Page 1

Reliability Solutions

AMS Machinery Manager

Dashboard overview for status at a glance

Analysis tools for diagnosis and prognosis

of machinery health

Real-time asset health integration with

process automation systems

Integration with multiple predictive

maintenance technologies for a complete

picture of mechanical asset health

AMS Machinery Manager provides you with the tools that you

need to determine your plant’s machinery health.

Product Data Sheet

January 2021

A Comprehensive View with Accurate Diagnosis

At some point, mechanical equipment will break down.

With luck, the breakdown won’t occur at the peak of your

production schedule or be caused by an out-of-inventory part.

By knowing the health of your rotating mechanical assets,

you can plan for repairs rather than react to failures.

You can also share the information between maintenance

and operations so that repairs are anticipated and production

schedules are adjusted accordingly. Your facility can achieve

increased availability and performance from production assets,

rather than experience expensive downtime and costly repairs.

AMS Machinery Manager combines predictive maintenance

techniques with comprehensive analysis tools to provide

easy and accurate assessment of the machinery health in

your facility.

Integrated Solution

AMS Machinery Manager can integrate with multiple predictive

diagnostic technologies to monitor different types of

mechanical assets and identify unique failure symptoms.

The modular technology applications incorporate diagnostic

and reporting sources into a common database for analysis

of machinery health across the entire plant.

Through this integration, you gain a comprehensive view of

each monitored machine and more accurate diagnosis of

developing problems. Correlation from multiple technologies

allows you to identify and x the root cause of issues once,

instead of xing the symptoms over and over again.

Integrated Technology Solutions Include:

Portable vibration analysis

Continuous online machinery monitoring

with the AMS 6500 Machinery Health Monitor

Wireless vibration analysis with the

AMS 9420 Wireless Vibration Transmitter

Page 2

Lubrication analysis

Infrared thermography

Laser alignment

AC motor diagnostics

Dynamic balancing

Easy to Understand for Users of All Levels

January 2021AMS Machinery Manager

While maintenance personnel may specialize in different

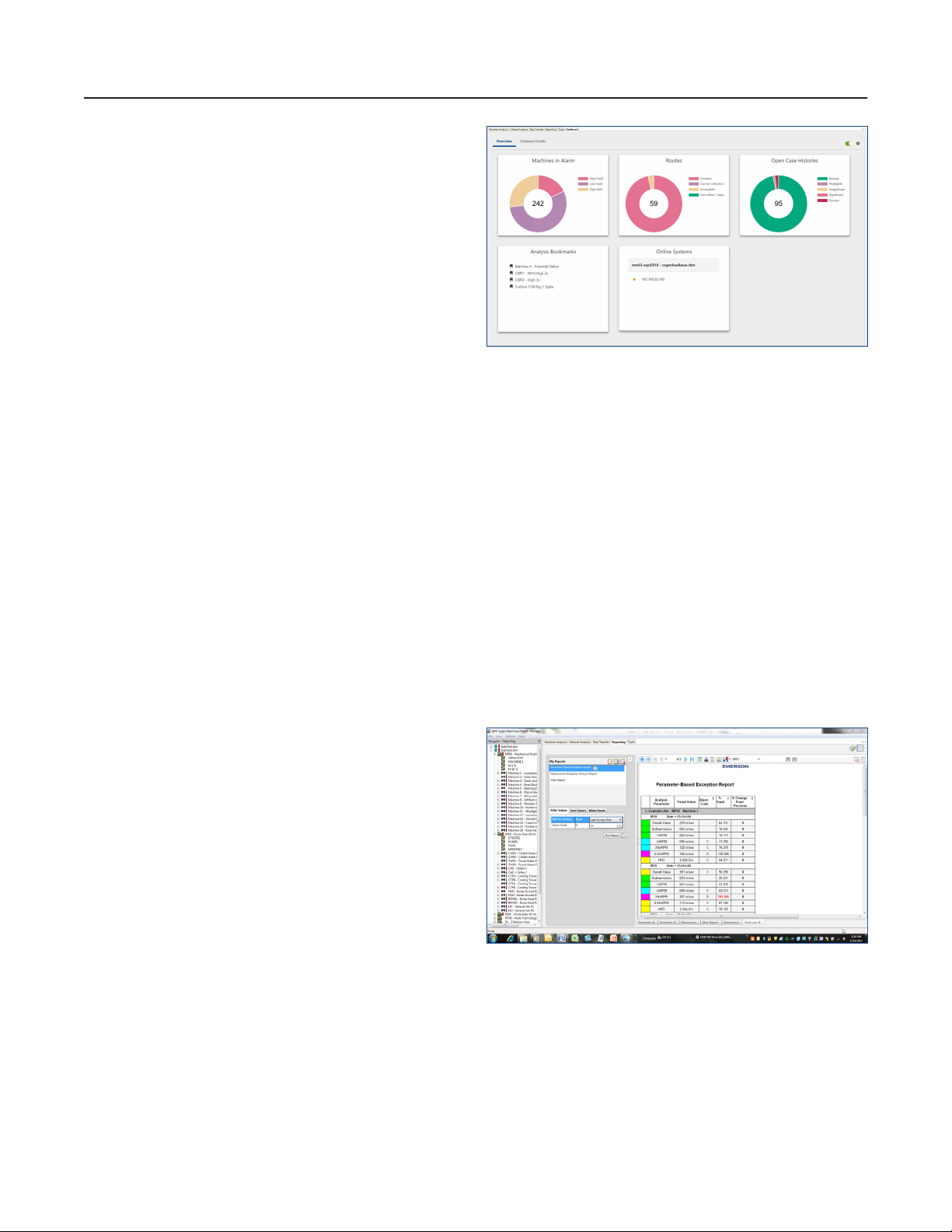

monitoring technologies, the centralized dashboard,

common user interface, and database administration tools

in AMS Machinery Manager modules make the integration

of asset health information easy to understand for all users.

Users have a shorter learning curve with each new technology,

and some technology modules include different levels of

functionality, to give both the beginner and advanced user

the experience and information they need.

Simple to Install

Information Technology personnel appreciate the ease of

installation and the self-contained database tools that allow

a software administrator to handle any issues that may arise,

from granting user access to managing the database.

Report, Track, and Trend in a Central Location

AMS Machinery Manager provides a central location

for all current and historical reporting, shareable across

the organization. Graphical representation from

equipment problem trends, work order status, cost savings,

and management style reporting are easily generated through

an established case history repository.

The dashboard allows you to quickly assess the status of your

machines and reliability program, then launch directly to areas

of importance.

A web-based Machine History Viewer allows diagnostics to be

viewed from any computer with Internet Explorer access to your

intranet or internet. Management and maintenance personnel

can access machinery health status and historical information

to make informed decisions.

Machine History Viewer allows the user to select the elds

to display for fast review of critical asset information.

You can also search on specic items, lter by dates,

and print detailed reports. In addition, the Machine History

Viewer is an array of web parts. Each web part can be

minimized, maximized, moved, closed, and reopened.

This functionality provides added exibility to arrange

the web application in any manner desired.

The case history module is a multi-technology asset information

repository, so it allows you to view case history information

from many different technologies. This allows you to be well

informed on the status of your assets through information

logged by oil analysts, vibration analysts, infra red analysts

and others. The inclusions of asset images, diagnostic plots,

Windows audio and video les, and Microsoft les such as

Word and Excel give you the complete information you need

in order to make the best diagnosis.

Interactive reports allow you to customize what information will be

included and how it will appear.

www.emerson.com/ams 2

Page 3

January 2021AMS Machinery Manager

Machine Train

Interactive Reporting

The Reporting Application allows you to generate interactive

reports from their databases. You can sort, expand and

collapse asset results, and select parameter data in the report

to be viewed in the vibration plot. Print and customize the

reports with company logos and export reports to Word,

Excel and or .pdf for further edits. This Reporting application

allows you to dene exactly what types of parameters to

view within a report as well as to share ‘your setup’ with

other AMS Machinery Manager users.

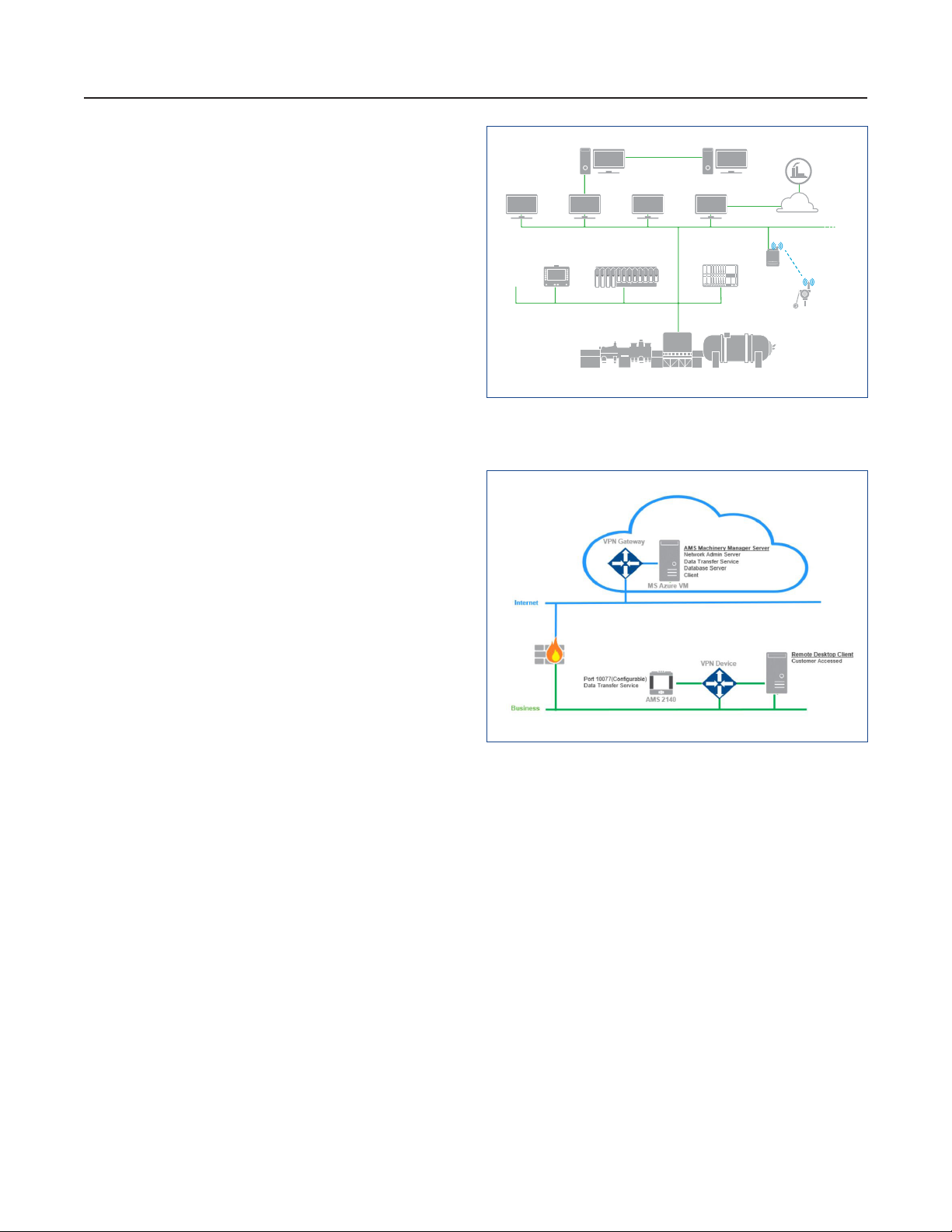

Deployment Options to Fit Any Organization

Whether you are a small organization or a global multi-plant

operation, AMS Machinery Manager’s platform offers a wide

variety of licensing and deployment options to t your needs.

From a standalone system to wide area networking capabilities,

AMS Machinery Manager provides efcient and reliable storage

and analysis of data that can be accessed from anywhere in

your organization.

Single-Users

Single-user, standalone systems operate on a single PC.

If you operate two or more single-user PCs, a keyed version

will allow you to run AMS Machinery Manager based on

the computer with the key. The keyed version is great for

consultants or co-workers.

Other

CSI Technologies

Portable

Vibration Analysis

AMS Asset Portal

AMS Machinery

Manager Server

Process Automation System

CMMS/EAM System

Citrix or

Terminal Server

Online

Machinery Monitoring

Additional Facility

WAN

PVN

Vibration Monitoring

A wide area network allows communication and analysis of

machinery health information around the globe.

Wireless

Local Area Networks (LAN)

Local area networks are perfect for organizations that need

to share their data internally. The network license has read

access capability for up to 249 users. This allows other plant

personnel to access and view the data concurrently. Write seats,

database access, analysis, reporting, and communications are

controlled by the user’s job responsibilities.

Wide Area Network (WAN)

For a global environment, a wide area network license

allows for communication around the world. Data transfer

can be completed by simply uploading a route by ethernet

or intermediate le transfer. In addition, route denition

information can be emailed to personnel and uploaded to an

analyzer at any time without having access to a client or server

software application.

Analysis and other tasks can be performed globally as if

you were at the server site. Read access for up to 249 users

and congurable write access customized to a user’s job

responsibilities are a part of the WAN environment.

Cloud based installations can reduce maintenance costs and

provides an alternative to wide area network installations.

To better enable digital transformation, AMS Machinery

Manager can also be deployed in the Microsoft Azure cloud,

removing the need to install software locally. The supported

architectures in the cloud can support single servers, as well as

client/server architectures including data lockers, and allow for

up to ten concurrent users. Please note, cloud deployment is

supported for AMS 2140 users only.

www.emerson.com/ams 3

Page 4

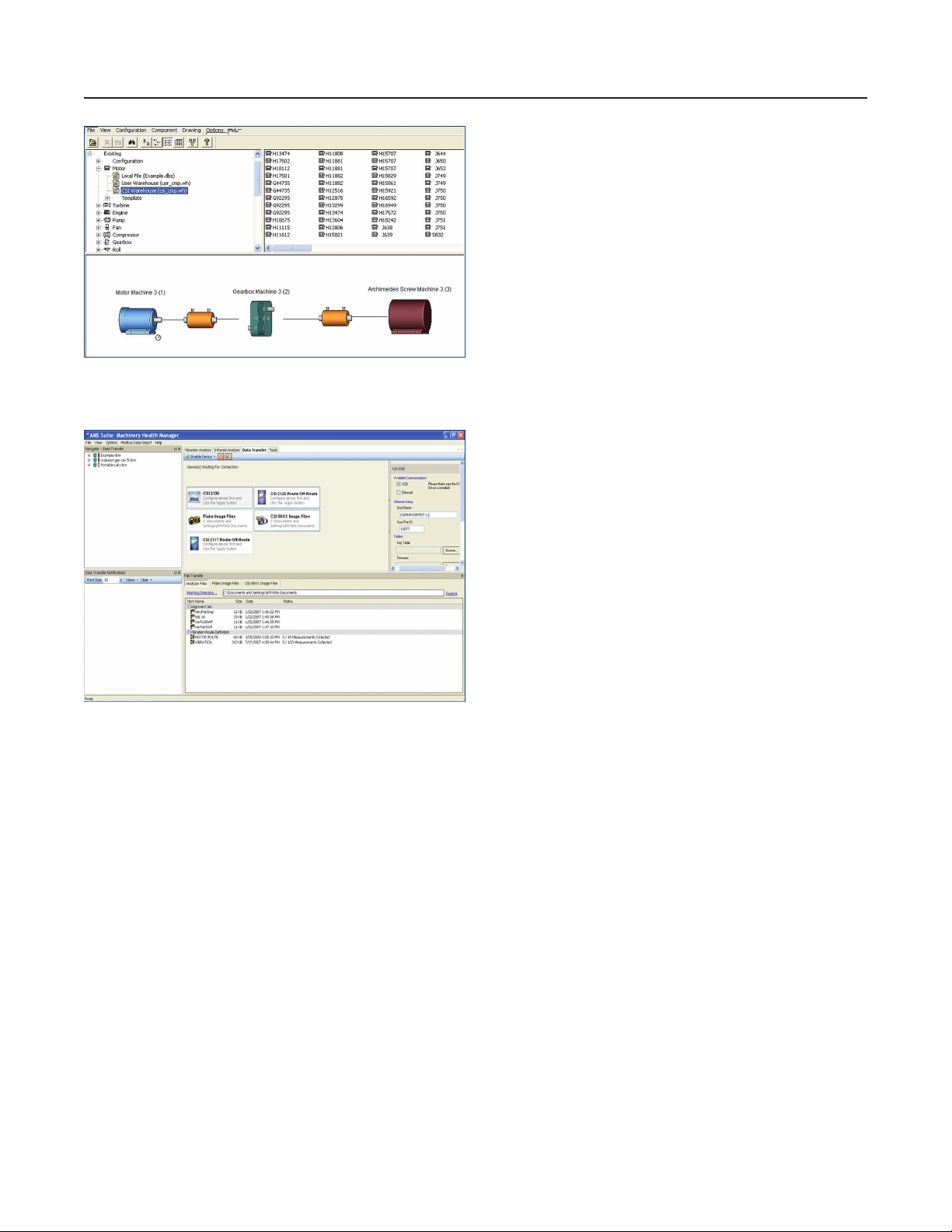

Quickly build a predictive maintenance database through the

step-by-step, graphical, drag-and-drop wizard application.

January 2021AMS Machinery Manager

Within a network environment, you can communicate with

other AMS Machinery Manager users logged into the system

through the Collaboration Tool. See which other users are

currently available online and exchange messages on problem

assets with appropriate personnel. These messages can contain

les and images related to the asset, including vibration plots

and thermographic images. The tool also displays current

conversations between users, allowing others to participate

in the conversation as needed.

Build Databases in Minutes and Access Predictive Diagnostics Immediately

Setting up your database can be one of the most challenging

parts of building a predictive maintenance program.

Gathering and organizing the appropriate asset information

is a daunting task, especially for novice users.

With AMS Machinery Manager, a database wizard eliminates

the guesswork by stepping you through the entire process

with a graphical drag-and-drop interface. You can set up

everything you need – from individual machine components

to machine trains.

Drag-and-drop your route to upload and download your data.

Automatically Setup Alarms, Analysis Parameters,

and Measurement Points

Simply choose assets from an extensive library of motors,

bearings, gearboxes, belts, and other components.

A knowledge engine compiled from years of eld analyst

experience automatically creates multi-technology

measurement points, analysis parameter sets, and alarm

limit settings along with congurations for the automated

diagnostic system.

With a few simple keystrokes, you can build the database,

download route information, analyze data, and report your

machinery health ndings.

www.emerson.com/ams 4

Page 5

January 2021AMS Machinery Manager

Efficient Route Setup

A route is an ordered list of asset data collection points that

can be used to efciently acquire data. Route collection options

allow you to determine the type of data you wish to store,

along with when and how to store the data.

Choose the assets you want to include in the route by simply

right-clicking on the navigator and selecting Create Route.

Then drag-and-drop the routes to the portable analyzer or

folder on your computer. Once you have collected your data,

drag-and-drop the route information back to AMS Machinery

Manager for analysis.

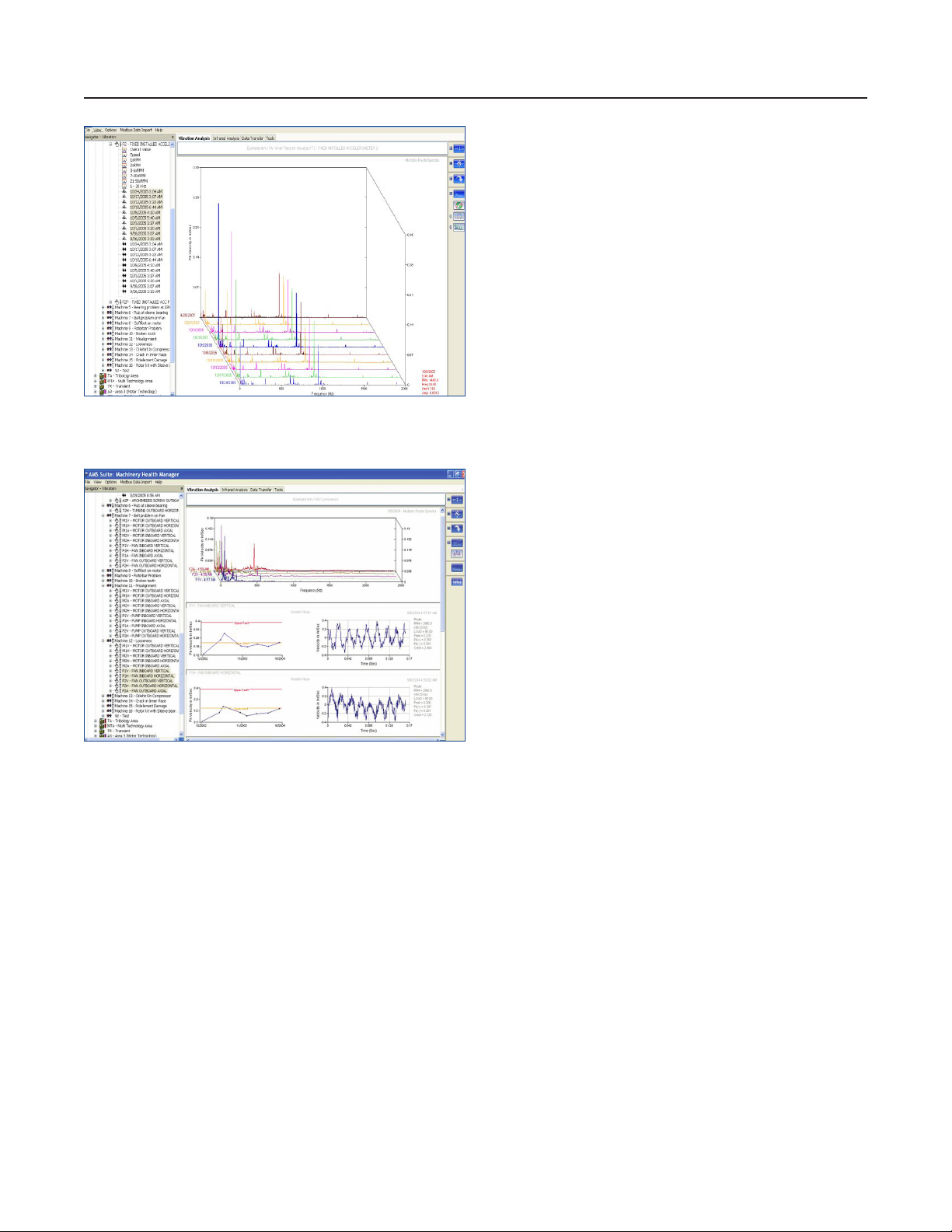

Flexible Analysis Interface

Dynamic display controls allow you to adjust the angle of the

plot display.

View a complete machine at one time and customize your plot view

by selecting what you want to see on the screen. This view shows

spectrum, waveform, and trend plots.

With AMS Machinery Manager, you can view data more

efciently because you don’t need to constantly switch screens.

All plots can be displayed as full screen or several plots can be

combined in a single window. With multiple monitor support,

separate plots can be displayed on up to three monitors.

Common applications of this powerful exibility include:

Looking at three directions: the X, Y, and Z plot in a

single screen

Viewing the complete machine component:

all measurement points on a motor in a single screen

Viewing a complete machine

Viewing similar machines from more than one database

Selecting how many and what types of plots will appear

in your view

Identifying changes in data from month to month

www.emerson.com/ams 5

Page 6

January 2021AMS Machinery Manager

Quickly Determine Machine Status

Use the AMS Machinery Manager Parameter Status Prole

to quickly view parameter alarm status of a machine with

a simple, congurable color selection (like green, yellow,

and red). This capability helps you to determine where

additional attention is needed.

Quickly determine the status of a machine with the Parameter

Status Prole.

Fine Tune Alarms

During your analysis or after you have had time to acquire

several months of data, you may need to adjust your original

alarm setups. The Automated Statistical Limit Calculation

module can take data from vibration patterns and construct

narrowband alarms. Envelope alarms can also be manually

dened and created from a reference spectrum.

Waveform Audio Replay

Replay the audio from a periodic or online waveform,

a transient detailed waveform, or an analyze job waveform.

A loop button is available to continuously repeat shorter

waveforms. You can also compare the audio from two

waveforms. For example, a waveform collected from a problem

machine will often sound different than a waveform from a

similar machine without a fault present. The audio output

can be saved as a .wav le and attached to reports for sharing.

Navigational Ease

Navigational functionality allows you to maneuver between

different plot types like single spectrum, multiple-point

wavefoms, and trends. Navigation between data, measurement

points, machines, areas, and multiple databases is easy with the

navigational tree.

Prescreen to narrow the search by selecting only points in

alarm, survey dates, or notes that have been assigned to a

machine or data point.

Automated Diagnostics Narrow the Search

When you are unsure or need a second opinion on your

analysis, the Automated Diagnostic module can conrm

your diagnosis or point you to other underlying faults. The

Automated Diagnostic program will help you understand how

it reached its conclusion and can also be used as a training tool.

The module steps you through reasoning, rules, and facts as

it analyzes the collected data to increase your knowledge and

diagnostic skills.

Compare the audio from two different waveforms with the

Waveform Audio Replay option.

www.emerson.com/ams 6

Page 7

Viewing a waterfall plot in color allows you to see the difference in

the amplitudes more readily.

January 2021AMS Machinery Manager

Advanced Analytical Tools

AMS Machinery Manager offers extensive analysis tools to

enable accurate diagnosis of machine health.

Analysis tools are available for specic challenges,

such as slow or variable speed equipment, rolls, waveform

analysis, early bearing or gear impacting, electrical defects,

and more. Advanced tools include:

Colored waterfall plots

Waveform autocorrelation

Waveform Audio Replay

Circular waveform plot

Orbits/ltered orbits

Bode nyquist

Full Spectrum & Cascade Full Spectrum (online data)

3D Shaft Centerline Animation Plot (online data)

With Cascade Full Spectrum, the user can quickly differentiate

between a rub and an oil swirl anomaly.

Transient replay that replays a AMS 2140 transient signal,

including the startup of your critical machinery

Transient waveform runout correction

Customizable narrow band trends

Dynamic display control to customize the view of 3D plots

www.emerson.com/ams 7

Page 8

January 2021AMS Machinery Manager

The Perfect Vibration Analysis Package for Your Organization

AMS Machinery Manager provides a wide breadth of vibration

capabilities – from entry level packages with basic vibration

analysis tools to more advanced capabilities like dual-channel

and transient analysis.

Advanced Vibration Analysis Module

The Advanced Vibration Analysis module provides in-depth

analysis options for transient and cross-channel data

collected with a AMS 2140 Machinery Health Analyzer,

including cross-channel phase, coherence, and transfer

functions. You can post process transient data to show the

vibration frequency characteristics during machine coastdown

or startup.

Export data directly from AMS Machinery Manager to a

companion software module for Operating Deection Shape

(ODS) and Modal analysis.

Create a machine model and animate vibration readings

to generate powerful documentation on machinery faults.

Perform in-depth structural analysis with the Modal Analysis

module and test virtual design modications to eliminate the

root cause of reliability issues.

Continuous Online Machinery Monitoring

The same powerful predictive analysis tools available for

the portable vibration analysis module are available online

monitoring systems, including plotting, trending, transient,

spectral analysis, PeakVue™ technology, autocorrelation,

and statistical analysis.

Predictive monitoring and analysis features include:

Web-based current and historical data

Web-based asset prioritization and maintenance planning

Web-based performance monitoring

Customized graphical user interface

Integration to 3rd party control systems via Modbus protocol

Shaft animation plots for transient archives

Full spectrum and cascade full spectrum

www.emerson.com/ams 8

Page 9

January 2021AMS Machinery Manager

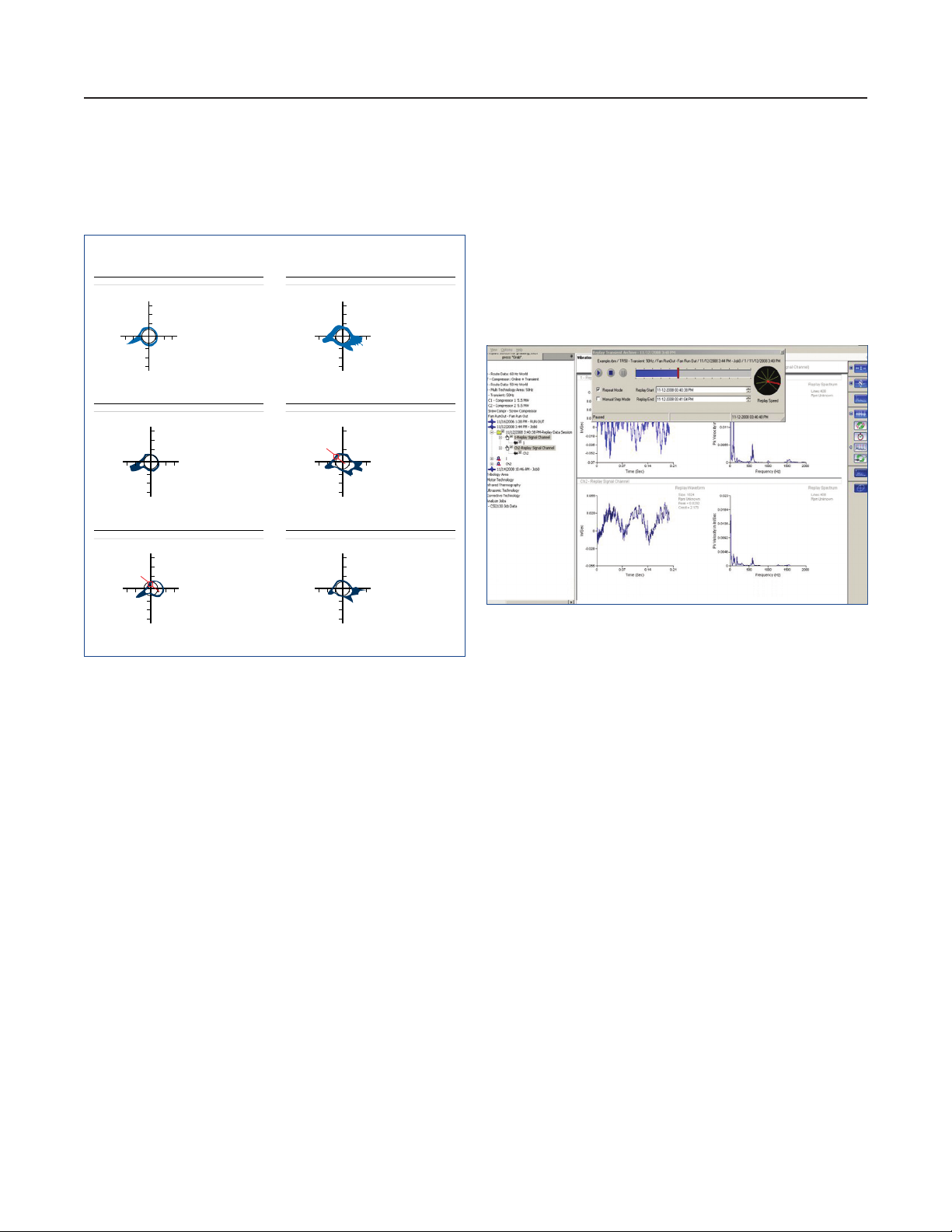

Easy Reciprocating Compressor Monitoring

AMS Machinery Manager displays PeakVue waveforms on a

circular polar plot for easy identication of leaking exhaust

valves on reciprocating compressors.

Properly operating valve Leaking exhaust valve

Peakvue

0°

105

270° 90°

0

180°

Peakvue 10K

0°

76

270° 90°

0

180°

Peakvue 20K

0°

45

270° 90°

0

180°

Units=G’s

Exceptional

Peakvue

HP 5k Hz

RPM = 999.60

(16.66 Hz)

LOAD = 0.00

RMS = 9.591

Pk (+) = 100.84

Crest = 10.51

Units=G’s

Routine

Peakvue

HP 10k Hz

RPM = 999.40

(16.66 Hz)

LOAD = 0.00

RMS = 12.49

Pk (+) = 75.33

Crest = 6.032

Units=G’s

Routine

Peakvue

HP 20k Hz

RPM = 998.93

(16.65 Hz)

Rev:4.845

Time:0.291

Amp:1.610

Peakvue

0°

38

270° 90°

0

180°

Peakvue 10K

0°

44

270° 90°

0

180°

Peakvue 20K

0°

29

270° 90°

0

180°

Units=G’s

Routine

Peakvue

HP 5k Hz

RPM = 998.92

(16.65 Hz)

LOAD = 0.00

RMS = 7.655

Pk (+) = 37.20

Crest = 4.880

Units=G’s

Routine

Peakvue

HP 10k Hz

RPM = 999.51

(16.66 Hz)

Rev:4.848

Time:0.291

Amp:5.211

Units=G’s

Routine

Peakvue

HP 20k Hz

RPM = 999.48

(16.66 Hz)

Waveform data incorporated onto circular polar plots delivers

insight to developing valve faults.

Transient Live Display Mode

The live mode in AMS Machinery Manager provides real-time

data plots, including overall levels, orbits, shaft centerline,

Bode/Nyquist, cascade, waveform, and spectrum.

Overlay baseline plots (from portable or online systems)

on good startup plots to view differences.

With the transient live mode, you can make real-time decisions

with operators and production staff to bring a turbine up for

critical production needs or to shut down to protect the asset.

Transient data collection allows for continuous data recording

simultaneously on all channels. You can replay the stored data

for detailed analysis at any moment within the collection cycle.

www.emerson.com/ams 9

Page 10

Live 3D shaft animation plots show the actual motion of the shaft

around the average shaft position.

Shaft Animation Plots

The shaft animation plot shows the actual motion of the shaft

around the average shaft position. Click on displayed sensors

to bring up detailed spectrum, waveform, waterfall or bode/

Nyquist plots, while clicking on a bearing brings up orbit and

shaft centerline plots. Orbit and waveform plots have animated

cursors that update as the shaft rotates. You control the setup

information for the animation, including graphics quality,

play speed, and resting voltage and bearing clearance data

crucial for accuracy in the animation. The View Control buttons

provide four default views (front, side, top, and a combination

of the three). Or you can also rotate or pan across the view by

holding down either the left or right mouse button over the plot

and dragging. Rotating the mouse wheel changes the zoom.

January 2021AMS Machinery Manager

Wireless and Wired Transmitters

AMS Machinery Manager supports the import of advanced

diagnostic data, including spectra and waveforms from the

AMS 9420 Wireless Vibration Transmitter. This data along with

other types of process variables are imported via the Smart

Wireless Gateway. In addition, process data from any IEC

-approved WirelessHART®-enabled transmitter can be imported

into AMS Machinery Manager through the Smart Wireless

Gateway. Correlating both vibration and process data allows

for a more comprehensive analysis of developing problems.

With data import, you can view process automation information

or diagnostics from WirelessHART devices.

Conguration and user interface options in AMS Machinery

Manager optimize bandwidth usage, battery life, and time

spent interacting with transmitters:

Spectrum-on-Alert automatically retrieves only the data

you need, when you need it

Select spectrum resolution - from 400 to 1,600 lines -

to conserve power and bandwidth

Use efciency tools for easy mapping and conguration

of transmitters

Auto-calculate capabilities optimize network trafc

Use the device log to identify and resolve system issue

quickly by providing insight into transmitter operations

www.emerson.com/ams 10

Page 11

Vibration Analysis Packaging

Module/Package

Database Management

January 2021AMS Machinery Manager

A472008 A472001 A472002 A472003 A474505

Vib View

Transmitter

4 4 4 4 4

Vib View

Silver

Vib View

Gold

Vib View

Platinum

Vib View

Online

OilView Trivector Lab

ODBC Driver

Trend Plotting

Fault Frequencies

Advanced Plotting and Analysis Tools

Wizard Database Setup

CMMS Interface Tools

Advanced Reporting

Machine History Viewer

Asset History Management

Basic Statistical Alarm Management

Multi Window Plotting and Analysis

Dual-Monitor Support

Management Reporting

Multi Speed-Multi Plane Balance Calculator

Manual Data Entry

Route Management

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4

4 4 4 4

4 4 4

Advanced Statistical Alarm Management

Rule-Based Automated Diagnostics

Additional Management Reporting

Dual-Channel and Transient Analysis Support

Advanced Cross-Channel Analysis, ODS/Modal Support

Online Database Conguration

Dashboard View of Monitored Equipment

4 4

4 4

4

4

4

4

4

www.emerson.com/ams 11

Page 12

January 2021AMS Machinery Manager

Oil Analysis

The AMS Machinery Manager Oil Analysis module turns oil

data into maintenance information. Applications for onsite oil

analysis, offsite laboratory data, and wear debris analysis can

be used individually or together to turn oil analysis data into a

predictive maintenance tool.

The Oil Analysis module performs automated analysis,

plotting and trending, data storage, and reporting,

and has a tutorial to get you running quickly.

The Trivector Plot condenses rows of data into one intuitive

plot with three vectors: chemistry, contamination, and wear.

Alarm levels on each vector are customized to the type of

machine and the operating environment.

The Minilab application supports both the AMS 5200 Machinery

Health Oil Analyzer and the Spectro 5200 oil analysis minilab.

Oil Analysis Packaging

It includes easy-to-understand graphical plots and trends for

each measurement, automated diagnostic interpretations and

recommendations, and step-by-step operational instructions for

each instrument.

The Lab Information Management System (LIMS) is a

comprehensive oil analysis management application that

imports data from most oil labs as well as oil analyzers and

minilabs from Spectro Incorporated. In addition to importing

data, LIMS also exports oil route information to Spectro

Scientic’s Q1100, Q230, and Q3050 mini-lab instrumentation.

The LIMS applications offers automatic reporting and

distribution, detailed sample tracking, and a custom

address book. Use of the LIMS package results in an efcient,

versatile oil analysis operation.

The Wear Debris Analysis application allows you to analyze

and compare images, store data, and report your ndings

on particulate material in the oil.

A475100 A475101 A475103

Module/Package Minilab LIMS Wear Debris Analysis

Advanced Plotting and Analysis Tools

Wizard Database Setup

Import Lab and Diagnosis

Step-by-Step Operational Instructions

Calibration, Operation, and Data Storage for each

Minilab Instrument

Automated Interpretation and Recommendations

Trivector Plot of Wear, Contamination,

and Chemistry

Database of Common Lubricants

Alarm Management

Create and Manage Batches

Sample Scheduling with Tools

Export Data and Reports

Print oil route point labels

Export oil route to Q1100, Q230, and Q3050

Import oil data from most Spectro Inc. analyzers

4 4 4

4 4 4

4 4 4

4

4

4

4

4

4 4

4

4

4

4

4

4

View and Analyze Wear Debris

WDA Image Library

4

4

www.emerson.com/ams 12

Page 13

January 2021AMS Machinery Manager

Infrared Thermography

A successful and efcient infrared thermography inspection

program is more than just an infrared camera. With AMS

Machinery Manager, you can execute a well-planned program

that mirrors the structure of your vibration analysis program –

from setup to reporting.

The Infrared Analysis module features a Diagnostic Fault

Tree that contains a log of equipment types, fault types,

and recommended actions.

Rather than simply annotating IR images, you can create a

detailed fault analysis of the image. The Fault Diagnostic Tree

reduces the time needed to analyze and report on images

and provides consistent analysis of anomalies, even between

different thermographers.

Tools for both analysis and reporting are available on a single

screen, allowing you to go directly from an IR image to detailed

analysis to a machinery health report quickly.

The Infrared Analysis module provides a complete set

of postscan analysis tools, allowing you to:

Indicate specic location temperatures with spot

meter placement

Draw lines across an image and produce a temperature prole

plot that indicates the temperature change along

the line

Place shapes on the image to produce a temperature

histogram plot

Identify locations of a specic temperature on an image

Users can view and analyze FLIR® visual and thermal images

using AMS Machinery Manager. The Infrared Analysis Module

supports FLIR Thermal Images for all current FLIR cameras.

The module also supports FLIRspecic palette types of Rainbow

and Rainbow High contrast and FLIR polyline annotation types.

AMS Machinery Manager also supports Fluke® infrared camera

images. With this functionality, you can view and fully analyze

Fluke visual and thermal images. IR reporting formats provide

selectable items for inclusion within the reports.

Because the database seamlessly integrates IR analysis with

other machinery health technologies, reports generated from

AMS Machinery Manager are powerful cross-technology tools

for verifying the fault and severity of machinery problems.

Infrared Packaging

A479400

Module/Package Infrared Thermography Silver

Database Management

Import/Export of IR data

Import IR Off-Route Image Files

Infrared Event Management

Information Framework

Set Environmental and Electrical Parameters

Detection of High-Resistance Joints

Thermal Prole Plot, Histogram, Isotherms, and Temperature Table

Over Ten Available Temperature Pallettes

Associate Temperature with Isotherms

Data Transfer

4

4

4

4

4

4

4

4

4

4

4

www.emerson.com/ams 13

Page 14

January 2021AMS Machinery Manager

Motor Diagnostics

AMS Machinery Manager provides analysis and diagnostic

tools for electric motor condition monitoring using Emerson’s

nonintrusive Flux Coil and Current Clamp. The Motor Diagnostic

module in AMS Machinery Manager detects motor-related

electrical faults, such as broken rotor bars, high-resistance

joints, voids in aluminum cast rotors, and cracked rotor end

rings in squirrel-cage induction motors.

The gold version of the Motor Diagnostics module can be

used to detect additional electrical problems, such as voltage

imbalance and faults in rotors and stators.

The Motor Diagnostics module features expert diagnostic

systems with patented technology to perform automated

analysis of collected ux, temperature, and shaft voltage/

current data. After diagnosis, AMS Machinery Manager provides

recommendations for appropriate follow-up actions – taking

the guesswork out of your analysis.

Laser Alignment and Dynamic Balancing

AMS Machinery Manager includes software modules for

laser alignment and dynamic balancing corrective actions.

The software archives job documentation generated by

AMS-brand alignment and balancing tools.

Results are automatically compared to original condition

tolerance specication for display and reporting. Once the job

is complete, data can be stored in AMS Machinery Manager for

reporting and future use. If it is necessary to revisit the same

machine at a later time, data can be downloaded to provide

an opportunity for a one-shot rebalance.

Laser alignment and precision balancing jobs can be stored and

reported in AMS Machinery Manager.

MotorView Packaging

A473001 A473002

Module/Package MotorView Silver MotorView Gold

Database Management

Analyzer Data Transfer

Route Management

Trend Plotting

Fault Frequencies

Motor Diagnostic Plotting and Analysis Tools

Detection of Rotor Related Faults

Detection of Broken Rotor Bars

Detection of High-Resistance Joints

Detection of Voids in Aluminum Cast Rotors & Cracked Rotor End Rings

in Squirrel-Cage Induction Motors

Detect Rotor and Voltage Imbalance

Flux Motor Analysis

Motor Surface Temperature Trending

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4

4

Detect Electrical Problems in Rotors, Stators, and Voltage

4

www.emerson.com/ams 14

Page 15

January 2021AMS Machinery Manager

Continuing Support to Ensure Success

Training Courses Build Expertise

Emerson Educational Services help maximize the return on

your technology and personnel investment. Courses are taught

by professionals with experience in developing or working

within actual plant predictive or reliability-based maintenance

programs. Training is offered in Emerson’s state-of-the-art

training facilities or onsite, giving you expert training

without leaving your facility. Emerson also offers virtual

classroom training.

Certied instructors deliver the curriculum using Adobe

Connect Meeting Room with full audio and video support.

Students can pose question directly to the instructor or share

them with the classroom.

Technical Support You Can Count On

Your company makes signicant investments in technology

to safeguard its production assets. Emerson is committed to

providing quality technical support for your machinery analysis

tools. Our Technical Support Agreements for hardware and

software products do more than keep your technologies

running smoothly. They provide the latest functionality

for your existing technologies and protect your investment

through priority access to support and repair services.

AMS Machinery Manager Cloud Hosted Solution

Emerson has partnered with Microsoft to offer AMS Machinery

Manager Cloud Hosted Solution in the Azure platform.

This eliminates the need for customers to deploy and maintain

on-premise installations of the software along with costly

infrastructure investment. Available functionality includes

route vibration data upload and download, use of data lockers,

and the full breadth of vibration analysis and reporting tools

traditionally supported for the AMS 2140 in AMS Machinery

Manager.

Having your system on the cloud means that authorized

staff can securely access information and data anytime

and anywhere. This translates into enhanced mobility,

exibility and collaboration within your teams, with your

corporate analyst pool, or even with Emerson experts.

Asset Condition Monitoring Services

Emerson’s team of machinery monitoring experts can

supplement plant programs with Asset Condition Monitoring

Services. Specialists are available to monitor and analyze data

from Emerson’s route-based vibration analyzers, wireless

vibration devices, and online systems. They follow up with

easy-to-read, actionable periodic reports for your maintenance

department.

Contact Us

www.emerson.com/contactus

©2021, Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. The AMS logo is

a mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while

diligent efforts were made to ensure their accuracy, they are not to be construed as warranties

or guarantees, express or implied, regarding the products or services described herein or their

use or applicability. All sales are governed by our terms and conditions, which are available on

request. We reserve the right to modify or improve the designs or specifications of our products

at any time without notice.

Loading...

Loading...