Page 1

Operator’s Manual ASCO 336 / 337

g

Operator’s Manual

336 /337 Generator Paralleling System

DANGER

!

DANGER is used in this manual to warn of a

hazard situation which, if not avoided, will result in

death or serious injury.

WARNING is used in this manual to warn of a

hazardous situation which, if not avoided, could

result death or serious injury.

CAUTION is used in this manual to warn of a

hazardous situation which, if not avoided, could

result in minor or moderate injury.

WARNING

!

CAUTION

!

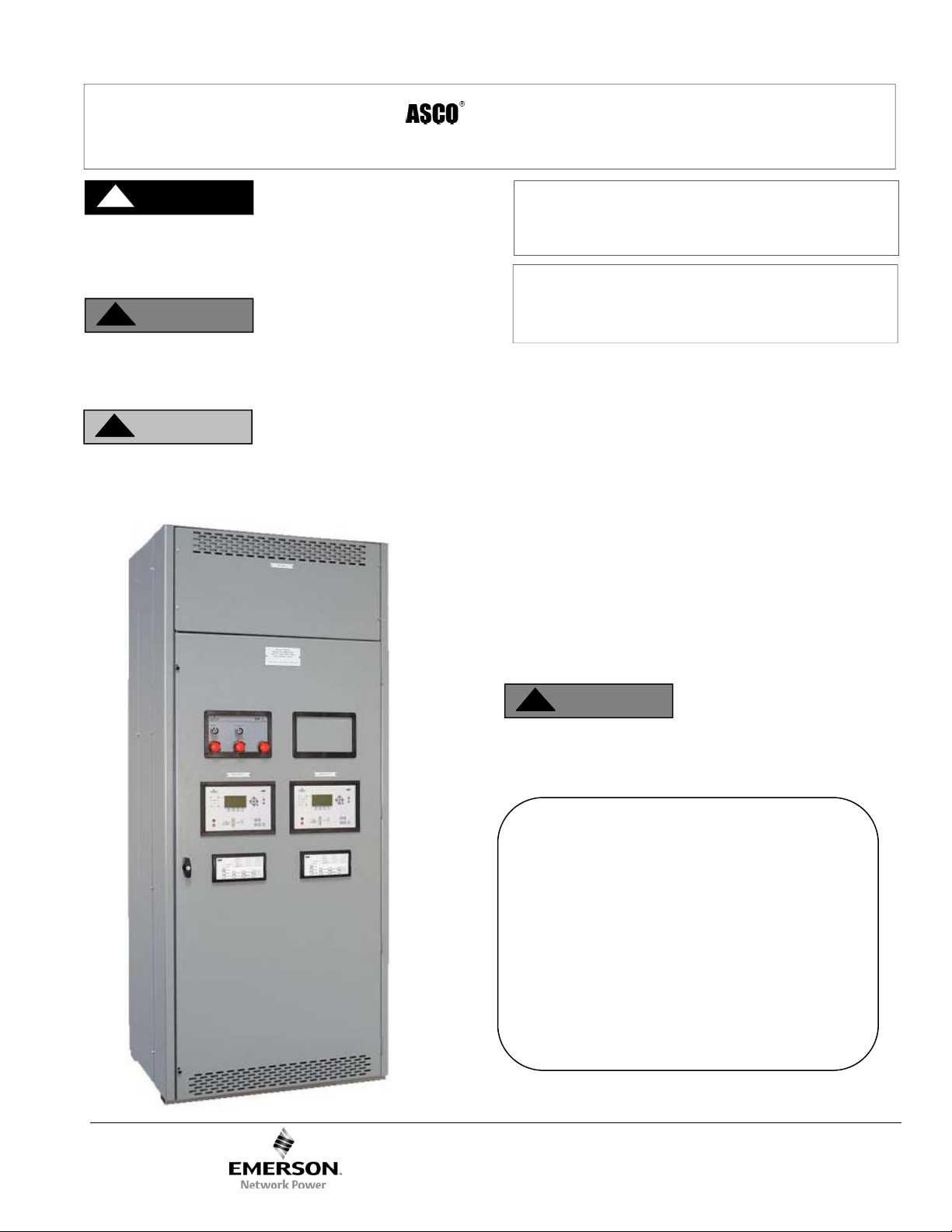

300 Series Power Control System

Refer to the outline and wiring drawings provided

with the 336 / 337 for all installation and connection

details and accessories.

Refer to the Controller User’s Guide for status

display messages, time delays, pickup and dropout

settin

s, and adjustments.

Rating Label

Each 336/337 PCS contains a rating label to define the loads

and fault circuit withstand/closing ratings. Refer to the label

on the transfer switch for specific values.

In a non-redundant system, that is, the load current is more

than one generator’s full load current and the generators are

being paralleled to provide more power to the load, the CTTS

current rating must be equal to or greater than the sum of the

two generator’s full load amps.

If the application is a redundant system, that is, the load

current is equal to or less than the full load amps of one

generator and the generators are being paralleled for

redundancy, the 336 or 337 rating must be equal to or greater

than the full load current of the biggest generator. In addition,

the output of the CTTS unit must be protected by an over

current device, like a circuit breaker, equal to or less than the

CTTS rating label.

WARNING

!

Do not exceed the values on the rating label.

Exceeding the rating can cause personal injury or

serious equipment damage.

Table of Contents

page

INSTALLATION ............................................... 3

FUNCTIONAL TEST .................................... 5-8

OPERATIONAL TESTING ........................ 9-10

FEATURES & OPTIONS ......................... 11-13

PROTECTIVE RELAY FUNCTIONS ............. 14

TESTING & SERVICE ................................... 15

INDEX ............................................................ 16

381333-427 A

381333-427 A ASCO Power Technologies Page 1

Page 2

ASCO 336 / 337 Operator’s Manual

300 Series PCS Family of Products

The ASCO 300 Series Power Control System (PCS) is a

family of affordable and feature-rich products for paralleling

generators, controlling loads, and connecting generators to the

utility power system or grid. Transfer switch based or circuit

breaker based power switching options are available to meet

the requirements of all applications. The PCS 300 Series

control system is an integrated platform that provides

sequencing, synchronizing, generator load sharing, protective

functions, power management, and many other industryleading features, all while minimizing costs.

Upper

Customer

Terminal

CTs

CTTS

Transfer

Switch

CTs

Lower

Customer

Terminal

Block

Typical 336 Series PCS H-design 800-1200 ampere

336 / 337 PCS

The ASCO 336 / 337 PCS utilize the ASCO Power

Technologies industry-leading and time-proven Closed

Transition Transfer Switch (CTTS) mechanism to parallel two

generators per CTTS unit. The 336 manages the first two

generators of any system. The 337 can be added to manage

the third and fourth generators of a four generator system.

Due to the fault currents available, usually four generators is

the limit of a 336/337 PCS system. There are alternatives

within the 300 Series for paralleling more generators: co nt act

ASCO Power Technologies for more information.

A 337 may be added later as long as the electrical power

infrastructure is compatible. Options must be the same in a

336 and 337 for proper operation.

Controller

Operator

Interface

Terminal

OIT

Page 2 ASCO Power Technologies 381333-427 A

Page 3

Operator’s Manual ASCO 336 / 337

E

Automatic Control System

The 336 / 337 is an automatic control system that may start

and/or stop generators and operate the transfer switch at any

time to maintain power to the load.

WARNING

!

NOTIC

Protect the transfer switch from construction grit

and metal chips to prevent malfunction or

shortened life of the transfer switch.

Line Connections

Proper precautions must be taken, including tag out

/ lock out procedures, to ensure personnel safety.

Installation

The system is factory wired and tested. Installation requires

mounting, connecting service cables, and connecting generator

control and generator circuit breaker control circuits.

System installation and startup by ASCO Power

Technologies is recommended.

An experienced licensed electrician must install the system.

The supporting foundation for the enclosure must be level and

straight. Refer to the applicable enclosure outline drawing

included with the system for all mounting details including

door opening space.

If bottom cable entry is used, the foundation must be prepared

so that the conduit stubs are located correctly. Refer to the

enclosure outline drawing for specified area and location.

Provide cable bending space and 1 inch minimum clearance to

live metal parts. When a concrete floor is poured, use

interlocking conduit spacer caps or a wood or metal template

to maintain proper conduit alignment.

Refer to the outline and mounting diagram and mount the

transfer switch according to details and instructions shown on

the diagram. Mount it vertically to a rigid supporting

structure. Level all mounting points by using flat washers

behind the holes to avoid distortion of the transfer switch.

NOTICE

Supporting Foundation

Mounting

Refer to the wiring diagram provided with the transfer switch.

All wiring must be made in accordance with the National

Electrical Code and local codes.

DANGER

!

De-energize the conductors before making any line

or auxiliary circuit connections. Be sure that the

Generator 1 and Generator 2 line connections are

in proper phase rotation. Place the engine

generator starting controls in the OFF position.

Make sure engine generators are not in operation.

Testing Power Conductors

Do not connect the power conductors to the transfer switch

until they are tested. Installing power cables in conduit, cable

troughs, and ceiling-suspended hangers ofte n req ui res

considerable force. The pulling of cables can damage

insulation and stretch or break the conductor’s strands. For

this reason, after the cables are pulled into position, and before

they are connected, they should be tested to verify that they

are not defective or have been damaged during instal l a ti on .

Connecting Power Cables

After the power cables have been tested, connect them to the

appropriate terminal lugs (if provided) on the transfer switch

as shown on the wiring diagram provided with the transfer

switch. Make sure that the lugs are suitable for use with the

cables being installed. Be careful when stripping insulation

from the cables; avoid nicking or ringing the conductor.

Remove surface oxides from cables by cleaning with a wire

brush. When aluminum cable is used, apply joint compound

to conductors. Tighten cable lugs to the torque specified on

rating label.

381333-427 A ASCO Power Technologies Page 3

Page 4

ASCO 336 / 337 Operator’s Manual

E

Generator Circuit Breaker Control Circuits

The generator circuit breaker control connections are located

on customer terminal block. Connect signal wires to

appropriate terminals as specified on the wiring diagram.

Generator circuit breaker

The generator circuit breaker provides the overcurrent (short

circuit) protection for the system and functions as a back-up to

protect/isolate the system upon a fault during the loss of AC

control power. It does not matter if the generator circuit

breaker is manually operated close or electrically operated

close, but it must have a shunt trip and auxiliary contacts.

The control system has a dry contact (CTBx:19 to CTBx: 20,

rated at 8A, 30VDC or 8A, 250VAC, tripping duty) available

for shunt tripping the generator circuit breaker. This contact

must be connected during installation.

There is an option to have wire break monitoring of this shunt

trip coil. This requires (1) the shunt trip coil to be 24Vdc, (2)

supplied from the same source as the control system (normally

the generator batteries), and (3) not connected to any other

tripping circuit devices. This wire break system functions by

passing a small amount of current thru the breaker trip coil; if

this current gets too low, a wire break is assumed. If any other

devices are connected, for example indicating lights or other

trip devices, the wire break function may not work. The

maximum resistance of the trip coil circuit that this function

will work is 100 ohms. That is, if the circuit resistance exceeds

100 ohms, this function will alarm a wire break. Default from

the factory is this feature is not enabled; ASI may enable it

during startup.

If the generator circuit breaker is open the control system

needs to know that this gen-set is not available. This requires a

normally open dry contact (52/a: closed when the circuit

breaker main contacts are closed) to be wired to the control

system, CTBx:9 to CTBx:10. There should be no other

connections to this circuit. This is a contact input, wetted by

internal 24VDC (interrogation voltage) from the controller

power. If the generator circuit breaker is open, this generator

is not available and the Power Management option will not

include this generator in the gen shed/gen add program.

CTBx: x is the generator number.

Gen1 is CTB1, Gen 2 is CTB2.

Grounding different generator DC controls

Generators paralleled by the 336/337 system do not have to be

the same size or even manufacturer. However, different DC

grounding schemes may not be compatible with each other.

Optional DC to DC isolators can be added to the DC Control

Power circuit to prevent circulating currents and/or

unintentional grounds.

NOTIC

Optional DC to DC isolators are recommended for

all applications.

If all the generators utilize the same type of grounding – for

example, the negative pole of the batteries are all solidly

grounded – and the grounding system installation is good, this

may not be necessary. But, by example, if one generator uses a

solidly grounded DC scheme and the second generator uses a

floating DC system or the integrity of the DC ground

connection(s) is/are not known or reliable, then this option is

required. If the all generators use the same grounding scheme

for the DC control power and the installation is perfect, this

optional feature may not be needed.

Changing settings

Most settings require a password to change. There are 3 levels

of passwords: Customer, Service, and Master. The Customer

password is 1111 and will allow access to the nominal settings

like voltage, frequency, generator KW, etc. The Service level

password is known to authorized ASI service representatives

and is required for startup. The Master level password is

reserved for factory use.

While it is possible to program the controller from the keypad,

most users will find it more efficient to use a laptop computer,

an A/B USB cable (see Figure 1), and the free Utility Software

available from the 336/337 website. In the Designer’s

Reference Handbook are directions for installing the software,

connecting the controller to the laptop, and making changes to

the settings.

If the generator circuit breaker opens for any reason, the CTTS

will open when AC control power is available. The control

system will alarm and not be available until the generator

circuit breaker is closed again and the alarm is reset. If this is

the only generator running and the circuit breaker trips, the

CTTS may be closed. See AC Control Power Circuit

description.

Figure 1. A/B USB cable for programming controller.

Page 4 ASCO Power Technologies 381333-427 A

Page 5

Operator’s Manual ASCO 336 / 337

Functional Test

The functional test consists of three checks: manual

operation, voltage checks, and electrical operation.

Do these checks in the order presented to avoid

damaging the transfer switch.

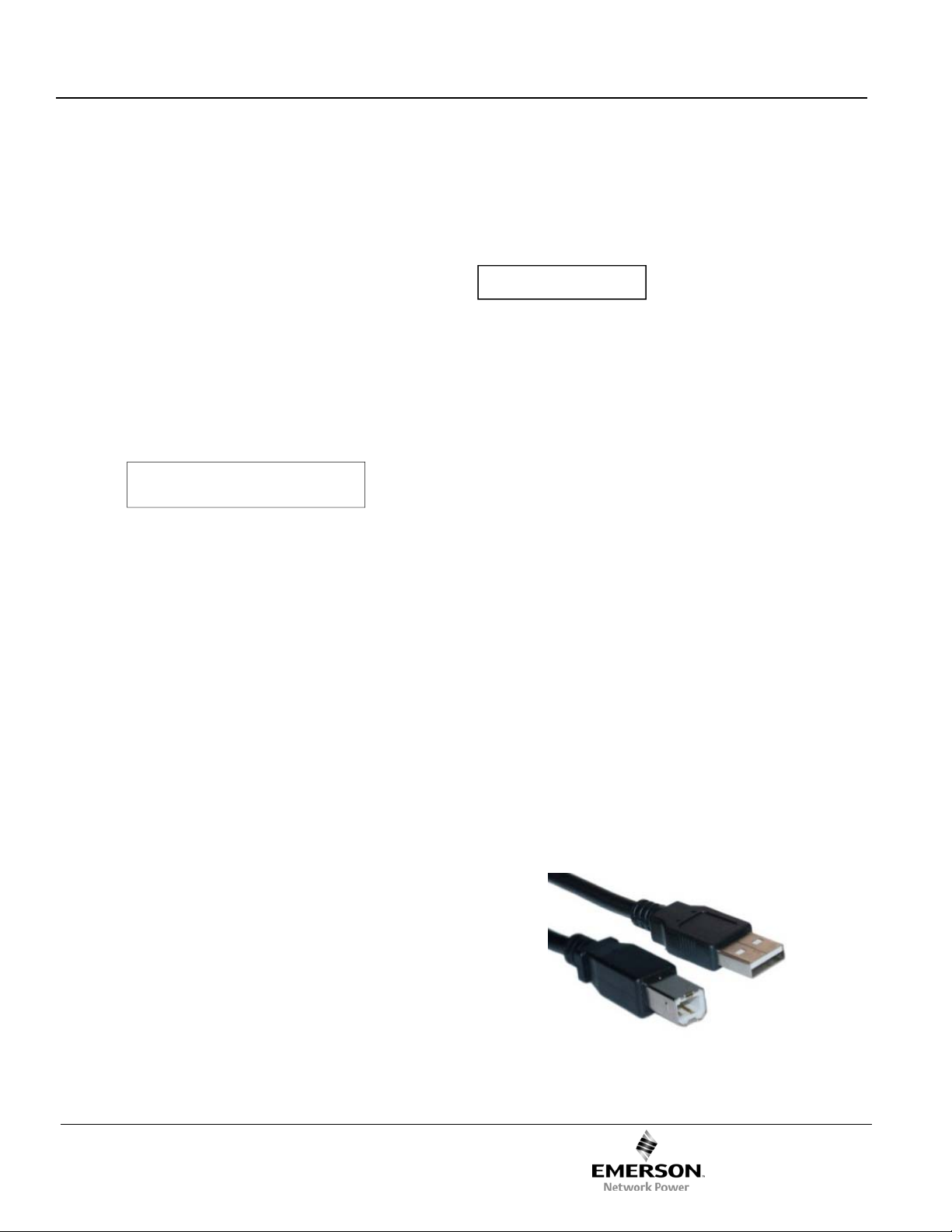

A maintenance handle is provided on the transfer switch for

maintenance purposes only. Manual operation of the transfer

switch should be checked before it is energized (before it is

operated electrically). Note the contact position indicators.

Do not manually operate the transfer switch until all

power sources are disconnected: open both

generator circuit breakers and all load circuit

breakers.

NOTICE

1 – Manual Operation

WARNING

!

Left side of the

transfer switch

Maintenance handle

Generator 2

contact shaft hub

Clip

Generator 1

contact shaft hub

Hubs shown with

Generator 1 source

contacts open and

Generator 2 source

contacts closed.

Figure 2. J-design transfer switch maintenance handle.

1. After deenergizing both power sources, open the enclosure

door. Locate and remove the maintenance handle. Select

either H-design or G-design. See Figures 2 and 3.

J & H-design see Figures 2 & 3

The maintenance handle is stored in clips on the left side

of the transfer.

G-design see Figure 4

The maintenance handle, hub, and pin are stored on the

center frame of the transfer.

2. Install the handle into the hole in the molded hub. Move

the handle up or down as shown to manually operate the

transfer switch to close and reopen the contacts. It should

operate smoothly without any binding. If it does not, check

for shipping damage or construction debris.

J & H-design see Figures 2 & 3

The transfer switch has two contact shaft hubs Install the

maintenance handle into the hole in the molded hub. The

upper hub operates the Generator 2 contacts. The lower

hub operates the Generator 1 contacts.

G-design see Figure 4

Install the hub (with pin) onto the shaft. Insert the

maintenance handle into the side hole in the hub. Push in

the shaft to operate the Generator 1 contacts. Pull out the

shaft to operate the Generator 2 contacts.

3. After checking manual operation, return all transfer switch

contacts to the open position. Generator 1 and Generator 2

contacts must be open. Check contact position indicators.

4. Remove the maintenance handle and store it on the transfer

switch in the place provided.

J & H-design see Figures 2 & 3

Store the maintenance handle in the clips on the left side of

the transfer.

G-design see Figure 4

Store the maintenance handle, hub, and pin on the center

frame of the transfer.

Note: If Generator 1 and Generator 2 connecti ons a re reve rsed

this operation is also reversed.

WARNING

!

Verify that the maintenance handle has been

removed and stored properly before electrically

operating the transfer switch.

381333-427 A ASCO Power Technologies Page 5

Page 6

ASCO 336 / 337 Operator’s Manual

Hubs shown with

Generator 1 source

contacts open and

Generator 2 source

contacts closed.

Left side of the

transfer switch

Generator 2

contact shaft hub

Maintenance

handle

clips

Generator 1

contact shaft hub

Generator 2

contacts

window

indicators

OPEN or

CLOSED

Generator 1

contacts

contact position

indicators (left side)

UPPER SHAFT

Generator 2 contacts

UP opens the contacts

DOWN closes the contacts

hub

Window indicators

O is open, C is closed

hub

LOWER SHAFT

Generator 1 contacts

UP closes the contacts

DOWN opens the contacts

Figure 3. H-design Transfer Switch Maintenance Handle Operation.

With all power OFF,

Turn counterclockwise

to OPEN contacts.

grasp handle firmly

with both hands.

Turn clockwise to

CLOSE contacts.

Slide the hub onto the

shaft and insert the pin.

counterclockwise DOWN

OPENS the contacts

Pull out shaft (upper) to open Gen.

2 source contacts (upper).

Push in shaft (upper) to open Gen.

1 source contacts (lower).

clockwise DOWN CLOSES the contacts

Pull out shaft (upper) to close Gen. 2

source contacts (upper).

Push in shaft (upper) to close Gen. 1

source contacts (lower).

Figure 4. G-design Transfer Switch Maintenance Handle Operation.

Gen. 2

contacts

Gen. 1

contacts

Contact position

indicators

(right side)

Insert handle

into hole

(spring fully

compressed

Page 6 ASCO Power Technologies 381333-427 A

Page 7

Operator’s Manual ASCO 336 / 337

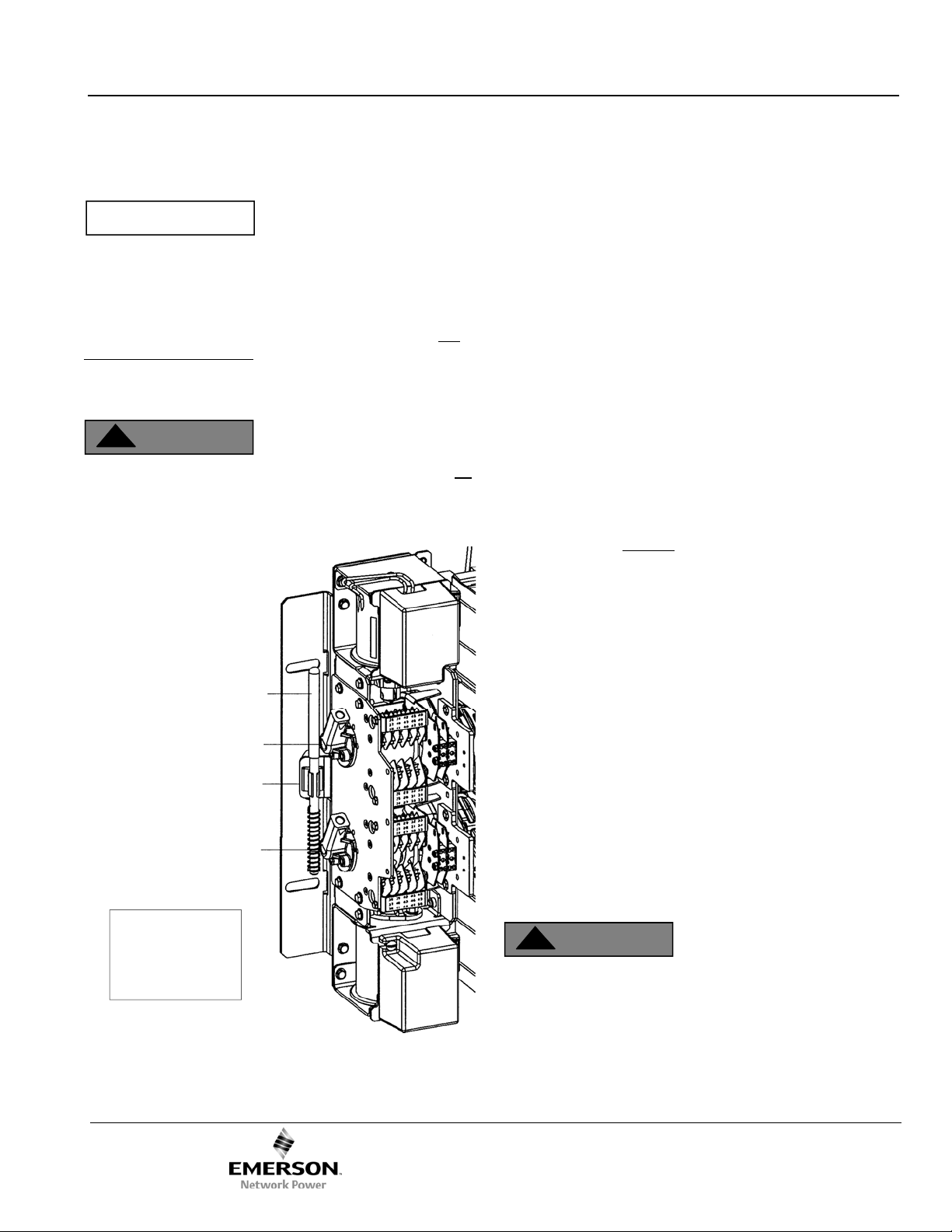

Start button

Stop button

Generator running light

Figure 5. Buttons and indicator lights on generator controller for voltage checks.

2 – Voltage Checks

First check the nameplate on the PCS 336 System and the

transfer switch; the rated voltage must be the same as

Generator 1 & 2 rated output voltages. Be sure that thes e

controls are the following positions before starting:

Master Control Switch in Off position

Power Management Selector switch in Off position

Generator 1 Circuit Breaker closed (on)

Generator 2 Circuit Breaker closed (on)

Both Generators off, not running

Transfer switch contacts open (both upper & lower)

DANGER

!

Use extreme caution when using a meter to

measure voltages in the following steps.

Do not touch power terminals; shock, burns,

or death could result!

Multiple sources of potentially lethal voltages

may be present in any one enclosure!

Perform steps 1 through 6 at the right. Observe the indicator

lights. See Figure 5.

* If necessary, adjust the voltage regulator on the generator

according to the manufacturer’s recommendations. The PCS

336 System will respond only to the rated voltage specified on

the transfer switch nameplate.

Also see the controller manual for settings.

DANGER

!

Generator voltage and frequency acceptable light

Press the MAN (manual)

1

button on both controllers.

Press the start button for

Generator 1. The generator

2

running light and generator

acceptable light should both

come on.

Press the start button for

Generator 2. The Generator 2

3

acceptable light should come

on.

Use an accurate voltmeter to

check phase to phase and

4

phase to neutral voltages

present at the transfer switch

Generator 1 & 2 terminals.*

Use a phase rotation meter to

check phase rotation of

Generator 1 & 2 at the

5

transfer switch. They must

be the same.

Shut down Generator 1 & 2 by

pressing both stop buttons.

The Generator 1 & 2 accepted

6

lights should go off. Then put

starting controls (on generator

sets) in the automatic position.

MAN (manual) button

Gen 1 Acceptable

Gen 2 Acceptable

Gen 1 and Gen 2

Continue to 3 – Electrical Operation on the next page.

381333-427 A ASCO Power Technologies Page 7

Page 8

ASCO 336 / 337 Operator’s Manual

Generator

running light

AUTO (automatic)

button

Generator voltage & frequency acceptable light

Transfer switch closed light

Power on the

Figure 6. Button and indicator lights on generator controller for electrical operation.

3 – Electrical Operation

This procedure will check the electrical operation of the 336

system. The generators will be started and connected to the

load bus. Be sure that these controls are the following

Press the AUTO (automatic)

1

button on both controllers.

positions before starting:

Master Control Switch in Off position

Power Management Selector switch in Off position

Generator 1 Circuit Breaker closed (on)

Turn the Master Control

2

Switch to the On position.

Generator 2 Circuit Breaker closed (on)

Both Generators off, not running

Generator starting controls in Automatic position

Transfer switch contacts open (both upper & lower)

WARNING

!

Close the system enclosure door and tighten the

screws (if provided) before you test electrical

operation.

Both generators should start. Both generator

running lights and both generator acceptable

lights should come on. The transfer switch

should operate to close one set of contacts.

3

The close light should come on, and the power

on the load bus light should come on. The

connection of the second generator to the load

bus occurs when the generators are in

synchronism.

Perform steps 1 through 5 at the right. Observe the status

lights. See Figure 6.

NOTE:

See controller manual settings in the controller.

NOTICE

The speed, KW, voltage, & KVAR regulators should

be properly tuned during start up for stable system

operation by a qualified ASI service technician.

This completes the functional test of the transfer switch.

Leave the engine-generator starting controls in the automatic

position.

Turn the Master Control

4

Switch to the Off position.

The transfer switch contacts should operate

again to open both sets of contacts. The close

5

lights should go off. The power on the load bus

light should also go off. After a cool-down

period, both generators should shut down.

Page 8 ASCO Power Technologies 381333-427 A

Page 9

Operator’s Manual ASCO 336 / 337

Transfer Load & Shut Down button

Figure 7. Operator Interface Terminal (OIT) with Power Management option.

Operational Testing

Load testing on optional power management systems may be

done by turning off power management. That will start all

available generators that were shed by the generator she d

function. Individual generators may then be taken off line by

pressing the Transfer Load & Shut Down button on OIT.

The Transfer Load & Shut Down button may not s hut o ff

a generator if doing so might overload the remaining

generator(s) or additional generator(s) are not available to take

over the load. To manually operate the system, the SemiAutomatic (Semi) mode may be used. Semi-Automatic is also

known as assisted automatic mode. Here are two examples:

1. On the generator that is to be started to accept the load:

a. Press the Semi button.

b. Press the green 1 button.

If available, the generator will start.

c. Press the Close button.

The generator will synchronize and close to the bus.

2. On the generator that is to be shut down

a. Press the Semi button.

b. Press the Off/Cooldown button. (Off/Cooldown

may be cancelled at any time by pressing the Auto

button.)

Pressing Auto on the generator that has been shut down may

or may not return it to service depending upon the generator

shed/add status and the Run Time Management status.

In a system without power management, all generators will be

running when the Master Control Switch is in the On

position or in Auto with the customer remote control contact

closed.

No load testing may be done by selecting MAN mode from

the front panel, then press the green 1 button to start the

generator. When test is complete, press the red 0 button to

stop the generator then the Auto but t o n t o retur n t he gene rator

to automatic mode.

Mode Selection

This system is designed to stay in Auto mode all the time. If

the controller is not in Auto or will not switch to Auto mode,

check the alarm log and reset any active alarms. One possible

cause is the status of the generator circuit breaker. If it trips,

the system will fault and go to manual mode.

Manual Mode may be used to run the generator for no load

test, see Operational Testing.

Semi automatic mode is also known as assisted automatic

mode. It is not often used on this system. For more details, see

the detailed documentation available on the website.

Off mode turns off the control system and takes the generator

out of system control. The Transfer Load & Shut Down

command turns off a running generator. It is necessary to press

Auto mode, either on th e OIT or the controller itself to return

the system to automatic mode.

Note: The green 1 and red 0 buttons are disabled in Auto

mode. The Transfer Load & Shut Down button on the OIT

will shut down a running generator via the normal shut down

and cool down processes. An Emergency Stop will

immediately trip the CTTS contacts and immediately

shutdown a generator. Emergency Stop should not be used

on a hot, running, generator unless necessary. Engines may be

damaged if they are not allowed to follow the normal cool

down process.

381333-427 A ASCO Power Technologies Page 9

Page 10

ASCO 336 / 337 Operator’s Manual

Load Bus Ready for First Generator

CTBx: 11,12, First CTTS Close Enable

If it is possible that the connected load would exceed the

capacity of first gen, it is necessary to open the load ATSs or

CBs before the first gen could come on the bus.

Once any generator starts, generator AC power is available

from the AC Control Power Selector Circuit for this purpose,

but the 336 or 337 CTTS main power contacts may not be

closed until this load is off the load bus, else it will trip

immediately on overload. Interlock contacts will need to be

connected from the load device(s) to all the controllers. This is

a contact input, wetted by internal 24VDC (interrogation

voltage) from the controller power. Conducting means the

load is below the capacity of that generator and it is ok to

bring that generator on the bus. All generators will start, but

none will energize the bus if this contact is open on all of

them. Do not parallel contact inputs from different controllers

together: the system could be damaged. Separate contacts

must be wired to each controller. Separate contacts are used

because it is possible to have different size generators. Once

the first generator is on the load bus, this contact is ignored

and the other generators parallel normally to share the load.

Neutral or Ground current CT

If the power system is 3 phase 4 wire, the fourth CT input is

designed to measure the neutral current. If the power system 3

phase 3 wire, this input may be used to measure ground

current. It is critical the power system grounding is connected

correctly for this current, neutral or ground, to be measured

properly. See drawings for details.

AC Control Power Selector Circuit

and the Loss of AC Control Power

The generated voltage is available from the AC Control Power

Selector Circuit (fused at 20A) before the primary power

contacts close. This AC power could be used to operate loa d

ATSs or other system requirements. It is also used to open

any CTTS contacts left closed by unintentional or emergency

operations.

Loss of AC Control Power is not necessarily a fatal error: the

control system monitors AC Control Power and can take other

actions if a trip is needed. See Protective Relaying Functions.

The generator circuit breakers are normally closed so AC

Control Power is available from the line (generator) side of

both halves of the CTTS before the main power contacts close.

The AC Control Power Selector Circuit provides AC power

from either of the 2 generators (any one of the gens in a 4 gen

system). The voltage of this AC Control Power Selector

Circuit will be the system phase-to-phase voltage. If several

load ATSs are to be operated, it might be necessary to stagger

their operation to prevent blowing the control power fuse.

In a 336, one Source Selector Relay (SSR1) will switch AC

control power from either Gen1 OR Gen 2. I n a 4 gen syst e m,

SSR1 in the 337 will switch between Gen3 and Gen4. The

output of the 2 SSR relays, 1 in the 336 and the other in the

337, will feed SSR2 in the 337. In Boolean logic terms, SSR2

switches [(Gen1 OR Gen2) OR (Gen3 OR Gen4)]. Thus if any

generator is running, AC Control Power will be available to

all.

WARNING

!

There could be several different sources of AC

Control Power in the system. If any generator is

running, there will be potentially lethal voltages in

every section.

Loss of AC will be detected by the controller, alarmed, and

indicated on the controller. Each controller will detect its own

generator AC power and pass this information to the other

controllers via internal communications link, thus if any gen is

on, all controllers will know the status of the AC Control

Power.

Page 10 ASCO Power Technologies 381333-427 A

Page 11

Operator’s Manual ASCO 336 / 337

E

Master Control Switch

Features and Options

The standard 336/337 system is automated and simple to

operate. When the Master Control Switch is turned to On

or a remote control contact closes while in Auto mode, all

available generators start and synchronize to the load bus.

Power Manager Selector

Generator Emergency

Stop button

Figure 8. Emergency Stop buttons for generators.

The Generator Management sequence is:

1) All generators will start or are running before Power

Management is switched on.

2) All loads will be allowed to close onto the load bus if

Available Power (see load control) settings are met.

Generator Emergency Stop

Direct wired system and individual generator Emergency

Stop buttons are standard. These are emergency only

controls. Under normal operation, generators should go

through a cool-down process before turning off.

Power Management Selector

The Power Manager Selector controls the optional Power

Management system to provide four additional features:

Generator Management or Gen shed / Gen add

Load Management or Load shed / Load add

Run Time Management or Run Time Equalization

Start Next Gen on Alarm

Generator Management, or Gen shed / Gen add will add and

remove generators to the bus as needed to maintain a certain

percentage of spinning reserve KW. Spinning reserve is the

sum of the KW of the available generators minus KW

consumed. Numbers in brackets [8013, 70%] below are the

memory locations of that setting and typical values. These are

the factory default settings and should work for most

installations, but they can be changed by trained perso n nel

with the necessary password(s).

3) If the remaining generators will stay below the Load

Dependent Stop Setpoint [8013, 70%] when the next

generator is off line, the system will, after a

programmable time delay [8014, 30 sec], deload and shut

down the next generator.

4) If the spinning reserve falls below the Load Dependent

Start setpoint [8003, 70%], the next lowest generator will

be added to the bus.

All generators share the percent of load equally, thus all

controllers see the same value. Generator management is

based on this percentage of load.

This feature is a Power Management function. Turning off

Power Management will remove the shed signal and start all

available generators.

NOTIC

These values are examples and should be set to

the correct system-specific values during startup.

381333-427 A ASCO Power Technologies Page 11

Page 12

ASCO 336 / 337 Operator’s Manual

E

Load Management or Load Shed / Load Add will work in

cooperation with Generator Management to keep the highest

priority loads energized. In the event of a generator(s)

becoming overloaded, Generator Management will add the

next available generator to the bus automatically. If this is not

possible due to generator failure or until the next generator is

available, Load Management will keep the most critical loads

energized by removing non-essential loads. Fo ur le vel s of

load shed/load add are available with the highest level (P1)

never being shed.

This system is designed to interface with ATSs with

Accessory 30A, thus the logic is setup to de-energize relays

PR2, PR3, and PR4 to open contacts to request the

downstream ATS’s shed load (or stay on Normal).

Conversely, PR2, PR3 and PR4 relays will be energized to

allow the downstream ATSs to close. (PR = Priority control

Relay) Each generator has its own PR relays, thus the Load

Management system will function with any number of

generators operating.

There are three Available Power setpoints, one for each

Priority Load. They are factory set to be the same value,

105%. Please note that P1 loads are never shed, so this

discussion only concerns loads P2, P3, and P4 controlled by

PR2, PR3, and PR4 respectively. All generators share load in

terms of percent of KW, so if one generator is at 105% load,

all generators will be at 105% load.

These values are examples and should be set to

the correct system-specific values during startup.

Load Shed

1) If the load on any one generator exceeds [1880, 105%] for

[1882, 1 sec], P4 loads will shed. (drop out PR4)

2) If the load on any one generator exceeds [1870, 105%] for

[1872, 5 sec], P3 load will be shed. (drop out PR3)

3) If the load on any one generator exceeds [1860, 105%] for

[1882, 10 sec], P2 load will be shed. (drop out PR2)

4) If the load on any one generator exceeds [1490, 110%] for

[1492, 0.1 sec] OR generator Hz drops below [1260,

58.5 Hz] for [1262, 1 sec], ALL lower priority loads (P2,

P3, and P4) are shed.

5) If Power Management is turned on before the system is

given a start command, the Load Management becomes

active when the first generator energizes the bus. As

spinning reserve becomes available, the contacts will

close and allow the downstream ATSs to close onto the

load bus.

NOTICE

This is a Power Management function, thus turning off Power

Management will return all loads to service, possibly resulting

in a system overload.

Load Add

The controller calculates the spinning reserve KW, also called

Available Power KW. Note that while Load Shed is done by

the percent of load of a/any generator, Load Add is done by

KW. Thus this function will work with any number of

generators running. There are no typical values for Available

Power set points: these must be set during startup. Available

Power 1 should be the expected KW of the P2 loads,

Available Power 2 the expected KW of P3 loads, and

Available Power 3 the expected KW of the P4 loads.

1) If the spinning reserve is greater than Available Power 1

KW [8220] for [8222, 1 sec], PR2 will pick up and allow

P2 loads on the bus.

2) If the spinning reserve is greater than Available Power 2

KW [8230] for [8232, 5 sec], PR3 will pick up and allow

P3 loads on the bus.

3) If the spinning reserve is greater than Available Power 3

KW [8240] for [8242, 10 sec], PR4 will pick up and allow

P4 loads on the bus.

It is possible to set Available Power more than one generator

can handle, thus a load may not be added until more than one

generator is running. Generators are added by Gen Add

function, described above.

It is important to note that the controller does not actually

control the load ATS, rather it signals the ATS to allow the

ATS to decide if it will return the load to the bus. It is possible

there is a control function or problem in the ATS that will not

allow it to switch.

Loads always shed and add in order: PR4 always sheds first

and adds last. PR2 always sheds last and adds first. It is not

possible to skip a priority but loads may be manually forced

on by pressing P2, P3, or P4 Force On buttons.

Note: Be careful manually adding loads that were shed. If too

much load is manually forced on, it is possible to overload the

system and the protective relaying function may trip the

generator(s) or if any one generator exceeds [1490, 115%] for

[1492, 0.1 sec] or the load bus frequency drops below [1260,

97.5%] for [1262, 1 sec], ALL P2-P4 loads will be shed.

Reset Load Control to Auto button returns to automatic

load control, possibly shedding some loads. There is no ‘force

off’ function; normally this can often be done at the individual

ATS.

NOTIC

This is a Power Management function, thus turning off Power

Management will return all loads to service, possibly resulting

in a system overload.

Page 12 ASCO Power Technologies 381333-427 A

Page 13

Operator’s Manual ASCO 336 / 337

Run Time Management or Run Time Equalization

Run Time Management (RTM) function may be set to keep

the generators roughly equal in running hours. This could

result in all generators requiring maintenance at the same time,

so RTM may be also be set to run a generator(s) more hours so

maintenance is staggered. When the run hours timer setting

[8111, 24 hours] expires, the generator with the lowest

running hours will be started, synchronized, soft loaded, and

the one with the highest hours will be shut down. Setting

[8111] to 24 hours will equalize running hours every day.

Setting it to 30 days will run one generator for 30 days, then

run the next one for 30 days, intentionally staggering the

running hours.

Start Next Gen On Alarm

If Power Management is On and one or more generators have

been turned off by Generator Shed and a running generator

goes into a warning or has a non-fatal alarm, the next available

generator will start automatically, synchronize, and take on the

load. Then the generator in alarm will shut down.

This feature requires either a hardwired contact input from the

generator controls to CTBx:1 or a J1939 CANBUS connection

to the ASCO Power Technologies control system on CTBx:37,

38, 39 and that correct programming be done during startup.

If a generator has a fault that results in an immediate

shutdown, Power Management will start the next generator,

switch the CTTS mechanisms as needed, and restore power to

the load. See also AC Control Power Selector circuit.

If only 1 generator is running and the circuit breaker trips, it is

could be due to a short circuit. If the Power Management

Option is not installed, the system will be off and require

operator intervention to return to service. If the Power

Management option is installed, it is possible to either (1) start

the next generator and energize the load bus or (2) lock out the

system to prevent any generator from starting until the

operator resets the system. This is selected during startup. The

factory default is to lock out the system and wait for an

operator reset. With the sudden loss of AC power the CTTS

cannot switch the dead generator off the bus, so as soon as

another generator starts, the closed CTTS on the genset with

the tripped circuit breaker will open. If this is not possible, for

example if only 1 gen is available and it is the one that tripped,

obviously the system will not automatically return to service.

381333-427 A ASCO Power Technologies Page 13

Page 14

ASCO 336 / 337 Operator’s Manual

Protective relay functions

Most protective functions will open the CTTS contacts and not

the generator circuit breaker. There are two conditions that

will trip the generator circuit breaker: (1) short circuit or fault

currents detected by the circuit breakers’ internal protective

device and (2) if there is a loss of AC control power and a

protective system fault resulting in a protective relaying trip,

then the control system knows the CTTS will not operate and

will trip the generator circuit breaker.

Just losing AC control power is not a fatal problem: the

system will not shut down on loss of AC control power, it just

shifts the protective trips (like ANSI 32R, 32RV, 27, 59, 81,

etc.) to the generator circuit breaker.

Once the generator circuit breaker trips, how e ver , operator

intervention will be required to close manually operated

circuit breakers in order to return the generator to service. For

more details, see Generator Circuit Breaker section.

Electrically closed circuit breakers may be controlled by the

control system: contact factory for details.

Various electrical protective functions may be programmed in

the controller. This section describes the function and the table

at the end of this section lists the factory test and default

values. Since every power system is unique, it is the

customer’s responsibility to set ALL protective functions to

the correct value for a specific installation. Normally this

requires a power system study, also the responsibility of

others.

Note: Since the current transformers are in the CTTS, any

faults between the generator and the CTTS must be detected

and protected by the generator circuit breaker.

Over current, ANSI 50/51. Time over current and

instantaneous over current protection may be set in the

controller, but primary protection for these faults is the

generator circuit breaker. The 50/51 elements in the controller

are factory set to alarm only.

There is a 4th CT input that may be used for one of these

functions:

1. Ground current detection and over current (50/51G) on

3P3W systems.

2. Neutral current detection and over current (50/51N) on

3P4W systems.

3. A single input differential (87G) protection. Requires

additional, field installed, CTs. Contact factory for details.

Reverse power, 32R, may be set to protect both the generator

and engine by detecting power flow into the generator.

Forward power, 32F, may be set to protect against overload.

Reverse Vars / Field loss, ANSI 40/32RV. Var flow into the

generator means the voltage of the generator is below the

voltage of the system or other generators. Reverse var flow is

also an indication of field loss that could indicate a problem

with the generator’s excitation system.

Over/under voltage, (59 and 27), Over/under frequency, (81O

and 81U) are primarily set to protect the loads, but overvoltage

may also damage the generator.

Negative sequence current (46) and voltage (47) may be used

to detect an open phase on systems using fuses.

Other protective functions are available, see controller

documentation.

ANSI Description

27 Under voltage T/A 90% for 10 sec

59 Over voltage T/A 110% for 10 sec

32R Reverse Power, power

flow into Generator

32RV Reverse Vars, var flow

into Generator,

voltage below system

volts

32F Forward Power, power

out of Generator

46 Negative Sequence

Current or phase loss

detection

47 Negative Sequence

Voltage or phase loss

detection

81U Under Frequency T/A 90% for 10 sec

81O Over Frequency T/A 110% for 10 sec

50 Instantaneous Over

current

51 Time Over current A 125% for 5 sec*

Trip/

Alarm

Factory Test Values

/ Default Settings

T/A 20% for 5 sec

T/A 50% for 2 sec

T/A 120% for 10 sec

T/A 20% for 1 sec

T/A 20% for 1 sec

A 150% for 1 sec*

*These protective functions must be provided by generator

circuit breaker. It is possible to program the controller to trip

on these functions. ASCO CTTSs are rated to interrupt up to 6

times rated frame current, so it is quite possible that the CTTS

could function as the over current trip device for the system

protection. However the current is being sensed at the CTTS

and the system relies upon the generator circuit breaker to

protect the power system between the generator output

terminals and the CTTS input.

Page 14 ASCO Power Technologies 381333-427 A

Page 15

Operator’s Manual ASCO 336 / 337

p

Testing & Service

Transfer Test

Operate the transfer switch at least once a month by following

the Electrical Operation procedure on page 8.

Preventive Maintenance

Reasonable care in preventive maintenance will insure high

reliability and long life for the transfer switch. An annual

preventive maintenance program is recommended.

ASCO Services, Inc. (ASI) is ASCO Power

Technologies’ national service organization.

ASI can be contacted at 1-800-800-2726 for

information on

When ordering replacement parts provide the Serial No., Bill

of Material No. (BOM), and Catalog No. from the transfer

switch nameplate. In the US call 800-800-2726 (ASCO) or

contact customercare@asco.com.

reventive maintenance agreements.

Replacement Parts

Yearly Inspection

DANGER

!

Hazardous voltage capable of causing shock,

burns, or death is used in this transfer switch.

Deenergize both Normal & Emergency power

sources before performing inspections!

Clean the enclosure. Deenergize all sources, then brush

and vacuum away any excessive dust accumulation. Remove

moisture with a clean cloth.

Inspect the transfer switch contacts. Deenergize all

sources, then remove the transfer switch barriers and check the

contact condition. Replace contacts when pitted or worn

excessively. Reinstall the barriers carefully.

Maintain transfer switch lubrication. Under normal

operating conditions no further lubricating is required. Renew

factory lubrication if the transfer switch is subjected to severe

dust, abnormal operating conditions, or if the TS coil is

replaced. Order lubrication kit 920799 for J & H design and

kit 920836 for G design.

Check all cable connections & retighten them.

Torque to values shown on the transfer switch label.

381333-427 A ASCO Power Technologies Page 15

Page 16

ASCO 336 / 337 Operator’s Manual

INDEX

A

ASI is ASCO Services Inc.

800-800-2726(ASCO)

customercare@asco.com

AUTO button, controller, 7

see controller manual

automatic operation, 7, 10

HELP 800-800-2726(ASCO)

customercare@asco.com

inspection, 10

installation, 3

B

buttons, 7, 8, 9, 11

C

cables, power, 3

circuit breaker, 4, 6

close, light, 8

connections, 3, 4

controller, 4, 7, 8, 9, 13

see controller manual

cooldown, generator, 5, 8

current transformers, 14

D

DANGER statements, 1, 3, 7, 10

device, protective functions, 13

lights, 7, 8, 9

load add, 12

load management, 11

load shed, 11

lubrication, 9

maintenance, 15

maintenance handle, 5

WARNING, 5

MAN button, controller, 6

see controller manual

manual transfer, 6

Master Control Switch, 8, 9

mode selection, 8

E

electrical operation, 8

Emergency Stop, button, 9, 11

engine starting contacts, 3

F

frequency, 8

functional test, 5, 6, 7, 8

functions, protective relay, 13

G

generator, 3, 4, 6, 7

generator acceptable light, 6

generator circuit breaker,

4, 5, 7, 8, 10, 13

generator emergency stop, 11

generator running, light, 7, 8

generator V & F acceptable, 7, 8

grounding, 4, 10

Printed in U.S.A. © ASCO Power Technologies, L.P. 2014

negative sequence I & V, 13

neutral or ground current CT, 10

operation, electrical, 5

OIT, operator interface terminal, 9

password, controller, 4, 11

Power Management Selector,

7, 11

power on the load bus, light, 7

preventive maintenance, 15

protective relay functions, 12

H

I

L

M

N

O

P

rating label, 1

regulator, 7, 8

replacement parts, 10

reset load control, 12

runtime management, 12

SEMI button, controller, 9

see controller manual

service, ASI is ASCO Services Inc.

800-800-2726(ASCO)

customercare@asco.com

setpoint, 11

settings, controller, 4

see controller manual

source acceptable lights, 7, 8

start button, controller, 7

see controller manual

start next generator on alarm, 12

starting control, 7

startup, system, 3, 4

stop button, controller, 7

see controller manual

stop, generator emergency, 11

testing, 5, 6, 7, 8

testing & service, 15

Transfer Load & Shut Down

button, OIT, 9

transfer switch, 3, 5, 6, 10

voltage checks, 7

WARNING statements,

1,3, 5, 8, 10

R

S

T

V

W

Page 16 ASCO Power Technologies 381333-427 A

Loading...

Loading...