Page 1

36J22, 36J24, 36J54 and 36J55

DSI and HSI Single and Two Stage

Combination Gas Valves

INSTALLATION INSTRUCTIONS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

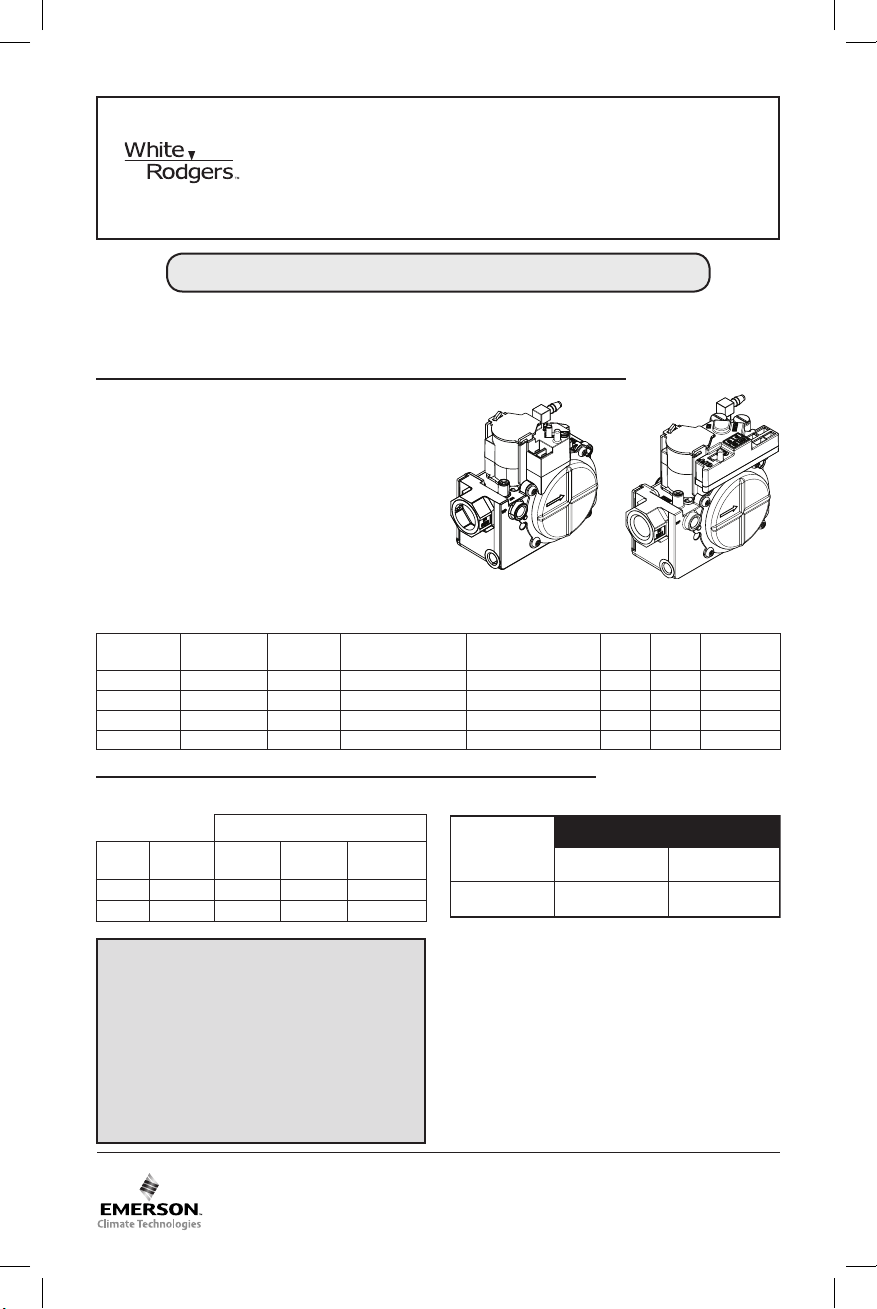

DESCRIPTION

The 36J22/24/54/55 combination gas valves are designed for direct spark ignition (DSI) and hot surface

ignition (HSI) system applications. These valves

are equipped with redundant and main solenoid

valves that control gas ow to the main burners, a

pressure regulator and a two-position on/o switch

for regulation and electrical shut-o of the solenoid

valves. The 36J24 and 36J55 are also equipped

with a slow-opening pressure regulator for softer

lighting characteristics. When the second solenoid

on 2-stage valves is energized the valve operates

at the second stage (high) outlet pressure setting.

Model

Number

36J22 24V 1 Fast No Yes Yes No

36J24 24V 1 Slow No Yes Yes No

36J54 24V 2 Fast No Yes Yes No

36J55 24V 2 Slow No Yes Yes No

Coil

Voltage

Stages

Opening

Characteristics

36J Single Stage

Intermittent Pilot

Proven Pilot

Fig. 1

HSI DSI

36J Two-Stage

Standing

Pilot

Pressure Regulator Adjustment Range (in W.C.)

Two Stage

Gas

Single

Type

Stage

Natural 2.5 – 5.0 1.0 – 4.0 2.0 – 5.0 1

LP 7.0 – 12.0 4.0 – 10.0 6.0 – 12.0 2

Low High

Min. Di.

Low to High

CONTENTS

Description ........................................................ 1

Specications .................................................... 1

Precautions ....................................................... 2

Installation

System Wiring ...................................... 3

Adjustment

Pressure Regulator Adjustment ............ 6

Lighting Instructions .......................................... 8

Contents French ................................................ 9

Contents Spanish ............................................ 17

www.white-rodgers.com

www.emersonclimate.com

SPECIFICATIONS

PIPE SIZES/CAPACITIES

Capacity (BTU/hr) at

Pipe Sizes

Available

(inches)

1

/2" x 1/2" NPT 140,000

Type of Gas: Natural gas

LP gas (use conversion kit)

Ambient Temperature: -40° to 175°F

Pressure Rating: 14" W.C. (½ PSI) max.

Voltage: 24 VAC

Frequency: 50/60 Hz

Current: Single Stage – 0.28A

Two-Stage – 0.43A

Mounting Positions: Multipoise – Control may

be mounted in any position

1” pressure drop across valve

AGA Std. Nat. Gas

(1,000 BTU/cu. ft.)

PART NO. 37-7338A

LP Gas

(2,500 BTU/cu. ft.)

226,800

1224

Page 2

SPECIFICATIONS

Parts and Accessories:

Natural to Regulated LP Gas Conversion Kits

• F92-0659 for Single Stage

• F92-1008 for Two-Stage

Natural to Unregulated LP Gas Conversion Kit

• F92-0737

LP to Natural Gas Conversion Kits

• F92-0656 for Single Stage

• F92-1011 for Two-Stage

Note: Two single stage kits may be used for twostage valve

PRECAUTIONS

DO NOT BEGIN INSTALLATION UNTIL YOU READ THE FOLLOWING

PRECAUTIONS.

WARNING

!

1. Failuretoturnoelectricormaingas

supply to heating system could cause

personal injury and/or property damage

byshock,gassuocation,re,and/or

explosion.

2. Do not use this control on circuits

exceedingspeciedvoltage.Higher

voltage will damage the control and may

causeshockorrehazard.

3. NEVER USE FLAME OR ANY KIND OF

SPARK TO CHECK FOR GAS LEAKS–

COULD CAUSE FIRE AND/OR EXPLOSION.

4. Do not use a control set for natural gas

with LP gas, or a control set for LP gas

with natural gas. Personal injury and/or

Properly install gas piping to control.

• Donotremoveprotectiveinletoroutletcapsuntilreadytoconnectsupplypipetogasvalve.

• Usenewsupplypipe,properlythreaded,reamed,de-burred,andcleaned.

• Usebackupwrench,appliedonlytoprovidedwrenchatsoninletboss,whentighteningthe

supply pipe. Do not grip bracket, solenoid or any other part of control.

• Donotover-tightenpipetocontrol(50ft-lbs max.)

• Alwaysinstallsedimenttrapinthegassupplylinetopreventcontaminationofgasvalve.

Failuretoinstallproperlycancausegasleakageresultingininjuryduetoreorexplosion.

Ifyoudonotfollowtheseinstructionsexactly,areorexplosion

may result, causing property damage, personal injury or loss of life.

propertydamage,gassuocation,re,

and/or explosion may result.

5. Do not use a gas valve which appears to be

damaged. A damaged valve may cause

personal injury and/or property damage

duetoshock,gassuocation,reand/or

explosion. Contact supplier to replace any

valve that appears to have been damaged.

6. Do not use a gas valve that has been in

direct contact with water. Water entering

gas valve may result in concealed internal

damage to gas valve. Personal injury and/

orpropertydamage,gassuocation,re

and/or explosion may result.

WARNING

!

CAUTION

!

1. Do not short out terminals on gas valve or primary control to test. Short or incorrect wiring

can cause equipment damage, property damage, and/or personal injury.

2. This control is not intended for use in locations where it may come in direct contact with water.

Suitable protection must be provided to shield the control from exposure to water (dripping,

spraying, rain, etc.).

3. Cleangaspipingofcontaminants,cuttinguid,orotherchemicalswhichmightreactharm-

fully with the gas valve components before install.

2

Page 3

INSTALLATION

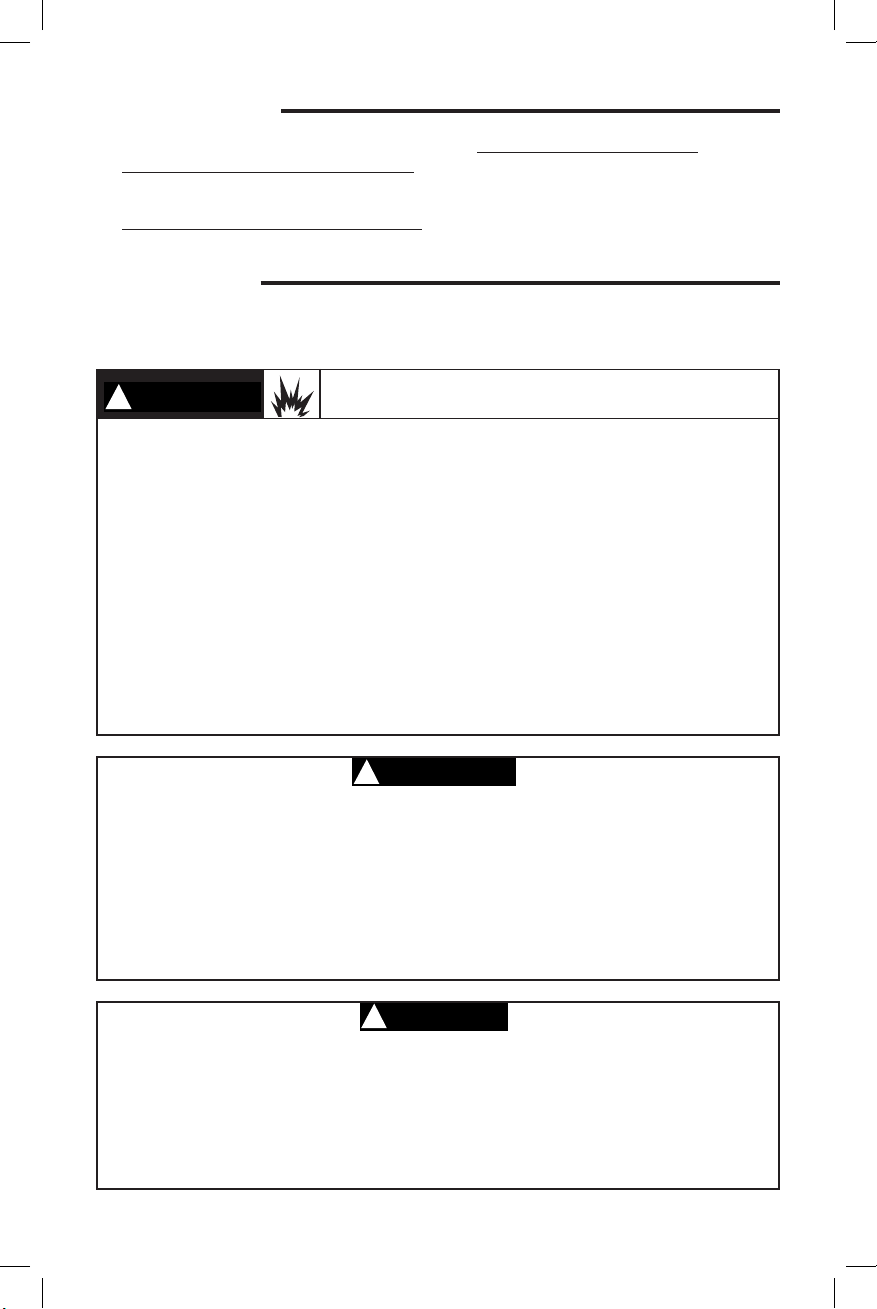

MAIN PIPING CONNECTIONS

NOTE

Refer to warnings and cautions on page 2 before

attempting installation. All piping must comply

with local codes, ordinances, and/or national

fuel gas codes.

1. Turn o electrical power to the system at the

fuse box or circuit breaker. Also turn o the

main gas supply.

2. If replacing an existing valve, disconnect all

plumbing and electrical connections from the

old control.

3. The control may be installed in any position.

The arrow on the bottom plate indicates the

direction of inlet gas ow.

Gas Flow

Direction

4. You should use new pipe that is properly

chamfered, reamed, and free of burrs and

chips. If you are using old pipe, be sure it is

clean and free of rust, scale, burrs, chips, and

old pipe joint compound.

5. Apply pipe joint compound (pipe dope) that

is approved for all gases, only to the male

threads of the pipe joints. DO NOT apply

compound to the rst two threads (see gure

2 for typical piping connections).

6. If you are using a vise or open-end wrench to

hold the valve while installing piping, do not

tighten excessively, as this may damage the

valve. (Torque: 375 in-lb maximum.) Do not

cross-thread during installation as this may

damage the valve.

7. See SYSTEM WIRING when making electrical

connections. After all gas and electrical con-

nections are completed, turn gas on and check

for gas leaks with leak detection solution or

soap suds. Bubbles forming indicate a leak.

SHUT OFF GAS AND FIX ALL

LEAKS IMMEDIATELY.

LP GAS CONVERSION

For LP gas conversion, use the LP conversion kit

supplied with this control. Refer to the instructions packed with LP conversion kit.

All piping must comply with local codes, ordinances,

and/or national fuel gas codes.

NOTE: A MANUAL SHUTOFF VALVE

MUST BE INSTALLED WITHIN

6 FEET OF THE EQUIPMENT

Drop

Horizontal

3 in.

minimum

Piped Gas

Gas Valve

Supply

NOTE

Gas Valve

Riser

3 in.

minimum

Piped Gas

Supply

Fig. 2 – Typical Gas Valve Piping

NOTE: ALWAYS INCLUDE A

DRIP LEG IN PIPING

Drop

Horizontal

3 in.

minimum

Riser

Tubing Gas

Supply

Gas Valve

3

Page 4

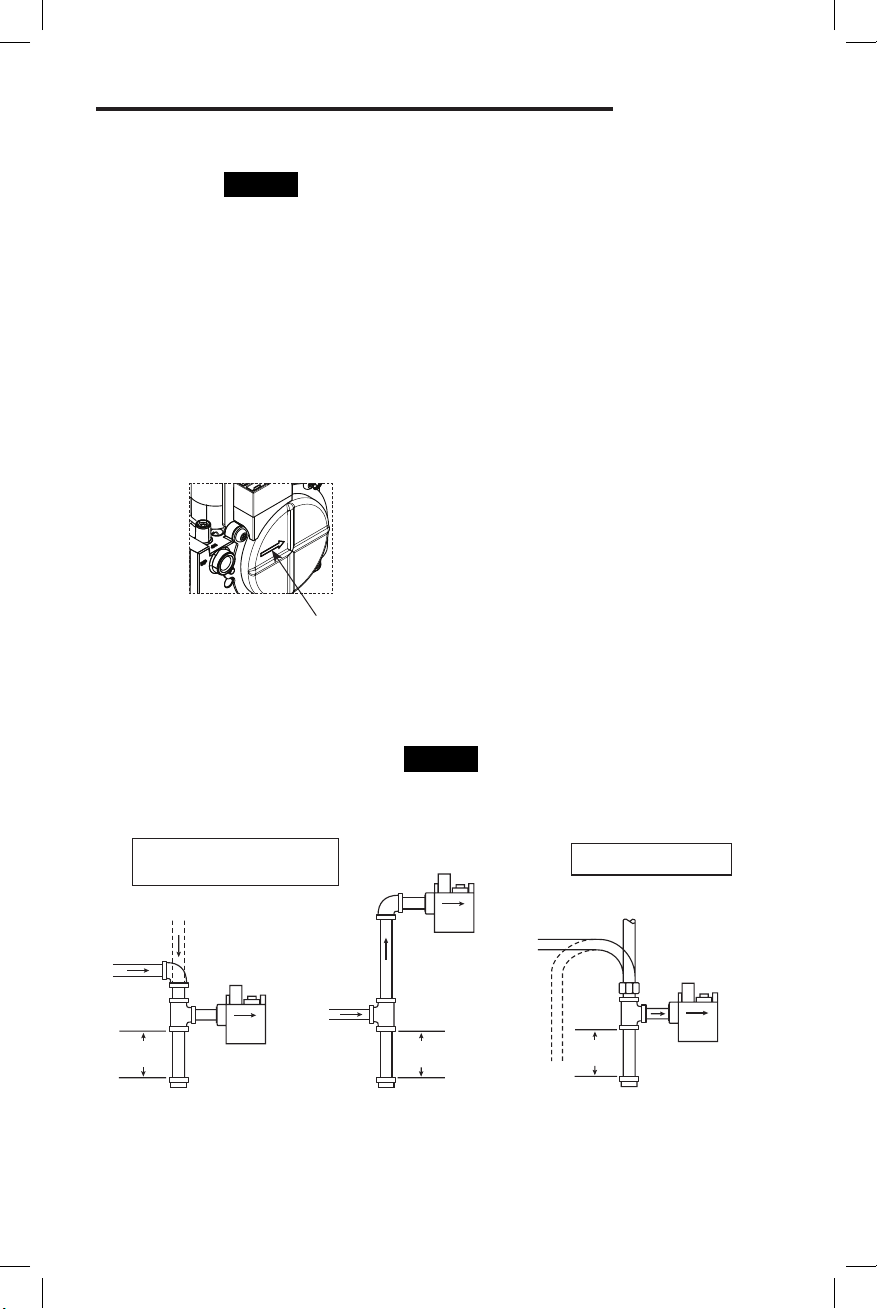

Outlet Pressure Post

On/Off

Switch

Hi

M

Main and

Redundant

Valves (Low Fire)

2nd Stage

Valve (High Fire)

C

C

INSTALLATION

SYSTEM WIRING

REFER TO AND FOLLOW THE APPLIANCE

MANUFACTURER'S WIRING DIAGRAM.

REFER TO FIGURES 3 AND 4 FOR TERMINAL

IDENTIFICATION.

4.693” Inlet to Outlet

Inlet Pressure Post

.339 Dia. +DFT.

(Set Screw: 3/32” Hex Head)

Accept 5/16” I.D. Hose

Connecon

Fig. 3 – Single Stage Valve Features, Terminals and Wiring

4.693” Inlet to Outlet

On/Off

Switch

1/4” x .032” THK. Male

Spade Terminals (2)

Set Screw: 3/32” Hex Head

(.339 Dia. + DFT.)

Accepts 5/16” Hose Connection

NOTE

All wiring should be installed according to local

and national electrical codes and ordinances.

Always check that the electrical power supply

used agrees with the voltage and frequency

shown on the gas control.

Outlet Pressure Post

.339 Dia. +DFT.

(Set Screw: 3/32” Hex Head)

Accept 5/16” ID Hose Connection

On/Off

Switch

Regulator Cover Screw

(Reg. Adj. Beneath This Screw)

3/16” Ground Terminal

Control I.D. Label

Main and

Redundant

Valves

High Fire Regulator

Cover Screw

(Reg. Adj. Beneath

Inlet Pressure Post

Set Screw: 3/32” Hex Head

(.339 Dia. + DFT.)

Accepts 5/16” Hose Connecon

4

Fig. 4 – Two-Stage Valve Features, Terminals and Wiring

On/Off Switch

Control I.D. Label

3/16” Ground Terminal

the Screw)

Low Fire Regulator

Cover Screw

(Reg. Adj. Beneath

the Screw)

3/16” x .032” Thick Male

Spade Terminal (1)

1/4” x .032” Thick Male

Spade Terminals (3)

Page 5

M – Main

INSTALLATION

ALTERNATE

LIMIT

TRANSFORMER

THERMOSTAT OR

CONTROLLER

L1 (HOT)

L2

SPARK

PROBE

MV

(GND)

LIMIT

CONTROLLER

FLAME

GAS

VALV E

MV

VAL

TR

TH

GND

FLY

LEAD

SPARK

Burner Ground

FLAME

PROBE

(GND)

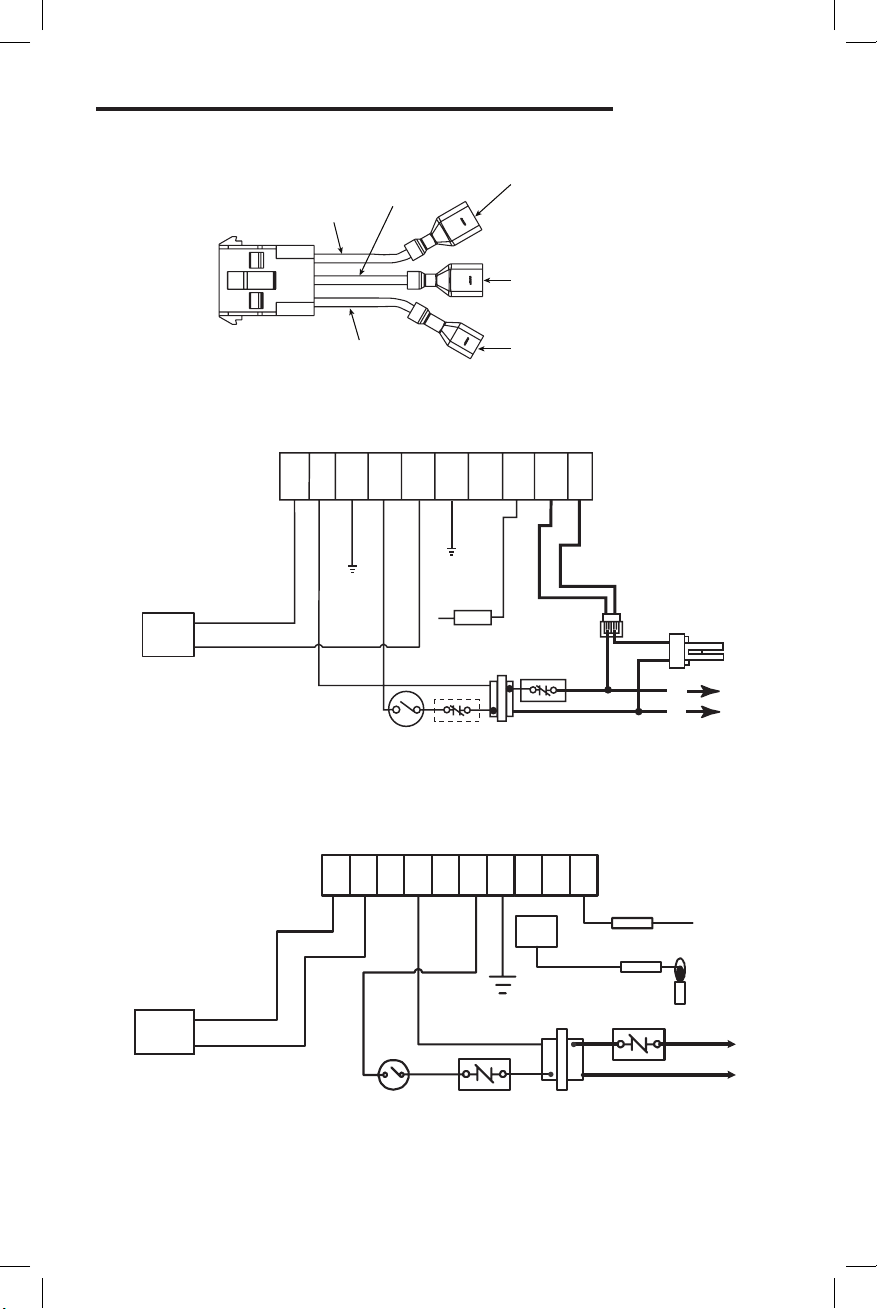

If system requires 3-pin connector for 2-stage valve, use wire harness adapter, see gure 5

This end plug

to Furnace

3-pin connector

GAS

VALV E

White

Black

Red

Fig. 5 – Wire Harness Adapter

L

2

FLAME

PROBE

ALTERNATE

LIMIT

H

S

2

TRANSFORMER

MV2

MV1

M

V

2

G

T

N

R

D

BURNER

GROUND

THERMOSTAT OR

CONTROLLER

M

T

V

H

1

Fig. 6 – Typical Wiring for Hot Surface Ignition System

1/4" Female Receptacle

C – Common

1/4" Female Receptacle

Hi – High

3/16" Female Receptacle

LIMIT

1

RED

ADAPTER

H

S

1

BLUE

FPL

CONTROLLER

HOT

SURFACE

IGNITER

L1

(HOT)

L2

To new

gas valve

Fig. 7 – Typical Wiring for Direct Spark Ignition System, Single Stage Valve

5

Page 6

Regulator

ADJUSTMENT

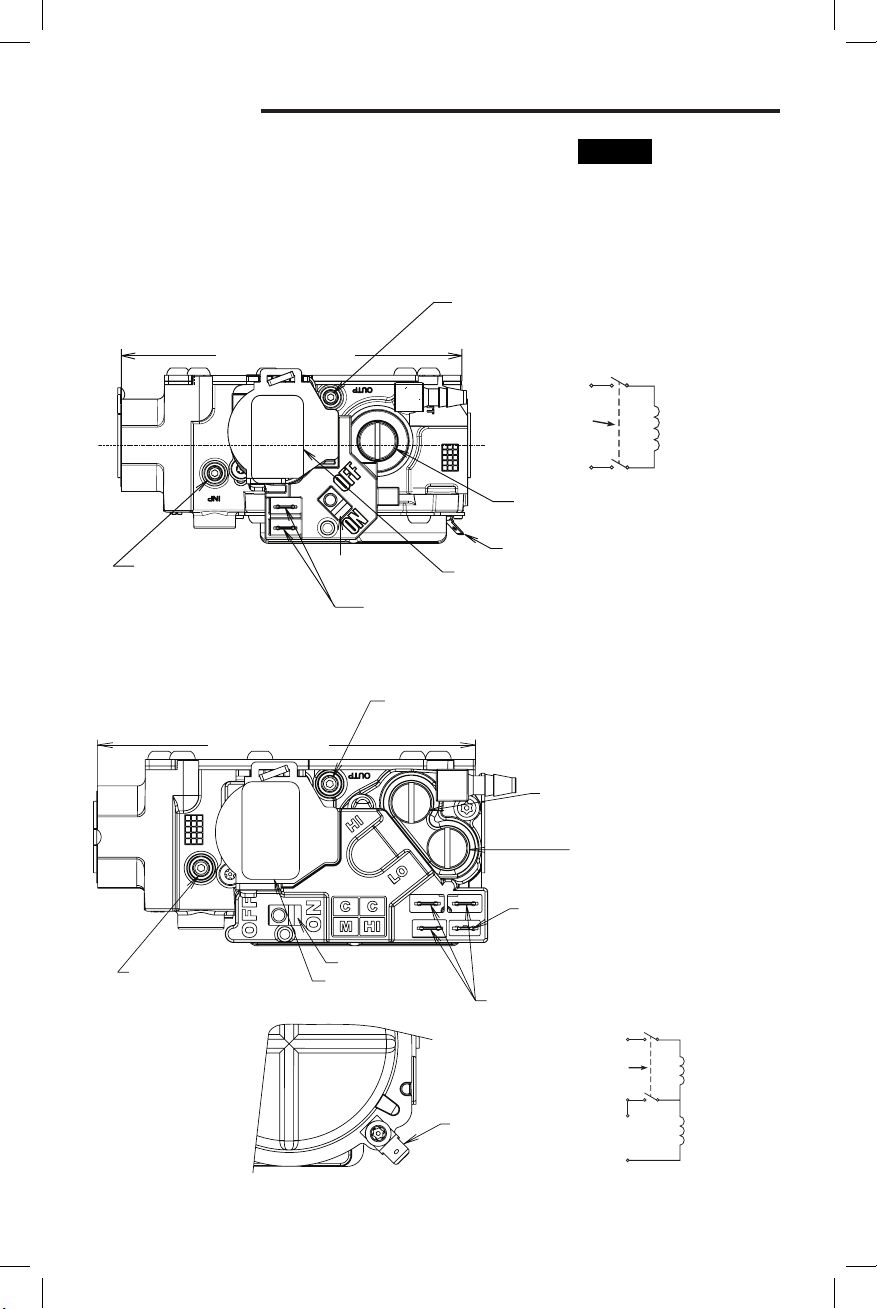

PRESSURE REGULATOR

ADJUSTMENT

These controls are shipped from the factory set

for Natural Gas with the regulator set as specied

on the control label. Consult the appliance rating

plate to ensure burner manifold pressure is as

specied. If another outlet pressure is required,

follow these steps. For LP gas conversion, use LP

conversion kit.

NOTE

NATURAL GAS

Single Stage Models – Outlet pressure will be

factory-adjusted in the 2.5" to 5" range. The valve

cannot be adjusted outside this range.

Two-Stage Models: Low outlet pressure will be

factory- adjusted in the 1 to 4" W.C. range and

high outlet pressure will also be factory-adjusted

in the 2 to 5" W.C. range.

The valve cannot be adjusted outside this range

and the high outlet pressure setting must always

be set at least 1" above the low outlet pressure

setting.

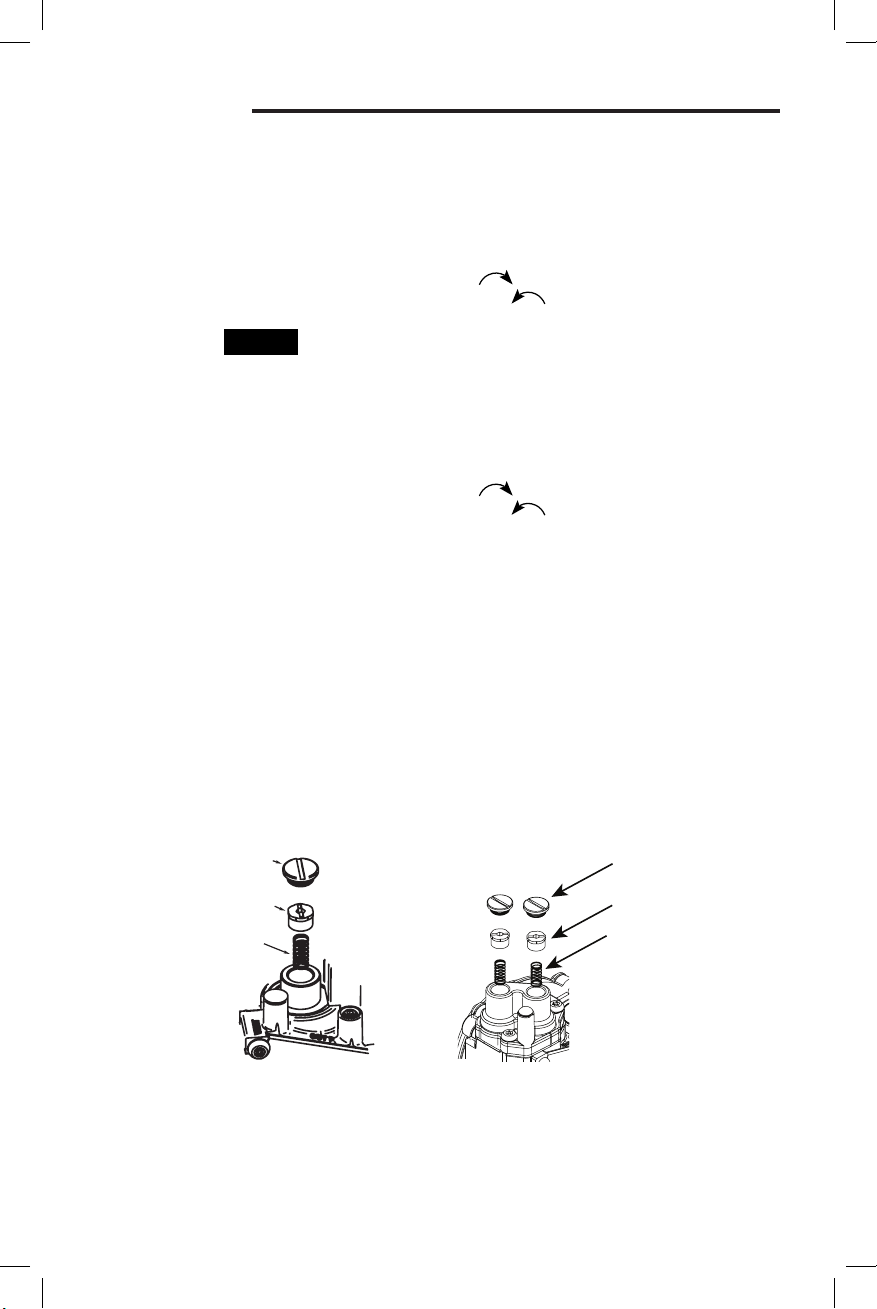

OUTLET PRESSURE ADJUSTMENT

1. Turn o all electrical power to the system.

2. Back outlet pressure test screw out one turn,

counterclockwise, not more than one turn.

(see g. 8)

3. Attach a hose and manometer to the outlet

pressure boss of the valve.

4. Turn on system power. Set thermostat to call

for heat (low stage for two-stage systems).

Main burner should light. Proceed to step 7 for

single stage systems.

5. (2-stage only) Remove regulator cover screw

from the low outlet pressure regulator adjust

tower (g. 8) and turn screw clockwise

( ) to increase pressure, or counterclockwise ( ) to decrease pressure. Always

adjust regulator according to original equip-

ment manufacturer's specications listed on

the appliance rating plate. Replace regulator

cover screw.

6. (2-stage only) Set thermostat to call for high

stage.

7. Remove regulator cover screw from the single

stage or high outlet pressure regulator adjust

tower (g. 8) and turn screw clockwise

( ) to increase pressure, or counterclockwise ( ) to decrease pressure. Always

adjust regulator according to original equip-

ment manufacturer's specications listed on

the appliance rating plate. Replace regulator

cover screw.

8. Turn o all electrical power to the system.

9. Remove manometer hose and turn outlet

pressure test screw in to seal pressure port

(clockwise, 7 in-lb minimum).

10. Turn on electrical power to the system.

11. Turn on system power and energize valve.

12. Using a leak detection solution or soap suds,

check for leaks at pressure boss screw. Bubbles

forming indicate a leak. SHUT OFF GAS AND

FIX ALL LEAKS IMMEDIATELY.

Cover Screw

Plastic

Adjust Screw

Regulator

Spring

Single Stage Valve

Two-Stage Valve

Regulator Cover Screw

Plastic Adjust Screw

Regulator Spring

Fig. 8

6

Page 7

FOR YOUR SAFETY READ BEFORE OPERATING

OPERATING INSTRUCTIONS

TO TURN OFF GAS TO APPLIANCE

WARNING

!

If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

LIGHTING INSTRUCTIONS

A. This appliance does not have a pilot. It is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

B. BEFORE OPERATING smell all around the appli-

ance area for gas. Be sure to smell next to the oor

because some gas is heavier than air and will settle

on the oor.

FOR YOUR SAFETY

“WHAT TO DO IF YOU SMELL GAS”

• Donottrytolightanyappliance.

• Donottouchanyelectricalswitch;donotuse

any phone in your building.

1. STOP! Read the safety information above on this

page.

2. Set the thermostat to lowest setting.

3. Turn o all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the burner. Do not try

to light the burner by hand.

•Immediatelycallyourgassupplierfromaneigh-

bor’s phone. Follow the gas supplier’s instructions.

• Ifyoucannotreachyourgassupplier,callthe

redepartment.

C. Use only your hand to move the gas control

switch. Never use tools. If the switch will not

move by hand, don’t try to repair it, call a qualied

service technician. Force or attempted repair may

result in a re or explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualied service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

5. Remove control access panel.

6. Wait ve (5) minutes to clear out any gas. If you

then smell gas, STOP! Follow “B” in the safety

information above on this page. If you don’t smell

gas, go to the next step.

7. Push gas control switch to “ON.”

NOTE: Do not force.

8. Replace control access panel.

9. Turn on all electric power to the appliance.

10. Set thermostat to desired setting.

11. If the appliance will not operate, follow the in-

structions “To Turn O Gas To Appliance” and call

your service technician or gas supplier.

1. Set the thermostat to lowest setting.

2. Turn o all electric power to the appliance if

service is to be performed.

3. Remove control access panel.

4. Push gas control switch to “OFF.” Do not force.

5. Replace control access panel.

7

Page 8

White-Rodgers is a business

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

www.white-rodgers.com

www.emersonclimate.com

Page 9

36J22, 36J24, 36J54 et 36J55

Robinets de gaz polycombustibles à allumage direct

par étincelle et allumage par surface chaude

mono-étage et bi-étage

INSTRUCTIONS D’INSTALLATION

Opérateur : Conservez ces instructions pour une utilisation ultérieure!

LIRE ET RESPECTER SOIGNEUSEMENT TOUTES LES INSTRUCTIONS AVANT

L’INSTALLATION OU L’UTILISATION DE CET APPAREIL POUR PRÉVENIR LES

BLESSURES ET LES DOMMAGES MATÉRIELS.

DESCRIPTION

Les robinets de gaz polycombustibles 36J22/24/54/55

sont conçus pour les applications à allumage direct par

étincelle et à allumage par surface chaude. Ces robinets

sont pourvus de robinets à solénoïde principal et redondant

pour contrôler le débit de gaz vers les brûleurs principaux,

d’un manostat et d’un commutateur de marche/arrêt à

deux positions pour la régulation et la coupure électrique

des robinets à solénoïde. Les modèles 36J24 et 36J55 sont

également pourvus d’un manostat à ouverture lente pour

des caractéristiques d’allumage plus douces. Lorsque le

deuxième solénoïde des robinets bi-étage est sous tension,

le robinet fonctionne sur le réglage de pression de sortie

bi-étage (maximale).

Numéro de

modèle

Plage de réglage du régulateur de pression (po C.E.)

Type

de gaz

Naturel 2,5 – 5,0 1,0 – 4,0 2,0 – 5,0 1

GPL 7,0 – 12,0 4,0 – 10,0 6,0 – 12,0 2

Tension au

serpentin

36J22 24 V 1 Rapide Non Oui Oui Non

36J24 24 V 1 Lent Non Oui Oui Non

36J54 24 V 2 Rapide Non Oui Oui Non

36J55 24 V 2 Lent Non Oui Oui Non

Mono-

Inférieure Supérieure

étage

Étages

Caractéristiques

d’ouverture

Bi-étage

Di. min.

minimal

à maximal

TABLE DES MATIÈRES

Contenu en anglais .................................................. 1

Description ............................................................ 9

Spécications ....................................................... 10

Précautions .......................................................... 11

Installation

Câblage du système ................................ 13

Réglage

Ajustement du régulateur de pression .... 14

Instructions d’allumage .......................................... 15

Contenu en espagnol ...............................................17

36J mono-étage

Pilote intermittent

Pilote contrôlé

Fig. 1

Allumage

par surface

chaude

36J bi-étage

Allumage

direct par

étincelle

SPÉCIFICATIONS

TAILLES/CAPACITÉS DES TUYAUX

Capacité (BTU/h) à chute de pression

Tailles de tuyaux

disponibles

(pouces)

½ po sur ½ po NPT 140 000

Type de gaz : Gaz naturel

GPL (utilisez une trousse de conversion)

Température ambiante : -40° à 175 °F

Pression nominale : 14 po C.E. (½ PSI) max.

Tension : 24 V c.a.

Fréquence : 50/60 Hz

Courant : Mono-étage – 0,28A

Bi-étage – 0,43A

Positions de montage : Positions multiples –

de 1 po CE à travers le robinet

Gaz nat. AGA std

(1 000 BTU/pi3)

Le contrôleur peut être monté

dans n’importe quelle position

Gaz de pétrole liquéfiés

permanente

(2 500 BTU/pi3)

Veilleuse

226 800

www.white-rodgers.com

www.emersonclimate.com

PIÈCE N° 37-7338A

1224

Page 10

SPÉCIFICATIONS

AVERTISSEMENT

Pièces et accessoires :

Trousses de conversion du gaz naturel au GPL

à régulation

• F92-0659 pour mono-étage

• F92-1008 pour bi-étage

Trousse de conversion du gaz naturel au GPL

sans régulation

• F92-0737

Trousses de conversion du GPL au gaz naturel

• F92-0656 pour mono-étage

• F92-1011 pour bi-étage

Remarque : Deux trousses mono-étage simples peuvent

être utilisées pour un robinet bi-étage

PRÉCAUTIONS

NE COMMENCEZ PAS L’INSTALLATION AVANT D’AVOIR LU LES

PRÉCAUTIONS SUIVANTES.

Si ces instructions n’étaient pas respectées à la lettre, un incendie

AVERTISSEMENT

!

1. Le fait de ne pas couper l’alimentation électrique

ou l’alimentation principale de gaz du système

de chauage pourrait entraîner des blessures ou

des dommages matériels par choc électrique,

suocation au gaz, incendie ou explosion.

2. Ne pas utiliser cet appareil de contrôle sur les

circuits qui excèdent la tension spéciée. Une

tension plus élevée pourrait endommager

l’appareil et présenter un risque de choc

électrique ou d’incendie.

3. NE JAMAIS UTILISER DE FLAMME NI TOUTE

AUTRE FORME D’ÉTINCELLE POUR DÉTECTER

LES FUITES DE GAZ – CELA POURRAIT CAUSER

UN INCENDIE OU UNE EXPLOSION.

4. Ne pas utiliser une trousse de commande pour

gaz naturel avec du gaz de pétrole liquéé, ni

une trousse de commande pour GPL avec du

gaz naturel. Cela pourrait entraîner des risques

de blessures ou de dommages matériels, de

ou une explosion pourrait survenir et causer des dommages

matériels, des blessures ou des pertes de vie.

suocation au gaz, d’incendie ou d’explosion.

5. Ne pas utiliser un robinet de gaz qui semble

endommagé. Un robinet endommagé peut causer

des blessures ou des dommages matériels par

choc électrique, suocation au gaz, incendie ou

explosion. Contactez le fournisseur pour remplacer

tout robinet qui semble avoir été endommagé.

6. Ne pas utiliser un robinet de gaz qui est entré en

contact direct avec de l’eau. L’inltration d’eau

dans un robinet de gaz peut causer des dommages

cachés à l’intérieur du robinet de gaz. Des blessures

ou dommages matériels, une suocation au gaz, un

incendie ou une explosion pourraient survenir.

!

Installez correctement les tuyaux de gaz du contrôleur.

• N’enlevez pas les capuchons protecteurs des orices d’entrée et de sortie avant d’être prêt à brancher le

tuyau d’alimentation sur le robinet de gaz.

• Utilisez un tuyau d’alimentation neuf, correctement leté, alésé, ébarbé et nettoyé.

• Utilisez une clé de rechange appliquée uniquement sur le plan de manœuvre de la butée d’entrée au

moment de serrer la tuyauterie d’alimentation. Ne saisissez pas la ferrure, le solénoïde ni toute autre pièce

du contrôleur.

• Ne serrez pas excessivement le tuyau sur le contrôleur (50 pi-lb max.)

• Installez toujours un collecteur de sédiments dans la conduite d’alimentation de gaz pour prévenir la

contamination du robinet de gaz.

Une installation incorrecte pourrait causer une fuite de gaz et entraîner un incendie ou une explosion causant

des blessures.

MISE EN GARDE

!

1. Ne court-circuitez pas les bornes sur le robinet de gaz ni sur le contrôleur principal au moment du test.

Un court-circuit ou un branchement incorrect peut causer des dommages à l’équipement ou à la propriété

ou encore des blessures.

2. Ce contrôleur n’est pas conçu pour être utilisé dans des endroits où il pourrait entrer en contact direct avec

de l’eau. Une protection adéquate doit être fournie pour protéger le contrôleur contre toute exposition

à l’eau (égouttement, pulvérisation, pluie, etc.).

3. Avant l’installation, retirez de la tuyauterie de gaz tout contaminant, liquide de coupe ou autre produit

chimique pouvant réagir dangereusement avec les composantes du robinet de gaz.

10

Page 11

INSTALLATION

PRINCIPAUX RACCORDS DE TUYAUX

REMARQUE

Prenez connaissance des avertissements et mises en

garde de la page 2 avant de commencer l’installation.

Tous les tuyaux doivent respecter les codes et

ordonnances locaux ainsi que les codes nationaux des

gaz combustibles.

1. Coupez l’alimentation électrique du système à

la boîte de fusibles ou au disjoncteur. Coupez

également l’alimentation de gaz principale.

2. Si vous remplacez un robinet existant, débranchez

tous les raccords de plomberie et les branchements

électriques de l’ancien contrôleur.

3. Le contrôleur peut être installé dans n’importe quelle

position. La èche sur la plaque inférieure indique la

direction du débit de gaz à l’entrée.

4. Utilisez un nouveau tuyau correctement chanfreiné,

alésé et exempt de barbes et d’éclats. Si vous utilisez

un tuyau usagé, assurez-vous qu’il est propre et

exempt de rouille, d’écailles, de barbes, d’éclats et de

pâte à joint.

5. Appliquez de la pâte à joint (pâte lubriante) ou

un ruban en téon approuvé pour tous les gaz

seulement sur les lets mâles des joints de tuyaux.

N’appliquez PAS de pâte à joint sur les deux premiers

lets (voir la gure 2 pour les branchements typiques).

6. Si vous utilisez une pince étau ou une clé à fourche

pour tenir le robinet pendant l’installation des tuyaux,

ne serrez pas excessivement, car cela pourrait

endommager le robinet. (Couple : 375 po-lb maximum.)

Ne faussez pas le letage pendant l’installation, car

cela pourrait endommager le robinet.

7. Consultez la section CÂBLAGE DU SYSTÈME pour

eectuer les branchements électriques. Une fois que

tous les branchements de gaz et les branchements

électriques ont été eectués, ouvrez le gaz et vériez

s’il y a des fuites avec une solution de détection

de fuites ou du savon. La formation de bulles

indique une fuite. COUPEZ LE GAZ ET RÉPAREZ

IMMÉDIATEMENT TOUTES LES FUITES.

Toute la tuyauterie doit respecter les codes et ordonnances

locaux et les codes nationaux des combustibles.

REMARQUE : UN ROBINET DE FERMETURE

Colonne descendante

Horizontal

3 po

minimum

Alimentation

de gaz par tuyau

MANUELLE DOIT ÊTRE

INSTALLÉ À MOINS DE 2 MÈTRES

DE L’ÉQUIPEMENT

Robinet de gaz

Pour la conversion au GPL, utilisez la trousse de

conversion au GPL qui accompagne ce contrôleur.

Débit de gaz

Direction

Suivez les instructions qui accompagnent la trousse

de conversion au GPL.

REMARQUE

CONVERSION AU GPL

Colonne

montante

Horizontal

Robinet de gaz

Colonne montante

3 po

minimum

Alimentation

de gaz par tuyau

Fig. 2 – Canalisation typique du robinet de gaz

REMARQUE : INCLUEZ TOUJOURS

Colonne descendante

3 po

minimum

UNE PATTE

D’ÉGOUTTEMENT

DANS LA TUYAUTERIE

Robinet de gaz

Alimentation

de gaz par tuyau

11

Page 12

Commutateur

marche/arrêt

Hi

M

Robinets principal

et redondant

(puissance minimale)

Robinet 2

e

étage

(puissance maximale)

C

C

INSTALLATION

CÂBLAGE DU SYSTÈME

CONSULTEZ ET SUIVEZ LE SCHÉMA DE

BRANCHEMENT DU FABRICANT DE L’APPAREIL.

CONSULTEZ LES FIGURES 3 ET 4 POUR

L’IDENTIFICATION DES BORNES.

4,693 po entrée à sortie

Borne de pression d’entrée

Diam. 0,339 + DFT.

(Vis de réglage : 3/32 po

à tête hexagonale)

Convient aux raccords

de flexible 5/16 po

Fig. 3 – Caractéristiques, bornes et câblage du robinet mono-étage

4,693 po entrée à sortie

Commutateur

marche/arrêt

1/4 po sur 0,032 po THK.

Borne embrochable mâle (2)

REMARQUE

Tout le câblage doit être installé conformément aux

codes et ordonnances locaux et nationaux de l’électricité.

Assurez-vous toujours que l’alimentation électrique

utilisée correspond à la tension et à la fréquence qui

gurent sur le contrôleur de gaz.

Borne de pression de sortie

Diam. 0,339 + DFT.

(Vis de réglage : 3/32 po à tête hexagonale)

Convient aux raccords de flexible 5/16 po

Commutateur

marche/arrêt

Vis du couvercle du régulateur

(Ajust. régl. sous la vis)

Borne de mise à la terre de 3/16 po

Étiquette de contrôle de d.i.

Borne de pression de sortie

Vis de réglage : 3/32 po à tête hexagonale

(Diam. 0,339 + DFT.)

Convient aux raccords de flexible 5/16 po

Robinets

principal et

redondant

Vis du couvercle

du régulateur

puissance maximale

(Ajust. régl. sous la vis)

Vis du couvercle

du régulateur

puissance minimale

(Ajust. régl. sous la vis)

Borne embrochable mâle

épaisse 3/16 po sur 0,032 po (1)

Borne de pression d’entrée

Vis de réglage : 3/32 po

à tête hexagonale

(Diam. 0,339 + DFT.)

Convient aux raccords

de flexible 5/16 po

12

Fig. 4 – Caractéristiques, bornes et câblage du robinet bi-étage

Commutateur

marche/arrêt

Étiquette de contrôle

de d.i.

Borne embrochable mâle épaisse

1/4 po sur 0,032 po (3)

Borne de mise

à la terre de 3/16 po

Page 13

INSTALLATION

LIMITE DE

RECHANGE

TRANSFORMATEUR

THERMOSTAT

OU CONTRÔLEUR

L1 (CHARGÉ)

L2

DÉTECTEUR

D’ÉTINCELLE

MV

(GND)

LIMITEUR

FLAMME

ROBINET

DE GAZ

MV

VAL

TR

TH

GND

FICHE

CONN

ÉTINCELLE

Prise de terre du brûleur

DÉTECTEUR

DE FLAMME

(TERRE )

Si le système requiert un connecteur à 3 tiges pour un robinet bi-étage, utilisez l’adaptateur de harnais de ls,

Blanc

Cette extrémité

s’embroche dans

le connecteur à

3 tiges de la

fournaise

Fig. 5 – Adaptateur de harnais de ls

Rouge

voir la gure 5

Noir

M – principal

Prise femelle 1/4 po

C – commun

Prise femelle 1/4 po

Hi – maximum

Prise femelle 3/16 po

Vers le nouveau

robinet de gaz

ROBINET

DE GAZ

L

2

DÉTECTEUR

DE FLAMME

LIMITE

DE RECHANGE

H

FPL

S

2

TRANSFORMATEUR

1

ROUGE

ADAPTATEUR

LIMIT

CONTROLLER

MV2

MV1

M

G

T

V

N

R

2

D

PRISE DE

TERRE DU

BRÛLEUR

THERMOSTAT OU CONTRÔLEUR

M

T

V

H

1

Fig. 6 – Câblage typique pour système d’allumage par surface chaude

H

S

1

BLEU

ALLUMEUR PAR

SURFACE

CHAUDE

L1

(CHARGÉ)

L2

Fig. 7 – Câblage typique pour un système à allumage direct par étincelle, robinet mono-étage

13

Page 14

AJUSTEMENT

AJUSTEMENT DU RÉGULATEUR

DE PRESSION

Ces contrôleurs sont expédiés par l’usine avec la trousse

de régulation spéciée sur l’étiquette du contrôleur.

Consultez la plaque signalétique de l’appareil pour vous

assurer que la pression de la canalisation du brûleur est

telle que spécié. Si une autre pression de sortie est

requise, suivez ces étapes. Pour la conversion au GPL,

utilisez une trousse de conversion au GPL.

REMARQUE

GAZ NATUREL

Modèles mono-étage : La pression de sortie est réglée

en usine entre 2,5 po et 5 po. Le robinet ne peut pas être

réglé en dehors de cette plage.

Modèles bi-étage : La pression de sortie minimale

est réglée en usine entre 1 po et 4 po CE et la pression

de sortie maximale est également réglée en usine entre

2 po et 5 po CE.

Le robinet ne peut pas être ajusté en dehors de ces

plages et le réglage de pression de sortie supérieure doit

toujours être au moins 1 po plus élevé que le réglage de

basse pression de sortie.

RÉGLAGE DE LA PRESSION DE SORTIE

1. Coupez toute alimentation électrique du système.

2. Dévissez la vis d’essai de pression de sortie d’un tour,

dans le sens contraire aux aiguilles d’une montre,

mais pas plus d’un tour. (voir la g. 8)

3. Fixez un exible et un manomètre sur la bosse de

pression de sortie du robinet.

4. Allumez l’alimentation du système. Réglez le

thermostat pour qu’il commande le chauage (étage

inférieur sur les systèmes bi-étage). Le brûleur

principal devrait s’allumer. Passez à l’étape 7 pour les

systèmes mono-étage.

5. (bi-étage seulement) Enlevez la vis du couvercle du

régulateur de la tour d’ajustement du régulateur

de pression de sortie inférieure (g. 8) et tournez la

vis dans le sens des aiguilles d’une montre ( )

pour augmenter la pression, ou dans le sens inverse

( ) pour réduire la pression. Ajustez toujours

le régulateur conformément aux spécications

du fabricant d’origine qui gurent sur la plaque

signalétique de l’appareil. Remettez la vis du

couvercle du régulateur.

6. (bi-étage seulement) Réglez le thermostat pour qu’il

commande l’étage supérieur.

7. Enlevez la vis du couvercle du régulateur de la tour

d’ajustement du régulateur de pression de sortie

supérieure (g. 8) et tournez la vis dans le sens des

aiguilles d’une montre ( ) pour augmenter

la pression, ou dans le sens inverse ( ) pour

réduire la pression. Ajustez toujours le régulateur

conformément aux spécications du fabricant

d’origine qui gurent sur la plaque signalétique de

l’appareil. Remettez la vis du couvercle du régulateur.

8. Coupez toute alimentation électrique du système.

9. Enlevez le exible du manomètre et tournez la vis

d’essai de pression de sortie vers l’intérieur pour

sceller l’orice de pression (sens des aiguilles d’une

montre, minimum 7 po-lb).

10. Rétablissez l’alimentation électrique du système.

11. Mettez le système en marche et le robinet sous

tension.

12. Utilisez une solution de détection de fuite ou du savon

pour détecter les fuites autour du bouchon de la prise

de pression. La formation de bulles indique une fuite.

COUPEZ LE GAZ ET RÉPAREZ IMMÉDIATEMENT

TOUTES LES FUITES.

14

Vis du couvercle

du régulateur

Vis de réglage

en plastique

Ressort du

régulateur

Robinet mono-étage

Fig. 8

Robinet bi-étage

Vis du couvercle

du régulateur

Vis de réglage

en plastique

Ressort du régulateur

Page 15

POUR VOTRE SÉCURITÉ, LIRE AVANT L’UTILISATION

INSTRUCTIONS D’UTILISATION

COUPEZ L’ALIMENTATION DE GAZ DE L’APPAREIL

INSTRUCTIONS D’ALLUMAGE

Si ces instructions n’étaient pas respectées à la lettre, un incendie

!

AVERTISSEMENT

A. Cet appareil n’a pas de pilote. Il est équipé d’un

dispositif d’allumage qui allume automatiquement

le brûleur. Ne tentez pas d’allumer le brûleur

manuellement.

B. AVANT L’UTILISATION, sentez le pourtour

de l’appareil pour détecter toute odeur de gaz.

Assurez-vous de vérier près du plancher parce

que certains gaz sont plus lourds que l’air et se

déposent sur le plancher.

• Ne tentez pas d’allumer quelque appareil que

ce soit.

• Ne touchez à aucun commutateur électrique;

n’utilisez aucun téléphone dans l’édice.

POUR VOTRE SÉCURITÉ

« QUE FAIRE SI VOUS DÉTECTEZ UNE ODEUR

DE GAZ »

ou une explosion pourrait survenir et causer des dommages

matériels, des blessures ou des pertes de vie.

• Appelez immédiatement votre fournisseur de gaz

en utilisant le téléphone d’un voisin. Suivez les

instructions du fournisseur de gaz.

• Si vous ne pouvez pas joindre le fournisseur de

gaz, contactez les pompiers.

C. Utilisez seulement votre main pour actionner le

commutateur de gaz. N’utilisez jamais d’outils.

Si le commutateur ne bouge pas sous la force de

votre main, ne tentez pas de le réparer; appelez

un technicien qualié. La force excessive et les

tentatives de réparation peuvent causer un incendie

ou une explosion.

D. N’utilisez pas cet appareil s’il a été en contact avec

de l’eau de quelque façon que ce soit. Appelez

immédiatement un technicien qualié pour qu’il

inspecte l’appareil et remplace toute partie du

système de commande et tout contrôle de gaz qui

est entré en contact avec de l’eau.

1. ARRÊTEZ! Lisez l’information de sécurité qui gure

ci-dessus sur cette page.

2. Réglez le thermostat sur la valeur la plus basse.

3. Coupez toute alimentation électrique à l’appareil.

4. Cet appareil est pourvu d’un dispositif d’allumage

qui allume automatiquement le brûleur. Ne tentez

pas d’allumer le brûleur manuellement.

5. Enlevez le panneau de restriction d’accès.

1. Réglez le thermostat sur la valeur la plus basse.

2. Coupez toute alimentation électrique de l’appareil

s’il doit être entretenu.

3. Enlevez le panneau de restriction d’accès.

6. Attendez cinq (5) minutes pour éliminer tout gaz

résiduel. Si vous sentez du gaz, ARRÊTEZ! Suivez

la section « B » des informations de sécurité qui

gurent ci-dessus , sur cette page. Si vous ne sentez

aucun gaz, passez à l’étape suivante.

7. Enfoncez le commutateur de gaz vers la position

« ON ».

REMARQUE : N’utilisez pas une force excessive.

8. Replacez le panneau de restriction d’accès.

9. Allumez l’alimentation électrique de l’appareil.

10. Réglez le thermostat sur le réglage désiré.

11. Si l’appareil ne fonctionne pas, suivez les

instructions de la section « Pour couper le gaz

de l’appareil » et appelez un technicien ou le

fournisseur de gaz.

4. Poussez le commutateur de gaz vers la position

« OFF ». N’exercez pas une force excessive.

5. Replacez le panneau de restriction d’accès.

15

Page 16

White-Rodgers est une entreprise

d’Emerson Electric Co.

Le logo d’Emerson est une marque

de commerce et une marque de

service d’Emerson Electric Co.

www.white-rodgers.com

www.emersonclimate.com

Page 17

36J22, 36J24, 36J54 y 36J55

Válvulas de gas de combinación

DSI y HSI de una y dos etapas

INSTRUCCIONES DE INSTALACIÓN

Operador: ¡Guarde estas instrucciones para uso futuro!

EL NO LEER Y SEGUIR CON CUIDADO TODAS LAS INSTRUCCIONES

ANTES DE INSTALAR O UTILIZAR ESTE CONTROL PODRÍA CAUSAR

LESIONES PERSONALES Y/O DAÑOS MATERIALES.

DESCRIPCIÓN

Las válvulas de gas de combinación 36J22/24/54/55 están

diseñadas para aplicaciones en sistemas de encendido de

chispa directa (DSI) y encendido de supercie caliente (HSI).

Estas válvulas están equipadas con válvulas solenoides

redundantes y principales que controlan el ujo de gas a

los quemadores principales, un regulador de presión y un

interruptor de encendido/apagado de dos posiciones para

la regulación y apagado eléctrico de las válvulas solenoides.

Las 36J24 y 36J55 también están equipadas con un

regulador de presión de apertura lenta para características

de encendido más suaves. Cuando se energiza el segundo

solenoide en las válvulas de la segunda etapa, la válvula opera

en el ajuste de presión de salida (alta) de la segunda etapa.

Número de

modelo

Voltaje de

la bobina

Etapas

Características

de apertura

36J22 24V 1 Rápido No Sí Sí No

36J24 24V 1 Lento No Sí Sí No

36J54 24V 2 Rápido No Sí Sí No

36J55 24V 2 Lento No Sí Sí No

36J de una etapa

Piloto intermitente

Piloto probado

Fig. 1

HSI DSI

36J de dos etapas

Piloto en

espera

Rango de ajuste del regulador de presión (en W. C.)

Dos Etapas

Tipo

de gas

Una sola

etapa

Bajo Alto

Dif. mínimo

de bajo a alto

Natural 2.5 – 5.0 1.0 – 4.0 2.0 – 5.0 1

LP 7.0 – 12.0 4.0 – 10.0 6.0 – 12.0 2

CONTENIDO

Contenido en inglés ........................................... 1

Contenido en francés ......................................... 9

Descripción ...................................................... 17

Especicaciones .............................................. 17

Precauciones ................................................... 18

Instalación

Conexiones del sistema ...................... 19

Ajuste

Ajuste del regulador de presión .......... 23

Instrucciones de encendido .............................. 24

www.white-rodgers.com

www.emersonclimate.com

ESPECIFICACIONES

TAMAÑOS/CAPACIDADES DE LAS TUBERÍAS

Tamaños de

tuberías

disponibles

(pulgadas)

½ pulg. x ½ pulg. NPT

Tipo de gas: Gas natural

Temperatura ambiente: -40 a 175 °F (-40 a 79 °C)

Presión nominal: 14 pulg. W.C. (½ PSI) máx.

Voltaje: 24 VC A

Frecuencia: 50/60 Hz

Corriente: Una sola etapa – 0.28 A

Posiciones de montaje: Uso múltiple: el control se

Dos etapas – 0.43 A

Capacidad (BTU/hora) a una caída de presión

de 1 pulg. a través de la válvula

Gas nat. est. AGA

(1,000 btu/pie cúbico)

140,000

Gas LP (use el kit de conversión)

puede colocar en cualquier

posición

(2,500 btu/pie cúbico)

Nº DE PIEZA 37-7338A

Gas LP

226,800

1224

Page 18

ESPECIFICACIONES

ADVERTENCIA

Piezas y accesorios:

Kits de conversión de gas natural a LP regulado

• F92-0659 para una sola etapa

• F92-1008 para dos etapas

Kit de conversión de gas natural a LP no regulado

• F92-0737

Kits de conversión de gas LP a natural

• F92-0656 para una sola etapa

• F92-1011 para dos etapas

Nota: Se pueden usar dos kits para una sola etapa para

válvulas de dos etapas

PRECAUCIONES

NO COMIENCE LA INSTALACIÓN HASTA QUE LEA LAS SIGUIENTES

PRECAUCIONES.

Si no sigue estas instrucciones exactamente, se podría producir un

!

1. No apagar la electricidad o el suministro de gas

principal al sistema de calefacción podría causar

lesiones personales y/o daños materiales por

descarga, asxia por gas, incendio y/o explosión.

2. No se debe utilizar este control en circuitos que

excedan el voltaje especicado. Los voltajes más

altos dañarán el control y pueden causar riegos

de descarga o incendio.

3. NO UTILICE NUNCA UNA LLAMA NI NINGÚN

TIPO DE CHISPA PARA DETECTAR FUGAS DE

GAS, YA QUE PODRÍA CAUSAR UN INCENDIO

Y/O UNA EXPLOSIÓN.

4. No utilice un juego de control para gas natural

con gas de petróleo licuado o un juego de control

para gas de petróleo licuado con gas natural.

Pueden producirse lesiones personales y/o

daños materiales, asxia con gas, incendio y/o

explosión.

incendio o explosión, causando pérdida material, lesiones personales

o pérdida de vidas.

5. No utilice una válvula de gas que parezca estar

dañada. Una válvula dañada puede causar

lesiones personales y/o daños materiales debido

a descarga, asxia por gas, incendio y/o explosión.

Comuníquese con su proveedor para cambiar

cualquier válvula que parezca estar dañada.

6. No utilice una válvula de gas que haya estado en

contacto directo con agua. El agua que entra en

una válvula de gas puede producir daños internos

no visibles en la válvula de gas. Se podrían

producir lesiones personales y/o daños materiales,

asxia por gas, incendio y/o explosión.

Instale correctamente las tuberías de gas al control.

• No quite las tapas protectoras de la entrada o la salida hasta que esté listo para conectar el tubo de

abastecimiento a la válvula de gas.

• Utilice un tubo de abastecimiento nuevo, debidamente roscado, fresado, sin rebabas y limpio.

• Utilice la llave auxiliar sólo en las partes planas de la llave suministradas en la saliente de entrada, para

ajustar la tubería de suministro. No la utilice en la abrazadera, el solenoide ni otras partes del control.

• No ajuste excesivamente la tubería al control (50 pies/lbs. máx.).

• Instale siempre el ltro de sedimentos en la tubería de abastecimiento de gas, para evitar la contaminación

de la válvula de gas.

Si no se instala correctamente puede producirse una pérdida de gas que cause lesiones como consecuencia

de incendio o explosión.

1. No ponga en cortocircuito las terminales de la válvula de gas ni del control principal para probarlas. Los

cortocircuitos o las conexiones incorrectas pueden producir daños en el equipo, daños materiales y/o

lesiones personales.

2. Este control no está diseñado para usarse en lugares en los que pueda entrar en contacto directo con el

agua. Se debe proporcionar la protección adecuada que proteja al control de la exposición al agua (goteo,

rocío, lluvia, etc.).

3. Limpie la tubería de gas de contaminantes, líquido de corte u otras sustancias químicas que podrían

reaccionar en forma nociva con los componentes de la válvula de gas antes de instalarla.

18

ADVERTENCIA

!

PRECAUCIÓN

!

Page 19

CONEXIONES DE LAS TUBERÍAS

PRINCIPALES

NOTA

Reérase a las advertencias y precauciones de la página 2

antes de realizar la instalación. Todas las tuberías

deben cumplir con las normas y decretos locales, y/o las

normas nacionales relativas al gas combustible.

1. Apague la alimentación eléctrica al sistema en la

caja de fusibles o en el disyuntor. Apague también el

suministro de gas principal.

2. Si cambia una válvula existente, desconecte toda la

instalación de plomería y conexiones eléctricas del

control viejo.

3. El control se puede instalar en cualquier posición.

La echa en la placa inferior indica la dirección del

ujo de gas de entrada.

Dirección del

ujo de gas

INSTALACIÓN

4. Se recomienda utilizar tuberías nuevas debidamente

biseladas, fresadas y libres de rebaba y astillas.

Si utiliza tuberías viejas, asegúrese de que estén

limpias y libres de óxido, sedimentos, rebaba, astillas

y compuesto sellador viejo.

5. Aplique compuesto sellador para tuberías aprobado

para todos los tipos de gases, sólo a las roscas

macho de las uniones. NO aplique compuesto a las

primeras dos roscas (vea en la g. 2 las conexiones de

tuberías típicas).

6. Si usa un tornillo de banco o una llave de tuercas

para sostener la válvula mientras instala la tubería,

no apriete en exceso, pues podría dañar la válvula.

(Apriete: 375 pulg./lb. máximo.) No estropee la rosca

durante la instalación, pues esto puede dañar la

válvula.

7. Vea la sección CONEXIONES DEL SISTEMA para

hacer las conexiones eléctricas. Después de nalizar

todas las conexiones de gas y eléctricas, encienda

el gas y verique que no haya fugas de gas con

una solución de detección de fugas o espuma de

jabón. La formación de burbujas indica una fuga.

CIERRE EL GAS Y REPARE TODAS LAS FUGAS

INMEDIATAMENTE.

CONVERSIÓN PARA GAS DE

PETRÓLEO LICUADO

Para la conversión para gas de petróleo licuado, utilice

el kit de conversión para gas de petróleo licuado

suministrado con este control. Consulte las instrucciones

incluidas con dicho kit.

NOTA

Todas las tuberías deben cumplir con las normas y decretos

locales, y/o las normas nacionales relativas al gas combustible.

NOTA: DEBE HABER UNA VÁLVULA DE

CIERRE MANUAL INSTALADA

A MENOS DE 6 PIES DEL EQUIPO

Caída

Válvula de gas

Horizontal

3 pulg.

mínimo

Suministro de gas por tubería Suministro de gas por tubería Suministro de gas por tubería

Válvula de gas

Tubo de subida

3 pulg.

mínimo

Tubo de subida

Fig. 2 – Tubería de válvula de gas típica

NOTA: INCLUYA SIEMPRE UNA

PATA DE GOTEO EN LAS

TUBERÍAS

Caída

Horizontal

3 pulg.

mínimo

Válvula de gas

19

Page 20

INSTALACIÓN

CONEXIONES DEL SISTEMA

CONSULTE Y SIGA EL DIAGRAMA DE CONEXIONES

DEL FABRICANTE DEL APARATO. CONSULTE LAS

FIGURAS 3 Y 4 PARA LA IDENTIFICACIÓN

DE TERMINALES.

4.693 pulg. de entrada a salida

Poste de presión de entrada

.339 de Diám. +DFT.

(Tornillo de ajuste: 3/32 pulg.

de cabeza hexagonal)

Acepta una conexión de

manguera de 5/16 pulg. de DI

Fig. 3 – Características, terminales y cableado de la válvula de una sola etapa

4.693 pulg. de entrada a salida

Interruptor de

encendido/apagado

(On/Off)

(2) terminales de paleta macho

1/4 pulg. x 0.32 pulg. de espesor

Poste de presión de salida

Tornillo de ajuste: 3/32 pulg. de cabeza hexagonal

(.339 de Diám. +DFT)

Acepta una conexión de manguera de 5/16 pulg.

NOTA

Todas las conexiones se deben instalar de conformidad

con las normas y decretos relativos a la electricidad

locales y nacionales.

Compruebe siempre que el suministro de alimentación

eléctrica utilizado concuerde con el voltaje y la frecuencia

que se indican en el control de gas.

Poste de presión de salida

.339 de Diám. +DFT.

(Tornillo de ajuste: 3/32 pulg.

de cabeza hexagonal)

Acepta una conexión de

manguera de 5/16 pulg. de DI

Interruptor de

encendido/apagado

Equeta de idenficación del control

(On/Off)

Tornillo de la cubierta del regulador

(Ajuste el regulador detrás de este tornillo)

Terminal de erra de 3/16 pulg.

Válvula principal

y redundante

Poste de presión de entrada

Tornillo de ajuste: 3/32 pulg.

de cabeza hexagonal

(.339 de Diám. +DFT)

Acepta una conexión

de manguera de 5/16 pulg.

20

Tornillo de cubierta de

regulador de llama alta

(Ajuste de regulador

detrás del tornillo)

Tornillo de cubierta

de regulador de llama baja

(Ajuste de regulador

detrás del tornillo)

(1) terminal de paleta macho

de 3/16 pulg. x .032 pulg. de espesor

Interruptor de

encendido/apagado

(On/Off)

Etiqueta de identificación

del control

(3) terminales de paleta macho

de 1/4 pulg. x .032 pulg. de espesor

Interruptor de

encendido/apagado

(On/Off)

Terminal de tierra

de 3/16 pulg.

M

C

C

Hi

Fig. 4 – Características, terminales y cableado de la válvula de dos etapas

Válvula principal

y redundante

(llama baja)

Válvula de segunda

etapa (llama alta)

Page 21

INSTALACIÓN

LÍMITE

ALTERNO

TRANSFORMADOR

TERMOSTATO O CONTROLADOR

L1 (CALIENTE)

L2

DETECTOR

DE CHISPA

MV

(GND)

CONTROLADOR

DE LÍMITE

LLAMA

VÁLV ULA

DE GAS

MV

VAL

TR

TH

GND

ENCHUFE

DE CON.

CHISPA

Conexión a tierra del quemador

DETECTOR

DE LLAMA

(TIERRA)

Si el sistema requiere un conector de 3 espigas para la válvula de 2 etapas,

Este extremo se

conecta a un

conector de

3 espigas de

la caldera

use el adaptador para arnés de cables, vea la gura 5

M – Principal

Blanco

Negro

Rojo

Receptáculo hembra

de 1/4 pulg.

C – Común

Receptáculo hembra

de 1/4 pulg.

Hi – Alto

Receptáculo hembra

de 3/16 pulg.

Fig. 5 – Adaptador para arnés de cables

A la válvula

de gas nueva

L

2

LÍMITE

FLAME

PROBE

H

FPL

S

2

CONTROLLER

TRANSFORMADOR

1

ROJO

LIMIT

VÁLVULA

DE GAS

MV2

MV1

M

V

2

G

T

N

R

D

TIERRA

DEL QUEMADOR

TERMOSTATO O

M

T

V

H

1

Fig. 6 – Conexiones típicas para el sistema de encendido de supercie caliente

H

S

1

AZUL

ADAPTER

DISPOSITIVO DE

ENCENDIDO DE

SUPERFICIE CALIENTE

L1

(CALIENTE)

L2

Fig. 7 – Conexiones típicas para el sistema de encendido de chispa directa, válvula de una sola etapa

21

Page 22

AJUSTE

AJUSTE DEL REGULADOR

DE PRESIÓN

Estos controles se envían de fábrica preparados

para gas natural, con el regulador ajustado según lo

especicado en la etiqueta del control. Consulte la placa

de especicaciones del aparato para asegurarse de

que la presión del conducto del quemador sea según lo

especicado. Si se requiere otra presión de salida, siga los

pasos indicados a continuación. Para la conversión a gas

LP, use el kit de conversión de gas LP.

NOTA

GAS NATURAL

Modelos de una sola etapa – La presión de salida viene

ajustada de fábrica en el rango de 2.5 pulg. a 5 pulg.

La válvula no puede ajustarse fuera de este rango.

Modelos de dos etapas: La presión de salida mínima

viene ajustada de fábrica en el rango de 1 a 4 pulg. W.C.,

y la máxima en el rango de 2 a 5 pulg. W.C.

La válvula no puede ajustarse fuera de este rango, y el

ajuste de la presión de salida máxima siempre debe estar

al menos 1 pulg. por encima de la presión de salida mínima.

AJUSTE DE PRESIÓN DE SALIDA

1. Apague toda la alimentación eléctrica al sistema.

2. Gire una vuelta en el sentido contrario a las agujas

del reloj el tornillo de prueba de presión mínima,

pero no más de una vuelta. (Vea la gura 8)

3. Conecte una manguera y un manómetro a la saliente

de presión de salida de la válvula.

4. Encienda la alimentación al sistema. Ajuste el

termostato para una llamada de calor (etapa baja

para sistemas de dos etapas). El quemador principal

se debería encender. Siga con el paso 7 para sistemas

de una sola etapa.

5. (Sólo 2 etapas) Retire el tornillo de la cubierta del

regulador desde la torre de ajuste del regulador de

presión de salida mínima (g. 8) y gire el tornillo

hacia la derecha ( ) para aumentar la presión, o

hacia la izquierda ( ) para disminuir la presión.

Ajuste siempre el regulador de acuerdo a las

especicaciones del fabricante del equipo original

que se indican en la placa de especicaciones del

aparato. Vuelva a colocar el tornillo de la cubierta del

regulador.

6. (Sólo 2 etapas) Ajuste el termostato para llamada de

etapa alta.

7. Retire el tornillo de la cubierta del regulador desde

la torre de ajuste del regulador de presión de salida

máxima o de una sola etapa (g. 8) y gire el tornillo

hacia la derecha ( ) para aumentar la presión, o

hacia la izquierda ( ) para disminuir la presión.

Ajuste siempre el regulador de acuerdo a las

especicaciones del fabricante del equipo original

que se indican en la placa de especicaciones del

aparato. Vuelva a colocar el tornillo de la cubierta del

regulador.

8. Apague toda la alimentación eléctrica al sistema.

9. Retire la manguera del manómetro y gire el tornillo

de prueba de presión de salida hacia adentro para

sellar el puerto de presión (en el sentido de las agujas

del reloj, 7 pulg./lb. como mínimo).

10. Encienda la alimentación eléctrica del sistema.

11. Encienda el sistema y energice la válvula.

12. Utilizando una solución para detección de fugas o

espuma de jabón, verique que no haya fugas en

el tornillo del saliente de presión. La formación de

burbujas indica una fuga. CIERRE EL GAS Y REPARE

TODAS LAS FUGAS INMEDIATAMENTE.

22

Tornillo de la

cubierta del

regulador

Tornillo de ajuste

de plástico

Resorte del

regulador

Válvula de una sola etapa

Fig. 8

Válvula de dos etapas

Tornillo de la cubierta

del regulador

Tornillo de ajuste

de plástico

Resorte del regulador

Page 23

POR SU SEGURIDAD, LEA ANTES DE UTILIZAR

INSTRUCCIONES DE USO

PARA CERRAR EL GAS QUE LLEGA AL APARATO

ADVERTENCIA

!

Si no sigue estas instrucciones exactamente, puede producirse un

incendio o una explosión y, como consecuencia, daños materiales,

lesiones personales o la pérdida de vidas.

INSTRUCCIONES DE ENCENDIDO

A. Este aparato no tiene piloto. Cuenta con

un dispositivo de encendido que enciende

automáticamente el quemador. No intente

encender el quemador a mano.

B. ANTES DE UTILIZAR el aparato huela a su

alrededor para detectar si hay olor a gas. Asegúrese

de oler cerca del suelo, ya que algunos gases son

más pesados que el aire y se depositan sobre el

suelo.

POR SU SEGURIDAD

“¿QUÉ HACER SI SIENTE OLOR A GAS?”

• No intente encender ningún aparato.

• No toque ningún interruptor eléctrico; no utilice

ningún teléfono de su edicio.

1. ¡ALTO! Lea la información de seguridad que se

encuentra en la parte de arriba de esta página.

2. Ajuste el termostato al valor más bajo.

3. Apague toda la alimentación eléctrica al aparato.

4. Este aparato cuenta con un dispositivo de

encendido que enciende automáticamente el

quemador. No intente encender el quemador

a mano.

• Llame inmediatamente a su proveedor de

gas desde el teléfono de un vecino. Siga las

instrucciones del proveedor de gas.

• Si no puede encontrar a su proveedor de gas,

llame a los bomberos.

C. Utilice solamente la mano para mover el interruptor

de control de gas. No utilice herramientas en ningún

caso. Si el interruptor no se mueve a mano, no intente

repararlo; llame a un técnico de servicio calicado.

El uso de la fuerza o cualquier intento de reparación

pueden producir un incendio o una explosión.

D. No utilice este aparato si alguna parte ha estado

bajo el agua. Llame inmediatamente a un técnico de

servicio calicado para que inspeccione el aparato y

cambie las partes del sistema de control y cualquier

control de gas que haya estado bajo el agua.

5. Retire el panel de acceso del control.

6. Espere cinco (5) minutos para eliminar el gas.

Si huele gas, ¡DETÉNGASE! Siga el punto “B” de

la información de seguridad que se encuentra en

la parte de arriba de esta página. Si no huele gas,

continúe con el paso siguiente.

7. Coloque el interruptor de control de gas en la

posición de encendido (“ON”).

NOTA: No lo fuerce.

8. Vuelva a colocar el panel de acceso del control.

9. Encienda toda la alimentación eléctrica al aparato.

10. Ajuste el termostato al valor deseado.

11. Si el aparato no funciona, siga las instrucciones de

la sección “Para apagar el gas que llega al aparato”

y llame a su técnico o proveedor de gas.

1. Ajuste el termostato al valor más bajo.

2. Apague toda la alimentación eléctrica al aparato si

se debe realizar algún servicio de reparación.

3. Retire el panel de acceso del control.

4. Coloque el interruptor de control de gas en la

posición de encendido (“ON”). No lo fuerce.

5. Vuelva a colocar el panel de acceso del control.

23

Page 24

White-Rodgers es una empresa

de Emerson Electric Co.

El logotipo de Emerson es una

marca comercial y una marca de

servicio de Emerson Electric Co.

www.white-rodgers.com

www.emersonclimate.com

Loading...

Loading...