CLARKSON SERIES KGF AND KGF-HP SLURRY VALVES

InstallatIon and maIntenance InstructIons

Before installation these instructions must be fully read and understood

This instruction manual provides installation,

operation and maintenance recommendations

for both the Clarkson KGF and Clarkson

KGF-HP slurry knife gate valves. The standard

KGF is a 300psi CWP valve with optional

pressure ratings up to 450psi cwp and the

KGF-HP is rated to Class300 (740psi CWP).

Both products are very similar, however,

theKGF-HP has a higher pressure rating

andcritical parts are not interchangeable.

The KGF and KGF-HP are identified by

thevalvetag.

1 GENERAL INFORMATION

1. The KGF and KGF-HP are packingless,

slurry knife gate valves. All the sealing is

accomplished by the elastomeric sleeves

in the valve housing. The sleeves also form

the wear section for the valve. The gate is

INDEX

1. General information ...................................... 1

2. Initial inspection ............................................ 2

3. Installation instructions ................................ 2

4. Operation ....................................................... 5

5. Lockouts ....................................................... 6

6. General maintenance ................................... 7

7. Spare parts ................................................... 8

8. Storage .......................................................... 9

9. Sleeve replacement .................................... 10

10. Gate support replacement .......................... 12

11. Secondary seal replacement ...................... 12

12. Disassembly and assembly instructions ... 13

13. Field replacement of gates ......................... 16

14. Body flushing and discharge ...................... 17

15. Installation instructions for splash

guardbucket ................................................ 18

16. Installation instructions for splash

guardplate ................................................... 18

17. Lifting ........................................................... 18

18. Manual handwheel actuator assembly ...... 19

19. Bevel gear actuator assembly .................... 19

20. Air cylinder actuator assembly................... 20

21. Hydraulic cylinder actuator assembly ....... 20

removable for inspection or replacement

while the valve is in service. Refer to

Section 13 for gate removal cautions

andinstructions.

2. The KGF and KGF-HP are BIDIRECTIONAL

(two-way shut-off) product and can be

installed without concern over direction of

flow. Since they will shut-off equally with

in either direction, you will find no arrows

or other indicators of a direction of flow or

seatside.

3. Clarkson slurry knife gate valves are

suitable for on-off service only. They are

notto be used in a throttling application.

4. The style, size, pressure rating and material

selection are the responsibility of the piping

system designer.

5. All valves should be operated within the

design pressure and temperature ranges.

Under no circumstances should the valves

be operated at conditions outside these

parameters. Do not exceed 100% of the

maximum pressure rating of the valve at

anytime during its operation. Pressure

spikes beyond the valve’s pressure rating

are solely the responsibility of the user.

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCIOM-06613-EN 17/08

CLARKSON SERIES KGF AND KGF-HP SLURRY VALVES

InstallatIon and maIntenance InstructIons

2 INITIAL INSPECTION

1. Examine entire valve and report any

damageor discrepancies immediately.

2. Sleeves: visually examine the sleeves

interior, looking for chunking, irregularities

or other damage. It is not recommended

you remove the retainer flanges. Visually

examine the retainer flanges surfaces,

looking for tears, irregularities or other

damage. Check tightness of retainer

flangebolting.

3. Operators: standard manual handwheels

may be shipped loose for field installation,

be sure to fully tighten.

4. Valves are normally shipped with gate in

open position, the recommended position

for installation. Valves supplied with spring

to extend (fail close) cylinder actuators are

shipped with the gate in the closed position.

The KGF and KGF-HP should be installed

with the gate in the open position, exercise

caution when applying air to open this valve

and ensure that it is locked in the open

position when installing in the line.

5. Accessories: if provided, including

solenoids, limit switches, etc., are tested

for functionality prior to shipment. Examine

carefully for damage which may occur

during shipment.

6. Refer to lockouts Section 5 for additional

cautions on spring cylinders

3 INSTALLATION INSTRUCTIONS

Please take note of the specific installation

tagsprovided with each valve.

1. The KGF and KGF-HP are to be installed

with the gate in the fully open position with

the sleeves inserted into the housing halves.

2. KGF: standard mating flanges 3” (DN80)

through24” (DN600) match ASME

B16.5/300, sizes30” and larger are per

MSS-SP44/300 (see Table 4). Optional

drilling to ASME B16.5/150 is available

in certain circumstances. Other flange

drillings including PN10 or PN16 are

available depending on rated pressure of

valve.

KGF-HP: standard mating flanges 3”

(DN80) through 24” (DN600) match ASME

B16.5/300, sizes30” and larger are per

MSS-SP44/300 (see Table 4). Other flange

drillings are available depending on rated

pressure ofvalve.

CAUTION

Valves are normally shipped with gate in

open position, the recommended position for

installation. Valves supplied with spring to extend

(fail close) cylinder actuators are shipped with

the gate in the closed position. Gate should be

actuated to the open position prior to installation,

exercise extreme caution when applying air to

open this valve and ensure that gate is locked

in the open position for installation. Refer to

lockouts section 5 for additional cautions on

spring cylinders.

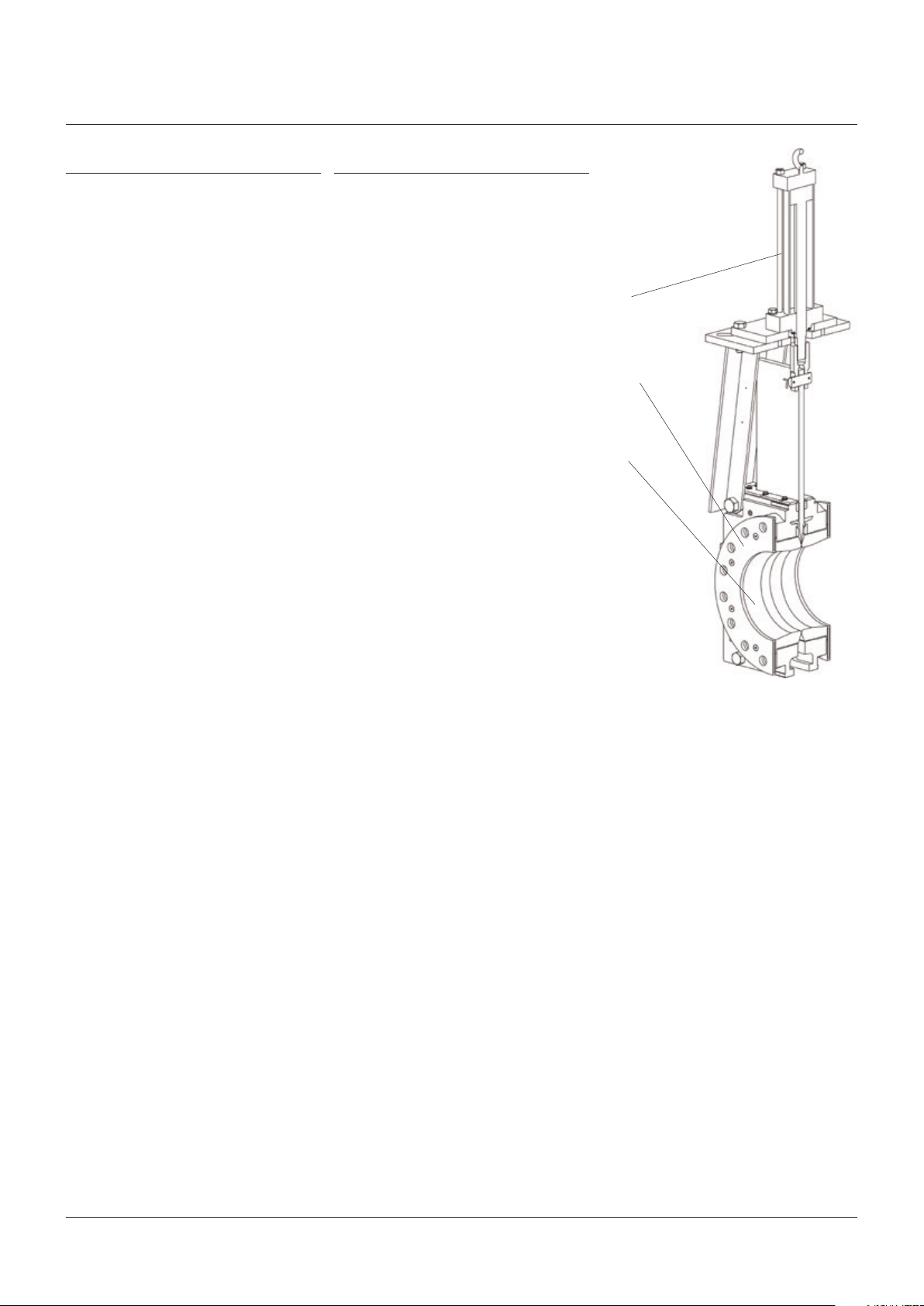

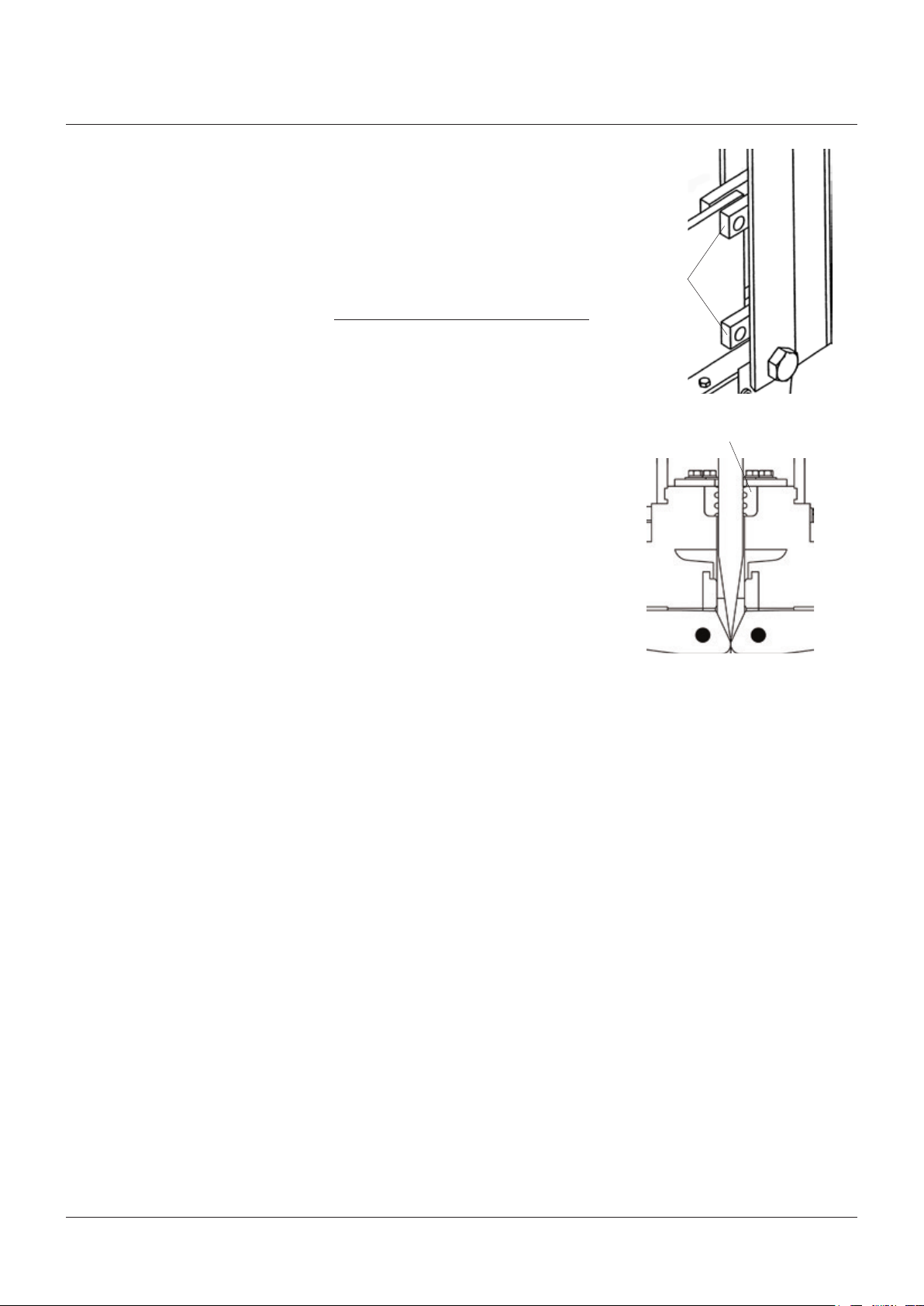

FIGURE 1

Operators

Retainer flanges

Sleeves

2

CLARKSON SERIES KGF AND KGF-HP SLURRY VALVES

InstallatIon and maIntenance InstructIons

3. Tables 1 and 2 state the maximum flange

bolt tightening torques for standard flange

patterns. While the KGF and KGF-HP are

provided with flange bolt patterns that

match ASME B16.5/150 or ASME B16.5/300

flange bolt patterns, they are not designed

to handle the same torque requirements

as an all-metal Class150 or Class300 gate

valve. The KGF and KGF-HP are specialty

valves with a specified maximum flange

torque. Exceeding recommended torque

values will reduce overall valve performance

and may permanently damage the sleeves

and or other components.

4. The KGF and KGF-HP are configured for

installation in conventional bolted flange

connections. Slip on or weld flanges can

be used. The pipeline companion flanges

should be raised or flat face type to insure

full sleeve support and a continuous,

unvarying I.D. If slip-on flanges are used,

the pipe should be cut square and welded

in position with the pipe end matched

evenly with the flange face. Studded flanges

are not compatible with these valves.

Use of other flange connections should

be reviewed and verified by the factory

forcompatibility prior to installation.

5. The mating line flanges must be properly

aligned prior to attempting installation.

Never try to make up for misaligned pipe

flanges by the line bolting.

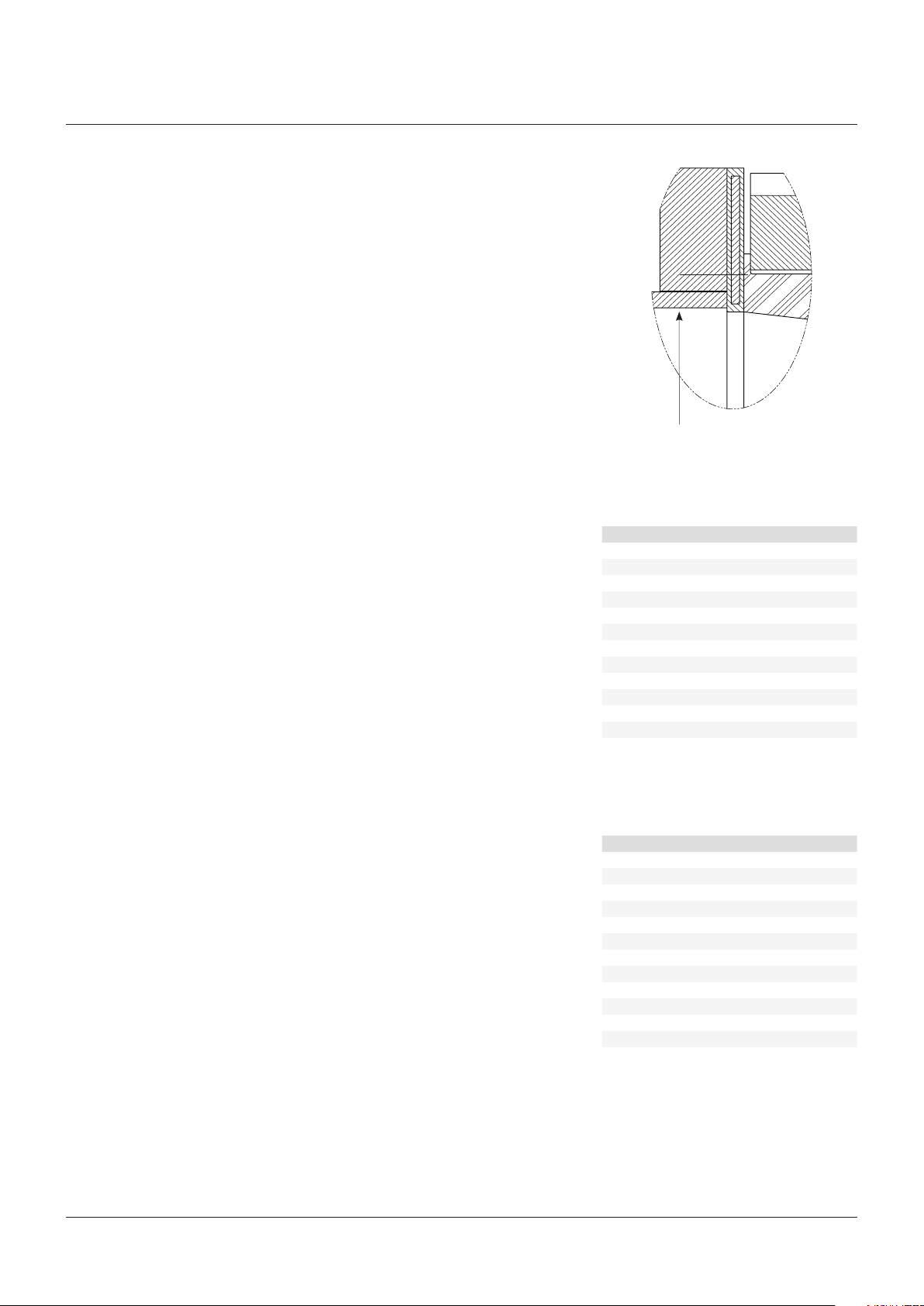

6. Optimum performance of the valve sleeves

may be achieved if the mating pipe I.D. is no

larger than +0.25” (6.5mm) of the retainer

flange I.D. (Refer to Table 4 for retainer

flange dimensions.) Oversized mating pipe

I.D. may subject retainer flange and sleeve

to additional wear.

7. Listed in Table 4 are the fasteners required

for installation.

8. Pipe supports and/or expansion joints

should be used to minimize pipe loads

onvalves.

9. The elastomer coated retainer flange

functions as the gasket for installation

into the pipeline, no additional gaskets

arerequired.

10. Valve is suitable for use in either vertical or

horizontal lines. The valve can be installed

in any position in vertical or horizontal

pipelines. However, valves installed in

an orientation with the actuator below

horizontal may require flushing to prevent

the buildup of solids in the housing and

mayrequire additional actuator support.

Installation notes

A) All slurry knife gate valves are designed and

manufactured to be installed in applications

where no more than 1g of force In excess

of gravity is applied to the valve in any

direction. This 1g force can be an effect

of traffic, wind, or earthquake, etc. Valves

should not be used in applications that

exceed 1g.

B) If valve stem or topworks protrude into

walkways or work areas, valve should

beflagged per company safety policy.

C) All piping systems should contain

independent support mechanisms and

should not utilize the valve as a sole

meansof support.

D) Do not install valve over walkways, electrical

or other critical equipment without the use

of a splash guard device (refer to section 14)

or similar considerations.

FIGURE 2

Retainer flange I.D.

TABLE 1 - MAXIMUM TIGHTENING TORQUE

STANDARD CLASS150 FLANGES

Valve size ft·lbs Nm

3 37 50

4 37 50

6 69 64

8 69 64

10 113 153

12 113 153

14 169 229

16 169 229

18 238 324

20 238 324

24 345 467

30 345 467

36 610 827

TABLE 2 - MAXIMUM TIGHTENING TORQUE

STANDARD CLASS300 FLANGES

Valve size ft·lbs Nm

3 69 94

4 69 94

6 69 94

8 113 153

10 169 229

12 238 324

14 238 324

16 345 467

18 345 467

20 345 467

24 610 827

30 1000 1355

36 1500 2035

3

CLARKSON SERIES KGF AND KGF-HP SLURRY VALVES

InstallatIon and maIntenance InstructIons

TABLE 3 - BOLTING DIMENSIONS CLASS150 FLANGES

Bolt size/

Valve size Retainer inlet diameter Flange diameter Bolt circle diameter Bolt holes

inch/mm inch mm inch mm inch mm UNC inch mm

3” / 80 2.81 71.4 7½ 190.5 6 152.40 4 ⅝-11 3 76.2

4” / 100 3.88 98.6 9 228.6 7½ 190.50 8 ⅝-11 3 76.2

6” / 150 5.81 147.6 11 279.4 9½ 241.30 8 ¾-10 3 76.2

8” / 200 7.75 196.9 13½ 342.9 11¾ 298.50 8 ¾-10 4 101.6

10” / 250 9.81 249.2 16 406.4 14¼ 362.00 12 ⅞-9 4 101.6

12” / 300 11.50 292.1 19 482.6 17 431.80 12 ⅞-9 4½ 114.3

14” / 350 13.25 336.6 21 533.4 18¾ 476.30 12 1-8 4½ 114.3

16” / 400 14.75 374.7 23½ 596.9 21¼ 539.80 16 1-8 4½ 114.3

18” / 450 16.75 425.5 25 635.0 22¾ 577.90 16 1⅛-7 5 127.0

20” / 500 18.50 469.9 27½ 698.5 25 635.00 20 1⅛-7 6 152.4

24” / 600 23.00 584.2 32 812.8 29½ 749.30 20 1¼-7 6½ 165.1

30” / 750 29.00 736.6 38¾ 984.3 36 914.40 28 1¼-7 9 228.6

36” / 900 35.00 889.0 46 1168.4 42¾ 1085.85 32 1½-6 9 228.6

NOTES

• Flange dimensions per ANSI B16.5/150 for 3”-24” and MSS SP44/150 for 30”-36”.

• Type B standard washers are not included in stud lenghts.

• Mating flange thickness assumed to match ANSI B16.5/150 for 3”-24” and MSS SP44/150 for 30”-36”.

• Flange drilled and tapped holes in body over 1” in diameter are normally provided with course threads.

• Stud lengths supplied are minimum for full thread engagement into tapped holes and stud lengths are rounded to nearest 0.5inch.

• Stud lengths are supplied rather than bolt lengths.

• Bolt hole quantity shown below is per side of valve.

no.

thread Stud length (see note)

TABLE 4 - BOLTING DIMENSIONS CLASS300 FLANGES

Bolt size/

Valve size Retainer inlet diameter Flange diameter Bolt circle diameter Bolt holes

inch/mm inch mm inch mm inch mm UNC inch mm

3” ⁄ 80 2.81 71.4 8¼ 209.6 6⅝ 168.30 8 ¾-10 3½ 88.9

4” ⁄ 100 3.88 98.6 10 254.0 7⅞ 200.00 8 ¾-10 3½ 88.9

6” ⁄ 150 5.83 148.1 12½ 317.5 10⅝ 269.90 12 ¾-10 3½ 88.9

8” ⁄ 200 7.86 199.6 15 381.0 13 330.20 12 ⅞-9 4 101.6

10” ⁄ 250 9.80 248.9 17½ 444.5 15¼ 387.40 16 1-8 4½ 114.3

12” ⁄ 300 11.50 292.1 20½ 520.7 17¾ 450.90 16 1⅛-7 5½ 139.7

14” ⁄ 350 13.30 337.8 23 584.2 20¼ 514.40 20 1⅛-7 5½ 139.7

16” ⁄ 400 14.75 374.7 25½ 647.7 22½ 571.50 20 1¼-7 6 152.4

18” ⁄ 450 17.00 431.8 28 711.2 24¾ 628.70 24 1¼-7 6 152.4

20” ⁄ 500 18.50 469.9 30½ 774.7 27 685.80 24 1¼-7 7 177.8

24” ⁄ 600 23.50 596.9 36 914.4 32 812.80 24 1½-6 7½ 190.5

30” ⁄ 750 29.00 736.6 43 1092.2 39¼ 996.95 28 1¾-5 10 254.0

36” ⁄ 900 35.00 889.0 50 1270.0 46 1168.40 32 2-4.5 11 279.4

NOTES

• Flange dimensions per ANSI B16.5/300 for 3”-24” and MSS SP44/300 for 30”-36”.

• Type B standard washers are not included in stud lenghts.

• Mating flange thickness assumed to match ANSI B16.5/300 for 3”-24” and MSS SP44/300 for 30”-36”.

• Flange drilled and tapped holes in body over 1” in diameter are normally provided with course threads.

• Stud lengths supplied are minimum for full thread engagement into tapped holes and stud lengths are rounded to nearest 0.5inch.

• Stud lengths are supplied rather than bolt lengths.

• Bolt hole quantity shown below is per side of valve.

no.

thread Stud length (see note)

4

CLARKSON SERIES KGF AND KGF-HP SLURRY VALVES

InstallatIon and maIntenance InstructIons

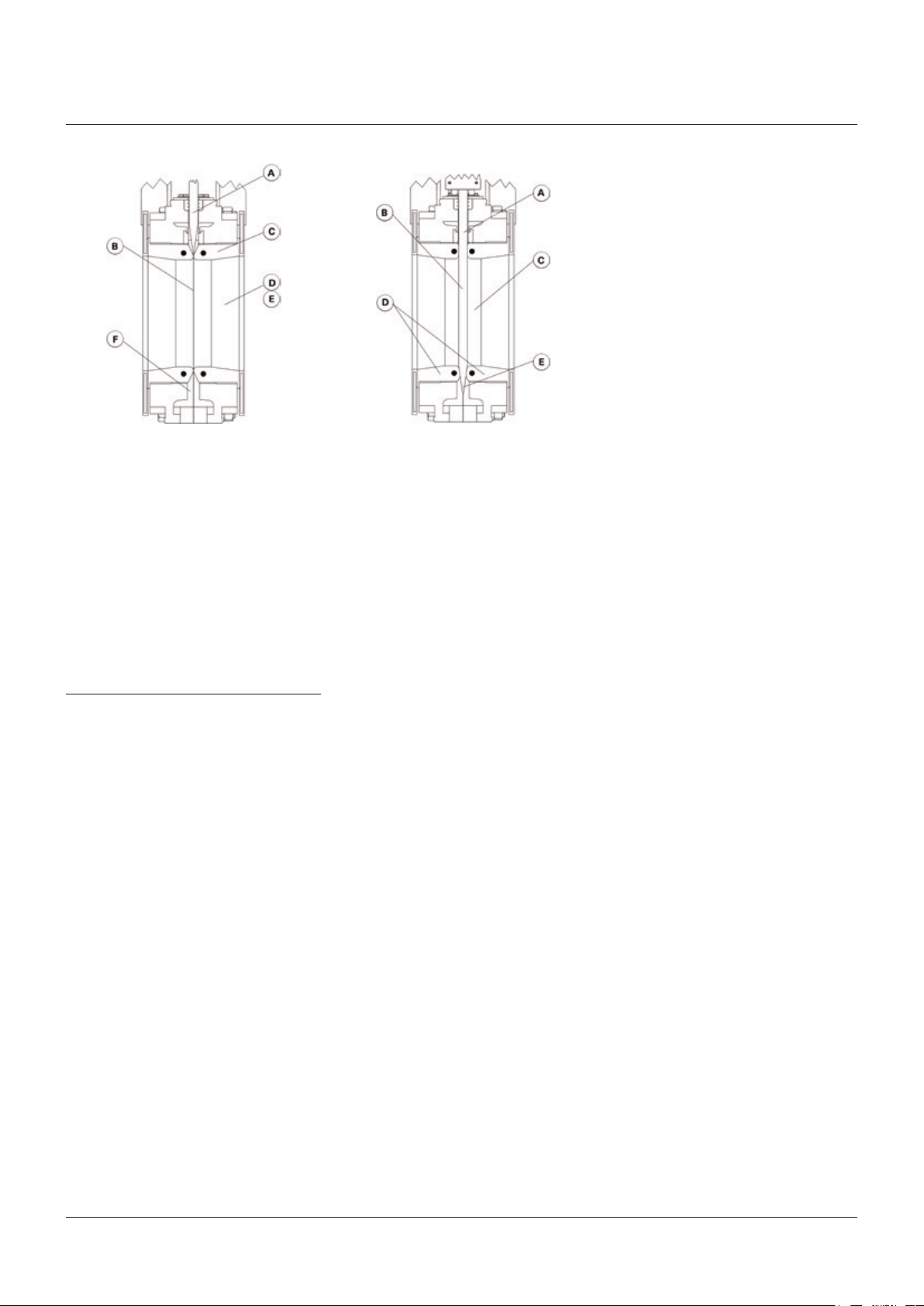

FIGURE 3 - OPEN POSITION FIGURE 4 - CLOSED POSITION

Open position

A) Gate positioned above seals, out of flow.

B) Matching elastomer sleeves seal against

each other under a high compression load.

C) Sleeves act as pressure vessel.

D) No metal parts in contact with slurry.

E) Unobstructed port area eliminates

turbulence, minimizes pressure drop

acrossvalve.

F) No seat cavity where solids can collect

andprevent full gate closure.

4 OPERATION

1. Clarkson slurry knife gate valves are

suitable for on-off service only. They are

notto be used in a throttling application.

2. To close the valve and provide isolation,

the actuator (handwheel, bevel gear,

air/hydraulic cylinder or electric motor

actuator) moves the metal gate in a linear

motion between the elastomeric sleeves

to shut off the flow. To open, reverse the

operation and the gate moves up and out

from between the sleeves, opening the

valveport.

3. Matching elastomer sleeves seal against

each under a high compression load

when the valve is open, creating the valve

pressure vessel. When the valve is closed,

the sleeves seal against the gate face,

isolating upstream from downstream.

SeeFigures 3 and 4.

It is normal for the KGF and KGF-HP

to discharge media during opening and

closing cycles. Some additional discharge

may continue for a time after completion

of the open cycle. This helps prevent

any solids from building up between the

sleeves that would prevent a tight seal

when the valve is fully open or closed.

Dischargecanbecontrolled with the use of

a splash guarddevice (refertosection 14).

Closed position

A) Gate travels through sleeves to provide

blindflange shut-off, allowing opportunity

for media to expel to atmosphere.

B) 100% Isolation-bubble tight shut-off results

in absolutely zero downstream leakage.

C) When properly installed and maintained,

the KGF is designed to provide

man-safeisolation.

D) Double-seated design provides bidirectional

flow and shut-off.

E) Controlled stroke prevents gate from

penetrating too far, minimizing stress

onsleeve.

Depending on the pressure rating, some

models of the KGF and KGF-HP include

a splash guard device as standard. Do

not install valve over walkways, electrical

or other critical equipment without the

use of a splash guard device or similar

considerations.

4. As the gate strokes, a gap is created

between the facing sleeves, allowing any

media that could potentially clog or jam

thevalve to be purged out from between

thesleeves, and potentially expelled

outsidethe valve housing to atmosphere.

5. The KGF and KGF-HP incorporate a

built-in clean-out area at the base of the

housing assembly. The clean-out area

may be enclosed by a removable splash

guard device. Depending on the pressure

rating, some models of the KGF and

KGF-HP include a splash guard device

as standard. This splash guard device

will allow controlled drainage of any

accumulated solids that may prevent full

gate closure. Flush water can be used to

improve the drainage efficiency. With the

splash guard device in place, any solids,

slurry, or flush water ejected from the valve

can be handled in a controlled manner.

See Section14forsplash guard device

installation instructions.

5

CLARKSON SERIES KGF AND KGF-HP SLURRY VALVES

InstallatIon and maIntenance InstructIons

6. All valves should be operated within the

design pressure and temperature ranges.

Under no circumstances should the

valves be operated at conditions outside

theseparameters.

Note: actuated Clarkson valves have a

maximum recommend stroke speed

of1”per second. Exceeding this speed can

shorten sleeve life and may void warranty.

Speed controls provided by factory will

require adjustment in the field to obtain

proper stroke speed against actual

operating conditions. Refer to Section 14

foradditional inormation on discharge.

7. The operator of any valve should have an

understanding of the effects of opening/

closing the valve with regards to its role

in the overall piping system. Operators

of valves under pressure should take

caution to ensure that the valve is in good

operatingcondition prior to operating it

under pressure.

8. Certain processes contain hazardous and/or

otherwise unstable media. Care should be

taken in these circumstances to ensure the

operator is aware of the specific health and

safety risks associated with that medium.

9. When operating the valve stand clear of any

moving parts such as the stem and/or gate

assembly, use of gloves is suggested when

operating manual valves to minimize the

risk of injury.

10. All manually operated valves are designed

for hand input. Do not apply excessive input

torque via pipe wrenches, ‘cheater bars’,

or other devices. If a manual handwheel

actuated valve is difficult to operate due to

torque requirements, it is recommended

that the valve be supplied with or converted

to a bevel gear, air/hydraulic cylinder or

electric motor actuator.

11. Electric motor actuated valves should be

left in their factory set condition, unless

the system operating parameters dictate

a change. If changes are necessary, they

should be performed in small increments

using the lightest/lowest setting possible

to achieve the desired performance and

then the valve/actuator function inspected.

Excess torque and/or thrust in the motor

settings may damage or lockup the valve.

12. Clarkson KGF and KGF-HP valves are

position seated and should never be

torqueseated. Do not use the motor

torquesettings to seat the valve.

13. Care should be taken to ensure that

electrical motors are wired correctly to the

power source. Incorrect phasing of 3-phase

wiring may cause valve/motor damage.

5 LOCKOUTS

Open and closed lockout positions are optional

on the KGF and KGF-HP. Optional lockout pins

may be supplied by Emerson or customer may

use their own suitable pin. (Contact factory

forpin specifications.)

CAUTION

If lockout pins are used on automated valves, the

open & closed lockout brackets are designed to

resist the normal valve operating thrust. In order

to assure complete lockout compliance, any

double acting air cylinder, hydraulic cylinder or

electric motor actuated valve must be placed in

a ZERO ENERGY STATE by isolating all potential

energy sources including electricity, operator air

supply or hydraulic fluids.

In the case of a single acting spring to close

or spring to open cylinder with the spring

compressed, the mechanical energy cannot

be placed in the ZERO ENERGY STATE. When

compressed, the spring will cause unwanted

gate movement if inlet air pressure is not

maintained on the non-spring side of the

actuator. Specific care must be taken to insert

or remove lockout pins. To insert or remove

lockout pins.

- Spring extended (uncompressed): isolate air

supply from cylinder actuator.

- Spring retracted (compressed): maintain

air pressure on the non-spring side of

theactuator.

Take great care when inserting and removing the

lockout pin. If the gate moves during the insertion

or removal process, injury may occur.

FIGURE 5

brackets

FIGURE 6

Lockout

Secondary seal

6

Loading...

Loading...