Page 1

Raven

Current Mode Servo Amplifiers for Brushless Motors with

Sinusoidal Commutation in

Extended Environmental Conditions

Installation Guide

April 2008 (Ver. 1.1)

www.elmomc.com

Page 2

Notice

This guide is delivered subject to the following conditions and restrictions:

This guide contains proprietary information belonging to Elmo Motion Control Ltd.

Such information is supplied solely for the purpose of assisting users of the Raven

servo drives in their installation.

The text and graphics included in this manual are for the purpose of illustration and

reference only. The specifications on which they are based are subject to change

without notice.

Elmo Motion Control and the Elmo Motion Control logo are trademarks of Elmo

Motion Control Ltd.

Information in this document is subject to change without notice.

Document No. MAN-RAVIG

Copyright 2008

Elmo Motion Control Ltd.

All rights reserved.

Raven Catalog

Number:

Revision History:

Ver. 1.1 April 2008 Updated Power Ratings Table in Appendix

Ver. 1.0 June 2007 Initial release

Elmo Motion Control Ltd.

64 Gisin St., P.O. Box 463

Petach Tikva 49103

Israel

Tel: +972 (3) 929-2300

Fax: +972 (3) 929-2322

info-il@elmomc.com

Elmo Motion Control Inc.

1 Park Drive, Suite 12

Westford, MA 01886

USA

Tel: +1 (978) 399-0034

Fax: +1 (978) 399-0035

info-us@elmomc.com

RAV-

Current

Maximum

Operating

Voltage

XX/YYY

(MAN-RAVIG.PDF)

Elmo Motion Control GmbH

Steinkirchring 1

D-78056, Villingen-Schwenningen

Germany

Tel: +49 (0) 7720-85 77 60

Fax: +49 (0) 7720-85 77 70

info-de@elmomc.com

www.elmomc.com

Page 3

Raven Installation Guide Contents

MAN-RAVIG (Ver. 1.1)

Contents

Chapter 1: Safety Information...............................................................................................1-1

1.1 Warnings .........................................................................................................................1-1

1.2 Cautions..........................................................................................................................1-2

1.3 Conformance to Standards............................................................................................1-2

1.4 Warranty Information....................................................................................................1-3

Chapter 2: Introduction...........................................................................................................2-1

2.1 ExtrIQ Product Family...................................................................................................2-1

2.2 Product Description.......................................................................................................2-2

2.3 Standard Features..........................................................................................................2-2

2.4 Fault Protection..............................................................................................................2-2

2.5 How to Use this Guide..................................................................................................2-4

Chapter 3: Installation ............................................................................................................3-1

3.1 Site Requirements...........................................................................................................3-1

3.2 Unpacking the Amplifier Components........................................................................ 3-1

3.3 Raven Dimensions.......................................................................................................... 3-2

3.4 Mounting the Raven ......................................................................................................3-3

3.4.1 Mounting the Heatsink .......................................................................................3-3

3.4.2 Mounting on the PC Board.................................................................................3-3

3.5 Wiring the Raven...........................................................................................................3-4

3.6 Connections....................................................................................................................3-5

3.6.1 Pin Functions........................................................................................................3-5

3.6.2 Connecting a Non-isolated Raven to an Isolating Power Transformer..........3-8

3.7 DC Power Supply........................................................................................................... 3-9

i

Chapter 4: Servo Control Operation..................................................................................... 4-1

4.1 Current Command Input...............................................................................................4-1

4.2 CFM.................................................................................................................................4-1

4.3 Current Gain Control (CGC).........................................................................................4-2

4.4 External Current Limit - Continuous (ECLC).............................................................4-3

4.4.1 External Voltage...................................................................................................4-3

4.4.2 External Resistor..................................................................................................4-3

4.5 External Current Limit - Peak (ECLP)..........................................................................4-3

4.5.1 External Voltage...................................................................................................4-3

4.5.2 External Resistor..................................................................................................4-4

4.6 Latch Mode (LM)............................................................................................................4-4

4.7 Amplifier Enable Logic..................................................................................................4-4

4.8 Status Indications...........................................................................................................4-5

Appendix: Technical Specifications....................................................................................A-1

A.1 Power Ratings................................................................................................................A-1

A.2 Electrical Specifications................................................................................................A-1

A.3 Mechanical Specifications.............................................................................................A-2

A.4 Environmental Conditions...........................................................................................A-2

A.5 Standards Compliance..................................................................................................A-3

A.5.1 Quality Assurance............................................................................................... A-3

A.5.2 Design ..................................................................................................................A-3

Page 4

Raven Installation Guide Contents

MAN-RAVIG (Ver. 1.1)

A.5.3 Safety....................................................................................................................A-3

A.5.4 EMC......................................................................................................................A-4

A.5.5 Workmanship......................................................................................................A-4

A.5.6 PCB.......................................................................................................................A-4

A.5.7 Packing.................................................................................................................A-4

A.5.8 WEEE*..................................................................................................................A-4

A.5.9 RoHS.....................................................................................................................A-4

ii

Page 5

Raven Installation Guide

MAN-RAVIG (Ver. 1.1)

Chapter 1: Safety Information

In order to achieve the optimum, safe operation of the Raven servo amplifier, it is

imperative that you implement the safety procedures included in t his user guide. Thi s

information is provided to protect you and to keep your work area safe when operating

the Raven and accompanying equipment. Read this chapter carefully before you begin

the installation process.

Ensure that all system components are connected to earth ground. Electrical safety is

provided through a low-resistance earth connect ion.

Only qualified personnel may install, adjust, maintain and repair the servo amplifier. A

“qualified person” has the knowledge and authorization to perform tasks such as

transporting, assembling, installing, commissioning and operating motors.

The Raven servo amplifier contains electrostatic-sensit iv e components t hat can be

damaged if handled incorrectly. To prevent any electrostatic damage, avoid contact with

highly insulating materials, such as plastic film and synthetic fabrics. Place the product

on a conductive surface and ground yourself in order to discharge any possible static

electricity build-up.

1-1

To avoid any potential hazards that may cause severe personal injury or damage to the

product during operation, keep all covers and cabinet doors shut.

The following safety symbols are used in this manual:

Warning:

This information is needed to avoid a safety hazard, which might cause

bodily injury.

Caution:

This information is necessary for preventing damage to the product or

to other equipment.

Note:

This is auxiliary information that ensures the correct operation of the

equipment.

1.1 Warnings

Cleaning after soldering

To avoid the damage of the product's acrylic coating the Raven must not

be cleaned after soldering by dissolving solve nts and / or "w ater" clea ning

process. For more details:

http://www.elmomc.com/applicat ions/ar ti cl e/Sol der ing-and Cleaning_Application-Note.pdf

Page 6

Raven Installation Guide Safety Information

MAN-RAVIG (Ver. 1.1)

To avoid electric arcing and hazards to personnel and electrical contacts,

never connect/discon nec t the se rvo amplifie r wh ile the pow er so urce is on .

Power cables can carry a high voltage, even when the motor is not in

motion. Disconnect the Raven from all voltage sources before it is opened

for servicing.

After shutting off the power and removing the power source from your

equipment, wait at least 5 minutes before touching or disconnecting parts

of the equipment that are normally loaded with electrical charges (such as

capacitors or contacts). Measuring the electrical contact points with a me ter

before touching the equipment is recommended.

1-2

1.2 Cautions

The Raven servo amplifier contains hot surfaces and electrically-charged

components during operation.

The maximum DC power supply connected to the ins trument must comply

with the parameters outlined in this guide.

1.3 Conformance to Standards

The Raven servo amplifier has been developed, produced, tested and documented in

accordance with the relevant standards. Elmo Motion Control is not responsible for any

deviation from the configuration and installation described in this documentation.

Furthermore, Elmo is not responsible for the performance of new measurements or

ensuring that regulatory requirements are met.

The Raven servo amplifier is intended f or in corporation in a mach ine or e nd produc t. The

actual end product must comply with all safety aspects of the relevant requirements of

the European Safety of Machinery Directive 89/392/EEC as amended, and with those of

the most recent versions of standards EN60204-1 and EN292-2 at the least.

According to Annex III of Article 13 of Council Directive 93/68/EEC, amending Council

Directive 73/23/EEC concerning electrical equipment desi gned for use wit hin certai n

voltage limits, the Raven meets the provisions outlined in Council Directive 73/23/EEC.

The party responsible for ensuring that the equipment meet the li mi ts requi red by EMC

regulations is the manufacturer of the end product.

Page 7

Raven Installation Guide

MAN-RAVIG (Ver. 1.1)

Chapter 2: Introduction

This user guide is intended for the design engineer who is integrating an Elmo Motion

Control Raven servo amplifier into a machine.

2.1 ExtrIQ Product Family

Elmo Motion Control's ExtrIQ product family is a set of durable motion control products

for applications operating under extreme environmental conditi ons. The products are

capable of withstanding the following extrem e condit ions:

2-1

Ambient

Temperature

Range

Temperature

Shock

Altitude

Maximum

Humidity

Vibration

Mechanical

Shock

Non-operating

conditions

-50 °C to +100 °C (-58 °F to 212 °F)

Operating conditions -40 °C to +70 °C (-40 °F to 160 °F)

Non-operating

conditions

Non-operating

-40 °C to +70 °C (-40 °F to 160 °F)

within 3 min.

Unlimited

conditions

Operating conditions -400 m to 155,000 m (-1,300 ft to 510,000 ft)

Non-operating

conditions

Up to 95% relative humidity noncondensing at 35 °C (95 °F)

Up to 95% relative humidity non-

Operating conditions

condensing at 25 °C (77 °F), up to 90%

relative humidity non-condensing at 42 °C

(108 °F)

Operating conditions 20 Hz –2,000 Hz, 14.6g

Non-operating

±40g; Half sine, 11 msec

conditions

Operating conditions

±20g; Half sine, 11 msec

ExtrIQ products have a high power density in the range of 10 W – 9000 W and current

carrying capacity of up to 200 A (400A peak). ExtrIQ has been tested using methods and

procedures specified in a variety of extended environmental conditions (EEC) standards

including:

• MIL-STD-704- Aircraft, Electric Power Characteristics

• MIL-STD-810- Environmental Engineering Considerations and Laboratory Tests

• MIL-STD-1275- Characteristics of 28 Volt DC Electrical Systems in Military Vehicles

• MIL-STD-461- Requirements for the Control of Electromagnetic Interference

Characteristics of Subsystems and Equipment

• MIL-HDBK-217- Reliability Prediction of Electronic Equipment

• ISO-9001:2000

Page 8

Raven Installation Guide Introduction

MAN-RAVIG (Ver. 1.1)

2-2

2.2 Product Description

The Raven is a series of miniature ExtrIQ current mode servo amplifiers for brushless

motors with sinusoidal commutation. Although highly compact, the Raven can withstand

extended environmental conditions and support up to 35 Amps. This high power density

servo amplifier can deliver up to 4800 W of peak power or 2400 W of continuous power

in a miniature package. The servo amplifier offers significant operating features

including excellent output linearity and zero dead band performance.

The Raven incorporates custom mixed analog/digital ICs and a hybrid power stage. The

basic configuration is a current mode amplifier targeting the OEM market. As such, no

trimmers are used in the basic version. In addition to its compliance with relevant MIL

standards, the Raven amplifier also meets UL508c and the relevant CE regulations.

The Raven power stage is implemented on a single ceramic substrate. This design enables

very high thermal conductivity, high current carrying capacity, improved EMC and good

mechanical strength. The control section is implemented by dedicated custom ICs that

contribute to enhanced performance.

2.3 Standard Features

Operation in current mode

Internal DC-to-DC converter, which allows for operation from a single supply

Zero deadband

Excellent linearity

One differential input

Motor current monitor

Current gain change for low inductance motors

Remote current gain control

Current feedback multiplier for low current motors

Status indication and remote control functions by four open collector transistors

External continuous and peak current-limit adjustments

Interface via soldering pins

Package: plated-copper base plate, plastic housing, UL94V0 recognized

Ultra-compact size

2.4 Fault Protection

Built-in protection against possible fault conditions, including:

Shorts between the outputs or between each output and the power input/return

Over-temperature

Under/over voltage

Failure of internal power supplies

Latch mode for each protective feature

Under/over voltage

Page 9

Raven Installation Guide Introduction

MAN-RAVIG (Ver. 1.1)

2-3

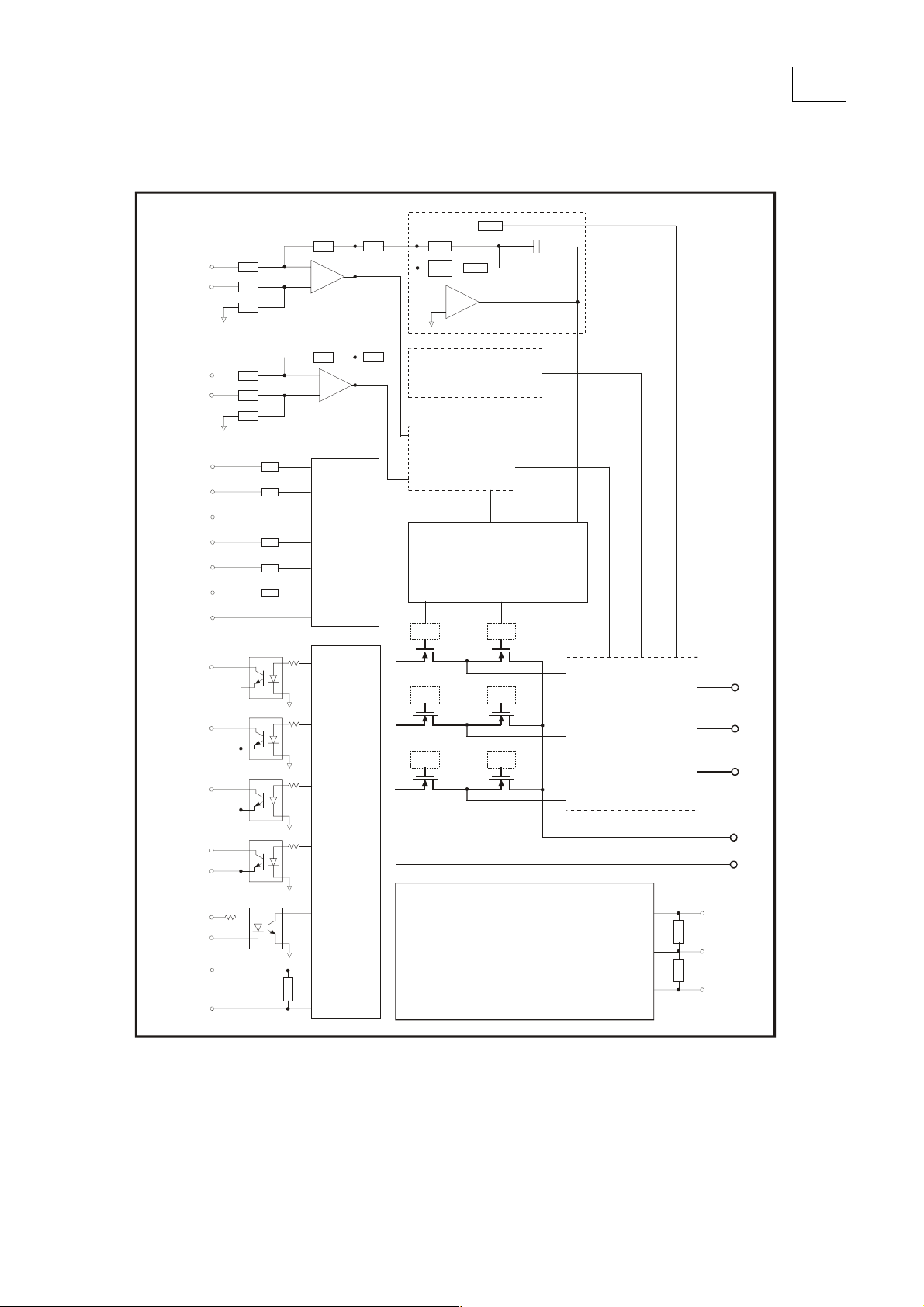

CREF1+ (J1,2)

CREF1- (J1,1)

CREF2+ (J1,4)

CREF2- (J1,3)

ECLC(J2,1)

ECLP(J2,3)

ECLRET(J2,2)

CM1(J1,7)

CM2(J1,8)

CM3(J1,9)

CMRET(J1,10)

AOK(J3,1)

20K

20K

20K

20K

20K

20K

21K

21K

21K

10.5K

AD

-

AD

+

Current

10K

10K20K

Limits

20K

-

+

1K

1K

100K

44.2K

AS

Current Loop

-

Amp.

A

+

Current loop Phase 1

Current loop Phase 2

Current loop Phase 3

10nF

PWM

Dr3Dr4

Dr2Dr5

M1

SO1(J3,2)

SO2(J3,3)

SO3(J3,4)

SORET(J3,5)

(J3,6)

EN+ (J2,9)

EN- (J2,10)

LM(J2,7)

LMRET(J2,8)

Protections

27.4K

Figure 2-1: Raven Block Diagram

Dr1Dr6

CFM&CGC

Logic

Current

Sensing

14.7K 27.4K

M2

M3

VP+

PR

CFM(J2,6)

CGC(J2,5)

CGCRET(J2,4)

Page 10

Raven Installation Guide Introduction

MAN-RAVIG (Ver. 1.1)

2-4

2.5 How to Use this Guide

Installation is the first step in integrating and operating the Elmo Raven servo amplifier.

After carefully reading the safety instructions in the first chapter, the following chapters

provide you with installation instructions as follows:

Chapter 3, Installation, provides step-by-step instructions for unpacking, mounting and

connecting the Raven.

Chapter 4, Servo Control Operation, explains how to control the operat ion of t he servo

amplifier.

The Appendix, Technical Specifications, lists all the drive ratings and specifications.

Page 11

Raven Installation Guide

MAN-RAVIG (Ver. 1.1)

Chapter 3: Installation

3.1 Site Requirements

You can guarantee the safe operation of the Raven by ensuring that it is installed in an

appropriate environment.

Feature Value

Ambient operating temperature -40 °C ~ 70 °C (- 40 °C ~ 160 °F)

Maximum case temperature 87 °C (188 °F)

Note: Models for extended environmental conditions are available.

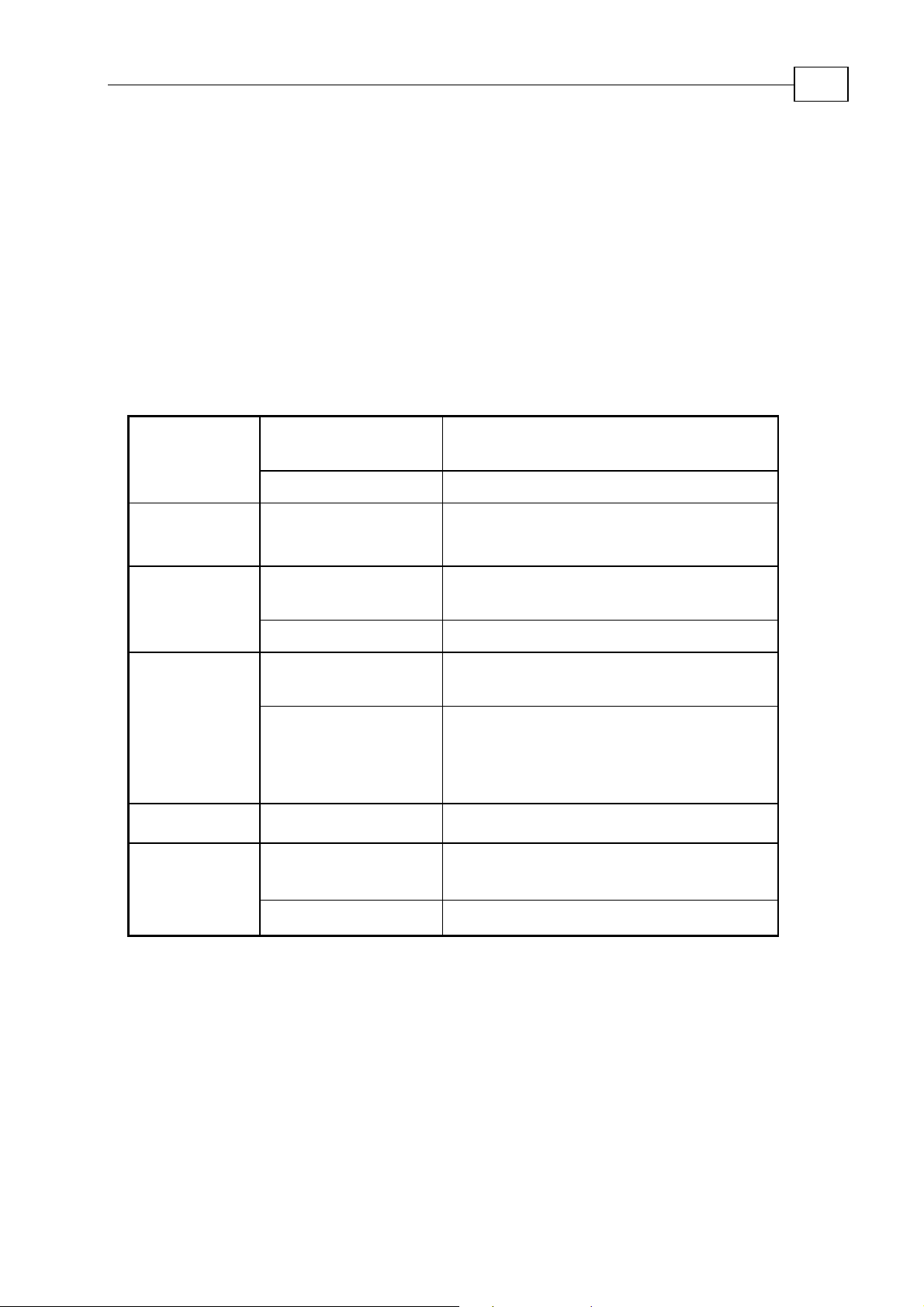

3.2 Unpacking the Amplifier Components

3-1

To unpack the Raven:

Carefully remove the servo amplifier from the box and the Styrofoam.

1. Check the amplifier to ensure that there is no visible damage to the instrument. If

any damage has occurred, report immediately to the carrier that delivered your

amplifier.

2. To ensure that the Raven you have unpacked is the appropriate type for your

requirements, find the part number sticker on the side of the Raven:

The P/N number at the top gives the type designation as follows:

RAV-

Current

Maximum

Operating

Voltage

XX/YYY

3. Verify that the Raven type is the one that you ordered, and ensure that the voltage

meets your specific requirements.

Page 12

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-2

3.3 Raven Dimensions

Figure 3-1: Raven Dimensions

Page 13

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-3

3.4 Mounting the Raven

3.4.1 Mounting the Heatsink

The Raven dissipates its heat by natural convection, up to loads of 500W. For higher

output loads, the amplifier should be mounted on an additional heatsink or cooled by

fan. There are two 4.5-mm holes in the base plate for mounting an additional heatsink

(see Figure

3.4.2 Mounting on the PC Board

When mounting the Raven on a PC board, four screws (in addition to the solder pins)

may be installed to provide a mechanical connection. It is important to provide a spacer if

any components are located above the amplifier. Failure to do so can warp the PC board

or puncture the amplifier case. When selecting screws, the following specifications

should be used. If a spacer has been added, the screw length must be calculated to

penetrate the case by no more than 2.6 mm.

3-1).

Screw Type: Phillips Pan Head Self-tapping (for plastic) screw – Nickel-plated Steel.

Meets standards ISO 1478, EN 21478, or DIN 7970.

d ST2.2

L 4.5*

P 0.8

dk 4.2

k 1.8

m≈ 2.6

Phillips size 1

*4.5 mm is typical for mounting on a

PC board assembly without spacers.

Table 3-1: Dimensions in Millimeters

Basic

Diameter

ISO

Nr.

Pitch

P

Main Diameter Minor Diameter Flat End Diameter

D

1max

D

D

1min

D

2max

D

2min

D

3max

3min

ST2.2 2 0.8 2.24 2.1 1.63 1.52 1.47 1.37

Table 3-2: Size Limits for Tapping Screw Thread

Page 14

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-4

3.5 Wiring the Raven

Figure 3-2: Basic Wiring

Page 15

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-5

3.6 Connections

3.6.1 Pin Functions

The Raven connections are described in the following figure and tables.

Figure 3-3: Raven Connector Locations

Pin Function Remarks

VP+ Positive power input

PR Power input return

M1

M2

M3

Motor power output 1

Motor power output 2

Motor power output 3

Table 3-3: Raven Power Connections

Page 16

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-6

Pin #/

Short Form

1

CREF1-

Function

Current command

input ( - )

Remarks

Negative input of a differential amplifier:

Input operating voltage range: ±3.75 V

Maximum input voltage: ±20 V

(see section 4.1)

Maximum common mode voltage: ±6 V

(referred to as CMRET)

Differential input impedance: 40 kΩ

2

CREF1+

3

CREF2-

4

CREF2+

Current command

input ( + )

Current command

input ( - )

Current command

input ( + )

Positive input of a differential amplifier.

Specification as for pin J1/1.

Negative input of a differential amplifier.

Specification as for pin J1/1.

Positive input of a differential amplifier.

Specification as for pin J1/1.

5 N/C

6 N/C

7

CM1

8

CM2

9

CM3

10

CMRET

Current monitor

for M1

Current monitor

for M2

Current gain

change return

Current monitor

return

Analog output with a scale of ±3.9 V for ±Ip.

Output resistance: 21 kΩ

Analog output with a scale of ±3.9 V for ±Ip.

Output resistance: 21 kΩ

Analog output with a scale of ±3.9 V for ±Ip.

Output resistance: 21 kΩ

Return for the current monitor (CM) signals.

Table 3-4: Connector J1

Page 17

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-7

Pin #/

Short Form

1

ELCL

Function

External current

limit - continuous

Remarks

External voltage scales down rated value.

Voltage range: 0 V to 3.75 V (3.75 V = rated Ic)

Internally limited to rated value

2

ECLRET

3

ECLP

Current limits

return

External current

limit - peak

Return for current limits signals.

External voltage scales down rated value.

Voltage range: 0 V to 3.75 V (3.75 V = rated Ip)

Internally limited to rated value

4

CGCRET

5

CGC

Current gain

change return

Current gain

change

Return for CGC signal.

Shorting this pin to the CGCRET pin (J2/4)

reduces the proportional gain (P) of the current

loop by 70%.

6

CFM

7

Current feedback

multiplier

Shorting this pin to pin J2/5 (CGC) multiplies

the current feedback signal by 2.

Latch mode Latch mode input.

LM

8

Latch mode return Return for Latch mode (LM).

LMRET

9

EN+

Enable ( + ) Positive voltage input of "Amplifier Enable”

function. To enable operation of the amplifier,

the opto must be switched on by applying

voltage between this pin (+) and pin J2/10 (-).

The opto is isolated from the amplifier. See

Figure 2-1.

10

EN-

Minimum “On” voltage: 3 V , current

consumption 0.6 mA.

Maximum “On” voltage: 15 V , current

consumption 5.4 mA.

Enable (-) Negative voltage input of “Amplifier Enable”

function. Opto is isolated from the amplifier. For

details, see pin J2/9.

Table 3-5: Connector J2

Page 18

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-8

Pin #/

Short Form

1

AOK

2

SO1

3

SO2

4

SO3

5

SORET

6

SORET

Function

Remarks

Amplifier OK “Amplifier OK” indication output pin. When the

amplifier is at normal operating conditions, this

output is in “active low “ state. When a failure

occurs, this output is changed to “open” state.

Opto isolated, open collector NPN type. See

Figure 2-1.

Maximum voltage = 30 V

Maximum current = 8 mA.

“On” voltage: V

OUT(On)

< 0.8 V

Status output 1 Status indication output 1. Specification as in pin

J3/1.

Status output 2 Status indication output 2. Specification as in pin

J3/1.

Status output 3 Status indication output 3. Specification as in pin

J3/1.

Status output

return

Status output return for AOK, SO1, SO2, SO3.

Isolated from power input return. for details, see

Figure 2-1.

Status output

return

Status output return for AOK, SO1, SO2, SO3.

Isolated from power input return. for details, see

Figure 2-1.

Table 3-6: Connector J3

3.6.2 Connecting a Non-isolated Raven to an Isolating

Power Transformer

Be sure to ground:

DC power common

Motor chassis

Amplifier heatsink

Do not ground the control common, which is internally connected to the power common.

Grounding the control common will create a ground loop.

Page 19

Raven Installation Guide Installation

MAN-RAVIG (Ver. 1.1)

3-9

3.7 DC Power Supply

The DC power supply can be at any voltage in the range defined in the technical

specifications (Appendix of this guide). The supply source must comply with the safety

aspects of the relevant requirements, in accordance with the most recent version of the

standard EN60950 or equivalent Low Voltage Directive Standard, all according to the

applicable over-voltage category. If the power source to the power supply is the AC line

(through a transformer), safety margins must be considered, in order to avoid activating

the under/over voltage protection due to line variations and/or voltage drop under load.

In addition to the above, the transformer must comply with the safety aspects of the

relevant requirements in accordance with the most recent version of the standard

EN60742 (Isolating and Safety Isolating Transformers). The nominal DC bus voltage

should be in the following range:

1.2 V

dcmin

< Vdc < 0.9

Vdcmax

where:

V

Vdcmax

is the minimum DC bus

dcmin

is the maximum DC bus

The recommended minimum power supply capacitance for single-phase connections is

as follows:

Amplifier Voltage Range 50 - 55 V 100 V 200 V

Recommended capacitance 5600 µF 3300 µF 1500 µF

The transformer power should be calculated such that it will be able to deliver power to

the amplifier (including peak power) without significant voltage drops.

The power supply should be located as close as possible to the amplifier. The maximum

distance is 30 cm (1 foot). While driving high-inertia loads, the power supply must be

equipped with a shunt regulator; otherwise, the amplifier will be disabled whenever the

capacitors are charged above the maximum voltage.

Page 20

Raven Installation Guide

MAN-RAVIG (Ver. 1.1)

Chapter 4: Servo Control Operation

4.1 Current Command Input

The Raven has two differential inputs. The input operating voltage range is ± 3.75 V,

meaning that a 3.75 V signal will result in a fully rated peak current. The current limit

circuits will override this signal if the peak duration exceeds 2.7 seconds and/or the

required current exceeds the values set by the ECLC and ECLP signals. If the input

command voltage exceeds 3.75 V, input scaling must be implemented by adding a pair of

external resistors, according to the following formula:

4-1

R

= (5.33 * Vin) - 20

in (KΩ)

Be careful not to apply input voltage above the maximum allowed input voltage as this

will cause the input operational amplifier to operate beyond its limits (+20 V) and in

extreme cases, may even damage it.

4.2 CFM

The amplifier is equipped with a current feedback multiplier (CFM). Connecting pin J2/6

to J2/5 multiplies the signal of the current feedback by 2 and consequently causes the

following changes to occur:

Current gains are divided by 2.

Current monitor is multiplied by 2.

Current limits are divided by 2.

This function should be activated whenever the rated current and the peak current of the

motor are less than 50% of the amplifier rated continuous and peak limits, respectively.

Continuous

Current limit

Peak Current

Limit

Current

Gain(A/V)

Current

Monitor

(V/A)

Differential

Input

Impedance

Without CFM Ic Ip Ip/3.75 3.9/Ip 40 kΩ

With CFM Ic/2 Ip/2 Ip/7.5 7.8/Ip 40 kΩ

Table 4-1: CFM Effects

The default (pin J2/6 left open) is the low current feedback.

For permanent selection, a simple short is recommended.

For remote selection, the scheme in Figure

4-1 should be used.

Page 21

Raven Installation Guide Servo Control Operation

MAN-RAVIG (Ver. 1.1)

4.3 Current Gain Control (CGC)

The Raven amplifier is equipped with Current Gain Control (CGC) for improved

performance of low induction motors. Connecting pin J2/5 to J2/4 reduces the gain of

the current loop, thus enabling the use of low inductance motors without the insertion of

an additional inductor. The default (pin J2/5 left open) is high gain.

Shorting this pin to the circuit common pin (J2/4) reduces the proportional gain (P) of the

current loop by approx. 70%.

For permanent selection, a simple short is recommended. For remote selection, the

following scheme should be used.

4-2

Figure 4-1: CFM and CGC Remote Control

The following table should be used for calculating minimum inductance values.

Minimum Inductance for High Gain Minimum Inductance for Low Gain

-3

-3

-3

* V

* V

-3

-3

* V

supply (Volt)

supply (Volt)

supply (Volt)

* V

supply (Volt)

* V

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

L

L

L

L

L

L

L

L

supply (Volt)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

L

Load (millihenry)

> 4.8*10 -3 * V

> 2.4*10 -3 * V

> 1.6*10 -3 * V

> 0.9*10 -3 * V

> 6.6*10 -3 * V

> 2.2*10 -3 * V

> 1.5*10 -3 * V

> 1.1*10 -3 * V

> 12*10 -3 * V

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

5/60 L

10/60 L

15/60 L

25/60 L

3/100 L

10/100 L

15/100 L

20/100 L

2/200 L

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

> 12*10

> 6*10

> 4*10

> 2.4*10

> 27*10

> 9*10 -3 * V

> 6*10 -3 * V

> 4*10 -3 * V

> 49.5*10 -3 * V

6/200 L

10/200 L

15/200 L

Load (millihenry)

Load (millihenry)

Load (millihenry)

> 16.5*10 -3 *V

> 10*10 -3 *V

supply(Volt)

> 6.5*10 -3 *V

supply(Volt)

supply(Volt)

L

Load (millihenry)

L

Load (millihenry)

L

Load (millihenry)

Table 4-2: Minimum Inductance Values

> 4*10 -3 * V

> 2.4 -3 * V

> 1.6 -3 * V

supply (Volt)

supply (Volt)

supply (Volt)

Page 22

Raven Installation Guide Servo Control Operation

MAN-RAVIG (Ver. 1.1)

4.4 External Current Limit - Continuous (ECLC)

The continuous current limit of the Raven amplifier can be scaled down by an external

voltage or by an external resistor connected from pin J2/1 (ECLC) to pin J2/2 (ECLRET).

4.4.1 External Voltage

An external positive voltage (0 to 3.75 V) to terminal J2/1 (ECLC) in reference to terminal

J2/2 (ECLRET) will control the continuous current limit from zero to Ic(nom).

V

V

ECLC

IC(new) =

IC(new) =

ECLC

3.75V

3.75V

* Ic(nom)

* Ic(nom)

4-3

The voltage is internally clamped to 3.75 V whenever the external V

is greater

ECLC

than 3.75 V.

The external voltage source must be able to source/ sink at least ±0.4 mA.

The maximum absolute V

ECLC

is 12 V.

4.4.2 External Resistor

Connect an external resistor between terminal J2/1 (ECLC) and terminal J2/2 (ECLRET).

The resistor value is given by:

Ic(new)

R

R

R

(Kohm) = 12.5 *

(Kohm) = 12.5 *

(Kohm) = 12.5 *

ECLC

ECLC

ECLC

0 < R

At R

< 11.4 K (1/8 Watt)

ECLC

greater than 11.4 K, the current limit will be internally clamped to the

ECLC

Ic(new)

Ic(nom)

Ic(nom)

- 1

- 1

nominal value.

I

is the nominal continuous current limit of the amplifier.

C(nom)

4.5 External Current Limit - Peak (ECLP)

The peak current limit of the Raven amplifier can be scaled down by an external voltage

or by an external resistor connected between pin J2/3 (ECLP) and pin J2/2 (ECLRET).

4.5.1 External Voltage

An external positive voltage (0 to 3.75 V) to terminal J2/3 (ECLP) in reference to terminal

J2/2 (ECLRET) will control the peak current limit from zero to Ip(nom).

V

V

ECLP

Ip(new) =

Ip(new) =

The voltage is internally clamped to 3.75 V whenever the external V

3.75 V.

The external voltage source must be able to source/sink at least ±0.4 mA.

The maximum absolute V

ECLP

3.75V

3.75V

* Ip(nom)

* Ip(nom)

ECLP

is 12 V.

is higher than

ECLP

Page 23

Raven Installation Guide Servo Control Operation

MAN-RAVIG (Ver. 1.1)

4.5.2 External Resistor

Connect an external resistor between terminal J2/3 (ECLP) and terminal J2/2 (ECLRET).

The resistor value is given by:

Ip(new)

R

R

R

(Kohm) = 12.5 *

(Kohm) = 12.5 *

(Kohm) = 12.5 *

ECLP

ECLP

ECLP

Ip(new)

Ip(nom)

Ip(nom)

- 1

- 1

4-4

0 < R

At R

< 11.4 K (1/8 Watt)

ECLP

greater than 11.4K, the current limit will be internally clamped to the

ECLP

nominal value.

I

is the nominal peak current limit of the amplifier.

P(nom)

4.6 Latch Mode (LM)

By connecting J2/7 to J2/8, the amplifier can be latched to Disable mode whenever a

Short or Over Temperature failure occurs. Disabling the amplifier temporarily (removing

the power from Enable pins J2/9 and J2/10) resets the latch. Be sure to restore the Enable

connection when the reason for the event no longer exists. For permanent selection, a

simple short is recommended. For remote selection, use the following scheme.

Figure 4-2: LM Remote Control

4.7 Amplifier Enable Logic

Pins J2/9 and J2/10 are the inputs of an opto-coupler, which must be energized to enable

operation of the amplifier. If the Enable input is kept high before turning on the

amplifier, the amplifier power output will be active immediately upon power on.

Page 24

Raven Installation Guide Servo Control Operation

MAN-RAVIG (Ver. 1.1)

4.8 Status Indications

The following table lists the Raven amplifier status indications.

4-5

Function

1 Amplifier OK

Latch

Option AOK

SO1

SO2

SO3

N/A Low Open collector Open collector Open collector

(AOK)

2 External disable No Low Low Open collector Low

3 Current limit No Low Open collector Open collector Low

4 Short Yes Open collector Low Open collector Low

5 Over

Yes Open collector Open collector Low Low

temperature

6 Internal supplies

No Open collector Low Low Open collector

protection

7 Under voltage No Open collector Low Open collector Open collector

8 Over voltage No Open collector Open collector Low Open collector

9 Shunt* No Low Open collector Low Open collector

10 Power Up Reset No Open collector Open collector Open collector Open collector

* This indication can be used as a digital input for activating an external shunt regulator.

Notes:

Without latch mode:

The status indications are reset when the fault disappears.

With latch mode:

The Short and Over Temperature Failure status indications are reset when the

enable signal is temporarily removed from the enable input.

Multiple faults:

Only the reading of the first fault is reliable. Additional faults add on to the

status outputs and the indication is therefore meaningless.

Table 4-3: Raven Status Indications

Page 25

Raven Installation Guide

MAN-RAVIG (Ver.1.1)

Appendix: Technical Specifications

A.1 Power Ratings

A-1

Feature Units

Minimum supply

voltage

Nominal supply

voltage

Maximum supply

voltage

Maximum continuous

power output

Efficiency at rated

power (at nominal

conditions)

Maximum output

voltage

Sinusoidal continuous

current magnitude

Peak current limit A 2 x Ic

Mounting method PCB mount

VDC 10 20 40

VDC 50 85 170

VDC 59 95 195

W 240 480 720 1200 260 800 1200 1600 360 960 1600 2400

% > 97

Up to 100% of DC bus voltage

A 5 10 15 25 3.3 10 15 20 2.25 6 10 15

5/60

10/60

15/60

25/60

3/100

10/100

15/100

20/100

2/200

6/200

10/200

15/200

A.2 Electrical Specifications

Feature Details

Switching frequency on the load 32 kHz (±5%)

Current loop bandwidth Up to 4 kHz

Current step response <70 µsec

Peak current duration (full rated peak current) 2.7 sec ±15%

Continuous current limit tolerance -1% +5%

Peak current limit tolerance -1% +5%

Current gain linearity

Current gain accuracy

Current monitor accuracy

Better than ±1% of rated continuous cu rre nt

Better than ±5% for 0.05 Ic < lmotor > Ip

Better than ±5% for 0.05 Ic < lmotor > Ip

Page 26

Raven Installation Guide Technical Specifications

MAN-RAVIG (Ver.1.1)

A-2

A.3 Mechanical Specifications

Feature Details

Size 82 x 62 x 25.4 mm (3.228 x 2.440 x 1.000 in)

Weight 250 g (8.8 oz)

Power pin material Brass with tin plating

Power pin size 1.14 mm (0.45 in) square

Power pin PCB layout 1.8 ± 0.05 mm (0.071 ± 0.002 in)

Signal pin (J1, J2) mate ria l Phosphor bronze with 10µ gold plating

Signal pin (J1, J2) size 0.5 ± 0.1 mm (0.02 ± 0.004 in) square

Signal pin (J1, J2) PCB layout 1 ± 0.05 mm (0.04 ± 0.002 in)

A.4 Environmental Conditions

Ambient

Temperature

Range

Temperature

Shock

Altitude

Maximum

Humidity

Vibration

Mechanical

Shock

Non-operating

conditions

-50 °C to +100 °C (-58 °F to 212 °F)

Operating conditions -40 °C to +70 °C (-40 °F to 160 °F)

Non-operating

conditions

Non-operating

-40 °C to +70 °C (-40 °F to 160 °F)

within 3 min.

Unlimited

conditions

Operating conditions -400 m to 155,000 m (-1,300 ft to 510,000 ft)

Non-operating

conditions

Up to 95% relative humid ity non-cond ensing

at 35 °C (95 °F)

Up to 95% relative humid ity non-cond ensing

Operating conditions

at 25 °C (77 °F), up to 90% relative humidity

non-condensing at 42 °C (108 °F)

Operating conditions 20 Hz –2,000 Hz, 14.6g

Non-operating

±40g; Half sine, 11 msec

conditions

Operating conditions

±20g; Half sine, 11 msec

Page 27

Raven Installation Guide Technical Specifications

MAN-RAVIG (Ver.1.1)

A-3

A.5 Standards Compliance

A.5.1 Quality Assurance

Specification Details

ISO 9001:2000 Quality Management

A.5.2 Design

Specification Description

In compliance with MIL-STD-704

In compliance with MIL-STD-810

Aircraft, Electric Power Characteristics

Environmental Engineering Considerations and

Laboratory Tests

In compliance with MIL-STD-1275

Characteristics of 28 Volt DC Electrical Systems in

Military Vehicles

In compliance with MIL-STD-461

Requirements for the Control of Electromagnetic

Interference Characteristics of Subsystems and

Equipment

In compliance with MIL-HDBK-217

IPC-D-275

IPC-SM-782

IPC-CM-770

UL508c

UL840

Reliability Prediction of Electronic Equipment

Reliability prediction of electronic equipment

(rating, de-rating, stress, etc.)

Printed wiring for electronic equipment

(clearance, creepage, spacing, conductors sizing,

etc.)

In compliance with VDE0160-7 (IEC68) Type testing

A.5.3 Safety

Specification Details

Recognized UL508c Power conversion equipment

In compliance with UL840 Insulation coordination, including clearance and

creepage distances of electrical equipment

In compliance with UL60950 Safety of information technology equipment,

including electrical business equipment

In compliance with EN60204-1 Low voltage directive, 73/23/EEC

Page 28

Raven Installation Guide Technical Specifications

MAN-RAVIG (Ver.1.1)

A-4

A.5.4 EMC

Specification Details

In compliance with

Electromagnetic compatibility (EMC)

EN55011 Class A with EN61000-6-2:

Immunity for industrial environment,

according to:

IEC61000-4-2 / criteria B

IEC61000-4-3 / criteria A

IEC61000-4-4 / criteria B

IEC61000-4-5 / criteria B

IEC61000-4-6 / criteria A

IEC61000-4-8 / criteria A

IEC61000-4-11 / criteria B/C

A.5.5 Workmanship

Specification Details

In compliance with IPC-A-610, level 3 Acceptability of electronic assemblies

A.5.6 PCB

Specification Details

In compliance with IPC-A-600, level 3 Acceptability of printed circuit boards

A.5.7 Packing

Specification Details

In compliance with EN100015 Protection of electrostatic sensitive devices

A.5.8 WEEE*

Specification Description

In compliance with 2002/96/EC Waste Electrical and Electronic Equipment

regulations

* Please send out-of-service Elmo drives to the nearest Elmo sales office.

A.5.9 RoHS

Specification Description

In compliance with 2002/95/EC

(effective July 2006)

Restrictions on Application of Hazardous

Substances in Electric and Electronic Equipment

Page 29

Raven Installation Guide Technical Specifications

MAN-RAVIG (Ver.1.1)

A-5

Loading...

Loading...