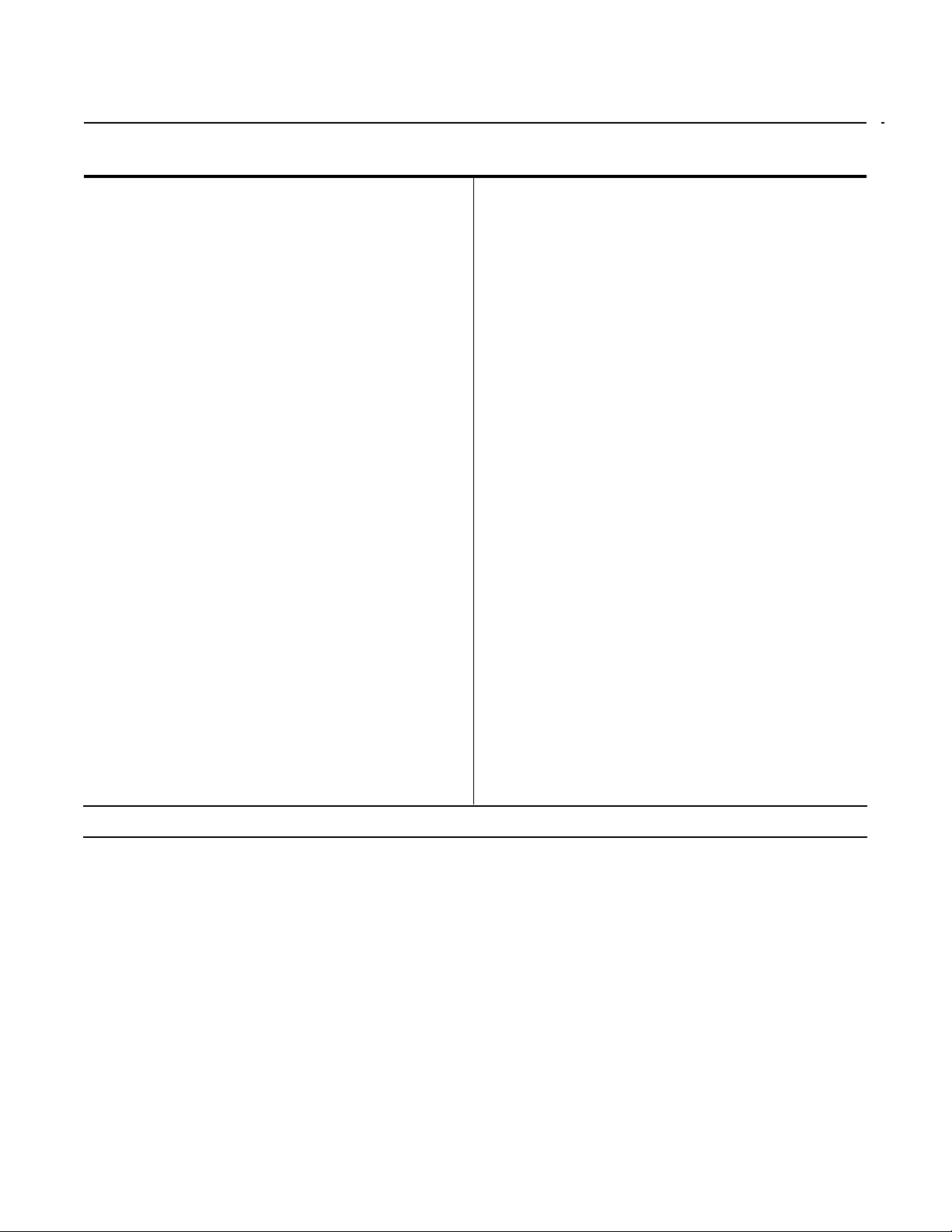

Figure 1. Fisher D4 Valve Dimensions, Spring-To-Close (also see tables 12 and 13)

EMAX

C

F

Product Bulletin

51.2:D4

November 2013

GE02329-C

1/4-18 NPT

CONTROL

D

G

A/2

A

9

Page 10

Product Bulletin

51.2:D4

November 2013

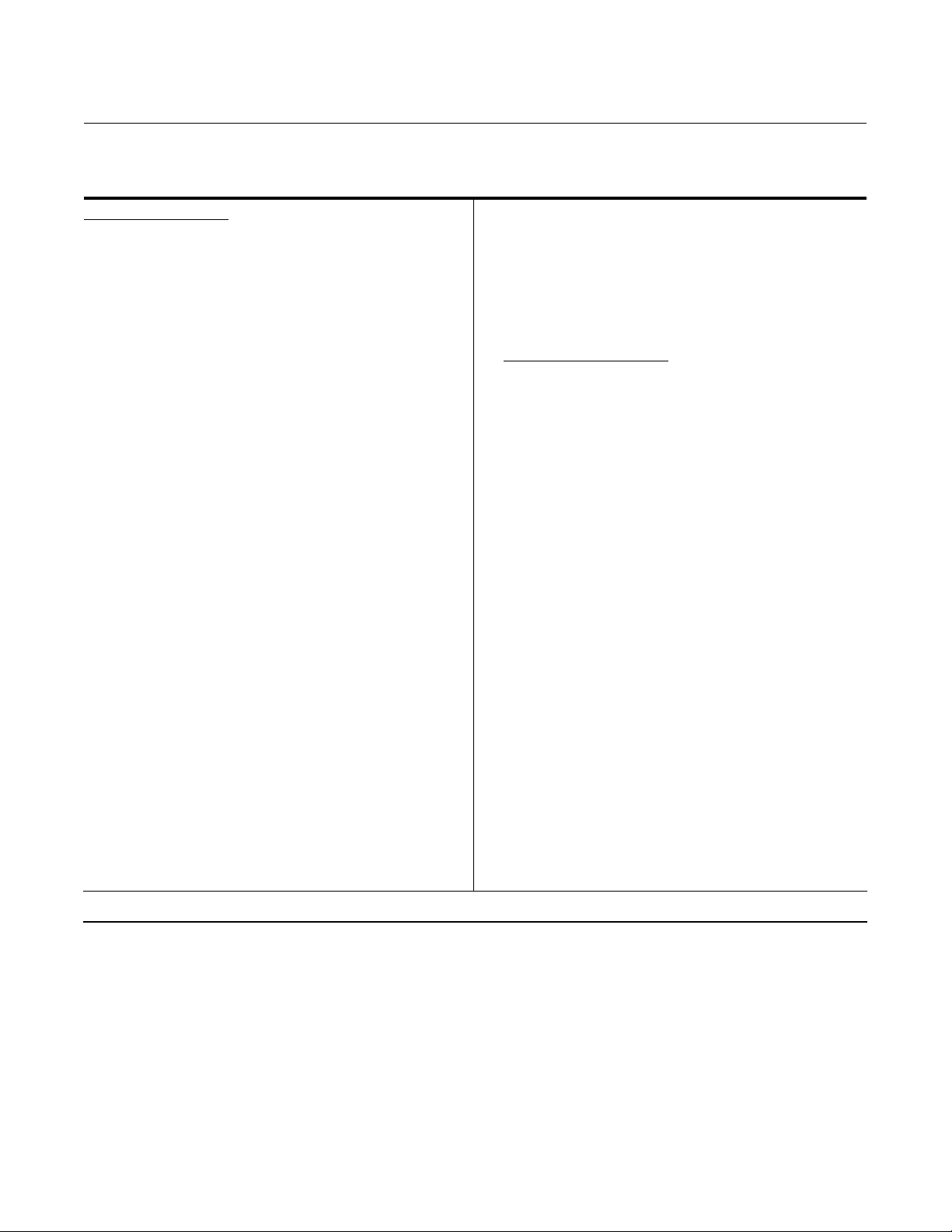

Figure 2. Fisher D4 Valve Dimensions, Spring-To-Open (also see tables 12 and 13)

D4 Valve

D103039X012

C

E

D

GE02330-E

10

G

A/2

A

Page 11

D4 Valve

D103039X012

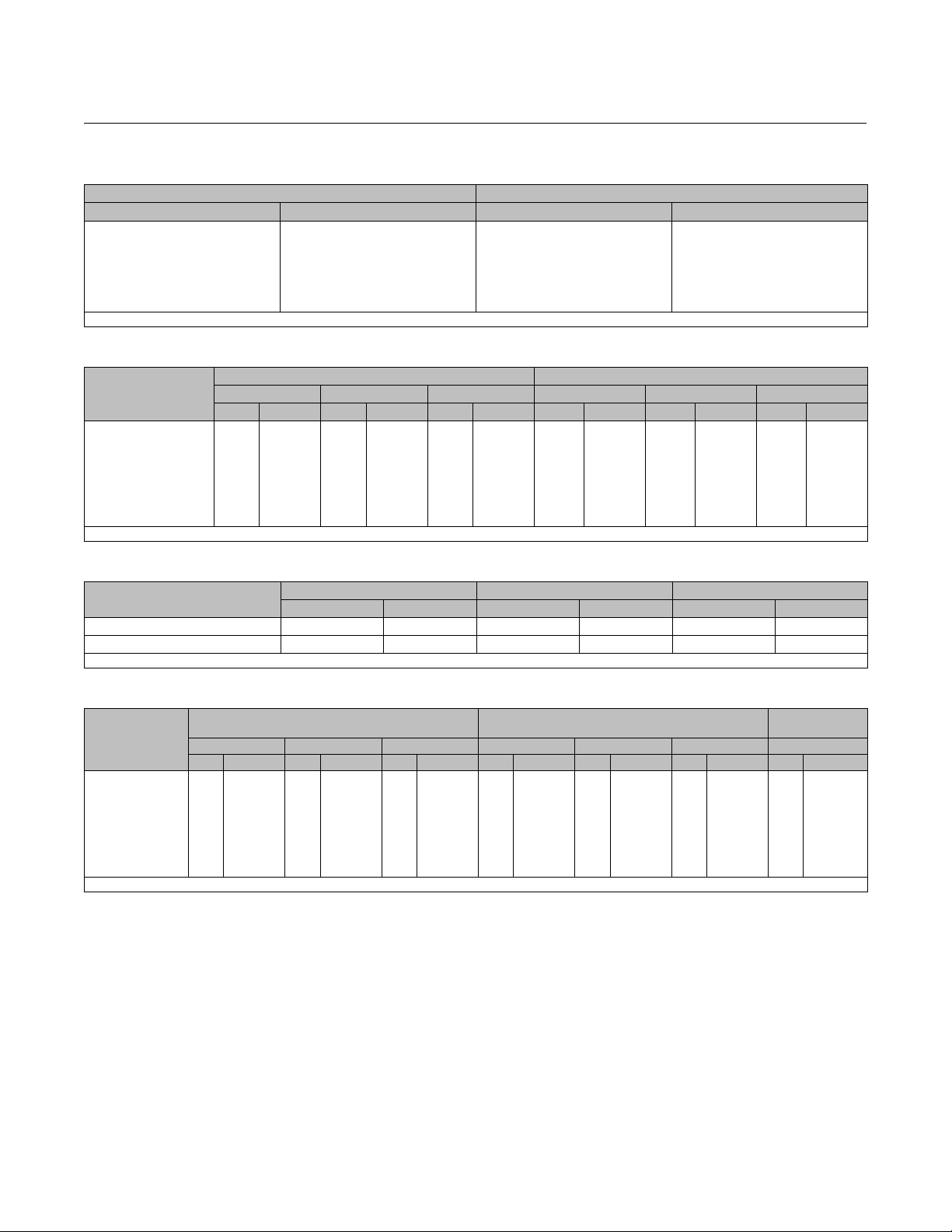

Figure 3. Fisher D4 Control Valve with easy-Drive Electric Actuator and NPS 2 Flanged Valve Body

D

Product Bulletin

51.2:D4

November 2013

A/2

C

B

A

11

Page 12

Product Bulletin

51.2:D4

November 2013

D4 Valve

D103039X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for properselection, use,and maintenanceof any product remains solely with thepurchaser andend user.

Fisher, easy-Drive, and ENVIRO-SEAL are marks owned by one of the companies in the EmersonProcess Management business unit of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reservethe right to modify or improve the designs or specificationsof such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2002, 2013 Fisher ControlsInternational LLC. All rights reserved.

12

Loading...

Loading...