Page 1

Installation and Maintenance Manual

CbN Series 3000

Gearmotors and Reducers

Emerson Industrial Automation

7120 New Bufngton Road

Florence, KY 41042

Application Engineering: 800 626 2093

www.emerson-ept.com

F O R M

8772E

Revised

May 2012

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

Safety First

High voltage and rotating parts can cause serious or fatal injury. Safe installation,

operation and maintenance must be performed by qualied personnel. Familiarization with and adherence to NEMA MG2, the National Electric Code and local codes

is recommended. It is important to observe safety precautions to protect personnel

from possible injury. Personnel should be instructed to:

1. Avoid contact with energized circuits or rotating parts.

2. Disconnect all power sources before initiating any maintenance or repair.

3. Act with care in accordance with prescribed procedures in handling and

lifting this equipment.

4. Be sure the unit is electrically grounded in accordance with code

requirements.

5. Be sure equipment is properly enclosed to prevent access by children

or other unauthorized personnel in order to prevent possible accidents.

6. Be sure shaft key is fully captive before unit is energized.

7. Avoid contact with capacitors until safe discharge procedures have

been completed.

8. Most units are shipped with oil. Always be sure oil lubricated units are

lled with correct oil to proper level before operating.

9. Provide proper safeguards for personnel against rotating parts and

applications involving high inertia loads, which can cause overspeed.

10. Avoid extended exposure to equipment with high noise levels.

11. Be familiar with the equipment and read all instructions thoroughly

before installing or working on equipment.

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

Installation Instructions

Start-Up

Before operating the reducer or gearmotor, the following must be done:

• Install the drive on a rigid and vibration-free surface.

• Remove the protective coating on the shaft and ange. Use solvent

if necessary.

• Carefully install coupling, sheaves, sprockets, or pinions on shaft.

Mount as close to the shaft shoulder as possible.

• It is preferable to use heat instead of force. Do not hammer on shaft!

• Check shaft alignment when using direct coupling.

• Check shaft parallelism when using belt or chain drive.

CAUTION: Refer to belt manufacturer's recommendation for belt tension.

(Tension should not be applied on chain drives.)

• Check oil level in oil lubricated reducer.

• Install breather plug in the plug hole per recommendations shown on

page (5, 7, or 9) for sizes larger than frame 30.

Maintenance

Safe operation and product performance is improved with periodic inspections. It is

recommended the reducer or gearmotor be inspected every 50 hours of operating

time.

• Check mounting bolts and belt tension (if applicable).

Note: The preventative maintenance list below should be performed every

5000 hours of operating time:

• Check oil level and add oil if necessary.

• Make sure the vent plug pin in the breather is clean.

Browning, Emerson and Emerson Industrial Automation are trademarks of

Emerson Electric Co. or one of its affiliated companies.

©2007, 2010, 2012 Emerson Power Transmission Corp., All Rights Reserved.

MCIM12004E • Form# 8772E • Printed in USA

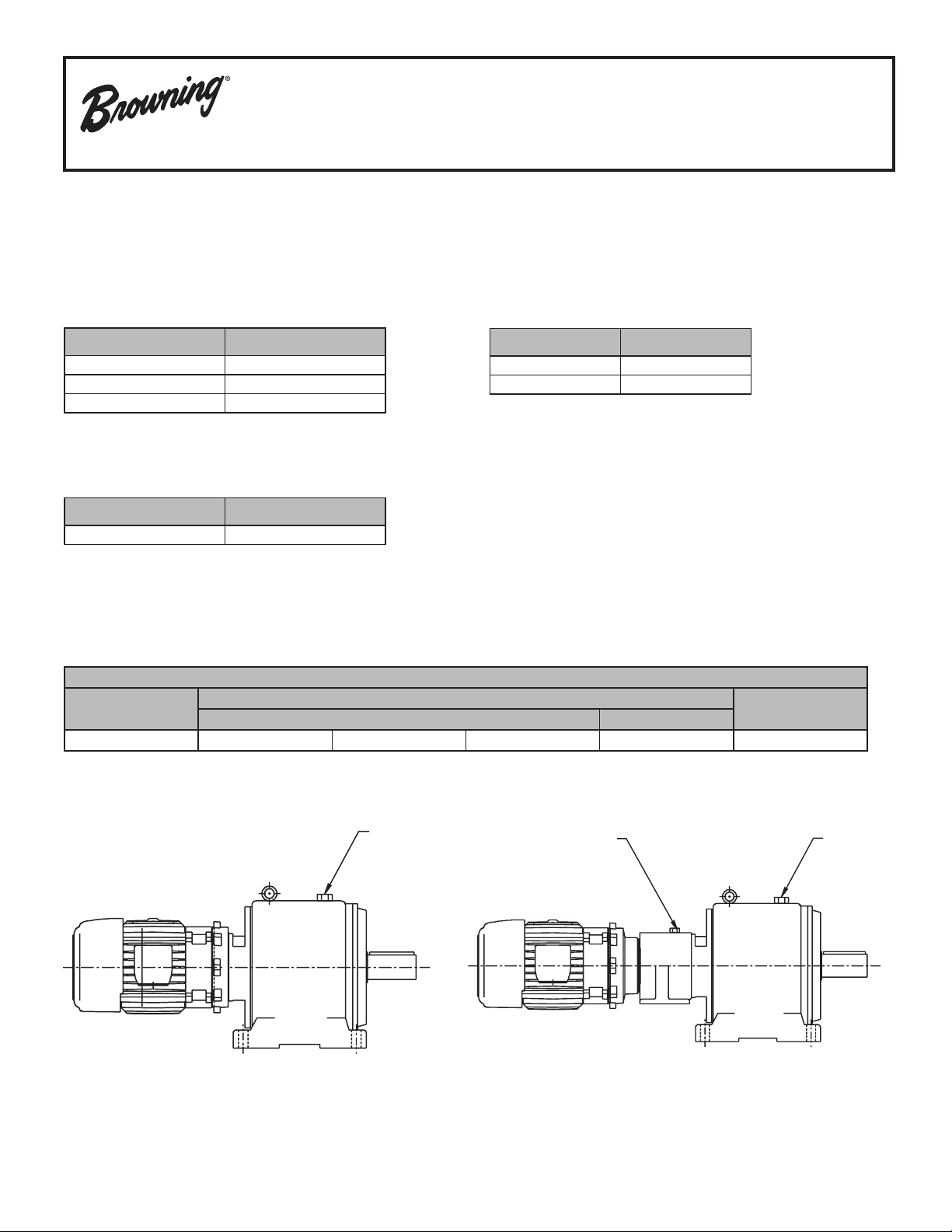

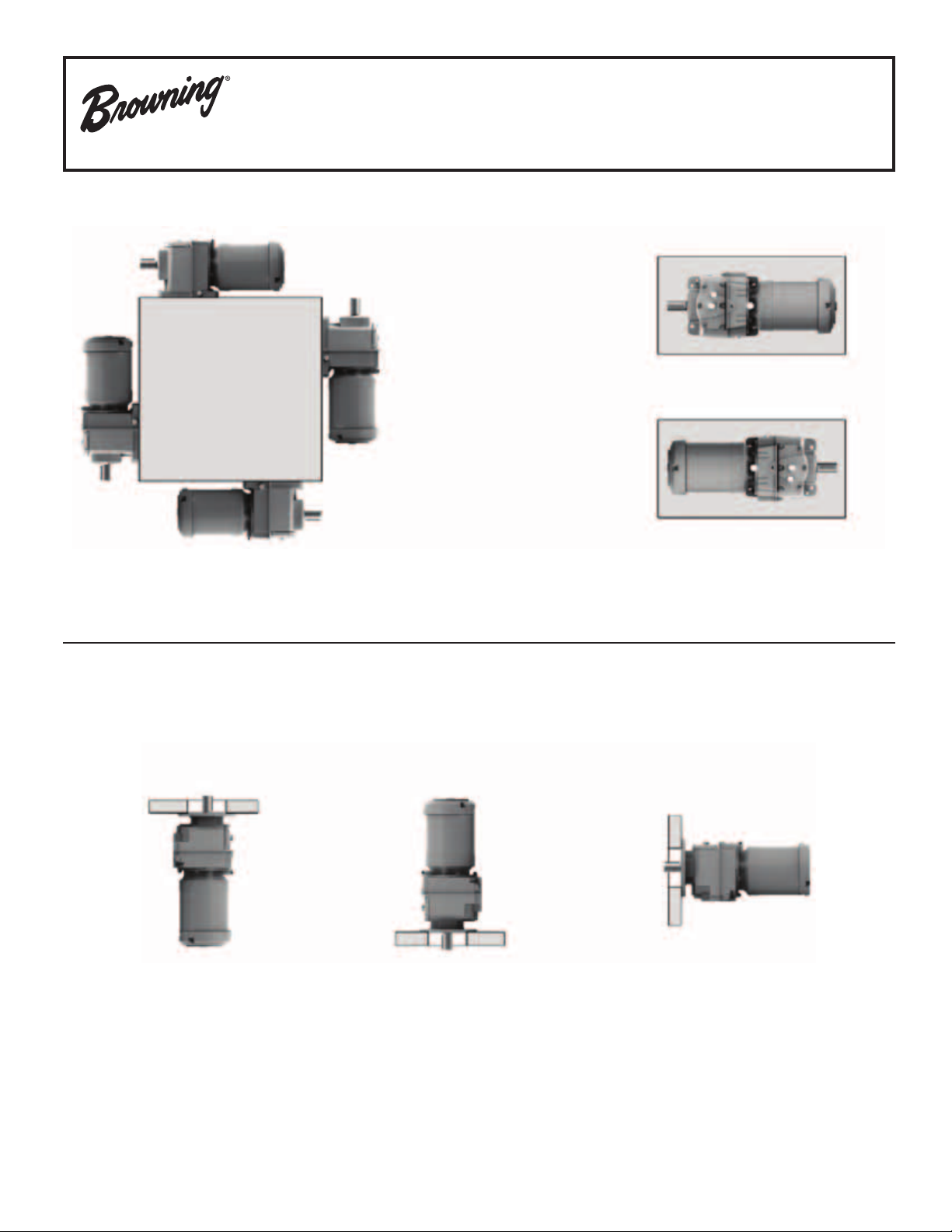

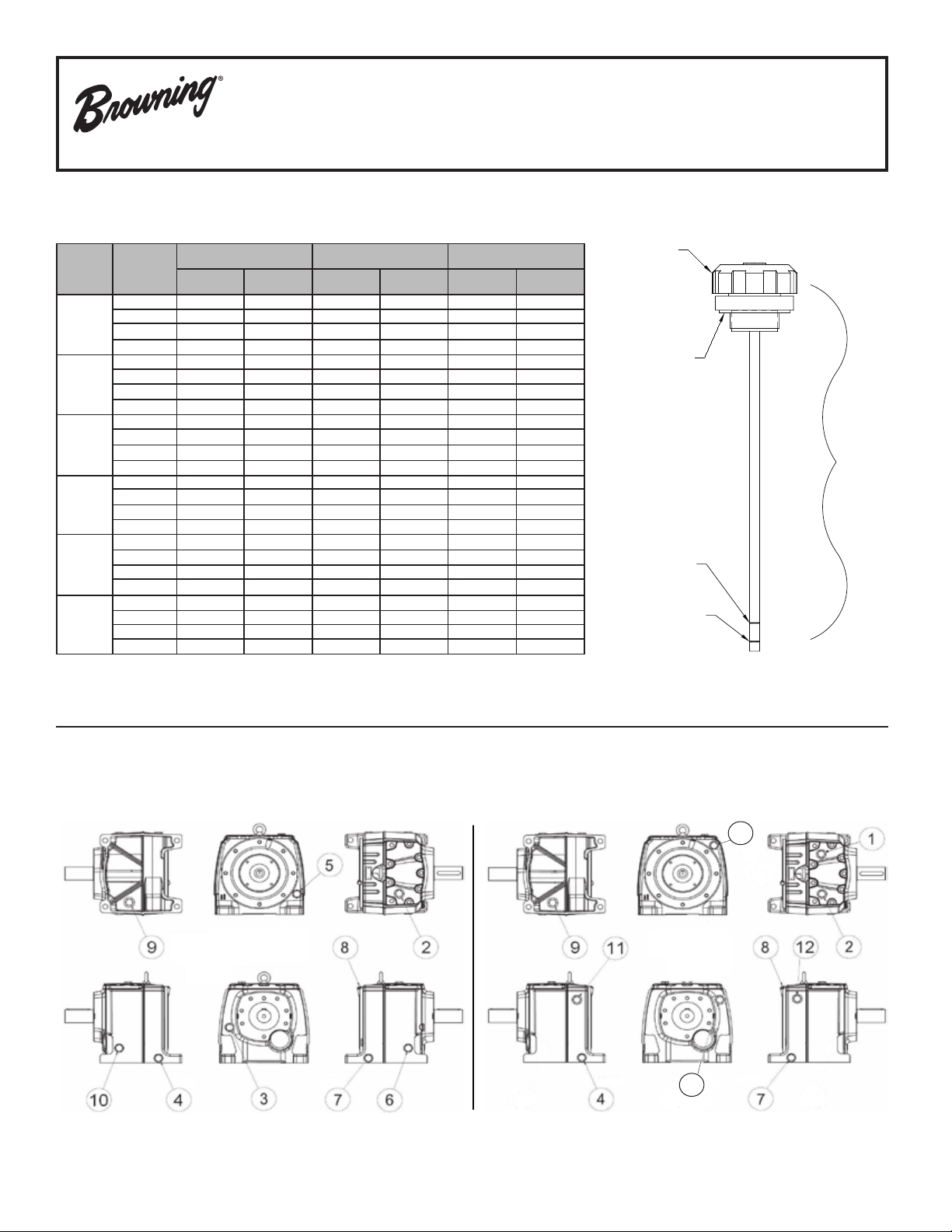

Page 2

Lubrication

Primary

Series 3000 CbN gearing is shipped with one of the following synthetic lubricants

per the table below and tted with a magnetic drain. Each reducer is lled according

to the mounting position specied when ordered. Refer to the unit nameplate and

the chart to the right for the mounting position arrangement for your unit.

In the case of synthetic oil, the lubricant does not require changing, but it is

recommended that proper oil level be checked periodically.

Standard Synthetic Gear Oil (Non-Food Grade)

No Backstop

Manufacturer

Fuchs * Sintogear 125

Mobil * Mobilgear SHC 150

Shell * Omala Fluids HD 150

-25° F to 125° F

(-30° C to 50° C)

With Backstop (1)

Manufacturer

Shell * Omala RL 100

Mobil * SHC 629

(-30° C to 50° C)

-25° F to 125° F

Standard Synthetic Gear Oil (H1 Rated Food Grade Requirements)

No Backstop

Manufacturer

Mobil * SHC Cibus 150

CAUTION!

• Never mix synthetic oil and mineral oil.

• Never use extreme pressure (EP) oil in a reducer with a backstop.

22° F to 125° F

(-20° C to 50° C)

Acceptable Mineral Oil Lubricants

Ambient Range of Installation

-4°F to 14°F

(-20°C to 10°C)

ISO VG 68 ISO VG 100 ISO VG 150 ISO VG 220 ISO VG 150 ISO VG 320

14°F to 122°F (-10°C to 50°C)

No Backstop With Backstop

122°F and Above

(50°C +)

One Thru Three Stage

Secondary

Combined

Primary

* The following trade names, trademarks and/or registered trademarks are used in this material by Emerson Power Transmission Corporation are NOT owned or controlled by Emerson Power

Transmission Corporation and are believed to be owned by the following parties: Fuchs and Sintogear: Fuchs Corporation, Mobil and Mobilgear. Exxonmobil Oil Corporation; Shell and Omala: Shell

Petroleum Incorporated. Emerson Power Transmission Corporation cannot and does not represent or warrant the accuracy of this information.

2

Page 3

One to Three Reduction

Stages

ONE

TWO

THREE

Gear

Frame

30 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33

31 0.37 0.37 0.53 0.53 0.74 0.53 0.74 0.53 0.58 1.06 0.58 1.06

32 0.26 0.26 0.58 0.58 0.79 0.58 0.79 0.58 0.63 0.84 0.63 0.84

33 0.95 0.95 1.48 1.48 2.01 1.48 2.01 1.48 2.22 2.22 2.22 2.22

34 2.11 2.11 3.17 3.38 4.44 3.17 4.44 3.38 4.02 3.17 4.02 3.17

(single reduction)

(Double Reduction)

(Triple Reduction)

35 3.38 3.38 5.49 5.28 7.71 5.49 7.71 5.28 6.13 5.81 6.13 5.81

30 0.63 0.63 0.63 0.63 0.63 - - - 0.63 0.63 0.63 0.63

31 0.63 0.63 1.00 0.90 1.16 - - - 1.22 1.48 1.22 1.48

32 1.00 1.00 1.85 1.64 2.38 - - - 2.38 2.85 2.38 2.85

33 1.69 1.69 3.49 3.12 4.70 - - - 4.75 4.65 4.75 4.65

34 3.49 3.49 7.40 4.97 7.08 - - - 7.93 7.93 7.93 7.93

35 5.49 5.49 10.46 8.98 13.95 - - - 15.53 14.48 15.53 14.48

36 8.45 8.45 12.69 19.02 23.77 - - - 25.36 25.89 25.36 25.89

37 13.74 13.74 22.19 33.81 40.15 - - - 44.91 43.85 44.91 43.85

38 17.96 17.96 26.42 53.89 61.30 - - - 68.68 64.46 68.68 64.46

30 0.74 0.74 0.74 0.74 0.74 - - - 0.74 0.74 0.74 0.74

31 0.63 0.63 1.30 0.90 1.16 - - - 1.22 1.48 1.22 1.48

32 1.00 1.00 2.43 1.64 2.38 - - - 2.38 2.85 2.38 2.85

33 1.69 1.69 4.62 3.12 4.70 - - - 4.75 4.65 4.75 4.65

34 3.49 3.49 7.40 4.97 7.08 - - - 7.93 7.93 7.93 7.93

35 5.49 5.49 13.21 8.98 13.95 - - - 15.53 14.48 15.53 14.48

36 8.45 8.45 15.85 19.02 23.77 - - - 25.36 25.89 25.36 25.89

37 13.74 13.74 28.50 33.81 40.15 - - - 44.91 43.85 44.91 43.85

38 17.96 17.96 45.44 53.89 61.30 - - - 68.68 64.46 68.68 64.46

B3 B5 B6 B7 B8 B52 B53 B54 V1 V3 V5 V6

Lubrication

Oil Capacities (U.S. Quarts)

Mounting Positions *

* refer to page illustrating mounting positions based on reduction stage(s) and gear frame to be checked or filled

Combined Gear Units -

Composition NOTE:

Stages

FOUR

FIVE

SIX

Combined

Gear Frame

3254 32 Two CbN 30 Two CbN that is factory lled and requires monitoring

3374 33 Two CbN 30 Two CbN before start-up and during operation. The table

3484 34 Two CbN 31 Two CbN at left denes the gear size, and type for each

3594 35 Two CbN 31 Two CbN CbN gear of a specic “combined” gear reducer.

3604 36 Two CbN 32 Two CbN

3734 37 Two CbN 32 Two CbN Refer to the table above for oil volume based

3844 38 Two CbN 34 Two CbN on mounting position specied

3255 32 Two CbN 30 Three CbN

3375 33 Two CbN 30 Three CbN

3485 34 Two CbN 31 Three CbN Oil sumps of frames 36, 37, and 38 are equipped

3595 35 Two CbN 31 Three CbN with a dipstick (with breather) for the

3605 36 Two CbN 32 Three CbN purposes of oil level monitoring when a unit

3735 37 Two CbN 32 Three CbN is not operating.

3845 38 Two CbN 34 Three CbN

3256 32 Three CbN 30 Three CbN

3376 33 Three CbN 30 Three CbN Oil sumps of frames 31 through 35 are equipped

3486 34 Three CbN 31 Three CbN with an oil level plugs for the purposes of

3596 35 Three CbN 31 Three CbN oil level monitoring when that unit is not

3606 36 Three CbN 32 Three CbN operating .

3736 37 Three CbN 32 Three CbN

3846 38 Three CbN 34 Three CbN

Frame Stages Type Frame Stages Type together. Each gear unit has a separate oil sump

Primary Secondary These consist of 2 CbN gear units assembled

3

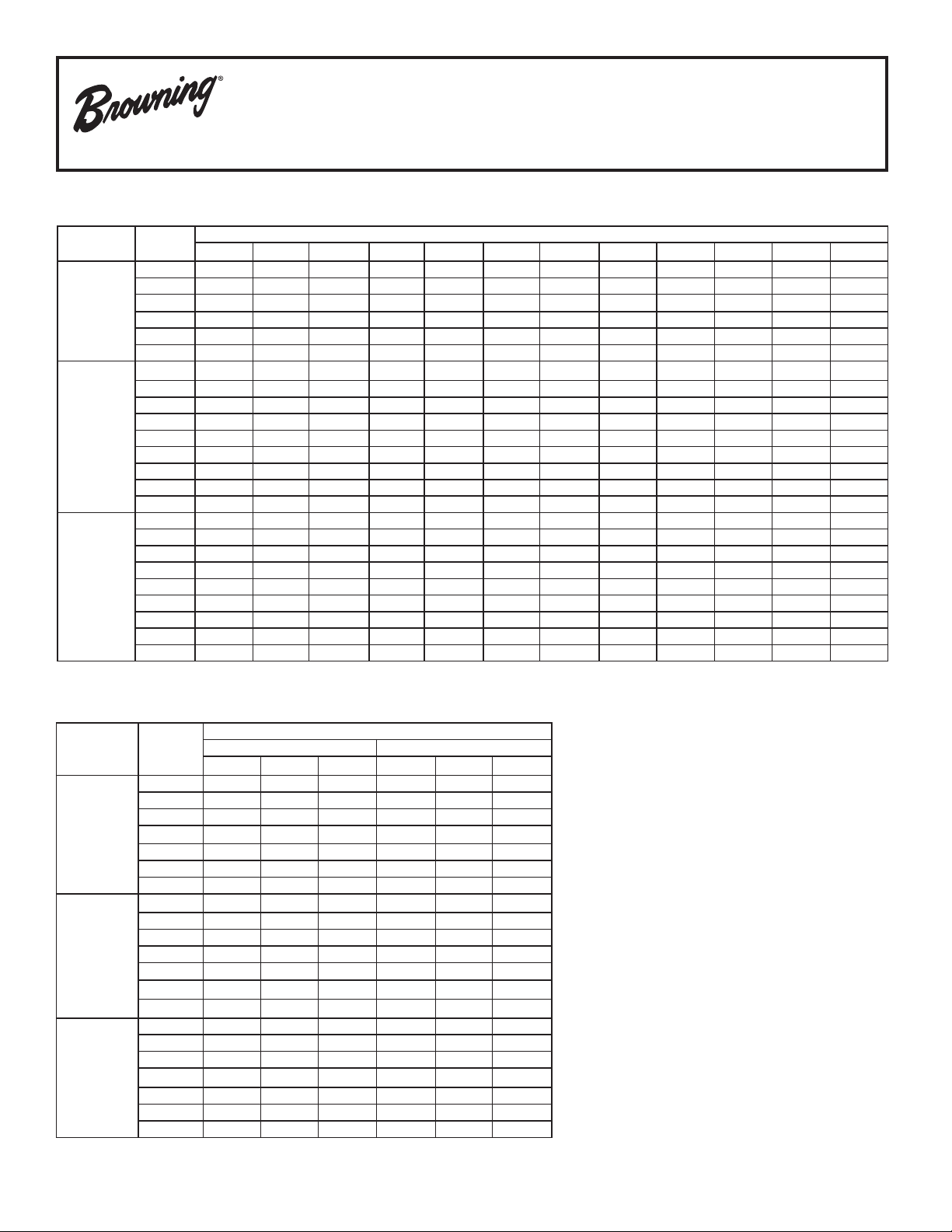

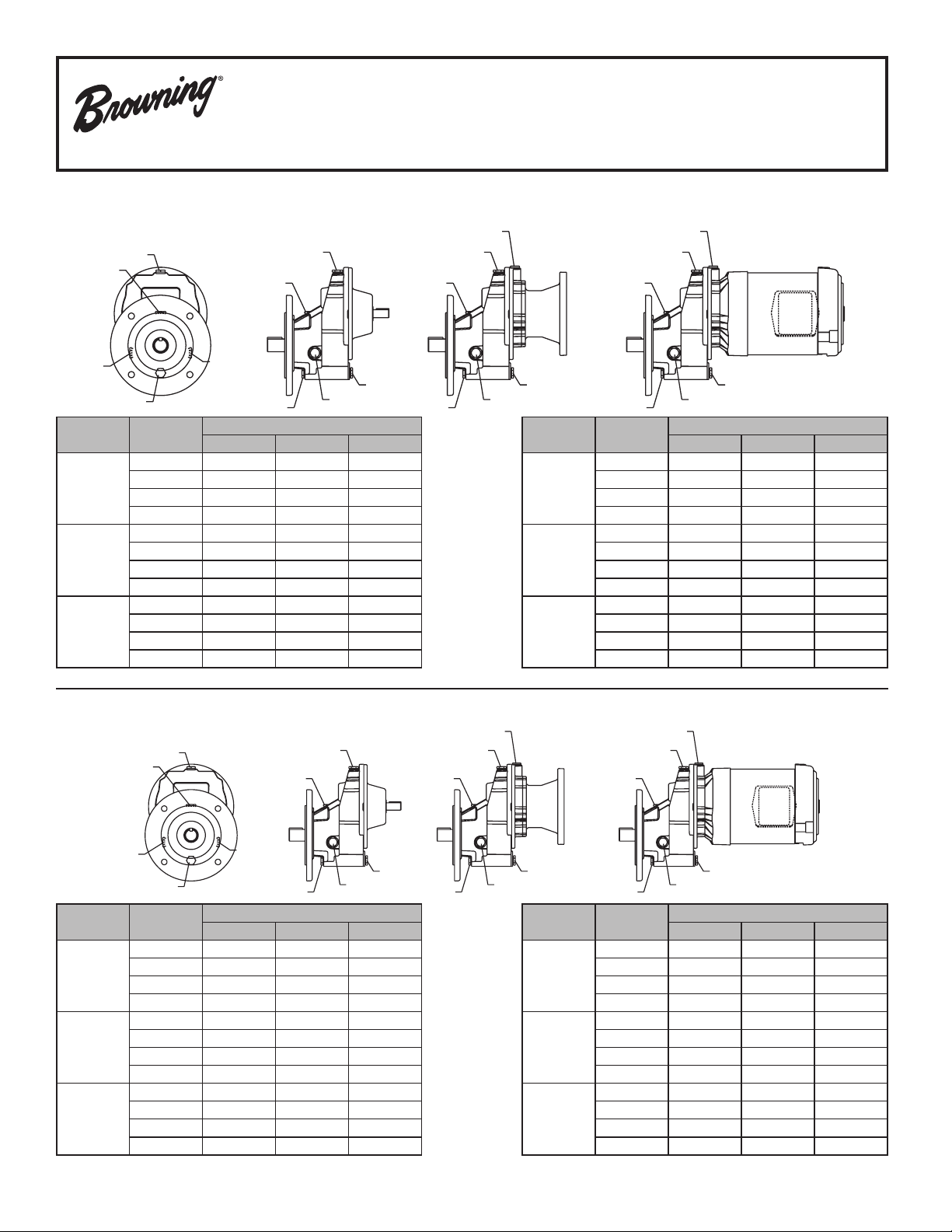

Page 4

Single Reduction Mounting Positions

Frames 31 Thru 35

Foot Mounted

(with/without ange)

Flange Mounted (Footless)

4

Page 5

Single Reduction Plug Location and Assignments

2

1

6

3

4

5

2

4

6

11

8

5

6

4

2

1

8

5

6

4

2

Frames 31 Thru 35

Foot Mount - S, SB14, SBS, SBD2

1

6

3

Mounting

Position

B3

B6

B7

* Frame 32 only

2

4

Plug

Function

Breather 1 or 6 8 8

Level 2 or 3 2 or 3 2 or 3

Drain 4 4 4

Filling 1 1 1

Breather 3 3 or 8 3 or 8

Level 1 or 4 1 or 4 1 or 4

Drain 2 2 2

Filling 3 3 3

Breather 2 2 or 8 2 or 8

Level 1 or 4 1 or 4 1 or 4

Drain 3 3 3

Filling 2 2 2

Input Shaft C-Face Gearmotor

6

4

Type Unit

Input Shaft

C-Face

8

11

6

5

2

4

5

2

Mounting

Position

B8

V5

V6

Gearmotor

8

1

6

5

4

Plug

Function

Breather 4 or 5 4 or 5 4 or 5

Level 2 or 3 2 or 3 2 or 3

Drain 1 1 1

Filling 4 or 5 4 or 5 4 or 5

Breather 5 5 or 8 5 or 8

Level 1 1 1

Drain 4 4 4

Filling 5 5 5

Breather 4 4 4

Level 2 or 3 2 or 3 2 or 3

Drain 1 8 8

Filling 4 4 4

2

Type Unit

Input Shaft C-Face Gearmotor

Flange Mounted - Footless

Mounting

Position

B5

B52

B54

* Frame 32 only

Plug

Function

Breather 1 or 6 8 8

Level 2 or 3 2 or 3 2 or 3

Drain 4 4 4

Filling 1 1 or 8 1 or 8

Breather 3 3 or 8 3 or 8

Level 1 or 4 1 or 4 1 or 4

Drain 2 2 2

Filling 3 3 3

Breather 2 2 or 8 2 or 8

Level 1 or 4 1 or 4 1 or 4

Drain 3 3 3

Filling 2 2 2

Input Shaft C-Face Gearmotor

Type Unit

Input Shaft C-Face Gearmotor

Mounting

Position

B53

V1

V3

Plug

Function

Breather 4 or 5 4 or 5 4 or 5

Level 2 or 3 2 or 3 2 or 3

Drain 1 1 1

Filling 4 or 5 4 or 5 4 or 5

Breather 5 5 5

Level 1 1 1

Drain 4 4 4

Filling 5 5 or 8 5 or 8

Breather 4 4 4

Level 2 or 3 2 or 3 2 or 3

Drain 5 8 8

Filling 4 4 4

Input Shaft C-Face Gearmotor

Type Unit

5

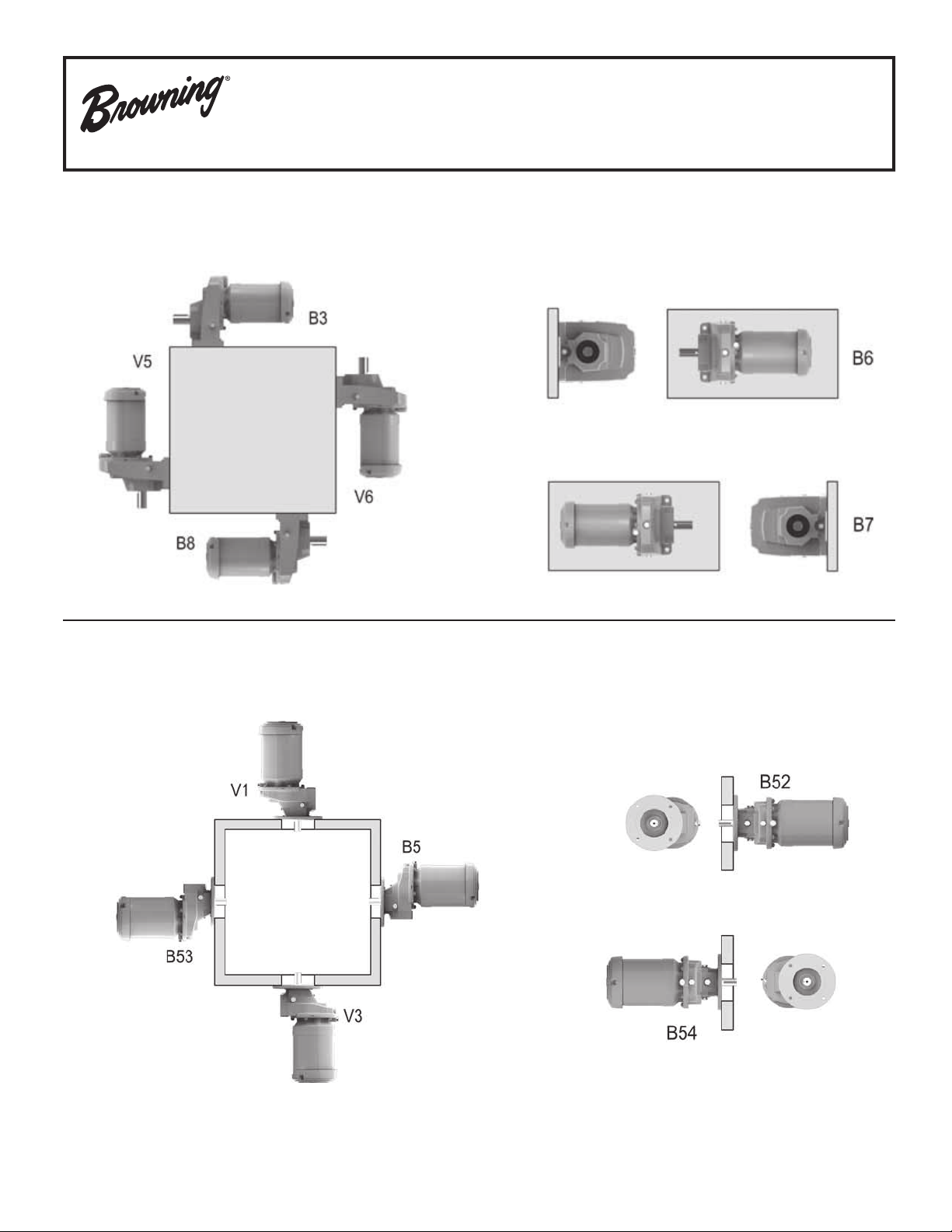

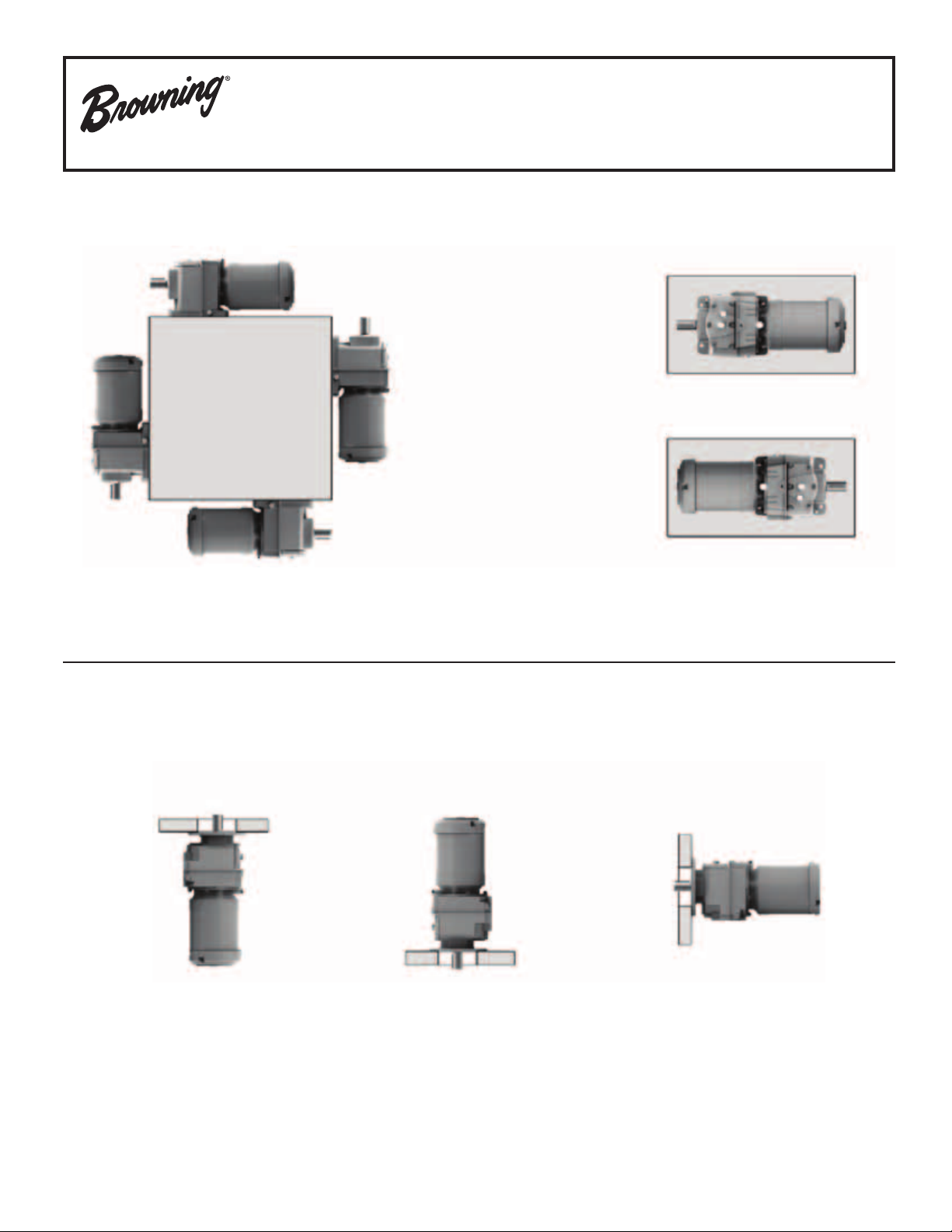

Page 6

V5

Multiple Reduction Mounting Positions

Frames 31 Thru 35

Foot Mounted (with/without ange)

B3

B6

B8

V3

V6

Flange Mounted (Footless)

V1

B7

B5

6

Page 7

Foot Mount

88

88

1

2

3

Multiple Reduction Plug Locations and Assignments

Frames 31 Thru 35

Input Shaft C-Face Gearmotor

1141

4

Mounting

Position

B3

B6

B7

Plug

Function

Breather 1 or 2 1, 2 or 8 1, 2 or 8

Level 3 3 3

Drain 4 4 4

Filling 1 or 2 1 or 2 1 or 2

Breather 3 3 or 8 3 or 8

Level ** ** **

Drain 4 4 4

Filling 3 3 3

Breather 4 4 or 8 4 or 8

Level 1 1 1

Drain 3 3 3

Filling 4 4 4

Input Shaft C-Face Gearmotor

** Double Reduction (except size 34) = 1, Triple Reduction = 2

Type Unit

Flange or Face Mount - Footless

1

2

3

Input Shaft C-Face Gearmotor

11 1

Mounting

Position

B8

V5

V6

4

Plug

Function

Breather 4 4 or 8 4 or 8

Level 3 3 3

Drain 1 or 2 1 or 2 1 or 2

Filling 4 4 4

Breather 4 8 8

Level 4 4 4

Drain 3 3 3

Filling 4 8 8

Breather 3 3 3

Level 1 or 2 1 or 2 1 or 2

Drain 4 8 8

Filling 3 3 3

Input Shaft C-Face Gearmotor

Type Unit

Mounting

Position

B5

V1

V3

44

Plug

Function

Breather 1 or 2 1, 2 or 8 1, 2 or 8

Level 3 3 3

Drain 4 4 4

Filling 1 or 2 1 or 2 1 or 2

Breather 4 8 8

Level 4 4 4

Drain 3 3 3

Filling 4 8 8

Breather 3 3 3

Level 1 or 2 1 or 2 1 or 2

Drain 4 8 8

Filling 3 3 3

Input Shaft C-Face Gearmotor

Type Unit

4

7

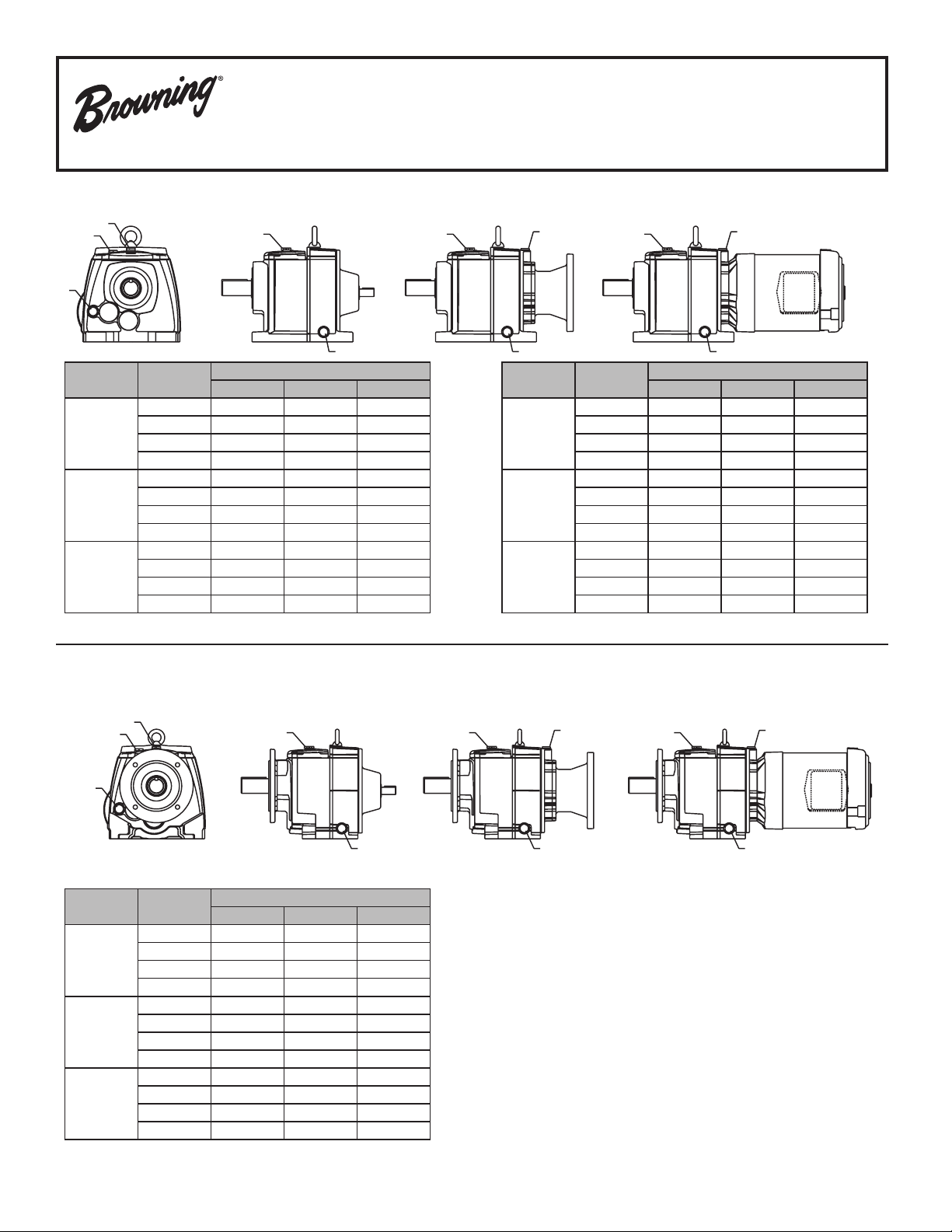

Page 8

Multiple Reduction Mounting Positions

Frames 36 thru 38

Foot Mounted (with/without ange)

B3

V5

B6

V6

B7

B8

Flange Mounted

V3

V1

B5

8

Page 9

Multiple Reduction Plug Locations and Assignments

BREATHER

All Foot, Flange, and Face Mounted Units

Frames 36 thru 38

Mounting

Position

B3 and

B5

B6

B7

B8

V5 and

V1

V6 and

V3

* Alternative oil level indication plug for anged mounted units

** This location will have dipstick for monitoring oil level unless noted

*** Level plug positioned on 90 degree elbow tting

**** Sight tube supplied at position #2 for oil level indication

Plug

Function

Breather 2 2 2 2 2 2

Level ** 2 2 2 2 2 2

Drain 4 4 7 7 4 4

Filling 2 2 2 2 1 1

Breather 6 6 6 6 12 12

Level ** 6 6 6 6 12 12

Drain 10 10 10 10 4 4

Filling 6 6 6 6 7 7

Breather 10 10 10 10 11 11

Level ** 10 10 10 10 11 11

Drain 6 6 6 6 7 7

Filling 10 10 10 10 4 4

Breather 9 9 9 9 9 9

Level 3*** 3*** **** **** **** ****

Drain 2 2 2 2 2 2

Filling 4 4 6 6 9 9

Breather 5 5 5 5 13 13

Level ** 5 5 5 5 13 13

Drain 3 3 3 3 14 14

Filling 5 5 5 5 13 13

Breather 3** 3** 3** 3** 14 14

Level 6* 6* 3 3 14 14

Drain 5 8 5 8 13 13

Filling 3 3 3 3 14 14

Frame 36 Frame 37 Frame 38

Input

Shaft

C-face and

Gearmotor

Input

Shaft

C-face and

Gearmotor

Input

Shaft

C-face and

Gearmotor

GASKET

BOTTOM

OIL

MAX.

MIN.

DIPSTICK

OIL

Views

CbN36-37

13

CbN38

14

9

Page 10

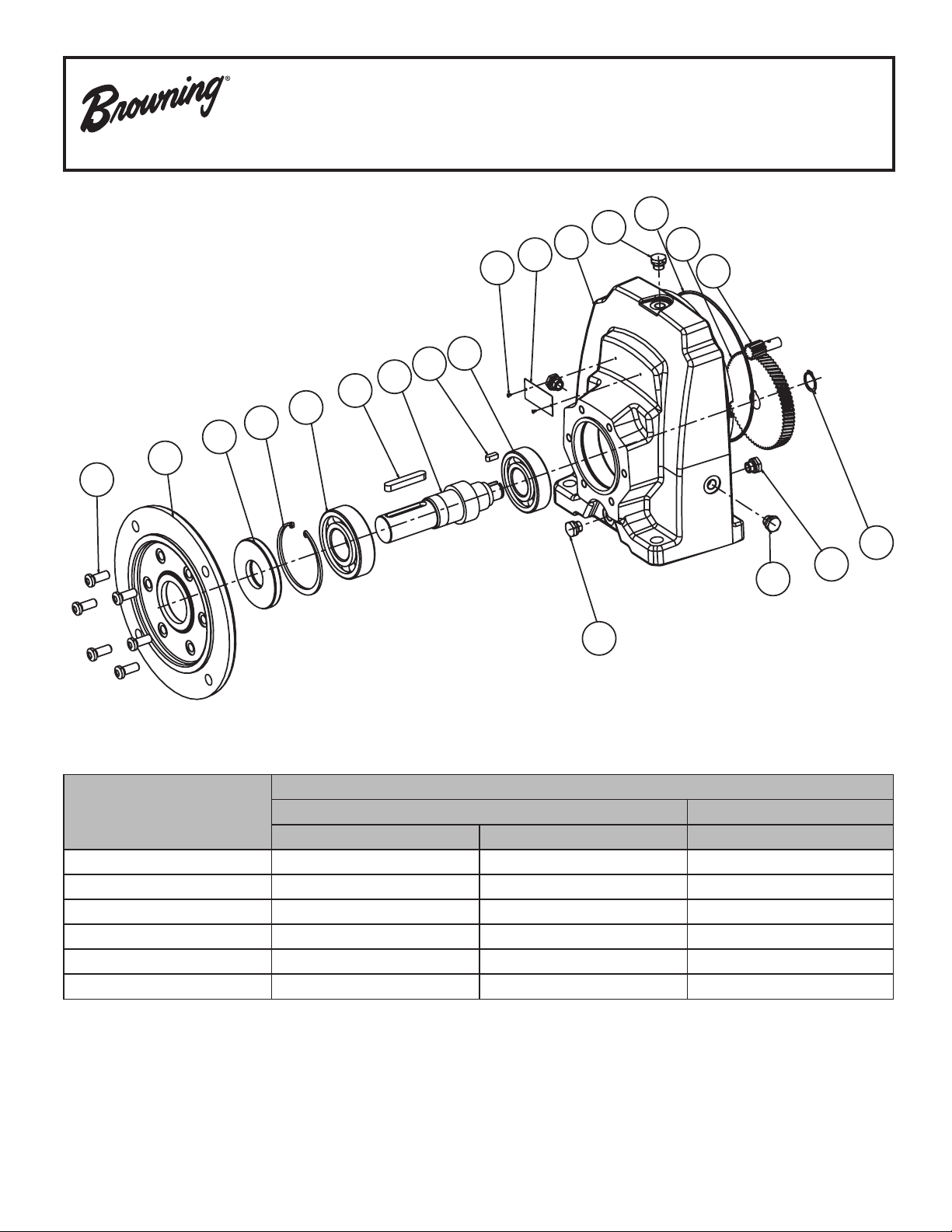

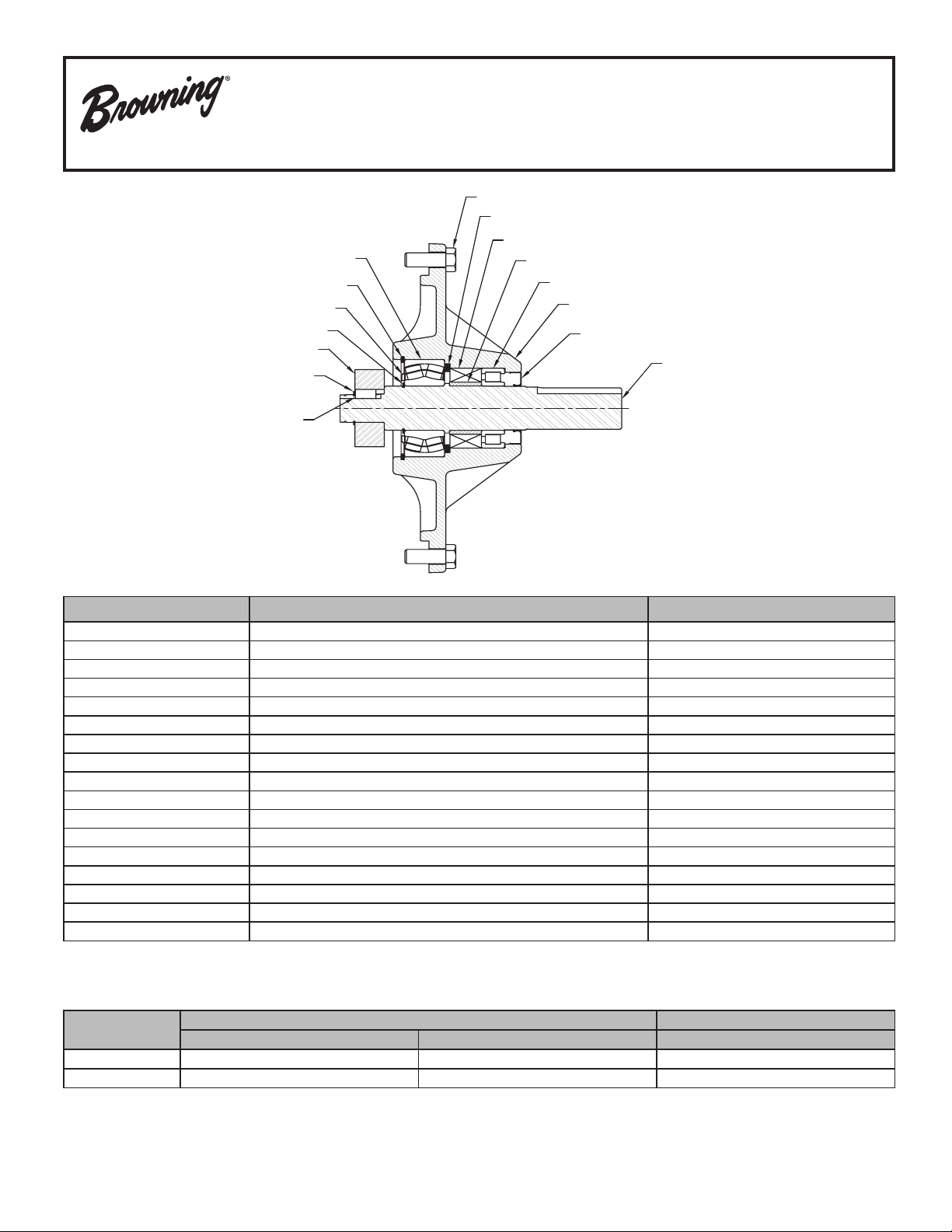

Single Reduction Parts Lists

009

090

187

130

061

077

031

080

062

284

282

001

255

097

052

042

128

258

256

257

CbN 30 - 35

10

Gear Frame

061 062 090

30 6205 ZZ 6005 25 x 52 x 7 DL, nitrile

31 6205 1RS 6304 25 x 52 x 7 DL, nitrile

32 6206 RS 6305 30 x 62 x 7 DL, nitrile

33 6308 RS 6307 40 x 90 x 8 DL, nitrile

34 6309 ZZ BHT C3 6308 45 x 100 x 8 DL, nitrile

35 6310 RS 6309 50 x 110 x 12 DL, nitrile

Bearings Seal (mm)

Item Description by Location

Page 11

CbN 30 - 35 (Quantity Per Unit)

Single Reduction Parts Lists

CbN 30 - 35

Rep Description 30 31 32 33 34 35

001 Housing 1 1 1 1 1 1

009 Output Flange Ring 1 1 1 1 1 1

031 Output Shaft 1 1 1 1 1 1

042 Pinion 1 1 1 1 1 1

052 Gear 1 1 1 1 1 1

061 Bearing Front 1 1 1 1 1 1

062 Bearing Back 1 1 1 1 1 1

077 Output Shaft Key 1 1 1 1 1 1

080 Gear Key 1 1 1 1 1 1

090 Oil Seal 1 1 1 1 1 1

Input "O" Ring Seal

097

(optional)

127 Bearing Snap Ring* 1 0 0 0 0 0

128 Gear Snap Ring 0 1 1 1 1 1

* Not illustrated.

** Design revision 4/03.

1 1 1 1 1 1

Rep Description 30 31 32 33 34 35

130 Bearing Snap Ring 1 1 1 1 1 1

140 Gear Spacer* 0 1** 1** 0 0 0

175 Screw for Face-Plate* 4 0 0 0 0 0

185 Washer for Gear* 1 0 0 0 0 0

186 Screw Washer* 1 0 0 0 0 0

187 Bolt 4 4 4 6 6 6

213 Flange Dowel Pin* 0 1 1 1 1 1

255 Breather Plug 0 1 1 1 1 1

256 Level Plug 0 2 2 2 2 2

257 Drain Plug 0 1 1 1 1 1

258 Drain Plug 0 1 1 1 1 1

282 Nameplate 1 1 1 1 1 1

284 Nameplate Pin 0 2 2 2 2 2

11

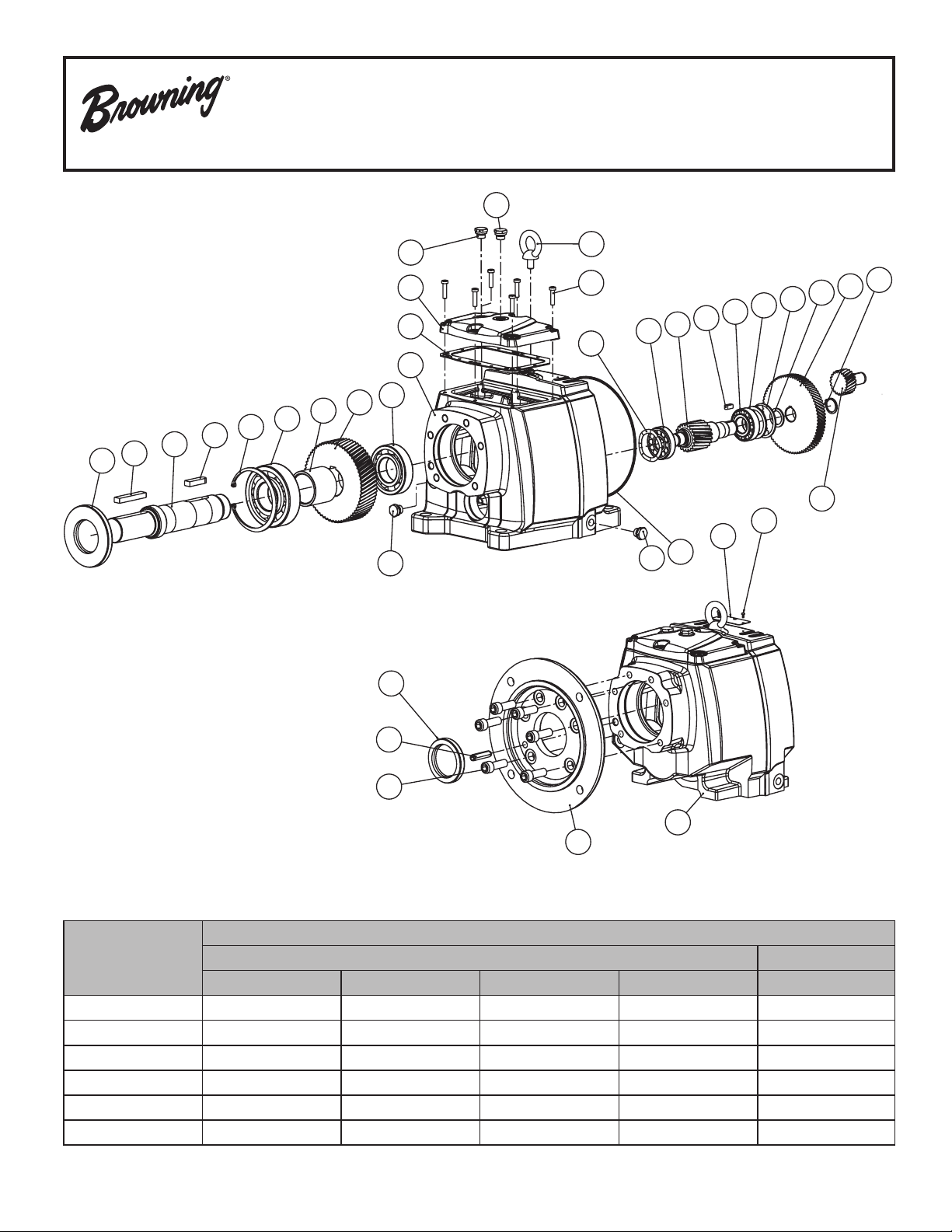

Page 12

Double Reduction Parts List

CbN 30 - 35

254

090

077

031

076

130

061

140

051

062

254

092

255

002

099

001

250

193

161

063

257

041

097

080

282

064

111

284

138

144

042

052

128

213

187

Typical Maintenance Items - Bearings and Seals (Double Reduction)

Item Description by Location

Gear Frame

061 062 063 064 090

30 6205 6202 6300 6301 25 x 52 x 7 DL, nitrile

31 6206 ZZ BHT C3 6205 NJ 202 ECP 6202 35 x 62 x 6 DL, nitrile

32 6207 ZZ BHT C3 6206 60203 30203 42 x 72 x 8 DL, nitrile

33 6309 ZZ BHT C3 6208 30304 30205 52 x 100 x 10 DL, nitrile

34 6311 ZZ BHT C3 6310 30306 30306 62 x 120 x 12 DL, nitrile

35 6313 ZZ BHT C3 6310 33207 33207 72 x 140 x 12 DL, nitrile

12

Bearings Seal (mm)

001

009

Page 13

CbN 30 - 35 (Quantity Per Unit)

Double Reduction Parts List

CbN 30 - 35

Rep Description 30 31 32 33 34 35

001 Housing 1 1 1 1 1 1

002 Cover 1 1 1 1 1 1

009 Output Flange Ring 1 1 1 1 1 1

031 Output Shaft 1 1 1 1 1 1

041 Pinion Axis 3 1 1 1 1 1 1

042 Pinion (primary) 1 1 1 1 1 1

043 Pinion Axis 2 0 0 0 0 0 0

051 Gear Axis 4 1 1 1 1 1 1

052 Gear Axis 2 1 1 1 1 1 1

053 Gear Axis 3 0 0 0 0 0 0

061 Bearing Front Axis 4 1 1 1 1 1 1

062 Bearing Back Axis 4 1 1 1 1 1 1

063 Bearing Front Axis 2 1 1 1 1 1 1

064 Bearing Back Axis 2 1 1 1 1 1 1

065 Bearing Front Axis 3 0 0 0 0 0 0

066 Bearing Back Axis 3 0 0 0 0 0 0

076 Gear Key 1 1 1 1 1 1

077 Output Shaft Key 1 1 1 1 1 1

080 Gear Key 1 1 1 1 1 1

081 Gear Key Axis 3 0 0 0 0 0 0

090 Oil Seal 1 1 1 1 1 1

092 Flange Oil Seal (Opt.) 0 1 1 1 1 1

097 Input O-Ring (Opt.) 1 1 1 1 1 1

099 Cover Gasket 1 1 1 1 1 1

Bearing Spacer

111

Axis 2*

Bearing Spacer

112

Axis 3

Bearing Spacer Axis

114

3 *

115 Bearing Spacer Axis 2* 0 0 1 0 1 1

127 Bearing Snap Ring * 1 0 0 0 0 0

* Not Illustrated

0 0 0 1 0 0

0 0 0 0 0 0

0 0 0 0 0 0

Rep Description 30 31 32 33 34 35

128 Gear Snap Ring 0 1 1 1 1 1

130 Bearing Snap Ring 1 1 1 1 1 1

132 Bearing Snap Ring * 0 0 1 0 1 1

133 Bearing Snap Ring 0 0 0 0 0 0

134 Bearing Snap Ring * 0 0 0 0 0 0

138 Bearing Snap Ring 1 1 1 1 0 0

140 Gear Spacer Axis 4 0 1 1 1 1 1

143 Bearing Spacer 0 0 0 0 0 0

144 Gear Spacer (primary) 0 1 1 1 1 1

161 Flexible Wavy Washer * 0 0 0 1 1 1

162 Flexible Wavy Washer 0 0 0 0 0 0

163 Flexible Wavy Washer * 0 0 0 0 0 0

164 Flexible Wavy Washer * 0 0 1 0 0 0

175 Screw For Face Plate * 4 0 0 0 0 0

183 Input Cover Stud 0 4 5 6 4 8

185 Washer To Gear * 1 0 0 0 0 0

186 Screw Washer * 1 0 0 0 0 0

187 Fixing Screws 4 4 6 6 6 6

193 Cover Fixing Screw 4 4 6 6 8 8

213 Flange Dowel Pin 0 1 1 1 1 1

250 Lifting Eye 0 0 1 1 1 1

251 Plug * 0 0 1 0 1 1

252 Gear Case Plug 0 0 0 0 0 0

254 Drain Plug 0 1 1 1 1 1

255 Breather Plug 0 1 1 1 1 1

256 Level Plug 0 1 1 1 1 1

257 Drain PLug 0 1 1 1 1 1

282 Nameplate 1 1 1 1 1 1

13

Page 14

090

077

031

076

130

061

140

Triple Reduction Parts List

CbN 30 - 35

254

255

002

099

001

062

051

250

193

064

183

043

080

063

143

138

144

052

128

042

256

065

053

081

041

066

162

112

133

252

213

187

092

Typical Maintenance Items - Bearings and Seals (Triple Reduction)

Item Description by Location

Gear Frame

061 062 063 064 065 066 090

30 6205 6202 6201 6201 6300 6300 25 x 52 x 7 DL, nitrile

31 6206 ZZ BHT C3 6205 6201 6202 6202 6202 35 x 62 x 6 DL, nitrile

32 6207 ZZ BHT C3 6206 6203 6203 30203 30203 42 x 72 x 8 DL, nitrile

33 6309 ZZ BHT C3 6208 6304 6205 30304 30304 52 x 100 x 10 DL, nitrile

34 6311 ZZ BHT C3 6310 6306 6306 30305 30305 62 x 120 x 12 DL, nitrile

35 6313 ZZ BHT C3 6310 6306 6207 32207 32207 72 x 140 x 12 DL, nitrile

Bearings Seal (mm)

097

257

001

009

DL = Double lipped.

14

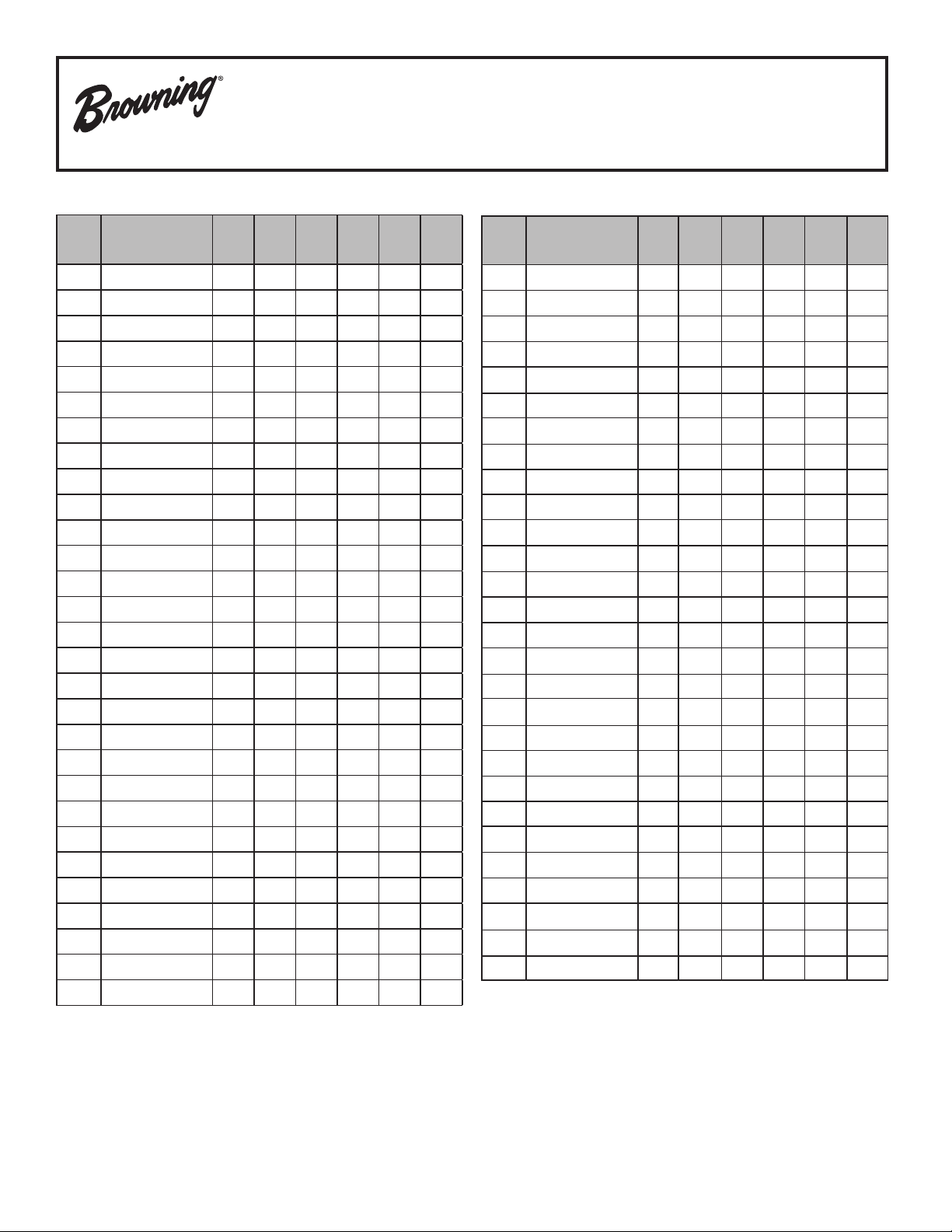

Page 15

Triple Reduction Parts List

CbN 30 - 35

CbN 30 - 35 (Quantity Per Unit)

Rep Description 30 31 32 33 34 35 Rep Description 30 31 32 33 34 35

001 Housing 1 1 1 1 1 1 128 Gear Snap Ring 0 1 1 1 1 1

002 Cover 1 1 1 1 1 1 130 Bearing Snap Ring 1 1 1 1 1 1

009 Output Flange Ring 1 1 1 1 1 1 132 Bearing Snap Ring * 0 0 1 0 1 1

031 Output Shaft 1 1 1 1 1 1 133 Bearing Snap Ring 0 1 1 1 1 1

041 Pinion Axis 3 1 1 1 1 1 1 134 Bearing Snap Ring * 1 0 0 0 0 0

042 Pinion (primary) 1 1 1 1 1 1 138 Bearing Snap Ring 1 1 1 1 0 0

043 Pinion Axis 2 1 1 1 1 1 1 140 Gear Spacer Axis 4 0 1 1 1 1 1

051 Gear Axis 4 1 1 1 1 1 1 143 Bearing Spacer 0 0 0 1 0 0

052 Gear Axis 2 1 1 1 1 1 1 144 Gear Spacer (primary) 0 1 1 1 1 1

053 Gear Axis 3 1 1 1 1 1 1 161 Flexible Wavy Washer * 0 0 0 1 0 0

061 Bearing Front Axis 4 1 1 1 1 1 1 162 Flexible Wavy Washer 0 0 0 1 1 1

062 Bearing Back Axis 4 1 1 1 1 1 1 163 Flexible Wavy Washer * 0 0 1 0 0 0

063 Bearing Front Axis 2 1 1 1 1 1 1 164 Flexible Wavy Washer * 0 0 0 0 0 0

064 Bearing Back Axis 2 1 1 1 1 1 1 175 Screw For Face Plate * 4 0 0 0 0 0

065 Bearing Front Axis 3 1 1 1 1 1 1 183 Input Cover Stud 0 4 5 6 4 8

066 Bearing Back Axis 3 1 1 1 1 1 1 185 Washer To Gear * 1 0 0 0 0 0

076 Gear Key 1 1 1 1 1 1 186 Screw Washer * 1 0 0 0 0 0

077 Output Shaft Key 1 1 1 1 1 1 187 Fixing Screws 4 4 6 6 6 6

080 Gear Key 1 1 1 1 1 1 193 Cover Fixing Screw 4 4 6 6 8 8

081 Gear Key Axis 3 1 1 1 1 1 1 213 Flange Dowel Pin 0 1 1 1 1 1

090 Oil Seal 1 1 1 1 1 1 250 Lifting Eye 0 0 1 1 1 1

092 Flange Oil Seal (Opt.) 0 1 1 1 1 1 251 Plug * 0 0 1 0 1 1

097 Input O-Ring (Opt.) 1 1 1 1 1 1 252 Gear Case Plug 0 1 1 1 1 1

099 Cover Gasket 1 1 1 1 1 1 254 Drain Plug 0 1 1 1 1 1

Bearing Spacer Axis

111

2*

112 Bearing Spacer Axis 3 0 0 0 1 1 1 256 Level Plug 0 1 1 1 1 1

Bearing Spacer Axis

114

3 *

Bearing Spacer Axis

115

2*

127 Bearing Snap Ring * 1 0 0 0 0 0

* Not Illustrated

0 0 0 1 0 0 255 Breather Plug 0 1 1 1 1 1

0 1 1 0 0 0 257 Drain PLug 0 1 1 1 1 1

0 0 0 0 0 0 282 Nameplate 1 1 1 1 1 1

15

Page 16

090

130

127

061

501

213

Multiple Reduction Parts List

CbN 36 - 38

009

187

502

051

076

031

077

062

099

002

193

254

250

261

282

284

042

052

186

185

090

130

127

061

187

501

213

077

009

031

076

252

133

051

065

502

500

251

062

132

041

254

081

063

099

002

500

193

053

041

066

250

080

257

261

064

001

282

257

284

063

001

Double Reduction

186

042

052

117

064

080

043

Triple Reduction

185

111

138

16

Page 17

CbN 36 to 38 (Quantity Per Unit)

Multiple Reduction Parts List

CbN 36 - 38

Item # Description

001 Housing 1 1 1 1 1 1 127 Bearing snap ring 0 1 1 0 1 1

002 Cover 1 1 1 1 1 1 128 Washer Gear Axis 2 0 0 0 1 0 0

009 Output Flange Ring 1 1 1 1 1 1 130 Bearing Snap Ring 1 1 1 1 1 1

031 Output Shaft 1 1 1 1 1 1 132 Bearing Snap Ring 1 1 1 0 0 0

041 Pinion Axis 3 0 0 0 1 1 1 133 Bearing Snap Ring 0 0 0 1 1 1

042 Pinion Axis 1 1 1 1 1 1 1 137 Snap Ring 0 1 1 0 0 0

043 Pinion Axis 2 0 0 0 1 1 1 138 Snap Ring 0 1 0 1 1 1

051 Gear Axis 4 1 1 1 1 1 1 142

052 Gear Axis 2 1 1 1 1 1 1 154 Gear Spacer 0 0 0 1 0 0

053 Gear Axis 3 0 0 0 1 1 1 187 Fixing Screws 7 9 11 7 9 11

061 Bearing Front Axis 4 1 1 1 1 1 1 193

062 Bearing Back Axis 4 1 1 1 1 1 1 213 Flange Roll Pin 1 1 2 1 1 2

063 Bearing Front Axis 2 1 1 1 1 1 1 250 Lifting eye 1 1 1 1 1 1

064 Bearing Back Axis 2 1 1 1 1 1 1 251 Bore plug 1 1 1 0 0 0

065 Bearing Front Axis 3 0 0 0 1 1 1 252 Gearcase Bore plug 0 0 0 1 1 1

066 Bearing back Axis 3 0 0 0 1 1 1 254 Plug 5 5 7 5 5 7

076 Gear Key 1 1 1 1 1 1 257 Magnetic drain plug 1 1 1 1 1 1

077 Output Shaft Key 1 1 1 1 1 1 261 Dipstick/Breather 1 1 1 1 1 1

080 Gear Key 1 1 1 1 1 1 282 Nameplate 1 1 1 1 1 1

081 Gear Key Axis 3 0 0 0 1 1 1 284 Rivet 2 2 2 2 2 2

090 Oil seal 1 1 1 1 1 1 500 Nilos ring Axis 2 0 0 1 0 0 1

099 Cover gasket 1 1 1 1 1 1 501 Nilos ring Axis 4 front 1 1 1 1 1 1

111 Bearing Spacer Axis 2 0 0 0 1 0 1 502 Nilos ring Axis 4 back 0 0 1 0 0 1

Double Reduction Triple Reduction

36 37 38 36 37 38 36 37 38 36 37 38

Item # Description

Bolt For Gear

Axis 2

Cover Fixing

Screws

Double Reduction Triple Reduction

1 2 2 0 1 2

9 12 11 9 12 11

117 Shims 0 0 0 0 0 1 517 Snap Ring

119 Bearing Spacer Axis 2 0 0 0 0 1 1

Typical Maintenance Items - Bearings and Seals (Double Reduction)

Item Description

Gear Frame

061 062 063 064 090

36 22217E NJ214 ECP 22308E 22208E 85x150x12 DL, nitrile

37 22220 NJ217 22311 22310E 100x180x12 DL, nitrile

38 23124E NJ220 22312E 22312E 120x200x14 DL, nitrile

Bearings Seal (mm)

Typical Maintenance Items - Bearings and Seals (Triple Reduction)

Item Description

Gear Frame

061 062 063 064 065 066 090

36 22217E NJ214 ECP 32206B 32207 22308E 22208E 85x150x12 DL, nitrile

37 22220 NJ217 30308 30308 22311 22310E 100x180x12 DL, nitrile

38 23124E NJ220 30310 30310 22312E 22312E 120x200x14 DL, nitrile

Bearings Seal (mm)

1 0 0 1 0 0

17

Page 18

C-Face Input Parts Lists (Quantity Per Unit)

CbN 30 - 38

16

15

14

9

10

11

8

18

3

17

6

5

2

7

1

19

4

13

No. Description 56C 140TC 180TC 210TC 250TC 280TC

1 Non-Metallic Liner 1 1 1 1 1 1 1

2 Seal 1 1 1 1 1 1 1

3 Motor Adapter 1 1 1 1 1 1 1

4 Capscrew 6 6 6 6 6 6 6

5 Bearing 1 1 1 1 1 1 1

6 Spacer 1 † 1 † 1 1 1 1 1

7 Input Shaft 1 1 1 1 1 1 1

8 Bearing 1 1 1 1 1 1 1

9 Internal Snap Ring 1 1 1 1 1 1 1

10 Key* 1 1 1 1 1 1 1

11 Pinion 1 1 1 1 1 1 1

12 Nuts† ** ** ** ** ** ** **

13 Studs† ** ** ** ** ** ** **

14 Adapter Flange 1 † 1 † 1 1 1 1 1

15 Gasket 1 † 1 † 1 1 1 1 1

16 Plug (1/4") 1 † 1 † 1 1 1 1 1

17 Motor Adapter Flange N/A N/A N/A N/A 1*** 1 N/A

18 Backstop Kit (option) 1 † 1 † 1 1 1 1 1

19 Seal 0 0 0 0 0 1 1

* Pin used with 9mm, 12mm, 15mm and 18mm pinion.

** Depending on gear frame size: 31 = 4, 32 = 5, 33 = 6, 34 = 4, 35 = 8.

***Applicable to size 33.

† Not applicable to size 30.

Not applicable to sizes 36 and 37

Gear Frame (s) Motor Frame (s)

30 56C, 140TC 6006 2RS 6004 2RS 55 X 30 X 10 (mm)

31 to 36 56C, 140TC 6007 ZZ C3 6207 ZZ C3 2 X 1.375 X .312

31 to 37 180TC 6012 ZZ C3 6210 ZZ C3 4 X 2.250 X .468

32 to 37 210TC 6012 ZZ C3 6210 ZZ C3 4 X 2.250 X .468

38 210TC 6014 ZZ C3 NJ210 4.438 X 2.625 X .437

34 to 38 250TC , 280TC 6014 ZZ C3 NJ210 4.438 X 2.625 X .437

35 * 320TC 6216 ZZ C3 NJ310 140 X 90 X 12 (mm)

* For 36 through 38 frame with 320TC input, refer to opposing page

12

Bearings Oil Seal (inches)

5 8 9

320TC

18

Page 19

C-Face Input Parts Lists (Quantity Per Unit)

8

9

CbN 36 - 38

10

11

12

13

14

15

16

17

18

19

20

No. Description of Part 320TC/360TC

1 Setscrew 1

2 Motor Coupling 1

3 Motor Adapter 1

4 Coupling Sleeve 1

5 Seal 1

6 Internal Snap Ring 1

7 Bearing 1

8 External Snap Ring 1

9 Adapter Flange 1

10 Capscrew 8

11 Backstop 1

12 Capscrew 12

13 Spacer 1

14 Bearing 1

15 Internal Snap Ring 1

16 Bearing Seal 1

17 Pinion 1

18 Key 1

19 External Snap Ring 1

20 Input Shaft 1

7

6

5

4

3

2

1

Gear Bearings Oil Seal (inches)

Frame 7 14 9

36 to 38 6216 ZZ C3 NJ310 140 x 110 x 12 (mm) nitrile

19

Page 20

Gearmotor Input Parts Lists (Quantity Per Unit)

CbN 30 - 38

1

254

11

4

6

10

3

5

9

8

2

183

7

184

No. Description 30 31 32 33 34 35

1 Motor Adapter 1 1 1 1 1 1

2 Input Shaft 1 1 1 1 1 1

3 Pinion 1 1 1 1 1 1

4 Internal Snap Ring 1 1 1 1 1 1

5 Bearing Cap** † 1 1 1 1 1

6 Bearing 1 1 1 1 1 1

7 Adapter Flange † 1 1 1 1 1

8 External Snap Ring 1 1 1 1 1 1

9 Seal 1 1 1 1 1 1

10 Pinion Pin 1 1 1* 1* 1* 1*

11 Capscrew** † 2 2 2 2 2

183 Stud 4 4 5 6 4 8

184 Nut 4 4 5 6 4 8

254 Plug (or Breather) † 1 1 1 1 1

* Key used with 23mm and 32mm pinion.

** Explosionproof motor only, except on frame 30.

† Not applicable to size 30.

Gear Frame Motor Frame

30 56, 140T 6005 ZZ C3 47 x 25 x 7 (mm)

31 48 6005 ZZ C3 1.50 x .937 x .250

31 to 37

38 210T 6310 ZZ C3 3.500 x 2.250 x .375

33 250T 6209 ZZ C3 2.875 x 1.750 X .375

34 to 38 250T , 280T 6310 ZZ C3 3.500 x 2.250 x .375

35 to 38 320T 6311 ZZ C3 3.875 x 2.5 x .470

56, 140T 6007 ZZ C3 2.25 x 1.375 x .312

180T, 210T 6207 ZZ C3 2.25 x 1.375 x .312

Bearings Seal (inches)

6 9

20

Page 21

AP Input Shaft Parts Lists (Quantity Per Unit)

CbN 30 - 35

2

3

13

7

6

8

10

4

5

1

12

11

No. Description 30 31 32 33 34 35

1 Seal 1 1 1 1 1 1

2 Nuts 1 4 5 6 4 8

3 Studs 4 4 5 6 4 8

4 Housing 1 1 1 1 1 1

5 External Snap Ring 1 1 1 1 1 1

6 Bearing 1 1 1 1 1 1

7 Spacer 0 1 1 1 1 1

8 Bearing 1 1 1 1 1 1

9 Input Shaft 1 1 1 1 1 1

10 Internal Snap Ring 1 1 1 1 1 1

11 Pinion 1 1 1 1 1 1

12 Key* 1 1 1 1 1 1

13 Backstop Kit (Option) † 1 1 1 1 1

* Pin used with 9mm, 15mm and 18mm pinion.

† Not applicable to size 30.

9

Gear Frame

30 6203 2RS 6204 2RS 28 x 17 x 7 (mm) DL, nitrile

31, 32 6206 ZZ C3 6207 ZZ C3 1.875 x 1.125 x .25 DL, nitrile

33 6308 ZZ C3 6309 ZZ C3 2.5 x 1.50 x .312 DL, nitrile

34 NJ209 6311 ZZ C3 2.5 x 1.50 x .312 DL, nitrile

35 NJ210 6312 ZZ C3 3.188 x 1.938 x .438 DL, nitrile

6 8 1

Bearings Oil Seal (inches)

21

Page 22

AP Input Shaft Parts Lists (Quantity Per Unit)

15

CbN 36 - 38

14

13

8

10

16

5

11

17

12

7

6

4

1

9

No. Description of Part All Reductions

1 Seal 1

2 Nuts 0

3 Studs 0

4 Housing 1

5 External Snap Ring 1

6 Bearing 1

7 Spacer 1

8 Bearing 1

9 Input Shaft 1

10 Internal Snap Ring 1

11 Pinion 1

12 Key 1

13 Backstop Kit (optional) 1

14 Spacer 1

15 Bolt 8

16 Bearing Seal 1

17 External Snap Ring 1

Gear Bearings Seal (inches)

Frame 6 8 1

36 & 37 NJ2210 22310 3.188 x 1.938 x .438 DL, nitrile

38 32213 32313 3.250 x 2.500 x .375, DL, nitrile

22

Page 23

TEFC Intergral "Modular Motor" Parts List

Frames 56, 140T Frames 180T, 210T, 250T, A280T

Part # Description Qty.

1 Fan Cover 1

2 Self Tapping Screw 3

3 Hex Nut 1

4 Stud 1

5 Retaining Snap Ring 1

6 Fan 1

7 Bracket 1

8 Screw 4

9 Bushing 4

10 Plastic Plug 4

11 Ball Bearing 1

12 Rotor Assembly (includes items 13 & 14) 1

13 Shaft 1

14 Rotor Core 1

15 Wound Stator Assembly 1

16 Gasket 1

17 Outlet Box Base 1

18 Self Tapping Screw 2

19 Outlet Box Cover 1

20 Self Tapping Screw 2

Part # Description Qty.

1 Fan Cover 1

2 Self Tapping Screw 4

3 Hex Nut 1

4 Stud 1

5 Fan 1

6 Bracket 1

7 Hex Head Bolt 4

8 Lifting Lug 1

9 Hex Countersunk Pipe Plug 2

10 Ball Bearing 1

11 Rotor Assembly (includes items 12 & 13) 1

12 Shaft 1

13 Rotor Core 1

14 Wound Stator Assembly 1

15 Gasket 1

16 Outlet Box Base 1

17 Self Tapping Screw 2

18 Outlet Box Cover 1

19 Self Tapping Screw 2

Browning, Emerson and Emerson Industrial Automation are trademarks of

Emerson Electric Co. or one of its affiliated companies.

©2007, 2010, 2012 Emerson Power Transmission Corp., All Rights Reserved.

MCIM12004E • Form# 8772E • Printed in USA

23

Loading...

Loading...