Page 1

Ultrasonic Vapor Degreaser

Model B252R Portable Ultrasonic

Degreaser

B-252R

The small but powerful Branson

B252R Vapor Degreaser

integrates state-of-the-art

controls with maintenance

practicality in an ultrasonic

vapor degreaser.

OVERVIEW

The Branson B252R Ultrasonic Vapor

Degreaser is one of a series of environmentally sound, cost effective precision

degreasers. This small but powerful

unit integrates state-of-the-art controls

with maintenance practicality in an

ultrasonic vapor degreaser. It incorporates all of the important environmental and safety features typically found

in larger units. All controls are clustered

on a compact front-mounted digital

control panel. The B252R features an

offset boiling chamber to reducing the

solvent/air interface reducing solvent

emissions and footprint. It is ideal for

use with most solvents including

HCFC, HFC, HFE, n-propyl bromide,

AK-225, and more. With a 4.8 gallon

solvent capacity, the compact B252R

is ideal for use at individual production

work stations or as a tool to develop

processes for larger equipment.

ENVIRONMENTAL FEATURES

The B252R is designed to comply with

EPA environmental regulations on

solvent emissions, an important environmental and economic consideration.

Some of these features also facilitate

OSHA compliance. The unit includes,

as standard, a number of engineered

improvements designed specifically to

minimize solvent losses. The following

list details some of these more important features:

• Freeboard ratio of 100% to minimize

diffusion losses due to drafts

• Peripheral refrigerated condensing

coil to efficiently condense solvent

vapors minimizing emissions

• Captured sliding cover to eliminate

drafts and help seal the unit during

periods of inactivity

• Offset boiling chamber to reduce

solvent air interface to below 1 ft

• Recirculating pump and cartridge

filter to remove particulate and extend

solvent life

SAFETY FEATURES

In addition to the benefits associated

with keeping solvent away from the

operator, the B252R has many other

features which contribute to safety and

reliability. Key among these are:

• Low voltage controls for operator

safety

2

Page 2

Ultrasonic Vapor Degreaser

B-252R

• "Ready" light to assure the unit is

set to run

• High vapor level sensor to prevent

solvent boil off

• Low solvent sensor to prevent

heater damage

• Boil sump temperature indicator

• Early warning contamination

indicator to signal the need for

solvent replacement

MAINTENANCE

All maintenance procedures can

be performed from the front or top

of the unit. All services also enter

conveniently from the front.

STANDARD FEATURES

• 24 Volt controls for safety

• Digital temperature readouts

• 40 kHz industrial ultrasonics

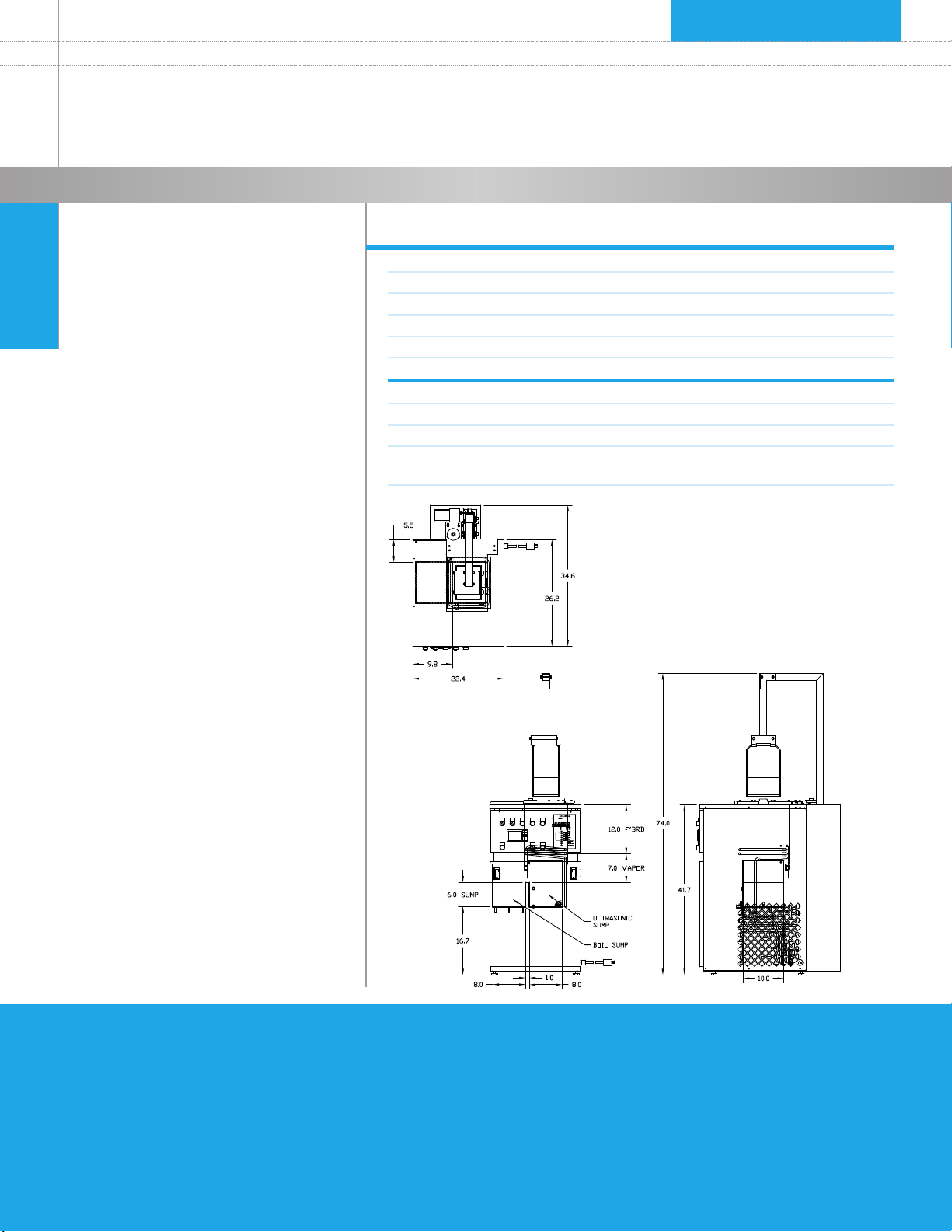

Specifications – Model B252R

Total solvent capacity: 4.8 gallon

Boil tank heat: 1200 Watts

Distillation rate based on HFC/HFE: 5.5 gph

Load capacity (steel): 80 lbs./hr.

Cooling: 1/2” HP compressor

Power requirements: 208/230V, 60 Hz, 1 ph, 16 amps

DIMENSIONS

Ultrasonic tank: 8” x 10” x 6”D

Vapor zone: 10.5” x 12.5” x 6”D

Overall: 22.4” x 26.2” x 41.7”H

with automation: 22.4" x 34.6" x 74"H

• 304 Stainless steel construction

• Full peripheral cooling coil

• One year warranty

OPTIONS

• Desiccant dryer kit for azeotropic

solvents

• Stainless steel mesh baskets

• Vertical lift mechanism with

power cover

Americas

Branson Ultrasonics Corp.

41 Eagle Road

Danbury, CT 06813-1961

T: 800-732-9262

F: 203- 796-2250

www.bransonultrasonics.com

Europe

Branson Ultraschall

Niederlassung der Emerson

Technologies GmbH & Co. OHG

Waldstrasse 53-55

63128 Dietzenbach, Germany

T: +49-6074-497-0

F: +49-6074-497-199

www.branson.eu

Asia

Branson Ultrasonics (Shanghai) Co., Ltd.

758 Rong Le Dong Road

Song Jiang, Shanghai, PRC, 201613

T: 86-21-3781-0588

F: 86-21-5774-5100

www.branson-china.com

Model B252R © Branson Ultrasonics

Corporation 2013

The Emerson logo is a trademark

and service mark of Emerson

Electric Co. Revised and printed

in the U.S.A. 5/13

Loading...

Loading...