Page 1

READ AND SAVE THESE INSTRUCTIONS

CONTEMPORARY

™

IDEAL

54” Ceiling Fan Owner's Manual

Model Numbers

CF330BQ00 - Barbeque Black

CF330GRT00 - Graphite

CF330SW00 - Satin White

Net Weight: 15.8 Lbs.

Questions, problems, missing parts: Before returning to the store call

Emerson Electric Customer Service - 8 a.m. - 6 p.m., Eastern, Monday-Friday

• Español - página 29

1-800-654-3545

Part No. F40BP75220000 Form No. BP7522

Revision: 170215 ETL Model No.: CF330

www.emersonfans.com

• Français - page 57

Page 2

Table of Contents

Section Page

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

. Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2

3. Ceiling Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

4. How to Hang Your Ceiling Fan . . . . . . . . . . . . . . . . . . . . 10-11

5. How to Wire Your Ceiling Fan . . . . . . . . . . . . . . . . . . . . 12-13

6. Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

7. Wall Control Installation . . . . . . . . . . . . . . . . . . . . . . . . . 16-20

8. Programming the Receiver Operating Frequency &

High Speed Conditioning of Fan Control . . . . . . . . . . . . . 21

READ AND SAVE THESE INSTRUCTIONS

Safety Instructions

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK,

OR INJURY TO PERS O NS, OBSERVE TH E

FOLLOWING:

a. Use this unit only in a manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

b. Before servicing or cleaning unit, switch power off

at service pa nel and loc k service pan e l

disconnecting means to prevent power from being

switched on ac c identally . W hen the servic e

disconnecting means cannot be locked, securely

fasten a warning device, such as a tag, to the

service panel.

!

Section Page

9. Using Your Ceiling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

0. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1

11. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

12. Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-25

13. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

14. Energy Efficient Use of Ceiling Fans . . . . . . . . . . . . . . . . . 26

Ceiling Fan Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Spanish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

French . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4. The downrod furnished with the fan provides the

minimum recommended floor to fan blade clearance

for an 8 foot ceiling.

5. The fan must be mounted with the fan blades at least

7 feet from the floor to prevent accidental contact with

the fan blades.

6. Follow the recommended instructions for the proper

method of wiring your ceiling fan. If you do not know

enough about electrical wiring, have your fan installed

by a licensed electrician.

NOTE: This fan is suitable for use with solid-state speed

controls.

NOTE: All set screws must be checked and re-tightened

where necessary before installation.

1. Read your owner’s manual carefully and keep it for

future reference.

2. Be careful of the fan and blades when cleaning,

painting, or working near the fan. Always turn off the

power to the ceiling fan before servicing.

3. Do not put anything into the fan blades while they are

turning.

Additional Safety Instructions for Installation

1. To avoid possible shock, be sure electricity is turned

off at the fuse box before wiring, and do not operate

fan without blades.

2. All wiring must be in accordance with the National

Electrical Code “ANSI/NFPA 70-2014” and Local

Electrical Codes. Use the National Electrical Code if

Local Codes do not exist. The ceiling fan must be

grounded as a precaution against possible electrical

shock. Electrical installation should be made or

approved by a licensed electrician.

3. The outlet box and joist must be securely mounted and

capable of reliably supporting at least 50 pounds. Use

only U.L. outlet boxes listed as “Acceptable for Fan

Support of 22.7kg. (50 lbs.) or less”, and use the

mounting screws provided with the outlet box. Most

outlet boxes commonly used for support of light fixtures

are not acceptable for fan support and may need to be

replaced. Consult a qualified electrician if in doubt.

WARNING

To reduce the risk of electrical shock, this fan must be

installed with an isolating wall control/switch.

To reduce the risk of fire or electrical shock, this fan

should only be used with fan speed control, Model No.

FR-Y786N-01, manufactured by Rhine Electric Co., Ltd.

This product is designed to use only those parts

supplied with this product and/or any accessories

designated specifically for use this product by Emerson

Electric Co. Substitution of parts or accessories not

designated for use with this product by Emerson could

result in personal injury or property damage.

To reduce the risk of personal injury, do not bend the

blade flange when instal l ing the blade flan g es,

balancing the blades or cleaning the fan. Do not insert

foreign objects in between rotating fan blades..

!

ETL Model No.: CF330

2

Page 3

1. Unpacking Instructions

K

A

J

B

C

H

E

D

F

G

I

WARNING

Do not install or use fan if any part is damaged or

missing. Call Toll-Free:

!

1-800-654-3545

WARNING

This product is designed to use only those parts

supplied with this product and/or any accessories

designated specifically for use with this product by

Emerson El e ctric Co. S u bstitution of p a rts or

accessories not designated for use with this product

by Emerson Electric Co. could result in personal injury

or property damage.

!

1.1

Open ca r ton con t a ining f a n. Remo v e top ha l f of

styrofoam unit. Remove parts and check to see that you

have received the following parts:

NOTE: If you are uncertain of part description, refer

to exploded view illustration.

he hardware bags i

t

rom

o

t

re

part

s f

keep

i

m

s

ss

bef

hem

t

ng,

i

ore

bei

rom

f

1

l

l

a

c

proceedi

-

ng

8

ng.

.

ost

l

-

4

5

6

0-

0

N

sm

f

I

or

f

OTE

al

any

repl

P

:

cont

l

ace t

l

pa

acem

ai

rt

he part

ner

a

s

ent

PACKAGE CONTENTS

Part Description Quantity

A Fan Motor Assembly 1

B Hanger Bracket 1

C Hanger Ball / 4.5” Downrod 1

D Ceiling Cover 1

E Motor Coupler Cover 1

F LED Array 1

G Light Kit Housing Assembly 1

H Fan Blade Flanges 3

I Fan Blades 3

J Shade with Decorative Finial Nut 1

K Wall Control with Hardware 1

35

n a

4

5

HARDWARE BAG CONTENTS

Part Description Qty

1 Threaded Studs, #8-32 x 1-1/4” 2

2 Lockwashers, External Tooth, #8 2

3 Knurled Knobs, #8-32 2

4 Wire Connectors 5

5 Clevis Pin 1

6 Hairpin Clip 1

7 #8-32 x 1/4” Washer Head Screws 10

8 1/4-20 x 1/2” Oval Head Screws 7

9 #6-32 x 1/4” Tress Head Screws with Lockwashers 4

10 #6-32 x 3/8” Tress Head Screws with Lockwashers 1

11 Blade Balance Kit 1

1

4

2

7

3

5

11

6

10

98

emersonfans.com

Please contact 1-800-654-3545 for further assistance

3

ETL Model No.: CF330

Page 4

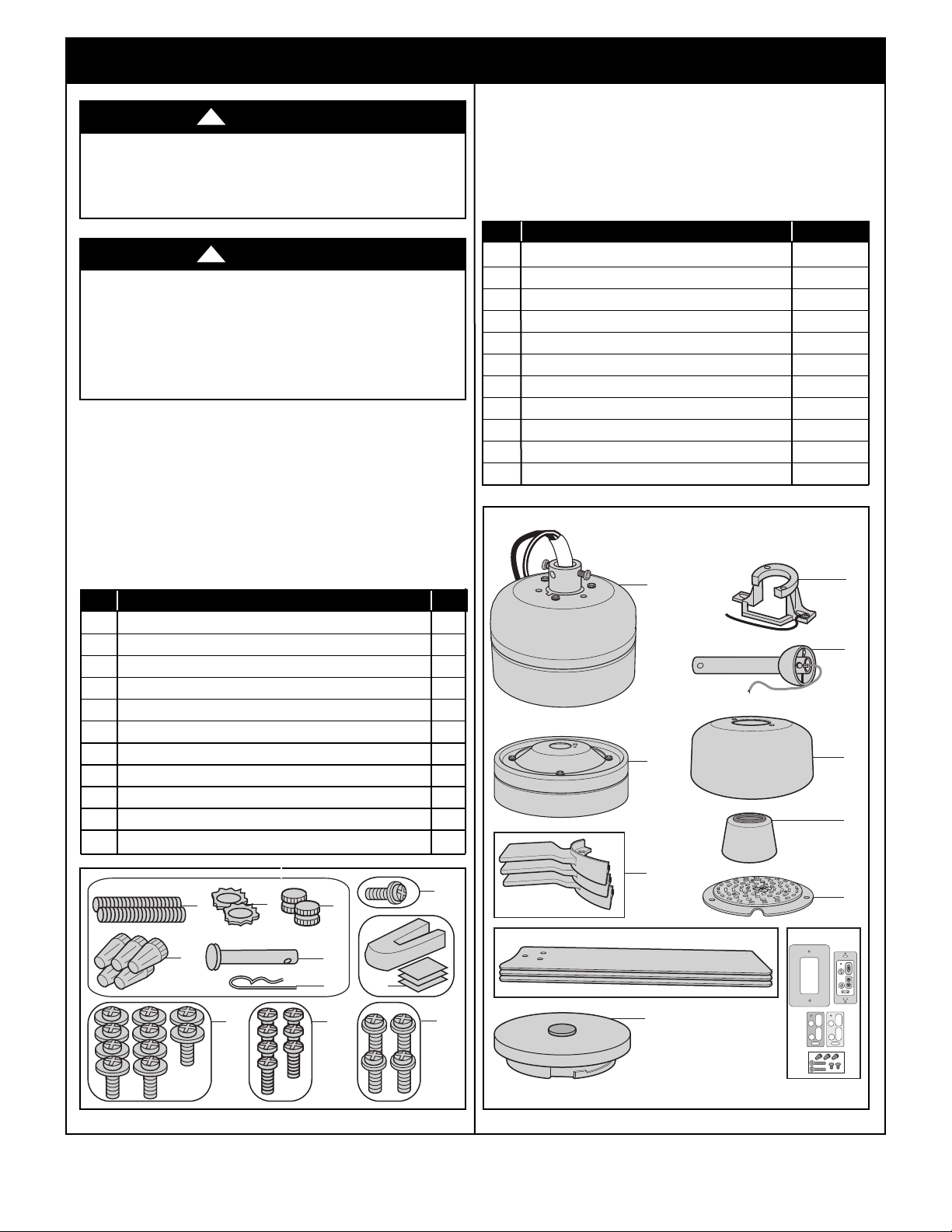

1. Unpacking Instructions (Continued)

This Manual Is Designed to Make it as Easy as Possible for You to Assemble,

Install, Operate and Maintain Your Ceiling Fan

Tools Needed for Assembly

One Phillips Head Screwdriver One Stepladder

One 1/4” Blade Screwdriver One Wire Stripper

Materials

Wiring outlet box and box connectors must be of type

required by the local code. The minimum wire would be

a 3-conductor (2-wire with ground) of following size:

Installed Wire Length Wire Size A.W.G.

Up to 50 ft. 14

50-100 ft. 12

2. Electrical Requirements

Your Emerson Ceiling Fan comes suppl ied wi th a

C Receiver and Fan Wall Control. This system allows

D

you to regulate your ceiling fan speed and light control.

This Emerson Ceiling Fan m a y b e u s e d with the

following accessory (purchased separately): SR600

Remote Control.

WARNING

Before assembling your ceiling fan, refer to section on

proper method of wiring your fan (page 12). If you feel

you do not hav e enough wirin g knowledge or

experience, have your fan installed by a licensed

electrician.

!

Your new ceiling fan will require a grounded electrical

supply line of 120 volts AC, 60 Hz, 15 amp circuit.

WARNING

To reduce the risk of fire, electric shock, or personal

injury, mount fan to outlet box marked “Acceptable for

Fan Support of 22.7kg. (50 lbs.) or less”, and use

screws supplied with outlet box. Most outlet boxes

commonly used for support of light fixtures are not

acceptable for fan support and may need to be

replaced. Consult a qualified electrician if in doubt.

WARNING

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is turned

off at the main fuse box before wiring. All wiring must

be in accordance with National and Local codes and

the c e iling f an m u s t be properly grounded as a

precaution against possible electrical shock.

!

!

The outlet box must be securely anchored and capable

of withstanding a load of at least 50 pounds.

If your fan is to replace an existing ceiling light fixture,

turn electricity off at the main fuse box at this time and

remove the existing light fixture.

WARNING

To avoid fire or shock, follow all wiring instructions

carefully.

Any electrical wor k n o t d e scribed in these

instructions should be done or approved by a licensed

electrician.

Plea s e cal l Eme r son t e chni c al s u ppor t at

1-8 0 0 - 6 5 4 - 3545 if you have any questions about

installation and operation of this ceiling fan.

!

ETL Model No.: CF330

4

Page 5

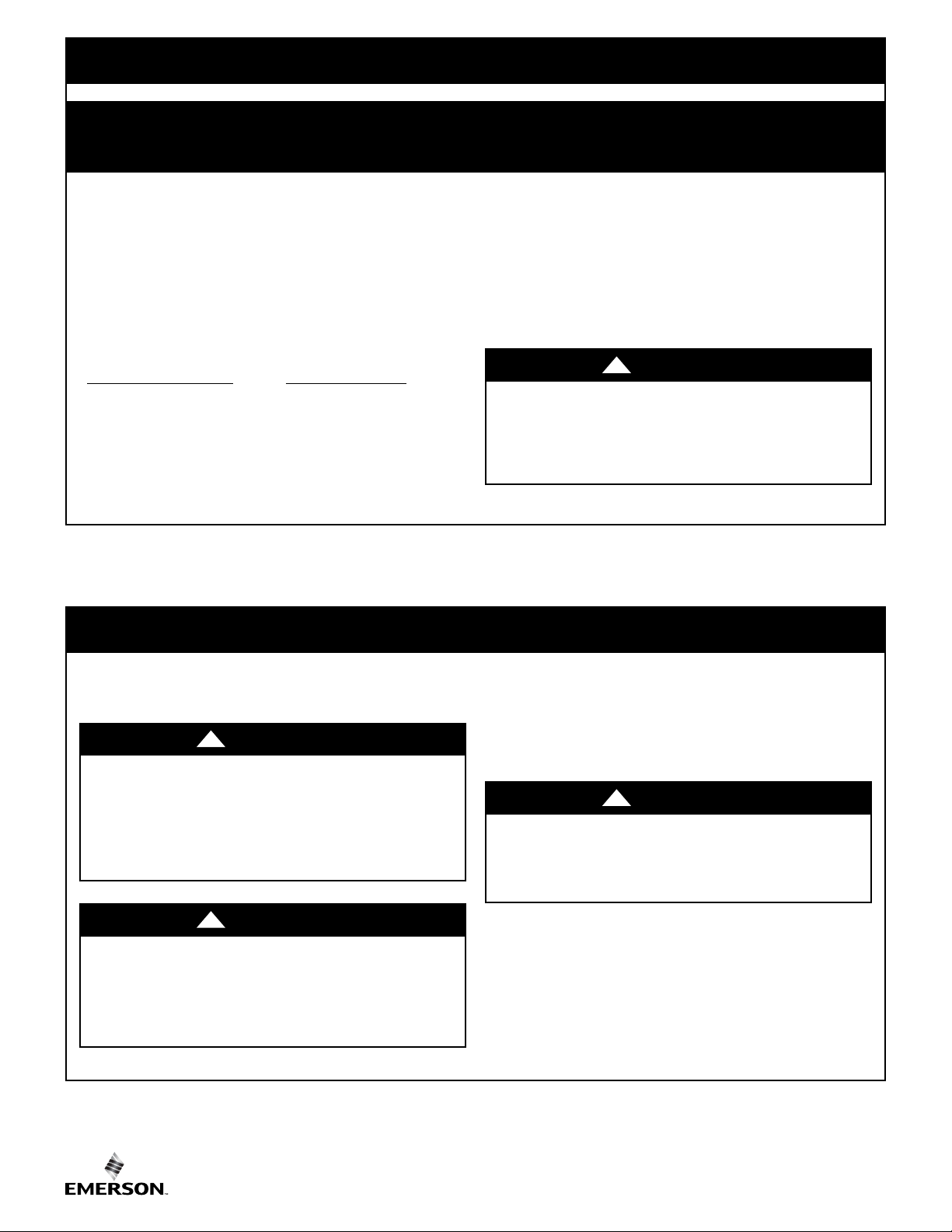

3. Ceiling Fan Assembly

SHIPPING

RETAINERS (3)

M

OTOR HUB

M

OTOR HOUSING

#8-32 x 1/4" WASHER HEAD

SCREWS (3 per blade)

FAN BLADE (3 per fan)

BLADE

FLANGE

(3 per fan)

THIS SIDE UP

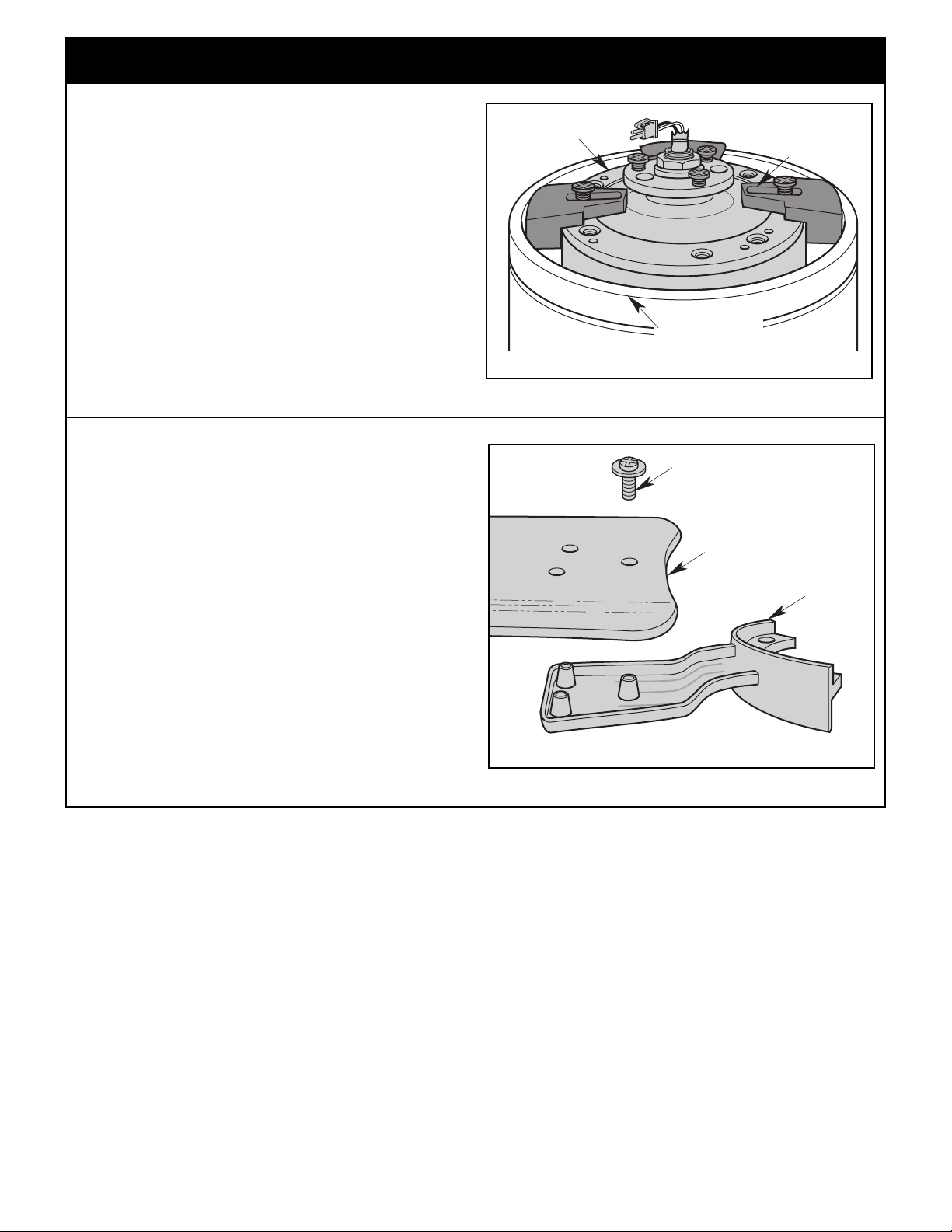

3.1

lip the upper foam pad over and place on a stable

F

working surface.

Remove the fan motor assembly from the protective

lastic bag.

p

Place fan motor assembly on top of the foam pad with

the upper motor cover supporting the weight of the

motor.

Remove and discard the three Shipping Retainers

securing the Motor Hub in the Motor Housing (Figure 1).

This will permit access for the blades to be installed.

3.2

Place the Fan Blade onto the Blade Flange, as shown.

NOTE: The blade must be installed with the blade

markings “THIS SIDE UP” facing up.

Figure 1

Mount the Fan Blade onto the Blade Flange using three

#8-32 x 1/4” Washer Head Screws (supplied) (Figure 2).

Repeat for all three blade/flange sets.

Figure 2

emersonfans.com

Please contact 1-800-654-3545 for further assistance

5

ETL Model No.: CF330

Page 6

3. Ceiling Fan Assembly (Continued)

LIGHT KIT HOUSING

ASSEMBLY

#6-32 x 3/8" TRESS

HEAD SCREW WITH

LOCKWASHER

ROTATE CLOCKWISE

MOTOR HUB

B

LADE FLANGE ASSEMBLY

1/4-20 x 1/2" OVAL HEAD SCREWS

(2 per assembly)

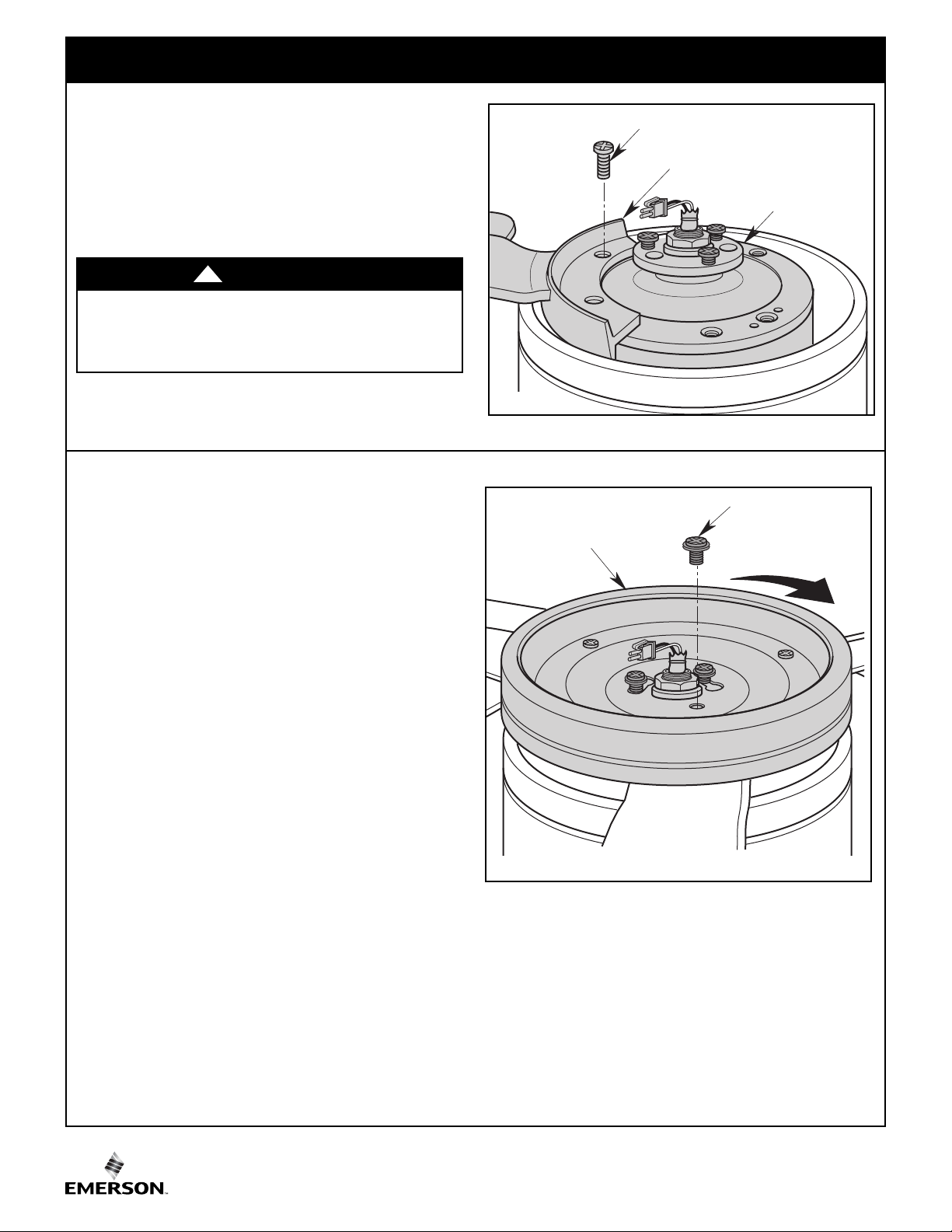

3.3

NOTE: Take care not to scratch the fan housing

hen installing the blade assemblies.

w

Attach the Blade Flange Assembly onto the Fan Motor/

ub by tightening the 1/4-20 x 1/2” Oval Head Screws

H

securely (Figure 3).

WARNING

To reduce the risk of personal injury, do not bend the

blade flange when instal l ing the blade fla n g es,

balancing the blades or cleaning the fan. Do not insert

foreign objects in between rotating fan blades.

!

3.4

Remove one of the three #6-32 x 3/8” Tress Head

Screw with Lockwasher from the Motor Assembly Hub,

retain the screw for future use.

Loosen the remaining two #6-32 x 3/8” Tress Head

Screws with Lockwashers.

Place the 2-pin motor assembly connector through the

large center hole of the Light Kit Housing Assembly

(Figure 4).

Position the Light Kit Housing Assembly key hole slots

onto the two loosened screw heads. Rotate the Light Kit

Housing Assembly clockwise to engage the two screws.

Verify that the serrated washers are not trapped

between the Light Kit Housing Assembly and the Motor

Assembly Hub.

Figure 3

Reinstall the previously removed #6-32 x 3/8” Tress

Head Screw with Lockwasher (Figure 4).

Retighten all three #6-32 x 3/8” Tress Head Screws with

Lockwashers to securely attach the Light Kit Housing

Assembly to the Motor Assembly Hub (Figure 4).

A spare #6-32 x 3/8” Tress Head Screw with Lockwasher

is in the hardware bag, if needed.

Carefully turn the partially assembled ceiling fan right

side up and position the fan on the styrofoam in

preparation for additional assembly.

ETL Model No.: CF330

Figure 4

6

Page 7

PHILLIPS HEAD SET SCREW

(LOOSENED)

H

ANGER BALL

4.5" DOWNROD

PIN

GREEN GROUND WIRE

TWO 80" MOTOR WIRES (UNTWISTED)

4.5" DOWNROD

MOTOR

COUPLER

4.5"

DOWNROD

LOOSEN

PHILLIPS HEAD

SET SCREWS (2)

3. Ceiling Fan Assembly (Continued)

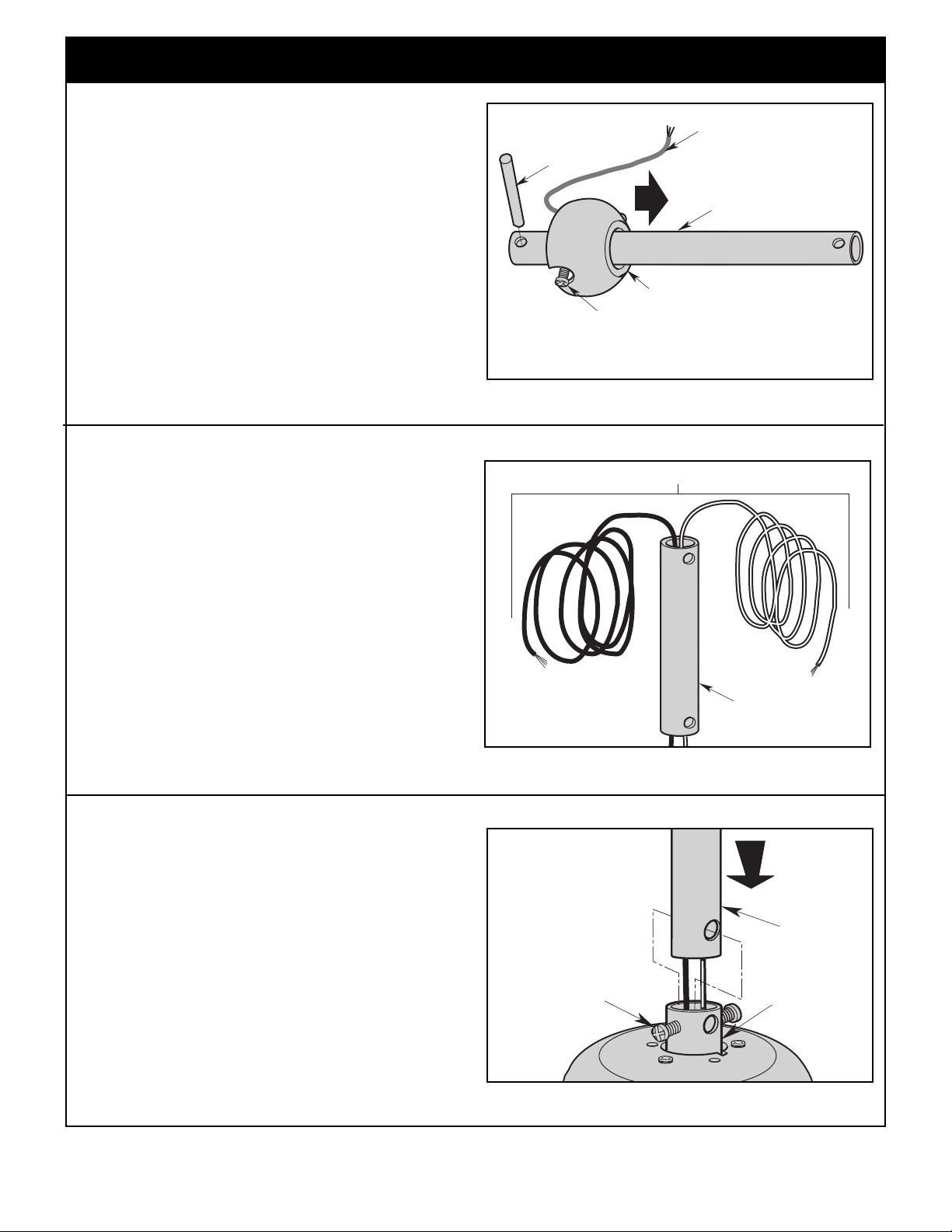

3.5

Remove the Hanger Ball by loosening the Phillips Head

Set Screw in the Hanger Ball until the Ball falls freely

down the 4.5” Downrod (Figure 5).

Remove the Pin from the 4.5” Downrod, then remove the

Hanger Ball (Figure 5).

Retain the Pin and Hanger Ball for reinstallation in

Step 3.11.

Note: Do not loosen the screw that attaches the

green ground wire to the hanger ball.

3.6

Separate, untwist and unkink the two 80” Motor Wires.

Figure 5

Route the two Motor Wires through the 4.5” Downrod

(Figure 6).

3.7

Loosen the two Phillips Head Set Screws in the Motor

Coupler for installation of the Downrod (Figure 7).

Seat the Downrod in the Motor Coupler (Figure 7).

Rotate and align the Downrod holes with all the holes in

the Motor Coupler (Figure 7).

Figure 6

7

Figure 7

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 8

3. Ceiling Fan Assembly (Continued)

DOWNROD

CEILING

COVER

GROMMET

MOTOR

COUPLER

COVER

MOTOR

HOUSING

DOWNROD

HAIRPIN

CLIP

CLEVIS

PIN

MOTOR

COUPLER

C

LEVIS

PIN

HAIRPIN

CLIP

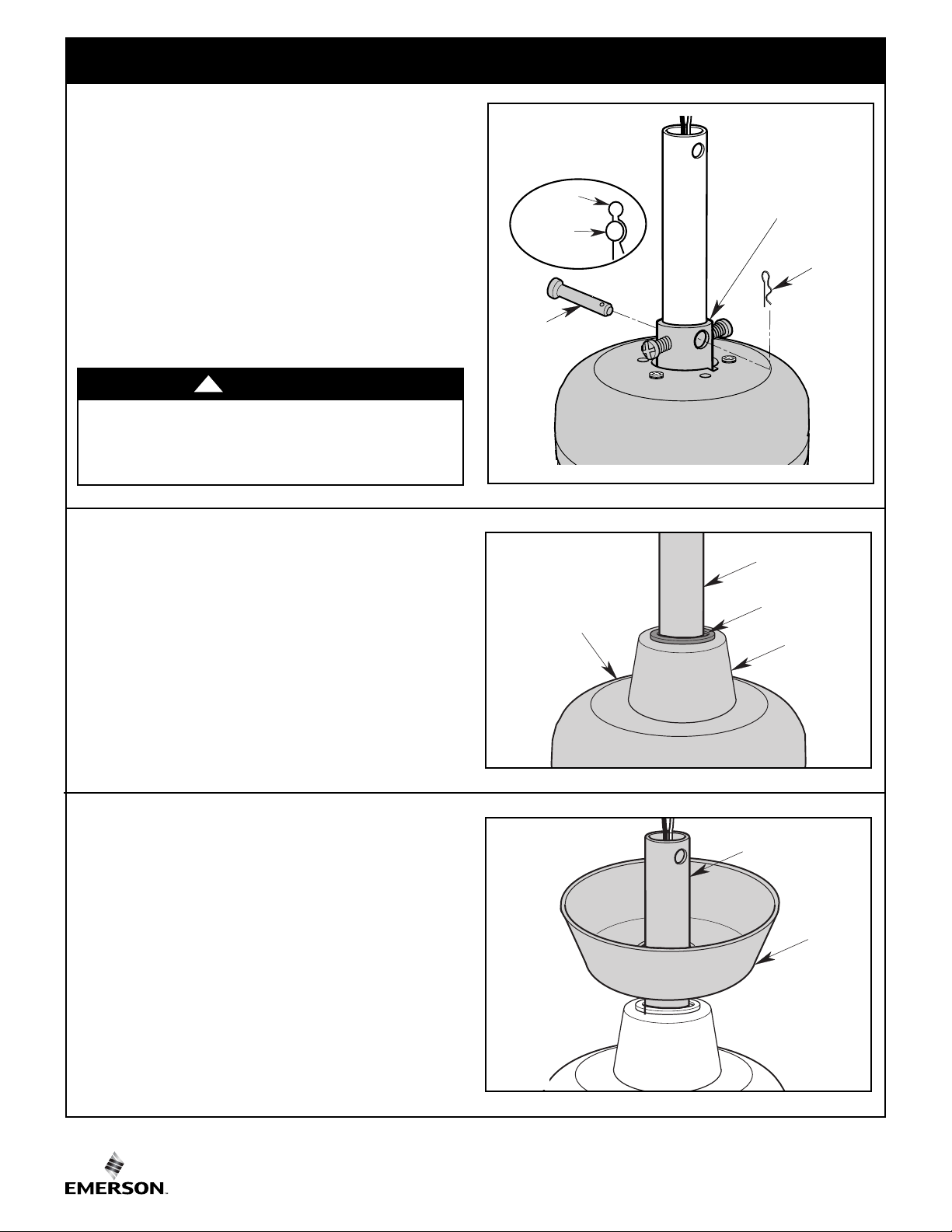

3.8

Align the Clevis Pin holes in the Downrod with the holes

in the Motor Coupler.

Install the Clevis Pin and secure with the Hairpin Clip

(Figure 8).

The Clevis Pin must go through the holes in the Motor

Coupler. It is critical that the Clevis Pin in the Motor

Coupler is properly installed and securely tightened.

Evenly retighten the two Phillips Head Set Screws to

secure the Downrod to the Motor Coupler in a vertical

position (Figure 8).

WARNING

It is critical that the clevis pin and set screws in the

motor coupler are properly installed and securely

tightened. Failure to verify that the pin and set screws

are properly installed could result in the fan falling.

!

3.9

Make sure the Grommet is properly installed in the Motor

Coupler Cover, then slide the Motor Coupler Cover on the

Downrod until it rests on the Motor Housing (Figure 9).

3.10

Place the Ceiling Cover over the Downrod (Figure 10).

Figure 8

Figure 9

Be sure that the Ceiling Cover and the Motor Coupler

Cover are both oriented correctly (Figure 10).

ETL Model No.: CF330

Figure 10

8

Page 9

PIN

HANGER BALL

P

HILLIPS HEAD

SET SCREW

DOWNROD

3. Ceiling Fan Assembly (Continued)

6 TO 9

INCHES

HANGER BALL

WHITE WIRE

BLACK WIRE

1/2-INCH

3.11

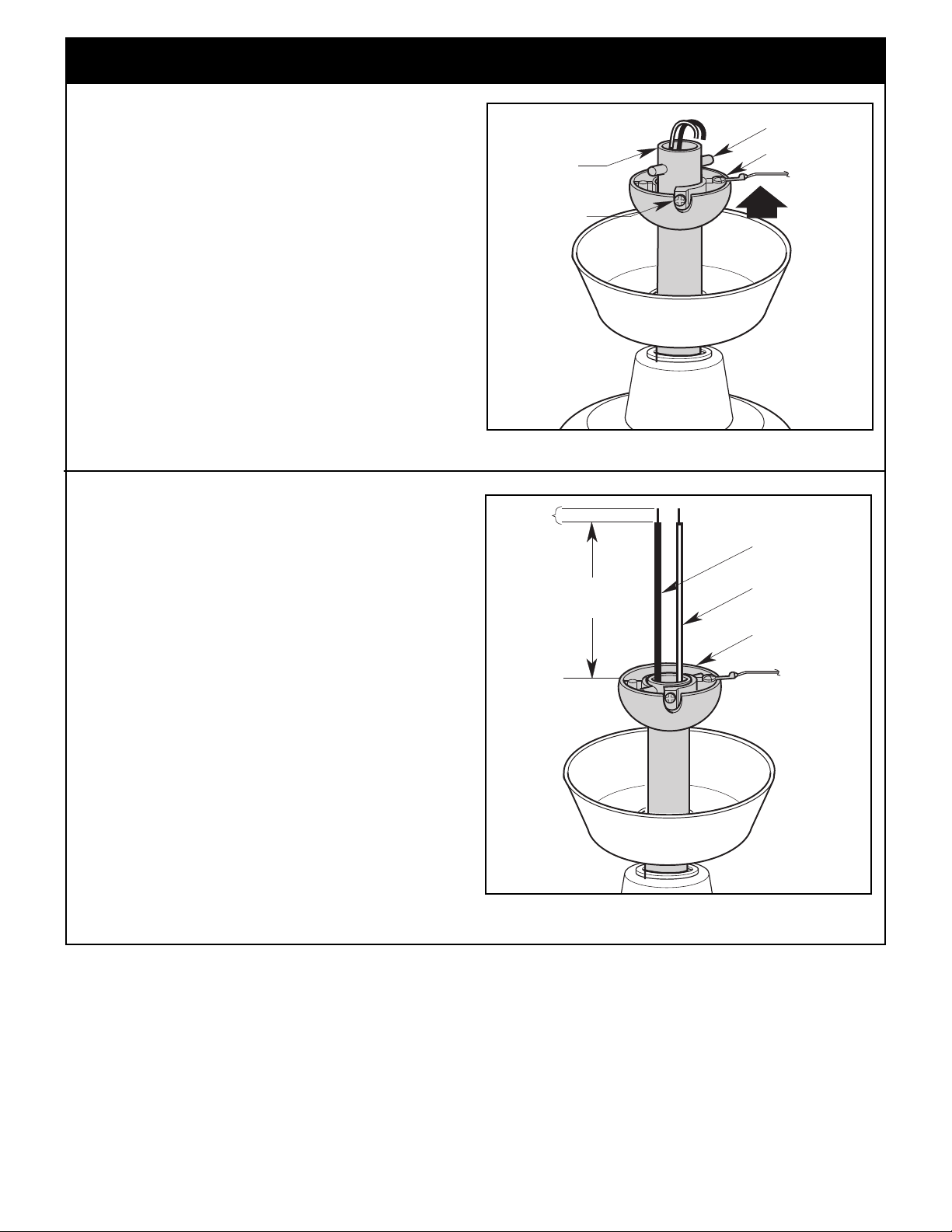

Route the two 80” Motor Wires through the Hanger Ball

(Figure 11).

Reinstall the Hanger Ball on the Downrod as follows:

Position the Pin through the two holes in the Downrod

and align the Hanger Ball so the Pin is captured in the

groove in the top of the Hanger Ball (Figure 11).

Pu l l the Hanger Ba ll up tight aga i nst the Pin and

securely tighten the Phillips Set Screw in the Hanger

Ball (Figure 11).

Loose set screw could create fan wobble.

3.12

The fan comes with Black and White Wires that are

80-inches long.

Figure 11

Measure up approximately 6 to 9-inches above top of

Hanger Ball / 4.5” Downrod Assembly (Figure 12).

Cut off excess wires and strip back insulation 1/2-inch

from end of wires.

You have now partially completed the assembly of your

new ceiling fan, proceed to How to Hang Your Ceiling

Fan. Final Assembly of the ceiling fan will be completed

once ceiling fan is hung and wired.

Figure 12

emersonfans.com

9

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 10

FLOOR

CEILING

AT

L

EAST

7'

4. How to Hang Your Ceiling Fan

WARNING

The fan must be hung with at least 7' of clearance from

floor to blades (Figure 13).

WARNING

To avoid possible electrical shock, be sure electricity

is turned off at the main fuse box before wiring.

NOTE: If you are not sure if the outlet box is grounded,

ontact a licensed electrician for advice, as it must be

c

grounded for safe operation.

WARNING

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is turned

off at the main fuse box before wiring. All wiring must

be in accordance with National and Local codes and

the c e iling f an m u s t be properly grounded as a

precaution against possible electrical shock.

!

!

!

4.1

Disconnect electrical power to the branch circuit at the

Circuit Breaker or Fuse Box before attempting to install

the Ceiling Fan on the Outlet Box.

Figure 13

WARNING

To avoid fire or shock, follow all wiring instructions

carefully.

Any electrical wor k n o t d e scribed in these

instructions should be done or approved by a licensed

electrician.

!

ETL Model No.: CF330

10

Page 11

4. How to Hang Your Ceiling Fan (Continued)

OUTLET

BOX

HANGER

BRACKET

HANGER BALL/

DOWNROD

ASSEMBLY

NOTE: CEILING COVER, SUPPLY WIRES AND FAN WIRES

OMITTED FOR CLARITY.

HANGER BRACKET

HANGER BALL

HANGER BALL

GROOVE

ANTI-ROTATION

TA B

TWO SCREWS

SUPPLIED WITH

OUTLET BOX

HANGER BRACKET

ANTI-ROTATION TAB

OUTLET BOX

WARNING

The outlet box and joist must be securely mounted and

capable of supporting at least 50 lbs. Use only a U.L.

utlet box listed as “Acceptable for Fan Support of

o

22.7 kg. (50 lbs.) or less”.

WARNING

To reduce the risk of fire, electric shock, or personal

injury, mount fan to outlet box marked “Acceptable for

Fan Support of 22.7 kg. (50 lbs.) or less”, and use

screws supplied with outlet box. Most outlet boxes

commonly used for support of light fixtures are not

acceptable for fan support and may need to be

replaced. Consult a qualified electrician if in doubt.

!

!

4.2

Securely attach the Hanger Bracket to the Outlet Box

using the two screws supplied with the Outlet Box.

(Figure 14).

Figure 14

WARNING

Hanger bracket must seat firmly against outlet box. If

the outlet box is recessed, remove wall board until

bracket contacts box. If bracket and/or outlet box are

not securely attached, the fan could wobble or fall.

!

4.3

Carefully lift the partially assembled ceiling fan and seat

the Hanger Ball / Downrod Assembly into the Hanger

Br acket that was just at tached to the Outle t B ox

(Figure 15).

Be sure the Groove in the Ball is engaged with the

Anti-rotation Tab on the Hanger Bracket (Figure 15).

NOTE: Be very careful not to bend the blade

assemblies while hanging the partially assembled

ceiling fan.

WARNING

Failure

groove could

possible

o s

t

shock

WARNING

To avoid possible fire or shock, do not pinch wires

be t ween the hanger ball/ d ownrod assembly a nd

hanger bracket.

!

i-rotation t

nt

a

eat the

cause damage t

ire haz

or f

!

ab int

o elect

ard.

he hanger ball

o t

rical wires and

Figure 15

11

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 12

5. How to Wire Your Ceiling Fan

G

ROUND

CONDUCTOR SUPPLY

LISTED WIRE

CONNECTOR

GREEN WIRE

(GROUND) FROM

HANGER BRACKET

G

REEN WIRE

(GROUND) FROM

H

ANGER BALL

If you feel that you do not have enough electrical

wiring knowledge or experience, have your fan

installed by a licensed electrician.

WARNING

To avoid possible electrical shock, be sure electricity

is turned off at the main fuse box before wiring.

NOTE: If you are not sure if the outlet box is grounded,

contact a licensed electrician for advice, as it must be

grounded for safe operation.

WARNING

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is turned

off at the main fuse box before wiring. All wiring must

be in accordance with National and Local codes and

the c e iling f an m u s t be properly grounded as a

precaution against possible electrical shock.

!

!

5.1

Connect the Green Ground Wire from the Hanger Ball

and the Green Ground Wire from the Hanger Bracket to

the Ground Conductor of Supply (this may be a bare

wire or wire with green colored insulation). Securely

conn e ct Wi r es wi t h Wir e Conn e ctor s (sup p lied )

(Figure 16).

Figure 16

WARNING

This product is designed to use only those parts

supplied with this product and/or any accessories

designated specifically for use with this product by

Emerson El e ctric Co. S u bstitution of p a rts or

accessories not designated for use with this product

by Emerson Electric Co. could result in personal injury

or property damage.

ETL Model No.: CF330

!

12

Page 13

5. How to Wire Your Ceiling Fan (Continued)

FAN MOTOR

BLACK WIRE

SUPPLY

BLACK

(HOT)

LISTED WIRE

CONNECTOR

BLACK WIRES

WHITE WIRES

GREEN

WIRES

LISTED WIRE

CONNECTOR

SUPPLY WHITE

(NEUTRAL)

FAN MOTOR

WHITE WIRE

5.2

Securely connect the Fan Motor White Wire to the

Supply White (neutral) Wire using Wire Connector

supplied) (Figure 17).

(

5.3

Securely connect the Fan Motor Black Wire to the

Supp l y Bl a c k (h o t) Wi r e us i ng Wi r e Co n nect o r

(supplied) (Figure 18).

Figure 17

5.4

After connections have been made, turn Wires upward

and carefully push Wires into the Outlet Box, with the

White and Green Wires on one side of the Outlet Box

and position the Black Wires on the other side of the

Outlet Box (Figure 19).

WARNING

Check to see that all connections are tight, including

ground, and that no bare wire is visible at the wire

connectors, except for the ground wire. Do not

operate fan until blades are in place. Noise and fan

damage could result.

!

13

Figure 18

Figure 19

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 14

6. Final Assembly

#6-32 x 1/4" TRESS

HEAD SCREWS WITH

LOCKWASHERS (3)

LED ARR AY

LIGHT KIT HOUSING

ASSEMBLY

LED ARR AY

2-PIN WIRE CONNECTOR

FAN MOTOR

2-PIN WIRE CONNECTOR

LED ARR AY

SHADE

SHADE FLAT

AREA (3)

LIGHT KIT

HOUSING

ASSEMBLY

DIMPLES (3)

ROTATE

CLOCKWISE

6.1

ngage the Fan Motor 2-Pin Wire Connector into the

E

2-pin Wire Connector of the LED Array (Figure 20).

he connection is complete when you hear a soft click.

T

6.2

Carefully tuck all the wires and connectors into the Light

Kit Housing Assembly.

Position the LED Array onto the Light Kit Housing

Assembly, aligning the three holes.

Figure 20

NOTE: Verify that the wires and connectors are not

trapped between the LED Array and the Light Kit

Housing Assembly.

Install and tighten the three #6-32 x 1/4” Tress Head

Screws with Lockwashers (Figure 21) for assembly of

the LED Array.

WARNING

To avoid possible fire or shock, do not pinch wires

between the Light Kit Housing Assembly and the

LED Array.

!

6.3

Place the Shade i nto the opening of the Light Kit

Housing Assembly, aligning the three flat areas on the

top edge of the Shade with the three raised dimples on

the Light Kit Housing Assembly and turn the Shade

clockwise until it stops (Figure 22).

NOTE: Periodically check that the shade is seated

fully clockwise in the Light Kit Housing Assembly.

Figure 21

ETL Model No.: CF330

Figure 22

14

Page 15

6. Final Assembly (Continued)

CEILING

COVER

LOCKWASHERS (2)

THREADED

STUDS (2)

KNURLED

KNOBS (2)

THREADED

STUDS (2)

HANGER

BRACKET

H

OLES (2)

6.4

Screw the two Threaded Studs (supplied) into the

tapped holes in the Hanger Bracket (Figure 23).

6.5

Lift the Ceiling Cover up to the Threaded Studs and

turn until studs protrude through the holes in the Ceiling

Cover (Figure 24).

Figure 23

Secu r e the C eili n g Cov e r in p l ace b y slid i ng

Lockwashers (supplied) over the Threaded Studs and

installing the two Knurled Knobs (supplied). (Figure 24).

Tighten the Knurled Knobs securely until the Ceiling

Cover fits snugly against the ceiling and the hole in the

Ceiling Cover is clear of the downrod.

WARNING

To avoid possible fire or shock, make sure that the

electrical wires are completely inside the outlet box and

not pinched between the ceiling cover and the ceiling.

!

You have now completed the complete assembly of

your new ceiling fan.

Plea s e ca ll Emers o n te chni c al supp o rt at

1-80 0 -654 - 354 5 if you h a ve an y ques t ions

about installation and operation of this ceiling fan.

Figure 24

15

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 16

7. Wall Control Installation

WALL CONTROL

CODE SWITCHES

1 - 5

O

N

1

234

5I

DIMMING

SWITCH

I

CODE

SWITCHES

WALL

CONTROL

7.1

Your Emerson Ceiling Fan/Light Control consists of wall

mounted transmitter and a receiver located inside the

motor assembly. The control is designed to remotely

operate your ceiling fan speed, light intensity and

irection of rotation.

d

Code s wit c hes i n the t ran s mitt e r ma y be s e t in

32 different positions. If your fan and light turn on and

off without using your control, you may be getting

interference from other remote units such as garage

door open e rs, car al arms or se c urit y sys t ems.

To remedy this situations, simply change the code

switches in your transmitter per the instructions of

Section 7.3.

7.3

Your wall control has code switches which must be set

in one of 32 possible code combinations (Figure 25).

The five levers (numbered 1, 2, 3, 4, and 5) on the

sw i t ches are factory-se t i n the ON (up) positi o n .

Change the switch settings as follows:

7.2

Preset Memory Feature: Your Emerson receiver is

quipped with a preset memory feature. If the AC

e

supply to the receiver is powered OFF through a wall

switch, the control will remember the light intensity and

fan speed. When the switch is turned back ON the light

and fan will resume operation as they were prior to the

switch being turned OFF.

Slide the five switch levers in the wall control to your

choice of ON (up) or down positions. Use a ball-point

pen or small screwdriver and slide the levers firmly up

or down.

The sixth switch marked ON and I is for dimming

control of lights: Set switch to ON to allow for dimming

of the lighting. Set switch to I for no dimming of the

lighting.

WARNING

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is turned

off at the main fuse or circuit breaker box before

wiring. All wiring must be in accordance with National

and Local codes and the ceiling fan must be properly

grounded as a precaution against possible electrical

shock.

!

CAUTION:

To reduce the ris k of electrical shock ,

disconnect the electrical supply circuit before

installing the fan, light kit or receiver.

Figure 25

NOTE: Make all wiring connections using wire

connectors (supp lied). Make sure that all

connections are tight, including ground, and that no

bare wire is visible at the wire connectors, except

for the ground wire.

7.4

Disconnect electrical power to the branch circuit at the

circuit breaker or fuse box before attempting to install

the ceiling fan wall control into the outlet box.

ETL Model No.: CF330

16

Page 17

T

O

P

O

W

E

R

S

U

P

P

LY

SW406 FAN/LIGHT

WALL CONTROL

WALL

BOX

B

L

A

C

K

BLACK

H

O

T

NEUTRAL

WIRES

DECORATIVE WALL PLATE

SCREWS (2)

SWITCH COVER

G

R

E

E

N

G

R

O

U

N

D

T

O

F

AN

T

O

1

2

0

V

A

C

S

O

U

R

C

E

T

O

L

O

A

D

GROUND

FACEPLATE

WALL

SWITCH

O

UTLET

BOX

SCREWS

7. Wall Control Installation (Continued)

7.5

This control is designed to operate only one ceiling fan

NOTE: Elect ric connec tions should be i n

ccordance with the National Electrical Codes and

a

all Local Codes. Before starting, disconnect power

to the circuit at the fuse box or circuit breaker

panel.

Remove the Faceplate and Screws from the Existing

Wall Switch. Pull Switch out from Wall Outlet Box.

De termine t he “hot” w ire and the “load” wi re and

disc o nnec t thes e wire s from e x isti n g con t rol

(Figure 26).

Do not attempt to disconnect any wires not already

connected to existing control.

Figure 26

Skip to Section 7.7 if using a 3-way switch

installation.

SINGLE-POLE INSTALLATION

7.6

Disconnect electrical power to the branch circuit at the

Circuit Breaker or Fuse Box before attempting to install

the Ceiling Fan Wall Control into the Outlet Box.

Before installing Wall Control, place Wall Control in

“OFF” mode by pushing “ON/OFF” Switch to the “OFF”

position.

WARNING

Do not connect any neutral (white) wire to this control.

Incorrect wiring will damage this control.

Connect the Wall Control Black Wire with the Yellow

Label marked “To Power Supply” to the “Hot” Wire in

the Wa l l B ox. Se c urel y c o nnec t W i res wi t h

Wire Connector (supplied) (Figure 27).

Connect the Wall Control Black Wire with Blue Label

marked “To Fan” to the “Load” (Black) Wire in the Wall

Box. Securely connect Wires with Wire Connector

(supplied) (Figure 27).

Connect the Wall Control Green Ground Wire to the

Bare Copper Wire or Green Ground Wire in the Wall

Box. Securely connect Wires with Wire Connector

(supplied) (Figure 27).

!

WARNING

!

Check to see that all connections are tight and that no

bare wires are visible at the wire connectors.

Screw Wall Control into Wall Box using the supplied

screws. Leave Wall Control in “OFF” mode until fan

installation is completed.

The Wall Control is supplied with a White, Ivory, and

Almond color Switch Covers. Choose the finish that

best suits your needs and snap the Cover onto the Wall

Control (Figure 27).

Install Decorator Wall Plate using the two screws

provided with Wall Plate. Leave Wall Control in “OFF”

mode until fan installation is completed (Figure 27).

Figure 27

emersonfans.com

17

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 18

7. Wall Control Installation (Continued)

FAN/L IG HT

HOT BLK

NEUTRAL

BLACK

GROUND

LOAD

BLACK

GROUND

SINGLE-POLE INSTALLATION

(One fan controlled by one wall control)

(See Figure 28).

Figure 28

WARNING

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is turned

off at the main fuse or circuit breaker box before

wiring. All wiring must be in accordance with National

and Local codes and the ceiling fan must be properly

grounded as a precaution against possible electrical

hock.

s

WARNING

Do not connect any neutral (white) wire to this control.

Incorrect wiring will damage this control.

WARNING

Check to see that all connections are tight and that no

bare wires are visible at the wire connectors.

!

!

!

ETL Model No.: CF330

18

Page 19

7. Wall Control Installation (Continued)

HOT

BLACK

F

AN/LIGHT

W

ALL

C

ONTROL

TRAVELER

WIRE

BLK

BLK

LOAD

GROUND

NEUTRAL

BLACK

BLK

GROUND

G

ROUND

SECONDWALL

CONTROL

PURCHASE

SEPARATELY

3-WAY INSTALLATION

One fan controlled by two different wall controls)

(

(See Figures 29 and 30).

WARNING

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is turned

off at the main fuse or circuit breaker box before

wiring. All wiring must be in accordance with National

and Local codes and the ceiling fan must be properly

rounded as a precaution against possible electrical

g

shock.

!

7.7

Disconnect electrical power to the branch circuit at the

circuit breaker or fuse box before attempting to install

the ceiling fan Wall Control into the Outlet Box.

At all wall box locations remove faceplates and screws

from existing controls. Pull controls out from wall boxes

and determine which wall box contains the “Hot” Wire

and w hich wal l box cont a ins the “ Load ” Wi r e.

Also, identify traveler wires which are common to both

wall boxes. Disconnect wires from existing controls only.

Do not attempt to disconnect any wires not already

connected to existing controls.

Before installing the Wall Control, place the Wall Control

in “OFF” mode by pushing “ON/OFF” switch to the

“OFF” position.

Figure 29

Install the first Wall Control in the Wall Box containing

the “Hot” Wire. Connect the Wall Control Black Wire

with the Yellow Label marked “To Power Supply” to the

“Hot” Wire in the Wall Box. Securely connect the Wires

with the Wire Connector (supplied) (Figure 29).

Connect the Wall Control Black Wire with the Blue

Label marked “To Fan” to the Traveler Wire in the Wall

Box. Sec u rely conn e ct t he W i res with the Wire

Connector (supplied) (Figure 29).

WARNING

Do not connect any neutral (white) wire to this control.

Incorrect wiring will damage this control.

!

Connect the Green Ground Wire to the Bare Copper

Wire or Green Ground Wire in the Wall Box Securely

conn e ct Wire s wi th Wir e Co n nec t or (sup p lied )

(Figure 29).

WARNING

Check to see that all connections are tight and that no

bare wires are visible at the wire connectors.

!

19

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 20

7. Wall Control Installation (Continued)

HOT

BLK

TRAVELER WIRES

BLACK

LOAD

EXISTING

WALL CONTROL

BLK

BLACK

LOAD

TRAVELER

WIRES

BLK

FAN/LIG HT

WALL

CONTROL

BLK

SECOND WALL CONTROL

PURCHASED

SEPARATELY

BLK

FAN/LIG HT

WALL

CONTROL

GND

HOT

GROUND

WARNING

Check to see that all connections are tight and that no

bare wires are visible at the wire connectors.

!

7.8

Disconnect electrical power to the branch circuit at the

Circuit Breaker or Fuse Box before attempting to install

the Ceiling Fan Wall Control into the Outlet Box.

Screw Wall Control into Wall Box using the supplied

screws. Leave Wall Control in “OFF” mode until fan

installation is completed.

Install the second Wall Control (sold separately) into the

Wall Box containing the “Load” Wire. Connect the Wall

Control Black Wire with the Yellow Label marked “To

Power Supply” to the Traveler Wire from the first Wall

Box. Securely connect Wires with Wire Connector

(supplied) (Figure 30).

Connect the Wall Control Black Wire with the Blue

Label marked “To Fan” to the “Load” Black Wire in the

Wall Box. Securely connect Wires with Wire Connector

(supplied) (Figure 30).

3-WAY WIRING DIAGRAM:

NOTE: Retrofit 3-way installations are likely to

include two traveler wires between the two wall

boxes. In new construction, only one traveler wire Is

equired (See Figure 30).

r

STANDARD WIRING FOR EXISTING

3-WAY CONTROLS

3-WAY WIRING DIAGRAM: RETROFIT

Connect the Wall Control Green Ground Wire to the

Bare Copper Wire or Green Ground Wire in the Wall

Box. Securely connect Wires with Wire Connector

(supplied) (Figure 30).

The Wall Control is supplied with a White, Ivory, and

Almond color Switch Covers. Choose the finish that

best suits your needs and snap the Cover onto the Wall

Control.

WARNING

Do not connect any neutral (white) wire to this control.

Incorrect wiring will damage this control.

!

Figure 30

ETL Model No.: CF330

20

Page 21

8. Programming the Receiver Operating Frequency

& High Speed Conditioning of Fan Control

-- Important - Read This Section Carefully and Follow

the High Speed Conditioning Instructions Closely --

PROGRAMMING THE RECEIVER

OPERATING FREQUENCY & HIGH SPEED

CONDITIONING OF FAN CONTROL

IMPORTANT: Ceiling fan blades MUST be installed

before high speed conditioning can begin.

NOTE: If using a 3-way switch installation, ensure

that both wall controls are using the same switch

code.

8.1

Turn the Wall Switch ON/OFF Switch to the "OFF"

position.

Restore electricity to the Ceiling Fan Branch Circuit at

the Circuit Breaker or Fuse Box.

Flip the Wall Control's ON/OFF Switch to "ON" position.

Within one minute of flipping the switch to "ON", push

and hold the FAN OFF button ( ) for 3 to 5 seconds to

set the code in the receiver. The ceiling fan lights

(if installed) will blink to indicate the wall control code

has been paired with the receiver.

8.2

If programming is unsuccessful, retry the previous

instructions after cycling the wall control ON/OFF switch

to restart the 1 minute programming time period.

If still unsuccessful, shut off the electricity at the fuse

box or breaker panel and change the wall control

frequency (Section 7.3, Page 16).

Afte r chan g ing t he fr e que n cy se t ting s , re p eat

instructions in Section 8.1 within one minute of restoring

the electricity.

IMPORTANT: Immediately after successful pairing,

the ceiling fan will automatically begin high speed

conditioning of the motor. During conditioning, the

electronic motor control software is calculating

speeds for the 2nd through 5th speed settings

based on the blades that were installed on the fan.

The fan will run for approximately 1 minute in the

upward direction then reverse direction to down flow

and run an additional 1 minute. When conditioning is

complete, the fan will come to complete stop.

IMPORTANT: Do not interrupt the conditioning until

the fan comes to a complete stop in approximately

3 minutes. All functions of the control will be

rejected during conditioning.

High speed conditioning is now complete.

21

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 22

AIRFLOW

D

IRECTION

POWER

BUTTON

P

OWER

INDICATOR

L

IGHT

FAN SPEED

BUTTONS

ON/OFF SWITCH

O = OFF / = ON

L

IGHT

I

NTENSITY

B

UTTON

IVORY

COVER PLATE

WHITE

COVER PLATE

LIGHT ALMOND

COVER PLATE

9. Using Your Ceiling Fan

WARNING

Fan installation must be completed, including the

installation of the fan blades, before testing the wall

control.

!

Your Wall Control has full control of your Fan and Light

(Figure 31).

NOTE: Prior to operation of the fan and light from

the wall control, set the fan speed to HIGH (

....

) and

turn the light ON ( ).

9.1

To set the desired Fan Speed, press the ( ) button to

decrease the speed and the ( ) to increase the speed.

The LED display will light up to indicate the new speed

selected.

To turn the Light on and off, press and release the

LIGHT ( ) button. To set the light intensity, press and

hold the LIGHT ( ) button. The light will turn on at the

light intensity previously selected (Figure 31).

If Airflow is desired in the opposite direction, press the

( ) butt o n o n t h e w a l l c o n t r o l . T h e f a n m u s t b e

operating at any speed for the reverse button to

function. The blades will turn in the opposite direction

and reverse the airflow.

Your Wall Control comes complete with your choice of

three Wall Cover Plates; Ivory, White and Light Almond

(Figure 31).

Your fan is now wired to be turned on and off from the

fan switch.

Figure 31

ETL Model No.: CF330

22

Page 23

10. Maintenance

MPORTANT CARE INSTRUCTIONS

I

for your Ceiling Fan

Periodic cleaning of your new ceiling fan is the only

maintenance that is needed.

When cleaning, use only a soft brush or lint free cloth to

avoid scratching the finish.

Abrasive cleaning agents are not required and should

be avoided to prevent damage to finish.

11. Accessories

WARNING

Do not use water when cleaning your ceiling fan.

It could damage the motor or the blades and create the

possibility of an electrical shock.

!

See your local Emerson dealer, www.emersonfans.com

or the Emerson Ceiling Fan catalog for these

accessories:

· Ceiling Fan Controls

· Downrod Extension Kits

WARNING

The use of any other control not specifically approved

for this fan could result in fire, shock and personal

injury.

!

WARNING

This product is designed to use only those parts

supplied with this product and/or any accessories

designated specifically for use with this product by

Emerson El e ctric Co. S u bstitution of p a rts or

accessories not designated for use with this product

by Emerson Electric Co. could result in personal injury

or property damage.

!

INSTRUCTION TO THE USER (if device contains a digital device)

This equipment has been tested and found to comply with the limits for a class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This equipment has been certified to comply with the limits for a class B computing device, pursuant to FCC Rules.

In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment. Operation

with non-approved equipment or unshielded cables is likely to result in interference to radio and TV reception. The

user is cautioned that changes and modifications made to the equipment without the approval of manufacturer

could void the user’s authority to operate this equipment.

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

emersonfans.com

ETL Model No.: CF330

23

Please contact 1-800-654-3545 for further assistance

Page 24

12. Repair Parts

1

2

15

5

3

6

7

8

16

9

17

HARDWARE BAG

4

5

8

10

6

7

9

18

10

THIS SIDE UP

19

11

20

23

22

21

11

12

12

13

14

13

25

24

ETL Model No.: CF330

24

Page 25

12. Repair Parts Listing

Key

No. Description CF330BQ00 CF330GRT00 CF330SW00

* Hanger Ball Assembly, 761655-19 761655-102 761655-92

Consisting of:

1 Hanger Bracket (1) — — —

2 Hanger Ball (1) — — —

3 4.5” Downrod (1) — — —

* Hardware Bag Containing: 764860-BLX 764860-BLX 764860-SW

4 Wire Connectors (5) — — —

5 Threaded Studs, #8-32 x 1-1/4” (2) — — —

6 Lockwashers, External Tooth, #8 (2) — — —

7 Knurled Knobs, #8-32 (2) — — —

8 Clevis Pin (1) — — —

9 Hairpin Clip (1) — — —

10 1/4-20 x 1/2” Oval Head Screw (7) — — —

11 #8-32 x 1/4” Washer Head Screw (10) — — —

12 #6-32 x 1/4” Truss Head w/Lockwasher Screw (4) — — —

13 #6-32 x 3/8” Truss Head w/Lockwasher Screw (1) — — —

14 Blade Balance Kit (1) — — —

Model Numbers

15 Ceiling Cover (1) 764838-BQ 764838-GRT 764838-SW

16 Motor Coupler Cover (1) 764839-BQ 764839-GRT 764839-SW

17 Light Kit Assembly Driver (1) 764855 764855 764855

18 Motor Control, Receiver (1) 764857 764857 764857

19 Fan Blades (Set of 3) 764847-BQ 764847-GRT 764847-SW

20 Fan Blade Flanges (Set of 3) 764845-PN 764845-BS 764845-PN

21 Light Kit Housing Assembly (1) 764849-BQ 764849-GRT 764849-SW

22 LED Array (1) 764853 764853 764853

23 Shade, LED (1) 764858 764858 764858

24 Finial Nut Decorative (1) 764859-PN 764859-BS 764859-PN

25 Wall Control Transmitter w/Hardware (1) 763980-1 763980-1 763980-1

— Owner's Manual BP7522 BP7522 BP7522

Before discarding packaging material, be certain all parts have been removed.

HOW TO ORDER REPAIR PARTS

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION:

• PART NUMBER • NAME OF ITEM

• PART DESCRIPTION • MODEL NUMBER

The model number of your Fan will be found on a label attached to the top housing.

For repair parts, phone 1-800-654-3545.

Please contact 1-800-654-3545 for further assistance

25

emersonfans.com

ETL Model No.: CF330

Page 26

1

3

g

n

i

t

o

o

h

s

e

l

b

u

o

r

T

.

!

E

W

O

P

F

F

O

N

R

U

T

Y

T

E

F

A

S

N

W

O

R

U

O

Y

R

O

F

.

N

A

F

R

U

O

Y

G

N

I

T

O

O

H

S

E

L

B

U

O

R

T

E

S

U

A

C

E

L

B

A

B

O

R

P

E

L

B

U

O

R

T

e

h

t

n

i

s

n

o

i

t

c

e

n

n

o

c

l

a

c

i

r

t

c

e

l

e

e

s

o

o

L

.

1

.

t

r

a

t

s

t

o

n

l

l

i

w

n

a

F

.

1

.

r

e

v

o

c

g

n

i

l

i

e

c

a

l

B

.

1

.

y

s

i

o

n

s

d

n

u

o

s

n

a

F

.

2

r

i

W

.

2

e

r

a

r

c

S

.

3

o

o

l

e

S

.

1

s

e

l

b

b

o

w

n

a

F

.

3

.

y

l

e

v

i

s

s

e

c

x

e

e

S

.

2

s

s

a

r

c

S

.

3

o

m

a

H

.

4

x

o

b

t

o

n

s

e

d

e

n

n

o

c

e

g

n

i

l

t

t

a

r

o

h

s

w

e

.

e

s

s

w

e

r

c

s

t

w

e

r

c

s

t

i

y

l

b

m

e

c

e

s

s

w

e

l

e

r

a

r

o

t

a

r

b

r

e

g

n

s

t

o

n

s

i

d

e

h

c

a

t

t

a

s

n

i

s

r

o

t

c

.

a

l

b

g

n

i

d

l

o

t

o

m

n

i

e

g

n

a

h

n

i

.

e

s

o

o

l

s

a

f

g

n

i

r

u

.

e

s

o

o

d

n

a

t

e

k

c

y

l

e

r

u

c

e

.

n

a

f

o

t

h

g

i

l

e

d

i

m

o

t

s

e

d

e

l

p

u

o

c

r

o

d

/

l

l

a

b

r

s

e

d

a

l

b

n

i

l

i

e

c

r

o

/

d

e

n

e

t

s

a

f

e

s

s

a

t

i

k

t

e

r

a

r

o

t

o

o

o

l

e

r

a

r

d

o

r

n

w

o

t

t

e

l

t

u

o

g

n

.

R

A

W

T

A

R

y

l

b

m

.

e

s

G

N

I

N

E

R

O

F

E

B

R

E

K

A

E

R

B

T

I

U

C

R

I

C

R

O

X

O

B

E

S

U

F

Y

D

E

M

E

R

D

E

T

S

E

G

G

U

S

.

r

e

v

o

c

g

n

i

l

i

e

c

e

h

t

t

a

s

n

o

i

t

c

e

n

n

o

c

l

a

c

i

r

t

c

e

l

e

e

h

t

k

c

e

h

C

.

1

!

WARNING

.

1

.

2

.

3

.

1

.

2

.

3

.

4

Make sure main power is turned OFF.

e

p

o

e

r

o

f

e

b

n

a

f

o

t

s

e

d

a

l

b

h

c

a

t

t

A

e

n

n

o

c

e

r

i

w

e

r

u

s

e

k

a

m

o

t

k

c

e

h

C

h

t

o

h

c

a

e

t

s

n

i

a

g

a

g

n

i

l

t

t

a

r

t

o

n

e

r

a

.

y

l

b

m

e

s

s

a

t

i

k

t

h

g

i

l

e

h

t

f

o

l

l

a

w

!

WARNING

Make sure main power is turned OFF.

.

y

l

e

r

u

c

e

s

s

w

e

r

c

s

n

e

t

h

g

i

T

e

r

u

c

e

s

s

w

e

r

c

s

t

e

s

h

t

o

b

n

e

t

h

g

i

T

n

a

h

e

h

t

n

i

w

e

r

c

s

t

e

s

e

h

t

n

e

t

h

g

i

T

.

y

l

b

m

e

s

s

a

h

c

i

h

w

s

w

e

r

c

s

e

r

u

s

e

b

o

t

k

c

e

h

C

.

t

h

g

i

t

e

r

a

r

o

t

o

m

e

h

t

o

t

e

r

c

s

t

e

k

c

a

r

b

r

e

g

n

a

h

e

h

t

n

e

t

h

g

i

T

.

x

o

b

t

e

l

t

u

o

e

r

u

c

e

s

r

o

/

d

n

a

.

g

n

i

t

a

r

y

l

b

m

e

s

s

a

t

i

k

t

h

g

i

l

n

i

s

r

o

t

c

r

o

i

r

e

t

n

i

e

h

t

t

s

n

i

a

g

a

r

o

r

e

.

r

e

l

p

u

o

c

r

o

t

o

m

e

h

t

n

i

y

l

d

o

r

n

w

o

d

/

l

l

a

b

r

e

g

s

e

d

a

l

b

n

a

f

e

h

t

h

c

a

t

t

a

,

x

o

b

t

e

l

t

u

o

e

h

t

o

t

s

w

14. Energy Efficient Use of Ceiling Fans

Ce iling fan performa nce and en ergy savin gs rely

heavily on the proper installation and use of the ceiling

fan. Here are a few tips to ensure quality and product

performance.

Choosing the Appropriate Mounting Location.

Ceiling fans should be installed, or mounted, in the

middle of the room and at least 7 feet above the floor

and 18 inches from the walls. If ceiling height allows,

install the fan 8 - 9 feet above the floor for optimal

airflow. Consult your Emerson Retailer for optional

mounting accessories.

ETL Model No.: CF330

Using the Ceiling Fan Year Round. In the summer,

use the ceiling fan in the counter-clockwise direction.

The airflow produced by the ceiling fan creates a windchill effect, making you "feel" cooler. Select a fan speed

that provides a comfortable breeze, lower speeds

consume less energy. In the winter, reverse the motor

and o p erat e the c e i ling f an at l ow sp e ed in t he

clockwise direction. This produces a gentle updraft,

which forces warm air near the ceiling down into the

occupied space. Remember to adjust your thermostat

when using your ceiling fan - additional energy and

dollar savings could be realized with this simple step!

Turn Off When Not in the Room. Ceiling fans cool

people, not rooms. If the room is unoccupied, turn off

the ceiling fan to save energy.

26

Page 27

Emerson Air Comfort Ceiling Fan Limited Warranty

What The Limited Warranty Covers:

This limited warranty is offered by Air Comfort Products division of Emerson Electric Co. ("Emerson" "we" or "us") located at the address stated below to the original retail

purchaser ("you" or "your") of an Emerson Air Comfort Ceiling Fan product ("Emerson Ceiling Fan") and covers the motor and the other components and accessories of the

Emerson Ceiling Fan against all defects in workmanship and materials.

What The Period Of Coverage Is:

This limited warranty will cover the Emerson Ceiling Fan motor for the expected lifetime of your Emerson Ceiling Fan (when operated in accordance with your Owner's Manual or other

instructions provided by Emerson to you with the Emerson Ceiling Fan). LED drivers are covered for a period of three (3) years, and any LED array is covered for a period of five (5) years.

All other components and accessories of the Emerson Ceiling Fan are covered by this limited warranty for a period of one (1) year. All warranty periods begin on the date of original retail

purchase. ANY IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE THAT

IS AVAILABLE TO YOU UNDER THE LAWS OF YOUR STATE OR PROVINCE SHALL COVER THE MOTOR FOR THE EXPECTED LIFETIME OF THE MOTOR (SUBJECT TO

PROPER USE), AND FOR ONE YEAR WITH RESPECT TO COMPONENTS AND ACCESSORIES.

No Other Express or Implied Warranty Applies:

THE LIMITED WARRANTIES PROVIDED ABOVE ARE THE SOLE AND EXCLUSIVE WARRANTIES PROVIDED BY EMERSON TO YOU FOR YOUR EMERSON CEILING FAN,

AND ARE IN LIEU OF ALL OTHER WARRANTIES, WRITTEN OR ORAL, EXPRESS OR IMPLIED, WHETHER ARISING BY OPERATION OF LAW OR OTHERWISE, WHETHER

OR NOT THE PURPOSE HAS BEEN DISCLOSED AND WHETHER OR NOT THE EMERSON CEILING FAN HAS BEEN SPECIFICALLY DESIGNED OR MANUFACTURED FOR

YOUR USE OR PURPOSE. EMERSON HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION, IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE FOR COMPONENTS AND ACCESSORIES AS OF THE EXPIRATION OF THE ONE YEAR WARRANTY

PERIOD FOR SUCH COMPONENTS AND ACCESSORIES. IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE FOR THE MOTOR

PORTION OF THE EMERSON CEILING FAN ARE LIKEWISE DISCLAIMED BY EMERSON AT SUCH TIME THAT THE EXPECTED LIFETIME OF THE EMERSON CEILING FAN

UNDER NORMAL USAGE HAS BEEN REACHED. EXCLUSIONS OR LIMITATIONS OF IMPLIED WARRANTIES MAY VARY FROM STATE TO STATE AND PROVINCE TO

PROVINCE SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

What We Will Do To Correct Problems:

If during the one (1) year warranty period the motor or any component or accessory of your Emerson Ceiling Fan is defective in materials or workmanship, or if during the expected

lifetime of the Emerson Ceiling Fan (when used in accordance with the User Manual or other instructions) the motor is defective in materials or workmanship, you must contact

Emerson during the applicable warranty period. If the defect is covered by warranty, Emerson will repair or replace the defective motor, component or other accessory at no charge

to you. If repair of the motor, component or accessory is not practical or possible within a reasonable time and no replacement Emerson Ceiling Fan can be provided, Emerson will

refund to you the actual purchase price of your Emerson Ceiling Fan. We will ship the repaired or the replacement Emerson Ceiling Fan to you at no charge, but you are responsible

for all costs of removal and reinstallation of your Emerson Ceiling Fan.

How You Can Receive Warranty Service:

You must be the original retail purchaser and have proof of your purchase of the Emerson Ceiling Fan to obtain your remedy under this limited warranty. You can return your

Emerson Ceiling Fan to your place of purchase, or you can call Emerson Customer Service at 1-800-237-6511 to obtain a return authorization and service identification tag. In order

for us to confirm that your Emerson Ceiling Fan is still under warranty, please retain your receipt or other proof of purchase and have that information readily available when returning

your Emerson Ceiling Fan to your place of purchase, or upon calling Emerson Customer Service. If you call Emerson Customer Service, prior to your call please be prepared to

provide all model numbers shown on your Emerson Ceiling Fan. Once we have processed your return authorization request, we will provide you with a postage paid return label

which should be affixed to the Emerson Ceiling Fan package you ship to the address listed at the end of this limited warranty. The return label will be sent to the mailing address you

provide to us by phone.

What Is Not Covered:

This limited warranty does not extend to and expressly excludes:

• The glass globes and light bulbs of your Emerson Ceiling Fan,

• Loss or damage to the motor or any component or accessory caused by normal wear and tear, rather than due to defects in materials or workmanship,

• Loss or damage resulting from conditions beyond our reasonable control, including without limitation, repairs not made at our factory or authorized service center, use of parts or

accessories not provided to you as part of this warranty by our factory or authorized service center, mishandling, unreasonable use, misuse, abuse, modifications or other

damage caused by you or a third party to your Emerson Ceiling Fan while not in our possession,

• Loss or damage resulting from improper installation, or other failure to comply with instructions in your Owner's Manual.

This limited warranty is deemed null and void upon the occurrence of either of the following events:

• You cease to own the Emerson Ceiling Fan product, or

• The Emerson Ceiling Fan is moved from its original point of installation.

This limited warranty is only valid within the 50 United States, the District of Columbia, and Canada. No other written or oral warranties apply, and no employee, agent, dealer or

other person is authorized to give any warranties on behalf of Air Comfort Products or Emerson Electric Co.

Limitation of Liability

REPAIR, REPLACEMENT OR A REFUND ARE THE EXCLUSIVE REMEDIES AVAILABLE TO YOU UNDER THIS LIMITED WARRANTY. TO THE EXTENT PERMITTED BY LAW,

IN NO EVENT SHALL EMERSON OR ANY EMERSON AUTHORIZED DEALER BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

INCLUDING ANY ECONOMIC LOSS, WHETHER RESULTING FROM NONPERFORMANCE, USE, MISUSE OR INABILITY TO USE THE EMERSON CEILING FAN OR FOR THE

NEGLIGENCE OF EMERSON OR AN EMERSON AUTHORIZED DEALER. EMERSON SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE AND

IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT

LIABILITY, OTHER TORT OR OTHERWISE), SHALL EMERSON'S OR ANY EMERSON AUTHORIZED AGENT'S LIABILITY TO YOU OR ANY INDIVIDUAL USING THE

EMERSON CEILING FAN EXCEED THE PRICE PAID BY THE ORIGINAL OWNER FOR THE EMERSON CEILING FAN. The term "consequential damages" shall include, but not

be limited to, loss of anticipated profits, business interruption, loss of use or revenue, cost of capital or loss or damage to property or equipment.

How State and Provincial Law Relates To The Warranty:

Some states and provinces do not allow the exclusion or limitation of incidental or consequential damages so the above exclusion or limitation may not apply to you. This limited

warranty gives you specific legal rights, and you may also have other rights which vary from state to state or province to province.

27

emersonfans.com

Please contact 1-800-654-3545 for further assistance

ETL Model No.: CF330

Page 28

SERIAL NUMBER: DATE CODE:

The serial number of this fan can be found on the nameplate on top of the fan housing. The date code

can be found on the carton and on top of the fan housing, stamped in ink on a white label. You should

record this data above and keep it in a safe place for future use.

Air Comfort Products

DIVISION OF EMERSON ELECTRIC CO.

8100 W. Florissant • St. Louis, MO63136

Questions, problems, missing parts: Before returning to the store call

Emerson Electric Customer Service

8 a.m. - 6 p.m., Eastern, Monday-Friday

1-800-654-3545

www.emersonfans.com

Retain this manual for future use.

Part No. F40BP75220000 Form No. BP7522

Revision: 170215 ETL Model No.: CF330

Printed in China

02/17

Loading...

Loading...