Emerson Copeland EazyCool OMQ-56-Nxx-TWD, Copeland EazyCool OMTQ-60-Nxx-TFD, Copeland EazyCool OLQ-33V-Nxx-TWD, Copeland EazyCool OMTQ-60D-Nxx-TFD, Copeland EazyCool OMTQ-76-Nxx-TFD Application Manuallines

...Page 1

TM

Copeland EazyCool

outdoor condensing units

for refrigeration networks

Application Guidelines

Page 2

Condensing Unit For Refrigeration Networks

AApppplliiccaattiioonn GGuuiiddeelliinnee

1 SAFETY INSTRUCTIONS...........................................................................................2

1.1 ICON EXPLANATION.................................................................................................. 2

1.2 SAFETY STATEMENTS ..............................................................................................2

1.3 GENERAL INSTRUCTIONS .........................................................................................3

1.4 ABOUT THIS GUIDELINE:........................................................................................... 3

2 PRODUCT DESCRIPTION..........................................................................................4

2.1 COPELAND EAZYCOOL™ CONDENSING UNITS FOR REFRIGERATION NETWORKS ......... 4

2.2 NETWORK CONFIGURATIONS .................................................................................... 4

2.3 PRODUCT NAMEPLATE .............................................................................................4

2.4 NOMENCLATURE ..................................................................................................... 5

2.5 APPLICATION RANGE ............................................................................................... 5

2.6 MAIN COMPONENT DESCRIPTION ..............................................................................6

3 INSTALLATION.........................................................................................................13

3.1 CONDENSING UNIT HANDLING................................................................................. 13

3.2 CONNECTION ACCESS ........................................................................................... 15

3.3 ELECTRICAL BOX ACCESS ......................................................................................15

3.4 ELECTRICAL CONNECTION...................................................................................... 16

3.5 REFRIGERATION CONNECTIONS.............................................................................. 18

3.6 2 UNIT NETWORK : INSTALLATION ..........................................................................20

3.7 3 & 4 UNIT NETWORK ...........................................................................................23

3.8 ELECTRONIC CONTROLLER EC2-551..................................................................... 29

4 STARTING UP & OPERATION.................................................................................31

4.1 CHARGING PROCEDURE ........................................................................................31

4.2 SOUND .................................................................................................................31

4.3 ROTATION DIRECTION OF SCROLL COMPRESSORS ...................................................31

4.4 MAXIMUM COMPRESSOR CYCLE ............................................................................. 32

4.5 CHECKS BEFORE STARTING & DURING OPERATION .................................................. 32

5 MAINTENANCE & REPAIR: REPLACING A COMPRESSOR................................32

6 CERTIFICATION AND APPROVAL .........................................................................32

7 DISMANTLING AND DISPOSAL..............................................................................32

C6.1.4/0305/E 1 Part no: 3136433

Page 3

Condensing Unit For Refrigeration Networks

1 Safety instructions

The Copeland EazyCool™ condensing units are manufactured according to the latest

and valid industrial standards.

Particular emphasis has been placed on the user safety.

These condensing units are intended for installation in machines and systems according

to the EC Machines directive. They may be put to service only, if they have been installed

in these machines according to the existing instruction and as a whole agree with the

corresponding provisions of legislation (standards to apply: refer to Manufacturers

declaration).

Manufacturer declaration and declarations of conformity are available on request.

Retain these operating instructions during the entire lifetime of the compressor as well as

the condensing unit.

We strongly advise to follow these safety instructions.

1.1 Icon explanation

WARNING

This Icon indicates instructions to avoid heavy personnel injuries and heavy material

damage.

High Voltage

This icon indicates operations with a danger of an electric shock.

Danger of burning or frostbite

This icon indicates operations with a danger of burning or frostbite.

Explosion Hazard

This Icon indicates operations with a danger of explosion.

CAUTION

This Icon indicates instructions to avoid property damage without or with low personnel

injuries.

IMPORTANT

This icon indicates instructions to avoid malfunction of the compressor.

NOTE this word indicates a recommendation for easier operations.

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

1.2 Safety statements

Refrigerant compressors must be employed only for the use they are made for.

Only qualified and authorised refrigeration personnel are allowed to do the

installation, commissioning and maintenance.

Qualified electrical personnel must connect the condensing unit and its

accessories.

All valid standards for connecting electrical and refrigeration equipment must be

observed.

Use personnel safety equipment. This is important to avoid

injuries from the refrigerant.

C6.1.4/0305/E 2 Part no: 3136433

Dismantling &

Disposal

Page 4

Condensing Unit For Refrigeration Networks

1.3 General instructions

WARNING

System breakdown! Personnel injuries! Never install a system in the field and leave it

unattended when it has no charge, a holding charge, or with the service valves closed

without electrically locking out the system.

System breakdown! Personnel injuries! Only approved refrigerant and refrigerating oils

must be used.

High Shell Temperature! Burning! Do not touch the compressor until it has cooled

down. Ensure that other materials in the area of the compressor do not get in touch with

it. Lock and mark accessible sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without refrigerant charge or

without being connected to the system.

IMPORTANT

Transit damage! Compressor malfunction! Use original packaging. Avoid collisions and

tilting.

Only qualified personnel should install and intervene on COPELAND condensing units.

The contractor, responsible for the installation of the unit, should ensure sufficient liquid

sub-cooling in the line to the expansion valve(s) to avoid “flash-gas” in the liquid line.

It is of vital importance that the discharge stop valve has been fully opened before the

compressor is started. If the discharge stop valve is closed or partly closed an

unacceptable pressure with accordingly high temperatures may develop in the cylinder

head. When operating with air the so-called diesel effect may occur, i.e. the air sucked in

is mixed with oil gas and can explode due to the high temperature in the cylinder head,

and thereby destroy the compressor.

Safety

Instructions

Product

Description

Installation Electrical

Connection

1.4 About this guideline:

These guidelines ensure the safe installation, starting, operation and maintenance of

Copeland EazyCool™ condensing units.

In case of a failure, important topics are mentioned in the chapter causes of failure.

These guidelines are not meant to replace the system expertise available from system

manufacturers.

For additional information, please refer to the “Product Catalogue“ or to the “Copeland

Selection Software” accessible from the Copeland website at www.ecopeland.com

.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 3 Part no: 3136433

Page 5

Condensing Unit For Refrigeration Networks

2 Product Description

2.1 About Copeland EazyCool™ condensing units for refrigeration

networks

Copeland has developed a special version of Copeland EazyCool condensing units that

can be used to create medium and larger size refrigeration network systems. The range

consists of Copeland EazyCool condensing units for medium and low temperature

applications and covers units from 7.5 to 15 hp. It includes units with two compressors,

allowing modulation in two steps as well as Copeland EazyCool Digital Scroll™

Condensing Units, which feature continuous modulation from 10 to 100%.

The concept of a condensing unit refrigeration network is based on connecting up to four

condensing units mechanically (tubing) and electronically (control system). The control

and oil distribution system is a Master/Slave configuration in which the Master unit takes

care of:

Compressor staging based on suction pressure

Oil distribution (oil reservoir in master unit)

Communication for remote monitoring

The Slave unit takes care of:

Fan speed control

And emergency control in case of communication line disruption between the unit

(master/slave)

Each Network should have only one master unit.

2.2 Network configurations

Safety

Instructions

Product

Description

Installation Electrical

Connection

Basically there are three different configurations possible: two-unit network, three-unit

network and four-unit network. The three and four condensing unit network requires an

external receiver. Copeland offers a LRU (Liquid Receiver Unit) which contains a 90 l

receiver. If a larger receiver is required, this should be obtained from a third party. The

two-unit network consists of units with internal receivers, which allow faster installation.

2 Unit Network 3 Unit Network with LRU 4 Unit Network with LRU

LRU: Liquid Receiver Unit

2.3 Product nameplate

The condensing unit nameplate shows model designation and serial number.

The compressor has its own nameplate with all electrical characteristics.

The medium temperature range features ZB Scroll compressors, some models include a

Digital Scroll™ compressor.

The low temperature range features ZF Scroll compressors with vapour injection using a

pre-installed sub-cooler.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 4 Part no: 3136433

Page 6

Condensing Unit For Refrigeration Networks

2.4 Nomenclature

The model designation contains the following technical information about the condensing

unit:

OM T Q 90 D

1 2 3 4 5

N L O

6 7 8

TFD

9

Specific for Network

models

1 - Condensing unit family:

OM = Medium temperature Copeland EazyCool™ unit

OL = Low temperature Copeland EazyCool™ unit

2 - Number of compressor: “blank” = single compressor, “T” = two compressors

3 - Quiet version

4 - Compressor size: 90 = 1 x ZBD45KCE (digital), 1 x ZB45KCE

5 - D = Copeland Digital Scroll™

- V = Low temperature:Copeland Scroll™ with vapour injection (EVI)

6 - N = Unit suitable for creation of a refrigeration network

7 - L = Liquid receiver included (only for 2 unit network)

8 - O = Oil reservoir included (always Master)

9 - Motor version: TFD or TWD: 380-420V/3Ph/50H

Safety

Instructions

Product

Description

Installation Electrical

Connection

2.5 Application range

2.5.1 Qualified refrigerants and oils

OMQ-56-Nxx

~

OMQ-110-Nxx

R404A/R507

Qualified refrigerant

Qualified Servicing Oil

Table 1: Qualified refrigerants and oils

2.5.2 Application limits

For Application envelope, please refer to the Compressor application envelope available

in Copeland Selection Software version 6.

Medium temperature range

Evaporating Temperature: from –30°C up to 12.5°C

Low temperature range

Evaporating Temperature: from –40°C up to 7°C

R134a,R407C

R22

OMTQ-60(D)-Nxx

OMTQ-76-Nxx

OMTQ-90(D)-Nxx

R404A/R507

R22

ICI Emkarate RL 32 CF

Mobil EAL Artic 22 CC

OLQ-24V-Nxx ~ OLQ-48V-Nxx

OLTQ-26V-Nxx & OLTQ-36V-Nxx

R404A/R507

R22

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 5 Part no: 3136433

Page 7

Condensing Unit For Refrigeration Networks

2.6 Main component description

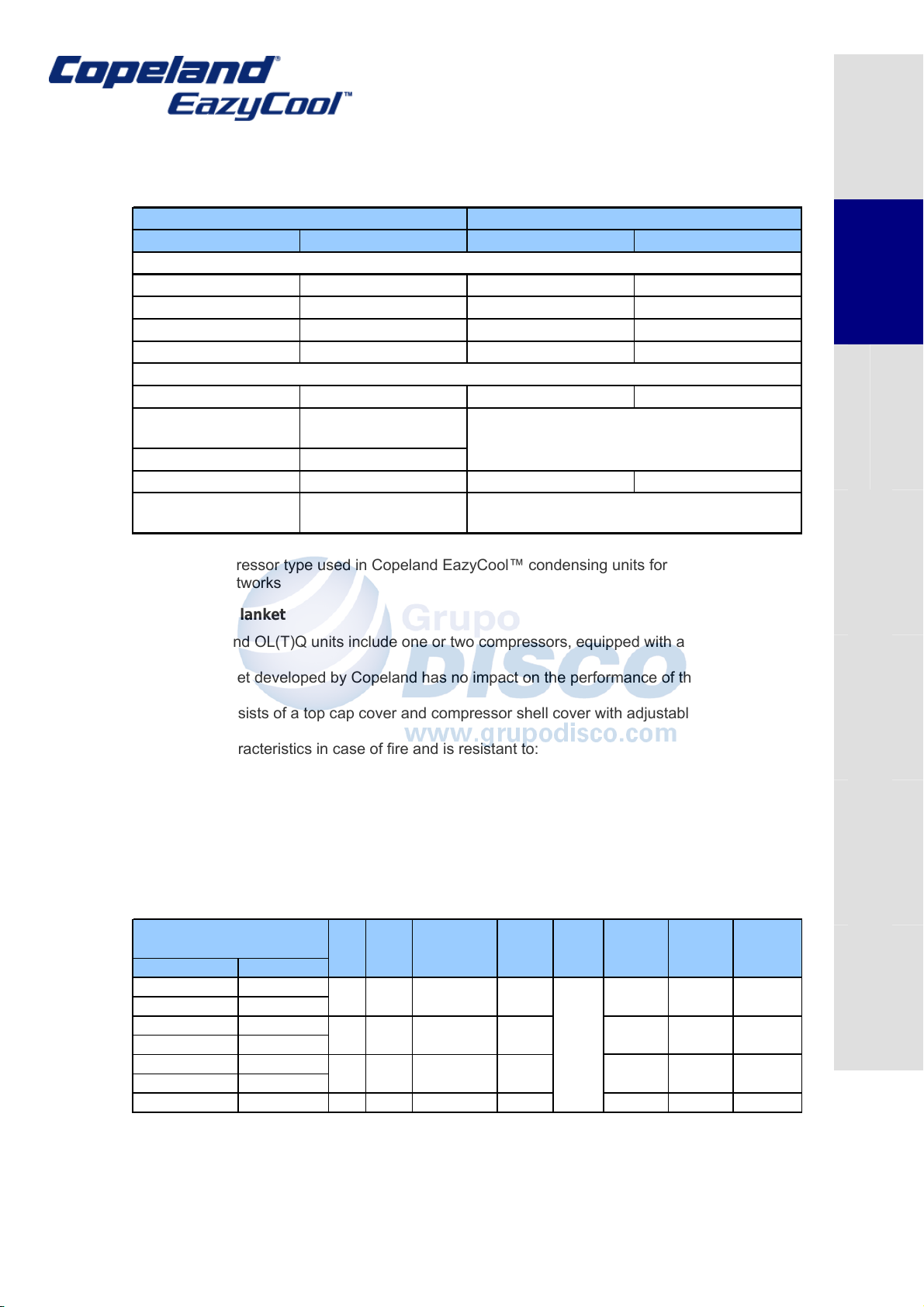

2.6.1 Compressor

Low TemperatureMedium Temperature

Unit Model Compressor Model Unit Model Compressor Model

Single compressor unit

OMQ-56-Nxx-TW D ZB56KCE-TWD-551 OLQ-24V-Nxx-TW D ZF24KVE-TWD-551

OMQ-75-Nxx-TW D ZB75KCE-TWD-551 OLQ-33V-Nxx-TW D ZF33KVE-TWD-551

OMQ-92-Nxx-TW D ZB92KCE-TWD-551 OLQ-40V-Nxx-TW D ZF40KVE-TWD-551

OMQ-110-Nxx-TWD ZB11MCE-TWD-551 OLQ-48V-Nxx-TWD ZF48KVE-TWD-551

Two compressor unit

OMTQ-60-Nxx-TFD 2 x ZB30KCE-TFD-551 OLTQ-26V-Nxx-TFD 2 x ZF13KVE-TFD-556

1 X ZBD30KCE-TFD-250

OMTQ-60D-Nxx-TFD

OMTQ-76-Nxx-TFD 2 x ZB38KCE-TFD-551

OMTQ-90-Nxx-TFD 2 x ZB45KCE-TFD-551 OLTQ-36V-Nxx-TFD 2 x ZF18KVE-TFD-556

OMTQ-90D-Nxx-TFD

(*)

Digital ScrollTM available in Master version only (NLO & NO)

Table 2: Compressor type used in Copeland EazyCool™ condensing units for

refrigeration networks

2.6.2 Sound Blanket

(*)

1 x ZB30KCE-TFD-551

1 X ZBD45KCE-TFD-250

(*)

1 x ZB45KCE-TFD-551

Safety

Instructions

Product

Description

Installation Electrical

Connection

The OM(T)Q and OL(T)Q units include one or two compressors, equipped with a sound

jacket.

The sound jacket developed by Copeland has no impact on the performance of the

compressor.

The design consists of a top cap cover and compressor shell cover with adjustable Velcro

system.

It has good characteristics in case of fire and is resistant to:

Mineral and Polyolester oil

Refrigerants R22/R404A

Temperature up to 150°C

Water

2.6.3 Condenser Fan(s)

The condensers of the OM (T) Q & OL (T) Q units for refrigeration networks are equipped

with single-phase fans, with low speed (910 rpm) 6 pole single-phase motor.

ø

420

500

420

Voltage

V/ph/Hz

220-240

1~50

Power

input (W)

145

290

145

Current

input (A)

0.67

1.4

0.67

Winding

resistance

Ohm (Ω)

Condensing unit

Medium Temp Low Temp

OMQ-56-Nxx OLQ-24V-Nxx

OMQ-75-Nxx OLQ-33V-Nxx

OMQ-92-Nxx OLQ-40V-Nxx

OMQ-110-Nxx OLQ-48V-Nxx

OMTQ-60(D)-Nxx OLTQ-26V-Nxx

OMTQ-76-Nxx

OMTQ-90(D)-Nxx OLTQ-36V-Nxx 2 301 8µF-400V 500 290 1.4 25

Electrical data @ 50 Hz

N° of

Fan

2

2

2

Fan

Model

145

301

145

Run Capacitor

Capacity

4µF-400V

8µF-400V

4µF-400V

Diameter

(mm)

Table 3: Condenser fan: technical data

70

25

70

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 6 Part no: 3136433

Page 8

Condensing Unit For Refrigeration Networks

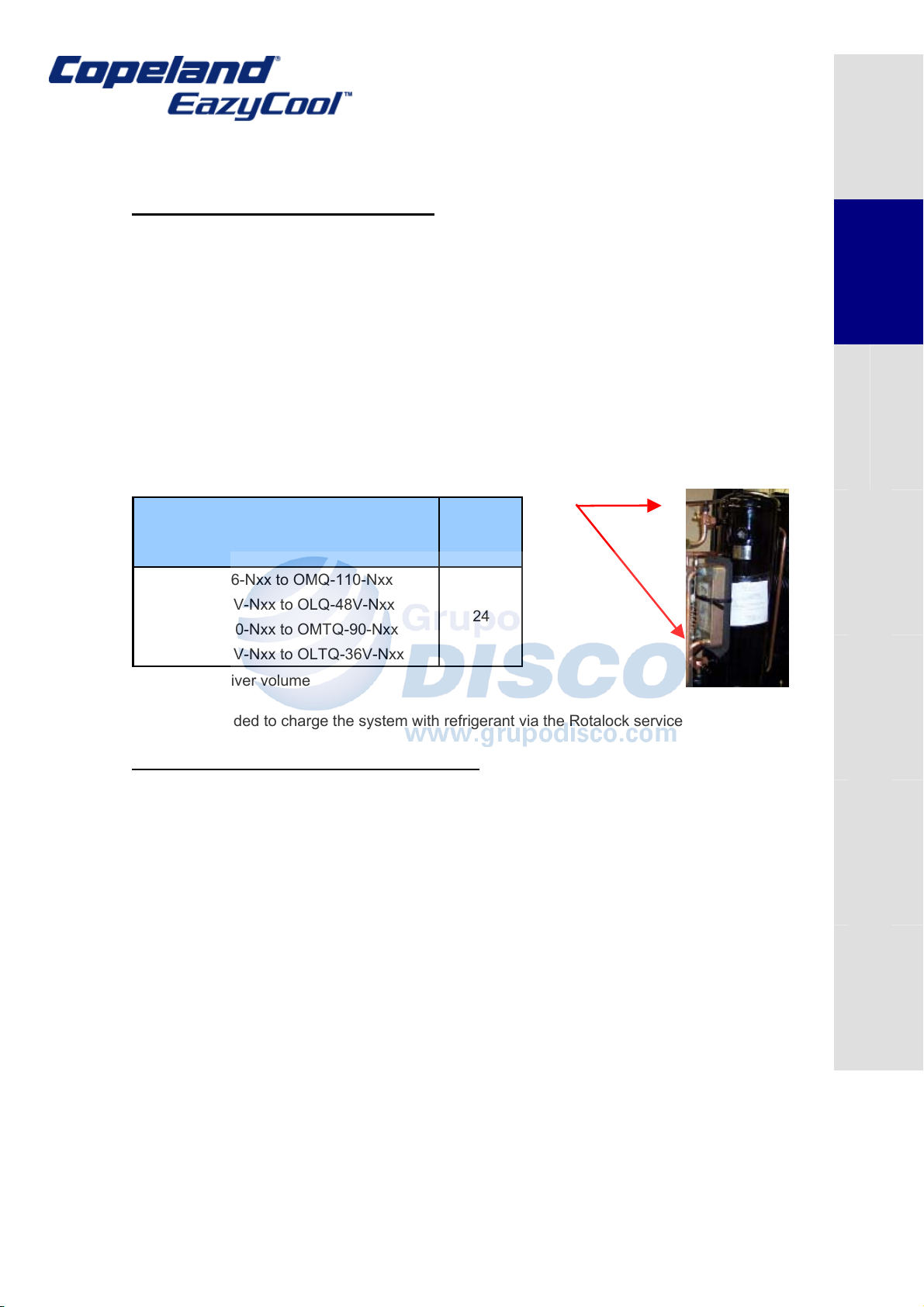

2.6.4 Liquid receiver

Liquid receiver for 2 unit network system

Master and Slave units for 2-unit network configuration are equipped with a liquid

receiver.

The liquid receivers are equipped with:

Rotalock service valves for connection of a liquid level equalisation line as well as

a gas pressure equalisation line between the receivers to ensure equal liquid

levels in both receivers. Both lines are partly pre-installed and protrude at the rear

of the units.

Rotalock service valve on top of the receiver for liquid outlet line.

3/8’’–14 NPTF connection for relief valve. Maximum allowable working pressure -

MAWP 33 Bar

Fitting a pressure relief device according to standard EN378-2 is the responsibility of the

installer.

Rotalock service valve

Model Type

OMQ-56-Nxx to OMQ-110-Nxx

OLQ-24V-Nxx to OLQ-48V-Nxx

OMTQ-60-Nxx to OMTQ-90-Nxx

OLTQ-26V-Nxx to OLTQ-36V-Nxx

Receiver

volume

l

24

Safety

Instructions

Product

Description

Installation Electrical

Connection

Table 4: Receiver volume

It is recommended to charge the system with refrigerant via the Rotalock service valves.

Liquid receiver for 3 and 4 unit network system

With larger systems (refrigeration systems requiring 3 or 4 units in a network) a remote

liquid receiver should be used. The condensing unit models for systems with remote

receivers are provided without liquid receiver. The condenser liquid outlet line protrudes

from the rear of the unit to allow an easy connection to a remote liquid receiver.

Copeland offers a LRU (Liquid Receiver Unit), which contains a 90 litres liquid receiver

for remote use with filter drier, sight glass with moisture indicator and ball valves for liquid

inlet and outlet. If a larger receiver is required, this should be obtained from a third party.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 7 Part no: 3136433

Page 9

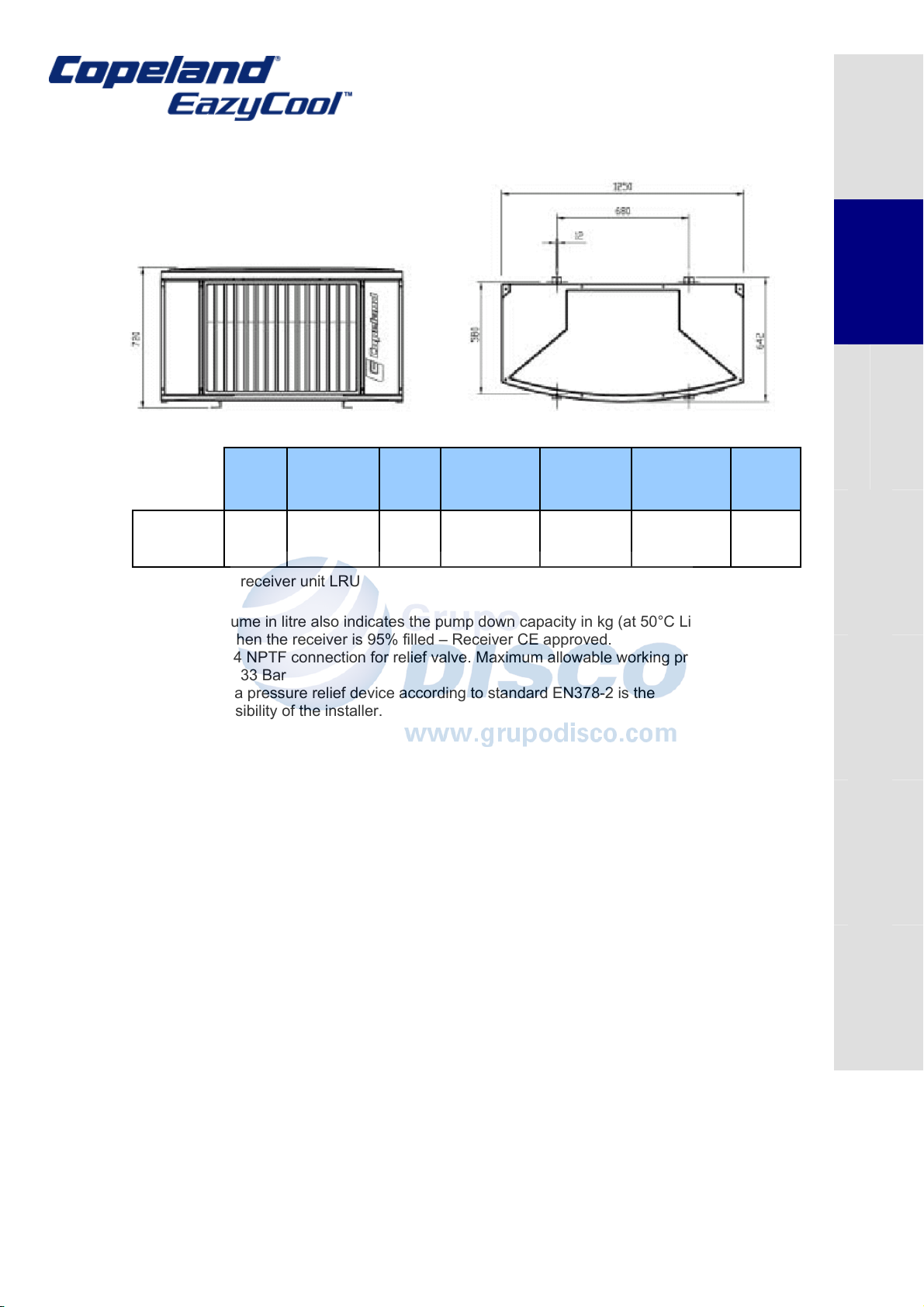

Condensing Unit For Refrigeration Networks

The LRU collects liquid refrigerant from each condenser in a network. It has a single

liquid inlet and outlet line.

Safety

Instructions

Product

Description

Receiver Depth / Width Height Dimensions Liquid Liquid Weight

Capacity T/B H (holes) Inlet diameter Outlet diameter Net/Gross

1)

l

Liquid

Receiver

Unit

Table 5: Liquid receiver unit LRU

1)

Receiver volume in litre also indicates the pump down capacity in kg (at 50°C Liquid

temperature) when the receiver is 95% filled – Receiver CE approved.

1/2’’–14 NPTF connection for relief valve. Maximum allowable working pressure -

MAWP 33 Bar

Fitting a pressure relief device according to standard EN378-2 is the

responsibility of the installer.

2.6.5 Electrical box: components

All electrical components are pre-wired into the panel.

This panel contains:

Compressor contactor(s)

Fuse

Terminal blocks

DIN rail mounted terminals

Electronic controller

Fan Speed controller

Alarm relays

90 630 / 1250 720 680 x 580 (12) 1 5/8 1 3/8 120 / 142

mm mm b x t,(ø mm) ø (inch) ø (inch) kg

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

2.6.6 Pressure switch

All single compressor Copeland EazyCool™ condensing units for refrigeration networks

are equipped with:

Single low pressure switch with automatic reset: ALCO PS1-W3A

Electronic Condensing Unit Controller with HP and LP pressure transmitters

All two-compressor Copeland EazyCool™ condensing units for Refrigeration Network are

equipped with:

Single low pressure switch with automatic reset: ALCO PS1-W3A

Two high pressure switches ALCO PS3-WF4-HNS

Electronic Condensing Unit Controller with HP and LP pressure transmitters

C6.1.4/0305/E 8 Part no: 3136433

Dismantling &

Disposal

Page 10

+

+

Condensing Unit For Refrigeration Networks

1) PS2-W7A: Alco Controls® dual pressure switch with automatic reset (fo r single

compressor unit)

The switch is equipped with display scale and pointers to indicate the

approximate settings. The display scales are printed in relative pressure

units “bar” and “psi”.

For precise setting of the control, external gauges must be used.

The PS2-W7A has the following characteristics:

Automatic reset dual pressure controls

Combined pressure limiter for low pressure / high-pressure

protection.

On pressure rise above the upper setpoint, contacts 1-2 open and

contacts 1-4 close.

On decreasing pressure below lower setpoint contacts 1-4 open and

contacts 1-2 close.

Adjustable dual pressure switch

Setpoint adjustment range: LP (left) = -0.5 to 7 bar and HP (right) = 6 to 31 bar.

Differential adjustment range: LP = 0,5 to 5 bar, HP = 4 bar.

Factory setting: LP = 3,5 / 4,5 bar, HP = 20 bar.

2) PS1-W3A: Alco Controls single low pressure switch with automatic

reset

The control is equipped with display scale and pointers to indicate the

approximate settings.

The display scales are printed in relative pressure units “bar” and “psi”.

For precise setting of the control, external gauges must be used.

The PS1-W3A has the following characteristics:

Automatic reset single pressure controls

Pressure limiter for low-pressure protection.

On decreasing pressure below lower set-point contacts 1-4 open and

contacts 1-2 close.

Adjustable single pressure switch

Setpoint adjustment range: = -0.5 to 7 bar.

Differential adjustment range: = 0,5 to 5 bar.

Factory setting: = 3,5 / 4,5 bar.

3) PS3-WF4-HNS: Alco Controls high pressure switch with an automatic reset

Automatic reset single pressure switch

Pressure limiter for high-pressure protection.

Switches from 1-2 to 1-4 on rising pressure and from 1-4 to 1-2 on falling

pressure.

Fixed switch point settings

Cut-out point: 22 bar

Cut-in point: 26.2 bar.

p

-

p

-

2 4

1

2 4

1

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 9 Part no: 3136433

Page 11

Condensing Unit For Refrigeration Networks

4) PT3 Pressure Transmitter (Alco Controls)

Two compressor-condensing units are equipped with HP and LP pressure transmitters

that are connected to the EC2 electronic controller.

The EC2 controller description and programming instructions are available in the

corresponding guideline (C6.1.5/E, Part no: 3136444) which is shipped with the units. It

is also available for download on www.eCopeland.com.

An Alco PT3-30A pressure transmitter is used at the high-pressure part of the system.

An Alco PT3-07A pressure controller is used at the low-pressure part of the system.

The PT3 pressure transmitter converts a pressure into a linear electrical 4-20 mA

current output signal. The heart of the transmitter is a piezo resistive chip enclosed in an

oil capsule.

Features:

Pressure sensitive piezo-based cell with strong primary output signal for precise

and sound-free operation

Vibration and pulsation resistant

2.6.7 Fan speed controller (FSP150) Alco Controls

An electronic speed control is fitted as standard in units

suitable for refrigeration networks. It controls the speed of the

fans based on condenser pressure. Fan speed is controlled by

the EC2-551 condensing unit controller in combination with a

FSP-150 fan speed controller.

Two fans are controlled at the same time.

The control operates with single-phase motors.

The electrical connection is made in the terminal box of the condensing

unit.

Using a fan speed controller offers the following benefits for your

application:

The head pressure can be kept high enough to ensure proper operation of the

expansion valve, and hence, sufficient mass flow through the expansion valve to

feed the evaporator. This maintains the required cooling capacity and avoids a

drop of evaporator temperature.

The sound level of fan motors can be kept at a minimum by avoiding the

permanent on/off cycling of the fan motor. The Alco Controls fan speed control

can be delivered with the Copeland units or as a separate accessory.

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

2.6.8 Liquid line equipment (only for 2 unit network configuration)

a) Filter drier Alco Controls ADK-plus

ADK-plus liquid line filter-drier is for new installation or after service.

Optimum blend of molecular sieve and activated alumina

b) Liquid sight glass Alco Controls AMI 1SS*

The AMI series of moisture indicator is designed to monitor the moisture

content within the liquid line of a refrigeration system. When the line is empty

of liquid, circles may be seen in the glass. However, when the liquid refrigerant

touches the glass, the circles disappear indicating the system is fully charged.

2.6.9 Liquid line solenoid valve (for low temp. model only) Alco

Controls 200 RBT 5

This is used in low temperature with 2, 3 & 4 unit network systems

Compact size

Snap-on clip for attaching solenoid coils

∆p minimum = 0,05 bar

C6.1.4/0305/E 10 Part no: 3136433

Maintenance

Dismantling &

& Repair

Disposal

Page 12

Condensing Unit For Refrigeration Networks

2.6.10 Liquid sub-cooler

Condensing units for low temperature applications are equipped with a liquid sub-cooler.

This heat exchanger is used to provide additional sub-cooling to the refrigerant before it

enters the evaporator. This sub-cooling provides a considerable cooling capacity

increase. During the sub-cooling process, a small amount of refrigerant is evaporated in

the liquid sub-cooler. It (sub) cools high-pressure refrigerant liquid that will be injected

into the evaporator. The small amount of evaporated refrigerant in the liquid sub-cooler is

injected into the compressor and provides additional cooling at higher compression ratios,

similar to liquid injection. The diagram below explains the refrigerant flows.

Since the liquid temperature can be as low as –15°C, liquid line insulation

applied to avoid freezing of water on the outside of the lines.

VO = Vapour Out, vapour leaving to compressor injection

VI = Vapour In, vapour interring the economiser

LO = Liquid Out, sub-cooled liquid leaving the economiser

LI = Liquid In, Liquid from condenser

Liquid sub-cooler characteristics:

Standard connection size = 1", Material EN 10272-1.4401 (AISI 316)

Brazing material = pure copper

LI

LO

should be

VO

VI

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 11 Part no: 3136433

Page 13

Condensing Unit For Refrigeration Networks

2.6.11 Solenoid Valve for Digital Scroll™ compressor

Digital Scroll™ compressors in Copeland EazyCool™ condensing units are equipped

with a 24 Volt AC solenoid valve.

The Electronic Condensing Unit Controller operates the solenoid valve used for

digital compressor modulation based on the suction pressure.

Solenoid valve: Copeland part number 8400784

2.6.12 Oil separator: Alco Controls OSH

The Alco OSH oil separator is fitted as standard on all Copeland EazyCool™ outdoor

units for refrigeration networks.

The oil separator has the following characteristics:

Hermetic construction

Comply with UL standard and HP German pressurised vessel regulations (CE

standard effective Nov. 1999)

PED category I

Safety

Instructions

Product

Description

Installation Electrical

2.6.13 Electronic oil control system (Alco OM3)

Each compressor is fitted with an Alco Controls OM3 oil level controller, which supplies oil

only when required. An oil reservoir is provided on the “Master” unit in a network, and

hence variations in oil quantity in the system can be accommodated.

Model OM3-CCA

- Oil Fill Yes

- Alarm Yes

- Compressor Lockout Yes

- Level control 40%~60%

- Time Delay Alarm 20 sec

- Time Delay Filling 10 sec

Table 6: Properties OMA Traxoil

2.6.14 High pressure oil reservoir (Master unit only)

The master unit in network is equipped with a large oil reservoir of 8 litres, which collects

oil from Master & Slave oil separators. Oil is re-distributed to each compressor via the oil

level controller OM3.

PED category I

Connection

Operation

Starting up &

& Repair

Maintenance

Dismantling &

C6.1.4/0305/E 12 Part no: 3136433

Disposal

Page 14

Condensing Unit For Refrigeration Networks

3 Installation

The Copeland EazyCool™ condensing units are delivered with a holding charge of

neutral gas.

WARNING

High pressure! Injury to skin and eyes possible! Be careful when opening connections

on a pressurized system.

The condensing unit should be located in such a place to prevent any dirt, plastic bag,

leaves or papers from covering the condenser and its fins.

A clogged condenser will increase the condensing temperature, thus reduce the cooling

capacity, and lead to a high pressure switch tripping. Clean the condenser fins on a

regular basis.

3.1 Condensing unit handling

3.1.1 Transport and storage

It is recommended to keep the unit packaged until final

installation.

We recommend handling large outdoor units (when boxed) with a forklift on the position

indicated on the box.

Compressor(s) and liquid receiver compartment

2

11

Storage Transport

Safety

Instructions

Product

Description

Installation Electrical

Connection

Side loading for forklift Front loading for forklift at Approx. location of

the side of the unit where centre of gravity

the centre of gravity is shown

The unit without packaging must be handled by a forklift truck, while taking care of the

centre of gravity of the unit. See also pictures above (front view). Weights: please refer to

table 7.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 13 Part no: 3136433

Page 15

Condensing Unit For Refrigeration Networks

Weight (kg) Weight (kg)

Net Gross Net Gross

Condensing unit with single compressor

OMQ-56 NLO/NL/NO/N 234 278 OLQ-24V NLO/NL/NO/N 226 270

OMQ-75 NLO/NL/NO/N 234 278 OLQ-33V NLO/NL/NO/N 226 270

OMQ-92 NLO/NL/NO/N 244 288 OLQ-40V NLO/NL/NO/N 236 280

OMQ-110 NLO/NL/NO/N 253 297 OLQ-48V NLO/NL/NO/N 245 289

Condensing unit with two compressors

OMTQ-60 NLO/NL/NO/N 216 260 OLTQ-26V NLO/NL/NO/N 218 262

OMTQ-60(D) NLO /NO 216 260

OMTQ-76 NLO/NL/NO/N 218 262

OMTQ-90 NLO/NL/NO/N 222 266 OLTQ-36V NLO/NL/NO/N 224 268

OMTQ-90(D) NLO/NO 222 266

Table 7: Weights twin fan units

Net weight = bare unit; Gross weight = unit + packaging

Low temperature un it sMedium temperature units

Safety

Instructions

Product

Description

Installation Electrical

3.1.2 Dimensions in mm

Copeland EazyCool™ units NLO / NL / NO /N

OMQ-56 to OMQ-110, OMTQ(D)-60 to OMTQ(D)-90

OLQ-24V to OLQ-48V, OLTQ-26V & OLTQ-36V

Connection

Operation

Starting up &

& Repair

Maintenance

Dismantling &

C6.1.4/0305/E 14 Part no: 3136433

Disposal

Page 16

Condensing Unit For Refrigeration Networks

3.2 Connection access

Access door to electrical and refrigeration components.

Access door opening: use supplied key to open and close the access door.

3.3 Electrical box access

OMQ-56-Nxx to OMQ-110-Nxx, OMTQ-60(D)-Nxx to OMTQ90(D)-Nxx

OLQ-24V-Nxx to OLQ-48V-Nxx, OLTQ-26V-Nxx & OLTQ-36V-Nxx

Safety

Instructions

Product

Description

Installation Electrical

Open the latch on the top of the electrical panel to open it forward

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 15 Part no: 3136433

Page 17

Condensing Unit For Refrigeration Networks

3.4 Electrical connection

3.4.1 Power supply connections

Electrical connection of the outdoor condensing unit network to the power supply must be

made by qualified technicians, who should refer to the electrical diagrams located inside

the electric connection panel.

Safety

Instructions

Product

Description

Installation Electrical

Main electrical cable entry Contactor

Access to the

Mounting area for main isolator switch electrical components.

3.4.2 Electrical components pre-wired

Compressor(s) contactor

Condenser Fan motors

Fan Speed controller

High and Low pressure switches

Electronic controller

Crankcase heater(s)

Care should be taken for electrical connection to avoid reverse rotation

6.6)

3.4.3 Discharge temperature protection

Discharge line thermostat

Under extreme operating conditions internal discharge temperatures can reach very high

levels. To avoid compressor damage, the ZF13KVE & ZF18KVE compressors are

equipped with an external discharge line thermostat. Digital Scroll™ compressors ZBD30-KCE & ZBD-45-KCE are also equipped with a discharge line thermostat.

INT 69 SCY module

Compressors ZF24-KVE, ZF33-KVE, ZF40-KVE & ZF48-KVE are equipped with an INT

69 module.

(see paragraph

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 16 Part no: 3136433

Page 18

Condensing Unit For Refrigeration Networks

3.4.4 Electric protection standard

Scroll compressors up to ZB45 / ZF18 are IP 21 according to IEC 34. All larger

compressors are IP54.

Fan IP54 according to IEC 34.

HP-LP and HP safety pressure switches (Alco PS2 and PS1) are IP44 according

to IEC 529/EN 60529.

PS3 switch with cable assy IP65 according to EN 175301-803/IEC 529.

Fan speed controller FSM is IP 65 according to IEC529/DIN 40050.

Solenoid valve coils: IP65 according to DIN 43650

EC2-5X1: IP65 (frontal protection with gasket)

Electrical panel IP Rating: IP54

3.4.5 Condensing unit electrical data

Safety

Instructions

Product

Description

Single compressor

condensing unit

Medium Temperature TWD TWD 230V / 1~/50Hz TW D

OMQ-56-NLO/NL/NO/N 15.4 99 2 x 145 0.67 16.74

OMQ-75-NLO/NL/NO/N 21.7 127 2 x 145 0.67 23.04

OMQ-92-NLO/NL/NO/N 25.1 167 2 x 301 1.56 28.22

OMQ-110-NLO/NL/NO/N 29.2 198 2 x 301 1.56 32.32

Low Temperature TWD TWD 230V / 1~/50Hz TW D

OLQ-24V-NLO/NL/NO/N 16.1 2 x 145 0.67 17.44

OLQ-33V-NLO/NL/NO/N 22.3 2 x 145 0.67 23.64

OLQ-40V-NLO/NL/NO/N 25.1 2 x 301 1.56 28.22

OLQ-48V-NLO/NL/NO/N 30.6 2 x 301 1.56 33.72

Two compressor

condensing unit

Medium Temperature TFD TFD 230V / 1~/50Hz TFD

OMTQ-60-NLO/NL/NO/N 10.3 49 2 x 145 0.67 21.94

OMTQ-60(D)-NLO /NO

OMTQ-76-NLO/NL/NO/N 12.8 66 2 x 145 0.67 26.94

OMTQ-90-NLO/NL/NO/N 13.1 74 2 x 301 1.56 29.32

OMTQ-90(D)-NLO/NO

Low Temperature TFD TFD 230V / 1~/50Hz TFD

OLTQ-26V-NLO/NL/NO/N 8 52 2 x 145 0.67 17.34

OLTQ-36V-NLO/NL/NO/N 12 74 2 x 301 1.56 27.12

1)

Data for one compressor

2)

Digital ScrollTM / Standard Compressor

3)

Data for one fan motor

Max. operating

Current

(compressor)

AA AA

Max. operating

Current

(compressor)

AA AA

7.9 / 10.3

11.4 / 13.1

1)

2)

2)

Locked Rotor

Current

(compressor)

Locked Rotor

Current

(compressor)

52 2 x 145 0.67 19.54

74 2 x 301 1.56 27.62

Fan

Model

Fan

Model

1)

Max. fan

Current

Max. fan

Current

3)

Max. operating

Current (Unit)

Max. operating

Current (Unit)

Table 8: Electrical data

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 17 Part no: 3136433

Page 19

Condensing Unit For Refrigeration Networks

3.5 Refrigeration connections

Master unit oil in / out connections

1 = Suction line

2 = Liquid outlet line

3 = Liquid level equalisation line (receiver)

4 = Liquid receiver pressure equalisation line (receiver)

5 = Outlet oil distributing circuit

“Oil Out” of the Master unit should be connected to the “Oil In” connection of

the Slave unit, this line is oil from the oil reservoir (Master unit) to the slave unit(s)

compressor(s)

6 = Inlet oil distributing circuit

“Oil In” of the Master unit should be connected to the “Oil Out” connection of

the Slave unit, this is oil from Slave unit oil separator to the Master unit oil reservoir.

(*)

Only on condensing units in network of 2 units. (Liquid line should be insulated on

OLQ-24V-N to OLQ-48V-N, OLTQ-26V-N & OLTQ-36V-N. Temperature could be as low

as –15°C).

3.5.1 Brazing recommendation

(*)

(*)

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

Remove the plugs in the following sequence:

1. Remove the discharge connection plug

2. Then remove the suction connection plug

Removing the plugs in this sequence prevents oil mist from coating the suction

tube making brazing difficult.

Be sure tube fitting inner diameter and tube outer diameter are clean prior to

assembly.

Both tubes are extended from the condensing unit housing, therefore we

recommend isolate the housing by using a wet cloth on the copper tubing.

Recommended brazing materials: A copper/phosphorous or

copper/phosphorous/silver alloy rod should be used for joining copper to copper

whereas to join dissimilar or ferric metals a silver alloy rod either flux coated or

with a separate flux would be used.

Maintenance

Dismantling &

C6.1.4/0305/E 18 Part no: 3136433

& Repair

Disposal

Page 20

Condensing Unit For Refrigeration Networks

Use a double-tipped torch

Sectional view

End of tube

Safety

Instructions

Product

Description

Installation Electrical

During brazing

protect housing

with a damp cloth

Brazing of the tubes:

For brazing of the tubes see illustration below and the following procedures:

Fit the copper tube into the compressor tube.

NOTE: The time spent heating area 3 should be minimal. As with any brazed joint,

overheating may be detrimental to the final result.

To disconnect:

Heat joint areas 2 and 3 slowly and uniformly until solder softens and tube can be pulled

out of the fitting.

To reconnect:

See the procedure above.

1. Heat area 1. As the tube approaches brazing temperature:

2. Heat area 2 until braze temperature is attained. It is necessary

to heat the tube evenly. Move the torch up and down and

rotating around the tube.

3. Add braze material to the joint while moving the torch around

the joint to flow braze material around the circumference.

4. Then heat area 3. This will draw the brazing material down into

the joint.

During brazing pull

back line insulation.

Connection

Operation

Starting up &

& Repair

Maintenance

Dismantling &

C6.1.4/0305/E 19 Part no: 3136433

Disposal

Page 21

Condensing Unit For Refrigeration Networks

3.6 2 Unit Network : installation

Connection

1 Suction line 1 3/8

2 Liquid line 5/8

3 Liquid line equalizarion line (between receivers) 1 1/8

4 Liquid line pressure equalization line (between receivers) 5/8

5 Oil distribution lines with Schraeder valves 1/4

Table 9: Connection Sizes

In a 2-unit network, the tubing arrangement for low temperature as well as medium

temperature is similar.

Pipe position at rear of the unit is identical for single compressor condensing units.

IMPORTANT

For low temperature network systems, Copeland recommends to insulate the complete

liquid outlet line to the evaporator expansion valve in order to optimise the sub-cooling

effect.

ø (inch)

Safety

Instructions

Product

Description

Installation Electrical

Connection

Slave

Master

3.6.1 2 Unit Network: Master/Slave selection recommendations

As compressor-starting priority is based on balancing running hours, Copeland

recommends the compressor used in the Master unit to be bigger and/or equal in

capacity as in Slave units, in order to achieve identical capacity modulation steps.

Therefore a network could be composed of either only single compressor units or twocompressor units.

Network configuration could be composed also by a single compressor unit (as master,

which will start first always) and a two-compressor unit as slave.

NOTE: Configuration with a two compressor unit as master and a single compressor unit

as slave is not recommended as modulation steps would not be all the time equal.

3.6.2 2 Unit network: Possible Master/Slave configurations

Master unit is base load:

Master Q

Suction line Liquid line (*) Suction & liquid line to evaporator(s)

> Slave Q0

0

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 20 Part no: 3136433

Page 22

Condensing Unit For Refrigeration Networks

3.6.3 Installation, dimensions and piping details

Put the units in their final position as indicated:

Air Flow

12

1

2240 mm

> 1000 mm

Liquid pipe to evaporato r(s)

2 Suction pipe from evaporator(s)

Safety

Instructions

Product

Description

Installation Electrical

Unit length: 2100 mm

Air Flow

Connection

Liqui d pipe to evaporator(s )

Suct ion pip e from evap orato r(s)

> 600 mm

Operation

Starting up &

& Repair

+/- 500 mm

+/- 4700 mm

Maintenance

Dismantling &

C6.1.4/0305/E 21 Part no: 3136433

Disposal

Page 23

Condensing Unit For Refrigeration Networks

Suction line connections

An adequately sized suction header providing equal distribution of returning refrigerant to

each condensing unit must be used. Suction type diameter at the rear of the unit is 1 3/8.

Copper connection

To

Condensing

Unit

evapo rato r(s)

Liquid line

Each unit outlet liquid line should be connected to a liquid line header.

For low temperature system Copeland recommends to insulate liquid line to evaporator in

order get keep the sub-cooling effect from the heat exchanger.

Receiver equalization lines

Liquid equalization line to be connected between 2 receivers is on the middle

bottom of the unit.

Copper connection. Diameter 1 1/8.

Gas pressure equalization

Copper connection. Diameter 5/8.

Oil inlet and outlet

The oil distribution lines with Schraeder valves need to

be connected with flexible hoses

(Option proposed by Copeland).

2 unit Network back to back configuration:

Copeland recommends the 2 metres flexible

kit.

For 2 unit Network side by side configuration:

Copeland recommends 4 metres flexible kit.

Care should be taken when connecting the hoses, “oil in” of the master unit should

connected the to “oil out” of the slave unit.

Communication cable

A communication cable with M12 connectors (option proposed by Copeland) needs to be

connected between units. A 4 metres cable is recommended for 2-unit network

configuration. If connection to a monitoring system is required, an additional cable is

needed.

Condensing

From

To

Unit

From

To

condensing unit

evaporators

To

condensing unit

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Communication cable

Dismantling &

C6.1.4/0305/E 22 Part no: 3136433

Disposal

Page 24

Condensing Unit For Refrigeration Networks

3.7 3 & 4 Unit Network

Connection

1 Suction line 1 3/8

2 Liquid line to liquid receiver unit (LRU) 1 1/8

3 Oil distribution lines with Schraeder valves 1/4

Only for low temperature units:

4 Liquid line from receiver to heat exchanger (sub-cooler) 1 1/8

5 Liquid outlet to liquid header 5/8

ø (inch)

Safety

Instructions

Product

Description

Installation Electrical

Connection

Table 10: Connection Sizes

The pipe position at the rear of the unit is identical for single compressor condensing

units.

IMPORTANT

For low temperature network systems, Copeland recommends to insulate the complete

liquid outlet line to the expansion valve in order to optimise the sub-cooling effect.

3.7.1 3 & 4 Unit Network: Master/Slave selection recommendations

As compressor-starting priority is based on balancing running hours, Copeland

recommends the compressor used in the Master unit to be bigger and/or equal in

capacity as in Slave units, in order to achieve identical capacity modulation steps.

Therefore a network could be composed of either only single compressor units or twocompressor units.

A network could be composed also by a single compressor unit (as master, which will

start first always) and 2 or 3 two-compressor unit as slaves.

NOTE: Configuration with a two compressor unit as master and 2 or 3 single compressor

unit as slaves is not recommended as modulation steps would not be all the time equal.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 23 Part no: 3136433

Page 25

Condensing Unit For Refrigeration Networks

3.7.2 3 Unit network: Possible Master/Slave configurations

3.7.3 4 Unit network: Possible Master/Slave configurations

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Dismantling &

C6.1.4/0305/E 24 Part no: 3136433

Disposal

Page 26

Condensing Unit For Refrigeration Networks

3.7.4 3 Unit Network : Installation, dimensions and piping details

Medium Temperature Network

Safety

Instructions

Air Flow

2240 mm

1000 mm

Low Temperature Network

Oil distribution circuit

Air Flow

+/- 4900 mm

+/- 600 mm

Product

Description

Communication cable

Installation Electrical

Air Flow

Liquid pipe to evaporator(s)

Suction pipe from evaporator(s)

Connection

Air Flow

Air Flow

+/- 4900 mm

+/- 600 mm

2240 mm

1000 mm

Low temperature networks need additional piping between each unit heat exchanger and

the receiver, in order to get liquid for vapour injection.

IMPORTANT

For low temperature network systems, Copeland recommends to insulate the complete

liquid outlet line to the expansion valve in order to optimise the sub-cooling effect.

Oil distribution circuit

Air Flow

Liquid pipe to evaporator(s)

Suction pipe from evaporator(s)

Communication cable

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 25 Part no: 3136433

Page 27

Condensing Unit For Refrigeration Networks

Suction Header

An adequately sized suction header providing equal distribution of returning refrigerant to

each condensing unit must be used.

Suction type diameter at the rear of the unit is 1 3/8.

Copper connection

From

evapo rator(s)

To

Condensing

Unit

To

Condensing

Unit

To

Condens ing

Unit

From

evaporator(s)

To

Condens ing

Unit

The non-symmetrical design as shown is acceptable and does not create oil level

problems between units.

Safety

Instructions

Product

Description

Liquid line from receiver to Heat Exchanger (for low temperature networks)

Each condensing unit needs to be connected to the liquid receiver to supply liquid to heat

exchanger.

A copper pipe of 1 1/8” needs to be connected from the receiver to each heat exchanger.

Liquid line from Heat Exchanger (for low temperature networks)

The liquid outlet line from the heat exchanger to the system (to evaporators) needs to be

insulated.

Liquid outlet diameter is 5/8.

Oil inlet and outlet

The oil distribution lines with Schraeder valves need to be connected with flexible hoses

(option proposed by Copeland).

Care should be taken when connecting the hoses, “oil in” of the master unit should

connected the to “oil out” of the slave unit.

Flexible hoses kit of 0.5 metres

could be connected to a copper line

of ¼”.

Communication cable

2 communication cables with M12 connectors (option proposed by Copeland) need to be

connected between units.

It is possible to add a cable to close the communication network and insure back up when

communication fails between master and the slave 1. In this configuration 3 kits will be

needed. If connection to a monitoring system is required, an additional cable is needed.

FTT-10

Termination box

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

Communication cables

Alternative

Emergency link - In case of

cable rupture communication

still intact

C6.1.4/0305/E 26

Part no: 3136433

Page 28

Condensing Unit For Refrigeration Networks

3.7.5 4 Unit Network: Installation, dimensions and piping details

Medium Temperature Network

+/-6000 mm

Safety

Instructions

620 m m

+/- 500 mm

Air Flow

Oil distribution circuit

Low temperature Network

Air Flow

+/-6000 mm

+/- 600 mm

Air Flow

Communication cable

Liquid pipe to evaporator(s)

Suction pipe from evaporator(s)

Product

Description

2240 mm

> 1000 mm

Air Flow

Installation Electrical

Connection

620 mm

+/- 500 mm

Air Flow

+/- 600 mm

Air Flow

Communication cable

Oil distribution circuit

Air Flow

Liquid pipe to evaporator(s)

Suction pipe from evaporator(s)

Air Flow

IMPORTANT

For low temperature network systems, Copeland recommends to insulate the complete

liquid outlet line to the expansion valve in order to optimise the sub-cooling effect.

> 1000 mm

2240 mm

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 27 Part no: 3136433

Page 29

Condensing Unit For Refrigeration Networks

Suction Header

An adequately sized suction header providing equal distribution of returning refrigerant to

each condensing unit must be used.

Suction type diameter at the rear of the unit is 1 3/8.

Copper connection

From evapora tor( s)

To

Condensing

Unit

From

evaporato r(s)

Safety

Instructions

Product

Description

To

Condensing

Unit

Liquid line from receiver to Heat Exchanger (for low temperature networks)

Each Condensing unit needs to be connected to the liquid receiver to supply liquid to heat

exchanger.

A copper pipe of 1 1/8” needs to be connected from the Receiver to each heat

exchanger.

Liquid line from Heat Exchanger (for low temperature networks)

Liquid outlet line from the heat exchanger to the system (to evaporators) needs to be

insulated.

Liquid outlet diameter is 5/8.

Oil inlet and outlet

The oil distribution lines with Schraeder valves need to be connected with flexible hoses

(option proposed by Copeland).

Care should be taken when connecting the hoses, “oil in” of the master unit should

connected the to “oil out” of the slave unit.

Communication cable

3 communication cables with M12 connectors (option proposed by Copeland) need to be

connected between the units.

It is possible to add a cable to close the communication network and insure back up when

communication failed between master and slave 1. In this configuration 4 kits will be

needed. If connection to monitoring system is required, an additional cable is needed.

Flexible hoses kit of 0.5 metres

could be connected to a copper

line of ¼”.

Communication cables

To

Condensing

Unit

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

Alternative

Emergency link - In case of

cable rupture communication

still intact

C6.1.4/0305/E 28 Part no: 3136433

Page 30

A

Condensing Unit For Refrigeration Networks

3.8 Electronic Controller EC2-551

3.8.1 Binding Process

EC2-551 controllers are pre-programmed as “Master” controllers by default.

However, in a condensing unit network only one “Master” is allowed, all other controllers

need to become “Slaves”.

Controller 1: Compressor

Controller 2: Fan

Value to be displayed :

LED ON: pressure

LED OFF: temperature

ctive alarm

The number of controllers that can communicate is limited to 4 (maximum 4 units in a

network).

The following steps should be taken to set the communication links between the

controllers (“binding”):

1) Press the “defrost” button for 5 sec. min. on the unit which should become

2) Enter the “password” : default = 12

3) Press “Sel” key. The Display shows a blinking b1 (master unit)

4) Press the “Service Pin” button for 1 sec. min. on every slave unit that will take

5) The display on the master increments the digit following the “b”. The number

6) To execute the binding process, press the “defrost” button for 5 sec. Min.

7) Enter the “password” : default = 12

8) Press “Sel” key

9) The Display on every controller shows “---“ for 10 sec, resets and goes to

Automatically the controller where the binding process was initiated will become the

master and all other units will be configured as slaves. This avoids setting manually the

configuration parameter “c3” on every controller

If the binding process was successful, the service LED should blink on every controller in

the binding group when traffic arrives on the input network variable

By altering parameters, controllers

IR service LED

Compressor 2 :on

Compressor 1 :on

the Master (this unit will take care of compressor staging). The master unit

will be also typically the one with a digital compressor (if applicable) or the

one with a compressor to cover the base load).

part of the paralleling group.

of slave units is restricted to 3. (b2 to b4)

normal operation.

Fan : on

can be turned into Slaves and the

Master can identify which

controllers it has to communicate

with. This process is called

“binding” and is almost automatic.

Commission the controllers

together before modifying the

system parameters.

NOTE Digital Scroll™ condensing

unit needs to be allocated as

Master unit always! (Modulated

compressor should always start

first.)

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

3.8.2 Timeout on binding process (Escape function)

When the binding process is initiated on a controller (display shows blinking “b1”) and

the operator doesn’t press any key during 2 minutes, a timeout brings the controller back

into normal operation without changing anything.

3.8.3 Delete bindings

1) Initiate binding process on a controller (display shows blinking “b1”).

2) Terminate binding process on this controller without pressing any service key

on other controllers. (“b1” is still displayed)

3) The binding memory on the local controller will be cleared and the controller

will be set to master mode.

C6.1.4/0305/E 29 Part no: 3136433

Disposal

Dismantling &

Page 31

Condensing Unit For Refrigeration Networks

3.8.4 Back-up in case of communication cable or controller failure

In case of communication breakdown or controller failure, all units will start to operate in

“stand alone mode”.

To enable this (and to prevent a shortage of capacity due to compressors not starting),

setpoints for suction pressure should be set as in the Master controller (parameter P0),

but with a slightly higher values (0.1 bar higher versus the value of P0 in the Master unit).

3.8.5 Parameters information

3.8.5.1 Parameters

The configuration parameters can be protected by a numerical password. A value of “0”

disables this protection (default password: 12).

To select the parameter configuration:

Press the Prg button for more than 5 seconds

In case of password value equal to “0”:

The first modifiable parameter code is displayed (/1).

To modify parameters see Parameters modification below.

In case of password value not equal to “0”:

A flashing 0 is displayed

Press or until the password value is displayed.

Press Sel to confirm password

The first modifiable parameter code is displayed (/1).

To modify parameters see Parameters modification below.

3.8.5.2 Parameters modification

Press or to show the code of the parameter that has to be changed;

Press Sel to display the selected parameter value;

Press or to increase or decrease the value;

Press Sel to temporally confirm the new value and display its code

Repeat the procedure from the beginning "press or to show..." to modify another

parameter, etc.

To exit modifying the parameters with the new values:

Press Prg to confirm the new values and exit the parameter modification

procedure.

To exit without modifying any parameter:

Do not press any button for at least 60 seconds (TIME OUT).

For more information please refer to the corresponding application guideline (C6.1.5/E,

Part no.: 3136444), which is provided with the unit.

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Dismantling &

C6.1.4/0305/E 30 Part no: 3136433

Disposal

Page 32

Condensing Unit For Refrigeration Networks

4 Starting up & Operation

4.1 Charging Procedure

It is recommended to charge the unit with refrigerant into the receiver, via the Rotalock

service valve.

4.2 Sound

Sound data is given in the Copeland Selection software, available on

www.eCopeland.com.

The value published is the A-weighted average sound pressure level at 10 metres, with a

free sound propagation.

You can calculate the sound pressure for a further distance by using the following

formula:

= LPA1m-20 Log (d) LPAd = A-weighted sound pressure level at a "d" distance

LPA

d

LPA

D = distance

The sound pressure values measured on the field might be slightly different from the

published value due to the surrounding, different room characteristics, reverberating

object or walls, etc.

The unit must be installed without restricting the airflow.

All sound levels stated are with condenser fan(s) running at full speed. During reduced

ambient temperatures if optional fan speed controller is operating, lower sound levels will

be achieved.

= A-weighted sound pressure level at 1 metre

1m

Safety

Instructions

Product

Description

Installation Electrical

Connection

4.3 Rotation direction of scroll compressors

Scroll compressors, like several other types of compressors, will only compress in one

rotational direction. Direction of rotation is not an issue with single-phase compressors

since they will always start and run in the proper direction. Three-phase compressors will

rotate in either direction depending upon phasing of the power. Since there is a 50-50

chance of connecting power in such a way as to cause rotation in the reverse direction, it

is important to include notices and instructions in appropriate locations on the

equipment to ensure proper rotation direction when the system is installed and

operated.

4.3.1 Units OMQ-56, OMQ-75, OMQ-92, OMQ-110, OLQ-24V, OLQ-33V, OLQ-40V &

OLQ-48V

Compressors assembled on above units are equipped with the INT69SCY module, which

acts as internal protection and checks the phasing. The module will trip in case of reverse

rotation.

4.3.2 Units OMTQ-60(D), OMTQ-76, OMTQ-90(D), OLTQ-26V & OLTQ-36V

Please follow the underneath procedure:

Observing that suction pressure drops and discharge pressure rises when the

compressor is energized makes verification of proper rotation direction possible. There is

no negative impact on durability caused by operating three-phase Copeland Scroll™

compressors in the reversed direction for a short period of time (less than one hour), but

oil may be lost. After several minutes of operation in reverse, the compressor's protection

system will trip due to high motor temperature. However, if allowed to repeatedly restart

and run in reverse without correcting the situation, the compressor will be permanently

damaged.

All three-phase scroll compressors are identically wired internally. Therefore, once the

correct phasing is determined for a specific system or installation, connecting properly

phased power leads to the identified terminals in the electrical panel will insure proper

rotation direction.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 31 Part no: 3136433

Page 33

Condensing Unit For Refrigeration Networks

4.4 Maximum compressor cycle

Maximum start per hour: 10 times

4.5 Checks before starting & during operation

Please check that all Rotalock valves are fully opened.

Check that the electrical panel is closed.

After starting and operation conditions are stabilised, we recommend to check the oil

level in compressor(s) and if needed add oil to insure a sufficient oil level (middle of oil

sight glass).

5 Maintenance & Repair: Replacing a compressor

De-energize the condensing unit before any intervention.

Unscrew and lift the housing top panel to get access from the top to the

compressor.

Close Rotalock valves or ball valve to isolate the compressor from the system

and unscrew the flare Rotalock connector from the compressor.

Release the compressor mounting parts and then lift it to replace with a new

compressor.

6 Certification and Approval

The piping is in compliance with the Pressure Equipment Directive 97/23/EEC

(Art.3§3 - Sound Engineering Practice)

Components of the condensing units carry a CE mark as far as required and

thereby establish conformity with the relevant directives.

Conformity Declarations for components are available as far as required.

The units are in conformity with the low voltage directive. The applied harmonised

standard is EN 60335-1 (Safety Household and Similar Electrical Appliance, Part

1: General Requirements)

To incorporate these products into a machine the Manufacturer's Declaration of

incorporation has to be respected.

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

7 Dismantling and Disposal

Removing oil and refrigerant:

Do not disperse it in the environment.

Use the correct equipment and method of removal.

Dispose oil and refrigerant properly.

Dispose the compressor properly.

Maintenance

Dismantling &

C6.1.4/0305/E 32 Part no: 3136433

& Repair

Disposal

Page 34

Benelux Eastern Europe, Turkey & Iran

Deltakade 7 27, Rue des Trois Bourdons

NL-5928 PX Venlo B-4840 Welkenraedt

Tel. +31 (0) 77 324 0234 Tel. +32 (0) 87 305 061

Fax +31 (0) 77 324 0235 Fax +32 (0) 87 305 506

Deutschland/Österreich & Schweiz Poland

Senefelder Straße 3 11A, Konstruktorska

D-63477 Maintal P-02-673 Warszawa

Tel. +49 (0)6109 6059 0 Tel. +48 225 458 9205

Fax +49 (0)6109 6059 40 Fax +48 225 458 9255

France/Greece & Maghreb Russia & CIS

8, Allee Du Moulin Berger Malaya Trubetskaya, 8-11th Floor

F-69130 Ecully RUS-119881 Moscow

Tel. +33 (0)4 78668570 Tel. +7 095 232 94 72

Fax +33 (0)4 78668571 Fax +7 095 232 03 56

Italia Middle East & Africa

Via Ramazzotti, 26 PO Box 26382, R/A 8, FD-2

I-21047 Saronno (va) Jebel Ali, Dubai - UAE

Tel. +39 02 961781 Tel. +9714 883 2828

Fax +39 02 96178888 Fax +9714 883 2848

España & Portugal

Diputacion, 238 AT.8

E-08007 Barcelona

Tel. +34 93 4123752

Fax +34 93 4124215

UK & Ireland

Colthrop Way

GB- Thatcham, Berkshire - RG19 4 NQ

Tel. +44 (0)1635 87 6161

Fax +44 (0)1635 877111

Asia/Pacific

10/F, Pioneer Building, 213 Wai Yip Street,

Kwun Tong, Kowloon - Hong Kong

Tel. +852 28 66 31 08

Fax +852 25 20 62 27

Latin America

7975 North West 154Th Street - Suite 300

Miami Lakes, FL, 33016 - USA

Tel. +1 305 818 8880

Fax +1 305 818 8888

Sweden/Denmark/Norway & Finland

Östbergavägen 4, P.O.Box 10

S-59021 Väderstad

C6.1.4 / 0305/E

Tel. +46 (0) 142 70520

Fax +46 (0) 142 70521

Copeland Marketing & Sales - 27, Rue des Trois Bourdons - B 4840 Welkenraedt, Belgium

Tel. +32 (0) 87 305411 - Fax +32 (0) 87 305506 - internet: www.ecopeland.com - email: eCommerce@eCopeland.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. Copeland Corporation is a division of Emerson Electric Co. Copeland is a registered trademark and Copeland EazyCool is

a trademark of Copeland Corporation. All other trademarks are the property of their respective owners. Information contained in this brochure is subject to change without notification.

© 2005 Copeland

Loading...

Loading...