Emerson N1652, E171230 User Manual

Unidrive SP

230V / 460V Servo Drive Systems

Unidrive SP – Advanced Solutions Platform for Servo Motor Control

Control Techniques’ Unidrive SP delivers dynamic performance to operate a wide array of servo motor types and power ratings. Snap-in SM option modules allow the addition of programming platforms, distributed or centralized control architecture, I/O, communications and feedback to tailor the solution to specific application needs.

Drive identification marker rail

Optional keypad, available as highbrightness LED or multi-language LCD with plain text

Modbus  communications port for PC programming and device interfacing

communications port for PC programming and device interfacing

Universal encoder  port supporting Incremental, SinCos, SSI, EnDAT and HIPERFACE encoder types

port supporting Incremental, SinCos, SSI, EnDAT and HIPERFACE encoder types

* Features and their locations vary on some drive sizes

SmartCard for parameter, PLC program storage

Terminal cover for DC bus, low voltage power supply and on board

Terminal cover for DC bus, low voltage power supply and on board

EMC filter

Internal EMC filter with

Internal EMC filter with

easy disconnect

Power On / Drive

Power On / Drive

Status LED

Aluminium heatsink: drive can be mounted on a flat surface, or through panel mounted so that the heat is dissipated outside the enclosure*

Aluminium heatsink: drive can be mounted on a flat surface, or through panel mounted so that the heat is dissipated outside the enclosure*

3 universal SM option

3 universal SM option

module slots for communications, I/O, additional

feedback devices and automation/motion controllers*

Relay connections

Relay connections

Power connections with removable terminals*

Power connections with removable terminals*

Plug-in connections with removable terminals*

|

|

|

|

ENVIROMENTAL |

|

|

QUALITY |

|

|

|

|

|

|

||

|

|

|

|

MANAGEMENT |

|

|

MANAGEMENT |

E171230 |

N1652 |

Certificate No. EMS 54446 |

003 |

Certificate No. Q 05176 |

003 |

||

ISO 14001 |

|

ISO 9001 |

|||||

|

|

|

|||||

2 |

www.controltechniques.com |

One Drive, Any Power, Any Motor

The Unidrive SP is a universal AC and Servo drive with ratings from 0.5 to 2,900hp. This field-proven drive features dynamic servo performance with a wide array of power, motor types and snap-in SM option modules

including programming/automation platforms, distributed or centralized control, I/O, communications and feedback to tailor the solution to your exact needs. (For full details on the wide range of available option modules, please see the Control Techniques SM Option Modules brochure.)

Panel Mount – Standard Drives

0.5 - 200hp (0.37kW to 132kW)

Unidrive SP Panel Mount drives are standard AC input, AC output sizes for installation within a control panel. Optional conduit boxes are available for wall mounting.

Ratings |

|

|

Input |

Normal Duty |

Heavy Duty |

Voltage |

|

|

200-240V, 1Ø

200-240V, 3Ø

380-480V, 3Ø

500-575V, 3Ø

500-690V, 3Ø

20 50

0.5 |

2 3 |

25 |

60 |

100 |

125 |

150 |

175 |

200 |

Horsepower Range

Performance Advantage

Servo Motor Control

Closed-loop servo motor control and power regeneration control features in one drive

Dual Duty Ratings — Normal and Heavy

Provides cost-effective sizing choices for all applications

24Vdc Auxiliary Power Supply Input

Maintains control, network communications and position loop on input AC power loss, minimizing system recovery time

Comprehensive Auto-Tune

Inertia monitoring and static auto-tune reduce startup time

Universal Feedback Interface

Supports 14 different types of feedback devices, including several absolute encoders; multiple encoders can be connected to a single drive with SM option modules

High-Resolution Analog Input

16-bit, 250µsec interface for high-performance applications; two additional 10-bit analog inputs for lower level controls

Extensive Fieldbus Connectivity

ModbusRTU (Standard), Profibus-DP (V1), Ethernet, DeviceNet, CAN, CANOpen, EtherCAT, SERCOS, Interbus-S and CTNet/CTSync optional via zero-space option modules; up to four fieldbus devices can connect to a single drive, eliminating the need for expensive gateways

Universal SM Option Module Slots

Unidrive SP size 0 has two slots; Unidrive SP sizes 1 and up have three option module slots; SM-Fieldbus, I/O and Application modules fit in any of the open module slots

Safe Torque Off Function

Conforms to IEC61800-5-1, SIL 3 and EN954-1 Category 3 for machine safety and system cost reduction

SmartCard for Simple Set-up and Cloning

Easy-to-use card stores drive configuration for simple startup and parameter cloning — supplied free with every Unidrive SP

Keypad Options

Choose no keypad, LED keypad or LCD keypad based on the system design and operating environment

Drive-Mounted Brake Resistors

Unidrive SP sizes 0, 1 and 2 feature a drive-mounted brake resistor option to reduce panel space requirements

www.controltechniques.com |

3 |

Automation Solutions

Unidrive SP programmable drives offer more compact, higher-performance and lower-cost solutions in machinery automation applications. Over the past 20 years, Control Techniques has pioneered the embedding of programmable automation, motion control and communications features within its drive products.

Featured SM Option Modules

To provide the best possible dynamic motor performance, the following Control Techniques SM option modules contain a high-performance microprocessor that allows the base drive to be dedicated to shaft control as well as machine control.

SM-EZMotion

The SM-EZMotion option module and Control

Techniques’ FREE PowerTools Pro software

provide a user-friendly environment for

“out-of-the-box” configuration and motion programming. The EZMotion approach is ideal for rapid development of motion application solutions. The module has four digital inputs and two digital outputs for high-speed I/O operations.

“out-of-the-box” configuration and motion programming. The EZMotion approach is ideal for rapid development of motion application solutions. The module has four digital inputs and two digital outputs for high-speed I/O operations.

SM-Applications Plus

SM-Applications Plus offers all of the features

of the SM-Applications Lite V2 module plus

Control Techniques’ CTNet network tool (see below), RS485 serial port and high-speed I/O. The

SM-Applications Plus option module is programmed using SyPTPro (System Programming Tool).

•Drive-to-drive communications: SM-Applications Plus option modules include a high-speed, drive-to-drive network called CTNet. This network is optimized for intelligent drive systems offering flexible peer-to-peer communications. CTNet has the capability to connect to remote I/O, operator panels, Mentor MP DC drives and PCs providing the ability to perform true parallel multi-tasking.

•Control Techniques’ CTSync is also standard on the SM-Applications Plus module, providing the drive clock synchronization with <4µsec jitter.

•Inputs/Outputs: This module has two digital inputs and two digital outputs for high-speed I/O operations such as position capture and actuator firing.

SM-Applications Lite V2

The SM-Applications Lite V2 option module

provides programmable control for standalone

drive applications or when the drive is connected

to a centralized controller via I/O or fieldbus. SM-

Applications Lite V2 may be programmed using Ladder Logic with SyPTLite or can use the full automation and motion control capabilities contained within SyPTPro, IEC 61131-3 software (see page 8 for more information).

•Real-time control: The SM-Applications Lite V2 module provides real-time access to all of the drive’s parameters plus access to data from I/O and other drives. The module uses a high-speed multi-tasking operating system with task update times as low as 250µs. Tasks are synchronized to the drive’s own control loops to give you the best possible performance for drive control and motion.

SM-Register

The SM-Register option module is designed to

provide a flexible, high-performance solution

for programmable motion requiring high-speed registration features – ideal for applications such

as printing, packaging and cutting machinery.

Features include:

•Motion programming using PLCopen or Control Techniques’ Advanced Position Controller (APC)

•Two fully independent registrations capture channels

•Storage for 256 events per channel, microseconds apart

•Pattern recognition

•Speed capacity in excess of 3000ft/min

•Abilitytofilterunwantedmarks(i.e.splashes,dirt,text,etc.)

•Minimum and/or maximum pulse width

•Distance from previous edge

•Compensation for registration sensor throughput delay

•CTNet and CTSync functionality

4 |

www.controltechniques.com |

“Made-to-Order” Drive Configurations

Feature-rich Unidrive SP drives are optimized for servo applications requiring high peak torque, dynamic response, ease of use and versatileintegrationfeatures.Severalcoreconfigurationsarelistedbelowtowhichfeedback,communicationsorI/Ooptionmodules canbeaddedforcustomsolutions.Allinall,thereareover10,000possibleUnidriveSPconfigurationsallowingyoutomatch your specific application and development requirements. The following combination examples also offer the option of adding two additional option modules.

Unidrive SP “Base.” With up to 14 different motor feedback options, the base Unidrive SP can be easily controlled with singleand multi-axis controllers, PLC’s and host controllers for mediumto high-power applications. The analog torque or velocity modes can be used with classic position controllers using analog outputs and encoder inputs. The drive can be controlled over a SERCOS or EtherCAT network with the addition of an SM-SERCOS or SM-EtherCAT option module.

Drive set-up parameters can be easily stored on a credit card- sized SmartCard. Simple sequencing logic can be accomplished using the onboard Ladder editor. Configuration and diagnostics is done using the FREE CTSoft software tool.

Unidrive SP “EZ” (Base drive + SM-EZMotion module).

Without-of-the-boxmotioncontrolinlessthanfiveminutes, the Unidrive SP is the ultimate servo drive in terms of ease of use and motion performance. Utilizing a familiar Windows® interface, machine builders can use PowerTools Pro software to quickly set up and program the Unidrive SP “EZ” to perform almostanymotionprofile.Applicationsrequiring camming, indexing, electronic gearing, velocity and torque modes

canbeaccomplishedthroughsimpledrag-and-drop,fill- in-the-blank set-up. Real-time programs with “Basic-like” command structured text can be used to program the machine sequencing. The programming interface guides the user throughthedrive,I/Oandmotionconfigurations.Thedrive offers a standalone solution for many common indexing and synchronized motion applications.

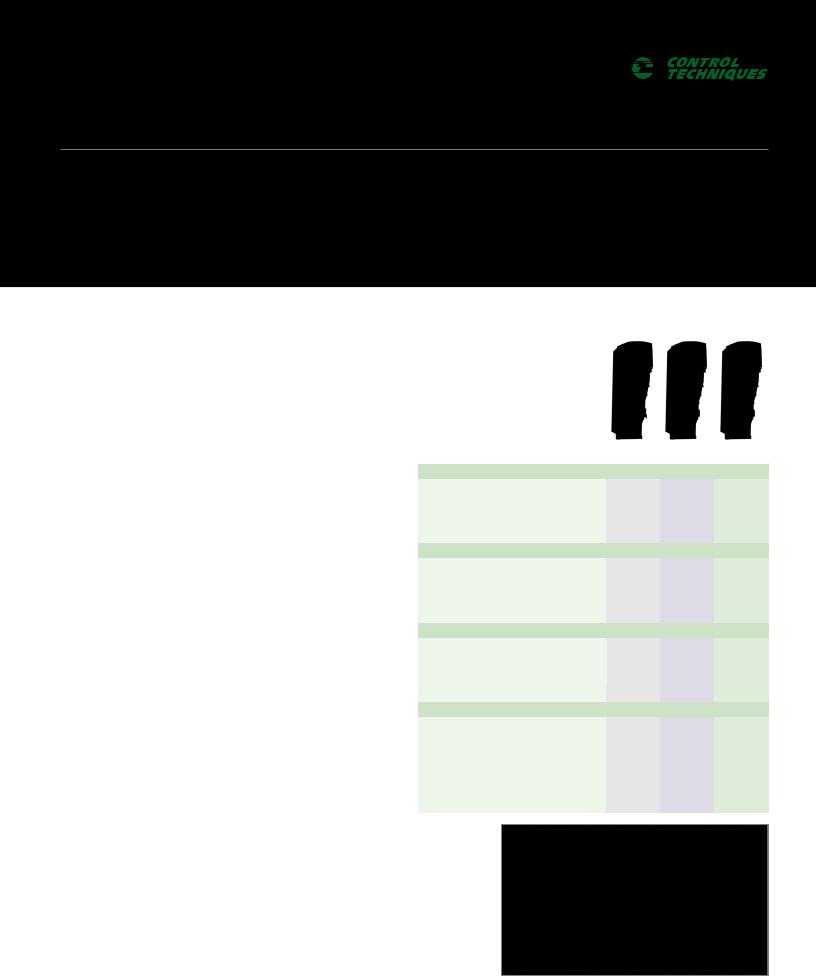

Product Styles

Unidrive SP Configuration |

“Base” |

“EZ” |

“Plus” |

Control Hierarchy |

|

|

|

Centralized Control System |

ü |

|

|

Decentralized Control System |

|

ü |

ü |

Hybrid |

|

ü |

ü |

Standalone Applications |

|

ü |

ü |

Motion Control Functionality |

|

|

|

Velocity, Torque Mode |

ü |

|

|

Position-Indexing |

|

ü |

ü |

Synchronization, Electronic Gearing |

|

ü |

ü |

CAMS |

|

ü |

ü |

Programming Environment |

|

|

|

Drag-and-Drop, Fill-in-the-Blank |

|

ü |

|

Text Programming |

|

ü |

ü |

PLC Open |

|

|

ü |

IEC 61131 Programming |

|

|

ü |

FREE Application Software |

|

|

|

PowerTools Pro |

|

ü |

|

SyPTPro |

|

|

ü |

SyPTLite |

ü |

|

|

CTSoft |

ü |

|

ü |

CTScope |

ü |

ü |

ü |

CTOPCServer |

ü |

ü |

ü |

Unidrive SP “Apps” (Base drive + SM-Applications Plus module). This full-functionality machine control set-up is optimized for high-performance machine cells requiring drive-to-drive networking and precision motion control synchronization. SyPT Pro is an IEC61131-3 compliant software development environment used to provide effective machine control, motion and network communications. Ethernet and I/O connectivity enable interfacing with other automation components and intellectual property protection ensures your valuable knowledge remains secure.

www.controltechniques.com |

5 |

Motion Made Easy™ Solutions

“Motion Made Easy™ ”

Each step is configured using simple check boxes, drop-down selections and drag-and-drop functionality. A straightforward programming language allows users to develop more complex applications and advanced sequencing by simply dragging functions onto the work area and dropping them in place.

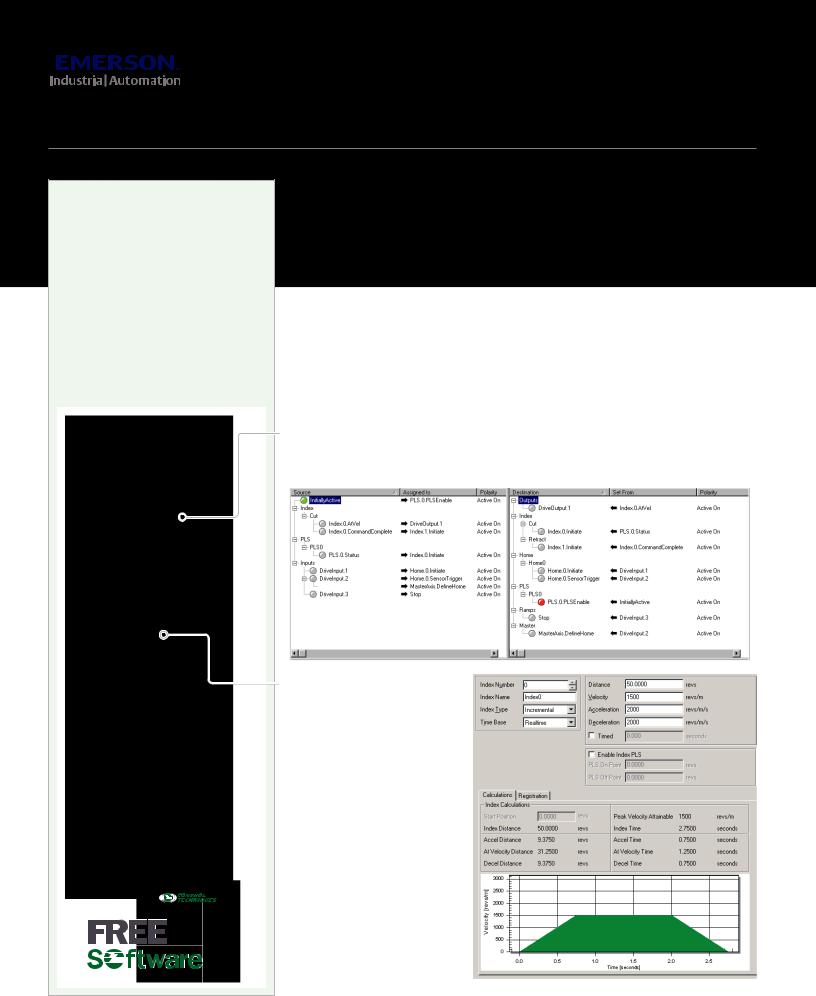

PowerTools Pro Software for Unidrive SP EZMotion

PowerTools Pro software provides advanced motion control programming for Control Techniques drives with internal motion controller. This FREE software enables users to fully realize the power of our EZMotion motion controller. A familiar Microsoft®

Windows® interface provides operators and machine builders with the tools needed to access everything they need for complete servo control — PLS, Queueing, High-Speed Capture, Electronic Gearing, Event Assignments and more.

Developing motion applications with PowerTools Pro is a simple “five-step, topdown” process. The five steps are displayed in a familiar “explorer” bar (insert, left) for easier navigation:

• Hardware |

• |

Drive setup |

• |

Motion |

configuration |

• |

I/O setup |

• |

Programs |

Assignments – Use “virtual wiring” to create programs right out of the box without writing a single line of code. For example, the assignment screen (below) allows you to drag-and-drop the desired machine function onto the digital inputs and outputs.

Assignments – Use “virtual wiring” to create programs right out of the box without writing a single line of code. For example, the assignment screen (below) allows you to drag-and-drop the desired machine function onto the digital inputs and outputs.

Indexes – Indexes are easilysetupbyfillinginthe screen’s blanks to create an indexprofile.Selectfrom

Indexes – Indexes are easilysetupbyfillinginthe screen’s blanks to create an indexprofile.Selectfrom

Incremental, Absolute, Registration or Rotary Plus and Minus types. “Position Tracker™” synchronization is easily achieved using menu selections. Choose the time base of the index by selecting either real-time or

synchronization with a master.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and other countries.

6 |

www.controltechniques.com |

Loading...

Loading...