Page 1

EMC® Data Domain® DS60 Expansion

Shelf Installation and FRU Replacement

Hardware Guide

302-002-099

REV. 02

Page 2

Copyright © 2015-2017 EMC Corporation All rights reserved.

Published January 2017

Dell believes the information in this publication is accurate as of its publication date. The information is subject to change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED “AS-IS.“ DELL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WITH RESPECT TO THE INFORMATION IN THIS PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. USE, COPYING, AND DISTRIBUTION OF ANY DELL SOFTWARE DESCRIBED

IN THIS PUBLICATION REQUIRES AN APPLICABLE SOFTWARE LICENSE.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may be the property of their respective owners.

Published in the USA.

EMC Corporation

Hopkinton, Massachusetts 01748-9103

1-508-435-1000 In North America 1-866-464-7381

www.EMC.com

2 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 3

CONTENTS

Figures

Tables

Chapter 1

Chapter 2

7

11

Preface 13

Revision history 15

Technical Specifications 17

Disk drive type............................................................................................ 18

Network cabling.......................................................................................... 18

System operating limits...............................................................................18

Shipping and storage requirements.............................................................19

Dimensions and weight................................................................................19

Shelf Installation and Removal 21

Shelf installation......................................................................................... 22

Installing rails................................................................................. 22

Working with the portable lift........................................................ 25

Reconfiguring the lift with Voyager kit.......................................... 26

Adjusting the arms for a frontal lift................................................ 27

Installing the shelf onto the rails.................................................... 27

Inserting and securing the top cover and chassis........................... 31

Shelf removal............................................................................................. 35

Working with the portable lift........................................................ 35

Planning your lift........................................................................... 35

Removing the front bezel.............................................................. 36

Pulling the shelf chassis out...........................................................37

Removing a shelf from the cabinet................................................ 38

Using the lift on a shelf more than 49" above the floor.................. 44

Using the Lift on a shelf 49" or less above the floor.......................48

1U cable management tray installation (underneath)..................................52

Racks and rails...............................................................................52

Installing the 1U cable management tray........................................53

Disconnecting cables for an shelf installed with the 1U cable

management tray.......................................................................... 59

1U cable tray removal................................................................................. 59

Removing the 1U cable tray........................................................... 59

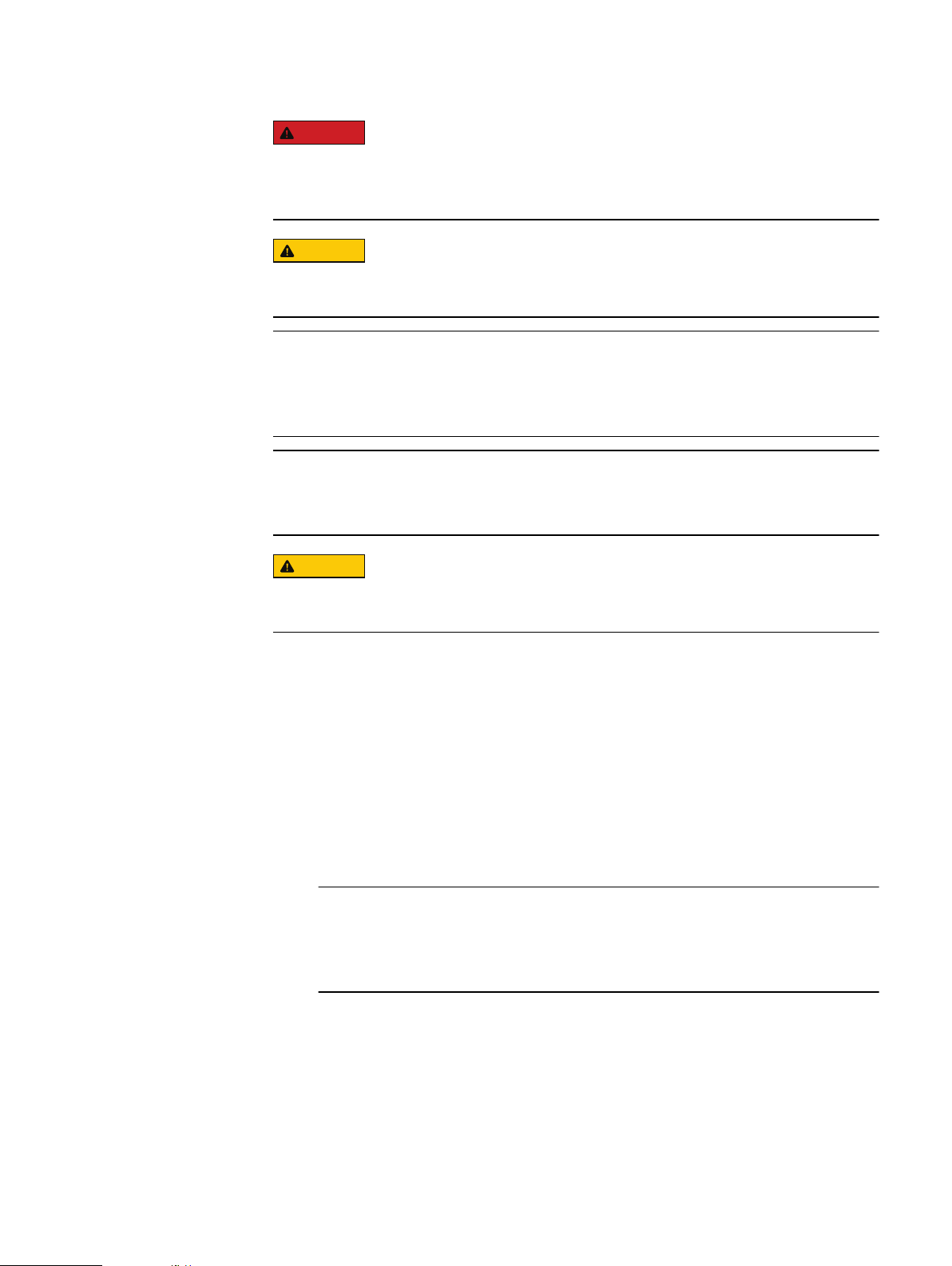

Non-EMC rack installation..........................................................................62

Shelf rail installation in non-EMC racks......................................... 62

Removing the universal rails....................................................................... 74

Chapter 3

EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide 3

Removing and Replacing FRUs 75

Common procedures ..................................................................................76

Avoiding electrostatic discharge (ESD) damage ........................... 76

Emergency procedures (without an ESD kit).................................76

Page 4

CONTENTS

Hardware acclimation times........................................................... 77

Removing, installing, or storing replaceable units...........................78

Unpacking a part............................................................................79

Standard touch point colors...........................................................79

Power supply replacement......................................................................... 80

Identify the failed power supply unit..............................................80

Removing a power supply unit........................................................81

Replacing a power supply............................................................... 81

Verify the power supplies.............................................................. 82

Complete the procedure................................................................ 83

LCC replacement........................................................................................83

Identify the failed ..........................................................................83

Removing an LCC.......................................................................... 84

Replacing an LCC.......................................................................... 84

Verify the ......................................................................................85

Complete the procedure................................................................86

Disk replacement........................................................................................86

Identify the failed drive..................................................................86

Opening the console...................................................................... 89

Removing the front bezel.............................................................. 89

Pulling the shelf chassis out.......................................................... 90

Removing a disk drive.....................................................................91

Installing a disk.............................................................................. 92

Verify the operation of the new disk drive .................................... 93

Installing the front bezel................................................................ 94

Complete the procedure................................................................ 94

Fan replacement.........................................................................................94

Identify the failed fan unit..............................................................94

Removing the front bezel.............................................................. 95

Pulling the shelf chassis out...........................................................96

Removing a fan module................................................................. 96

Installing a fan................................................................................97

Verify the fans............................................................................... 98

Installing the front bezel................................................................ 99

Complete the procedure................................................................99

Chassis removal..........................................................................................99

Working with the portable lift........................................................ 99

Reconfiguring the lift with Voyager kit.........................................100

Adjusting the arms for a frontal lift............................................... 101

Removing a power supply unit......................................................102

Removing an LCC.........................................................................103

Opening the console.....................................................................104

Removing the front bezel............................................................. 104

Removing a disk drive.................................................................. 105

Removing a fan module................................................................ 106

Removing a shelf from the cabinet............................................... 107

Chassis replacement..................................................................... 113

Installing the front bezel...............................................................128

DS60 bezel replacement........................................................................... 128

Removing the front bezel............................................................. 128

Installing the front bezel...............................................................129

DS60 cable management assembly (CMA) bezel...................................... 129

Removing the CMA front bezel.................................................... 129

Installing the CMA front bezel......................................................130

DS60 cable management assembly (CMA) replacement...........................130

Removing the 1U cable tray..........................................................130

4 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 5

CONTENTS

Installing the 1U cable tray............................................................133

Connecting cables to the shelf..................................................... 137

DS60 rail replacement............................................................................... 137

Working with the portable lift....................................................... 137

Reconfiguring the lift with Voyager kit......................................... 138

Adjusting the arms for a frontal lift...............................................138

Removing a power supply unit......................................................139

Removing an LCC.........................................................................140

Opening the console..................................................................... 141

Removing the front bezel..............................................................141

Removing a disk drive...................................................................142

Removing a fan module................................................................ 143

Removing a shelf from the cabinet............................................... 144

Removing the universal rails..........................................................151

Installing rails............................................................................... 152

Installing the shelf onto the rails...................................................155

Inserting and securing the top cover and chassis......................... 159

Replacing a power supply............................................................. 163

Replacing an LCC......................................................................... 163

Installing a disk............................................................................. 164

Installing a fan.............................................................................. 165

Connecting cables to the shelf..................................................... 166

Verify the chassis replacement.....................................................167

Installing the front bezel...............................................................167

DS60 cable management assembly (CMA) rail replacement..................... 167

1U cable tray removal................................................................... 167

1U cable management tray installation (underneath)....................170

Chapter 4

Adding Disks 177

Verify system health..................................................................................178

Identify the first empty disk pack in the target enclosure..........................178

Locate the target enclosure in the rack.....................................................179

Opening the console..................................................................................179

Removing the front bezel.......................................................................... 179

Pulling the shelf chassis out...................................................................... 180

Add new disks............................................................................................181

Close the shelf chassis.............................................................................. 182

Verify and configure the new storage........................................................182

Installing the front bezel........................................................................... 185

EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide 5

Page 6

CONTENTS

6 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 7

FIGURES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

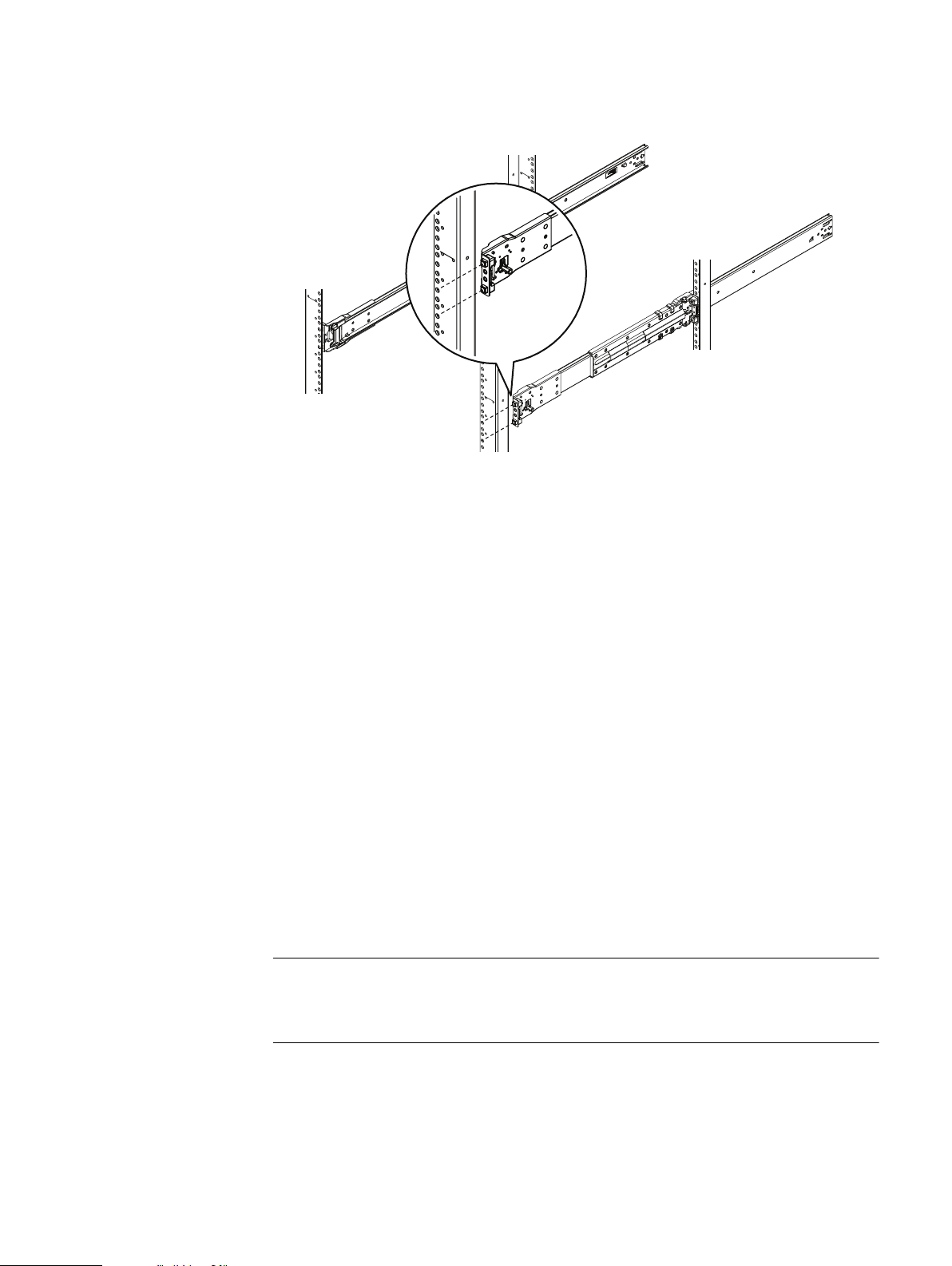

Rail installation........................................................................................................... 23

Installing the right rail to the rear channel ..................................................................24

Installing the right rail to the front channel ................................................................ 25

Reconfiguring the portable lift with the Voyager conversion kit ................................ 26

Adjusting the lift arm bar to just under 17 inches ........................................................27

Sliding the shelf chassis into the rails ........................................................................ 29

Unlocking the casters................................................................................................. 29

Locking the casters.................................................................................................... 30

Removing the straps...................................................................................................30

Inserting and securing the chassis to the cabinet........................................................ 31

Inserting and Securing the Chassis to the Cabinet (Shoulder Screw Configuration)

................................................................................................................................... 32

Removing semi-captive screws...................................................................................32

Installing ears to rack using truss head screws........................................................... 33

Installing top cover using truss head screws...............................................................34

Removal of semi-captive screws................................................................................ 35

Best Practice: Using the portable lift adjacent to the long side of the shelf................36

Removing the front bezel ...........................................................................................37

Pulling the Chassis Out (Two shoulder Screw Configuration).....................................38

Example of adjusting the lift arm/tray to just under 17-inches....................................39

Releasing chassis from the rails.................................................................................. 40

Removing the shipping screws, if present.................................................................. 40

Pulling the chassis out (two shoulder screw configuration).........................................41

Reconfiguring the Alum-A-Lift with the conversion kit................................................41

Locking the casters.................................................................................................... 42

Removing a shelf from rails more than 49" above the floor ........................................43

Tightening the straps..................................................................................................44

Unlocking the casters................................................................................................. 44

Adjusting the arm for a high rail position.....................................................................45

Locking the Casters....................................................................................................46

Removing a Shelf from rails more than 49" above the floor ....................................... 46

Tightening the straps..................................................................................................47

Unlocking the casters................................................................................................. 47

Support table..............................................................................................................48

Removing the straps...................................................................................................48

Adjusting the arm for a low rail position...................................................................... 49

Locking the casters.................................................................................................... 50

Removing a shelf from rails 49" or less above the floor ............................................. 50

Tightening the straps.................................................................................................. 51

Unlocking the casters..................................................................................................51

Removing the straps...................................................................................................52

Blue tab on rail must be pushed in.............................................................................. 53

Installing/Securing rails - front................................................................................... 54

Installing/Securing rails - rear.................................................................................... 54

Installing tray..............................................................................................................55

Spring Clips - push up to release tray......................................................................... 55

Opening the cable chain lids....................................................................................... 55

Cable positioning in cable chains................................................................................ 56

1-Inch graduation label................................................................................................56

Attaching cable chains to tray.................................................................................... 57

Installing the chassis bracket into the shelf................................................................ 57

Installing the chassis bracket......................................................................................58

Installing the bezel......................................................................................................58

EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide 7

Page 8

FIGURES

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

Remove the bezel.......................................................................................................59

Remove chassis bracket from chassis........................................................................ 60

Remove the chassis bracket.......................................................................................60

Unclip the cable chains from the tray..........................................................................61

Push spring clips up to release the tray.......................................................................61

Remove the tray.........................................................................................................62

Screw and nut placements......................................................................................... 63

18"-22" marking..........................................................................................................64

26"-30" Marking........................................................................................................ 65

30"-34" Marking........................................................................................................ 65

Rail installation........................................................................................................... 68

Securing a rail with a single screw ............................................................................. 70

Location of securing screws and alignment pins ......................................................... 71

Nutbar installation (Left nutbar shown)......................................................................73

Removing the universal rails....................................................................................... 74

Opening the console...................................................................................................89

Removing the front bezel .......................................................................................... 90

Pulling the Chassis Out (Two shoulder Screw Configuration)..................................... 91

Removing a disk drive.................................................................................................92

Installing a disk........................................................................................................... 93

Removing the front bezel .......................................................................................... 95

Pulling the Chassis Out (Two shoulder Screw Configuration).................................... 96

Reconfiguring the portable lift with the Voyager conversion kit ................................101

Adjusting the lift arm bar to just under 17 inches ...................................................... 102

Opening the console..................................................................................................104

Removing the front bezel .........................................................................................105

Removing a disk drive............................................................................................... 105

Example of adjusting the lift arm/tray to just under 17-inches.................................. 108

Releasing chassis from the rails................................................................................ 109

Removing the shipping screws, if present................................................................. 109

Pulling the chassis out (two shoulder screw configuration)....................................... 110

Reconfiguring the Alum-A-Lift with the conversion kit.............................................. 110

Locking the casters.................................................................................................... 111

Removing a shelf from rails more than 49" above the floor .......................................112

Tightening the straps.................................................................................................113

Unlocking the casters................................................................................................ 113

Reconfiguring the portable lift with the Voyager conversion kit ................................115

Adjusting the lift arm bar to just under 17 inches .......................................................116

Sliding the shelf chassis into the rails ........................................................................118

Unlocking the casters................................................................................................ 118

Locking the casters....................................................................................................119

Removing the straps..................................................................................................119

Inserting and securing the chassis to the cabinet...................................................... 120

Inserting and Securing the Chassis to the Cabinet (Shoulder Screw Configuration)

.................................................................................................................................. 121

Removing semi-captive screws..................................................................................121

Installing ears to rack using truss head screws.......................................................... 122

Installing top cover using truss head screws..............................................................123

Removal of semi-captive screws............................................................................... 124

Installing a disk..........................................................................................................126

Removing the front bezel ......................................................................................... 129

Remove the bezel......................................................................................................129

Installing the bezel.................................................................................................... 130

Remove the bezel......................................................................................................130

Remove chassis bracket from chassis........................................................................131

Remove the chassis bracket...................................................................................... 131

8 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 9

FIGURES

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

Unclip the cable chains from the tray........................................................................ 132

Push spring clips up to release the tray..................................................................... 132

Remove the tray........................................................................................................133

Spring Clips - push up to release tray........................................................................133

Opening the cable chain lids...................................................................................... 134

Cable positioning in cable chains............................................................................... 134

1-Inch graduation label.............................................................................................. 134

Attaching cable chains to tray...................................................................................135

Installing the chassis bracket into the shelf............................................................... 135

Installing the chassis bracket.................................................................................... 136

Installing the bezel.................................................................................................... 136

Reconfiguring the portable lift with the Voyager conversion kit ............................... 138

Adjusting the lift arm bar to just under 17 inches ...................................................... 139

Opening the console.................................................................................................. 141

Removing the front bezel ......................................................................................... 142

Removing a disk drive................................................................................................142

Example of adjusting the lift arm/tray to just under 17-inches.................................. 145

Releasing chassis from the rails.................................................................................146

Removing the shipping screws, if present................................................................. 146

Pulling the chassis out (two shoulder screw configuration).......................................147

Reconfiguring the Alum-A-Lift with the conversion kit..............................................147

Locking the casters................................................................................................... 148

Removing a shelf from rails more than 49" above the floor ...................................... 149

Tightening the straps................................................................................................ 150

Unlocking the casters............................................................................................... 150

Removing the universal rails...................................................................................... 151

Rail installation.......................................................................................................... 153

Installing the right rail to the rear channel ................................................................ 154

Installing the right rail to the front channel .............................................................. 155

Sliding the shelf chassis into the rails ....................................................................... 157

Unlocking the casters................................................................................................157

Locking the casters...................................................................................................158

Removing the straps................................................................................................. 158

Inserting and securing the chassis to the cabinet......................................................159

Inserting and Securing the Chassis to the Cabinet (Shoulder Screw Configuration)

................................................................................................................................. 160

Removing semi-captive screws................................................................................. 160

Installing ears to rack using truss head screws...........................................................161

Installing top cover using truss head screws............................................................. 162

Removal of semi-captive screws............................................................................... 163

Installing a disk..........................................................................................................165

Remove the bezel......................................................................................................168

Remove chassis bracket from chassis....................................................................... 168

Remove the chassis bracket......................................................................................169

Unclip the cable chains from the tray........................................................................169

Push spring clips up to release the tray..................................................................... 170

Remove the tray........................................................................................................170

Blue tab on rail must be pushed in............................................................................. 172

Installing/Securing rails - front..................................................................................172

Installing/Securing rails - rear................................................................................... 173

Installing tray.............................................................................................................173

Spring Clips - push up to release tray........................................................................ 174

Opening the cable chain lids...................................................................................... 174

Cable positioning in cable chains............................................................................... 174

1-Inch graduation label.............................................................................................. 175

Attaching cable chains to tray................................................................................... 175

EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide 9

Page 10

FIGURES

163

164

165

166

167

168

169

Installing the chassis bracket into the shelf............................................................... 175

Installing the chassis bracket.....................................................................................176

Installing the bezel.....................................................................................................176

Opening the console..................................................................................................179

Removing the front bezel ......................................................................................... 180

Pulling the Chassis Out (Two shoulder Screw Configuration)....................................181

Installing a disk.......................................................................................................... 182

10 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 11

TABLES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Document revision history...........................................................................................15

System operating limits...............................................................................................18

Shipping and storage requirements............................................................................. 19

Shelf with no FRUs installed, dimensions and weight ................................................. 19

Shelf with FRUs installed, dimensions and weight ...................................................... 19

Pins for non-EMC racks..............................................................................................22

Truss Head Screws ....................................................................................................34

Planning your lift ........................................................................................................36

Shelf rail kit contents..................................................................................................63

Required Tools............................................................................................................63

Pins for non-EMC racks............................................................................................. 66

List of parts used in illustration, shelf rail installation.................................................. 67

List of parts used in illustration, location of securing screws and alignment pins ....... 70

List of parts used in nutbar installation illustration...................................................... 72

Hardware acclimation times (systems and components)............................................ 77

Standard touch point colors........................................................................................79

Status lights............................................................................................................... 87

Truss Head Screws .................................................................................................. 123

Pins for non-EMC racks............................................................................................ 152

Truss Head Screws .................................................................................................. 162

EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide 11

Page 12

TABLES

12 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 13

Preface

Note

WARNING

CAUTION

Contact your EMC Data Domain technical support professional if a product does not

function properly or does not function as described in this document.

This document was accurate at publication time. Go to the EMC Online Support site,

https://support.emc.com/, to ensure that you are using the latest version of this

document.

Purpose

This guide describes the steps to install and configure an EMC Data Domain DS60

Expansion Shelf.

Audience

This guide is for trained service personnel who are authorized to install and repair Data

Domain systems and end-users who are using this product.

Related Documentation

The following Data Domain system documents provide additional information:

l

DD OS Release Notes Version 5.7

l

DD OS 5.7 Initial Configuration Guide

l

DD OS 5.7 Administration Guide

l

DD OS 5.7 Command Reference Guide

l

The Data Domain system installation and setup guides for each of the supported

platforms (for example, DD4200 and DD9500)

l

For Data Domain Systems that have ES20 shelves installed:

Data Domain ES20

Expansion Shelf Hardware Guide.

l

For Data Domain Systems that have ES30 shelves installed:

Data Domain ES30

Expansion Shelf Hardware Guide.

l

For Data Domain Systems that have DS60 shelves installed:

Data Domain DS60

Expansion Shelf Hardware Guide.

l

Data Domain System Safety and Regulatory Information

(P/N 770-0002-0002)

Special Notice Conventions Used in this Document

EMC uses the following conventions for special notices:

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Preface 13

Page 14

NOTICE

Note

Preface

Addresses practices not related to personal injury.

Presents information that is important, but not hazard-related.

Typographical conventions

EMC uses the following type style conventions in this document:

Bold

Use for names of interface elements, such as names of windows,

dialog boxes, buttons, fields, tab names, key names, and menu paths

(what the user specifically selects or clicks)

Italic

Monospace

Monospace italic

Monospace bold

Use for full titles of publications referenced in text

Use for:

l

System code

l

System output, such as an error message or script

l

Pathnames, filenames, prompts, and syntax

l

Commands and options

Use for variables

Use for user input

[ ] Square brackets enclose optional values

| Vertical bar indicates alternate selections - the bar means “or”

{ } Braces enclose content that the user must specify, such as x or y or

z

... Ellipses indicate nonessential information omitted from the example

Technical support

To resolve issues with EMC Data Domain products, contact your contracted support

provider or visit us online at https://support.emc.com/.

Your comments

Your suggestions will help us continue to improve the accuracy, organization, and

overall quality of the user publications. Send your opinions of this document to

DPAD.Doc.Feedback@emc.com.

14 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 15

Revision history

Table 1 Document revision history

Revi

Date Document

sion

part

number/

Revision

number

Software

version

Description

02 January

2017

01 October

2015

302-002-099

REV 02

302-002-099

REV 01

6.0

5.7 Initial publication.

l

Added FRU procedures for the

CMA, the shelf and CMA

bezels, and shelf and CMA rail

kits.

l

Added the disk pack upgrade

procedure.

Revision history 15

Page 16

Revision history

16 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 17

CHAPTER 1

Technical Specifications

l

Disk drive type.................................................................................................... 18

l

Network cabling..................................................................................................18

l

System operating limits...................................................................................... 18

l

Shipping and storage requirements.................................................................... 19

l

Dimensions and weight....................................................................................... 19

Technical Specifications 17

Page 18

Note

NOTICE

Technical Specifications

Disk drive type

Serial Attached SCSI (SAS) are 12-volt, and support the SAS interface. Firmware and

drive carriers are unique to EMC. Refer to EMC Online Support for a listing of the

supported drives.

Network cabling

Only 3M, 4M and 5M are used with Data Domain shelves.

System operating limits

The ambient temperature specification is measured at the front bezel inlet. The site

must have air conditioning of the correct size and placement to maintain the specified

ambient temperature range and offset the heat dissipation listed below.

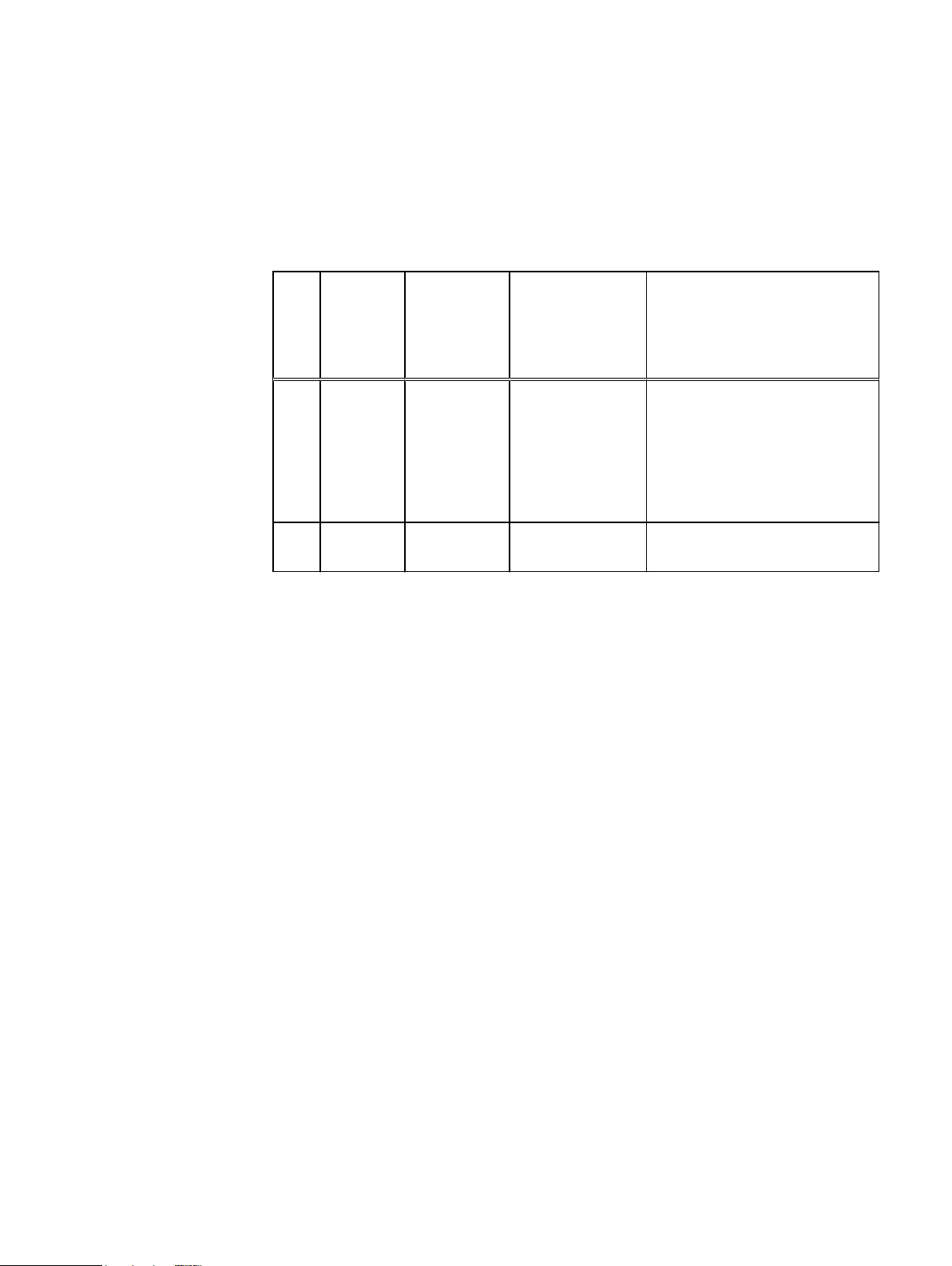

Table 2 System operating limits

Requirement Description

Ambient temperature 41°F to 104°F (5°C to 40°C)

Temperature gradient 18°F/hr (10°C/hr)

Relative humidity (extremes) 20% to 80% noncondensing

Relative humidity (recommended) 40% to 55% noncondensing

Elevation -50 to 35,000 ft (-16 to 10,600 m)

The allowable relative humidity level is 20 to 80% noncondensing. However, the recommended

operating environment range is 40 to 55%. To minimize the risk of hardware corrosion and

degradation, we recommend lower temperatures and humidity for data centers with gaseous

contamination such as high sulfur content. In general, the humidity fluctuations within the

data center should be minimized. We also recommend that the data center be positively

pressured and have air curtains on entry ways to prevent outside air contaminants and

humidity from entering the facility. For facilities below 40% relative humidity, we recommend

grounding straps when contacting the equipment to avoid the risk of Electrostatic discharge

(ESD), which can harm electronic equipment.

For systems mounted in a cabinet, the operating limits listed above must not be

exceeded inside the closed cabinet. Equipment mounted directly above or below an

shelf must not restrict the front-to-rear airflow of the storage system. Cabinet doors

must not impede the front-to-rear airflow. The cabinet must exhaust air at a rate that

is equal to or greater than the sum of the exhaust rates of all the equipment mounted

in the cabinet.

18 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 19

Shipping and storage requirements

NOTICE

Systems and components must not experience changes in temperature and humidity

that are likely to cause condensation to form on or in that system or component. Do

not exceed the shipping and storage temperature gradient of 45°F/hr (25°C/hr).

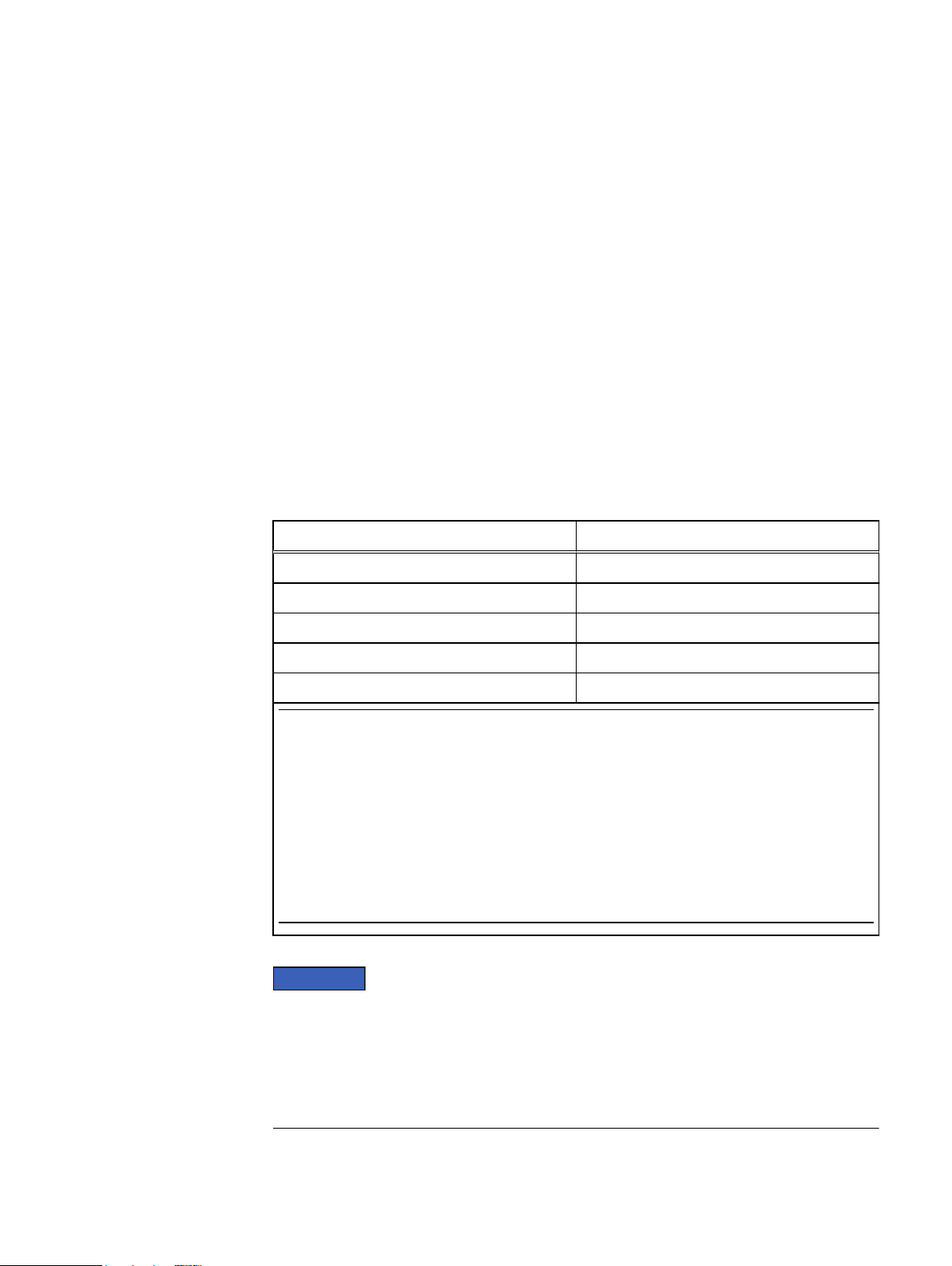

Table 3 Shipping and storage requirements

Requirement Description

Ambient temperature -40° F to 149°F (-40°C to 65°C)

Temperature gradient 45°F/hr (25°C/hr)

Relative humidity 10% to 90% noncondensing

Elevation -50 to 35,000 ft (-16 to 10,600 m)

Technical Specifications

Dimensions and weight

Table 4

Table 5 Shelf with FRUs installed, dimensions and weight

Shelf with no FRUs installed, dimensions and weight

Dimensions Vertical size Weight

Height: 8.75 in (22.23 cm) 5U

( 4U plus 1U cable

management tray)

Width, including rails: 17.50 in

(44.45 cm)

Depth: Chassis only: 34.5 in

(92.23 cm)

Greatest Feature Depth

36.35in (92.33 cm)

Dimensions Vertical size Weight

Height: 8.75 in (22.23 cm) 5U

( 4U plus 1U cable

management tray)

Standard IEC-310 NEMA 19" 55.0 lb (20.4 kg)

Width: 17.50 in (44.45 cm)

Depth: 34.5 in (92.23cm)

Greatest Feature Depth

36.35in (92.33 cm)

Standard IEC-310 NEMA 19" 225.0 lb (90.7 kg)

Shipping and storage requirements 19

Page 20

Technical Specifications

20 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 21

CHAPTER 2

Shelf Installation and Removal

l

Shelf installation.................................................................................................22

l

Shelf removal..................................................................................................... 35

l

1U cable management tray installation (underneath)......................................... 52

l

1U cable tray removal.........................................................................................59

l

Non-EMC rack installation................................................................................. 62

l

Removing the universal rails............................................................................... 74

Shelf Installation and Removal 21

Page 22

CAUTION

Shelf Installation and Removal

Shelf installation

This section describes how to install a shelf into a rack.

Installing rails

You should install the rails from the front of the cabinet into which you are installing

the shelf. The 4U includes "inner rails" that slide into the cabinet rail assembly.

Exercise care when installing the short rails. Exposed metal edges may be sharp

and could damage cabling or cause injury to personnel.

Procedure

1. Locate the 4U cabinet space designated for the enclosure.

2. If the rails need to be adjusted, refer to Modifying rail lengths

3. The rails are shipped with M5 adaptors which are designed to fit into the NEMA

channels of an EMC rack. If the rails are being installed in an EMC rack.

Proceed to step 3. If the rails are being installed in a non-EMC rack, proceed as

follows:

a. Using a flat-bladed screwdriver, remove the two M5 adaptors from the

adaptor mounting block on the rails.

b. Identify the correct adaptors needed from the hardware kit and install the

adaptors into the adaptor mounting block. Refer to the following table.

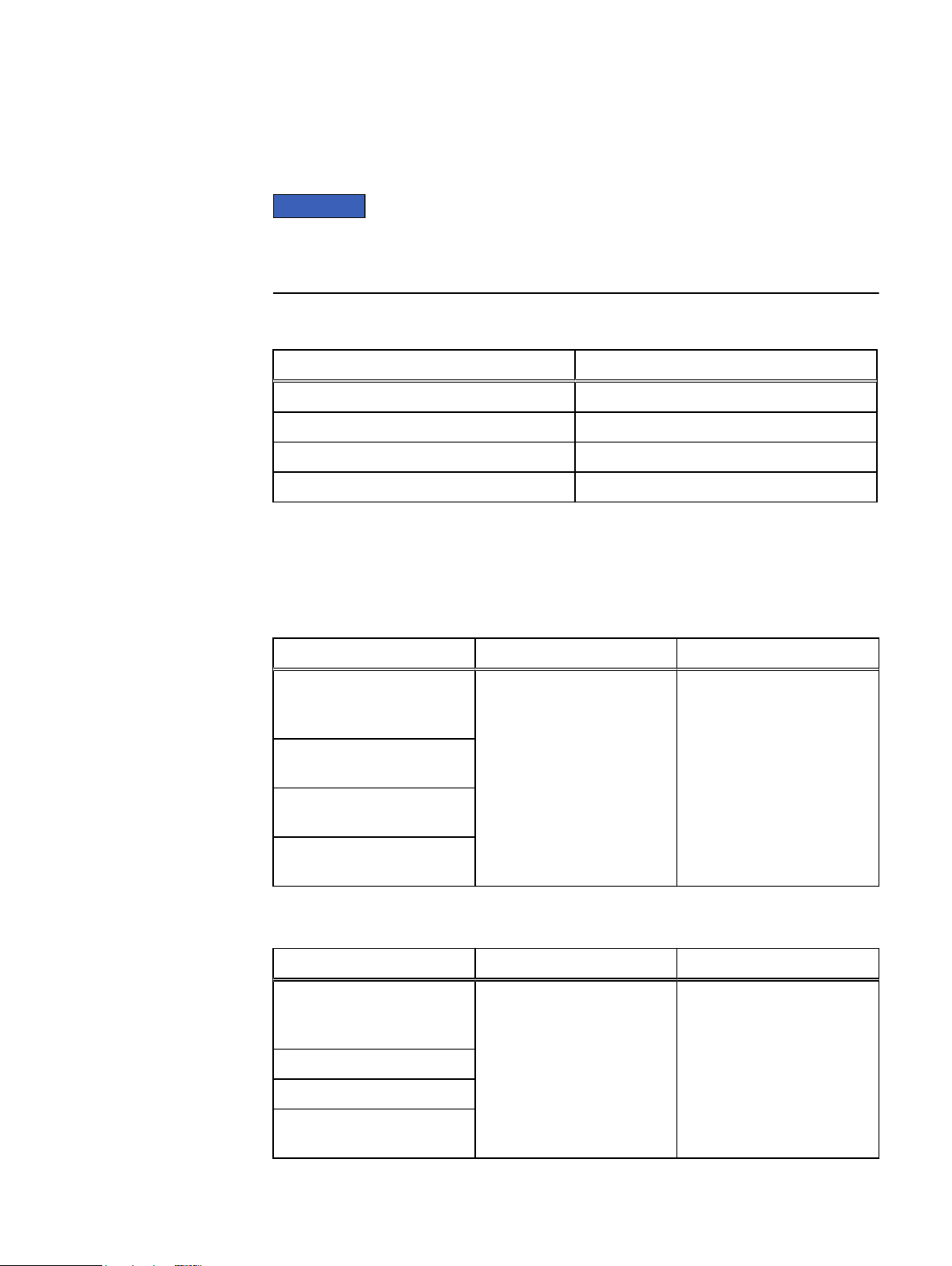

Table 6

Pins for non-EMC racks

Rail Pins from kit Part Number and

Suggested Use

Description

036-028-018

Custom screw, M4 x 10MM

(Quantity: 4 per kit)

036-028-016

3.8MM Alignment Pin

(Quantity: 8 per kit)

036-028-017

4.8MM Alignment Pin

(Quantity: 8 per kit)

Used for any non-EMC

rack. Can be used in racks

with threaded holes.

Used in racks that have

M5, #10, or #12 threaded

holes.

Used in racks that have M6

threaded holes.

22 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

4. Install the right rail to the rack rear channel. Later sections will detail how to

adjust rails, if necessary.

Page 23

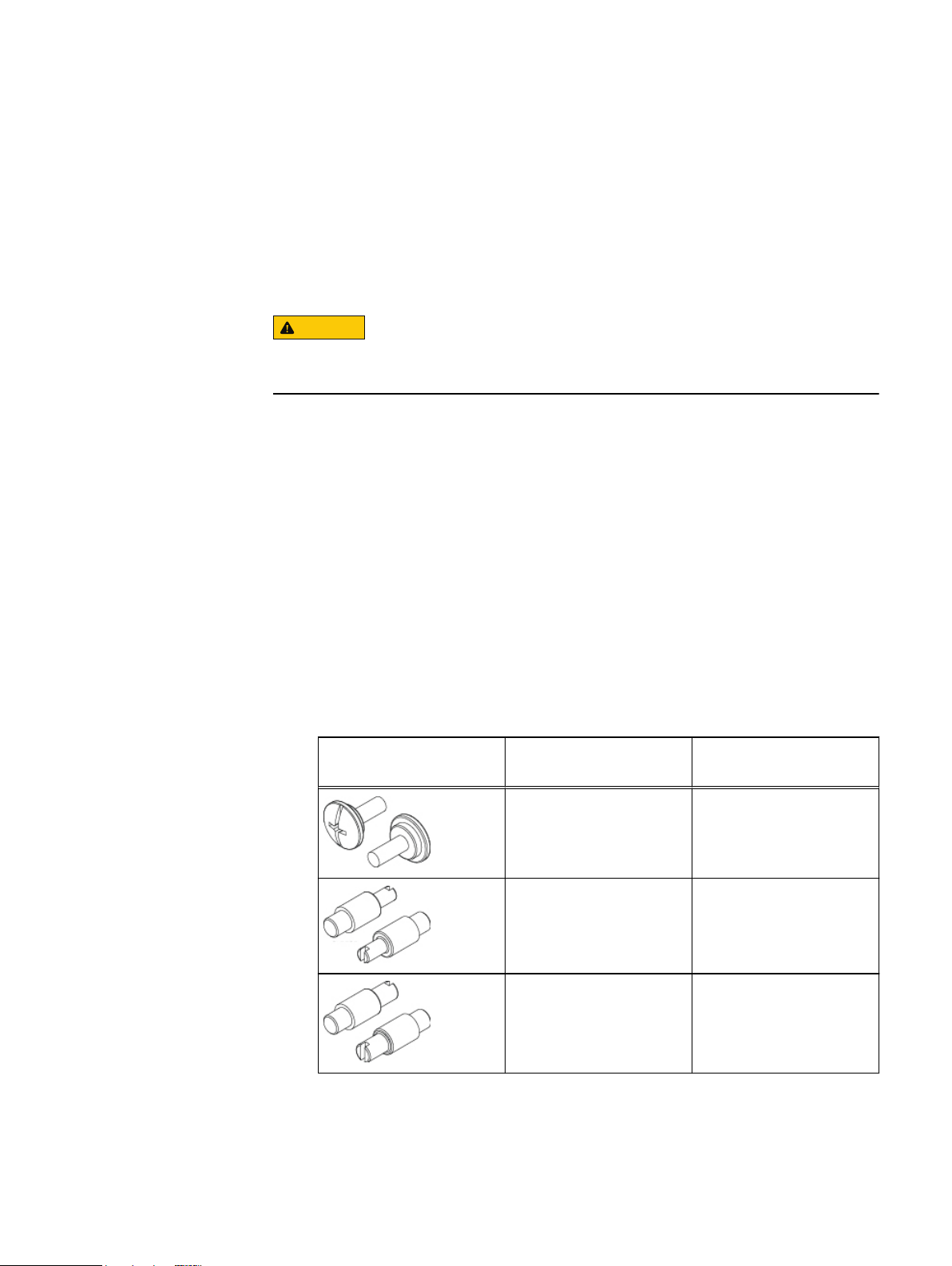

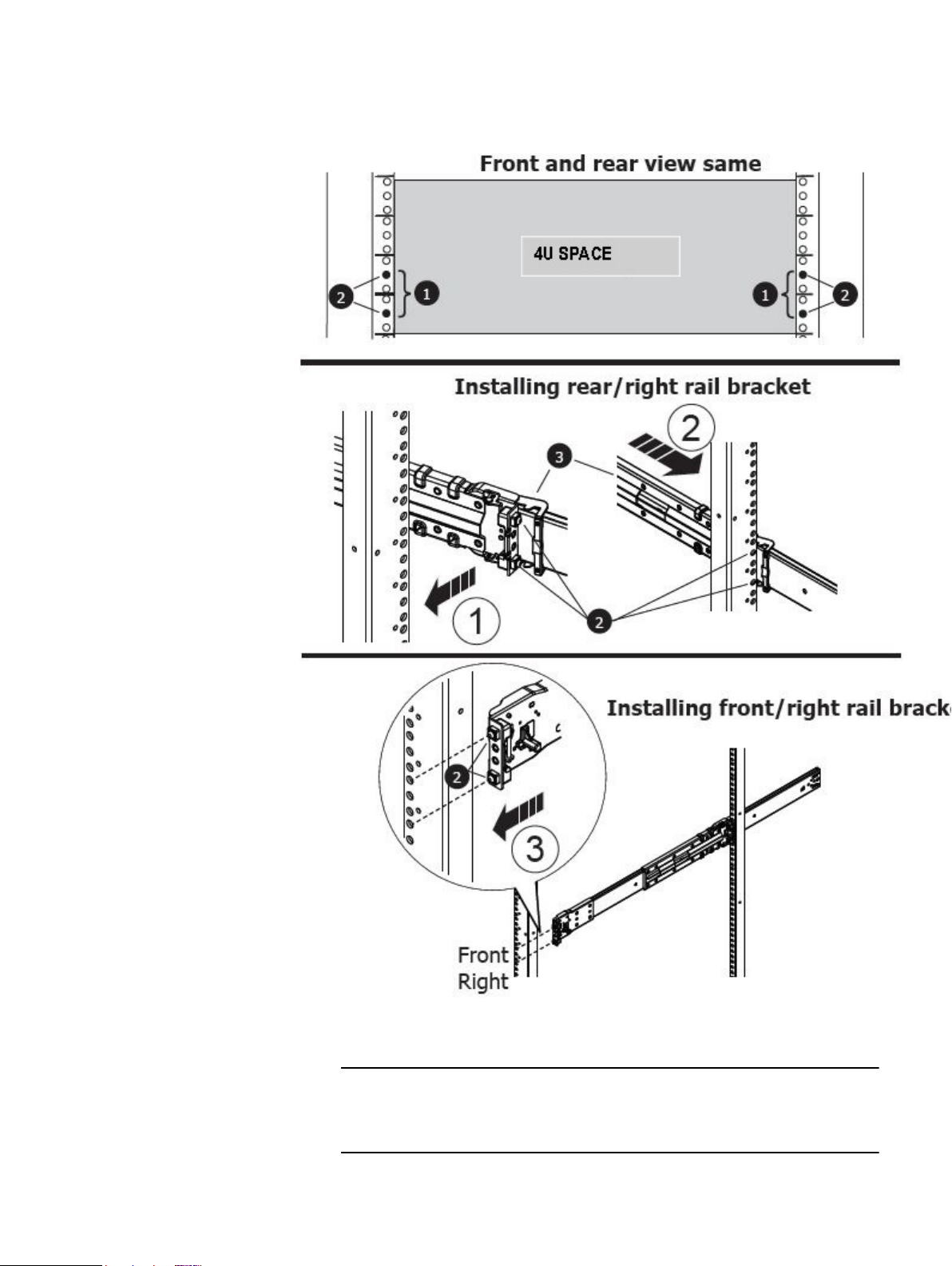

Figure 1 Rail installation

Note

Shelf Installation and Removal

a. Align the right rail with the lower U of the allotted 4U space.

Each of the rail alignment pins must be located in the middle holes of the

bottom two U spaces of the 4U space.

Installing rails 23

Page 24

2

43

CL4868

1

Shelf Installation and Removal

b. With the release latch on the outer (rear) part of the rear channel, place the

catch mechanism over the channel.

c. Push the rail back to secure the rail adaptors in the cabinet channel. An

audible click indicates that the rail is secure in the channel.

d. Make sure the rear post/catch mechanism is secure and attached.

Figure 2 Installing the right rail to the rear channel

5. Install the right rail to the front channel.

a. Align the front of the right rail so that it is level and the front rail pins are

aligned with the middle holes of the bottom two U spaces of the 4U space.

b. Pull the rail forward, with the adaptors aligned with the middle holes of the

bottom two U spaces of the 4U space.

An audible click indicates that the connection is secure.

24 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 25

Front

Right

CL4866

Note

Shelf Installation and Removal

Figure 3 Installing the right rail to the front channel

6. Install the left rail by repeating step 3 and step 4.

7. On both left and right rail assemblies, install a single long screw between the rail

posts in the upper screw hole to secure the rails as follows:

a. If the rails are being installed in an EMC rack or a rack that does not have

threaded holes, insert a single M5 screw into the larger of the two screw

holes.

b. If the rails are being installed in a non-EMC rack with threaded holes, insert

the M4 screw into the smaller of the two screw holes. The screw will be

smaller than the threaded hole and will pass through the threads.

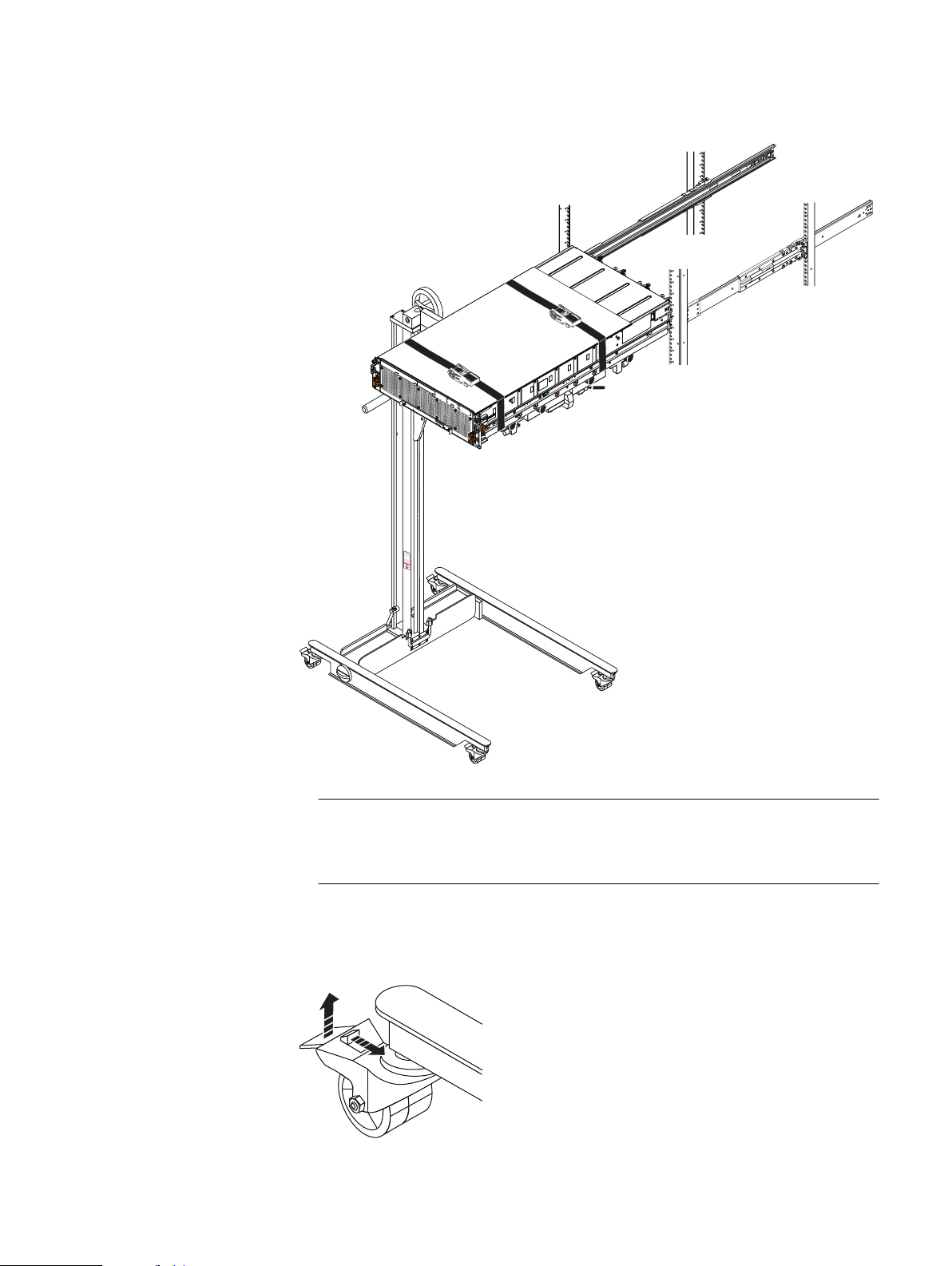

Working with the portable lift

If a shelf with all of the FRUs removed is being installed, the chassis can be installed

without using the lift. If the shelf is populated with FRUs prior to installing, then this

task requires the use of a portable lift.

The portable lift commonly used by EMC service personnel is manufactured by AlumA-Lift. Instructions for this lift are included in the lift kit. Refer to "http://

www.corkc4.isus.emc.com/wiki/index.php/Lift_Tool". which describes the Lift

equipment, the ordering process, and Links to training material. The Lift Tool Training

Video and Demo on Lift tool using the Voyager assembly (Voyager is the name given

to a Disk enclosure used on many of EMC's product range), are also linked on this

page.

If you are using a portable lift other than the Alum-A-Lift, adapt these instructions as

necessary while following all required safety requirements.

Working with the portable lift 25

Page 26

CAUTION

NOTICE

CL5422

1 2

Shelf Installation and Removal

The portable lift commonly used by EMC service personnel has two

configurations - one with the lower mast only and one with both the lower and

upper masts. The lower mast configuration is rated for 400 pounds and is for

raising or lowering objects 28U (49 inches) or less above the floor. The dual mast

configuration is rated well under 200 pounds and is for raising objects more than

28U (49 inches) above the floor.

l

For installations at or below 49 inches, you must use the lower mast

configuration.

l

For installations above 49 inches, use the "Voyager" conversion kit, rated for

225 pounds, and a support table with the lower mast configuration.

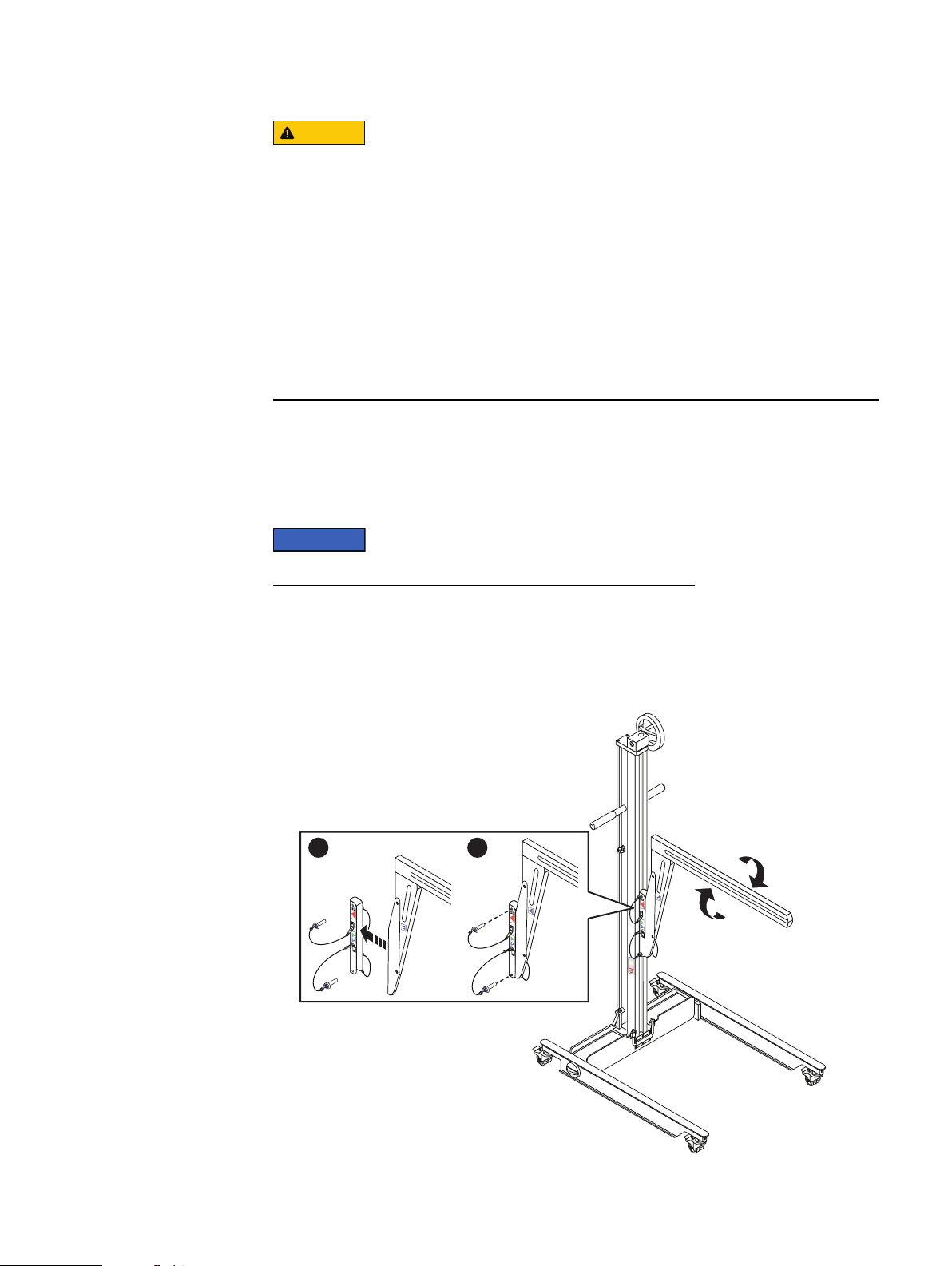

Reconfiguring the lift with Voyager kit

If you are using the Alum-A-Lift for installations or removals above 49 inches (28U),

you must use the single (lower) mast configuration with the "Voyager" conversion kit

and support table.

The "Voyager conversion kit," is used with multiple systems.

Procedure

1. Unpack the Voyager kit.

2. Use the instructions to provided within the kit to reconfigure the lift.

Figure 4

Reconfiguring the portable lift with the Voyager conversion kit

26 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 27

Adjusting the arms for a frontal lift

1

2

<17”

CL4900

If you plan to use the mechanical lift directly in front of the cabinet, adjust the lift

arm/tray width to just under 17 inches apart to ensure that the arms will stay under

the chassis. Figure 5 on page 27 shows an example of adjusting the lift arm/tray to

just under 17 inches.

Procedure

1. Add the two arms with rollers 17 inches apart measured from the outside edge

of each arm.

2. Tighten the arms to secure them.

Figure 5 Adjusting the lift arm bar to just under 17 inches

Shelf Installation and Removal

Installing the shelf onto the rails

Before you begin

If a shelf with all of the FRUs removed is being installed, the chassis can be installed

without using the lift. If the shelf is populated with FRUs prior to installing, then this

task requires the use of a portable lift.

Adjusting the arms for a frontal lift 27

Page 28

DANGER

CAUTION

Note

Note

CAUTION

Note

Shelf Installation and Removal

DO NOT ATTEMPT to install a populated shelf without a mechanical lift.

Attempting to install a populated shelf without a lift could damage the equipment

and cause injury to personnel

You should only install a shelf into a cabinet if the cabinet is equipped with antitip features.

The following procedure shows an installation using the Alum-a-Lift portable lift. If

another lift is being used, follow the manufacturer's instructions for that lift as

applicable.

A populated shelf requires two people and a lift to install. A de-populated chasses

requires three people to install.

Secure the enclosure to the portable lift using the securing straps before moving

the lift.

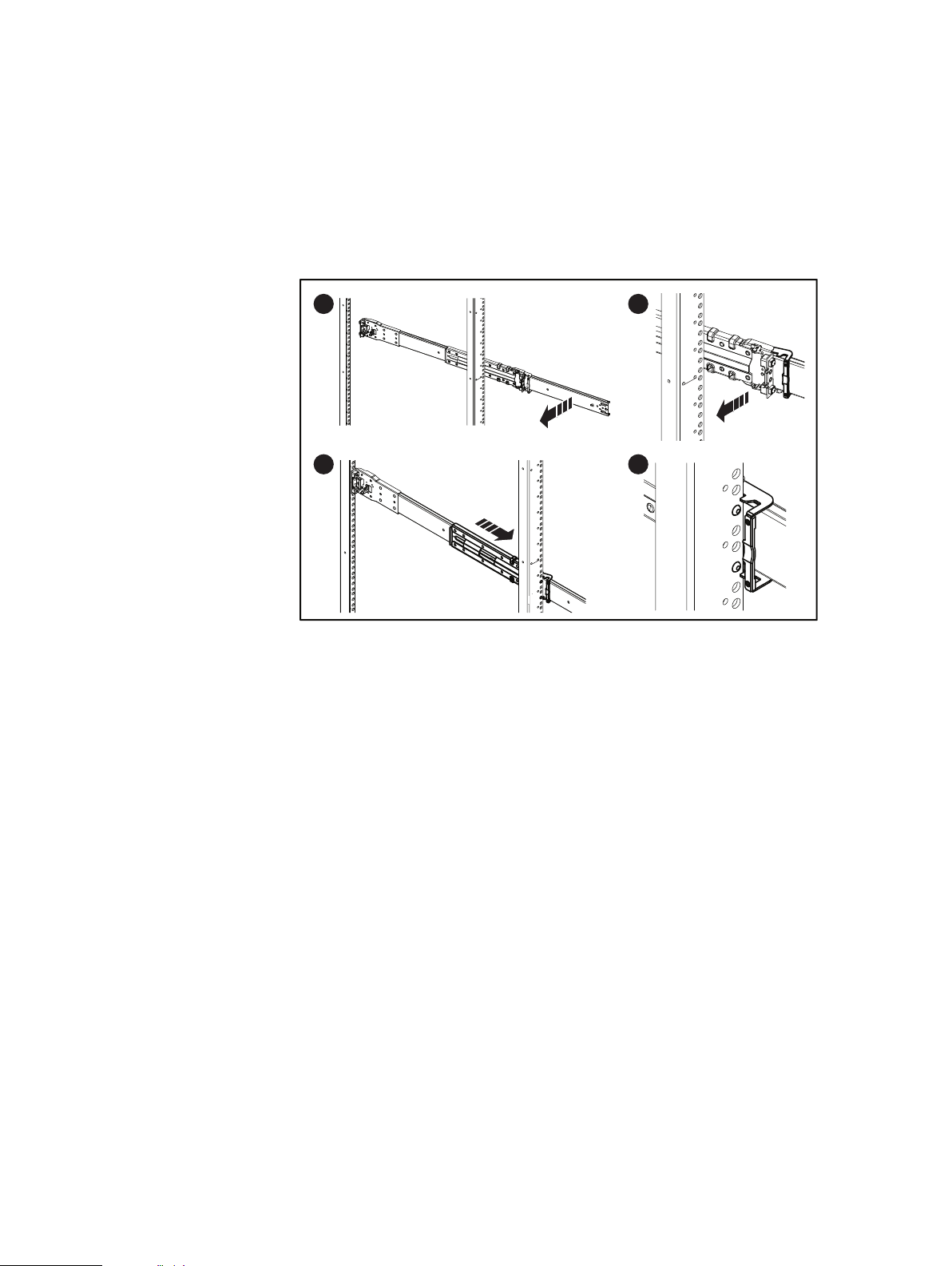

Procedure

1. If a portable lift is not available or cannot access the rack, the shelf must be depopulated before it is installed on the rails. Do the following:

a. Refer to the procedures for removing the Power Supplies, LCCs, and Fan

Modules and remove each FRU.

b. Refer to the procedure for removing the disk drives and remove the disk

drives. Label each disk drive as to its exact location so that it can be reinstalled once the chassis is installed in the cabinet.

2. Manually, or using the portable lift (shown below), align the chassis rails with

the inner rails attached to the cabinet. If using a lift, lock the casters into place.

If the chassis is being installed manually without a lift, it generally requires three

people to install. Two people to hold the chassis in place at the correct height,

and one person to align and manage the slides.

3. Manually slide the inner rail over the chassis rail 2-3 inches to line them up.

28 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 29

Figure 6 Sliding the shelf chassis into the rails

CL5431

Note

CL5424

Shelf Installation and Removal

You may need to release sagging tension on the shelf by pulling the lift arms and

tray up slightly.

4. Unlock the casters by lifting up on the locking tabs and carefully slide the shelf

into the cabinet as far as the lift will allow.

Figure 7

Unlocking the casters

Installing the shelf onto the rails 29

Page 30

CL5423

1

CL5430

2

CAUTION

Shelf Installation and Removal

5. Release the lift casters

6. Lock all four casters by pressing down on the locking tab so the lift will not roll

as the shelf is pushed into the cabinet.

Figure 8 Locking the casters

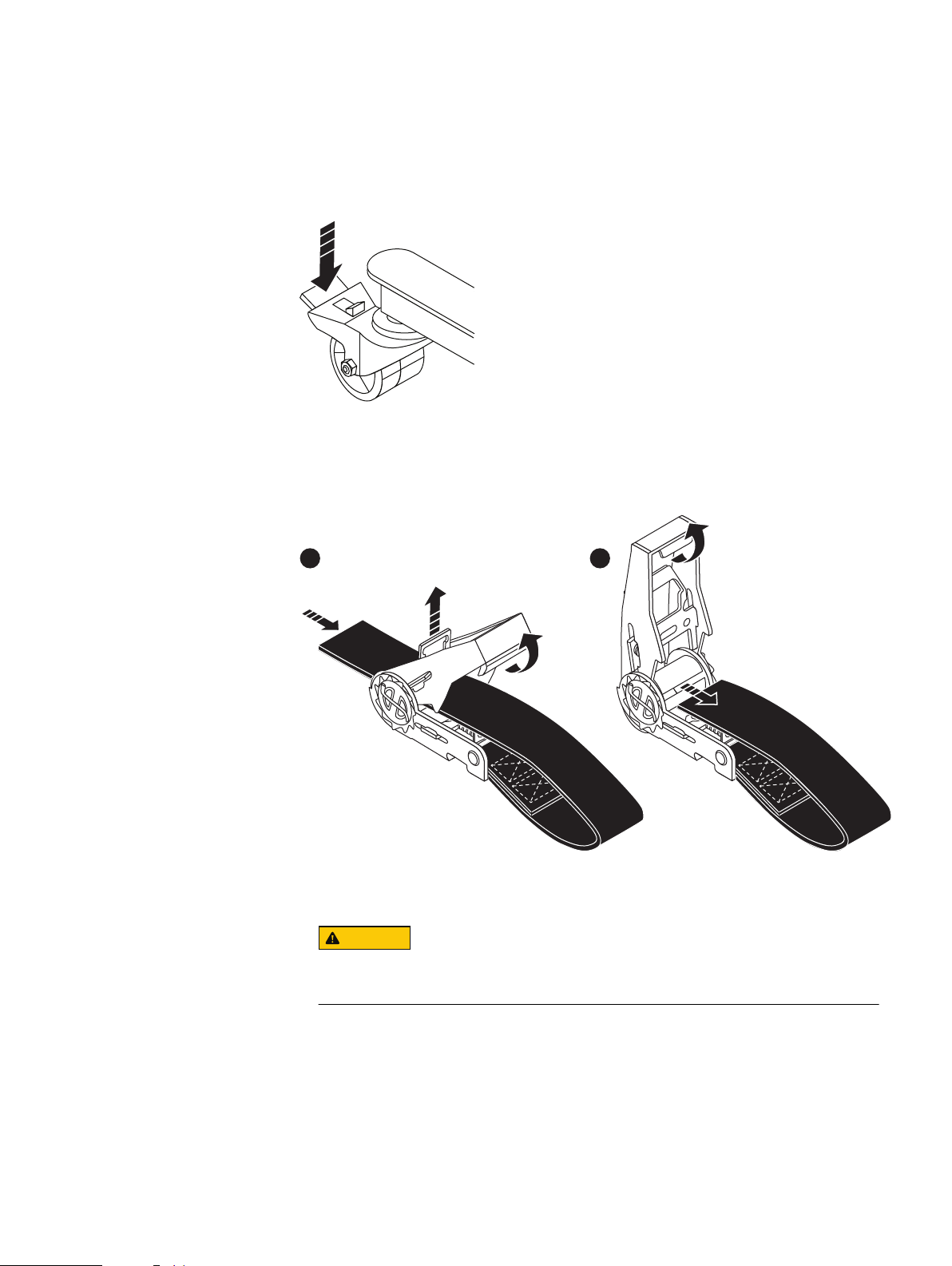

7. Remove the securing strap by pulling up on the retaining key and pull the

ratchet handle upwards as needed.

Figure 9 Removing the straps

8. Carefully push the shelf off the lift arms/tray and into the cabinet.

Make sure to leave the lift under the chassis until the shelf is safely

balanced and secured within the cabinet.

9. If the shelf was de-populated prior to installation, re-populate the shelf as

follows:

a. Re-install the disk drives in the exact location from which they were

removed.

b. Re-install the Fan modules.

c. Slide the shelf into the cabinet.

30 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 31

d. From the rear of the cabinet, re-install the power supplies and the LCCs into

CL4898

21

the shelf.

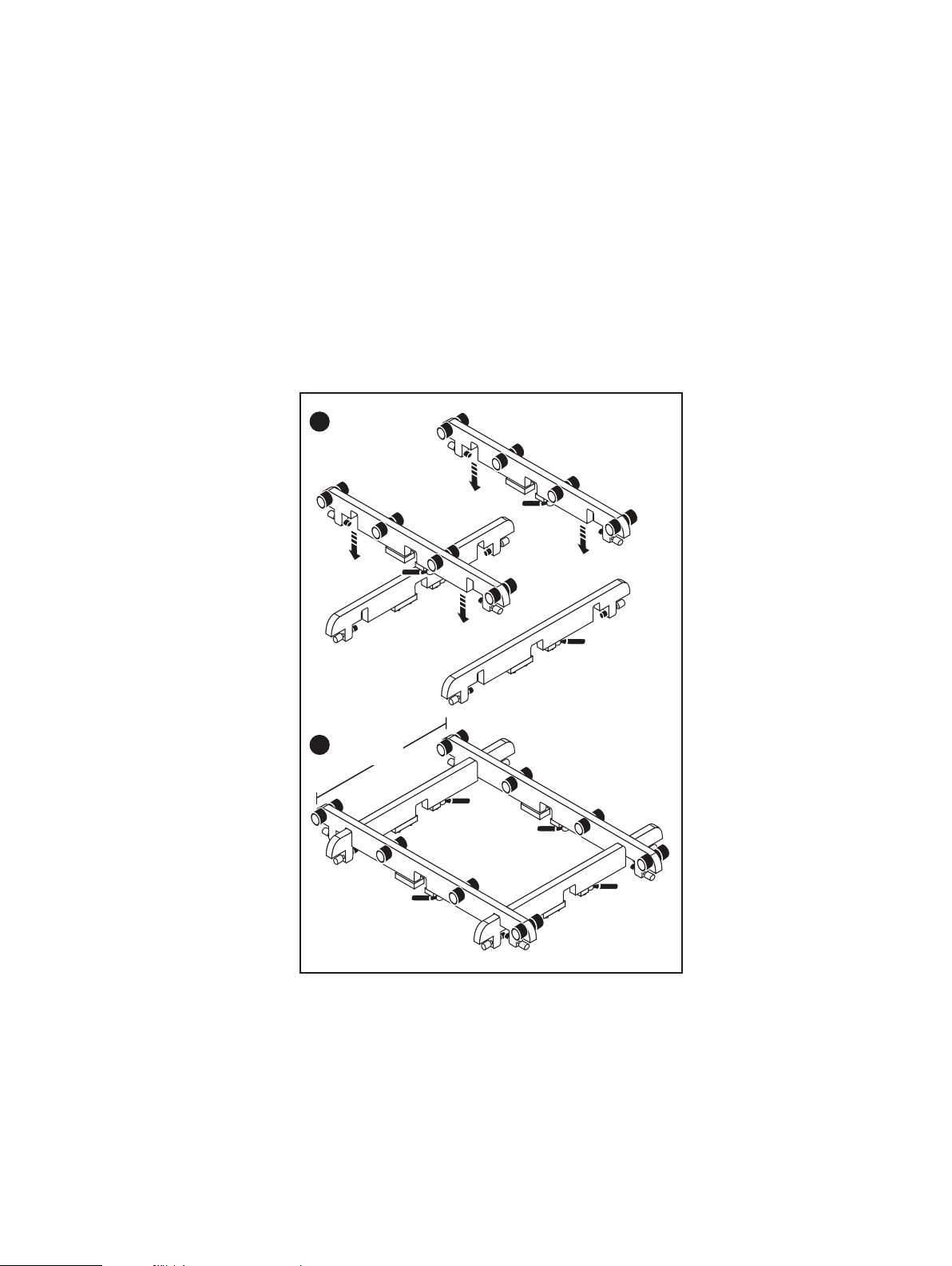

Inserting and securing the top cover and chassis

How the chassis is inserted and secured into the cabinet depends upon which

configuration of securing mechanism is installed on the shelf. The first configuration

has orange self-locking latches above the enclosure latch handles. The second

configuration has captive shoulder screws which attach the chassis to the cabinet.

Procedure

1. If your shelf has the orange self-locking latches above the enclosure latch

handles, proceed as follows:

Figure 10 Inserting and securing the chassis to the cabinet

Shelf Installation and Removal

a. Using the orange enclosure latch handles, push the shelf completely into the

cabinet. Make sure the self-locking latches are pushed in and fully engaged,

and the enclosure cannot slide back out of the cabinet.

b. Secure the two knurled black captive screws to the NEMA channel and nut

clips. These screws secure the chassis cover and prevent the cover from

coming out of the cabinet during service.

2. If your shelf has the two-shoulder screw configuration, proceed as follows:

Inserting and securing the top cover and chassis 31

Page 32

Shelf Installation and Removal

Figure 11 Inserting and Securing the Chassis to the Cabinet (Shoulder Screw Configuration)

a. If the shelf is being installed in a non-EMC rack, proceed to substep b. If the

shelf is being installed in an EMC rack, use the orange enclosure latch

handles to push the shelf completely into the cabinet. Align the two semicaptive M5 shoulder screws on each side with the mounting holes on the

cabinet. Thread the shoulder screws into the mounting holes and fingertighten the shoulder screws.

b. To install the shelf into a non-EMC rack (not compatible with the M5

shoulder screws), do the following:

l

Figure 12

Removing semi-captive screws

Remove the semi-captive M5 screws by sliding them from the ears.

l

For non-threaded racks, place tinnernam clips which match the truss head

screws to be used over the mounting holes on the rack. Refer to the table at

the end of this procedure.

32 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 33

CL5541

3.

Note

Shelf Installation and Removal

l

Figure 13 Installing ears to rack using truss head screws

Use the orange enclosure latch handles to push the shelf completely into the

cabinet. Secure the enclosure to the rack using four truss-head screws.

The top cover can secure to the cabinet in one of two ways, depending upon

your configuration. Some configurations do not have any hardware installed into

the top cover. In these configurations, the appropriate truss head screw must

be used to attach the top cover to the cabinet. Some configurations have semicaptive screws in the top cover that will attach to EMC cabinets. If non-EMC

cabinets are being used, the semi-captive screws can be removed and truss

head screws can be used as required to attach the top cover to the cabinet.

To secure the top cover using a top cover that does not have any mounting

hardware, secure the top cover to the rack using the screws or pins from the kit

that accompanies the device. These screws secure the chassis cover and

prevent the cover from coming out of the cabinet during operation. Secure the

top cover to the rack as follows:

a. If the shelf is being installed into an EMC rack, secure the top cover to the

rack using M5 truss head screws from the kit. Tighten the screws until they

are finger tight.

b. If the shelf is being installed into a non-EMC rack, identify the mounting

holes on the rack that will line up with the mounting holes on the top cover.

Identify which truss head screws will be used to secure the top cover to the

rack (refer to the following table for guidance). For non-threaded racks,

place tinnernam clips over the rack mounting holes. Attach the top cover to

the rack using the appropriate truss head screws from the hardware kit that

comes with the shelf. Refer to the following figure and table for guidance

(shelf and rack not shown).

Inserting and securing the top cover and chassis 33

Page 34

Shelf Installation and Removal

Figure 14 Installing top cover using truss head screws

Table 7 Truss Head Screws

Truss Head Screw from

kit

Part Number and

Description

036-032-010

Screw, M5-0.8x12, Truss

Head Phillips with patch

036-032-011

Screw, M6-1.0x12, Truss

Head Phillips with patch

036-032-009

Screw, 10-32x.5, Truss

Head Phillips with patch

036-032-012

Screw, 12-24x.5, Truss

Head Phillips with patch

Suggested Use

Can be used in EMC racks

and third-party nonthreaded hole racks.

Can be used in non-EMC

racks.

Can be used in non-EMC

racks.

Can be used in non-EMC

racks.

4. To secure the top cover using a top cover with semi-captive screws, do the

following:

a. For an EMC rack, align the semi-captive screws with the mounting hole in

the cabinet and thread the screw into the mounting hole.

5. If a non-EMC rack is being used that is not compatible with the semi-captive

screw, remove the semi-captive screw by pulling the screw assembly out the

side of the top cover. Identify the mounting holes on the rack that will line up

with the mounting holes on the top cover. Identify which truss head screws will

be used to secure the top cover to the rack (refer to the following table for

guidance). For non-threaded racks, place tinnernam clips over the rack

mounting holes. Attach the top cover to the rack using the appropriate truss

head screws from the hardware kit that comes with the shelf.

34 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 35

Figure 15 Removal of semi-captive screws

CL5545

Note

CAUTION

Shelf removal

This section describes how to remove a shelf from a rack.

Working with the portable lift

If a shelf with all of the FRUs removed is being installed, the chassis can be installed

without using the lift. If the shelf is populated with FRUs prior to installing, then this

task requires the use of a portable lift.

The portable lift commonly used by EMC service personnel is manufactured by AlumA-Lift. Instructions for this lift are included in the lift kit. Refer to "http://

www.corkc4.isus.emc.com/wiki/index.php/Lift_Tool". which describes the Lift

equipment, the ordering process, and Links to training material. The Lift Tool Training

Video and Demo on Lift tool using the Voyager assembly (Voyager is the name given

to a Disk enclosure used on many of EMC's product range), are also linked on this

page.

Shelf Installation and Removal

Planning your lift

If you are using a portable lift other than the Alum-A-Lift, adapt these instructions as

necessary while following all required safety requirements.

The portable lift commonly used by EMC service personnel has two

configurations - one with the lower mast only and one with both the lower and

upper masts. The lower mast configuration is rated for 400 pounds and is for

raising or lowering objects 28U (49 inches) or less above the floor. The dual mast

configuration is rated well under 200 pounds and is for raising objects more than

28U (49 inches) above the floor.

l

For installations at or below 49 inches, you must use the lower mast

configuration.

l

For installations above 49 inches, use the "Voyager" conversion kit, rated for

225 pounds, and a support table with the lower mast configuration.

You can use the lift positioned along the side of the shelf or directly in the front of it.

If possible, position the lift adjacent to the LONG side of the enclosure. This reduces

the front clearance required to 50". Aligning the portable lift perpendicular to the

chassis also reduces the possibility of the chassis sliding off the lift and negates the

requirement to adjust the arm width to approximately 17".

Shelf removal 35

Page 36

CL5431

NOTICE

Shelf Installation and Removal

Table 8 Planning your lift

Lift

position

Side (long) 50" Greater than 18" Best practice, more stable

Front

(short)

Required front

Arm tray width Notes

clearance

60" Between 16-17" Requires arm adjustment, less stable

Refer to: Adjusting the arms for a frontal lift on page 27

Figure 16 Best Practice: Using the portable lift adjacent to the long side of the shelf

Removing the front bezel

You must remove the front bezel to gain access to the internal components. The bezel

is required for EMI compliance when the shelf is powered up. Remove it only to

replace or add an internal component.

36 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 37

CL4667

DANGER

Shelf Installation and Removal

Procedure

1. If the bezel has a lock, insert the key that shipped with your shelf into the lock,

and turn the key to unlock the bezel.

2. Press the two latch buttons on the bezel surface to release the bezel from the

cabinet.

3. Pull the bezel off the cabinet and put it on a clean, static-free surface.

Figure 17 Removing the front bezel

Pulling the shelf chassis out

Do not extend more than one shelf at a time. Extending more than one shelf at a

time can cause the rack to tip over, which will damage the equipment and may

injure personnel.

To access the internal components, you must release and pull the shelf out of the

cabinet. The shelf slides out of the cabinet far enough for you to access its internal

components and then locks on the rails in the service position so that you cannot pull

it out any farther. The chassis is freed from the cabinet by removing captive shoulder

screws which attach the chassis to the cabinet.

Procedure

1. Unscrew the attaching screws from the NEMA channel.

2. Unscrew the shoulder-screws until they are free from the cabinet. Using the

orange shelf latch handles, pull the slowly pull shelf completely out the cabinet.

Pulling the shelf chassis out 37

Page 38

Note

Shelf Installation and Removal

Figure 18 Pulling the Chassis Out (Two shoulder Screw Configuration)

Removing a shelf from the cabinet

Before you begin

The portable lift commonly used by EMC service personnel is manufactured by AlumA-Lift. Instructions for this lift are included in the lift kit. Refer to "http://

www.corkc4.isus.emc.com/wiki/index.php/Lift_Tool". which describes the Lift

equipment, the ordering process, and Links to training material. The Lift Tool Training

Video and Demo on Lift tool using the Voyager assembly (Voyager is the name given

to a Disk enclosure used on many of EMC's product range), are also linked on this

page.

If you are using a different lift, it must comply with the following requirements:

l

It must be capable of lifting a weight of 225 pounds.

l

It must be used with a rack that has an anti-tipping mechanism installed.

l

It must be capable of reaching the a minimum height of U1 position, and a

maximum height of U29-U31.

You should be able to lower the lift to a minimum height of U1. However, on some

installations you may not be able to install the shelf in the U1 position due to cabling

and other installation considerations.

38 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 39

Note

<17”

1

2

CL4900

Shelf Installation and Removal

If you plan to use the mechanical lift directly in front of the cabinet, adjust the lift

arm/tray width to just under 17 inches apart to ensure that the arms will stay under

the chassis. The following figure shows an example of adjusting the lift arm/tray to

just under 17 inches. If using a different lift, configure the lift arms and trays according

to the lift manufacturer's instructions.

Figure 19 Example of adjusting the lift arm/tray to just under 17-inches

Procedure

1. Assemble and align the mechanical lift.

2. Configure the lift for at least 225 pounds.

If you are using the Alum-A-Lift, make sure to configure the lift for a 400 pound

rating. Since the dual mast configuration to raise objects more than 28U (49

inches) is rated well under 200 pounds, you cannot use this configuration to

raise or lower a shelf more than 49 inches above the floor. Instead for

installations or removals above 49 inches you must use the single (lower) mast

configuration with the conversion kit and a support table, available from the lift

provider. This kit is rated for 225 pounds.

Removing a shelf from the cabinet 39

Page 40

CAUTION

CL4896

CL4897

Shelf Installation and Removal

The populated shelf can weigh 225 pounds. DO NOT ATTEMPT to lift or

move it without a lift.

3. Disconnect all cables from the rear of the shelf. Label each cable so they can be

re-connected correctly.

4. Refer to the following graphic. Unscrew the two knurled black captive screws

from the NEMA channel.

Figure 20 Releasing chassis from the rails

5. If the two small shipping screws (one per side) are present, remove them as

shown in the following figure.

Figure 21

Removing the shipping screws, if present

6. Unscrew the shoulder-screws until they are free from the cabinet. Using the

orange latch handles, slowly pull the shelf completely out the cabinet. Refer to

the following figure.

40 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 41

CAUTION

Note

Shelf Installation and Removal

Figure 22 Pulling the chassis out (two shoulder screw configuration)

Do not attempt to remove a populated shelf without a mechanical lift.

If the shelf that you are removing is 28U (49 inches) or more above floor

level, you need to use the conversion and support table kits from Alum-ALift as described in Step 2.

Instructions for the Alum-A-Lift and the conversion kit are included in the lift

kit.

Figure 23 Reconfiguring the Alum-A-Lift with the conversion kit

Removing a shelf from the cabinet 41

Page 42

CL5423

Shelf Installation and Removal

7. To lessen the front-of-cabinet clearance required from a minimum of 60 inches

to slightly more than 50 inches, position the lift on the side of the shelf rather

than directly in front of the shelf if possible.

Aligning the lift perpendicular to the shelf also reduces the possibility of the

shelf sliding off the lift, and negates the need to reduce the arm/tray width

below 18 inches.

8. Raise the lift to the height of the shelf, and lock all four casters by pressing

down on the locking tab so the lift will not roll as the shelf is placed onto it.

Refer to the following figure.

Figure 24 Locking the casters

9. With the shelf extended from the rack on the rails, lock the rails in the extended

position. Pull the shelf from the rails and onto the lift. Secure the shelf to the

portable lift using the securing straps as follows:

42 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 43

CL5431

Shelf Installation and Removal

Figure 25 Removing a shelf from rails more than 49" above the floor

a. Place the securing strap around the lift and the shelf.

b. Insert the free end of the securing strap into the slot on the ratchet

mechanism. Pull the ratchet handle down to tighten the securing strap

around the lift and the shelf.

Removing a shelf from the cabinet 43

Page 44

1 2

CL5429

CL5424

Shelf Installation and Removal

Figure 26 Tightening the straps

Using the lift on a shelf more than 49" above the floor

c. Make sure the shelf is securely strapped to the lift before moving. Once the

shelf is supported by the arm, lower the arm to the lowest point that still

permits travel.

This allows the shelf to be moved with minimal danger of tipping over.

10. Unlock the casters by lifting up on the locking tabs and move the shelf as

required.

Figure 27

Unlocking the casters

If you are using an Alum-A-Lift to work on a shelf that is more than 49 inches above

the floor, you must use the "Voyager" conversion kit and a support table with the

lower mast configuration.

Procedure

1. If necessary, orient the arm to the high-lift position as follows:

44 EMC Data Domain DS60 Expansion Shelf Installation and FRU Replacement Hardware Guide

Page 45

Figure 28 Adjusting the arm for a high rail position

CL5422

1 2

Shelf Installation and Removal

a. Remove the bottom ball lock pin first, by pressing the plunger on the pin and

pulling the pin out. It may be necessary to wiggle the pin with the plunger

pressed to free it from its mounting hole.

b. Hold the arm with one hand while pressing the plunger on the top ball lock

pin and pulling the pin out with the other hand. It may be necessary to wiggle