Emerson CF787CK01, CF787AW01, CF787AP01, CF787BS01, CF787GBZ01 Owner's Manual

...

Part No. F40BP73770005 Form No. BP7377-5

U.L. Model No.: CF787

READ AND SAVE THESE INSTRUCTIONS

Damp Location

Ceiling Fan Owner's Manual

CF787AW01 - Summer White

CF787AP01 - Antique Pewter

CF787BS01 - Brushed Steel

CF787CK01 - Chalk

CF787GBZ01 - Gilded Bronze

CF787GES01 - Golden Espresso

CF787ORB01 - Oil Rubbed Bronze

CF787VNB01 - Venetian Bronze

Model Numbers

CARRERA GRANDE

™

54”, 60” or 72” Fan Blades

Not Included

Net Weight: 25.3 Lbs.

WARNING: To avoid fire, shock, and serious personal injury, follow these instructions.

Safety Instructions

1. Read your owner’s manual carefully and keep it for future reference.

2. Before servicing or cleaning unit, switch power off at service panel and lock service panel

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a warning device, such as a tag, to the

service panel.

3. Be careful of the fan and blades when cleaning, painting, or working near the fan. Always turn off

the power to the ceiling fan before servicing.

4. Do not put anything into the fan blades while they are turning.

5. Do not operate reversing switch until fan blades have come to a complete stop.

Additional Safety Instructions for Installation

1. To avoid possible shock, be sure electricity is turned off at the fuse box before wiring, and do not

operate fan without blades.

2. All wiring must be in accordance with the National Electrical Codes “ANSI/NFPA 70-2008” and

Local Electrical Codes. Use the National Electrical Code if Local Codes do not exist. The ceiling

fan must be grounded as a precaution against possible electrical shock. Electrical installation

should be made or approved by a licensed electrician.

3. The outlet box and joist must be securely mounted and capable of reliably supporting at least 50

pounds. Use only U.L. outlet boxes listed as “Acceptable for Fan Support of 50 lbs or less”, and

use the mounting screws provided with the outlet box. Most outlet boxes commonly used for

support of light fixtures are not acceptable for fan support and may need to be replaced. Consult

a qualified electrician if in doubt.

4. The downrod furnished with the fan provides the minimum recommended floor to fan blade

clearance for an 8 foot ceiling.

5. The fan must be mounted with the fan blades at least 7 feet from the floor to prevent accidental

contact with the fan blades.

6. Follow the recommended instructions for the proper method of wiring your ceiling fan. If you do

not know enough about electrical wiring, have your fan installed by a licensed electrician.

NOTE: This fan is suitable for use with solid-state speed controls.

WARNING: To reduce the risk of fire or electric shock, this fan should only be used with fan speed

control, Model No. SW46/UL Model No. UDC9020 manufactured by Rhine Electric Co., Ltd.

WARNING: To avoid fire, shock or injury, do not use an Emerson or any other brand of control not

specifically approved for this fan.

WARNING: This product is designed to use only those parts supplied with this product and/or any

accessories designated specifically for use with this product by Emerson Electric Co. Substitution

of parts or accessories not designated for use with this product by Emerson Electric Co. could

result in personal injury or property damage.

WARNING: To reduce the risk of personal injury, do not bend the blade flange when installing the

blade flanges, balancing the blades or cleaning the fan. Do not insert foreign objects in between

rotating fan blades.

WARNING: To reduce the risk of electrical shock, this fan must be installed with an isolating wall

control/switch.

WARNING

2

!

DATE CODE:

The date code of this fan may be found on the box, stamped in ink on a white label.

You should record this data above and keep it in a safe place for future use.

U.L. Model No.: CF787

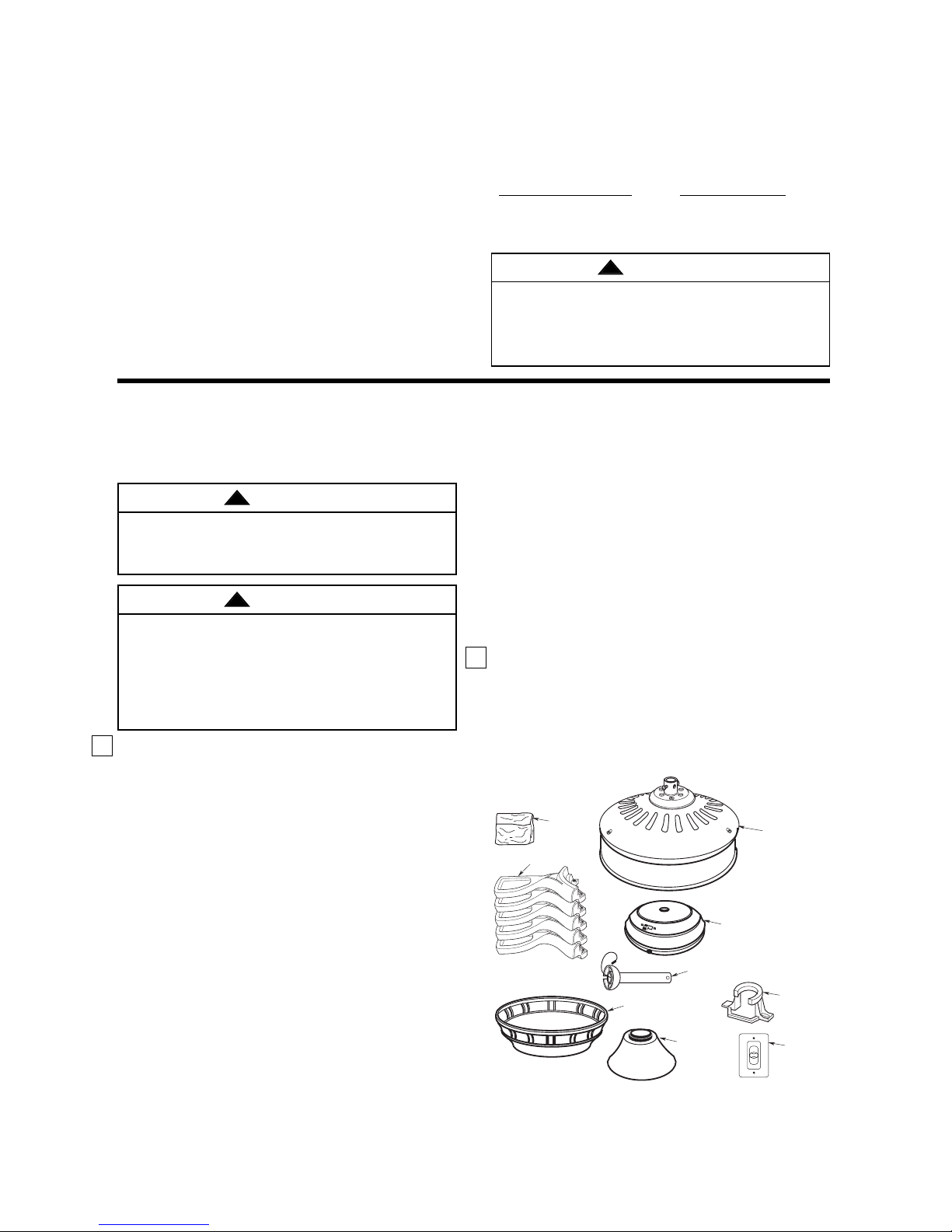

1. Check to see that you have received the following

parts:

NOTE: If you are uncertain of part description,

refer to exploded view illustration.

a. Fan motor assembly

b. One switch housing assembly

c. One ceiling cover

d. Five blade flanges

e. One hanger ball/4.5” downrod assembly

f. One hanger bracket

g. One coupling cover

h. One 4-speed slide wall control

i. One loose parts bag containing:

1. Twenty-one M5 x 12mm washer head

blade screws

2. Twenty-one 16mm OD flat washer

3. One M4 x 12mm flat head screw

4. One M6 x 14mm pan head screw with

lockwasher

5. Four wire connectors

6. Two threaded studs

7. Two knurled knobs

This Manual Is Designed to Make it as Easy as Possible for You to Assemble,

Install, Operate and Maintain Your Ceiling Fan

Tools Needed for Assembly

One Phillips head screwdriver One stepladder

One wire stripper

MATERIALS

Wiring outlet box and box connectors must be of type

required by the local code. The minimum wire would

be a 3-conductor (2-wire with ground) of the following

size:

3

Installed Wire Length Wire Size A.W.G.

Up to 50 ft. 14

50-100 ft. 12

Unpacking Instructions

For your convenience, check-off boxes are provided next to each step. As each step is completed, place a

check mark in the box. This will insure that all steps have been completed and will be helpful in finding

your place should you be interrupted.

Before assembly your ceiling fan, refer to section on

proper method of wiring your fan (page 8). If you feel

you do not have enough wiring knowledge or

experience, have your fan installed by a licensed

electrician.

Do not install or use fan if any part is damaged or

missing. Call Toll-Free:

1-800-654-3545

This product is designed to use only those parts

supplied with this product and/or any accessories

designated specifically for use with this product by

Emerson Electric Co. Substitution of parts or

accessories not designated for use with this product

by Emerson Electric Co. could result in personal

injury or property damage.

WARNING

!

WARNING

!

WARNING

!

U.L. Model No.: CF787

THESE FAN MODELS ARE SUITABLE FOR DAMP LOCATIONS SUCH AS COVERED PORCHES,

COVERED PATIOS, AND COVERED DECKS... ANYWHERE THERE IS A ROOF OVERHEAD.

8. Two lockwashers

9. One clevis pin

10. One hairpin clip

11. One balance kit

NOTE: Place the parts from the loose parts bags

in a small container to keep them from being lost.

If any parts are missing, contact your local

retailer or catalog outlet for replacement before

proceeding.

2. Remove the fan assembly from the protective

plastic bag. Place the fan assembly into the upper

foam pad with the bottom of the motor facing up.

The upper foam pad serves as a holder for the fan

during the first stages of assembly.

I. LOOSE

PARTS BAG

D. BLADE

FLANGES

C. CEILING

COVER

E. HANGER BALL/

DOWNROD ASSEMBLY

G. COUPLING

COVER

A. FAN MOTOR

ASSEMBLY

B. SWITCH HOUSING

ASSEMBLY

4

3

2

1

0

F. HANGER

BRACKET

H. WALL

CONTROL

4

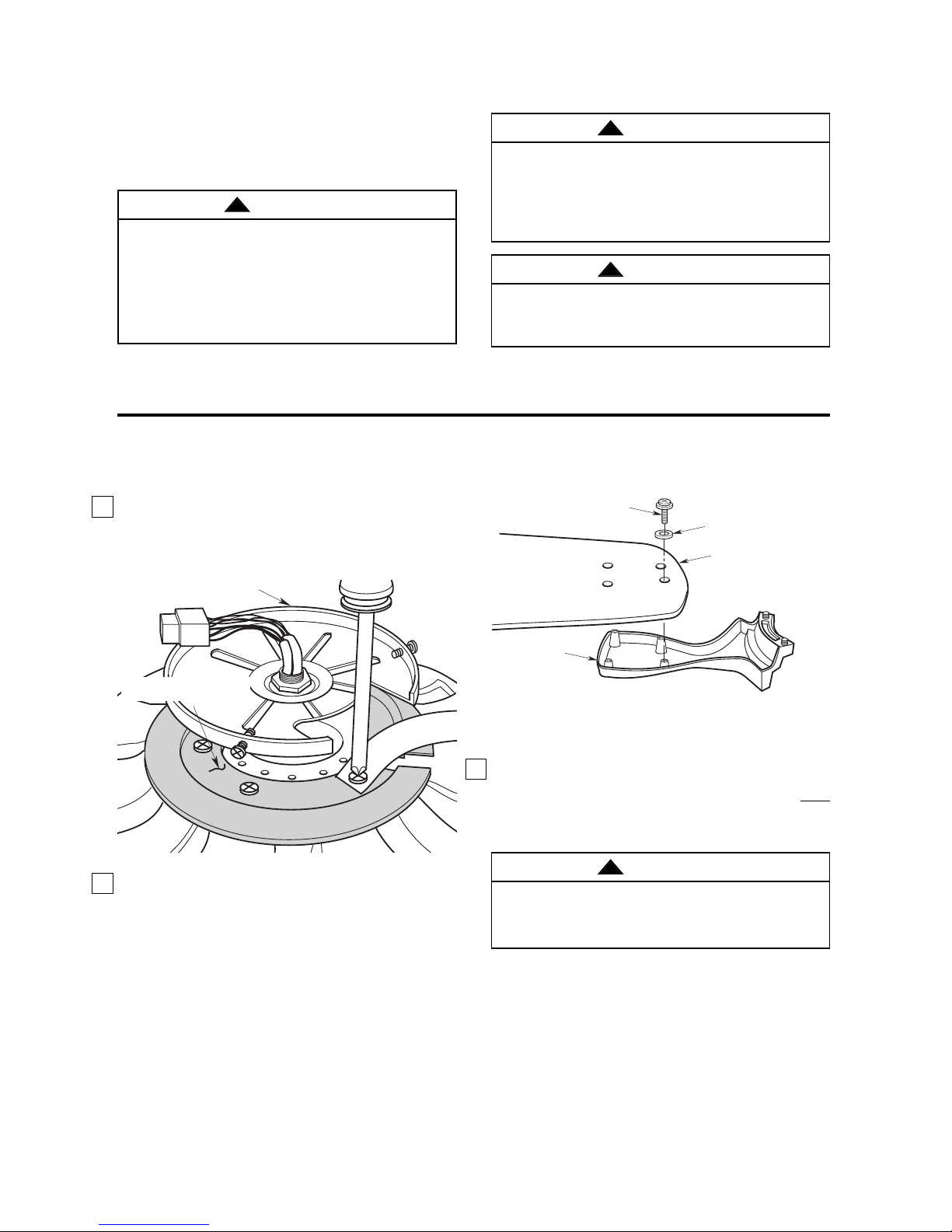

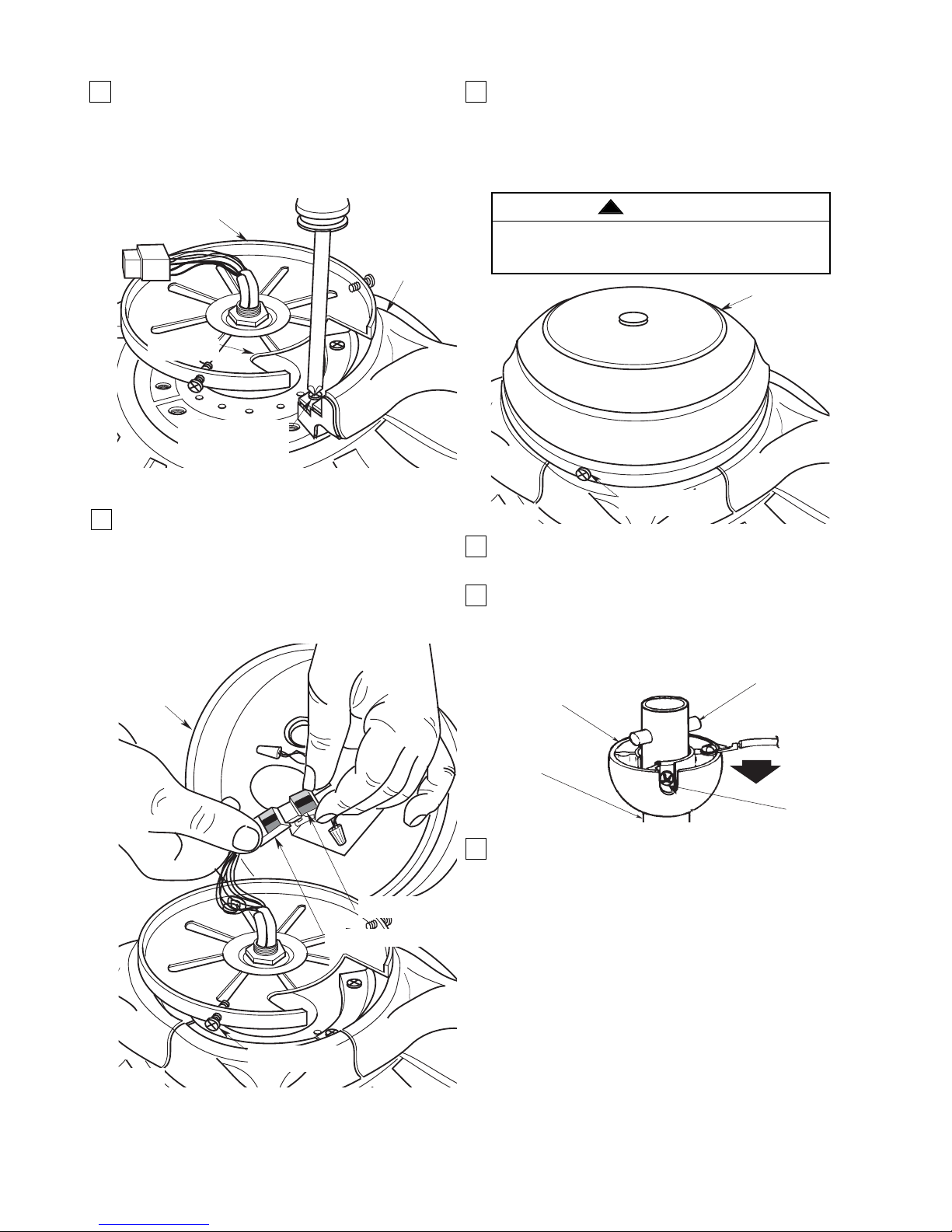

1. Rotate the motor hub to align the hub notch area

over each of the five screws which is holding the

shipping retainer to the motor assembly. One by

one unscrew each screw and discard screw and

shipping retainer (Figure 1).

To reduce the risk of personal injury, do not bend the

blade flange when installing the blade flanges,

balancing the blades or cleaning the fan. Do not

insert foreign objects in between rotating fan blades.

WARNING

!

Figure 2

Figure 1

2. Mount blade flanges (supplied with fan) to fan

blades (sold separately) using four M5 x 12mm

washer head blade screws and four 16mm flat

washers (supplied with fan) (Figure 2).

NOTE: Some accessory blades available are

supplied with shorter screws. These shorter

screws MUST be used to assemble the blades to

flanges.

3. Loosely attach one blade/flange assembly to the

motor hub by securing the two M6 x 14mm captive

pan head screws. Make sure the screws are NOT

tightened (Figure 3). Repeat this procedure for

other four blade assemblies.

How to Put Your Ceiling Fan Together

Electrical Requirements

If your fan is to replace an existing ceiling light fixture,

turn electricity off at the main fuse box at this time and

remove the existing light fixture.

Your new ceiling fan will require a grounded electrical

supply line of 120 volts AC, 60 Hz, 15 amp circuit.

The outlet box must be securely anchored and

capable of withstanding a load of at least 50 pounds.

To avoid fire or shock, follow all wiring instructions

carefully. Any electrical work not described in these

instructions should be done or approved by a

licensed electrician.

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is

turned off at the main fuse box before wiring. All

wiring must be in accordance with National and

Local codes and the ceiling fan must be properly

grounded as a precaution against possible electrical

shock.

WARNING

!

WARNING

!

To reduce the risk of fire, electrical shock, or

personal injury, mount fan to outlet box marked

“Acceptable for Fan Support of 50 lbs or less”, and

use screws supplied with outlet box. Most outlet

boxes commonly used for support of light fixtures

are not acceptable for fan support and may need to

be replaced. Consult a qualified electrician if

in doubt.

WARNING

!

U.L. Model No.: CF787

NOTE: Take care not to scratch fan housing when

installing blades.

MOTOR HUB

M5 x 12mm WASHER

HEAD BLADE SCREW

(4 per blade/flange)

BLADE FLANGE

FLAT WASHER 16 mm OD

(4 per blade/flange)

FAN BLADE

REMOVE SHIPPING RETAINER

BY REMOVING 5 SCREWS

a

P

r

e

b

i

t

b

a

l

u

l

a

R

t

s

e

p

n

o

v

I

S

o

e

s

r

m

o

o

o

e

L

f

L

r

R

e

r

a

!

r

a

B

i

t

E

i

T

d

u

T

r

Y

a

Q

O

e

c

!

N

J

s

A

i

a

T

D

l

a

O

b

N

m

E

d

n

A

s

t

n

u

o

M

g

n

i

k

a

r

a

c

P

a

.

n

m

o

i

c

o

a

.

l

a

G

t

n

s

e

n

o

I

D

a

L

s

e

e

t

D

r

s

o

e

t

n

A

s

5

Figure 4

4. The blade flanges have an interlocking feature that

must be fully engaged before tightening the screw.

Make sure all the flanges are properly engaged

and then tighten the flange screws. If one of the

flanges does not seat properly on the motor hub,

loosen the adjacent flange screws, re-engage and

reseat the flanges, then tighten the screws again.

Figure 3

5. Remove and retain the three switch housing

mounting screws (Figure 4) from the switch

housing plate. Engage the connector of the switch

housing assembly with the motor connector

(Figure 4). The two connectors are keyed and

color-coded and must be mated correctly (color-tocolor) before they can be engaged. Make sure the

connector latch closes properly.

8. Remove the hanger ball by loosening the setscrew

in the hanger ball until the ball falls freely down the

downrod (Figure 6). Remove the pin from the

downrod, then remove the hanger ball. Retain the

pin and hanger ball for reinstallation in Step 9.

9. Separate, untwist and unkink the three 80” motor

leads. Route the motor lead wires through the

downrod. Remove the upper setscrew from the

motor coupling. Align the clevis pin holes in the

downrod with the holes in the motor coupling.

Install the clevis pin and secure with the hairpin clip

(Figure 7). The clevis pin must go through the

holes in the motor coupling and the holes in the

downrod. Be sure to push the straight leg of the

hairpin clip through the hole near the end of the

clevis pin until the curved portion of the hairpin clip

snaps around the clevis pin. The hairpin clip must

be properly installed to prevent the clevis pin from

working loose. Pull on the downrod to make sure

the clevis pin is properly installed. Reinstall the

upper setscrew in the motor coupling. Check that

the lower setscrew is tightened securely (Figure 7).

Figure 5

To avoid possible fire or shock, do not pinch wires

between the switch cup assembly and the switch

cup plate.

WARNING

!

Figure 6

6. Position the switch housing assembly on the

switch housing plate and align the holes in the

switch housing assembly with the holes in the

plate. Secure the switch housing assembly by

installing the three M4 x 12mm flat head screws

(supplied) (Figure 5).

7. Carefully turn partially assembled fan upside down

and place in styrofoam form carton, in preparation

for final installation.

U.L. Model No.: CF787

MOTOR HUB

MOTOR HUB

NOTCHED AREA

M6 x 14mm CAPTIVE PAN

HEAD SCREW (2 per

blade/flange assembly)

BLADE/FLANGE

ASSEMBLY

M4 x 12mm FLAT HEAD

SCREW (3)

SWITCH HOUSING

ASSEMBLY

SWITCH HOUSING

ASSEMBLY

SWITCH HOUSING

CONNECTOR

MOTOR CONNECTOR

SWITCH HOUSING

MOUNTING SCREW (3)

HANGER

BALL

DOWNROD

PIN

SETSCREW

Loading...

Loading...