Page 1

Dragonfly/Butterfly

Current Mode Servo Amplifiers for DC Br ush and Brushless

Motors with Trapezoidal Commutation in

Extended Environmental Conditions

Installation Guide

April 2008 (Ver. 1.1)

www.elmomc.com

Page 2

Notice

This guide is delivered subject to the following conditions and restrictions:

This guide contains proprietary information belonging to Elmo Motion Control Ltd.

Such information is supplied solely for the purpose of assisting users of the Dragonfly

and Butterfly servo drives in their installation.

The text and graphics included in this manual are for the purpose of illustration and

reference only. The specifications on which they are based are subject to change

without notice.

Elmo Motion Control and the Elmo Motion Control logo are trademarks of Elmo

Motion Control Ltd.

Information in this document is subject to change without notice.

Document No. MAN-DRBUIG

Copyright 2008

Elmo Motion Control Ltd.

All rights reserved.

Hornet/Bee Catalog Numbers:

BUT- X/YYY

Continuous Current

Operating Voltage

Related Products:

Evaluation Board Catalog Number

Evaluation Board User Manual

Revision History:

Ver. 1.1 April 2008 Updated Power Ratings Table in Appendix

Ver. 1.0 June 2007 Initial release

Elmo Motion Control Ltd.

64 Gisin St., P.O. Box 463

Petach Tikva 49103

Israel

Tel: +972 (3) 929-2300

Fax: +972 (3) 929-2322

info-il@elmomc.com

(Amps)

Maximum DC

Elmo Motion Control Inc.

1 Park Drive, Suite 12

Westford, MA 01886

USA

Tel: +1 (978) 399-0034

Fax: +1 (978) 399-0035

info-us@elmomc.com

DRA-

Continuous Cu rrent

(Amps)

Maximum DC

Operating Voltage

X/YY

OCA-EVLBRD-1 (available upon request)

MAN-EVLBRD-OCA (available on our web site)

(MAN-DRBUIG.PDF)

Elmo Motion Control GmbH

Steinkirchring 1

D-78056, Villingen-Schwenningen

Germany

Tel: +49 (0) 7720-85 77 60

Fax: +49 (0) 7720-85 77 70

info-de@elmomc.com

www.elmomc.com

Page 3

Dragonfly/B utterfly Installation Guide

MAN-DRBUIG (Ver. 1.1)

i

Contents

Chapter 1: Safety Information...............................................................................................1-1

1.1 Warnings....................................................................................................................1-2

1.2 Cautions.....................................................................................................................1-2

1.3

Directives and Standards .........................................................................................1-3

1.4 CE Mark Conformance.............................................................................................1-3

1.5 Warranty Information...............................................................................................1-4

Chapter 2: Introduction...........................................................................................................2-1

2.1 ExtrIQ Product Family.............................................................................................. 2-1

2.2 Product Description..................................................................................................2-2

2.3 Highlights..................................................................................................................2-2

2.4 Fault Protection.........................................................................................................2-3

2.5 How to Use this Guide.............................................................................................2-3

Chapter 3: Installation ............................................................................................................3-1

3.1 Before You Begin.......................................................................................................3-1

3.1.1 Site Requirements.............................................................................................3-1

3.2 Unpacking the Amplifier..........................................................................................3-1

3.3 Dimensions................................................................................................................3-2

3.3.1 Butterfly Dimensions........................................................................................3-2

3.3.2 Dragonfly Dimensions.....................................................................................3-3

3.4 Mounting...................................................................................................................3-3

3.4.1 Butterfly..............................................................................................................3-3

3.4.2 Dragonfly...........................................................................................................3-3

3.5 Integrating the Dragonfly and Butterfly on a PCB................................................3-4

3.5.1 Traces..................................................................................................................3-4

3.5.2 Grounds and Returns.......................................................................................3-5

3.6 Pin Functions.............................................................................................................3-6

3.6.1 Pinouts................................................................................................................ 3-6

3.6.2 Connector J1 ......................................................................................................3-7

3.7 Dragonfly/Butterfly Connection Diagram.............................................................3-9

3.8 Evaluation Board and Cable Kit..............................................................................3-9

3.9 DC Power Supply....................................................................................................3-10

3.10 Heat Dissipation......................................................................................................3-12

3.10.1 Butterfly............................................................................................................3-12

3.10.1.1 Thermal Data.........................................................................................3-12

3.10.1.2 Heat Dissipation Data...........................................................................3-12

3.10.1.3 How to Use the Charts.........................................................................3-13

3.10.2 Dragonfly.........................................................................................................3-13

Chapter 4: Servo Control Operation.....................................................................................4-1

4.1 Current Command Input .........................................................................................4-1

4.2 External Current Limit - Continuous (ECLC)........................................................4-1

4.2.1 External Voltage............................................................................................4-1

4.2.2 External Resistor...............................................................................................4-2

4.2.3 External Current Limit - Peak (ECLP)...........................................................4-2

Page 4

Dragonfly/B utterfly Installation Guide Contents

MAN-DRBUIG (Ver. 1.1)

4.2.4 External Voltage................................................................................................4-2

4.2.5 External Resistor...............................................................................................4-3

4.2.6 Latch Mode (LM)..............................................................................................4-3

4.3 Status Indications ......................................................................................................4-3

Appendix: Specifications ......................................................................................................A-1

A.1 General Specifications.............................................................................................. A-1

A.1.1 Butterfly.............................................................................................................A-1

A.1.2 Dragonfly..........................................................................................................A-2

A.2 Environmental Specifications.................................................................................A-2

A.3 Standards Compliance.............................................................................................A-3

A.3.1 Quality Assurance...........................................................................................A-3

A.3.2 Design................................................................................................................A-3

A.3.3 Safety .................................................................................................................A-3

A.3.4 EMC...................................................................................................................A-4

A.3.5 Workmanship...................................................................................................A-4

A.3.6 PCB ....................................................................................................................A-4

A.3.7 Packing..............................................................................................................A-4

A.3.8 WEEE*...............................................................................................................A-4

A.3.9 RoHS..................................................................................................................A-4

ii

Page 5

Dragonfly/B utterfly Installation Guide

MAN-DRBUIG (Ver. 1.1)

1-1

Chapter 1: Safety Information

In order to achieve the optimum, safe operation of the Dragonfly and Butterfly servoamplifiers, it is imperative that you implement the safety procedures included in this

installation guide. This information is provided to protect you and to keep your work

area safe when operating the Dragonfly and Butterfly and accompanying equipment.

Please read this chapter carefully before you begin the installation process.

Before you start, ensure that all system components are connected to earth ground.

Electrical safety is provided through a low-resistance earth connection.

Only qualified personnel may install, adjust, maintain and repair the servo drive. A

“qualified person” has the knowledge and authorization to perform tasks such as

transporting, assembling, installing, commissioning and operating motors.

The Dragonfly and Butterfly servo drive contain electrostatic-sensitive components that

can be damaged if handled incorrectly. To prevent any electrostatic damage, avoid

contact with highly insulating materials, such as plastic film and synthetic fabrics. Place

the product on a conductive surface and ground yourself in order to discharge any

possible static electricity build-up.

To avoid any potential hazards that may cause severe personal injury or damage to the

product during operation, keep all covers and cabinet doors shut.

The following safety symbols are used in this manual:

Warning:

This information is needed to avoid a safety hazard, which might cause

bodily injury.

Caution:

This information is necessary for preventing damage to the product or

to other equipment.

Note:

This is auxiliary information that ensures the correct operation of the

equipment.

Page 6

Dragonfly/B utterfly Installation Guide Safety Information

MAN-DRBUIG (Ver. 1.1)

1.1 Warnings

Cleaning after soldering

To avoid the damage of the product's acrylic coating the

Dragonfly/Butterfly must not be cleaned after soldering by dissolving

solvents and /or "water" cleaning process. For more details:

http://www.elmomc.com/applicat ions/ar ti cl e/Sol der ing-and Cleaning_Application-Note.pdf

To avoid electric arcing and hazards to personnel and electrical contacts,

never connect/disconnect the servo drive while the power source is on.

Power cables can carry a high voltage, even when the motor is not in

motion. Disconnect the Dragonfly and Butterfly from all voltage sources

before they are opened for servicing.

1-2

The Dragonfly and Butterfly servo drive cont ain ground ing condui ts for

electric current protection. Any disruption to these conduits may cause

the instrument to become hot (live) and dangerous.

After shutting off the power and removing the power source from your

equipment, wait at least 1 minute before touching or disconnecting parts

of the equipment that are normally loaded with electrical charges (such as

capacitors or contacts). Measuring the electrical contact points with a

meter, before touching the equipment, is recommended.

1.2 Cautions

The Dragonfly and Butterfly servo drives contain hot surfaces and

electrically-charged components during operation.

The maximum DC power supply connected to the instrument must

comply with the parameters outlined in this guide.

When connecting the Dragonfly and Butterfly to an approved 12 ~ 95

VDC auxiliary power supply, connect them through a line that is

separated from hazardous live voltages using reinforced or double

insulation in accordance with approved safety standards.

Before switching on the Dragonfly and Butterfly, verify that all safety

precautions have been observed and that the installation procedures in

this manual have been followed.

Page 7

Dragonfly/B utterfly Installation Guide Safety Information

MAN-DRBUIG (Ver. 1.1)

1.3 Directives and Standards

The Dragonfly and Butterfly conform to the following industry safety standards:

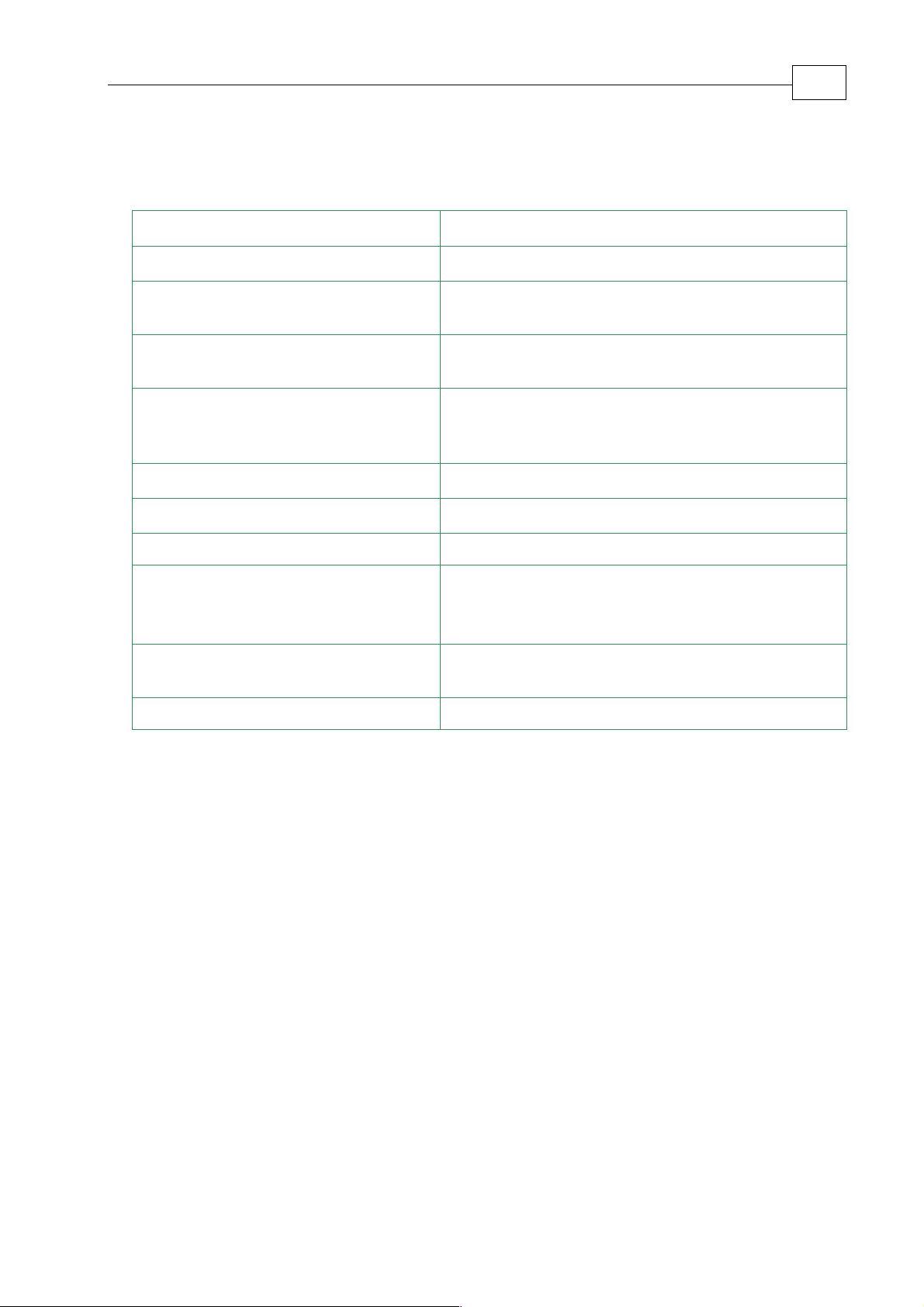

Safety Standard Item

1-3

In compliance with MIL-STD-704

In compliance with MIL-STD-810

Aircraft, Electric Power Characteristics

Environmental Engineering Considerations and

Laboratory Tests

In compliance with MIL-STD-1275

Characteristics of 28 Volt DC Electrical Systems in

Military Vehicles

In compliance with MIL-STD-461

Requirements for the Control of Electromagnetic

Interference Characteristics of Subsystems and

Equipment

In compliance with MIL-HDBK-217

In compliance with ISO-9001:2000

Reliability Prediction of Electronic Equipment

Quality Management

In compliance with UL508c Power Conversion Equipment

In compliance with UL840

Insulation Coordination, Including Clearance and

Creepage Distances of Electrical Equipment

In compliance with UL60950-1

(formerly UL1950)

Safety of Information Technology Equipment,

Including Electrical Business Equipment

In compliance with EN60204-1 Low Voltage Directive, 73/23/EEC

The Dragonfly and Butterfly servo drives have been developed, produced, tested and

documented in accordance with the relevant standards. Elmo Motion Control is not

responsible for any deviation from the configuration and installation described in this

documentation. Furthermore, Elmo is not r esponsib le for t he perform ance of new

measurements or ensuring that regulatory requirements are met.

1.4 CE Mark Conformance

The Dragonfly and Butterfly servo drives are intended for incorporation in a machine or

end product. The actual end product must comply with all safety aspects of the relevant

requirements of the European Safety of Machinery Directive 98/37/EC as amended, and

with those of the most recent versions of standards EN60204-1 and EN292-2 at the least.

According to Annex III of Article 13 of Council Directive 93/68/EEC, amending Council

Directive 73/23/EEC concerning electrical equipment desi gned for use wit hin certai n

voltage limits, the Butterfly and Dragonfly meet the provisions outlined in Council

Directive 73/23/EEC. The party responsible for ensuring that the equipment meets t he

limits required by EMC regulations is the manufacturer of the end product.

Page 8

Dragonfly/B utterfly Installation Guide Safety Information

MAN-DRBUIG (Ver. 1.1)

1.5 Warranty Information

The products covered in this manual are warranted to be free of defects in material and

workmanship and conform to the specifications stated either within this document or in

the product catalog description. All Elmo drives are warranted for a period of 12 months

from the time of installation, or 18 months from time of shipment, whichever comes first.

No other warranties, expressed or implied — and including a warranty of

merchantability and fitness for a particular purpose — extend beyond this warranty.

1-4

Page 9

Cymbal Installat ion Guide Introduction

MAN-CYMIG (Ver. 1.1)

Chapter 2: Introduction

This Installation Guide is intended for design engineers who are in tegrating Elmo Motion

Control Cymbal servo amplifiers into a machine.

2.1 Product Description

The Cymbal series of servo amplifiers is designed to operate in the current mode

controlling permanent-magnet trapezoidal brushless motor and DC brush motor.

The Cymbal exhibits “the highest density of power and intelligence” and can deliver up

to 11.3 kW of continuous power or 13.6 k W of peak power in a most compact and

efficient package.

The Cymbal operates from a DC power source in the range of 12 ~ 195 VDC.

2-1

The Power stage of the Cymbal is fully isolated from other sections of the Cymbal, such

as the control stage and the heatsink. This contributes very significantly to the safety and

the EMI immunity of the Cymbal. In addition it simplifies the requirements of the DC

power supply used to power the DC bus of the Cymbal and allows also the operation

with a non-isolated DC power source.

The Cymbal incorporates full custom mixed analog/digital ICs and a hybrid power

stage. The basic configuration is a current mode amplifier targeting the OEM market. As

such, no trimmers are used in the basic version. In addition to its compliance with

relevant MIL standards, the Cymbal amplifier also meets UL508c and the relevant CE

regulations.

The Cymbal power stage is implemented on ceramic substrates. This design enables very

high thermal conductivity, high current carrying capacity, improved EMC and good

mechanical strength. The control section is implemented by dedicated custom ICs that

contribute to enhanced performance and reliability.

2.2 Standard Features

• Operates in current mode

• Internal DC-to-DC converter, which allows for operation from a single supply

• Zero dead-band

• Excellent linearity

• One differential input

• Motor current monitor

• Current gain change for low inductance motors

• Remote current gain control

• Status indication and remote control functions by four open collector transistors

• External continuous and peak current-limit adjustments

• Package: plated-aluminum base plate, plastic housing, UL94V0 recognized

• Ultra-lightweight of 700 grams (24.7 oz)

Page 10

Cymbal Installat ion Guide Introduction

MAN-CYMIG (Ver. 1.1)

2.3 Fault Protection

Built-in protection against possible fault conditions, including:

• Shorts between the outputs or between each output and the power input/return

• Over-heating

• Under/over voltage

• Failure of internal power supplies

• Latch mode for each protective feature

2.4 How to Use this Guide

Installation is the first step in integrating and operating the Elmo Cymbal servo

amplifiers. After carefully reading the safety instructions in the first chapter, the

following chapters provide you with installation instructions as follows:

Chapter 3, Installation, provides step-by-step instructions for unpacking, mounting and

connecting the Cymbal.

2-2

Chapter 4, Servo Control Operation, explains how to control the operat ion of t he servo

amplifier.

The Appendix, Technical Specifications, lists all the drive ratings and specifications.

Page 11

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

Chapter 3: Installation

3.1 Before You Begin

3.1.1 Site Requirements

You can guarantee the safe operation of the Dragonfly and Butterfly by ensuring that they are

installed in an appropriate environment.

Feature Value

Ambient operating temperature -40 °C to +70 °C (-40 °F to 160 °F)

Maximum relative humidity 95% non-condensing

Operating area atmosphere No flammable gases or vapors permitted in area

Note: Models for extended environmental conditions are available.

3-1

The Dragonfly and Butterfly dissipate their heat by convection. The maximum

ambient operating temperature of –40 °C to +70 °C (-40 °F to 160 °F) must not

be exceeded.

3.2 Unpacking the Amplifier

To unpack the Dragonfly and Butterfly:

Carefully remove the servo amplifier from the box and the Styrofoam.

1. Check the amplifier to ensure that there is no visible damage to the instrument. If any

damage has occurred, report immediately to the carrier that delivered your amplifier.

2. To ensure that the Dragonfly or Butterfly you have unpacked is the appropriate type for

your requirements, find the part number sticker on the side of the product:

The P/N gives the type designation

as follows:

BUT- X/YYY

Continuous Current

Operating Voltage

(Amps)

Maximum DC

Page 12

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3-2

DRA-

Continuous Cu rrent

(Amps)

Maximum DC

Operating Voltage

X/YY

3. Verify that the Dragonfly or Butterfly type is the one that you ordered, and ensure that

the voltage meets your specific requirements.

3.3 Dimensions

3.3.1 Butterfly Dimensions

Figure 3-1: Butterfly Dimensions

Page 13

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.3.2 Dragonfly Dimensions

3-3

Figure 3-2: Dragonfly Dimensions

3.4 Mounting

3.4.1 Butterfly

The Butterfly was designed for mounting on a printed circuit board (PCB). It is connected by

2mm pitch 0.51 mm square pins. When designing the Butterfly into a device, be sure to leave

about 1 cm (0.4") outward from the heatsink to enable free air convection around the Butterfly.

We recommend that the Butterfly be soldered directly to the board. Alternatively, the Butterfly

can be attached to socket connectors mounted on the PCB. If the PCB is enclosed in a metal

chassis, we recommend that the Butterfly be screw-mounted to it as well to help with heat

dissipation. The Butterfly has screw-mount holes on each corner of the heatsink for this

purpose.

3.4.2 Dragonfly

The Dragonfly was designed for mounting on a printed circuit board (PCB). It is connected by

2mm pitch 0.51 mm square pins. When designing the Dragonfly into a device, be sure to leave

about 1 cm (0.4") outward from the lower board to enable free air convection around the

Dragonfly. We recommend that the Dragonfly be soldered directly to the board. Alternatively,

the Dragonfly can be attached to socket connectors mounted on the PCB.

Note: Elmo recommends you leave approximately 1 cm (0.4 in) of space on the side opposite

the terminals to allow for free air convection.

Page 14

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3-4

3.5 Integrating the Dragonfly and Butterfly on a PCB

The Dragonfly and Butterfly are designed to be mounted on a PCB, either by soldering the

pins directly to the PCB or by using suitable socket connectors. In both cases the following

rules apply:

3.5.1 Traces

1. The size of the traces on the PCB (thickness and width) is determined by the current

carrying capacity required by the application.

The rated continuous current limit (Ic)of the Dragonfly and Butterfly is the current

used for sizing the motor traces (M1, M2, M3 and PE) and power traces (VP+, PR

and PE).

For control, feedbacks and Inputs/ outputs conductors the actual current is very

small but “generous” thickness and width of the conductors will contribute to a

better performance and lower interferences.

2. The traces should be as short as possible to minimize EMI and to minimize the heat

generated by the conductors.

3. The spacing between the high voltage conductors (VP+, PR, M1, M2, M3, VL) must be

at least:

Surface layer: 1.5 mm

Internal layer: 0.10 mm

Complying with the rules above will help satisfy UL safety standards, MIL-STD-275 and the

IPC-D-275 standard for non-coated conductors, operating at voltages lower than 100VDC and

at "unlimited altitudes" (above 10,000 meters – 30,000 feet).

Page 15

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.5.2 Grounds and Returns

The “Returns” of the Dragonfly and Butterfly are structured internally in a star configuration.

The returns in each functional block are listed below:

Functional Block Return Pin

Power PR (Power Return)

Internal Switch Mode P.S. PR (Power Return)

Control section Internal, not accessible

Feedback SUPRET (J2/2)

The returns above are all shorted within the Dragonfly and Butterfly in a topology that results

in optimum performance.

1. When wiring the traces of the above functions, on the Integration Board, the Returns of

each function must be wired separately to its designated terminal on the Dragonfly and

Butterfly. DO NOT USE A COMMON GROUND PLANE. Shorting the commons on the

Integration Board may cause performance degradation (ground loops, etc).

3-5

2. Return Traces: The return traces should be as large as possible, but without shorting

each other, and with minimal cross-overs.

3. Main Power Supply and Motor Traces: The power traces must be kept as far away as

possible from the feedback and control traces.

4. PE Terminal: The PE terminal is connected directly to the Butterfly's heatsink or to the

Dragonfly's two PE strips on its lower board. In the Butterfly, the heatsink serves as an

EMI common plane. The PE terminal should be connected to the system's Protective

Earth. Any other metallic parts (such as the chassis) of the assembly should be connected

to the Protective Earth as well.

5. Under normal operating conditions, the PE trace carries no current. The only time these

traces carry current is under abnormal conditions (such as when the device has become a

potential shock or fire hazard while conducting external EMI interferences directly to

ground). When connected properly the PE trace prevents these hazards from affecting

the drive.

Follow these instructions to ensure safe and proper implementation.

Failure to meet any of the above-mentioned requirements can result in

drive/controller/host failure.

Page 16

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.6 Pin Functions

The Dragonfly and Butterfly are PCB mounted analog servo drives. Their pinouts are

described below.

3.6.1 Pinouts

3-6

No.

Pins Type

2X11 J1 I/O connector

Port Function Connector Location

2 M3 Motor power output 3

2 M2 Motor power output 2

2 M1 Motor power output 1

2 mm Pitch

0.51 mm SQ

2 PE Protective earth

2 PR Power input return

2 VP+ Positive power input

1

VL Auxiliary power input

Page 17

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.6.2 Connector J1

3-7

Pin # Short

Form Function

Description

1 EN+ Enable + Positive voltage input of the “Amplifier Enable” function.

To enable operation of the amplifier, the optocoupler

must be energized by applying voltage between this pin

(+) and pin J1/22 (-).

The optocoupler is isolated from the amplifier. See Figure

3-4.

“OFF” voltage: 0 V < Vin < 1 V.

“ON” voltage: 2.5 V < Vin < 10 V, 5 V typically with

current consumption 2.5 mA.

2 AOK Amplifier OK When the amplifier under normal operating conditions,

this output is in the “active low“ state. When a failure

occurs, this output is changed to the “open” state.

The optocoupler is an isolated, open collector NPN type.

See Figure

3-4.

Maximum voltage = 30 V

Maximum current = 8 mA

“On” voltage: V

OUT(On)

< 0.8 V

Refer to Section 4.3.

3 SO1 Status output 1 Specifications same as in pin J1/2.

4 HA Hall A input Logic levels: TTL

Maximum input voltage

: 15 VDC.

5 HB Hall B input Logic levels: TTL

Maximum input voltage

: 15 VDC.

6 HC Hall C input Logic levels: TTL.

Maximum input voltage: 15 VDC.

7 LATCH Latch mode Latch mode input. For more details see the Latch Mode

section in Chapter 4.

8 ECLRET Current limits

return

9 ECLC External

current limit

continuous

10 CM Current

monitor

11 CREF+ Current

command

positive

12 CREF- Current

command

negative

13 CMRET Current

monitor return

Current limit signals return.

External voltage scales down the rated value.

Voltage range: 0 V to 3.75 V (3.75 V = rated Ic)

Refer to Section 4.2.

Analog output with a scale of ± 3.9 V for ± Ip.

Output resistance: 1 kΩ

Positive input of a differential amplifier:

Input operating voltage range: ±3.75 V

Maximum input voltage: ±20 V

Maximum common mode voltage: ±6 V

Differential input impedance: 40 kΩ

Refer to Section 4.1.

Negative input of a differential amplifier.

Same specification as in pin J1/11.

Current monitor (CM) signal return.

Page 18

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

Pin # Short

Form Function

Description

3-8

14 ECLP External

current limit

peak

External voltage scales down the rated value.

Voltage range: 0 V to 3.75 V (3.75 V = rated Ip)

Refer to Section 4.2.

15 LMRET Latch Mode

Return for Latch Mode signals.

return

16 GAIN Current gain

change

17 HARET Hall supply

Shorting this pin to LMRET pin (J1/15) reduces

the proportional gain of the current loop by 70%.

Return used only for Hall supply.

voltage return

18 HALL+

5V

19 SORET Status output

+5 V Hall

supply voltage

return

+5 V supply voltage for Hall sensors.

Output current: maximum of 13 mA.

Status output common AOK, SO1, SO2, SO3.

Isolated from circuit common. See Figure

3-4.

20 SO2 Status output 2 Status indication output 2.

Same specification as in pin J1/2.

21 SO3 Status output 3 Status indication output 3.

Same specification as in pin J1/2.

22 EN- Enable - Negative voltage input of “Amplifier Enable” function.

Optocoupler is isolated from the amplifier.

For details, see pin J1/1.

Page 19

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.7 Dragonfly/Butterfly Connection Diagram

3-9

Figure 3-3: Dragonfly /Butterfly Connection Diagram

3.8 Evaluation Board and Cable Kit

The same circuit board used for the Ocarina and Castanet is also available for evaluating the

Dragonfly and Butterfly. It comes with standards terminal blocks for power connections and

D-sub plugs/sockets for signals connections. The Evaluation Board is provided with a cable

kit.

Evaluation Board Catalog Number

Evaluation Board User Manual

OCA-EVLBRD-1

MAN-EVLBRD-OCA (available on our web site)

Page 20

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.9 DC Power Supply

The DC power supply can be at any voltage in the range defined in the technical

specifications (the Appendix of this guide). The supply source must comply with the safety

aspects of the relevant requirements, in accordance with the most recent version of the

standard EN60950 or equivalent Low Voltage Directive Standard, all according to the

applicable over-voltage category. If the power source to the power supply is the AC line

(through an isolated transformer), safety margins must be considered in order to avoid

activating the under/over voltage protection due to line variations and/or voltage drop

under load.

In addition to the above, the transformer must comply with the safety aspects of the relevant

requirements in accordance with the most recent version of the standard EN60742 (Isolating

and Safety Isolating Transformers). The nominal DC bus voltage should be in the following

range:

3-10

1.2 V

< Vdc < 0.9 V

dcmin

dcmax

where:

V

Vdcmax

is the minimum DC bus

dcmin

is the maximum DC bus

The recommended minimum power supply capacitance for a single-phase rectified DC source

connection is as follows:

Amplifier Voltage Range 60 V 100 V

Recommended capacitance ≥ 470 µF ≥470 µF

The transformer power should be calculated such that it will be able to deliver power to the

amplifier (including peak power) without significant voltage drops.

The power supply should be located as close as possible to the amplifier. The maximum

distance is 30 cm (1 foot). While driving high-inertia loads, the power supply must be

equipped with a shunt regulator; otherwise, the amplifier will be disabled whenever the

capacitors are charged above the maximum voltage, during motor break down.

Page 21

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3-11

Figure 3-4: Detailed Dragonfly /Butterfly Internal Block Diagram

Page 22

s

y

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

3.10 Heat Dissipation

3.10.1 Butterfly

The best way to dissipate heat from the Butterfly is to mount it so that its heatsink faces up.

For best results leave approximately 10 mm of space between the Butterfly's heatsink and any

other assembly.

3.10.1.1 Thermal Data

• Heat dissipation capability (θ): Approximately 10 °C/W.

• Thermal time constant: Approximately 240 seconds (thermal time constant means

that the Butterfly will reach 2/3 of its final temperature after 4 minutes).

• Shut-off temperature: 86 °C – 88 °C (measured on the heatsink)

3.10.1.2 Heat Dissipation Data

Heat Dissipation is shown in graphically below:

3-12

10.0

Power Dissipation (Watt

Butterfl

Whistle - 60 Series Power Dissipation

9.0

8.0

7.0

6.0

5.0

Standard 40 °°°°C Ambient Temp.

4.0

3.0

2.0

1.0

0.0

2

1

0

0

.

.

5

7

5

3

.

2

5

3

4

5

.

.

7

5

Peak Current (A)

.

5

2

5

50V

40V

30V

20V

External

Heatsink

Required

Heatsink

not

Required

6

.

7

5

.

.

2

5

5

8

7

6

9

9

.

7

5

Page 23

)

Dragonfly/ Bu tter fly Installation G uide Installation

MAN-DRBUIG (Ver. 1.1)

Whistle 100 Series Power Dissipation

Butterfly -100

3-13

6.0

External

5.0

Standard 40 °°°°C Ambient Temp.

Heatsink

Required

4.0

Pow er D i ss ipati o n (W

3.0

2.0

1.0

Heatsink

not

Required

0.0

2

5

0

5

1

0.

1.5

2.

3

3.5

4

5

5

4.

Peak Curr ent (A)

85VDC

70VDC

50VDC

3.10.1.3 How to Use the Charts

The charts above are based upon theoretical worst-case conditions. Actual test results show

30% - 50% better power dissipation.

To determine if your application needs a heatsink:

1. Allow maximum heatsink temperature to be 80 °C or less.

2. Determine the ambient operating temperature of the Butterfly.

3. Calculate the allowable temperature increase as follows:

• for an ambient temperature of 40 °C , ∆T= 80 °C – 40 °C = 40 °C

4. Use the chart to find the actual dissipation power of the drive. Follow the voltage

curve to the desired output current and then find the dissipated power.

5. If the dissipated power is below 4 W the Butterfly will need no additional cooling.

Note: The chart above shows that no heatsink is needed when the heatsink temperature is

80°C, ambient temperature is 40 °C and heat dissipated is 4 Watts:

3.10.2 Dragonfly

The best way to dissipate heat from the Dragonfly is to mount it so that its lower board faces

upwards. For best results leave approximately 10 mm of space between the Dragonfly's lower

board and any other assembly.

Page 24

Dragonfly/B utterfly Installation Guide

MAN-DRBUIG (Ver. 1.1)

4-1

Chapter 4: Servo Control Operation

4.1 Current Command Input

The Dragonfly and Butterfly have a single differential input. The input operating voltage

range is ± 3.75 V, meaning that a 3.75 V signal will result in a fully rated peak current. The

current limit circuits will override this signal if the peak duration exceeds 2.7 seconds and/or

the required current exceeds the values set by the ECLC and ECLP signals. If the input

command voltage exceeds 3.75 V, input scaling must be implemented by adding a pair of

external resistors, according to the following formula:

Rin (kΩ) = (5.33 * Vin) - 20

Be careful not to apply input voltage above the maximum allowed input voltage as this will

cause the input operational amplifier to operate beyond its limits (±20 V) and in extreme

cases, may even damage it.

4.2 External Current Limit - Continuous (ECLC)

The continuous current limit of the Dragonfly and Butterfly amplifiers can be scaled down by

an external voltage or by an external resistor connected from pin J1/9 (ECLC) to pin J1/8

(ECLRET).

4.2.1 External Voltage

V

V

ECLC

IC(new) =

IC(new) =

An external positive voltage (0 to 3.75 V) to terminal J1/9 (ECLC) in reference to terminal J1/8

(ECLRET) will control the continuous current limit from zero to Ic (nom).

The voltage is internally clamped to 3.75 V whenever the external VECLC is greater than

3.75V.

The external voltage source must be able to source/ sink at least ±0.2 mA.

The maximum absolute VECLC allowed to be connected is 5 V.

ECLC

3.75V

3.75V

* Ic(nom)

* Ic(nom)

Page 25

Dragonfly/B utterfly Installation Guide Servo Control Operation

MAN-DRBUIG (Ver. 1.1)

4.2.2 External Resistor

Ic(new)

R

R

R

(Kohm) = 37.4 *

(Kohm) = 37.4 *

(Kohm) = 37.4 *

ECLC

ECLC

ECLC

Connect an external resistor between terminal J1/9 (ECLC) and terminal J1/8 (ECLRET).

The resistor value is given by:

0 < RECLC < 36.4 K (1/8 Watt)

At RECLC greater than 36.4 K, the current limit will be internally clamped to the nominal

value.

IC(nom) is the nominal continuous current limit of the amplifier.

Ic(new)

Ic(nom)

Ic(nom)

- 1

- 1

4-2

4.2.3 External Current Limit - Peak (ECLP)

The peak current limit of the Dragonfly and Butterfly amplifiers can be scaled down by an

external voltage or by an external resistor connected between pin J1/14 (ECLP) and J1/8

(ECLRET).

4.2.4 External Voltage

An external positive voltage (0 to 3.75 V) to terminal J1/14 (ECLP) in reference to terminal

J1/8 (ECLRET) will control the peak current limit from zero to Ip(nom).

V

V

ECLP

Ip(new) =

Ip(new) =

The voltage is internally clamped to 3.75 V whenever the external VECLP is higher than 3.75 V.

The external voltage source must be able to source/sink at least ±0.2 mA.

The maximum absolute VECLP allowed to be connected is 5 V.

ECLP

3.75V

3.75V

* Ip(nom)

* Ip(nom)

Page 26

Dragonfly/B utterfly Installation Guide Servo Control Operation

MAN-DRBUIG (Ver. 1.1)

4.2.5 External Resistor

Ip(new)

R

R

R

(Kohm) = 37.4 *

(Kohm) = 37.4 *

(Kohm) = 37.4 *

ECLP

ECLP

ECLP

Connect an external resistor between terminal J1/14 (ECLP) and terminal J1/8 (ECLRET).

The resistor value is given by:

Ip(new)

Ip(nom)

Ip(nom)

- 1

- 1

4-3

0 < R

< 36.4 K (1/8 Watt)

ECLP

At RECLP greater than 36.4K, the current limit will be internally clamped to the nominal

value.

IP(nom) is the nominal peak current limit of the amplifier.

4.2.6 Latch Mode (LM)

By connecting J1/7 to J1/15, the amplifier is latched to disable mode whenever a Short,

Commutation or Over Temperature failure occurs. Disabling the amplifier temporarily by

removing the power from Enable pin J1/1 resets the latch. Be sure to restore the Enable

connection when the reason for the event no longer exists.

4.3 Status Indications

The following table lists the Dragonfly and Butterfly amplifier status indications.

Function

Latch

Option

AOK

SO1

SO2

SO3

1 Amplifier OK (AOK) N/A Low Open

Open collector Open collector

collector

2 External disable No Low Low Open collector Low

3 Current limit No Low Open

Open collector Low

collector

4 Short Yes Open

Low Open collector Low

collector

5 Over temperature Yes Open

collector

6 Internal supplies

protection

No Open

collector

7 Under voltage No Open

Open

Low Low

collector

Low Low Open collector

Low Open collector Open collector

collector

8 Over voltage No Open

collector

9 Shunt* No Low Open

Open

collector

Low Open collector

Low Open collector

collector

Page 27

Dragonfly/B utterfly Installation Guide Servo Control Operation

MAN-DRBUIG (Ver. 1.1)

4-4

Function

10 Power up reset No Open

11 Commutation failure Yes Open

Latch

Option

AOK

collector

SO1

Open

SO2

Open collector Open collector

collector

Low Low Low

collector

* This indication can be used as a digital input for activating an external shunt regulator.

Table 4-1: Dragonfly/Butterfly Status Indications

Notes:

Without latch mode:

The status indications are reset when the fault disappears.

With latch mode:

The Short, Over Temperature and Commutation Failure status indications are reset

when the enable signal is temporarily removed from the enable input.

Multiple faults:

Only the reading of the first fault is reliable. Additional faults add on to the status

outputs and the indication is therefore meaningless.

SO3

Page 28

Dragonfly/B utterfly Installation Guide

MAN-DRBUIG (Ver. 1.1)

A-1

Appendix: Specifications

A.1 General Specifications

A.1.1 Butterfly

Feature Units 15/48 5/60 10/60 15/60 2.5/100 5/100 10/100 15/100

Minimum supply

voltage

Nomin al sup p l y volta g e V D C 42 50 85

Maximum supply

voltage

Maximum continuous

power output

Efficiency at Rated Power

(at nominal conditions)

Maximum output voltage 93% of DC bus voltage at f=32 kHz

DC and trapezoidal

commutation continuous

current limit (Ic)

Peak current limit A 2 x Ic

Weight g (oz) 45 g (1.6 oz)

Dimensions mm (in) 55 x 15 x 46.5 (2.2" x 0.6" x 1.8")

Mounting method PCB mount

VDC 11 11 20

VDC 48 59 95

W 700 280 570 850 230 460 920 1400

% Up to 99%

A 15 5 10 15 2.5 5 10 15

Page 29

Dragonfly/Butterfly Installation G uide Specifications

MAN-DRBUIG (Ver. 1.1)

A-2

A.1.2 Dragonfly

Feature Units 3/60 2.5/100

Minimum supply vo lt ag e VDC 11 20

Nominal supply vol tag e VD C 50 85

Maximum supply voltag e VDC 59 95

Maximum continuous power

output

Efficiency at rated power % Up to 99%

Maximum output voltage 93% of DC bus voltage at f=32 kHz

DC and trapezoidal commutation

continuous current limit (Ic)

Peak current limit A 2 x Ic

Weight g (oz) 21.5 g (0.76 oz)

Dimensions mm (in) 51 x 12.5 x 42 (2" x 0.49" x 1.65")

Mounting method PCB mount

W

A

190 240

3.3 2.5

A.2 Environmental Specifications

Ambient

Temperature

Range

Temperature

Shock

Non-operating

conditions

-50 °C to +100 °C (-58 °F to 212 °F)

Operating conditions -40 °C to +70 °C (-40 °F to 160 °F)

Non-operating

conditions

-40 °C to +70 °C (-40 °F to 160 °F)

within 3 min.

Altitude

Maximum

Humidity

Vibration

Mechanical

Shock

Non-operating

Unlimited

conditions

Operating conditions -400 m to 155,000 m (-1,300 ft to 510,000 ft)

Non-operating

conditions

Up to 95% relative humidity non-condensing

at 35 °C (95 °F)

Up to 95% relative humidity non-condensing

Operating conditions

at 25 °C (77 °F), up to 90% relative humidity

non-condensing at 42 °C (108 °F)

Operating conditions 20 Hz –2,000 Hz, 14.6g

Non-operating

±40g; Half sine, 11 msec

conditions

Operating conditions

±20g; Half sine, 11 msec

Page 30

Dragonfly/Butterfly Installation G uide Specifications

MAN-DRBUIG (Ver. 1.1)

A.3 Standards Compliance

A.3.1 Quality Assurance

Specification Details

ISO 9001:2000 Quality Management

A.3.2 Design

Specification Description

A-3

In compliance with MIL-STD-704

In compliance with MIL-STD-810

Aircraft, Electric Power Characteristics

Environmental Engineering Conside rations and

Laboratory Tests

In compliance with MIL-STD-1275

Characteristics of 28 Volt DC Electrical Systems in

Military Vehicles

In compliance with MIL-STD-461

Requirements for the Control of Electromagnetic

Interference Characteristics of Subsystems and

Equipment

In compliance with MIL-HDBK-217

IPC-D-275

IPC-SM-782

Reliability Prediction of Electronic Equipment

Reliability prediction of electronic equipment

(rating, de-rating, stress, etc.)

IPC-CM-770

UL508c

UL840

Printed wiring for electronic equipment (clearance,

creepage, spacing, conductors sizing, etc.)

In compliance with VDE0160-7 (IEC68) Type testing

A.3.3 Safety

Specification Details

Recognized UL508c Power conversion equipment

In compliance with UL840 Insulation coordination, including clearance and

creepage distances of electrical equipment

In compliance with UL60950 Safety of information technology equipment,

including electrical business equipment

In compliance with EN60204-1 Low voltage directive, 73/23/EEC

Page 31

Dragonfly/Butterfly Installation G uide Specifications

MAN-DRBUIG (Ver. 1.1)

A.3.4 EMC

Specification Details

A-4

In compliance with

Electromagnetic compatibility (EMC)

EN55011 Class A with EN61000-6-2:

Immunity for industrial environment,

according to:

IEC61000-4-2 / criteria B

IEC61000-4-3 / criteria A

IEC61000-4-4 / criteria B

IEC61000-4-5 / criteria B

IEC61000-4-6 / criteria A

IEC61000-4-8 / criteria A

IEC61000-4-11 / criteria B/C

A.3.5 Workmanship

Specification Details

In compliance with IPC-A-610, level 3 Acceptability of electronic assemblies

A.3.6 PCB

Specification Details

In compliance with IPC-A-600, level 3 Acceptability of printed circuit boards

A.3.7 Packing

Specification Details

In compliance with EN100015 Protection of electrostatic sensitive devices

A.3.8 WEEE*

Specification Description

In compliance with 2002/96/EC Waste Electrical and Electronic Equipment

regulations

* Please send out-of-service Elmo drives to the nearest Elmo sales office.

A.3.9 RoHS

Specification Description

In compliance with 2002/95/EC

(effective July 2006)

Restrictions on Application of Hazardous

Substances in Electric and Electronic Equipment

Loading...

Loading...