Emerson Anderson Greenwood 81P, Anderson Greenwood 81P Series Maintenance Instructions Manual

Page 1

ANDERSON GREENWOOD TYPE 81P DSO PRESSURE RELIEF VALVES

MAINTENANCE INSTRUCTIONS

Before installation these instructions must be fully read and understood

TABLE OF CONTENTS

1. General ........................................................... 1

2. Valve repair (-4, -8 orifice) ............................ 1

3. Valve repair (G, J orifice) ............................... 3

4. Valve adjustment ........................................... 4

5. Seat leakage .................................................. 5

1 GENERAL

The Anderson Greenwood Type 81P Direct

Spring Operated (DSO) Relief Valve is a direct

acting spring loaded valve for liquid service and

uses a plastic seat and O-ring seals.

The intent of these instructions is to acquaint

the user with the maintenance of this product.

Please read these instructions carefully. This

product should only be used in accordance

with the applicable operating instructions and

within the application specifications of the

original purchase order. The installation and

Operational Safety Instructions (available at

www.valves.emerson.com) should be fully read

and understood before returning this product to

service after maintenance.

WARNING

An attempt to repair this product by unauthorized

or unqualified persons voids the product warranty

and may cause damage to equipment and serious

injury or death to persons.

The product is a safety related component

intended for use in critical applications.

Theimproper application, installation or

maintenance of the product or the use of parts

or components not manufactured by Anderson

Greenwood may result in a failure of the product.

Any installation, maintenance, adjustment, test,

etc. performed on the product must be done

in accordance with the requirements of all

applicable Anderson Greenwood procedures and

instructions as well as applicable National and

International codes and standards.

2 VALVE REPAIR (-4, -8 ORIFICE)

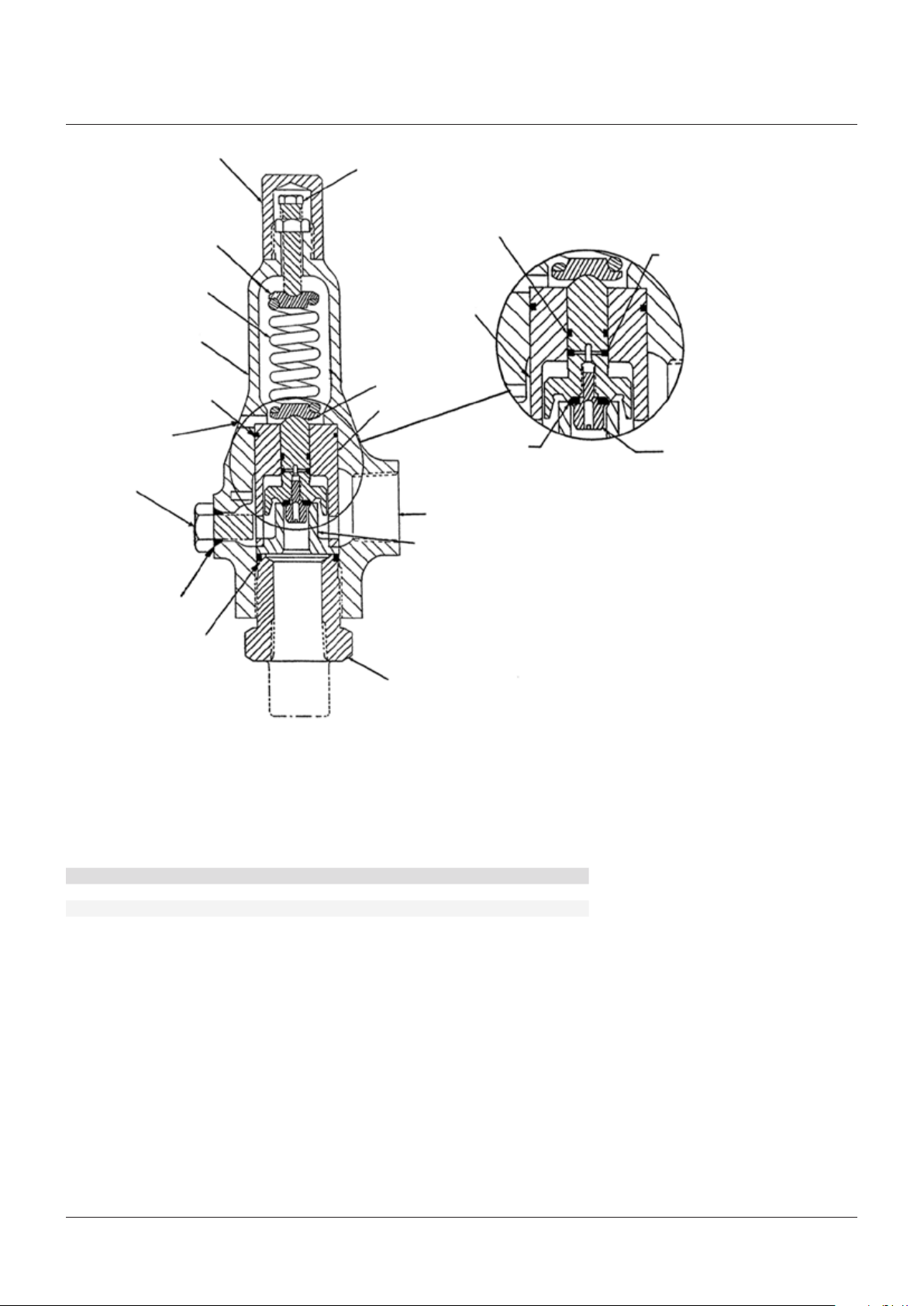

Refer to Figure 1

2.1 Disassembly

2.1.1 Relieve spring tension by turning the

pressure adjusting screw counterclockwise.

2.1.2 Remove inlet bushing, bushing seal and

valve internals.

2.1.3 Separate nozzle from guide by hitting

top of spindle on soft surface. Remove

spindle seals.

2.2 Repair

2.2.1 Hold spindle by skirt O.D. in soft jaw vise

and replace seat.

2.2.2 Examine nozzle and polish out any

scratches or nicks. Replace if necessary.

2.2.3 To obtain better seat seal with PTFE at

low set pressures, burnish seat against

nozzle by chucking spindle in lathe and

holding nozzle against spindle. Burnish

with small force and for short time as

PTFE deforms easily.

2.3 Assembly

Assemble in reverse order of

disassembly. Lubricate the parts listed

below with the specified lubricant. Make

sure the nozzle is fully and squarely

seated in guide.

LUBRICANTS

Part Set pressure Lubricant

Spindle seals 50-1000psig (3.4 - 69.0barg) Dow Corning FS3451

Above 1000psig (69.0barg) Desco 600

Thread and adjusting bolt tip All Dow Corning 33

Emerson.com/FinalControl © 2017 Emerson. All rights reserved.

Engineering Doc. #05.9040.072 Rev. K

VCIOM-01056-EN 16/12

Page 2

ANDERSON GREENWOOD TYPE 81P DSO PRESSURE RELIEF VALVES

MAINTENANCE INSTRUCTIONS

Spring washer

Vent

Plug

Spring

Body

Guide seal

Seal

Cap

Pressure adjustment screw

Spindle seal

Spindle skirt

Spindle

Guide

Outlet

Nozzle

Seat

Drag seal

Seat retainer screw

Seat detail

(-4 illustrated)

Bushing seal

Bushing

FIGURE 1

-4, -8 ORIFICE

2.4 Soft goods repair kit

The part numbers for soft goods repair kits are listed below. Each kit contains the seat and

seals for all pressure ranges and the lubricant specified in paragraph 2.3.

MATERIAL

Orifice NBR FKM EPR

-4 04.4805.029 04.4805.032 04.4805.071

-8 04.4805.029 04.4805.032 04.4805.071

2

Page 3

ANDERSON GREENWOOD TYPE 81P DSO PRESSURE RELIEF VALVES

MAINTENANCE INSTRUCTIONS

Cap

Pressure adjustment screw

Spring washer

Bonnet retainer ring

Outlet

Spring

Vent

Bonnet

flange

Seal

Bonnet

Flange bolt

Spindle

Seal

Nozzle

Body

Drag seal

Guide

Seal

Spindle seal

Seat

Seat retainer screw

Seat detail

Plug

FIGURE 2

G, J ORIFICE

3 VALVE REPAIR (G, J ORIFICE)

Refer to Figure 2

3.1 Disassembly

3.1.1 Relieve spring tension.

3.1.2 Remove spring bonnet and valve internals.

3.1.3 Separate nozzle from guide by hitting top of spindle on soft surface.

3.2 Repair

3.2.1 Hold spindle by skirt O.D. in soft jaw vise and replace seat.

3.2.2 Examine nozzle and polish seating surface as required. Replace if necessary.

3.3 Assembly

Assemble in reverse order of disassembly. Lubricate the parts listed below with the

lubricant specified. Make sure the nozzle is fully and squarely seated in guide.

3

Page 4

ANDERSON GREENWOOD TYPE 81P DSO PRESSURE RELIEF VALVES

MAINTENANCE INSTRUCTIONS

LUBRICANTS

Part Set pressure Orifice Lubricant

Spindle seals 50-300psig (3.4 - 20.7barg) G Dow Corning FS3451

50-100psig (3.4 - 6.9barg) J Dow Corning FS3451

Spindle seals Above 300psig (20.7barg) G Desco 600

Above 100psig (6.9barg) J Desco 600

Thread and adjusting bolt tip All G and J Dow Corning 33

3.4 Soft goods repair kit

The part numbers for soft goods repair kits are listed below. Each kit contains the seat and

seals for all pressure ranges and the lubricant specified in paragraph 3.3.

MATERIAL

Orifice NBR FKM EPR

G 04.4805.030 04.4805.033 04.4805.072

J 04.4805.031 04.4805.034 04.4805.073

4 VALVE ADJUSTMENT

4.1 General

The only adjustment required for the Type 81P valve is the set pressure. The reseat pressure

is not adjustable. Reseat will occur at approximately 75% to 80% of set pressure.

4.2 Proof test

The spindle seals and bonnet seal of the Type 81P valve shall be checked for integrity by

pressurizing the outlet with 30psig (207 kpag) of air. A soap solution shall be applied to the

exterior joints of the bonnet, including across the vent hole. There shall be no evidence of

leakage.

4.3 Set pressure

Type 81P liquid valves marked with the UV code stamp (relief capacity in volume of liquid per

time, GPM) shall be set using water and a 50 gallon pressure vessel.

When setting the valve using water, turn the spring adjustment screw on the bonnet in most

of the way. Increase the pressure to 107% ± 2% of nameplate set and back out screw until

the valve 'pops' or 'gushes' liquid. Set pressure is defined as 93% of that pressure where the

valve 'pops'.

Example liquid English liquid International liquid

Nameplate set = 75psig 5.2barg

'POP' or 'GUSH' = (107% ± 2%) 75 = 78.75 to 81.75psig (107% ± 2%) 5.2 = 5.4 to 5.6barg

Actual 'POP' = 80psig 5.5barg

Actual set = 80 (.93) = 74.4psig 5.5 (.93) = 5.1barg

4

Page 5

ANDERSON GREENWOOD TYPE 81P DSO PRESSURE RELIEF VALVES

MAINTENANCE INSTRUCTIONS

If the Type 81P liquid valve is not marked with the UV code stamp and if a water source is

not available valves with set pressures greater than 750psi (51.7barg) may be set on air

by adjusting the spring to obtain first crack at 95% of set pressure. The valve should not be

popped on air as this may damage the seat. For set pressures below 750psi (51.7barg), the

81P should only be set pressure adjusted using the water method above.

Note: valves with relief capacity in GPM must be set using water if the valve will bear the 'VR'

repair symbol stamp.

Type 81P air valves shall be set using an accumulator large enough to accurately measure

set pressure. Turn the spring adjustment screw on bonnet in most of the way. Increase

pressure to desired level and back out screw until valve pops. Lock screw with jam nut and

retest. Readjust as required.

4.4 Adjustment tolerances

Set pressure range Valve operating characteristics Tolerance or limit

Above 70psig (4.8barg) Set pressure ± 3% of nameplate set

70psig (4.8barg) and below Set pressure ± 2psig

100psig (6.9barg) and above Cracking pressure 92½% of nameplate set

50psig (3.4barg) to 99psig (6.8barg) Cracking pressure 80% of nameplate set

5 SEAT LEAKAGE

5.1 If the valve leaks after repair, check for the following:

5.1.1 Full and even seating of nozzle and guide.

5.1.2 Foreign particles trapped between the seat and nozzle. If any are found they may have

damaged the seat making it necessary to replace it.

5.1.3 Correct seat material for the valve set pressure. If item 1 and 2 reveal no evident seat

leakage source, the procedures described in section 5.2. may be used to eliminate seat

leakage. Section 5.2 applies only to PTFE seated -4 or -8 orifice type 81P with nameplate

set pressures that do not exceed 250 psig (1724 kPag).

5.2 Seat sealing procedures

Heat the valve for 15 to 30 minutes in an oven preheated to 250-265°F (121-129°C). A concentrated

heat source such as a heat gun or open flame must not be used. After the valve has air-cooled to

room temperature, retest per section 4 to ensure seat tightness. If results have not improved, the

valve should be disassembled and the seat replaced.

5

Loading...

Loading...