Page 1

Edition: 1.4.2014 · BA 231-EN

Original Operating Instructions

V-VC 50 | 75 | 100 | 150

Vacuum pump

V-Serie

V-Series

Drehschieber

Rotary Vane

Page 2

Table of contents

Table of contents

1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Supplier documentation and accompanying documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Directives, standards, laws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 Symbols and meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Technical terms and meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.8 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Warning instruction markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Unacceptable operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Personal qualifi cations and training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Safety-conscious work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7 Safety notes for the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Safety instructions for installing, commissioning and maintenance . . . . . . . . . . . . . . . . . . . . . . 9

2.9 Guarantee conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.1 Unpack and check the delivery condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.2 Lifting and transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Ambient conditions for storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Set up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Areas of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Connecting pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4 Filling with lubricating oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Connecting the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Commissioning and decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.1 Checking the rotation direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Decommissioning/ storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Re-commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

2

Page 3

Table of contents

7 Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1 Ensuring operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2.1 Air fi ltering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2.2 Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2.3 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.2.4 Oil removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 Repair/ Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8 Malfunctions: Causes and elimination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

3

Page 4

Foreword

1 Foreword

1.1 Principles

These operating instructions:

• are a part of the following oil-fl ooded rotary vane

vacuum pumps, V-VC 50, V-VC 75, V-VC 100 and

V-VC 150.

• describe how to use them safely and properly in

all life phases.

• must be available where the equipment is used.

1.2 Target group

The target group for these instructions is technically

trained specialists.

1.3 Supplier documentation and accompanying documents

Document Contents No.

Operating Instructions BA 231-EN

Supplier documentation

Declaration of Conformity C 0045-EN

Declaration of harmlessness 7.7025.003.17

Spare parts’ list Spare parts document E 231

Data sheet Technical data and graphs D 231

Info sheet

Water vapour compatibility for oil-fl ooded

vacuum pumps

I 200

Info sheet Storage guidelines for machines I 150

Manufacturer’s declaration

EU Directive 2002/95/EG (RoHS)

—

1.4 Abbreviations

Fig. Figure

V-VC Vacuum pump

3

/h Pumping capacity

m

mbar (abs.) Final vacuum, operating vacuum

1.5 Directives, standards, laws

See Conformity Declaration

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

4

Page 5

1.6 Symbols and meaning

Symbol Explanation

Condition, pre-requisite

#### Instructions, action

a), b),... Instructions in several steps

Results

Foreword

[-> 14]

Cross reference with page number

Information, note

Safety symbol

Warns of potential risk of injury

Obey all the safety instructions with this symbol in order to avoid injury

and death.

1.7 Technical terms and meaning

Term Explanation

Machines Pump and motor combination ready to be connected

Motor Pump drive motor

Vacuum pump Machine to create a vacuum

Rotary vane Machine’s design or active principle

Pumping capacity

Vacuum pump volume fl ow related to the condition in the suction connection

Final pressure (abs.) The maximum vacuum that a pump reaches when the suction opening is

closed. Given as absolute pressure.

Permanent vacuum The vacuum or the suction range at which the pump operates perma-

nently.

The permanent vacuum or intake pressure is ≥ than the fi nal vacuum and

< than the atmospheric pressure.

Noise emission

The noise emitted at a specifi c loading given as a fi gure, sound pressure

level dB(A) as per EN ISO 3744..

1.8 Copyright

Passing on or copying this document, using and

providing information on its contents are prohibited

unless expressly permitted.

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

5

Page 6

Safety

2 Safety

The manufacturer is not responsible for damage if

you do not follow all of this documentation.

2.1 Warning instruction markings

Warning Danger level Consequences if not obeyed

DANGER

WARNING

CAUTION

NOTICE

2.2 General

immediately imminent danger Death, severe bodily injury

possible imminent danger Death, severe bodily injury

possible hazardous situation Slight bodily injury

possible hazardous situation Material damage

These operating instructions contain basic instructions for installation, commissioning, maintenance

and inspection work which must be obeyed to ensure the safe operation of the machine and prevent

physical and material damage.

The safety instructions in all sections must be taken

into consideration.

The operating instructions must be read by the

responsible technical personnel/ operator before

installing and commissioning and must be fully understood. The contents of the operating instructions

must always be available on site for the technical

personnel / operator. Instructions fi xed directly onto

the machine must be obeyed and must always remain legible. This applies for example to:

• Symbols for connections

• Data and motor data plate

• Instruction and warning plates

The operator is responsible for observing local regulations.

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

6

Page 7

Safety

2.3 Designated use

The machine must only be operated in such areas

as are described in the operating instructions:

• only operate the machine in a technically perfect

condition

• do not operate the machine when it is only partially assembled

• the machine must only be operated at an ambient temperature and a suction temperature of

between 12 and 40°C

Please contact us for temperatures outside this

range.

• the machine may convey, compress or extract

the following media:

• Air

The air extracted may contain water vapour

but no water or other liquids. For water vapour compatibility see Info I 200

• all non-explosive, non-infl ammable, non-ag-

gressive and non-poisonous dry gases and

gas air mixtures

2.4 Unacceptable operating modes

• extracting, conveying and compressing explosive, infl ammable, aggressive or poisonous media, e.g. dust as per ATEX zone 20-22, solvents

as well as gaseous oxygen and other oxidants

• extracting, conveying and compressing explosive, infl ammable, aggressive, oxidative or

poisonous media, e.g. dust as per ATEX zone

20-22, solvents

• using the machine in non-commercial plants if

the necessary precautions and protective measures have not been taken in the plant

• installing in environments that are at risk of explosions

• using the machine in areas with ionising radiation

• back pressures on the outlet side of more than

+0,1bars

• modifi cations to the machine and accessories

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

7

Page 8

Safety

2.5 Personal qualifi cations and training

• Ensure that people entrusted with working on

the machine have read and understood these

operating instructions before starting work,

particularly the safety instructions for installation,

commissioning, maintenance and inspection

work.

• Manage the responsibilities, competence and

monitoring of staff

• all work must only be carried out be technical

specialists:

• Installation, commissioning, maintenance

and inspection work

• Working with electricity

• personnel being trained to work on the ma-

chine must be supervised by technical specialists only

2.6 Safety-conscious work

The following safety regulations apply in addition

to the safety instructions and intended use listed in

these instructions:

• Accident prevention regulations, safety and operating regulations

• the standards and laws in force

2.7 Safety notes for the operator

• hot parts of the machine must not be accessible

during operation or must be fi tted with a guard

• People must not be endangered by the free

extraction or discharge of pumped media

• Risks arising from electrical energy must be

eliminated.

• The machine must not be in touch with infl ammable substances.

Danger of fi re by hot surfaces, discharge of

pumped media or cooling air

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

8

Page 9

Safety

2.8 Safety instructions for installing, commissioning and maintenance

• The operator will ensure that any installation,

commissioning and maintenance work is carried out by authorised, qualifi ed specialists who

have gained suffi cient information by an in-depth

study of the operating instructions.

• Only work on the machine when it is idle and

cannot be switched on again

• Ensure that you follow the procedure for decommissioning the machine described in the operating instructions.

• Fit or start up safety and protective devices

again immediately after fi nishing work.

• Conversion work or modifi cations to the machine are only permissible with the manufacturer’s consent.

• Only use original parts or parts approved by the

manufacturer. The use of other parts may invalidate liability for any consequences arising.

• Keep unauthorised people away from the machine

2.9 Guarantee conditions

The manufacturer’s guarantee or warranty will no

longer apply in the following cases:

• Improper use

• Not complying with these instructions

• Operation by insuffi ciently qualifi ed staff

• Using spare parts that have not been approved

by Gardner Denver Schopfheim GmbH

• Unauthorised modifi cations to the machine or

the accessories supplied by Gardner Denver

Schopfheim GmbH

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

9

Page 10

Transport, storage and disposal

3 Transport, storage and disposal

3.1 Transportation

3.1.1 Unpack and check the delivery condition

a) Unpack the machine on receipt and check for

transport damage.

b) Notify the manufacturer of transport damage im-

mediately

c) Dispose of the packaging in accordance with the

local regulations in force.

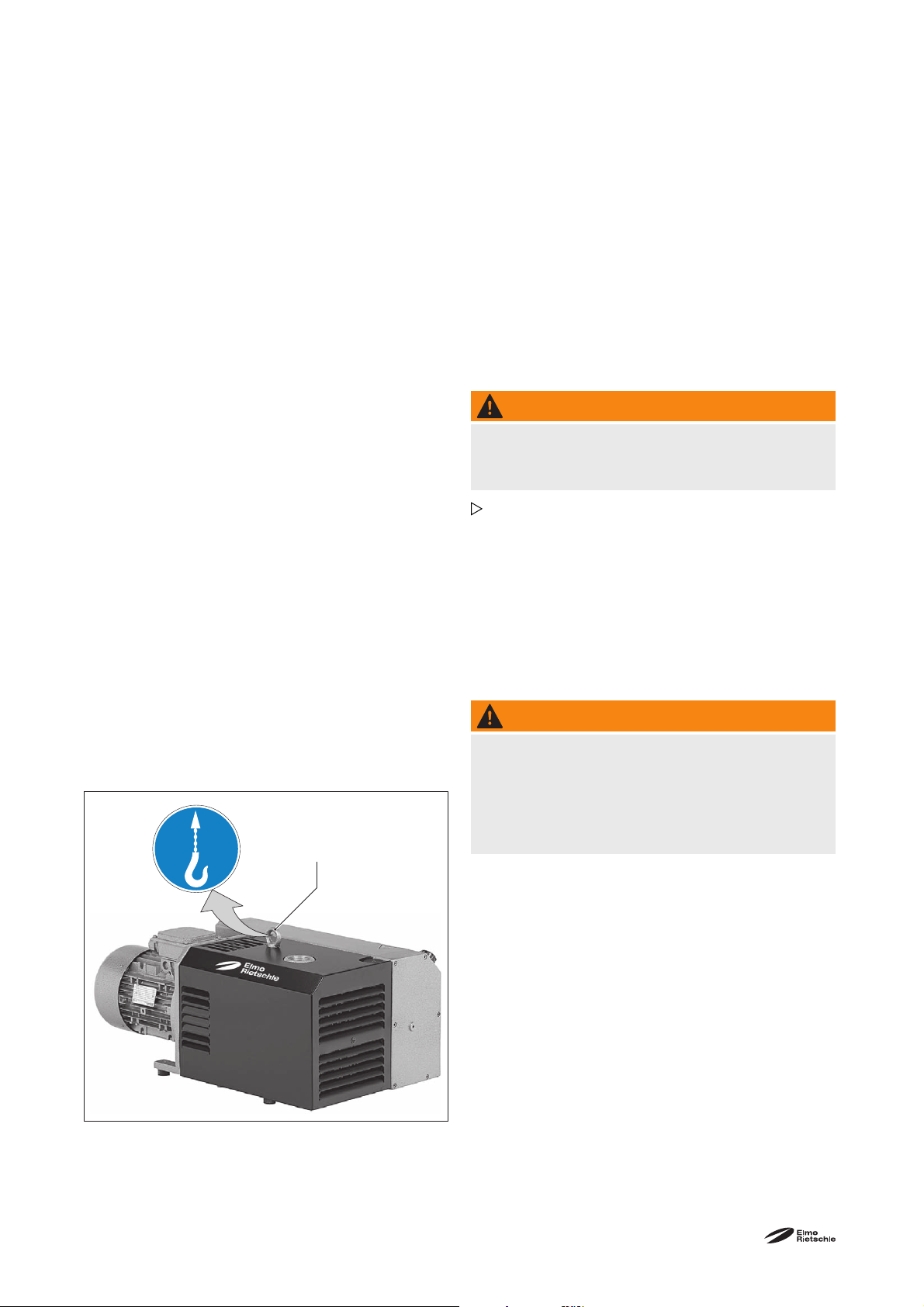

3.1.2 Lifting and transporting

a) Select the lifting device suitable for the total

b) Ensure that the machine cannot tip and fall.

c) Do not stop under a suspended load.

d) Put the goods to be conveyed on a horizontal

Lifting device/ Transporting with a crane

a) Tighten the eyebolts (Fig. 1/1) fi rmly.

b) The machine must be suspended on the eyebolt

1

WARNING

Death or limbs crushed as a result of the items

being transported falling or tipping over.

When transporting with the lifting device remem-

ber:

weight to be transported.

base.

WARNING

Bodily injury resulting from improper operation

a) Loads crosswise to the ring level are not per-

mitted.

b) Avoid impact stress.

using the lifting device for lifting and transporting.

Fig. 1 Lifting and transporting

1 Eyebolt

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

10

Page 11

3.2 Storage

Transport, storage and disposal

NOTICE

Material damage caused by improper storage.

Ensure that the storage area meets the following

conditions:

a) dust free

b) vibration free

3.2.1 Ambient conditions for storage

Ambient conditions Value

Relative humidity 0% to 80%

Storage temperature -10°C to +60°C

For long-term storage (more than 3 months), it is

useful to use a preservation oil rather than operating

oil.

See Info “Machine storage guidelines” I 150

3.3 Disposal

WARNING

Danger from infl ammable, corrosive or poisonous substances.

Machines that come into contact with hazardous substances must be decontaminated before

disposal.

When disposing ensure the following:

a) Collect oils and grease separately and dispose

of in accordance with the local regulations in

force.

b) Do not mix solvents, cold cleaner and paint resi-

dues

c) Remove components and dispose of them in

accordance with the local regulations in force.

d) Dispose of the machine in accordance with the

national and local regulations in force.

e) Parts subject to wear and tear (marked as such

in the spare parts list) are special waste and

must be disposed of in accordance with the

national and local waste laws.

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

11

Page 12

Set up and operation

4 Set up and operation

4.1 Setup

PP

1

B

F

A

E

F

E

F

E

F

D N

MH

OU

Q

I

K

Fig. 2 Vacuum pump V-VC 50 - V-VC 150

A

Vacuum connection

B Exhaust air outlet

D Suction fl ange

E Cooling air inlet

Cooling air outlet

F

Oil fi lling point

H

I Oil sight glass

K Oil discharge point

Oil separator element

L

M Oil recommendation plate

N Data plate

O Rotation direction plate

P

P

Q

T Oil remover housing

U Gas ballast valve

V-VC 50/ 75 -> 3 x • V-VC 100/ 150 -> 4 x

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

12

Drive motor

Motor data plate

1

hot surfaces > 70°C

T

LQ

Page 13

4.1.1 Data plate

Set up and operation

3

4 521

2 Serial number

1 Type/ Size (mechanical version)

616&

YDFXXPSXPS

99&

(1

6

0DGHLQ*HUPDQ\5RJJHQEDFKVWUDVVH'6FKRSIKHLPZZZJGHOPRULHWVFKOHFRP

,N:

,PLQ

,'

PEDUDEV

PñK

3 Year of construction

4 Item no

5 Ultimate vacuum (abs.)

6 Suction capacity 50 Hz/ 60 Hz

7 Speed 50 Hz/60 Hz

8 Motor rating 50 Hz/ 60 Hz

9 Operating mode

9

7

68

Fig. 3 Data plate

4.2 Description

V-VC 50, V-VC 75, V-VC 100 and V-VC 150 150 have a micro fi lter on the intake side and an oil and oil mist

separator for the return of the oil to the oil system on the outlet side. The vacuum pump is housed in a

sound cover. A fan between the pump housing and the motor cools the air in the pump housing and cools

the circulating oil.

An integral non-return valve prevents the evacuated system from being ventilated after the pump has

stopped. If the machine has been idle for more than two minutes the connected pipe should be ventilated to

atmospheric pressure.

A gas ballast valve fi tted as standard (Fig. 2/U) prevents condensation of water vapour in the inside of the

pump when low amounts of steam are sucked in when the pump is at operating temperature. A reinforced

gas ballast (optional) can be used if there is a higher amount of water vapour.

The pumps are driven by standard fl anged three-phase motors using a coupling.

4.3 Areas of application

These oil-fl ooded rotary vane vacuum pumps V-VC 50, V-VC 75, V-VC 100 and V-VC 150 are suitable for producing vacuums. The nominal pumping capacity with free suction is 100 50, 70, 100 and 150 m

3

/h at 50 Hz.

Data sheet D 261 shows the dependency of the pumping capacity on the intake pressure.

These types are suitable for the evacuation of closed systems or for a continuous vacuum within the follow-

ing intake pressure ranges: 0.5 to 500 mbar (abs.).

If the machine is operated continuously outside these ranges there is the risk of oil leaking through the outlet

opening. When evacuating closed systems the volume to be evacuated must be no more than 2% of the

nominal pumping capacity of the vacuum pump.

For permanent operation of > 100 mbar (abs.) the next larger motor output must be used.

If the unit is switched on more frequently (at regular intervals of about 10 times an hour) or at

higher ambient temperatures and intake temperatures, the excess temperature limit of the motor

winding and the bearings may be exceeded.

Please contact the manufacturer should the unit be used under such conditions

If it is installed in the open air the unit must be protected from environmental infl uences, (e.g. by a

protective roof).

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

13

Page 14

Installation

5 Installation

5.1 Preparing for installation

Check the following points:

• Machine freely accessible from all sides

• Do not close ventilation grids and holes

• Suffi cient room for installing and removing pipes

and for maintenance work, particularly for installing and dismantling the machine

• No external vibration effects

• Do not suck any hot exhaust air from other machines into the cooling system.

The suction fl ange (Fig. 2/D), oil fi lling point (Fig. 2/H), oil sight glass (Fig. 2/I), oil outlet (Fig. 2/K),

gas ballast (Fig. 2/U) a the oil removing device housing (Fig. 2/T) must be easily accessible.

The cooling air inlets (Fig. 2/E) and the cooling air outlets (Fig. 2/F) must be at least 30 cm away

from adjacent walls. Cooling air coming out must not be sucked in again.

For maintenance work there must be a space of at least 40 cm around the machine.

5.2 Installation

Ensure that the foundation complies with the follow-

• Level and straight

• The bearing surface must be at least the same

• The bearing surface must be able to bear the

NOTICE

The machine may only be operated when it is

set up horizontally.

Material damage resulting from the machine

tipping over and falling.

When installed at more than 1000 m above sea

level a reduction in power is noticeable. In this

case we would ask you to contact us.

ing conditions:

size as the machine

weight of the machine

It is possible to install the machine on a fi rm base without anchoring. When installing on a substructure we recommend fi xing with fl exible buffers

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

14

Page 15

5.3 Connecting pipes

Installation

WARNING

Sealing or constricting of the exhaust air outlet

(Fig. 2/B) may lead to severe or fatal injuries!

In the aggregate an inside pressure can be higher

and higher, which leads to the destruction of components!

NOTICE

Material damage resulting from the forces and

torques of the pipes on the unit being too high.

Only screw pipes in by hand.

The pumping capacity of the vacuum pump

is reduced if the suction pipe is too narrow

and/or too long.

Counter pressures on the outlet side are only

permissible up to + 0.1 bar.

Prevent liquids accumulating in the exhaust

line.

a) The vacuum connection (Fig. 2/A) can be found

on the suction fl ange (Fig. 2/D).

b) The discharged air can be freely blown out

through the exhaust air hole (Fig. 2/B) or conducted away using a hose or pipe.

5.4 Filling with lubricating oil

a) Fill the lubricating oil (for suitable types see the

“Maintenance” section) via the oil fi lling point

(Fig. 2/H) up to the upper edge of the sight glass

(Fig. 2/I).

b) Close the oil fi lling points.

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

15

Page 16

Installation

5.5 Connecting the motor

DANGER

Danger of death if the electrical installation has

not been done professionally.

The electrical installation must only be done by a

qualifi ed electrician observing EN 60204. The operating company has to provide the main switch.

a) The motor’s electrical data is given on the data

plate (Fig. 2/N) or on the motor data plate (Fig. 2/

). The motors comply with DIN EN 60034 and

P

1

are in protection class IP 55 and insulation class

F. The appropriate connection diagram is located

in the motor's terminal box (not for the plug connection version). Compare the motor data with

the data of the existing mains network (current

type, voltage, network frequency, permitted current value).

b) Connect the motor via the motor protection

switch (for safety reasons, a motor protection

switch is required and the connecting cable

must be installed via a cable fi tting to provide

strain relief).

We recommend using motor protection switches

with delayed switch off, depending on possible

excess current. Temporary excess current can

occur when the machine is started cold.

NOTICE

Power supply

The conditions at the installation location must match

the information on the motor data plate. Without

derating the following is permissible:

• ± 5% Voltage deviation

• ± 2% Frequency deviation

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

16

Page 17

6 Commissioning and decommissioning

6.1 Commissioning

Commissioning and decommissioning

WARNING

Improper use

May lead to severe or fatal injuries. Therefore be

sure to obey the safety instructions.

CAUTION

Hot surfaces

When the machine is at operating temperature the

surface temperatures on the components (Fig. 2/

Q) may go above 70°C.

You must avoid touching the hot surfaces

(marked with warning plates).

CAUTION

Noise emission

The highest noise pressure levels measured as

per EN ISO 3744 are given in Section 9.

When spending a long time in the vicinity of the

running machine use ear protectors to avoid permanent damage to your hearing.

CAUTION

Oil aerosols in the extracted air

In spite of the air oil removing system separating the

oil mist to a large extent, the extracted air contains

a small residue of oil aerosols. Breathing in these

aerosols all the time could damage your health.

Therefore you must ensure that the installation room

is well ventilated.

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

17

Page 18

Commissioning and decommissioning

6.1.1 Checking the rotation direction

The drive shaft direction of rotation is shown by

the rotation direction arrow (Fig. 2/O) on the motor fl ange.

a) Start the motor briefl y (max. two seconds) to

check the direction of rotation. When looking at

the motor fan, it must rotate clockwise.

NOTICE

Incorrect direction of rotation

Operating in the wrong direction of rotation leads

to damage to the machine.

Use a phase sequence indicator to check the direction of rotation (anti-clockwise rotating fi eld).

b) After correcting the direction of rotation if nec-

essary, start the motor again and stop it again

after 2 minutes in order to top missing oil up to

the upper edge of the sight glass (Fig. 2/I). This

topping up at the fi lling point (Fig. 2/ H) must be

repeated until all the oil pipes have been fi lled

completely. The fi lling point must not be open

when the pump is running.

6.2 Decommissioning/ storing

Stop the machine

a) Switch the machine off.

b) If available close the cut off device in the suction

and pressure pipe.

c) Disconnect the machine from the electricity

source.

d) Depressurise the machine:

Open the pipes slowly.

The pressure reduces slowly.

e) Remove the pipes and hoses.

f) Seal the connections for suction and pressure

nozzles using adhesive foil.

see also Section 3.2.1, Page 11

6.3 Re-commissioning

a) Check the condition of the machine (cleanliness,

cabling etc.).

b) Drain the preserving agents.

For installation see Section 5 Page 14

For commissioning see Section 6.1 Page 17

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

18

Page 19

7 Maintenance and repair

Maintenance and repair

DANGER

Danger of death from touching live parts.

Before maintenance work disconnect the machine

by pressing the main switch or unplugging it and

ensure that it cannot be turned on again.

WARNING

Hot surfaces and equipment

During maintenance work there is the danger of

getting burnt on hot components (Fig. 2/Q) and

by the machine lubricating oil.

Wait for the machine to cool down.

7.1 Ensuring operational safety

Regular maintenance work must be carried out in order to ensure operational safety.

Maintenance intervals also depend on the operational demands on the machine.

With any work observe the safety instructions described in Section 2.8 "Safety notes for installation, com-

missioning and maintenance".

The whole unit should always be kept in a clean condition.

7.2 Maintenance work

Interval Maintenance to be carried out Section

monthly Check the pipes and screws for leaks and to ensure they are

—

seated properly and if necessary seal again or tighten up.

monthly Check the terminal box and cable inlet holes for leaks and if

—

necessary re-seal.

monthly Clean the ventilation slots on the machine and the motor

—

cooling ribs.

depending on how dirty the

discharged medium is.

Clean intake air fi lter

Clean gas ballast valve fi lter

7.2.1

at least once a year Check for coupling wear 7.2.2

daily Check the oil level 7.2.3

500 - 2000 h Change the oil

2000 h Change the oil separator elements 7.2.4

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

19

Page 20

Maintenance and repair

7.2.1 Air fi ltering

Fig.. 4 Air fi ltering

D Suction fl ange

G Cover

U Gas ballast valve

f

Micro fi lter

2

h Valve

Lens fl ange screw

s

1

Screws

s

2

h

h

f

2

s

G

1

D

U

s

2

NOTICE

Insuffi cient maintenance on the air fi lter

The power of the machine lessens and damage may

occur to the machine.

Intake air fi lter:

The micro fi lter (Fig. 4/f

) must be cleaned by rinsing

2

out or purging or replaced more or less often depending on how dirty the discharged medium is.

Remove the cover (Fig. 4/G) after undoing the

screws ( Fig. 4/s1) and remove the suction fl ange

f

1

g

3

1

(Fig. 4/D) after undoing the screws (Fig. 4/s2).

Re-assemble in reverse order. After that check the

function of the valve. For this purpose fi t a shut-off

device (enclosed volume min. 1 litre) on the suction

side and starts vacuum pump shortly. Afterwards

the vacuum achieved must remain constantly.

Gas ballast valve fi lter:

The pumps work with a gas ballast valve (Fig. 4/U).

The inbuilt fi lter disc Fig. 5/f

Fig. 5/f4) must be cleaned more or less often by

purging depending on how dirty the medium fl ow-

f

f

4

4

ing through is. By undoing the countersunk screw

(Fig. 5/g1) and removing the plastic cover (Fig. 5/h1)

Fig. 5 Gas ballast valve

the fi lter parts can be removed for cleaning.

Re-assemble in reverse order.

h

Cover

1

f3 Filter disc

Countersunk screw

g

1

Micro fi lter discs

f

4

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

20

) and micro fi lter discs

3

Page 21

7.2.2 Coupling

Maintenance and repair

m

n

v

s

5

Fig.. 6 Coupling

k Coupling sprocket

m Motor

n Motor fl ange

q Coupling half on the motor side

Screws

s

5

v Fan

Cooling coil (only with V-VC 150)

v

1

The coupling sprocket (Fig. 6/k) is subject to wear

and must be checked regularly (at least once a

year). When doing this the cooling coil (Fig. 6/v

)

1

must be cleaned each time by purging.

q

CAUTION

k

v

1

Defective coupling sprocket

Defective sprockets may lead to the rotor shaft

breaking.

To check the coupling switch the motor (Fig. 6/m)

off and ensure that it cannot be switched on again.

Undo the screws (Fig. 6/s

) on the motor fl ange

5

(Fig. 6/n). Remove the coupling half on the motor

side (Fig. 6/q) and the motor fl ange (Fig. 6/n) axially

and suspend with a lifting device. If the sprocket

(Fig. 6/k) is damaged or worn, then replace it. The

fan (Fig. 6/v) should also be checked for damage

from time to time and replaced if necessary.

NOTICE

Frequent starting up and high ambient temperature

The service life of the sprocket (Fig. 6/k) is reduced

as a result of this.

Re-assemble in reverse order.

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

21

Page 22

Maintenance and repair

7.2.3 Lubrication

M

H

I

K

Fig. 7 Lubrication and removing oil

H

Oil fi lling point

Oil sight glass

I

Oil discharge point

K

L

Oil separator element

V-VC 50 / 75 -> 3 x

V-VC 100 / 150 -> 4 x

M Oil recommendation plate

L

NOTICE

Always change the oil when the machine is at

operating temperature and in an atmospherically

ventilated area.

If it is not completely emptied the amount that can

be refi lled is reduced.

The waste oil must be disposed of in compliance with

the local environmental protection regulations.

If you are going to use another oil type, empty the

oil removing device housing and oil cooler completely.

The oil level must be checked at least once a day,

if necessary top the oil up to the upper edge of the

sight glass (Fig. 7/I) First oil change after 500 hours

of operation. Subsequent oil changes after 5002000 hours of operation. Reduce the change intervals accordingly depending on how contaminated

the discharged medium is.

Only lubricating oils complying with DIN 51506

group VC/VCL or a synthetic oil approved by Elmo

Rietschle must be used. The viscosity of the oil must

comply with ISO VG 100 as per DIN 51519. Elmo Ri-

etschle oil types: MULTI-LUBE 100 (mineral oil) and

SUPER-LUBE 100 (synthetic oil) see also oil recommendation plate (Fig. 7/M)).

If the oil is subject to high temperatures (ambient or

intake temperatures over 30°C, insuffi cient cooling,

60 Hz operation etc.) the oil change interval may be

extended by using the recommended synthetic oil.

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

22

Page 23

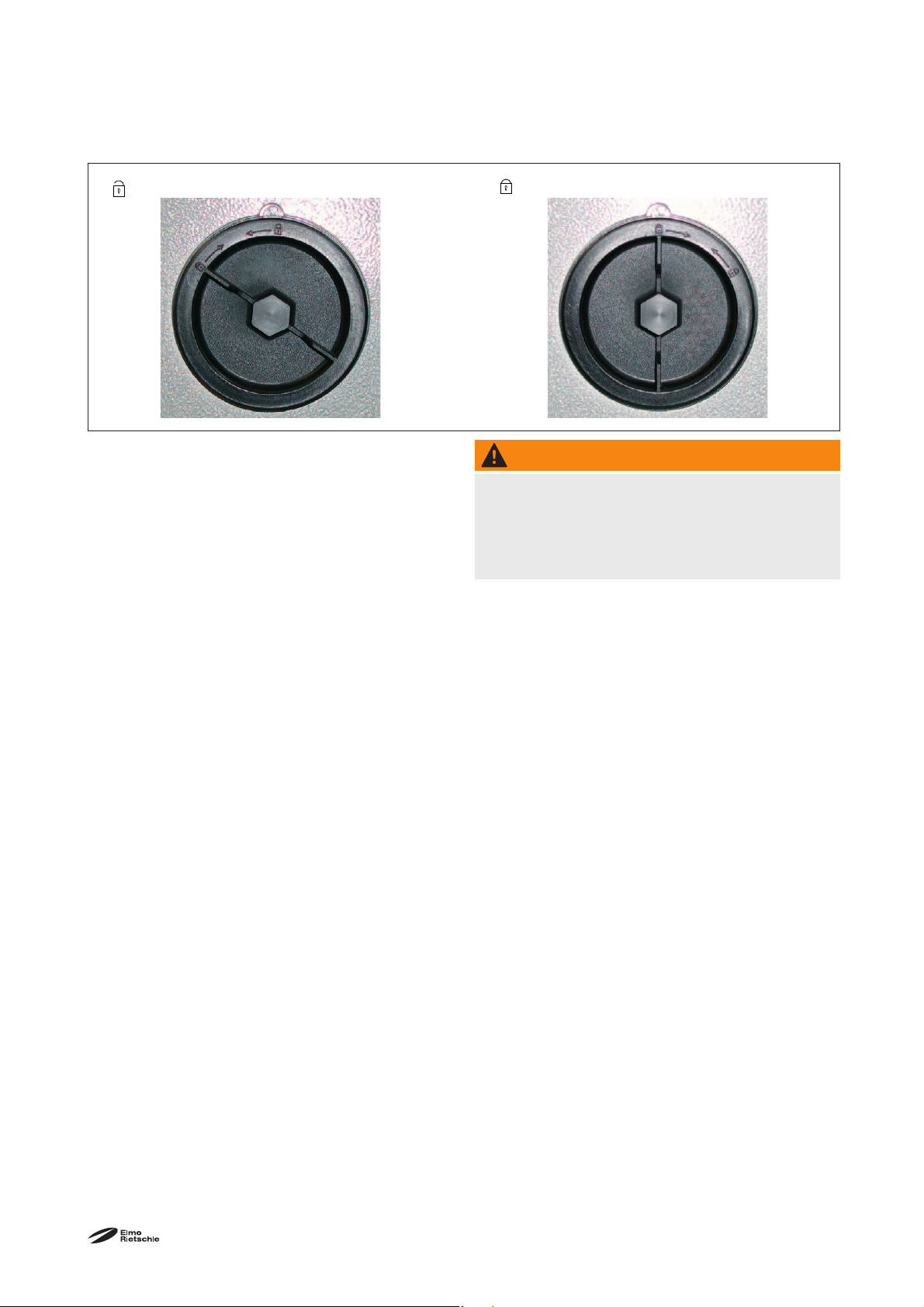

7.2.4 Oil removal

Maintenance and repair

open closed

Fig. 8 Air oil remover

WARNING

Heavily contaminated air oil removing devices lead

to increased pump temperatures and in extreme

cases may cause the lubricating oil to ignite spontaneously.

The oil separator elements (V-VC 50/ 75 ➝ 3x, V-VC

100/150 ➝ 4x) can become contaminated by dust

particles after they have been running for some time

(power consumption and pump temperature increase). Replace these components (Fig. 7/L) every

2000 operating hours or when the fi lter resistance is

0.7 bar (see pressure gauge ➝ Accessories, Checking with short term, atmospheric suction) because it

is not possible to clean them.

Reduce the change intervals accordingly depending

on how contaminated the discharged medium is.

Changing: Undo the air oil removers (Fig. 7/L) with a

ring spanner (spanner width 19 mm or 3/4”) rotating

counter clockwise. Insert new air oil removers with

the open lock symbol (see Fig. 8) with the arrow ▼

on the insert and fi x turning clockwise (until it clicks

into place).

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

23

Page 24

Maintenance and repair

7.3 Repair/ Service

a) For on site repair work the motor must be

disconnected from the mains by a qualifi ed

electrician so that it cannot be started up again

accidentally. For repairs use the manufacturer,

its branch offi ces or authorised dealers. Please

contact the manufacturer for the address of the

service centre responsible for you (see Manufacturer's address).

NOTICE

For each machine that is sent to an Elmo Rietschle Service centre for inspection, maintenance

or repair, a fully completed, signed declaration of

harmlessness must be enclosed.

The declaration of harmlessness is part of the

supplier’s documentation.

Fig. 9 Clearance certifi cate

7.7025.003.17

b) After a repair or re-commissioning, the actions

listed under “Installation” and “Commissioning”

must be carried out as for initial commissioning.

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

24

Page 25

7.4 Spare parts

Fig.. 10 Spare parts list

Maintenance and repair

Order spare parts in accordance with the:

• Spare parts list:

E 231 ➝ V-VC 50 - V-VC 150

• Download the PDF fi le:i:

tp://www.gd-elmorietschle.com

➝ Downloads

➝ Product Documents

➝ V-Series ➝ Spare Parts

• Parts subject to wear and gaskets are indi-

cated separately on the list.

• Web site:

http://www.service-er.de

• Select the type, size and design.

NOTICE

Only use original spare parts or parts approved by

the manufacturer. The use of other parts may lead to

malfunctions and invalidate liability or the guarantee

for any consequences arising.

Fig. 11 Web site:

http://www.service-er.de

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

25

Page 26

Malfunctions: Causes and elimination

8 Malfunctions: Causes and elimination

Fault Cause Troubleshooting Important

Machine is switched

off by the motor protection switch

Mains voltage/ Frequency

does not correspond with the

motor data

Connection to motor terminal

board is not correct

Motor protection switch is not

set correctly

Motor protection switch is

triggered too quickly

Vacuum pump or its oil is too

cold

The lubricating oil is too viscous

The air oil removers are dirty. Change the oil separator ele-

Check by qualifi ed electrician Section 5.5

Use a motor protection switch

with an overload-dependent

delayed switch off that takes

into consideration the short

term excess current at start

up (version with short circuit

and overload trigger as per

VDE 0660 Part 2 or IEC 947-4

Note the ambient temperature

and the intake temperature

The oil viscosity must comply

with ISO VG 100 as per DIN

51519

ments

Section 2.3

Section 7.2.3

Section 7.2.4

Pumping capacity is

insuffi cient

The back pressure is too high

when the exhaust air is being

discharged.

Permanent operation >100

mbar (abs.).

The suction pipe is too long or

too narrow

Leak on the suction side of

the vacuum pump or in the

system

The intake fi lter is dirty Clean or replace the intake

Check the hose or the pipe Section 5.3

Use next largest motor output Section 4.3

Check the hose or the pipe Section 5.3

Check the pipework and

screw connections for leaks

and to ensure that they are

fi rmly seated.

fi lter

Section 7.2

Section 7.2.1

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

26

Page 27

Malfunctions: Causes and elimination

Fault Cause Troubleshooting Important

Final pressure (max.

vacuum) is not

reached

Leak on the suction side of

the vacuum pump or in the

system

Incorrect oil viscosity The oil viscosity must comply

Machine gets too hot Ambient or intake temperature

is too high

Cooling air supply is obstructed

The lubricating oil is too viscous

The air oil removers are dirty. Change the oil separator ele-

The back pressure is too high

when the exhaust air is being

discharged.

Check the pipework and

Section 7.2

screw connections for leaks

and to ensure that they are

fi rmly seated.

Section 7.2.3

with ISO VG 100 as per DIN

51519

Ensure it is being used prop-

Section 2.3

erly

Check environmental condi-

Section 5.1

tions

Clean ventilation slots Section 7.2

The oil viscosity must comply

Section 7.2.3

with ISO VG 100 as per DIN

51519

Section 7.2.4

ments

Check the hose or the pipe Section 5.3

Exhaust air contains

visible oil mist

The air oil remover devices

are not inserted correctly or

Check that it is correctly

seated

Section 7.2.4

the O rings are missing.

Unsuitable oil is being used Use suitable types Section 7.2.3

The air oil removers are dirty. Change the oil separator ele-

Section 7.2.4

ments

The back pressure is too high

Check the hose or the pipe Section 5.3

when the exhaust air is being

discharged.

Ambient or intake temperature

is too high

Cooling air supply is obstructed

Ensure it is being used properly

Check environmental conditions

Section 2.3

Section 5.1

Clean ventilation slots Section 7.2

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

27

Page 28

Malfunctions: Causes and elimination

Fault Cause Troubleshooting Important

The vacuum pump

produces a abnormal

noise

(The blades making

a hammering noise

when starting from

cold is normal if it

disappears within

two minutes as the

operating temperature increases)

Water in lubricating

oil

The pump housing is worn

(chatter marks)

The vacuum adjustment valve

Repair by manufacturer or

authorised workshop

Replace the valve Section 7.4

(if available) is vibrating

Blades are damaged Repair by manufacturer or

authorised workshop

Vacuum pump or its oil is too

cold

The lubricating oil is too viscous

Note the ambient temperature

and the intake temperature

The oil viscosity must comply

with ISO VG 100 as per DIN

51519

Pump sucks in water Install water interceptor up-

stream of the pump

The pump sucks in more water vapour than is suitable for

Contact the manufacturer for

increased gas ballast —

its water vapour compatibility

Pump only works for a short

time and therefore does not

reach its normal operating

temperature

Let the pump continue to run

with a closed suction side

after extracting the water

vapour until the water has

evaporated from the oil

Elmo Rietschle

Service

Elmo Rietschle

Service

Section 2.3

Section 7.2.3

—

—

Please contact Elmo Rietschle Service for other malfunctions or those that cannot be eliminated.

| www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

28

Page 29

Technical Data

9 Technical Data

V-VC 50 75 100 150

Sound pressure level (max.)

EN ISO 3744

Toleranz ± 3 dB(A)

dB(A)

50 Hz 66 66 70 72

60 Hz 70 70 72 74

50 Hz 57 59 88 89

Weight * kg

60 Hz 57 59 90 98

50 Hz 585,5 639,5 707 707

Length * mm

60 Hz 585,5 639,5 724 724

Width mm 316,5 316,5 406 406

50 Hz 267 267 300 300

Height mm

60 Hz 267 267 300 315

Vacuum connection G 1

Exhaust air outlet Rp 11/

/

4

4

G 11/

Rp 11/

4

4

G 11/

2

Rp 2 Rp 2

G 11/

2

1

Correct amount of oil l 3,0 3,0 3,0 3,5

* The length and the weight may differ from the information listed here depending on the motor manufac-

turer.

Fig. 12 Data sheet

You will fi nd more technical data on the data sheet

D 231

• Download the PDF fi le:

D 231 ➝ V-VC 50 - V-VC 150

• Download the PDF fi le:

ttp://www.gd-elmorietschle.com

➝ Downloads

➝ Product Documents

➝ V-Series ➝ Data Sheets

NOTICE

Subject to technical changes.

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH |

29

Page 30

Elmo Rietschle is a brand of

Gardner Denver‘s Industrial Products

Division and part of Blower Operations.

www.gd-elmorietschle.com

er.de@gardnerdenver.com

Gardner Denver

Schopfheim GmbH

Roggenbachstraße 58

79650 Schopfheim · Deutschland

Tel. +49 7622 392-0

Fax +49 7622 392-300

Page 31

Hereby the manufacturer

confirms:

EC - declaration of conformity 2006/42/EC

Gardner Denver Schopfheim GmbH

Postfach 1260

D-79642 Schopfheim

that the machine:

of the:

Oil lubricated vacuum pump

Series: V-VC

Type: V-VC 50, V-VC 75, V-VC 100, V-VC 150,

V-VC 200, V-VC 202, V-VC 300, V-VC 303,

V-VC 400, V-VC 500, V-VC 700, V-VC 900,

V-VC 1100, V-VC 1300

is conform to the regulations of the guideline indicated above.

The following harmonized and national standards and specifications are applied:

EN 1012-1:2010

EN 1012-2:1996+A1:2009 Compressors and vacuum pumps — Safety requirements — Part 2:

Compressors and vacuum pumps — Safety requirements — Part 1:

Compressors

Vacuum pumps

These declarations of conformity are invalid when the machine has been modified without prior approval by us and the approval has been documented in writing.

Name and address of the EC person in

charge for documentation

Gardner Denver Schopfheim GmbH

Postfach 1260

D-79642 Schopfheim

Gardner Denver Schopfheim GmbH

Schopfheim, 1.8.2011

Dr. Friedrich Justen, Director Engineering

C_0045_EN

Page 32

Safety declaration form

s

.

s

/

A

.

3

S

for vacuum pumps and component

7.7025.003.17

Page 1 of 1

Gardner Denver Schopfheim GmbH

Roggenbachstr. 58, 79650 Schopfheim Phone: +49/(0)7622/392-0 Fax: +49/(0)7622/392-300

Repairs and/or maintenance of vacuum pumps and components will only be carried out if a declaration has been

filled in correctly and completely

.

If not, the repair work cannot be started and delays will result.

This declaration must only be filled in and signed by authorised qualified staff

2. Reason for the submission1. Type of vacuum pumps/ components

Type description:

Machine number

Order number:

Delivery date:

3. Condition of vacuum pumps/ component

4. Contamination of the vacuum pumps

Was this being operated? YES NO components when in use

Which lubrication was used? Toxic YES NO

Corrosive YES NO

Was the pump/ component emptied? Microbiological*) YES NO

(Product/Consumables) YES NO Explosive*) YES NO

Has the pump/ component been cleaned and decontaminaRadioactive*) YES NO

other YES NO

YES

Cleaning agent:

Cleaning method:

*) Microbiological, explosive or radioactively contaminated vacuum pumps/ components will only be accepted

with proof that they have been cleaned properly.

Type of toxic substance or process-related, dangerous reaction products with which the vacuum pumps/

components came into contact:

Trade name, manufacturer's Chemical Hazard

product name name class substances are released accidents

1

2

3

4

Personal protection measures:

ction to be taken if toxic First aid in the event of

Hazardous decomposition products when subjected to thermal load

YES NO

Which?

5. Legally binding declaration

We swear that the information in this declaration is accurate and complete and that I, the undersigned, am in a

position to judge this. We are aware that we are liable to the contractor for damage caused by incomplete and

inaccurate information. We undertake to release the contractor from any damage claims from third parties arising

from incomplete or incorrect information. We are aware that, regardless of this declaration, we are directly liable

to third parties including in particular the contractor's staff entrusted with handling or repairing the product

Company:

Street: Post code/ Town:

Phone: Fax:

Name (in capitals) Position:

Date:

Legally binding signature:

TOS no. / Index: 7.7025.003.17 / 0

Office responsible: G

Company stamp:

File management: ..\7702500317.xl

Gardner Denver Schopfheim GmbH Postfach 1260 D-79642 Schopfheim

Loading...

Loading...