Elmeco FC1USA Installation Manual

Elmeco srl

80025 Casandrino (Napoli) Italy

Via Circumvallazione esterna, 12

Uff. Commerciali:

Tel. +39 081.5055724•5054028•5057068

Fax +39 081.5055726

e-mail: info@elmeco.com

web page: www.elmeco.com

GRANITORI SORBETTIERE E FRIGOBIBITE

Elmeco - rev. 02/02

SLUSH MACHINES COLD DRINK DISPENSERS MACHINES FOR SORBET

Manuale

d’uso

e manutenzione

Use and

maintenance

manual

Manuel

pour l’emploi

et l’entretien

Gebrauchs- und

Wartungshandbuch

Manual

de empleo y de

mantenimiento

www.elmeco.com

info@elmeco.com

continuously

improve our

organization and

management,

according to the

ISO 9001.

It means placing

the customer at the

center of attention

and dedicating

investments and

resources to satisfy

his needs

continuously.

On the other hand,

to you, having

chosen the Elmeco

quality means

being able to

operate with

reliable and lasting

products, being

able to count on

timely and qualified

assistance, and

being able to always

work better with

greater profits.

Yes, because the

Elmeco quality

reflects the quality

of your work.

12

A quality

choice

You have

demonstrated your

sensitivity towards

innovation by

having chosen

Elmeco and,

especially, First

Class, the new, and

presently the only,

multifunctional

machine with a

double auger

system. We

therefore thank you

for having

understood the

importance of

working with a

company that

believes that the

word “quality” is

not an abstract

term.

All of us at Elmeco

know that quality

demands concrete

effort. It means

repeating the

innovative

distinctive qualities

that have set us

apart in the past as

inventors of the

first machine for

slush and that

today reassert us as

the leader in

groundbreaking

techniques and

technology.

It means operating

with the goal in

mind to

UNI EN ISO 9001

CERTIFICATE No.

9130 . ELM 9

ISO 9001

QUALITY CERTIFICATION

1

Indice

Istruzioni e avver tenze

generali . . . . . . . . . . . . . . . . . . .2

Installazione del nuovo

apparecchio . . . . . . . . . . . . . . . .3

Comandi e segnalazioni . . . . . . .4

Pulizia e manutenzione . . . . . . . .5

Come iniziare la produzione

di granita, sorbetto

o bibita fredda . . . . . . . . . . . . . .6

Defrost timer . . . . . . . . . . . . . . .6

Regole fondamentali

di sicurezza . . . . . . . . . . . . . . . .6

Smaltimento del vecchio

apparecchio . . . . . . . . . . . . . . . .7

Assistenza tecnica . . . . . . . . . . .7

Impianto elettrico . . . . . . . . . . . .8

Impianto frigorifero . . . . . . . . . . .9

Descrizione Codici . . . . . . . . . .10

Ricambi fuori dagli esplosi . . . .11

Esploso . . . . . . . . . . . . . . . . . .56

General instructions

and warnings . . . . . . . . . . . . . .13

Installing the new machine . . . .14

Controls and signals . . . . . . . . .15

Cleaning and maintenance . . . .16

How to begin producing slush,

sherbets or cold drinks . . . . . . . . . .

17

Defrost timer . . . . . . . . . . . . . . .

17

Fundamental safety rules . . . . . .

17

Disposal of the old machine . . . . .

18

Technical Assistance . . . . . . . . . .

18

Electric System

. . . . . . . . . . . . .19

Refrigerating System . . . . . . . . .

.20

Code description . . . . . . . . . . .21

Spare parts not indicated in the enlar-

ged drawings . . . . . . . . . . . . . . .

.22

Exploded view . . . . . . . . . . . . .56

Instrucciones

y advertencias generales..................

46

Instalación del nuevo aparato ...........

47

Mandos y señalizaciones..................

48

Limpieza y mantenimiento ................

49

Cómo empezar la producción

de granizada, sorbete

o bebidas frescas ............................

50

Defrost timer ...................................

50

Reglas fundamentales

de seguridad ...................................

50

Eliminación del viejo aparato ............

51

Asistencia técnica ......................51

Instalación Eléctrica.........................

52

Aparato Frigorífico ............................

53

Código Descripción.....................54

Piezas de repuesto

de los despieces .............................

55

Despiece ...................................56

Anweisungen

und allgemeine Hinweise ............35

Installation der neuen Maschine .......

36

Bedientasten und Meldungen

..........37

Reinigung und Wartung

..................38

Wie beginnt die Herstellung von

Gramolaten,

Eis oder kalten Getränken

...............39

Defrost timer ...................................

39

Grundlegende

Sicherheitsmaßnahmen....................

39

Entsorgung der alten Maschine.........

40

Kundendienst ..................................

40

Elektrik ...........................................

41

Kühlanlage

..................................42

Beschreibung der Ersatzteile .......43

Ersatzteile außerhalb der Explosion-

sdarstellungen ...........................44

Explosionsdarstellung .................56

Instructions et remarques

générales . . . . . . . . . . . . . . . . .24

Installation de l’appareil . . . . . .25

Commandes et signalisations . .26

Nettoyage et maintenance . . . . .27

Comment commencer

la production de granité,

sorbet ou boisson froide . . . . . .28

Defrost timer . . . . . . . . . . . . . .28

Règles fondamentales

de sécurité . . . . . . . . . . . . . . . .28

Mise au rebut

de l’appareil . . . . . . . . . . . . . . .29

Service après-vente . . . . . . . . . .29

Installation électrique . . . . . . . .30

Installation frigorifique . . . . . . . .31

Codes et description . . . . . . . . .32

Pièces non comprises

dans les vues éclatées . . . . . . .33

Vues éclatées . . . . . . . . . . . . . .56

Index

Índice

Inhaltsverzeichnis

I

GB

F

D

E

Index

13

ENGLISH

Disconnect the equipment

from the electrical source

during maintenance,

cleaning, and in case of faulty

operation by unplugging the

plug from the outlet (pull the

plug, not the cable)

(figs. and ).

Repairs must be carried out

exclusively by authorized and

specialized personnel. Faulty

repairs can be extremely

dangerous for the user.

Contact the Company for the

nearest Authorized Assistance

Center.

with care for your own

purposes and for future

owners of the machine, as

well.

The Manufacturer declines

all responsibility for

damages incurred due to

disregard of the following

instructions:

Carry out installation

according to the

instructions for assembly.

The electric circuit must

correspond to the rating

plate data placed on the

front part of the machine,

under the drip tray. (fig. ).

General

instructions

and

warnings

The First Class furnishings

have been studied down to

the last details, hence the

luminous display on the

front and back of the

cupola, designed for your

convenience (fig. ).

Before setting the machine

at work, carefully read the

instructions in this service

manual; having done this

you will be capable of

installing, using, and

carrying out maintenance

on the machine properly.

Conserve the use and

maintenance instructions

TOP LIGHT

SERVICE

KNOB

TRANSPARENT TANK

HOOKS FOR

CONTAINER

EXTRACTION

OUTLET

DRIP TRAY

GENERAL

SWITCH

1

4

2

3

1

1

2 3

14

Once you have removed the

packaging, check for any

missing pieces.

No packaging materials

(plastic bags, polystyrene

foam, nails, etc.) should be

left at a child’s reach

because they can be

dangerous.

Remove the protective

plastic bands, including

those inside the grilled

walls.

We do not recommend

using adapters, multiple

outlets or extension cords

for connection to the

electric system.

If they are necessary, only

use material that complies

with the safety standards in

force and only for current

intensity up to the amount

indicated in the rating plate

data (fig. ).

This model for making

grated ice-drinks, sherbets

and cold drinks guarantees a

completely homogenous

product with the ability to

adjust the product’s

density by using the

innovative electronic

controls.

Before installing the

machine check that:

• the machine has not been

damaged during

transportation. If you have

any doubts, contact your

supplier.

• The electric system is

grounded, according to laws

in force.

• The electric capacity of the

system is adequate to the

maximum power of the

machine (as indicated in the

rating plate data fig. )

If in doubt, contact

specialized personnel only.

To install the machine,

carefully read the following

instructions:

Installing the

new machine

Warning

This machine must be used

only for the purposes for

which it has been designed.

Any other use of the machine

is considered improper and is,

therefore, dangerous.

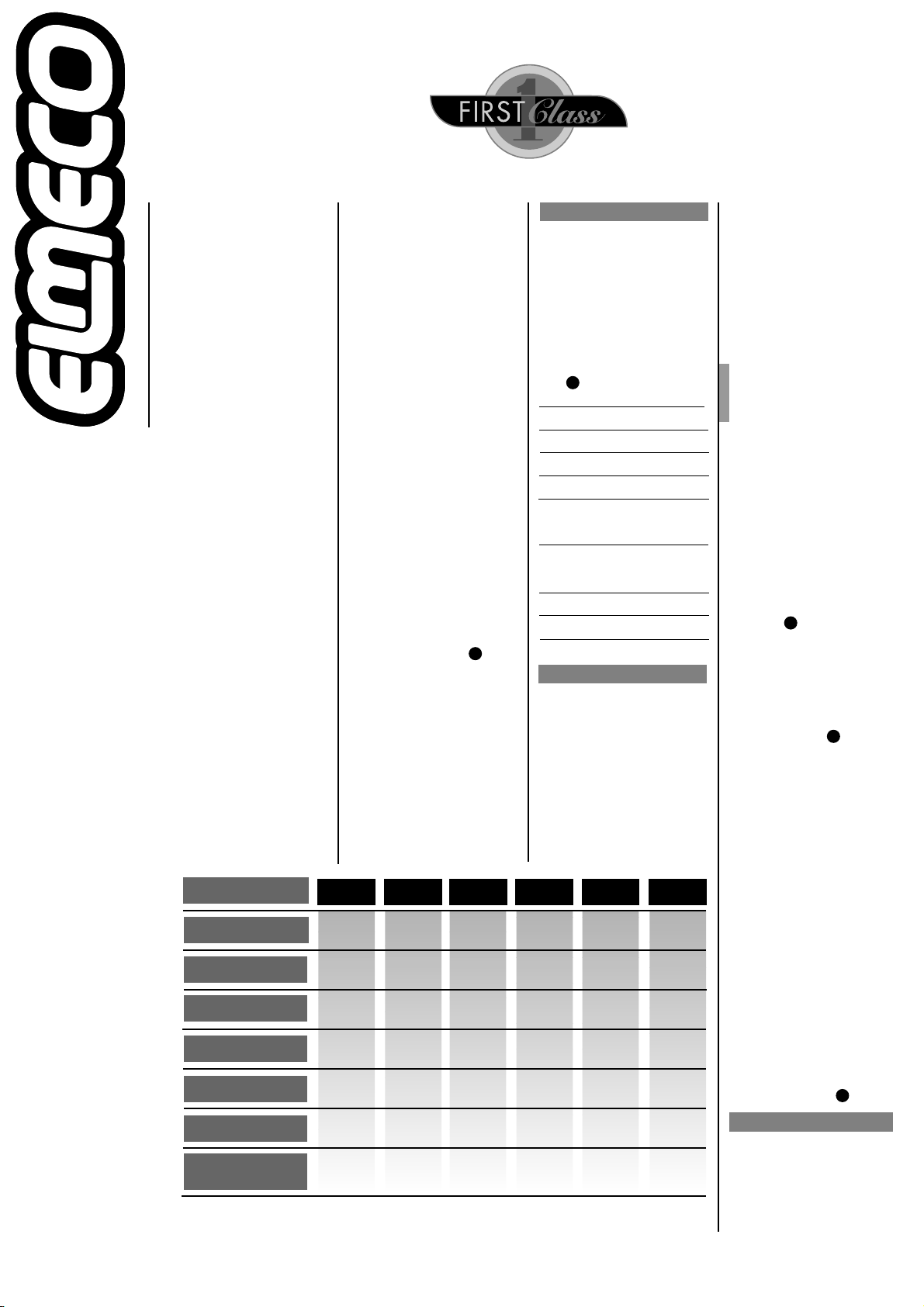

Machine description

(fig. ):

Top Lights

Transparent tanks

Service knob

Outlet

Hooks for container

extraction

Electronic

board

General switch

Drip Tray

1

4

Installation

It is best to have the

machine installed by

qualified personnel.

Incorrect installation can

cause harm to people or

things; the manufacturer

declines all responsibility

for improper installation.

4

The firm reserves the right to make any modifications without prior notice

MODEL

HEIGHT

WIDTH

DEPTH

WEIGHT

CAPACITY

POWER

VOLTAGE HZ

FC1

FC

1 USA

FC2 FC

2 USA

FC3 FC

3 USA

780 mm

30.7 inc 780 mm 30.7 inc 780 mm 30.7 inc

240 mm

9.45 inc 430 mm 16.1 inc 620 mm 24.4 inc

560 mm

22 inc 560 mm 22 inc 560 mm 22 inc

33 kg

72.7

pounds

53 kg

116.8

pounds

66 kg

145,5

pounds

12 lt

3.17 gal 12 lt x 2

3.17 gal

x 2

12 lt x 3

3.17 gal

x 3

500 w

0,67 hp 820 w 1 hp 950 w 1,3 hp

230/50

230/60

115/60

230/50

230/60

115/60

230/50

230/60

115/60

230/50

230/60

115/60

230/50

230/60

115/60

230/50

230/60

115/60

5

6

Place the machine so that no

heat sources are near the

grilled walls. Make sure that

there is a free space of at least

15 cm (12 inch.) all around

the machine

(fig. ).

Warning: If the machine is

not properly installed or the

condenser has not been

periodically cleaned, the

internal and condenser

temperatures may exceed

the maximum temperatures

allowed.

First Class is equipped with

a pressure switch with

indicator which switches off

the refrigerator in these

circumstances. Should this

occur call the technical

service to deal with the

cause and restore operation.

Once you have connected the

machine to the electric

system and have switched on

the general switch, check

that air is comes out from

the side grills (fig. ).

Proper use

Before setting the

machine at work you should

clean it as shown in the

“cleaning and maintenance”

paragraph.

15

ENGLISH

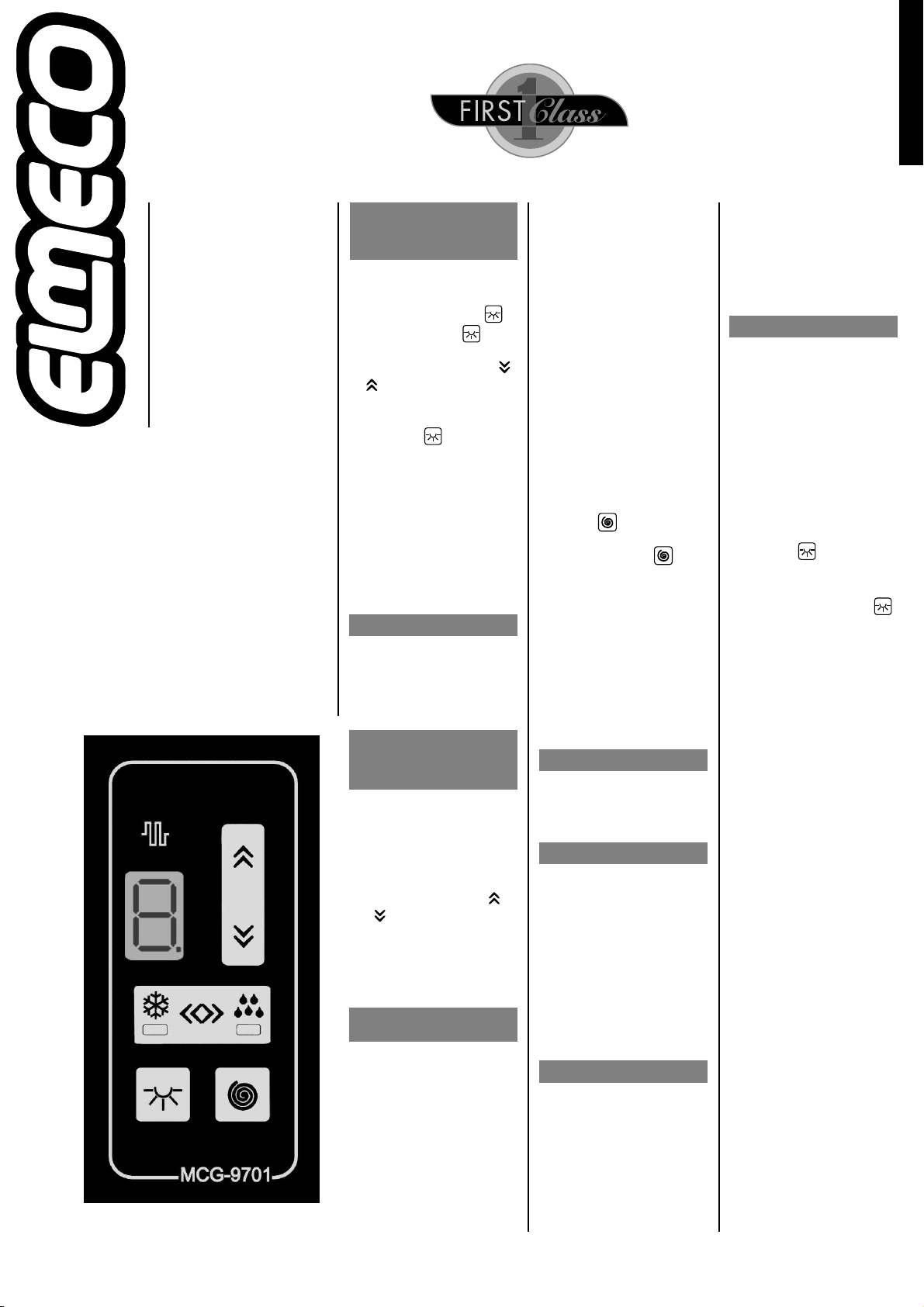

Controls

and signals

can activate the electronic

bypass function tender

pressed the key selection

slush-juice

«» till augers

turn.

Pay attention this system

disactive the safety system

and the “lock out keyboard” ).

Once replaced the defective contact, or installed

the lost contact, eliminating the electronic bypass

realized previously, must

be used the following procedure:

- up the lid;

- Stop the augers pressing

the key ;

- holding pressed the «» ,

to press the key to

have the augers left

again;

- Wait until the augers are

stopped and release the

keys;

- Put on the lid on the

tank;

the augers leaves again,

and the electronic bypass

has been eliminated.

Self-diagnostics

If the value 0, 1 or 2 flashes

on the display call the

service centre.

Memory configuration

All the operations and

adjustments set are

memorized in a non volatile

memory, that is, a memory

that is active even without

electricity; therefore, when you

switch on the machine, the tub

starts working with the

configuration which it had the

last time it was switched off.

Minimum level signal

Machines with a minimum

level probe have a local alarm

that is activated when the

product goes below this value;

the alarm causes the top light

to flash at

maximum intensity and a

signal available on the board

connector is activated; this can

be used to control a remote

alarm and/or a refilling

system. If the minimum level

continues, the light stops

flashing after 1 minute.

Lamp short circuit control

An accidental short circuit of

the lamp activates a

protective device with a quick

operating time that blocks

operation of the tub(s)

without causing the fuses to

open; this problem is

indicated by the flashing

display (value 8). All tubs

must be re-activated as

follows:

• press the key until the

display turns off (on model

with multiple tubs).

• When you let go of the

key, the machine begins

normal operation.

• Important: carry out the

procedure on all tanks.

• Call Assistance Office

• Note: the value 8 may also

flash if there are sudden

voltage spikes in the

building. Reactivate

according to the procedure

described previously.

Top Light

Switching On/Off

Adjusting the intensity

The top light can be

switched

on and off by using the

key; by keeping the key

pressed down and

simultaneously using the

or ‚ keys you can increase

or decrease the intensity of

the light, respectively; by

pressing the key, the

display shows the light’s

condition and it turns off if

you have turned off the light

with the key; if the light is

still on, it displays a number

indicating the level of the

lamp’s intensity (2 min. - 9

max.)

Operator safety

If you open the tub by lifting

the top light, the augers stop

turning.

Blocking the keyboard for

the auger and the cooling

unit

It is possible to block the

electronic board and all its

keys; you can connect or

disconnect the block if you

lift the top light and

simultaneously use the

and keys;

the decimal point of the

display lights up to signal

block status.

Bypass motor brake

As you know, for safety

demands, when the lid is

lifted, the corresponding

augers to that tank are

halted accordingly.

Sometimes it happens

that augers halted because deformed stainless

steel contacts or because

lost them. In this case you

Loading...

Loading...