Page 1

CC1000dm

Dual Mode PMC cPCI Carrier Card

User’s Manual

May 2006

Page 2

The information in this manual has been checked and is believed to be

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

accurate and reliable. HOWEVER, NO RESPONSIBILITY IS ASSUMED BY ARTESYN

COMMUNICATION PRODUCTS FOR ITS USE OR FOR ANY INACCURACIES.

Specifications are subject to change without notice. ARTESYN COMMUNICATION

PRODUCTS DOES NOT ASSUME ANY LIABILITY ARISING OUT OF USE OR OTHER

APPLICATION OF ANY PRODUCT, CIRCUIT, OR PROGRAM DESCRIBED HEREIN. This

document does not convey any license under Artesyn Communication Products patents

or the rights of others.

Artesyn and the Artesyn logo are registered trademarks of Artesyn Technologies and

are used by Artesyn Communication Products under license from Artesyn Technologies.

All other trademarks are property of their respective owners.

Revision Level Principal Changes Date

10004281-00 Current release information April 2004

10004281-01 Remove Ethernet configuration, add CE

10004281-02 RoHS compliance May 2006

Copyright © 2006 Artesyn Communication Products. All rights reserved.

certificate

October 2004

Page 3

R

T

EGULATORY

A

GENCY

W

ARNINGS

& N

OTICES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

he Artesyn CC1000dm meets the requirements set forth by the Federal Communications Commission (FCC) in Title 47 of the Code of Federal Regulations. The

following information is provided as required by this agency.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired operation.

FCC RULES AND REGULATIONS – PART 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense.

. . . . .

Caution: Making changes or modifications to the CC1000dm hardware without the explicit consent of

Artesyn Communication Products could invalidate the user’s authority to operate this equipment.

!

10004281-02 CC1000dm User’s Manual i

Page 4

Regulatory

EC Declaration of Conformity

According to EN 45014:1998

Manufacturer’s Name: Artesyn Technologies

Communication Products Division

Manufacturer’s Address: 8310 Excelsior Drive

Madison, Wisconsin 53717

Declares that the following product, in accordance with the requirements of 89/336/EEC, EMC directive and 99/5/EC, RTTE directive and their amending directives,

Product: Compact PCI Carrier Card

Model Name/Number: CC1000dm/10005129-xx

has been designed and manufactured to the following specifications:

EN55022:1998 Information Technology Equipment, Radio disturbance characteristics, Limits and

methods of measurement

EN55024:1998 Information Technology Equipment, Immunity characteristics, Limits and methods of

measurement

EN300386 V.1.3.1 Electromagnetic compatibility and radio spectrum matters (ERM);

Telecommunication network equipment; EMC requirements

As manufacturer we hereby declare that the product named above has been designed to comply with

the relevant sections of the above referenced specifications. This product complies with the essential

health and safety requirements of the EMC directive and RTTE directive. We have an internal production control system that ensures compliance between the manufactured products and the technical

documentation.

Issue date: May 10, 2006

ii CC1000dm User’s Manual 10004281-02

Page 5

C

ONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1Overview

Components and Features 1-1

Functional Overview 1-2

Additional Information 1-2

Product Certification 1-3

RoHS Compliance 1-3

Terminology and Notation 1-4

Technical References 1-4

2Setup

Electrostatic Discharge 2-1

CC1000dm Circuit Board 2-1

Identification Numbers 2-4

Connectors 2-4

Fuses and Jumpers 2-5

Reset Switch 2-6

LEDs 2-7

CC1000dm Setup 2-7

Multiple Option Selection (JP3) 2-7

Local VIO Selection 2-7

Monarch Selection 2-7

Auto Memory Selection 2-7

Oscillator Selection 2-8

Bridge Serial ROM Selection 2-8

Mode Selection (JP5) 2-9

PLD Header (JP6) 2-9

Power Requirements 2-10

Environmental Considerations 2-10

Operational Checks 2-10

Reset Methods 2-11

Troubleshooting 2-13

. . . . .

10004281-02 CC1000dm User’s Manual iii

Page 6

Contents

Technical Support 2-13

Service Information 2-13

3 PMC/PCI Interface

PCI Bridge Features 3-1

PMC Module Installation 3-1

Monarch Functionality 3-2

Device Mapping 3-2

Timing 3-3

Interrupts 3-3

Arbitration 3-3

Bridge EEPROM 3-6

PCI 6254 Configuration Registers 3-6

PCI Identification Values 3-11

JTAG Headers 3-11

PCI Bus Control Signals 3-12

PMC Connector Pin Assignments 3-14

4 Carrier Card Bus Interface

Features 4-1

Data Buffers 4-1

Arbitration and Device Selection 4-2

Clock Generation 4-2

Hot Swap 4-2

Overview 4-2

Implementation 4-4

Other Resources 4-4

CC1000dm Control Signals 4-5

Backplane Connector Pin Assignments 4-5

5Glossary

iv CC1000dm User’s Manual 10004281-02

Page 7

F

IGURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-1: General System Block Diagram 1-2

Figure 2-1: Component Map, Top (rev. 02) 2-2

Figure 2-2: Component Map, Bottom (rev. 02) 2-3

Figure 2-3: Jumper/Header Locations, Top View 2-6

Figure 2-4: Front Panel 2-7

Figure 2-5: Multiple Option Jumper, JP3 2-8

Figure 2-6: PLD Header, JP6 2-9

Figure 2-7: Basic Reset Diagram 2-11

Figure 2-8: PLD Signal Routing–All Modes 2-12

. . . . .

10004281-02 CC1000dm User’s Manual v

Page 8

Figures

vi CC1000dm User’s Manual 10004281-02

Page 9

T

ABLES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-1: Regulatory Agency Compliance 1-3

Table 1-2: Technical References 1-4

Table 2-1: Circuit Board Dimensions 2-1

Table 2-2: Multiple Option Jumper Selection, JP3 2-8

Table 2-3: System Controller Modes, JP5 2-9

Table 2-4: PLD Header Pin Assignments, JP6 2-9

Table 2-5: Power Requirements 2-10

Table 2-6: Environmental Requirements 2-10

Table 3-1: PMC Slots Available Power 3-2

Table 3-2: IDSEL Mapping for PCI Devices 3-2

Table 3-3: PMCx Interrupt Mapping 3-3

Table 3-4: cPCI Interrupt Mapping 3-3

Table 3-5: Request/Grant Assignments 3-5

. . . . .

Table 3-6: PLX PCI 6254 Configuration Signals 3-6

Table 3-7: PCI Identification Values 3-11

Table 3-8: Debug Header Pin Assignments (JP1, JP2) 3-11

Table 3-9: J1x PMC Connector Pin Assignments 3-14

Table 3-10: J2x PMC Connector Pin Assignments 3-15

Table 4-1: Hot Swap System Models 4-3

Table 4-2: Control Signals 4-5

Table 4-3: J1 Connector Pin Assignments 4-5

Table 4-4: J2 Connector Pin Assignments 4-6

Table 4-5: J3 Connector Pin Assignments 4-7

Table 4-6: J5 Connector Pin Assignments 4-8

10004281-02 CC1000dm User’s Manual vii

Page 10

Tables

viii CC1000dm User’s Manual 10004281-02

Page 11

R

EGISTERS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Register 3-1: Internal Arbiter Control Register 3-4

Register 3-2: PCI6254 Configuration Registers–Transparent Mode 3-6

Register 3-3: PCI6254 Configuration Registers–Non-Transparent Mode 3-8

REGISTERS

. . . . .

. . . . .

10004281-02 CC1000dm User’s Manual 1

Page 12

Registers

2 CC1000dm User’s Manual 10004281-02

Page 13

O

VERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

he Artesyn CC1000dm (dual mode) is a CompactPCI (cPCI) Processor Mezzanine

Card (PMC) carrier capable of supporting Processor PMC (PrPMC) in both trans-

T

parent and opaque (non-transparent) PCI to PCI bridge (PPB) modes of opera-

tion. The CC1000dm cPCI interface is compliant with both the PICMG® 2.0

CompactPCI® Specification and the PCI Local Bus Specification. The two PMC slots

conform to the extended Processor PMC for Processor PCI Mezzanine Cards, VITA 32 -

2003 standard. Applications include:

• Wireless base station and gateway

• Voice over Packet (VoP) Signaling Gateway (SG), Media Gateway Controller (MGC),

and SoftSwitch

• Access enterprise gateway

COMPONENTS AND FEATURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following is a brief summary of the CC1000dm hardware components and features:

. . . . .

1

PCI-to-PCI Bridge:

Blade Solution:

PMC Modules:

Reset Switch:

Switching Regulator:

The CC1000dm uses a 64-bit, up to 66 MHz, dual mode transparent/non-transparent

PCI bridge. The specific device is PLX Technology® PCI 6254 (HB6). The bridge chip

also provides EEPROM support for extra register control. The cPCI interface in legacy

mode is backwards compatible with the Artesyn CC1000 carrier card.

The CC1000dm supports four modes. One of these provides an ideal blade solution, as it

allows the CC1000dm to operate (via jumper selection) in a system without a cPCI system controller.

The PCI Mezzanine Card (PMC) is a 64-bit interface that allows you to customize the

CC1000dm by adding plug-on modules. The plug-on modules are based on the Peripheral Component Interconnect (PCI) specification. The CC1000dm accepts two singlewidth or one double-width PMC module. The PMC slots are compatible with IEEE Stan-

dard for a Common Mezzanine Card Family: CMC IEEE Std 1386-2001.

The CC1000dm has a front panel push button that provides a reset function for the card.

The Linear Technology LTC®3713 provides the 3.3 volt conversion from the 5 volt input

for the PMC slots.

10004281-02 CC1000dm User’s Manual 1-1

Page 14

1

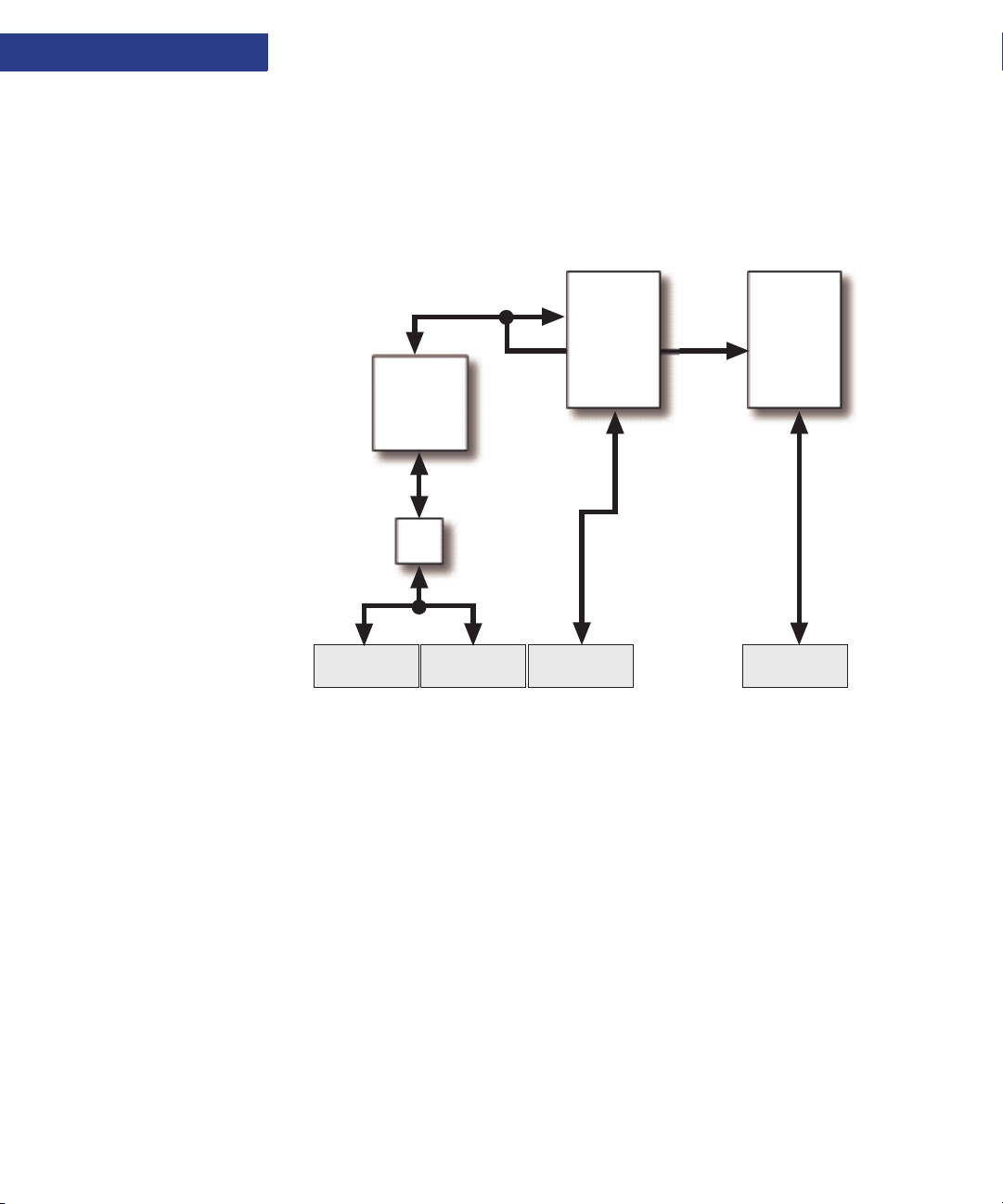

F i g u r e 1 - 1 :

General System Block Diagram

OVERVIEW

Functional Overview

FUNCTIONAL OVERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following block diagram provides a functional overview for the CC1000dm:

Monarch

PMC Site 2

64-bit PCI-PCI

Bridge

Hot

Swap

Monarch

PMC Site 1

J1

cPCI

ADDITIONAL INFORMATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J2

cPCI

This section lists the CC1000dm hardware’s regulatory certifications and briefly discusses the terminology and notation conventions used in this manual. It also lists general technical references.

Mean time between failures (MTBF) has been calculated at 1,251,602 hours using the

Method I Case 3, Telcordia Issue 1 model at 30

1-2 CC1000dm User’s Manual 10004281-02

J3

cPCI I/O

J5

cPCI I/O

O

C.

Page 15

OVERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Information

. . . . .

Product Certification

T a b l e 1 - 1 :

Regulatory Agency

Compliance

The CC1000dm hardware has been tested to comply with various safety, immunity, and

emissions requirements as specified by the Federal Communications Commission (FCC),

Underwriters Laboratories®, Inc. (UL), and others. The following table summarizes this

compliance:

Type: Specification:

Safety IEC60950/EN60950 — Safety of Information Technology Equipment

(Western Europe)

UL60950-1, CSA C22.2 No. 60950-1-03, 1st Edition — Safety of

Information Technology Equipment, including Electrical Business

Equipment (BI-National)

EMC FCC Part 15, Class A — Title 47, Code of Federal Regulations, Radio

Frequency Devices

ICES 003, Class A — Radiated and Conducted Emissions, Canada

EN55022 — Information Technology Equipment, Radio Disturbance

Characteristics, Limits and Methods of Measurement

EN55024 — Information Technology Equipment, Immunity

Characteristics, Limits and Methods of Measurement

ETSI EN300386 — Electromagnetic Compatibility and Radio Spectrum

Matters (ERM), Telecommunication Network Equipment, Electromagnetic

Compatibility (EMC) Requirements

Artesyn maintains test reports that provide specific information regarding the methods

and equipment used in compliance testing. Unshielded external I/O cables, loose screws,

or a poorly grounded chassis may adversely affect the CC1000dm hardware’s ability to

comply with any of the stated specifications.

The UL web site at ul.com has a list of Artesyn’s UL certifications. To find the list,

search in the online certifications directory using Artesyn’s UL file number, E190079.

There is a list for products distributed in the United States, as well as a list for products

shipped to Canada. To find the CC1000dm, search in the list for 10005129-xx, where xx

changes with each revision of the printed circuit board.

RoHS Compliance

The CC1000dm is compliant with the European Union’s RoHS (Restriction of Use of

Hazardous Substances) directive created to limit harm to the environment and human

health by restricting the use of harmful substances in electrical and electronic equipment. Effective July 1, 2006, RoHS restricts the use of six substances: cadmium (Cd),

mercury (Hg), hexavalent chromium (Cr (VI)), polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs) and lead (Pb). Configurations that are 5-of-6 are

built with tin-lead solder per the lead-in-solder RoHS exemption.

10004281-02 CC1000dm User’s Manual 1-3

Page 16

OVERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Additional Information

To obtain a certificate of conformity (CoC) for the CC1000dm, send an e-mail to

sales@artesyncp.com or call 1-800-356-9602. Have the part number(s) (e.g.,

C000####-##) for your configuration(s) available when contacting Artesyn.

Terminology and Notation

Active low signals:

Byte, word:

Radix 2 and 16:

Technical References

T a b l e 1 - 2 :

Technical Refe rences

An active low signal is indicated with an asterisk * after the signal name.

Throughout this manual byte refers to 8 bits, word refers to 16 bits, and long word refers

to 32 bits, double long word refers to 64 bits.

PLD:

This manual uses the acronym, PLD, as a generic term for programmable logic device

(also known as FPGA, CPLD, EPLD, etc.).

Hexadecimal numbers end with a subscript 16. Binary numbers are shown with a sub-

script 2.

Further information on basic operation and programming of the CC1000dm components can be found in the following documents:

Device / Interface: Document: 1

Bridge PCI 6254 (HB6) Dual Mode Universal PCI-to-PCI Bridge Data Book

CompactPCI PICMG® 2.0 CompactPCI® Specification/Revision 3.0. October 1, 1999

(PLX Technology, Inc.; Version 2.0 May 2003)

http://www.plxtech.com/

PICMG® 2.1 CompactPCI® Hot Swap Specification/Revision 2.0 January

17, 2001

PICMG® 2.2 VME64x on CompactPCI® Specification/Revision 1.0 August

7, 1998

PICMG® 2.3 PMC on CompactPCI® Specification/Revision 1.0 August 7,

1998

PICMG® 2.4 IP on CompactPCI® Specification/Revision 1.0 August 7,

1998

(PCI Industrial Computer Manufacturers Group, PICMG; Wakefield, MA)

http://www.picmg.org/

1-4 CC1000dm User’s Manual 10004281-02

Page 17

OVERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Information

. . . . .

Device / Interface: Document: 1 (continued)

PMC IEEE Standard for a Common Mezzanine Card Family: CMC IEEE Std

1386-2001 (Institute of Electrical and Electronics Engineers, Inc. (IEEE):

New York, NY)

http://www.ieee.org/

IEEE Standard Physical and Environmental Layers for PCI Mezzanine

Cards (PMC) IEEE Std 1386.1-2001

(IEEE: New York, NY)

http://www.ieee.org/

PCI Local Bus Specification

(PCI Special Interest Group, Revision 2.3 March 29, 2002)

http://www.pcisig.com/home

Processor PMC Standard for Processor PCI Mezzanine Cards, VITA 32 2003 Revision 1.0a, 29 April 2003 Draft

(VITA Standards Organization)

http://www.vita.com/

1. Frequently, the most current information regarding addenda/errata for specific documents may be

found on the corresponding web site.

10004281-02 CC1000dm User’s Manual 1-5

Page 18

OVERVIEW

1

Additional Information

1-6 CC1000dm User’s Manual 10004281-02

Page 19

S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ETUP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

his chapter describes the physical layout of the boards, the setup process, and

how to check for proper operation once the boards have been installed. This

T

chapter also includes troubleshooting, service, and warranty information.

ELECTROSTATIC DISCHARGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before you begin the setup process, please remember that electrostatic discharge (ESD)

can easily damage the components on the CC1000dm hardware. Electronic devices,

especially those with programmable parts, are susceptible to ESD, which can result in

operational failure. Unless you ground yourself properly, static charges can accumulate

in your body and cause ESD damage when you touch the board.

Caution: Use proper static protection and handle CC1000dm boards only when absolutely necessary. Always

wear a wriststrap to ground your body before touching a board. Keep your body grounded while

!

handling the board. Hold the board by its edges—do not touch any components or circuits. When

the board is not in an enclosure, store it in a static-shielding bag.

To ground yourself, wear a grounding wriststrap. Simply placing the board on top of a

static-shielding bag does not provide any protection—place it on a grounded dissipative

mat. Do not place the board on metal or other conductive surfaces.

. . . . .

2

CC1000DM CIRCUIT BOARD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The CC1000dm circuit board is a cPCI carrier card assembly. It uses a 12-layer printed

circuit board with the following dimensions:

T a b l e 2 - 1 :

Circuit Board Dimensions

Width: Depth:

9.2 in. (233.35 mm) 6.3 in. (160.00 mm)

10004281-02 CC1000dm User’s Manual 2-1

Page 20

SETUP

2

CC1000dm Circuit Board

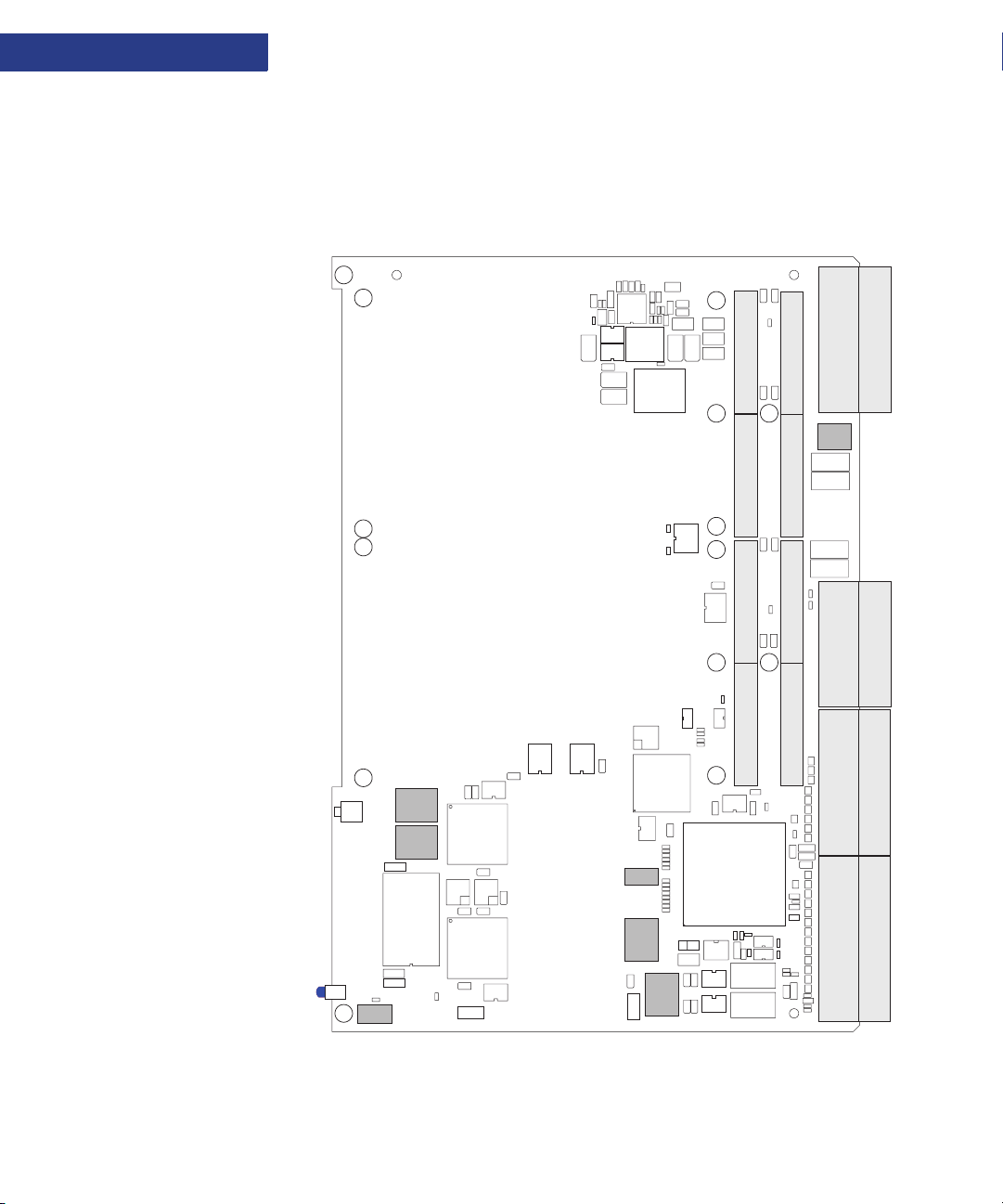

The following figures show the front panel, component maps, and jumper locations for

the CC1000dm circuit board.

F i g u r e 2 - 1 :

Component Map, Top (rev. 02)

CR1

SW1

C13

R4

C12

R5

C15

CR4

M1

M2

C16

C19

C18

R12

R14

R18

R6

U14

C17

C33

C27

C22

C32

R16

R17

C21

R13

R15

C31

R33

C43

L1

C42

C41

C28

C37

C23

L6

J21

C55

C49

R44

J5

J22

C54

C48

CR5

R8

R7

R11

R10

JP7

F4

J24

F3

U15

C25 C26

C53

C47

F2

F1

C40

J11 J23

U18

C39

U23

U19

R38

J13

R37

Y3

R36

R35

U8

U11

C11

U5

C7

JP2

JP1

C3

U1

C6

U3

C9

Y1

Y2

C10

C5

C8

U2

C2

C1

R1

J6

C4

U4

R2

R3

C14

JP5

JP3

C20

U13

C24

U12

R32

R31

R30

R29

R28

R27

R26

R25

R24

R23

R22

R21

R20

R19

CR6

C36

C30

C35

JP6

C29

R9

C34

U20

C38

U16

PCI 6254

U17

M6

M5

R428

R427

C44

R41

R40

R39

C45

C186

U22

U21

R426

R312

R56

R55

R43

C52

C46

J14 J12

RN24

RN23

RN22

RN21

RN20

RN19

R42

RN18

RN2

RN17

C58

RN16

R54

C57

R53

C63

RN15

RN14

RN1

RN13

R51

C59

RN12

R50

RN11

R49

RN10

RN9

RN8

C51

C50

R46

R45

J1 J2 J3

RN7

RN6

RN5

R48

RN4

RN3

R47

C56

C62

R52

C61

C60

2-2 CC1000dm User’s Manual 10004281-02

Page 21

F i g u r e 2 - 2 :

Component Map, Bottom (rev. 02)

SETUP

CC1000dm Circuit Board

. . . . .

R188

C94

C104

R418

R57

R58

R59

R60

R77

R61

R78

C64

R79

R80

C65

R89

R88

R90

C66

R91

C67

R62

R63

R64

R65

R66

R67

R68

R69

R70

R75

R76

R422

R171

R181

R402

R147

R120

R156

R184

R148

R174

R173

R419

R423C86

R121

C73C71

C81

R122

R123

C68

R124

R125

R126

R118

L2

R96

C88

R114R113

R81

R127

R82

L3

R128

R97

C74

C75

R83

R129

R115

R71

R109

R84

R130

R98

C82

R99

R73

R74

R100

C83

C84

R119

C69

R105

R110

R85

R111

R86

R112

R87

R131

C85

C76C72

R132

C70

R133

R134

R135

R116

L4

R136

R101

R92

R93

R94

R72

R95

C89

R117

R137

L5

C78

C77

R102

C79

C80

C87

R424

R106

R138

R421

R425

R420

R103

R107

R104

R108

F5

R180

R139

R149

C105

R161

R150

C109

C112

C97

C99

C90

R162

R140

R141

R163

R185

R189

C91

R190

R164

R165

C100

C101

R175C95

R191

R172

R166

R177

R183

R176

R182

R151

R157

R152

R142

R167

R143

R153

C102

C110

C98

C92

R154

R144

R158

R145

R155

R146

R168

C93

R187

R169

R170

C103

C111

C96

R178

R192

R159

R179

R193

R160

C114

C106

R197

R417

C107

C113

C108

R194

R195

R196

R198

R199

R202

C115

R203

R204C116

R209

R210

R206

C117

R211

R212

R200

C119

R201C118

R207

M8

C149

R310

C150R311

M9

R301

R302

C125

C127

C122

C132

C128

C126

R228

R222

C121

R229

R230

R231

R232

R233

R234

R235

R236

R237

R253C130

R238

R239

R240

R241

R242

R243

R244

R223

R224

C123

C120R205

R259

R260

R261

R248

R262

R213

R263

R264

R249

R265

R214

R266

R215

R267

C124

R268

R269

R270

R429

R271

R272

R273

R216

R217

R218

R219

R220

R208

R221

U24

R252

R307

R258

R303

R290

C129

R291

R276

R349

R277

R278

R279

R280

R281

C134

R282

R283

C131

C135

R34

R313

R284

R305

R274

R314

R306

R275

C141

R351

R285

R308

C147C148

R309

R286

R357

C140 C139

C142

R292

R293

R294

R295

R296

R297

R287

C136

C182

F6

R396

R397

C172

R398

RN27

C173

RN28

RN29

RN30

RN31

R405

C161C162

R347

R399

R354

RN32

R406

R400

R393R392

RN33

C165

R409

RN34

R140

RN35

C158

RN36

C174

R350

RN37

R355

RN38

R348

C145

RN39

C183

C175

C166

C146

C184

R411

C167

C185

RN40

R412

RN41

C171

C168

RN26

RN42

R401

R186

RN43

R352

RN44

R353

RN45

RN46

RN47

RN48

680-

XXXXXX

00000000-00 D

R413

C151

R135

R136

R298

R299

R300

C163

C137

C133

C143

R288

R289

R137

C138

R318

R319

R320

R321

R358

R359

R322

C154

R254

R225

R246

R226

R250

R251

R227

R255

R247

R256

R360

R323

R361

R257

R324

R362

R325

R363

R326

R364

R327

R365

R328

R366

R329

R367

R330

R368

R331

R369

R332

R370

R333

R371

R334

R372

R335

R373

R336

R374

R337

R375

R338

R376

R339

R377

R340

R378

R379

R380

R381

R382

R383

R341

R384

R385

R342

R386

R387

C144

R388

R389

R343

R344

R390

R391

R345

C157

R346

C177 C176R414

C152

R394

R395

C153

F7

C178R415

F8

R407

C169R403

F10

F9

C179

C155

C164

C180

C160

C156

C181

R404

R408

R416

C170

10004281-02 CC1000dm User’s Manual 2-3

Page 22

SETUP

2

CC1000dm Circuit Board

Identification Numbers

Connectors

P1–P2:

J1:

J2:

J3:

J5:

Before you install the CC1000dm circuit board in a system, you should record the following information:

❐ The board serial number: 680– ______________________________________ .

The board serial number appears on a bar code sticker located on the back of the

board.

❐ The board product identification: ___________________________________ .

This sticker is located near the board serial number.

It is useful to have these numbers available when you contact the Technical Support

department at Artesyn Communication Products.

The CC1000dm circuit board has various connectors (see the figures beginning on

page 2-3), summarized as follows:

These connectors are not installed on the CC1000dm.

This 110-pin connector has keying for 3.3 volt and 5 volt supplies. See Table 4-3 for the

pin assignments.

This 110-pin connector carries the PCI 64-bit extension signals. See Table 4-4 for the pin

assignments.

This is a 95-pin connector that routes the I/O signals for the PMC I/O, serial port, and

USB port. See

Table 4-5 for the pin assignments.

This 110-pin connector is used for PMC I/O. See Table 4-6 for the pin assignments.

J6:

This is a 3-pin header for the Hot Swap switch.

J11:

This connector shares the 32-bit PCI signals with the J12 connector (secondary bus). In

addition, J11 supports a V(I/O) power supply for universal PCI signaling. It uses 3.3 volt

PCI buffers with a 5 volt tolerance. See

J12:

This connector shares the 32-bit PCI signals with the J11 connector (secondary bus). It

also carries the 3.3 volt supply voltage. See

J13:

This connector carries the 64-bit PCI extensions (secondary bus). See Table 3-9 for the pin

assignments.

J14:

This connector is for user I/O, which routes to J3. See Table 3-9 for the pin assignments.

J21:

This connector shares the 32-bit PCI signals with the J22 connector (secondary bus). In

addition, J21 supports a V(I/O) power supply for universal PCI signaling. It uses 3.3 volt

PCI buffers with a 5 volt tolerance. See

J22:

This connector shares the 32-bit PCI signals with the J21 connector (secondary bus). It

also carries the 3.3 volt supply. See

2-4 CC1000dm User’s Manual 10004281-02

Table 3-9 for the pin assignments.

Table 3-9 for the pin assignments.

Table 3-10 for the pin assignments.

Table 3-10 for the pin assignments.

Page 23

CC1000dm Circuit Board

J23:

This carries the 64-bit PCI extensions (secondary bus). See Table 3-10 for the pin assignments.

J24:

This connector is for user I/O, which routes to J5. See Table 3-10 for the pin assignments.

SETUP

. . . . .

Fuses and Jumpers

F1-F4:

N o t e :

Fuses F5 through F10 are

located on the bottom side,

see Fig. 2-2.

JP1, JP2:

The CC1000dm has various jumpers, headers, and fuses. Please refer to Fig. 2-3 on the

following page for the jumper/header locations.

These are spare fuses on the top side of CC1000dm.

F5:

This fuse (.75 amp) provides protection for the 3.3 volt supply to the PMC JTAG header.

F6:

This fuse (.75 amp) provides protection for the PLD JTAG header.

F7:

This fuse (.75 amp) provides protection for the 5 volt supply to the backplane.

F8:

This fuse (.75 amp) provides protection for the 3.3 volt supply to the backplane.

F9:

This fuse (.75 amp) provides protection for the +12 volt supply to the backplane.

F10:

This fuse (.75 amp) provides protection for the -12 volt supply to the backplane.

Each PMC slot has an associated 10-pin debug header (see Table 3-8).

JP3:

This 10-pin jumper selects the following configurations: local VIO, Monarch, auto

memory, oncard oscillator and bridge serial ROM (see page 2 -7).

JP5:

This 4-pin jumper selects the mode: transparent, non-transparent, legacy (Artesyn

CC1000), or no system controller (see page 2 -9).

JP6:

The programmable logic device (PLD) uses this 10-pin JTAG header (see page 2-9).

JP7:

This is a spare header.

10004281-02 CC1000dm User’s Manual 2-5

Page 24

2

F i g u r e 2 - 3 :

Jumper/Header Locations, Top

View

SETUP

CC1000dm Circuit Board

SW1

CR1

PMC2 JTAG Header

1

9

JP2

2

10

PMC1 JTAG Header

9

1

JP1

10

2

Hot Swap Header

J6

PMC2

PMC1

Mode Select

43

JP5

2

1

Multiple Options Select

9

10

JP3

2

1

JTAG Header

9

10

JP6

2

1

J21

J22

J5

JP7

Spare

J23

J24

F3 F4F2F1

J11

J12

J3J2J1

J13

J14

Reset Switch

The CC1000dm has a push button switch (SW1) on the front panel to reset the secondary PCI bus and inform the CompactPCI bus of the need for enumeration.

2-6 CC1000dm User’s Manual 10004281-02

Page 25

SETUP

CC1000dm Setup

. . . . .

LEDs

F i g u r e 2 - 4 :

Front Panel

All CC1000dm carrier cards have a blue LED which indicates the Hot Swap status, as

shown in

vated by the card ejector handle. The micro-switch indicates to the PCI bridge when the

ejector is open or closed.

CC1000DM SETUP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

You will need the jumper settings and the PCI signaling in order to set up and check the

operation of the Artesyn CC1000dm carrier card. See

the CC1000dm.

Save the antistatic bag and box for future shipping or storage.

Multiple Option Selection (JP3)

LOCAL VIO SELECTION

The secondary (PMC) side of the PCI bridge can be set for either 3.3 volt or 5 volt signaling. Installing the jumper in JP3 pins 1-2, selects 3.3 volt signaling (default). The

primary (cPCI) side is set externally to the CC1000dm.

Fig. 2-4. The PCI bridge component monitors the micro-switch which is acti-

Fig. 2-3 for the jumper locations on

Caution: Incorrect installation of this jumper can damage PMC modules that only support 3.3 volt signaling.

!

MONARCH SELECTION

The PMC slots can be configured to support either Monarch or non-Monarch modules.

Setting the jumper to select PMC1 Monarch configures the board for a Monarch module

in PMC Slot 1 (factory default). Without a jumper installed in JP3 pins 3-4, this configures the board for a Monarch in PMC slot 2. Please refer to page 3 -2 for further details

regarding Monarch functionality.

AUTO MEMORY SELECTION

In non-transparent mode, the cross bridge memory (XB_MEM) setting allows the primary side to enumerate the primary bus with a default 16-megabyte window. Otherwise

the primary side may experience a delay in enumeration if the secondary side PMC has

a long enumeration time.

10004281-02 CC1000dm User’s Manual 2-7

Page 26

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F i g u r e 2 - 5 :

Multipl e Option Jumper, JP3

SETUP

CC1000dm Setup

If the Serial ROM (SROM) is enabled, it overrides the 16-megabyte window with the

applicable window. Install this jumper when using the SROM and also when the S-Port

ready and P-Port ready bits are to be set. This allows the bridge to be enumerated without any further interaction.

OSCILLATOR SELECTION

When the 66 MHz oncard oscillator is enabled, this allows the CC1000dm to produce its

own 33/66 MHz clock for the secondary side. This is independent of the primary frequency.

BRIDGE SERIAL ROM SELECTION

Installing the bridge SROM jumper disables the PCI 6254 bridge SROM. The EEPROM is

used to initialize the registers. If the EEPROM becomes corrupted and locks the system,

disabling the EEPROM allows default access to the CC1000dm.

12

Local VIO

T a b l e 2 - 2 :

Multipl e Option Jumper

Selection, JP3

Monarch

43

65

XB_MEM

78

910

Signal Name: Bit: Selection: Jumper:

VIO_SEL_3_3V*

PMC_Mon_SEL_1*

XB_MEM_SEL*

EXT_OSC*

Oscillator

Bridge EEPROM

0 3.3 V Local VIO (default) Install 1-2

1 5 V Local VIO Remove 1-2

0 PMC slot 1 (PMC1) is Monarch (default) Install 3-4

1 PMC slot 2 (PMC2) is Monarch Remove 3-4

0 Auto (cross bridge) memory window in non-

transparent mode enabled (default)

1 Auto (cross bridge) memory window in non-

transparent mode disabled

0 On-board 66 MHz oscillator enabled Install 7-8

1 On-board 66 MHz oscillator disabled (default) Remove 7-8

Install 5-6

Remove 5-6

2-8 CC1000dm User’s Manual 10004281-02

Page 27

SETUP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC1000dm Setup

. . . . .

Mode Selection (JP5)

T a b l e 2 - 3 :

System Controller Modes,

JP5

PLD Header (JP6)

F i g u r e 2 - 6 :

PLD Header, JP6

Signal Name: Bit: Selection: (continued) Jumper:

0 Bridge serial ROM enabled (default) Remove 9-10

BRIDGE_SEE_EN*

1 Bridge serial ROM disabled Install 9-10

The system controller modes are selected by jumper JP5. The legacy product is the Artesyn CC1000 carrier card.

Jumper Position: Mode_Sel (3:0): Mode:

1-2 1000 Non-Transparent (default)

3-4 1011 Transparent

2-4 0001 Legacy (CC1000)

None 1001 No System Controller

This 10-pin JTAG header is used by the PLD.

10

2

9

1

T a b l e 2 - 4 :

PLD Header Pin Assignments,

JP6

Pin: Signal: Pin: Signal:

1 PLD_TCK 2 ground

3PLD_TDO 4PLD_3_3V

5PLD_TMS

7 no connect 8 no connect

9 PLD_TDI 10 ground

6 no connect

10004281-02 CC1000dm User’s Manual 2-9

Page 28

SETUP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Operational Checks

Power Requirements

T a b l e 2 - 5 :

Power Requirements

Be sure your power supply is sufficient for the board. The combined power (3.3 volts

and 5 volts) for a CC1000dm is 27 watts.

for the CC1000dm. Please contact Artesyn Technical Support at 1http://www.artesyncp.com/support on the internet or send E-mail to support@artesyncp.com if you

have specific questions regarding the board’s power requirements.

Voltage: Range:

+3.3 V +5/-3% 1.0 Board logic

+5 V +5/-3% 0.4 Board logic

+12 V ±5% 0.5 PMC slot power

–12 V ±5% 0.5 PMC slot power

VIO ±5% 0.75 PCI signaling for board logic

Environmental Considerations

As with any printed circuit board, be sure that air flow to the board is adequate. Chassis

constraints and other factors greatly affect the air flow rate. The environmental requirements are as follows:.

T a b l e 2 - 6 :

Environmental Requirements

Voltage: Usage:

Operating Temperature 0 to +55O Centigrade, ambient (at board)

Table 2-5 lists the specific power requirements

Typical Current

(amps): Usage:

Relative Humidity Not to exceed 95% (non-condensing)

Storage Temperature -40 to +85

Shock and Vibration NEBS Level 3 compliant

OPERATIONAL CHECKS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All products are tested before they are shipped from the factory. When you receive your

CC1000dm, follow these steps to assure yourself that the system is operational:

1 Visually inspect the board for components that could have loosened during shipment.

2 Verify that the front panel is secure.

3 By default, the CC1000dm carrier card is configured to support 3.3 V I/O operation on the

secondary bus. Please be sure to select the appropriate voltage for your application.

2-10 CC1000dm User’s Manual 10004281-02

O

Centigrade, ambient

Page 29

F i g u r e 2 - 7 :

Basic Reset Diagram

SETUP

Reset Methods

. . . . .

RESET METHODS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 2-7 shows the basic reset diagram for the CC1000dm. For PLD signal routing changes

for each of the four modes, see

Fig. 2-8.

PCI_VIO

5.11 K 5.11 K

PMC Slots (2)

10 K

PMC_RSTOUT*

PCI_EREADY*

PCI_VIO

CONN_CPCI_RST

cPCI

CONN_CPCI_BD_SEL*

Backside

Voltage

Monitor and

PB Reset

Early Power

Voltage

Monitor

10

CPCI_RST*

BACKSIDE_PWR_GD

BACKSIDE_PWR_RST*

EP_BAD_RST*

EP_PWRGD

0

HS_FAULT*

PLD

HS_ON*

HS_PWRGD*

Hot Swap Controller

BRIDGE_RST*

BRIDGE_RST_OUT*

S_RSTIN*

S_RSTOUT*

PCI 6254

Bridge

10004281-02 CC1000dm User’s Manual 2-11

Page 30

SETUP

2

Reset Methods

F i g u r e 2 - 8 :

PLD Signal Routing–All Modes

Non-transparent

PCI_VIO

10 K

5.11 K

PMC_RSTOUT*

CONN_CPCI_RST

CONN_CPCI_BD_SEL*

10

BACKSIDE_PWR_GD

BACKSIDE_PWR_RST*

CPCI_RST*

PCIXCAP_HEALTHY*

(internal signal)

PLD

BRIDGE_RST_OUT*

HS_ON*

HS_PWRGD*

BRIDGE_RST*

S_RSTIN*

S_RSTOUT*

CONN_CPCI_RST

CONN_CPCI_BD_SEL*

Legacy

PCI_VIO

10 K

5.11 K

PMC_RSTOUT*

PLD

CONN_CPCI_RST

CONN_CPCI_BD_SEL*

10

BACKSIDE_PWR_GD

BACKSIDE_PWR_RST*

CPCI_RST*

BRIDGE_RST_OUT*

HS_ON*

HS_PWRGD*

BRIDGE_RST*

S_RSTIN*

S_RSTOUT*

CONN_CPCI_RST

CONN_CPCI_BD_SEL*

Any of the following methods reset the entire board:

10

CPCI_RST*

BACKSIDE_PWR_GD

BACKSIDE_PWR_RST*

10

CPCI_RST*

BACKSIDE_PWR_GD

BACKSIDE_PWR_RST*

Transparent

PCI_VIO

10 K

5.11 K

PMC_RSTOUT*

PCIXCAP_HEALTHY*

PLD

(internal signal)

(1)

HS_ON*

HS_PWRGD*

No System Controller

PCI_VIO

10 K

5.11 K

PMC_RSTOUT*

PLD

(0)

HS_ON*

HS_PWRGD*

BRIDGE_RST*

BRIDGE_RST_OUT*

S_RSTIN*

S_RSTOUT*

BRIDGE_RST*

BRIDGE_RST_OUT*

S_RSTIN*

S_RSTOUT*

• At power-up, the CC1000dm carrier card generates a hard reset.

• The voltage monitor detects voltage supplies of +5 V, +3.3 V, +12 V,-12 V, or

PMC_3_3V that fall below the minimum thresholds of +4.7 V, +3.1 V,

+11.4 V, -10.8 V, or 3.1 V, respectively.

• Input from the cPCI reset signal (except when in the no system controller mode)

• Pressing the reset switch (SW1) on the CC1000dm front panel

• Writing to the PLX PCI 6254 (HB6) Bridge Control register from the PCI address

space can generate a reset on the S-RST* signal.

• Input from the RSTOUT* signal from either PMC slot 1 or PMC slot 2.

2-12 CC1000dm User’s Manual 10004281-02

Page 31

SETUP

Troubleshooting

. . . . .

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In case of difficulty, use this checklist:

❐ Be sure the CC1000dm circuit board is seated firmly in the card cage.

❐ Be sure the system is not overheating.

❐ Check the cables and connectors to be certain they are secure.

❐ Verify that the PMC modules are fully installed and seated firmly in the PMC slots.

Technical Support

Service Information

If you need help resolving a problem with your CC1000dm, visit

http://www.artesyncp.com/support on the internet or send E-mail to

support@artesyncp.com. Please have the following information handy:

• CC1000dm serial number and product identification from the sticker

• version and part number of the operating system (if applicable)

• whether your board has been customized for options

• license agreements (if applicable)

If you do not have internet access, please call Artesyn at (800) 327-1251 for further

assistance.

If you plan to return the board to Artesyn Communication Products for service, visit

http://www.artesyncp.com/support on the internet or send E-mail to

serviceinfo@artesyncp.com to obtain a Return Merchandise Authorization (RMA) number. We will ask you to list which items you are returning and the board serial number,

plus your purchase order number and billing information if your CC1000dm hardware

is out of warranty. Contact our Test Services Department for any warranty questions. If

you return the board, be sure to enclose it in an antistatic bag, such as the one in which

it was originally shipped. Send it prepaid to:

Artesyn Communication Products

Test Services Department

8310 Excelsior Drive

Madison, WI 53717

RMA #____________

Please put the RMA number on the outside of the package so we can handle your problem efficiently. Our service department cannot accept material received without an

RMA number.

10004281-02 CC1000dm User’s Manual 2-13

Page 32

SETUP

2

Troubleshooting

2-14 CC1000dm User’s Manual 10004281-02

Page 33

PMC/PCI I

NTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

he CC1000dm has two 3.3 volt/5 volt, 64-bit, Processor PMC slots, designated

PMC1 and PMC2. Either slot can be configured as a Monarch module by means

T

of a ten-pin jumper (see JP3 on page 2 -7). When the CC1000dm is in transpar-

ent mode, neither PMC slot is selected as Monarch. The PMC slots comply with IEEE

Standard for a Common Mezzanine Card Family: CMC IEEE Std 1386-2001.

PCI BRIDGE FEATURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The CC1000dm supports PCI bus speeds of up to 66 MHz with the PLX PCI 6254 (HB6)

dual-mode (transparent and non-transparent), universal 64-bit PCI-to-PCI bridge. In

transparent mode, the PCI bus is connected to the primary port. In non-transparent

mode, the PCI bus is connected to the secondary port. Some additional features include:

• The PLX PCI 6254 bridge complies with the PCI Local Bus Specification Revision 2.3

Bus Interface

• 64-bit PCI address/data busses

• Asynchronous primary and secondary ports can operate at different frequencies–a

maximum ratio of 1:2:5 or 2:5:1 between primary and secondary bus clocks

. . . . .

3

• Serial ROM interface

•PCI bus arbiter

PMC MODULE INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The CC1000dm carrier card has two PMC expansion slots–J1x and J2x (PMC1 and

PMC2). A single-width PMC module may be installed at each of these slots. Each slot

includes a cutout on the front panel for I/O.

When installing a PMC module, follow these guidelines:

1 Before adding modules to the CC1000dm carrier card, be sure that the combined power

requirements of the CC1000dm carrier card and the PMC modules do not exceed the system’s power

supply rating or cPCI ratings. Table 3-1 . describes the power available at the PMC slots.

10004281-02 CC1000dm User’s Manual 3-1

Page 34

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T a b l e 3 - 1 :

PMC Slots Available Power

N o t e :

A maximum load current of 6

amps (worst case) results in a

voltage drop of approximately

100 mV to the PMC 5 volt

power supply inputs. To ensure

proper module operation,

adjust the CompactPCI power

supply to accommodate any

voltage drop or power supply

ripple that may occur when

operating the ca rrier card.

PMC/PCI INTERFACE

PMC Module Installation

3.3 Volts: 5 Volts: 3.3 and 5 Volts Combined:

8.5 amps 6 amps 28-30 watts

2 To prevent ESD damage to the CC1000dm carrier card and the PMC modules, wear a grounding

wriststrap and use a grounded work surface while handling the card.

3 Set up the PMC module and install it on the CC1000dm carrier card as specified in the module’s

hardware manual.

Monarch Functionality

Device Mapping

T a b l e 3 - 2 :

IDSEL Mapping for PCI

Devices

Each slot (PMC1 and PMC2) on the CC1000dm carrier card can be configured to function as either a Monarch or non-Monarch PMC slot (in non-transparency or legacy

mode), as described in the Processor PMC Standard for Processor PCI Mezzanine Cards,

VITA 32- 2003 Specification. Although only one slot can be a Monarch, there can be

as many non-Monarch PMCs as the carrier card can support. A module placed on the

Monarch slot performs local PCI bus enumeration and handles PMC interrupts. A module placed on the non-Monarch slot behaves in the traditional slave processor manner.

Both slots have the ability to be configured as either Monarch or non-Monarch by the

10-pin jumper at JP3.

Once the Monarch PMC module has completed initialization of the CC1000dm local

bus, the PCI agents located on that bus are available for access. There are up to two PCI

devices installed on the PLX PCI 6254 (HB6) secondary bus and two PCI IDSEL lines

allocated to each PMC slot.

PCI Address Line: Local PCI Device IDSEL Connection:

AD22 PMC 1

AD21 PMC 1 Alternate Device

AD20 PMC 2

AD19 PMC 2 Alternate Device

AD18 PLX PCI 6254 (HB6) PCI Bridge

Table 3-2 lists all the IDSEL mappings.

3-2 CC1000dm User’s Manual 10004281-02

Page 35

PMC/PCI INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PMC Module Installation

. . . . .

Timing

Interrupts

T a b l e 3 - 3 :

PMCx Interrupt Mapping

The module interface transfers data between the PCI and local memory at burst data

rates. When two modules are installed, they both contend for ownership of a common

bus, which may reduce the individual performance of each module. Specific transfer

rates to the PCI bus are dependent on the module design.

Many PMC modules also incorporate a bridge chip between their PCI and local busses,

essentially creating two bridges that must be crossed to complete a cycle. Often, the

second bridge is a source of long delays due to the associated bus acquisition latency.

Initialization and time-out values should be set up to accommodate any additional

latency.

External interrupts that are controlled by the CC1000dm carrier card are routed to the

on-board devices/slots as follows:

PMC1/ PMC2

Base PCI

Interrupt

Assignment (secondary):

INTA INTA (J21, pin 4) INTC (J11, pin 6)

INTB INTB (J21, pin 5) INTD (J11, pin 9)

INTC PLX PCI 6254 (HB6) INTC (J21, pin 6) INTA (J11, pin 4)

INTD INTD (J21, pin 9) INTB (J11, pin 5)

(Transparent, non-transparent, no

system controller modes)

System Controller PCI Interrupt Line:

PMC1

(Legacy mode only)

Non-System Controller

PCI Interrupt Line:

T a b l e 3 - 4 :

cPCI Interrupt Mapping

Arbitration

Base cPCI Interrupt

Assignment:

INTA (J1, pin A3) INTA INTA (PCI 6254 primary side)

INTB (J1, pin B3) INTB –

INTC (J1, pin C3) INTC –

INTD (J1, pin E3) INTD –

The CC1000dm arbitration control for the on-board PCI devices is provided by the PLX

PCI 6254 PCI-to-PCI bridge. The PCI 6254 arbitrates for use of the primary bus when

initiating upstream transactions and for use of the secondary bus when forwarding

downstream transactions. The primary bus arbiter is external to the PCI 6254, and the

secondary bus is an internal arbiter on the PCI 6254.

Transparent Mode

(secondary): Non-Transparent or Legacy Mode:

10004281-02 CC1000dm User’s Manual 3-3

Page 36

PMC/PCI INTERFACE

3

PMC Module Installation

R e g i s t e r 3 - 1 :

Intern al Arbiter Control Register

151413121110987654 3 210

BPC HPMHP HPMLP HPGAHPGFLPGALPG

The Internal Arbiter Control register is located at offset 50h. All bits are read/write.

LPGF:

Low Priority Group Fixed arbitration

F

1 Uses the fixed priority arbitration scheme

0 Uses the rotating priority arbitration scheme (default)

LPGA:

Low Priority Group Arbitration order

This bit is only valid when the low priority arbitration group is set to a fixed arbitration

scheme (relative to HPM).

1 Priority decreases in ascending numbers of the master

0 Priority increases in ascending numbers of the master (default)

HPGF:

High Priority Group Fixed arbitration

1 Uses the fixed priority arbitration scheme

0 Uses the rotating priority arbitration scheme (default)

HPGA:

High Priority Group Arbitration order

This bit is only valid when the high priority arbitration group is set to a fixed arbitration scheme (relative to HPM).

1 Priority decreases in ascending numbers of the master

0 Priority increases in ascending numbers of the master (default)

HPMLP:

Highest Priority Master in Low Priority group

This controls which master in the low priority group has the highest priority (only for

fixed arbitration scheme).

0000 Master#0 has highest priority (default)

0001 Master#1 has highest priority

to…

1001 PCI 6254 has highest priority

1010- 1111 r es er v ed

HPMHP:

Highest Priority Master in High Priority group

This controls which master in the high priority group has the highest priority. It is valid

only in the fixed arbitration scheme.

0000 Master#0 has highest priority (default)

0001 Master#1 has highest priority

3-4 CC1000dm User’s Manual 10004281-02

Page 37

. . . . . . . . . . . . . . . . . . . . . . . . . .

T a b l e 3 - 5 :

Request/Grant Assignments

PMC/PCI INTERFACE

PMC Module Installation

to…

1001 PCI 6254 has highest priority

1010- 1111 r es er v ed

BPC:

Bus Parking Control

This controls the bus grant behavior during idle.

0000 Last master granted is parked (default)

0001 Master #0 is parked

to…

1001 Mas te r #8 is parked

1010 PCI 6254 is parked

Others Grant is deasserted

The secondary arbiter implements a programmable two-level rotating algorithm

whereby the priorities are re-evaluated at the start of each new transaction on the secondary PCI bus. From this point until the time the next transactions starts, the arbiter

will assert grants corresponding to the highest priority request asserted. The arbiter supports up to ten request/grant pairs. The request/grant assignments for the arbiter are

shown in the following table. For more detailed information regarding arbitration, refer

to the PLX PCI 6254 documentation listed in the Technical References

CC1000dm

Request/Grant Local PCI Bus Device:

Table 1-2.

0PMC 1

. . . . .

1PMC 2

2 reserved

3 reserved

4 PMC 1 Alternate Device

5 PMC 2 Alternate Device

6 reserved

7 reserved

8 reserved

9 PCI 6254

10004281-02 CC1000dm User’s Manual 3-5

Page 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T a b l e 3 - 6 :

PLX PCI 6254 Configuration

Signals

PMC/PCI INTERFACE

3

Bridge EEPROM

BRIDGE EEPROM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The PLX PCI 6254 PCI-to-PCI bridge utilizes ROM interface signals to initialize the PCI

6254 registers. The following table briefly describes these signals (see the data book for

complete information):

Signal Description:

EEPCLK The EEPROM Clock output signal to the EEPROM interface is used during

autoload and for VPD functions. This pin is tri-stated if EE_EN* = 1.

EEPDATA The EEPROM Serial Data interfaces to the EEPROM (bi-directional). This pin

EE_EN* The EEPROM Enable LOW input enables EEPROM access.

is tri-stated if EE_EN* = 1.

0=enable EEPROM use

1=connect to logic 1 state

PCI 6254 CONFIGURATION REGISTERS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The PCI 6254 can be configured to act as either a transparent or non-transparent PCIto-PCI bridge by selecting the appropriate jumper on JP5 (see page 2-9). In transparent

R e g i s t e r 3 - 2 :

PCI6254 Configuration Registers–

Transparent Mode

Primary

Offset 31 24 23 16 15 8 7 0

00h Device ID Vendor ID

04h Primary Status Primary Command

08h Class Code Revision ID

0Ch BIST Header Type Primary Latency Time Cache Line Size

10h

18h Secondary Latency Timer

mode, the CC1000dm system PCI bus is connected to the PCI 6254 primary port. The

PCI 6254 non-transparent mode acts as a memory-mapped PCI device with the primary

port connected to the cPCI backplane.

reserved

Subordinate Bus Number Secondary Bus Number Primary Bus Number

1Ch

20h

24h

3-6 CC1000dm User’s Manual 10004281-02

Secondary Status I/O Limit I/O Base

Memory Limit Memory Base

Prefetchable Memory Limit Prefetchable Memory Base

Page 39

PMC/PCI INTERFACE

PCI 6254 Configuration Registers

. . . . .

28h

2Ch

30h

34h

38h

3Ch

40h

44h

48h

4Ch

50h

54h EEPROM Data EEPROM Address EEPROM Control

58h

Secondary Incremental

Prefetch Count

I/O Limit Upper 16 Bits I/O Base Upper 16 Bits

Bridge Control Interrupt Pin

Arbiter Control Diagnostic Control Chip Control

Miscellaneous Options Time-out Control

reserved

reserved Test Register Internal Arbiter Control

Prefetchable Memory Base Upper 32 Bits

Prefetchable Memory Limit Upper 32 Bits

reserved

reserved

Primary Incremental

Prefetch Count

Secondary Flow Through

Control

reserved

Secondary Prefetch Line

Count

Secondary Maximum

Prefetch Count

ECP Pointer

reserved

Primary Flow Through

Control

Primary Prefetch Line

Count

Primary Maximum Prefetch

Count

64h GPIO[3-0] Input Data

68h Clkrun Register P_SERR* Status Clock Control

6Ch Private Memory Li mit Private Memory Base

70h Private Memory Base Upper 32 Bits

74h Private Memory Limit Upper 32 Bits

78h

9Ch GPIO[7-4] Input Dataport GPIO[7-4] Output Enable GPIO[7-4] Output Data

A0h GPIO[15-8] Input Dataport GPIO[15-8] Output Enable GPIO[15-8] Output Data Power-up Status

GPIO[3-0] Output Enable

Control

10004281-02 CC1000dm User’s Manual 3-7

GPIO[3-0] Output Data P_SERR* Event Disable

reserved

Hot Swap Switch ROR

Control

Page 40

PMC/PCI INTERFACE

3

PCI 6254 Configuration Registers

ACh reserved

D0h Extended Register Index

reserved reserved reserved

D4h Extended Registers Dataport

D8h

reserved

DCh Power Management Capabilities Next Item Pointer=E4 Capability ID=01

E0h Power Management Data PMCSR Bridge Support Power Management CSR

E4h

reserved HSCSR=00 Next Item Pointer=E8 Capability ID=06

E8h VPD Register=0000 Next Item Pointer=00 Capability ID=03

ECh VPD Data Register=0000_0000

F0h

reserved

R e g i s t e r 3 - 3 :

PCI6254 Configuration Registers–

Non-Transparent Mode

Primary

31 24 23 16 15 8 7 0

Offset

00h Device ID Vendor ID

04h Primary Status Primary Command

08h Class Code Revision ID

0Ch BIST Header Type Primary Latency Time Primary Cache Line Size

10h Downstream I/O or Memory 0 Bar

14h Downstream Memory 1 Bar

18h Downstream Memory 2 Bar or Downstream Memory 1 Bar Upper 32 bits

1Ch

reserved

2Ch Subsystem ID Subsystem Vendor ID

30h

34h

3-8 CC1000dm User’s Manual 10004281-02

reserved Capability Pointer

reserved

Page 41

PMC/PCI INTERFACE

PCI 6254 Configuration Registers

38h reserved

3Ch Primary Maximum Latency Primary Minimum Grant Primary Interrupt Pin Primary Interrupt Line

40h Device ID Vendor ID

44h Secondary Status Secondary Command

48h Class Code Revision ID

4Ch BIST Header Type Secondary Latency Timer Secondary Cache Line Size

50h Upstream I/O or Memory 0 Bar

54h Upstream Memory 1 Bar

58h Upstream Memory 2 Bar or Upstream Memory 1 Bar Upper 32 bits

. . . . .

5Ch

6Ch Subsystem ID Subsystem Vendor ID

70h

74h

78h

7Ch Secondary Max Latency Secondary Minimum Grant Secondary Interrupt Pin Secondary Interrupt Line

80h XB Downstream Configuration Address

84h XB Downstream Configuration Dataport

88h XB Upstream Configuration Address

8Ch XB Upstream Configuration Dataport

90h

94h

98h GPIO[3-0] Input Data

reserved

reserved SERR* Event Disable Clock Control

reserved Capability Pointer

XB Config Access

Semaphore Status

GPIO[3-0] Output Enable

Control

reserved

reserved

reserved

XB Upstream Config Own

Semaphore

GPIO[3-0] Output Data SERR* Status

XB Downstream Config

Own Semaphore

10004281-02 CC1000dm User’s Manual 3-9

Page 42

PMC/PCI INTERFACE

3

PCI 6254 Configuration Registers

9Ch GPIO[7-4] Input Register GPIO[7-4] Output Enable GPIO[7-4] Output Data

A0h GPIO[15-8] Input Register GPIO[15-8] Output Enable GPIO[15-8] Output Data Power-up Status

A4h Upstream Message 3 Upstream Message 2 Upstream Message 1 Upstream Message 0

A8h Downstream Message 3 Downstream Message 2 Downstream Message 1 Downstream Message 0

ACh MSI Control Next Item Pointer=00 MSI Cap ID=5 (rev AA=8)

B0h MSI Address

B4h MSI U pper Address

B8h

BCh

C0h Downstream Doorbell Request Downstream Doorbell Enable

C4h Upstream Doorbell Request Upstream Doorbell Enable

C8h Upstream Interrupt Enable

CCh

Downstream Interrupt

Enable

reserved MSI Data

reserved

Downstream Interrupt

Status

Upstream Interrupt Status Upstream Doorbell Status

Downstream Doorbell Status

Hot Swap Switch ROR

Control

D0h Extended Register Index NT Config Own Semaphore

D4h Extended Registers Dataport

D8h Arbiter Control Diagnostic Control Chip Control

DCh Power Management Capabilities Next Item Pointer=E4 Capability ID=01

E0h Power Management Data PMSCSR Bridge Support Power Management CSR

E4h

E8h VPD Register=0000 Next Item Pointer=00 Capability ID=03

ECh VPD Data Register=0000_0000

F0h

3-10 CC1000dm User’s Manual 10004281-02

reserved HSCSR=00 Next Item Pointer=E8 Capability ID=06

reserved

reserved reserved

Page 43

PMC/PCI INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCI Identification Values

. . . . .

PCI IDENTIFICATION VALUES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Each CC1000dm configuration has a unique set of identification values. The base

address for these values is determined by the CC1000dm’s location in the cPCI rack and

the baseboard. The standard PCI hex offsets are:

T a b l e 3 - 7 :

PCI Identification Values

T a b l e 3 - 8 :

Debug Header Pin

Assignments (JP1, JP2)

Vendor ID 00

Device ID 02

Subsystem Vendor ID 2C

Subsystem ID 2E

All of these values are two bytes wide (half-word). Please refer to the PLX PCI 6254

data book for more information. The following table lists the identification values for

the different CC1000dm configurations:

Vendor

ID (hex):

3388 20 – – Transparent

Device

ID (hex):

21 1223 3A Non-transparent

Subsystem

Vendor ID (hex):

16

16

16

16

Subsystem

Device ID (hex): PCI 6254 Bridge Mode:

JTAG HEADERS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Each processor PMC slot has a 10-pin debug header (see Fig. 2-5). These headers are

located at JP1 (PMC1) and JP2 (PMC2) to provide easy access to the following signals

Table 3-8:

in

Pin: Signal: Pin: Signal:

1TCK 2ground

3TDO 45V (fused)

5TMS

7 no connect 8 no connect

9TDI 10ground

The signals for the JTAG header are defined as follows:

TCK:

Test Clock Input is clock state information and test data into and out of PMC slots during the test access port (TAP) operation. Scan data is latched at the rising edge of this

signal.

6 no connect

10004281-02 CC1000dm User’s Manual 3-11

Page 44

3

PMC/PCI INTERFACE

PCI Bus Control Signals

TDO:

Test Data Output signal acts as the output port for test data and test instructions out of

the PMC slots during TAP operation.

TMS:

Test Mode Select controls the state of the TAP controller in the PMC slots.

TDI:

Test Data Input signal acts as the input port for test data and test instructions into the

PMC slots during TAP operation.

PCI BUS CONTROL SIGNALS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following signals for the PCI interface are available on connectors J1x and J2x.

Refer to the PCI specification for detailed usage on these signals. All signals are bidirectional unless otherwise stated.

ACK64*, REQ64*:

AD00-AD63:

C/BE0* - C/BE7*:

CLK:

DEVSEL*:

EREADY:

FRAME*:

GNT*:

IDSEL:

ACKNOWLEDGE and REQUEST output signals are used to tell a 64-bit PCI device

whether to use the 64-bit or the 32-bit data width.

ADDRESS and DATA bus (bits 0-63) tri-state lines are used for both address and data

handling. A bus transaction consists of an address phase followed by one or more data

phases.

BUS COMMAND and BYTE ENABLES tri-state lines have different functions depending

on the phase of a transaction. During the address phase of a transaction these lines

define the bus command. During a data phase the lines are used as byte enables.

CLOCK input signal to the PMC modules provides timing for PCI transactions.

DEVICE SELECT sustained tri-state signal indicates when a device on the bus has been

selected as the target of the current access.

ENUMERATION READY open-drain output signal of a non-Monarch PrPMC indicates it

has completed its on-board initialization and can respond to PCI bus enumeration. As

an input signal to the Monarch PrPMC, it indicates all non-Monarchs have completed

their on-board initialization and can respond to PCI bus enumeration.

CYCLE FRAME sustained tri-state line is driven by the current master to indicate the

beginning of an access, and continues to be asserted until the transaction reaches its

final data phase.

GRANT input signal indicates that access to the bus has been granted to a particular

master. Each master has its own GNT*.

INITIALIZATION DEVICE SELECT input signal acts as a chip select during configuration

read and write transactions.

IDSELB:

3-12 CC1000dm User’s Manual 10004281-02

INITIALIZATION DEVICE SELECT B; if the optional second PCI agent is implemented,

then IDSELB is connected as its IDSEL input.

Page 45

PMC/PCI INTERFACE

PCI Bus Control Signals

. . . . .

INTA*, INTB*, INTC*, INTD*:

IRDY*:

LOCK*:

M66EN:

MONARCH:

PAR:

PAR64:

PERR*:

PME*:

PMC INTERRUPTS A, B, C, D lines are used to interrupt the CPU.

INITIATOR READY sustained tri-state signal indicates that the bus master is ready to

complete the data phase of the transaction.

LOCK sustained tri-state signal indicates an atomic operation to a bridge that may

require multiple transactions to complete.

66 MHZ ENABLE input pin indicates to a device whether the bus segment is operating

at 66 or 33 MHz.

MONARCH when grounded, indicates that the PrPMC module is a Monarch and must

provide PCI bus enumeration and interrupt handling.

PARITY is even parity across AD00-AD31 and C/BE0-C/BE3*. Parity generation is

required by all PCI agents. This tri-state signal is stable and valid one clock after the

address phase, and one clock after the bus master indicates that it is ready to complete

the data phase (either IRDY* or TRDY* is asserted). Once PAR is asserted, it remains

valid until one clock after the completion of the current data phase.

PARITY UPPER DWORD tri-state signal is even parity that protects AD[63:0] and

C/BE[7:0]*. PAR64 must be valid one clock after each address phase on any transaction

in which REQ64* is asserted.

PARITY ERROR sustained tri-state line is used to report parity errors during all PCI

transactions.

Power Management Event optional open-drain signal (pull-up resistor required) allows

a device to request a change in the power state. Devices must be enabled by software

before asserting this signal.

REQ*:

RST*:

SERR*:

STOP*:

TDI*:

TDO*:

TMS*:

REQUEST output pin indicates to the arbiter that a particular master wants to use the

bus.

RESET; assertion of this input line brings PCI registers, sequencers, and signals to a

consistent state.

SYSTEMS ERROR open-collector output signal is used to report any system error with

catastrophic results.

STOP is a sustained tri-state signal used by the current target to request that the bus

master stop the current transaction.

TEST DATA INPUT signal serially shifts test data and test instructions into the device

during test access port (TAP) operation.

TEST DATA OUTPUT signal serially shifts test data and test instructions out of the

device during TAP operation.

TEST MODE SELECT input signal controls the state of the TAP controller in the device.

10004281-02 CC1000dm User’s Manual 3-13

Page 46

PMC/PCI INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

J

A

3

PMC Connector Pin Assignments

TRDY*:

TRST*:

TARGET READY is a sustained tri-state signal that indicates the target’s ability to complete the current data phase of the transaction.

TEST RESET input signal provides an asynchronous initialization of the TAP controller.

PMC CONNECTOR PIN ASSIGNMENTS

a b l e 3 - 9 :

1x PMC Connector Pin

ssignments

Pin: J11: J12: J13: J14: Pin: J11: J12: J13: J14:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Each PMC expansion slot has four 64-pin connectors, see Table 3- 9 and Table 3-10.

. . . . .

1 TCK +12 V no connect P14.1 33 PCI_FRAME* ground ground P14.33

2 -12 V TRST* ground P14.2 34 ground IDSELB AD48 P14.34

3 ground TMS ground P14.3 35 ground PCI_TRDY* AD47 P14.35

4 PCI_INTA* TDO PCI_CBE7* P14.4 36 PCI_IRDY* +3.3 V AD46 P14.36

5 PCI_INTB* TDI PCI_CBE6* P14.5 37 PCI_DEVSEL* ground AD45 P14.37

6 PCI_INTC* ground PCI_CBE5* P14.6 38 +5 V PCI_STOP* ground P14.38

7

no connect ground PCI_CBE4* P14.7 39 ground PCI_PERR* V(I/O) P14.39

8+5 V

9PCI_INTD*

no connect ground P14.8 40 PCI_LOCK* ground AD44 P14.40

no connect V(I/O) P14.9 41 PCI_SDONE* +3.3 V AD43 P14.41

10

no connect no connect PCI_PAR64 P14.10 42 PCI_SBO* PCI_SERR* AD42 P14.42

11 ground PUP0 AD63 P14.11 43 PCI_PAR PCI_CBE1* AD41 P14.43

12 +3.3 V +3.3 V AD62 P14.12 44 ground ground ground P14.44

13 PCLK PCI_RST* AD61 P14.13 45 V(I/O) AD14 ground P14.45

14 ground PDN0 ground P14.14 46 AD15 AD13 AD40 P14.46

15 ground +3.3 V ground P14.15 47 AD12 PCI_M66EN AD39 P14.47

16 GNT* PDN1 AD60 P14.16 48 AD11 AD10 AD38 P14.48

17 REQ* PCI_PME* AD59 P14.17 49 AD9 AD8 AD37 P14.49

18 +5 V ground AD58 P14.18 50 +5 V +3.3 V ground P14.50

19 V(I/O) AD30 AD57 P14.19 51 ground AD7 ground P14.51

20 AD31 AD29 ground P14.20 52 PCI_CBE0* REQB* AD36 P14.52

3-14 CC1000dm User’s Manual 10004281-02

Page 47

PMC/PCI INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

J

A

PMC Connector Pin Assignments

. . . . .

Pin: J11: J12: J13: J14: Pin: J11: J12: J13: J14:

. . . . .

21 AD28 ground V(I/O) P14.21 53 AD6 +3.3 V AD35 P14.53

22 AD27 AD26 AD56 P14.22 54 AD5 GNTB* AD34 P14.54

23 AD25 AD24 AD55 P14.23 55 AD4

24 ground +3.3 V AD54 P14.24 56 ground ground ground P14.56

25 ground IDSEL AD53 P14.25 57 V(I/O)

26 PCI_CBE3* AD23 ground P14.26 58 AD3 PCI_EREADY AD32 P14.58

27 AD22 +3.3 V ground P14.27 59 AD2 ground

28 AD21 AD20 AD52 P14.28 60 AD1 PMC_RSTOUT*

29 AD19 AD18 AD51 P14.29 61 AD0 PCI_ACK64*

30 +5 V ground AD50 P14.30 62 +5 V +3.3 V ground P14.62

31 V(I/O) AD16 AD49 P14.31 63 ground ground ground P14.63

32 AD17 PCI_CBE2* ground P14.32 64 PCI_REQ64* Monarch

a b l e 3 - 1 0 :

2x PMC Connector Pin

ssignments

Pin: J21: J22: J23: J24: Pin: J21: J22: J23: J24:

no connect AD33 P14.55

no connect V(I/O) P14.57

no connect P14.59

no connect P14.60

no connect P14.61

no connect P14.64

. . . . .

1 TCK +12 V no connect P24.1 33 PCI_FRAME* ground ground P24.33

2 -12 V TRST* ground P24.2 34 ground IDSELB AD48 P24.34

3 ground TMS ground P24.3 35 ground PCI_TRDY* AD47 P24.35

4 PCI_INTA* TDO PCI_CBE7* P24.4 36 PCI_IRDY* +3.3 V AD46 P24.36

5 PCI_INTB* TDI PCI_CBE6* P24.5 37 PCI_DEVSEL* ground AD45 P24.37

6 PCI_INTC* ground PCI_BE5* P24.6 38 +5 V PCI_STOP* ground P24.38

7

no connect ground PCI_CBE4* P24.7 39 ground PCI_PERR* V(I/O) P24.39

8+5 V

9PCI_INTD*

10

no connect no connect PCI_PAR64 P24.10 42 PCI_SBO* PCI_SERR* AD42 P24.42

11 ground PUP0 AD63 P24.11 43 PCI_PAR PCI_CBE1* AD41 P24.43

12 +3.3 V +3.3 V AD62 P24.12 44 ground ground ground P24.44

no connect ground P24.8 40 PCI_LOCK* ground AD44 P24.40

no connect V(I/O) P24.9 41 PCI_DONE* +3.3 V AD43 P24.41

10004281-02 CC1000dm User’s Manual 3-15

Page 48

PMC/PCI INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

PMC Connector Pin Assignments