Page 1

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

Please read through this manual completely before operating the actuators

SECTION 1 - SAFETY PRECAUTIONS

Precautions for using AW, AWN type actuators

safely are highlighted with the following two

warning signs to indicate the level of danger

posed. Please read the postscript carefully to

ensure safety and prevent any damage from

occurring before starting to use the product.

WARNING

A potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

A potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

ACTUATOR USE

AW, AWN Type Actuators are suitable for

operating ball valves and V-port valves.

Please use the actuators according to warnings

and cautions described in this document.

Failure to do so could result in an accident

(due to wrong storage, installing, operation,

maintenance and disassembling) and/or

serious damage.

Please keep this manual in a handy place for

immediate reference; be sure to provide it to

purchaser, contractor, piping designer, user,

operator or maintenance technician.

KTM reserves the right to discontinue the

manufacture of, change or modify design and/

or construction of any KTM product during the

manufacturing procedure, without incurring

any obligation to accept for credit, to replace or

furnish or install such changes or modifications

on products previously or subsequently sold.

This document is subject to change without

notice.

SECTION 2 - SPECIFICATION

The performance and safety of AW, AWN type

actuators and conformity with your equipment

or system should be checked by the design

engineer or the person specifying your system

based on our catalog or specification data.

Upon arrival, the applicable conditions (double

acting, direct acting, reverse acting, operating

pressure, etc.) should be first checked to make

sure they are correct.

SECTION 3 - STORAGE

CAUTION

The following items should be strictly followed in

order for the actuators to be installed

and operated properly.

1. Do not unpack the actuator from shipping

package until just prior to installing it.

2. Store the package in dry and non-corrosive

atmosphere.

3. When unpacked, plug or cap inlet and outlet

port and direct these ports in horizontal and

downward position to protecting from entering

rain and dust.

Emerson.com/FinalControl © 2017 Emerson. All rights reserved. VCIOM-02905-EN 19/04

Page 2

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

SECTION 4 - MODEL IDENTIFICATION

Example: AW 17 S Q HW

Actuator type

AW (AWN only applicable for size 13)

Actuator size

13 20

17 28

Operation type Description (Supply pressure)

Blank Double acting type (0.3 to 0.7 MPa)

S Spring return type - Standard (0.4 to 0.7 MPa)

L Spring return type - Low pressure type (0.3 to 0.4 MPa)

Special (Option) Description

Blank No specials

A Direct-acting spring return

(Counter-clockwise rotation under supply pressure loss)

B Stainless steel external bolts and nuts

K For high temperature (0ºC to 120ºC)

T For low temperature (-45ºC to 60ºC)

Q High speed / frequency (500,000 cycles): Available for double acting type

High speed: Available for spring return type

S High torque type (spring return)

Accessories (Option) Description

Blank Without any accessories

CO ESDV of CO

H For double acting type with manual override handle lever:

Available for AWN13 only

HG For double acting type with manual gear operator:

Available for AW17 through AW28

HW For spring return type with manual override handle:

Available for AWN13S through AW28S

L With lift-limiting unit

PS Partial stroke test

gas type

2

2

Page 3

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

SECTION 5 - RANGE OF APPLICATION

Operating mechanism Operation Model no. Pressure (MPa)

Double acting AWN13 0.3 - 0.7

AW17

AW20

AW28

Single acting AWN13S 0.4 - 0.7

Scotch York

(Para-arm piston rod pin)

(Spring return) AW17S

AW20S

AW28S

Single acting AWN13L 0.3 - 0.4

for low pressure range AW17L 0.2 - 0.4

AW20L 0.3 - 0.5

AW28L 0.2 - 0.4

CAUTION

Use Torque Cylinders within operating pressure

ranges only.

Operation outside the specified range may cause

damage to the cylinder or malfunction.

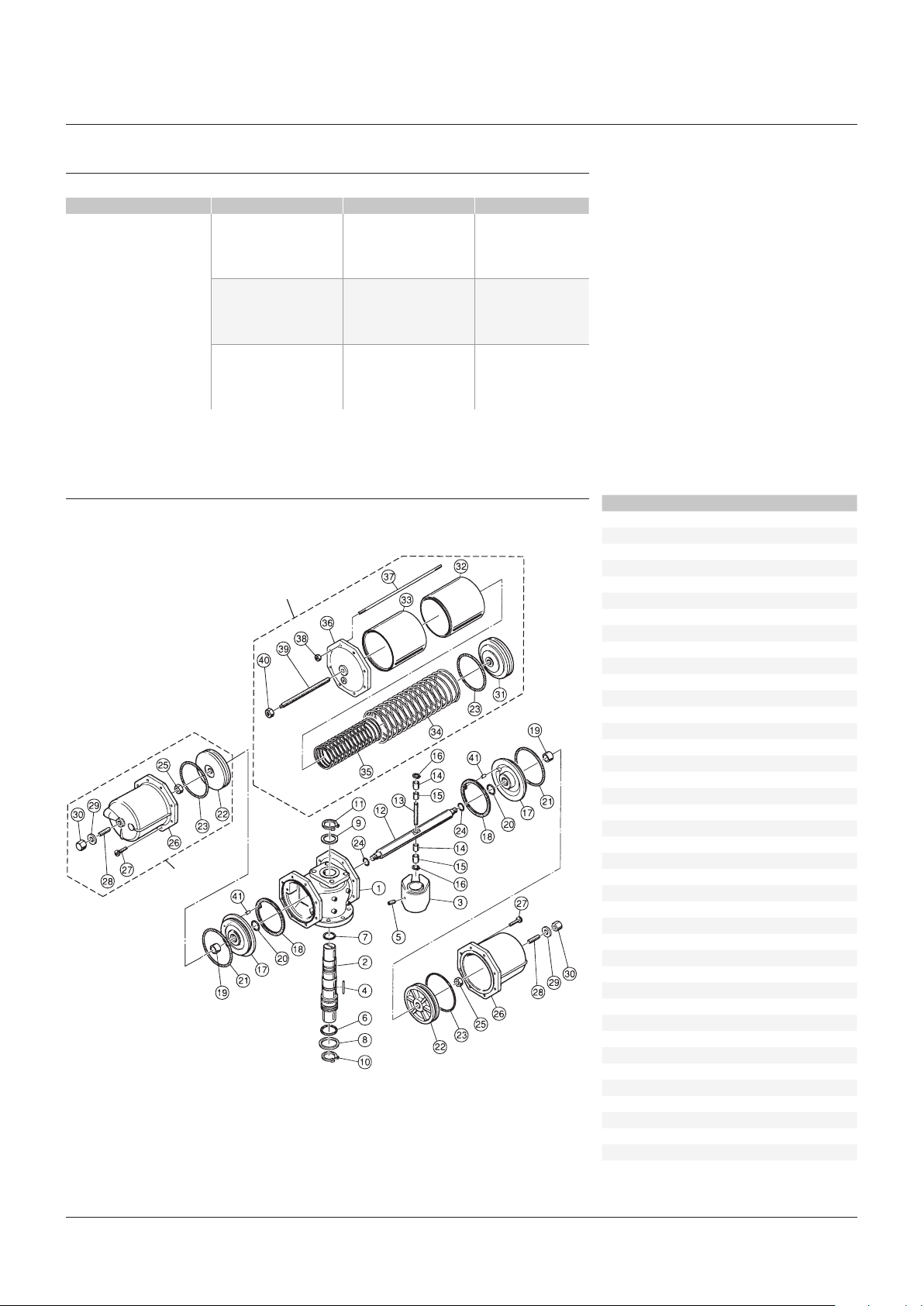

SECTION 6 - CONSTRUCTION

Spring return

Spring return

Double acting

Double acting

FIGURE 1

NOTE

Only AWN13 has an oval-shaped upper stem and a

square-shaped lower stem.

PARTS LIST

No. Parts Nme

1 Body

2 Stem

3 Para-arm

4 Key

5 Set screw

6 O-ring

7 O-ring

8 Thrust bearing

9 Thrust bearing

10 Snap ring

11 Snap ring

12 Piston rod

13 Pin

14 Roller

15 Bearing

16 Snap ring

17 Adapter

18 Gasket

19 Bearing

20 O-ring

21 O-ring

22 Piston

23 O-ring

24 O-ring

25 Nut

26 Cylinder

27 Cap screw

28 Stopper bolt

29 Gasket

30 Cap Nut

31 Spring retainer

32 Cylinder

33 Spring case

34 Spring (Outer)

35 Spring (Inner)

36 Spring cover

37 Long bolt

38 Nut

39 Stopper bolt

40 Nut

41 Pipe

3

Page 4

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

SECTION 7 - MOUNTING OF ACTUATOR TO VALVE

Ensure the following items before mounting the

actuator to the ball valve.

1. Cleanse flanges of actuator and valve of

dust and foreign substances.

2. When mounting, make sure that the valve

opening (fully open or fully closed) coincides

with the indicator position of the actuator.

Caution

Mismatching between indication of actuator and

valve opening may result in operation trouble,

which will cause accidents. Check the indication

matching once more.

3. Use the following bolts for connection,

which should be fastened in “criss-cross”

pattern.

Stainless steel: JIS: SUS304 (AISI 304) with

strength class more than 70

Carbon steel: JIS: S45C (AISI 1045) with

strength class more than 8.8

SECTION 8 - ADJUSTMENT OF VALVE OPENING

After mounting the actuator to the valve, adjust

fully open and fully closed position according to

the following manner.

CAUTION

Since the adjusting procedure is performed

during supplying compressed air, do not touch the

moving parts of the actuator. Doing so may cause

injury.

8.2 Procedure for Single Acting Actuator

(including the model with manual operator “HW”)

1. Supply compressed air to the inlet port to

the valve open and check fully open position

of the valve.

2. If the position is not correct, exhaust the

compressed air letting the valve to close the

valve. Then perform the following steps 3

and 4.

3. Loosen hexagon nut for locking open

side stopper bolt, turn the stopper bolt

in respective direction by using hexagon

bar wrench. Clockwise turning of the bolt

reduces travel angle of the actuator, and

counterclockwise turning widen the range of

the travel angle.

4. After ensuring correct position of the valve

by supplying compressed air to the actuator,

tighten the locking nut of the stopper bolt.

5. With no compressed air in the actuator,

check the fully closed position of the valve.

6. If the position is not correct, loosen the

hexagon nut for locking stopper bolt on

closed side, then perform the following

procedures 7 and 8.

7. Turn the stopper bolt in the respective

direction by using hexagon bar wrench.

Clockwise turning of the bolt reduces travel

angle of the actuator, and counterclockwise

turning widen the range of the angle.

8. After ensuring the correct position of the

valve, tighten the locking nut of the stopper

bolt.

SECTION 9 - PIPING AND INSTALLATION

CAUTION

In piping work, care should be taken for

fragments of the sealing tape not to enter in

the pipe. Foreign matters in the tube will cause

malfunctions of accessories.

WARNING

Never climb on the actuator or accessories in field

working, which will cause failure in adjustment or

human injury.

For supplying the compressed air, refer to

Section 9 “Piping and Installation”.

The procedure explained below applies to

the combination of actuator and valve, when

turning the stem clockwise operates the valve

to closed position.

8.1 Procedure for Double Acting Actuator

1. Supply compressed air to inlet port to open

the valve and check fully open position of the

valve.

2. If the position is not correct, exhaust the

compressed air and perform steps 4 and 5.

3. Loosen hexagon nut for locking stopper

bolt on open side, turn the stopper bolt

in respective direction by using hexagon

bar wrench. Clockwise turning of the bolt

reduces travel angle of the actuator, and

counterclockwise turning widens the range

of the travel angle.

4. After ensuring correct position of the valve

by supplying compressed air to the actuator,

tighten the locking nut of the stopper bolt.

5. Supply compressed air to inlet port to close

the valve and check the fully closed position.

6. If the position is not correct, perform the

above described procedure for closed side

stopper bolt.

When operating actuator in piping work, please

pay attention to the following points.

1. Avoid installing the actuators in a place

where they are exposed to seawater,

chemicals, and high- and/or lowtemperature (above 80ºC, under -20ºC).

If it is inevitable, protect the actuators by

appropriate covering, or protect sufficiently

with anticorrosive painting.

2. Usually, copper tubes are used for

connecting attachments. When the joints

loosen by intensive vibrations, air leakage

may occur. Additional tightening will be

necessary accordingly. In vibrational

environments, use Nylon tubing.

3. Since accessories have been adjusted

already in the factory, further adjustments

are not necessary.

4. For air piping of accessories, use Φ8 xΦ6

tube or larger for AWN13~AW20, and

Φ10 xΦ8 tube or larger for AW28. If quick

operation is required, use large size tube

according to the desired speed.

5. For air piping from compressor or air tank

to supply port of actuator (or inlet port of

attachment device, if equipped), use steel

pipe of size not smaller than the air supply

port of the actuator.

4

Page 5

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

6. When using the actuators outdoor in cold

or snowy areas moving parts of accessories

(positioner, limit switches, etc.) may be

frozen. Protect the devices by proper

covering in such cases.

7. When installation orientation of actuator is

changed for convenience of positioning, the

following caution should be taken.

1. Exhaust port of the actuator and

accessories (solenoid valve, air operate

valve, quick exhaust valve, etc.) should be

directed downward by attaching elbows.

If doing so is difficult due to surrounding

area environment, use elbow for

exhausting downward.

2. Since attaching orientation of filter

regulator or lubricator is limited, drains

should be directed downward.

CAUTION

Do not position single acting torque cylinders in

such orientation that springs are facing upward.

By doing since, the inside of the cylinder may be

corroded by entering of water, which may cause

malfunctions.

8. In piping for operating actuator work, care

should be taken as follows.

1. Clean joint and tubing sufficiently by using

compressed air before piping.

2. When sealing tape is used, apply tape to

thread starting two threads back from

end of fitting in order for the fragments of

the tape not to enter inside of the pipe.

3. Since copper tubes are regularly used for

connecting accessories, avoid vibrational

place for installing. In severe vibrational

environments, use Nylon tubing.

(The copper tube loosen by vibration may

cause leakage.)

4. Do not tighten the joint excessively to the

supply port of the actuator.

9. Pneumatic diagram for actuator and

accessories Schematic diagrams of piping

for solenoid valve to actuator are shown

below. Select appropriate mode according

to the operating purpose.

NORMALLY CLOSE (ENERGIZED TO OPEN) NORMALLY OPEN (ENERGIZED TO CLOSE)

• Double Acting type

AWN13

AW17

AW20

AW28

(4-Way

solenoid

valve)

(Filter Regulator)

FIGURE 3

Actuator

(Equalizing Valve)

Supply air

0.4 MPa

• Double Acting type

AWN13

AW17

AW20

AW28

(Equalizing Valve)

(4-Way

solenoid

valve)

(Filter Regulator)

FIGURE 5

Actuator

Supply air

0.4 MPa

CAUTION

Excessive fastening of joint may cause cracking of

supply port leading air leakage.

ca. two

threads

Wind tape in this area

FIGURE 2

• Single Acting type

AWN13S

AW17S

AW20S

AW28S

Actuator

(Pluged) (Pluged)

(Filter Regulator)

Supply air

0.4 MPa

• Single Acting type

AWN13S

AW17S

AW20S

AW28S

FIGURE 4 FIGURE 6

Actuator

(Filter Regulator)

Supply air

0.4 MPa

(Filter Regulator)(Filter Regulator)

5

Page 6

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

SECTION 10 - AIR SUPPLY FLOW RATE

The volume of air necessary for cylinder

operation is determined to obtain the following

two types of flow rates:

1. Momentary Flow Rate QD, QS

Calculation of the momentary flow rate

is necessary to determine operating

time. The shorter the operating time

with the same cylinder size, the larger

the momentary flow rate. In order to

obtain the desired operating time, the

supply source capacity, piping diameter,

pressure reducing valve capacity, solenoid

valve orifice diameter (C

value), etc. are

v

necessary. This enables the momentary

flow rate to be determined by the following

formulas (1) and (1’). If multiple cylinders

are operated simultaneously, then the

capacity of each devices used, multiplied

by the number of cylinders will provide the

momentary flow rate.

Momentary flow rate of Double Acting cylinder:

( )

Momentary flow rate of Spring Return type

Cylinder: ( )

2. Air consumption VD, VS

This shows the volume of air consumed

in a period of time. For the same size

cylinder, air consumption increases in

direct proportion to the operating time.

The consumption is determined by the

following formula. Incidentally, the total

air consumption is identical to a sum value

obtained for the total units.

Remarks

Q

D = Momentary flow rate in Double Acting

cylinder ( )

Q

S = Momentary flow rate in Spring Return

type cylinder ( )

V

D = Air Consumption of the Double Acting

cylinder ( )

V

S = Air Consumption of the Spring Return

A, B = Cylinder capacity ( )

P = Operating pressure (MPa)

T = Operating time (Sec)

n = Operating cycles in a time period

(One cycle means one reciprocating

action)

type cylinder ( )

Cylinder

model

AWN13 3.10 3.10 6.20

AW17 6.70 6.70 13.40

AW20 14.80 14.80 29.60

AW28 34.60 34.60 69.20

A B A + B

SECTION 11 - CAUTIONS PRIOR TO OPERATION

1. Check air leakage in pipeline from

compressor or tank to supply port by using

soap liquid or leak check liquid.

2. Be sure that supplying compressed air

pressure is within the range specified in

Section 5 “Range of Application”.

3. Check electric power supply voltage of

solenoid valve.

4. Check air pressure of filter regulator outlet

Cylinder capacity (ℓ)

SECTION 12 - CAUTIONS DURING OPERATION

1. Use clean and dry compressed air through

dryer and filter. (Dew point below -15ºC).

Drain sufficiently to prevent freezing

especially in cold areas.

2. Periodical draining of filter or filter regulator

should be performed.

3. Supply lubricating oil (turbine oil JIS K2213,

ISO VG32 with additives) periodically to

lubricator.

port if attached.

5. Check speed of speed controller or quick

exhaust valve if attached.

6. Ensure that the actuator and valve travel

CAUTION

Do not use machine oils and spindle oils, which

may cause troubles.

smoothly by operating accessories (solenoid

valve, air operate valve, positioner, etc.).

7. Ensure that electric wiring of solenoid valve

4. Manual operation is inhibited while

automatic operation.

or limit switches are shielded by cable

gland, cable protection tube, etc. Wiring

port should be directed in horizontal and

downward position.

WARNING

Never place or leave lever handles, spanners and

wrenches at the upper portion of the

stem. They are driven while operation and cause

human injury and equipment damages.

Air Consumption of Double Acting cylinder:

( )

Air Consumption of Spring Return type cylinder:

( )

a1 a2

A

b1 b2

B

FIGURE 7

6

Page 7

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

SECTION 13 - MANUAL OPERATION

WARNING

Manual operation must only be done after

stopping the air supply for both double and single

acting actuators. Manual operation while air

supply will cause injury. In operating single acting

actuator, use manual operating device “HW” for

single acting actuator. Never use spanners or

wrenches. Doing so may cause injury.

1. Manual operation of double acting actuators

(lever handle) AWN13

1. Stop compressed air supply.

2. Open equalizing valve if attached.

Otherwise, loosen the joint of supply

port of the actuator to purge air in the

actuator.

3. Apply lever handle at the upper portion of

stem to turn it. The turning range should

be within 90 degrees.

4. After manual operation, recover air supply

by closing equalizing valve or retighten

the joint at supply ports.

2. Double Acting (Manual Gear HG) AW17 to

AW28

3. Single acting actuator (Manual operator HW)

AWN13S to AW28S

The HW Type Side Handle can be used as

manual valve operation device when loss of

air supply occurs in single acting actuator.

The procedure of manual operation with HW

Type Side Handle is as follows.

1. Equalize pressure between inside of

cylinder and atmosphere by respective

methods according to the piping

configurations around the actuator.

For example: Switch the power off of

solenoid valve used for operating the

actuator. Manipulate pressure-exhausting

valve.

WARNING

1. After manual operation, be sure to remove

the lever handle. Pneumatic operation while

leaving the tools will cause injury.

2. Operate the valve with stable posture from

a set direction. Make sure that the handle

is reliably inserted into the stem’s end.

Insufficient insertion and forced operation of

the handle may result in damage or injury if

the handle slips out.

3. Excessive handle operation may break the

lever and injure the operator.

CAUTION

1. When valve is open or closed, indicator nut ➃

moves toward “OPEN” side or “SHUT” side.

Return the nut to “AUTO” position correctly by

turning Handle . Incorrect positioning of nut ➃

deviating from “AUTO” position will cause

insufficient opening or closing in automatic

operation or operation malfunctions.

2. After resetting the nut ➃ to correct “AUTO”

position, lock the Handle ➁ by chain and lock

to prevent misoperation.

CAUTION

Manual operation with side handle without

equalizing pressure between inside of cylinder

and atmosphere will bring extreme increase

in required operating force, which may cause

disabling operation or failure of actuator.

2. Operate valve by turning the side handle

manually

Reverse Acting type: Turning the handle

counterclockwise opens the valve.

Direct Acting type: Turning the handle

counterclockwise closes the valve.

CAUTION

Over winding by applying excessive force after

the valve is fully opened will cause failure of

the actuator. Never use pipe or such things to

lengthening the handle arm.

3. Be sure to turn the handle clockwise until

it stops to reset manual operation mode

before returning to pneumatic operation.

CAUTION

Leaving the handle halfway will cause trouble in

automatic operation, and the valve does not open

or close completely.

Padlock

Chain

Gear Case

Indicator

SHUT AUTO OPEN

Nut

Handle

FIGURE 8

a. Unlock Padlock ➅ of Manual operator and remove chain ➄.

b. Turning Handle ➁ enables operation of valve to open or close.

Turning the handle ➁ clockwise operates to valve closing, and counter clockwise operates valve opening.

7

Page 8

KTM PNEUMATIC ACTUATORS - AW, AWN SERIES

INSTALLATION AND OPERATION MANUAL

SECTION 14 - TROUBLESHOOTING

Trouble examples Causes Measures

Valve does not operate Failure in electric power source or control signal. Check and repair of electric power source and/or control devices.

No or insufficient supply air. Check and repair of air source and attachments

(compressor, filter, reducing valve, etc.)

Failure of attachments

(solenoid valve, air actuated control valve, positioner, etc.)

Failure in actuator. After operating actuator separately, disassemble and repair.

Failure of valve. Check and disassemble valve, and repair or replace it.

Unstable operation of valve Fluctuation or low supply air pressure

(insufficient supply or fluctuation).

Failure of attachments (solenoid valve, air actuated valve, positioner, etc.)

Leakage at or failure of piston. Replace piston O-ring.

Wear or damage of piston bearing. Replace piston bearing.

Seal leakage in stem. Replace sealing O-ring.

Insufficient power of actuator. Replace actuator with larger one.

Unstable valve operating torque or increase of valve operating torque. Disassembling and checking valve.

After checking each attachment separately, repair or replace it.

Increase capacity of compressed air supply.

Install accumulator.

Increase pipe diameter.

After trying each attachment separately, repair or replace it.

Increase supply pressure.

Repair or replace valve parts.

Replace actuator with larger one.

Increase supply pressure.

CAUTION

SECTION 16 - WARRANTY

If there are any troubles in valve, read the

Installation and Maintenance Instructions of

the valve thoroughly and disassemble the valve

carefully.

The warranty period is one year from the date

of installation by the first use of the goods, or

eighteen (18) months from the date of shipment

to the first user, whichever occurs first.

SECTION 15 - MAINTENANCE

Regular maintenance period depends on

the operating environment and conditions.

Generally maintenance after 100,000 operations

or after 24 months from initial operation,

(whichever comes earlier), is recommended.

Replacing of spring units of single acting

actuator after 200,000 operations or 60 months

from first operation, (whichever comes earlier),

is recommended.

Consumption supplies should be replaced with

new ones at the same time regardless the

degree of wear and deterioration.

For purchasing spare parts, please consult a

Service Company affiliated with Emerson or a

branch office of Emerson.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

KTM is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Emerson.com/FinalControl

8

Loading...

Loading...