Page 1

Information furnished by EMERSON Motion Control is believed to be accurate and

reliable. However, no responsibility is assumed by EMERSON Motion Control for its use.

EMERSON Motion Control reserves the right to change the design or operation of the

equipment described herein and any associated motion products without notice.

EMERSON Motion Control also assumes no responsibility for any errors that may appear

in this document. Information in this document is subject to change without notice.

P/N 400514-01

Rev.: A2

Date: October 22, 1999

© 1999 EMERSON Motion Control. All rights reserved.

ALP-130 and ALP-430

Auxiliary Logic Power Supply

Installation Manual

Page 2

ii

© 1999 EMERSON Motion Control. All rights reserved.

Part Number: 400514-01

Revision: A2

Date: October 1999

Printed in United States of America

Information in this document is subject to change without notice.

Companies, names, and data used in examples herein are fictitious

unless otherwise noted. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical, for

any purpose, without the express written permission of EMERSON

Motion Control.

The following are trademarks of EMERSON Motion Control and may

not be reproduced in any fashion without written approval of

EMERSON Motion Control.

Microsoft, Excel and Windows are registered trademarks of Microsoft Corporation.

IBM is a registered trademark of International Business Machines, Inc.

Modbus is a trademark of Modicon, Inc.

Data Highway Plus is a trademark of Allen-Bradley

Schaffner is a trademark of Schaffner

Commercial names of products from other manufacturers or developers

that appear in this manual are registered or unregistered trademarks

of those respective manufacturers or developers, which have expressed

neither approval nor disapproval of EMERSON Motion Control.

This document has been prepared to conform to the current released version of the

hardware and software system. Because of our extensive development efforts and our

desire to further improve and enhance the product, inconsistencies may exist between the

product and documentation in some instances. Call your customer support representative if

you encounter an inconsistency.

Page 3

iii

Customer Service

EMERSON Motion Control

12005 Technology Drive

Eden Prairie, Minnesota 55344-3620

U.S.A.

Telephone: (612) 995-8000 or (800) 397-3786

It is EMERSON Motion Control’s goal to ensure your greatest

possible satisfaction with the operation of our products. We are

dedicated to providing fast, friendly, and accurate assistance.

That is why we offer you so many ways to get the support you

need. Whether it’s by phone, fax or modem, you can access

EMERSON Motion Control support information 24 hours a

day, seven days a week. Our wide range of services include:

FAX (612) 995-8011

You can FAX questions and comments to EMERSON Motion

Control. Just send a FAX to the number listed above.

Website and Email www.emersonmotioncontrol.com

Website: www.emersonmotioncontrol.com

Email: info@emersonmotioncontrol.com

If you have Internet capabilities, you also have access to

technical support using our website. The website includes

technical notes, frequently asked questions, release notes and

other technical documentation. This direct technical support

connection lets you request assistance and exchange software

files electronically.

Page 4

iv

ALP-130 and ALP-430 Auxiliary Logic Power Supply Installation Manual

Technical Service (612) 995-8033

Email: service@emersonmotioncontrol.com

EMERSON Motion Control’s products are backed by a team of

professionals who will service your installation wherever it

may be. Our technical service center in Minneapolis,

Minnesota is ready to help you solve those occasional problems

over the telephone. Our technical service center is available 24

hours a day for emergency service to help speed any problem

solving. Also, all hardware replacement parts, should they ever

be needed, are available through our service organization.

When you call, please be at your computer, have your

documentation in hand, and be prepared to provide the

following information:

• Product version number, found by choosing About from the

Help menu.

• The type of controller or product you are using.

• Exact wording of any messages that appear on your screen.

• What you were doing when the problem occurred.

• How you tried to solve the problem.

Need on-site help? EMERSON Motion Control provides

service, in most cases, the next day. Just call EMERSON’s

technical service center when on-site service or maintenance is

required.

Training Services (612) 995-8000

Email: training@emersonmotioncontrol.com

EMERSON Motion Control maintains a highly trained staff of

instructors to familiarize customers with EMERSON Motion

Page 5

v

Control’s products and their applications. A number of courses

are offered, many of which can be taught in your plant upon

request.

Application Engineering (612) 995-8003

Email: applengr@emersonmotioncontrol.com

An experienced staff of factory application engineers provides

complete customer support for tough or complex applications.

Our engineers offer you a broad base of experience and

knowledge of electronic motion control applications.

Customer Service (Sales) (612) 995-8000

Email: sales@emersonmotioncontrol.com

Authorized EMERSON Motion Control distributors may place

orders directly with our Order Processing Department by

calling the number listed above. For information on your local

distributor, call EMERSON Motion Control.

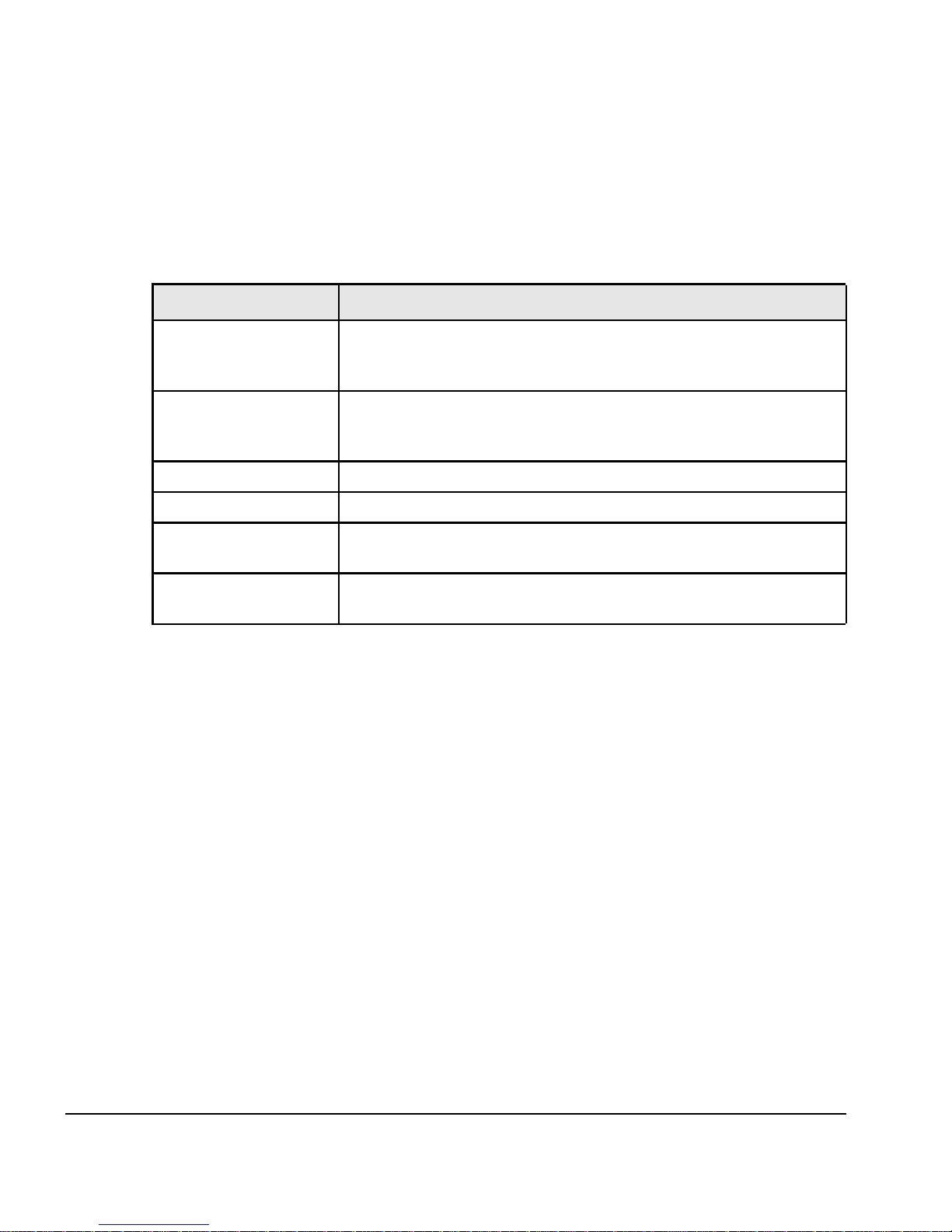

Document Conventions

Manual conventions have been established to help you learn to

use this manual quickly and easily. As much as possible, these

conventions correspond to those found in other Microsoft

Windows documentation.

Menu names and options are printed in bold type: the File

menu.

Dialog box names begin with uppercase letters: the Axis Limits

dialog box.

Dialog box field names are in quotes: “Field Name”.

Page 6

vi

ALP-130 and ALP-430 Auxiliary Logic Power Supply Installation Manual

Button names are in italic: OK button.

Source code is printed in Courier font: Case ERMS.

In addition, you will find the following typographic conventions

throughout this manual.

Safety Instructions

General Warning

Failure to follow safe installation guidelines can cause death or

serious injury. The voltages used in the product can cause

severe electric shock and/or burns, and could be

lethal.Extreme care is necessary at all times when working

with or adjacent to it. The installation must comply with all

relevant safety legislation in the country of use.

Qualified Person

For the purpose of this manual and product, a “qualified

person” is one who is familiar with the installation,

construction and operation of the equipment and the hazards

This Represents

bold

Characters that you must type exactly as they appear. For

example, if you are directed to type a:setup, you should type

all the bold characters exactly as they are printed.

italic

Place holders for information you must provide. For example, if

you are directed to type filename, you should type the actual

name for a file instead of the word shown in italic type.

ALL CAPITALS Directory names, file names, key names, and acronyms.

SMALL CAPS Non-printable ASCII control characters.

KEY1+KEY2

example: (Alt+F)

A plus sign (+) between key names means to press and hold

down the first key while you press the second key.

KEY1,KEY2

example: (Alt,F)

A comma (,) between key names means to press and release the

keys one after the other.

Page 7

vii

involved. In addition, this individual has the following

qualifications:

• Is trained and authorized to energize, de-energize, clear,

ground and tag circuits and equipment in accordance with

established safety practices.

• Is trained in the proper care and use of protective

equipment in accordance with established safety practices.

• Is trained in rendering first aid.

Warning

For the purpose of this manual and product, “Warning”

indicates death, severe personal injury or substantial

damage CAN result if proper precautions are not taken.

Caution

For the purpose of this manual and product, “Caution”

indicates minor personal injury or property damage CAN

result if proper precautions are not taken.

Note

For the purpose of this manual and product, “Note”

indicates information about the product or the respective

part of the manual which is essential to highlight.

Epsilon Only

For the purpose of this manual and product, the “Epsilon”

symbol indicates information about the Epsilon drive

specifically.

Page 8

viii

ALP-130 and ALP-430 Auxiliary Logic Power Supply Installation Manual

E Series Only

E

N

For the purpose of this manual and product, the “EN”

symbol indicates information about the E Series drive

specifically.

Throughout this manual, the word "drive" refers to an Epsilon

or E Series drive.

Page 9

ix

Underwriters Laboratories Listed

The ALP-130/-430 are marked with the “UL Listed” label after

passing a rigorous set of design and testing criteria developed

by UL (UL508C). This label indicates that the UL certifies this

product to be safe when installed according to the installation

guidelines and used within the product specifications.

The “conditions of acceptability” required by UL are:

• The ALP-130 ambient temperature must be 40° C (104° F)

or less.

• The ALP-430 ambient temperature must be 50° C (122° F)

or less.

CE Declaration of Conformity

The ALP-130/-430 (Auxiliary Logic Supply) is marked with the

“Conformite Europeenne Mark” (CE mark) after passing a

rigorous set of design and testing criteria. This label indicates

that this product meets safety standards when installed

according to the installation guidelines and used within the

product specifications.

LISTED 80XM

IND. CONT. EQ.

A

L

P

-

1

3

0

a

n

d

A

L

P

-

4

3

0

Page 10

x

ALP-130 and ALP-430 Installation Manual

Declaration of Conformity

Manufacturer’s Name:

EMERSON Motion Control

Manufacturer’s Address:

1365 Park Road

Chanhassen, MN 55317

USA

Declares that the following products:

Products Description:

Drive Accessories

Model Number:

RSR-2 and ALP-430

Conforms to the following product specification:

The products herewith comply with the requirements of the Low Voltage Directive (LVD) 73/23/EEC. These products are considered

components and as such, the EMC Directive (89/336/EEC) does not apply.

Supplementary information:

This electronic drive product is intended to be used with an appropriate motor, electrical protection components and other equipment to

form a complete end product or system. It must only be installed by a professional assembler who is familiar with requirements for safety

and electromagnetic compatibility (“EMC”). The assembler is responsible for ensuring that the end product or system complies with all the

relevant laws in the country where it is to be used. Refer to the product manual for installation guidelines.

August 18, 1999

Bradley Schwartz/ VP Engineering Date

European Contact:

Sobetra Automation

Langeveldpark Lot 10

P. Dasterleusstraat 2

1600 St. Pieters Leeuw, Belgium

Page 11

xi

Declaration of Conformity

Manufacturer’s Name:

EMERSON Motion Control

Manufacturer’s Address:

1365 Park Road

Chanhassen, MN 55317

USA

Declares that the following products:

Products Description:

E Series Digital Servo Drive

Model Number:

EN-204, EN-208 and EN-214

System Options:

This declaration covers the above products with the ALP-130 Backup Logic Power Supply and ECI-44

Screw Terminal Interface.

Conforms to the following product specification:

Electomagnetic Compatibility (EMC):

EN 55011/1991 Class A Group 1, CISPR 11/1990 Class A Group 1

EN 50082-2/1995: IEC 1000-4-2/1995; EN 61000-4-2, 4kV CD

IEC 1000-4-3/1995; EN 61000-4-3, ENV 50140/1993, 80% AM, 10V/m @ 3 m

IEC 1000-4-4/1995; EN 61000-4-4, 2 kV ALL LINES

IEC 1000-4-8/1993; EN 61000-4-8, 30 A/m

ENV 50141/1993, 80% AM, 10V, .15-80 MHz

ENV 50204/1995, Pulse, 900 MHz, 50% DTY, 200 Hz

Supplementary information:

The products herewith comply with the requirements of the Low Voltage Directive (LVD) 73/23/EEC and EMC Directive 89/336/EEC

This electronic drive product is intended to be used with an appropriate motor, electrical protection components and other equipment to form a complete end product or system.

It must only be installed by a professional assembler who is familiar with requirements for safety and electromagnetic compatibility (“EMC”). The assembler is responsible for

ensuring that the end product or system complies with all the relevant laws in the country where it is to be used. Refer to the product manual for installation guidelines.

December 2, 1997

Bradley Schwartz/ VP Engineering Date

European Contact:

Sobetra Automation

Langeveldpark Lot 10

P. Dasterleusstraat 2

1600 St. Pieters Leeuw, Belgium

Page 12

Page 13

xiii

Introduction

Auxiliary Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ALP-130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ALP-430 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation

ALP-130 Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ALP-430 Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ALPC-xxx Cable Installation Instructions . . . . . . . . . . . . . . . . . 7

Specifications

Power Supply Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ALP-130 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ALP-430 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table of Contents

A

L

P

-

1

3

0

a

n

d

A

L

P

-

4

3

0

Page 14

Page 15

1

Introduction

Auxiliary Power Supply

Note

ALP’s are intended for use with E Series drives only.

ALP-130

The ALP-130 supplies enough logic power for one E Series

drive with any function module (FM). It comes with the

hardware necessary for mounting to most DIN rail mounting

tracks and includes the screw terminal plug connectors to mate

with the auxiliary supply receptacle on the drive and the drive

end connector kit and includes a ALPC-xxx cable to mate with

the recepticle on the drive.

Note

The ALP-130 is considered a Class 2 device. As such, there

is not a connection for PE on the ALP-130. Protect Class 2

referes to any equipment in which protection against

electrical shock does not rely on basic insulation only, but in

which additonal safety precautions such as double

insulation or reinforced insulation are provided, there being

no provision for protective earthing or reliance upon

installation provisions according to EN 50178.

ALP-430

The ALP-430 has four isolated power supply outputs to provide

enough logic power for up to four E Series drives with function

modules. It comes with the hardware necessary for mounting

A

L

P

-

1

3

0

a

n

d

A

L

P

-

4

3

0

Page 16

2

ALP-130 and ALP-430 Installation Manual

to most mounting tracks or enclosures and includes the screw

terminal plug connectors to mate with the auxiliary supply

receptacle on the drives and the drive end connector kit and

includes four (4) ALPC-xxx cables to mate with the recepticle

on the drive.

Page 17

3

Installation

ALP-130 Wiring Example

230 VAC

Backup Power

ALPC-xxx Cable

A

L

P

-

1

3

0

a

n

d

A

L

P

-

4

3

0

Page 18

4

ALP-130 and ALP-430 Installation Manual

ALP-430 Wiring Example

230 VAC

Backup Power

ALPC-xxx

Cable

Page 19

5

Installation

Installation Procedure

Follow the wiring diagrams below for the ALP-130/-430

installation and fusing.

Use #16 to 18 AWG, 600V, insulated, stranded wire for AC in

and DC out wiring.

The ALP-130 and ALP-430 package includes the cable

assembly that mates with the 2-position header(s) on your

drive(s).

Figure 1: ALP-130 Connections and Internal Wiring

Diagram

Page 20

6

ALP-130 and ALP-430 Installation Manual

Figure 2: ALP-430 Connections and Internal Wiring

Diagram

Page 21

7

Installation

ALPC-xxx Cable Installation Instructions

The ALPC-xxx cable is designed to connect an auxiliary logic

power supply such as the ALP-130/430 to the E Series drive. It

includes a 2-position plug that mates with the 2-position

header (J3) on your E Series drive and flying leads that connect

to the auxiliary logic power supply.

Note

This manufactured cable must be used in order to maintain

the UL Listing on the drives and on the ALP-130/430 power

supplies.

Note

Refer to the “ALP-130 and ALP-430 Auxiliary Power Supply

Installation Manual” (P/N 400514-01) for power supply

installation instructions.

1. Break out the plastic knock-out tab in the J3 location on

the top of the drive.

2. Plug the connector end of the ALPC-xxx cable into the two

position receptacle in the J3 location.

3. route the cable to the power supply (i.e., ALP-130/430), cut

it to length, and connect the wires as shown below.

Red wire goes to +V

Black wire goes to -V

Page 22

8

ALP-130 and ALP-430 Installation Manual

Figure 1: Signal Description with the New Style Two Position

Receptacle in the J3 Location

All drives serial numbers 9747 and lower and some drive serial

number 9748 or higher, use a spring terminal for J3 rather

than a header. These drives will not use the ALPC-xxx cable.

See drawing below for connection descriptions for this type of

drive.

Figure 2: Signal Description with the Original Design

Spring Terminal in the J3 Location

Two position receptacle

The mating connector/cable assembly

ALPC-xxx plugs into the receptacle.

Additional cables available from

EMERSON Motion Control.

Page 23

9

Specifications

Power Supply Specifications

ALP-130 Dimensions

Model

Input Output IP

Rated

Ambient

Temperature

Weight

ALP-130

115/230 VAC

40 Watts

140 VDC

30 Watts

20 50° C (122° F)

1.6 lbs

(.07 kg)

ALP-430

115/230 VAC

130 Watts

140 VDC

(4) x 20 Watts

20 50° C (122° F)

7.7 lbs

(3.5 kg)

0.25

0.25

2.0 min.

2.0 min.

A

L

P

-

1

3

0

a

n

d

A

L

P

-

4

3

0

Page 24

10

ALP-130 and ALP-430 Installation Manual

ALP-430 Dimensions

6.53 0.18

2.25

7.05

7.50

0.23

2.95

0.35

0.22

2.0 min.

2.0 min.

0.25

0.25

Loading...

Loading...