Elmeco 113a Service Manual

SERVICE MANUAL MODEL 113A

FROSTY FACTORY OF AMERICA INC.

RUSTON, LA. 71270

(800)544-4071

All technical data, pictures and drawings contained in this manual are not binding on the

manufacturer nor can the manufacturer be held liable for any modifications to the

machine in whole or in part.

Rev. 03/18/05 rf.

1

TABLE OF CONTENTS

1.0 INTRODUCTION

1.1 Use of the Manual

1.2 Preliminary Inspection

1.3 Description

1.4 Dimensions

2.0 LOCATION AND INSTALLATION

2.1 Safety Precautions

2.2 Installation

3.0 OPERATION

3.1 Machine Controls

3.2 The Product You Serve

3.3 Product Consistency

3.4 Start Up

3.5 Freeze Time

4.0 MAINTENANCE

4.1 Cleaning

4.2 Re-Assembly

4.3 Preventative Maintenance

4.4 Extended Storage

4.5 Troubleshooting

4.6 Rear Cylinder and Drive Assembly Parts List

4.7 Torque Consistency Control

4.8 Faceplate/Faucet Assembly

4.9 Float Switch

4.9a Thermostat Assemblies

4.10 Using the Cleaning Brushes

4.11 Beater Bar Spring and Seal Installation

4.12 Beater Seal Assembly

4.13 Ceramic Seal Removal and Re-installation

5.0 SPARE PARTS LIST

6.0 WIRE DRAWING

7.0 ELECTRICAL SCHEMATIC

8.0 FACTORY ASSISTANCE

2

SECTION 1

INTRODUCTION

1.1 USE OF THIS MANUAL

Your service manual has been prepared as a guide to help you get the most from your

Petite Sorbeteer. It contains information about the installation and operation of your

machine. The manual also contains instructions for service and care. The manual should

be read carefully by the operator of the Petite Sorbeteer to become familiar with the

machine and the correct operating procedures described within. The following notations

are used throughout the manual to bring important facts to your attention:

“Warning” - This notation is used whenever the personal safety of the operator(s) might

be jeopardized, if procedures are not followed correctly.

DO NOT INSERT ANY OBJECTS

INTO CYLINDER OR HOPPER WHILE

WARNING

MACHINE IS RUNNING!

“Caution” - This notation is used whenever the operator may receive or cause injury if

not observed.

RISK OF ELECTRICAL SHOCK.

BEFORE SERVICING UNIT.

CAUTION

DISCONNECT POWER

CAUTION

MOVING PARTS

DO NOT OPERATE UNIT

WITH PANELS REMOVED

“Notice” - This notation is used to bring important information to your attention that

will enhance the performance of your machine.

1.2 PRELIMINARY INSPECTION

Unpack the unit as soon as possible upon

its arrival. Check the entire machine and

its contents for possible shipping damage.

Note damage, if any, and notify your

carrier immediately. Frosty Factory of

America cannot be held responsible for

damaged merchandise caused by shipping.

Inventory the accessories to be sure they

include the items you specified on your

order. Normally the accessories include :

Beater Bar, Drip Tray, Faceplate,

Faceplate Knobs, Hopper Cover, PetroGel, Sanitizer, Spare Faucet O-Rings,

Warranty Card, Wire Brushes

3

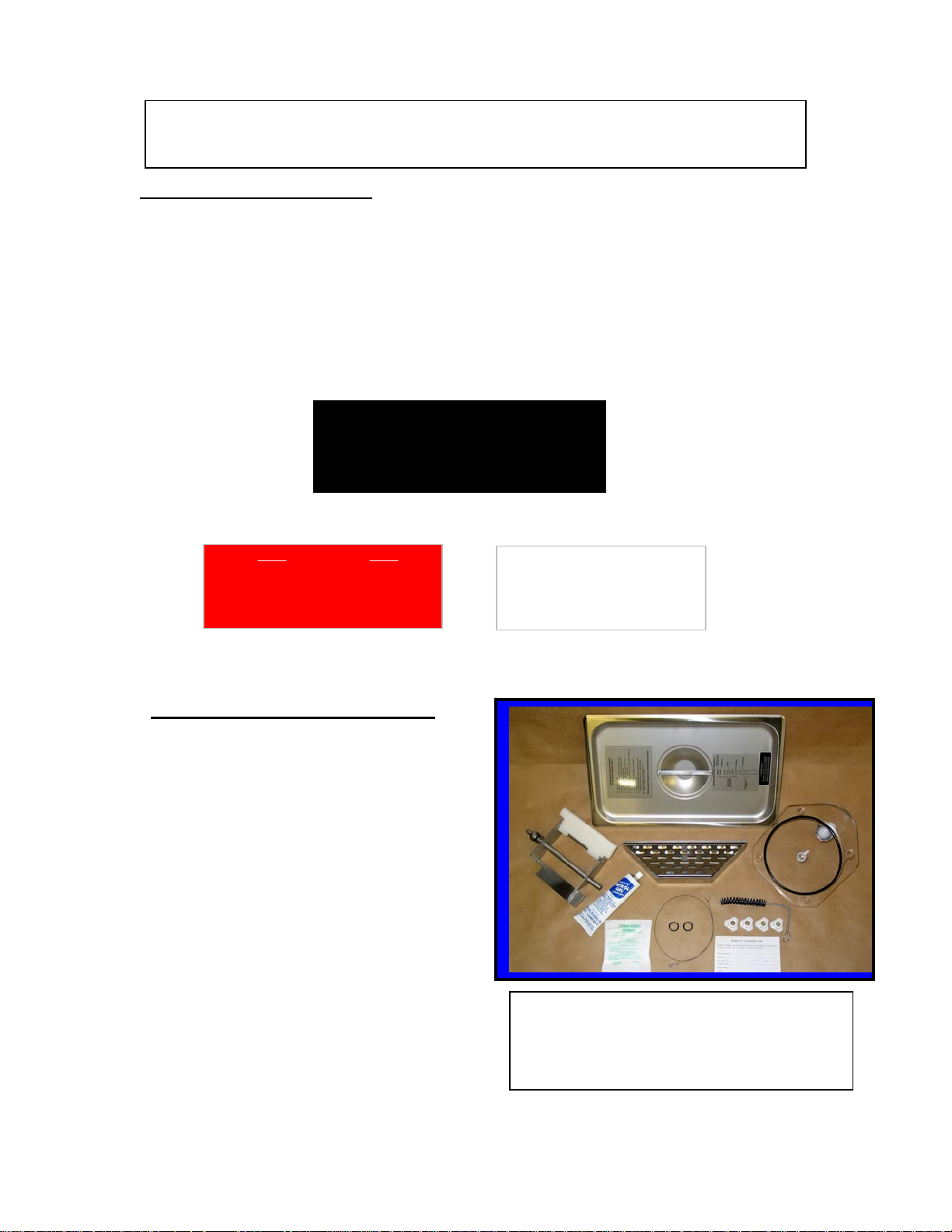

1.3 DESCRIPTION

Stainless

Steel Cabinet

Stainless

Steel

Cylinder

Faceplate

Knobs F0264

Clear Plastic

Faceplate C6521

Drip Tube

Drip Tray

F6603

1.4 DIMENSIONS

(54.6cm)

21.5”

Legs available in 4”(10cm)

or 1” (2.54cm) lengths.

11” (28cm)

19” (48cm)

24” (61cm)

Allow 6” ( 15.2cm) behind

unit for air circulation

Flavor Sign

F0171

Beater Bar

C6519

Scraper

Blade C6510

Faucet

Assembly

C6513

Fill Indicator

Light F0207

Control

Switches

Top F0416

4

SECTION 2

LOCATION & INSTALLATION

2.1 SAFETY PRECAUTIONS

Do not attempt to operate your Petite Sorbeteer until the safety precautions and operating

instructions in this manual are read completely and are thoroughly understood.

2.2 INSTALLATION

Placing your Petite Sorbeteer in a highly visible area will enhance sales.

CAUTION: Do not attempt to share the dedicated electrical outlet with any other

appliance; this will cause the circuit breaker to trip.

1. Remove the machine from the shipping container.

2. Place the unit on a sturdy platform able to hold the weight of the machine when full

of product. (Usually about 150 #)

3. Level the machine by turning the adjustable part of the leg. The machine must be level

front to back as well as left to right.

3. Air-cooled condensers must have correct ventilation. Air intake is at the rear of the

machine and discharge is through the sides. 8” clearance is required on both sides and

at the back. In addition, all Petite Sorbeteers require 6” clearance above the machine.

NOTICE: Locating the unit in direct sunlight, near cooking equipment or any high

heat area will reduce the performance of your machine.

CAUTION: Extended operations under severe heat condition can damage the

cooling system.

NOTICE: Establishments that serve beverages from frozen drink machines must

clean and sanitize them according to the procedures established by the

regulating agencies having jurisdiction.

4. Place the three-position switch in the OFF position (center).

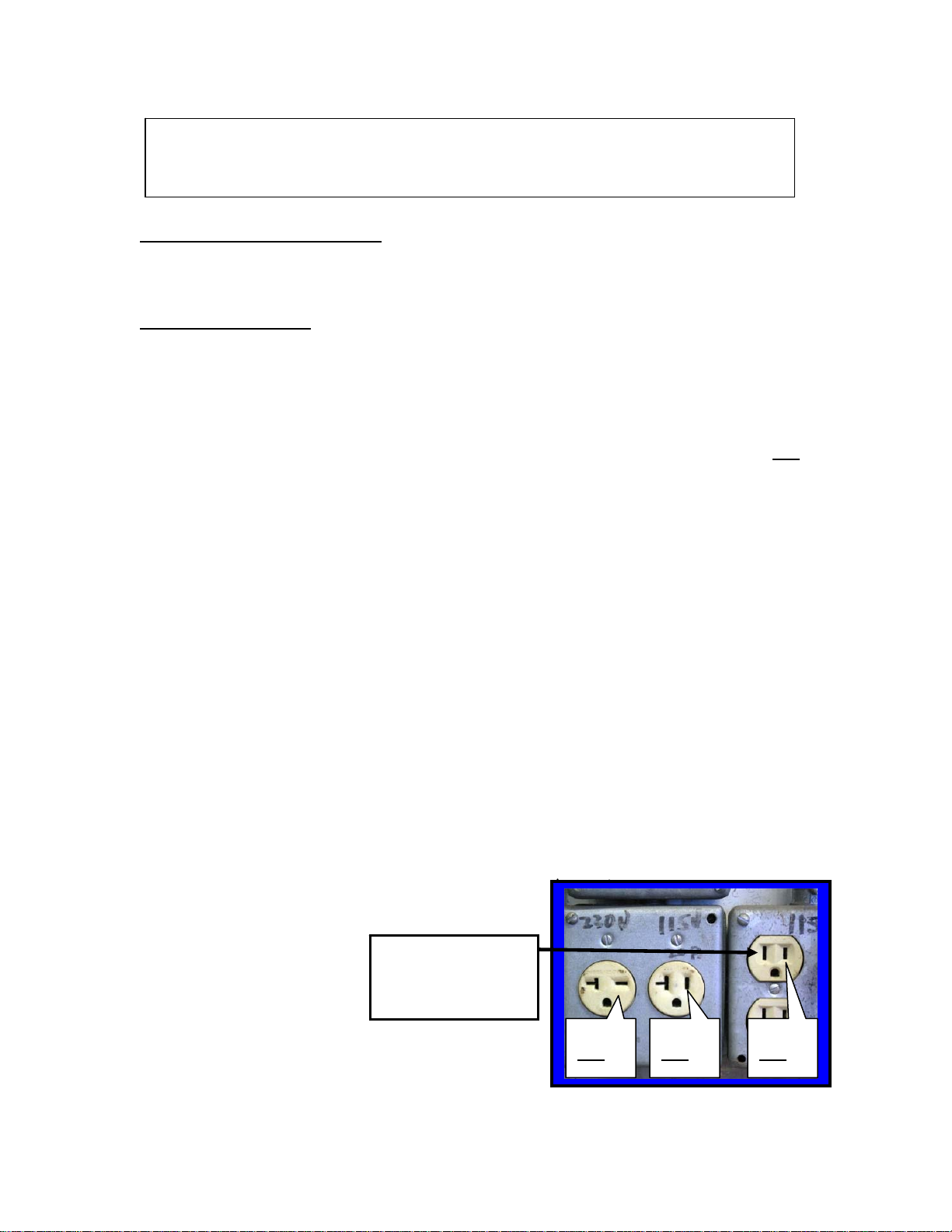

5. Connect the power cord. The Petite Sorbeteer must be connected to a properly

grounded receptacle. The electrical cord furnished as part of the Petite Sorbeteer has

a three prong grounding type plug. The use of an extension cord is not

recommended. If one must be used, refer to the national and local electrical codes.

Do not use an adapter to get around grounding requirements.

WARNING; Do not

attempt to alter the

electrical plug. Serious

injury or electrocution

may result.

6. Install the drip tray, cover, beater bar and

faceplate assemblies on the Petite Sorbeteer.

Notice: Your

receptacle should

look like this.

230V

20A

115V

20A

115V

15A

5

SECTION 3

OPERATION

3.1 MACHINE CONTROLS

Two selector switches located on the front of the machine control operation of the Petite

Sorbeteer. Selection of the right (snowflake) position, with both switches, will schedule

the machine for normal operation. The compressor cycle is protected by a time delay

circuit, which will engage the compressor approximately 2 minutes after normal

operation is initiated. A red fill light located above the switches will illuminate when the

level of mix is low in the hopper. A thermostat knob on the electrical control box of your

machine is set at the factory and should not be changed or adjusted except by an

authorized service repairman.

Refer to the information below for functions available with various combinations of

switch positions.

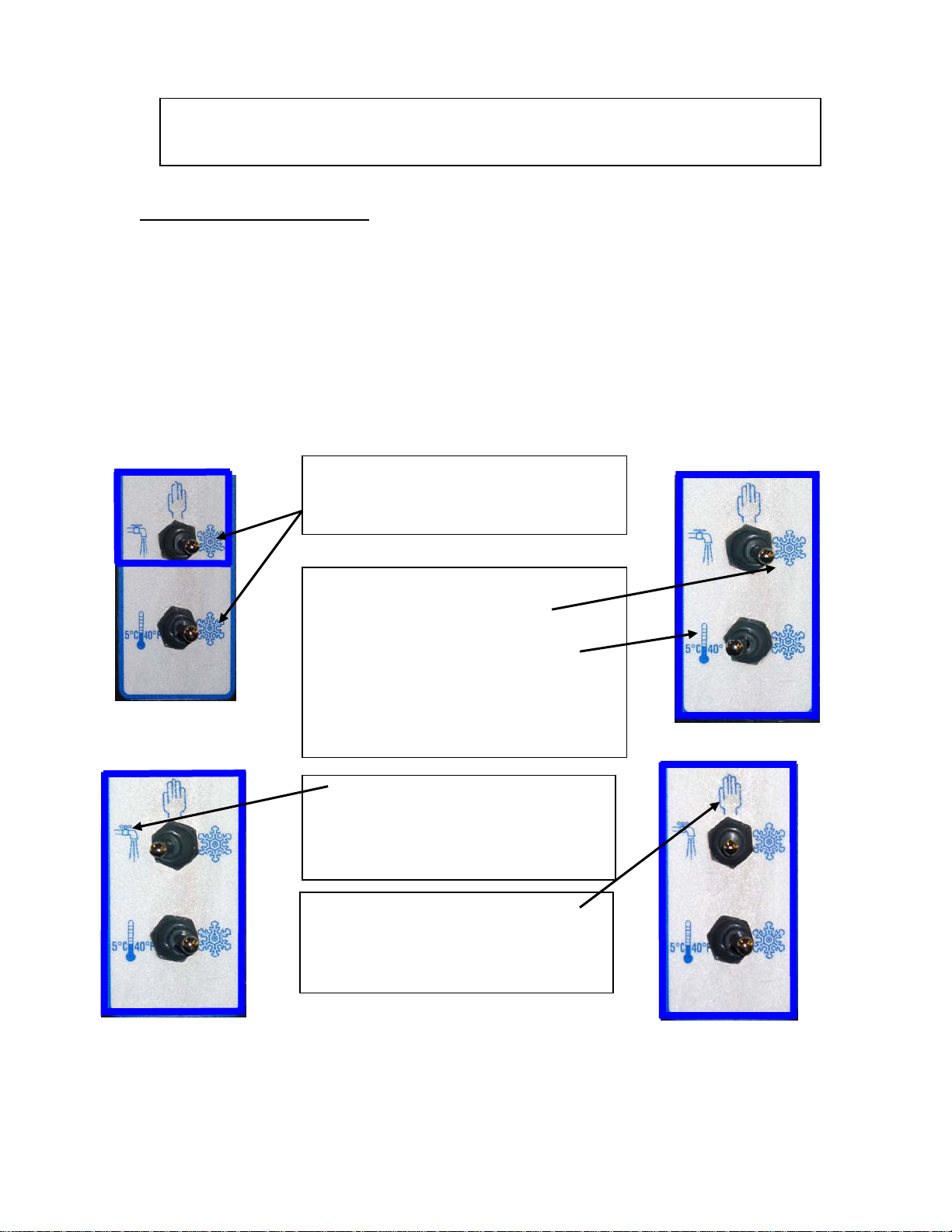

Normal Operation – Both switches on

snowflake. Machine will freeze mix to

provide frozen beverage as desired.

Cooling Operation – Top switch on

snowflake, Bottom switch on

thermometer symbol. Machine will

automatically come on whenever

necessary to keep mix cooled to

5ºC/40º F - used primarily for

overnight storage of mix remaining

in the machine.

Cleaning Operation - The drive

motor will run in the faucet position

to allow a stirring action of the rinse

water while cleaning.

Off - The hand symbol is the

recognized international symbol for

“stop”. In this position,

the machine will not run.

6

3.2 THE PRODUCT YOU SERVE

The Petite Sorbeteer will produce a fine grain, semi-frozen slush when the proper mix is

used. When measured with a refractometer, the proper mix will measure 12 to 18 “brix”.

Too little sugar in the mix will cause larger ice crystals to form. Too much sugar will

lengthen the freeze time.

CAUTION: Any attempt to freeze water only will cause severe damage to your

machine.

NOTICE: Do not add sugar directly into the machine, as some of it will settle and

result in an improper mix.

FRUIT JUICES with at least 32 grams of sugar per 8-oz. serving will freeze well in

the Petite Sorbeteer. They will remain stable during the freezing process while retaining

their natural color and flavor.

NEUTRAL BASES are used to produce a neutral frozen cocktail base. A wide variety

of different drinks can be created from one neutral base by the addition of various

flavors. Most brands of neutral bases specify a mixture of four parts water to one part

neutral base. However, before use in the Petite Sorbeteer, be sure the “brix” level is 12 to

18.

The amount of ALCOHOL in the recipe will affect the freezing process. As a rule of

thumb, for the mix to freeze properly, the recipe should contain no more than 25 percent

alcohol.

Suggestion for optimum production and sales:

1) Use the finest ingredients available.

2) Test the product before serving it.

3) Keep the machine clean - ALWAYS!

3.3 PRODUCT CONSISTENCY

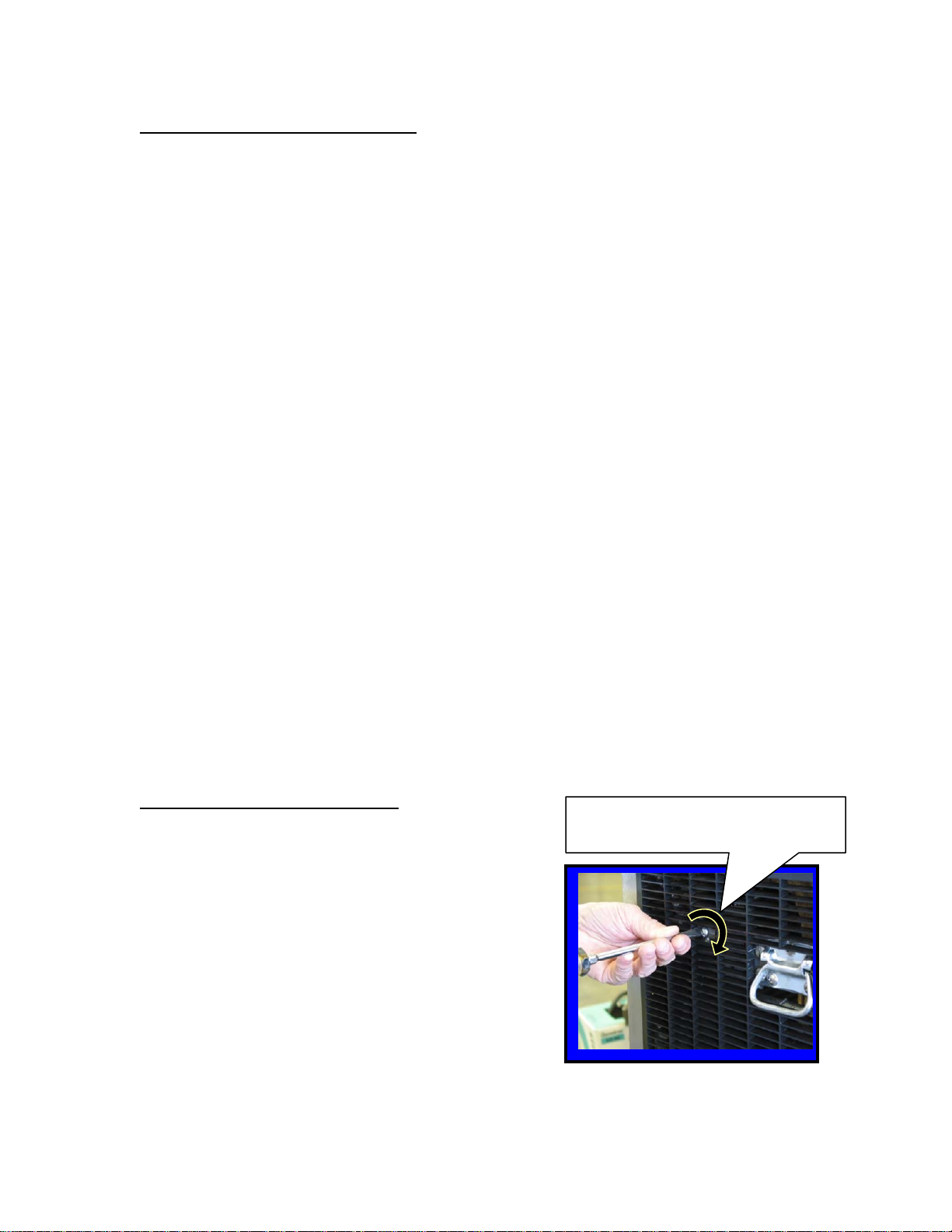

An exclusive, patented, torque consistency

control (TCC) developed by Frosty Factory of

America will allow for consistent texture and

thickness adjustments of your frozen beverages.

The adjustment screw (accessible through the

left side panel) is pre-set at the factory. Various

mix consistencies can be achieved by turning the

screw clockwise (thicker drink) or counter

clockwise (thinner drink). Turn the screw one

full turn then allow enough time to lapse (about

three minutes) for the compressor to complete a

cycle before sampling. Continue this process

until the desired result is obtained.

Turning the TCC screw clockwise

will make the beverage thicker

7

3.4 START UP

NOTICE: Before start-up, be sure the machine has been sanitized in accordance

with procedures set forth in the cleaning section of this manual.

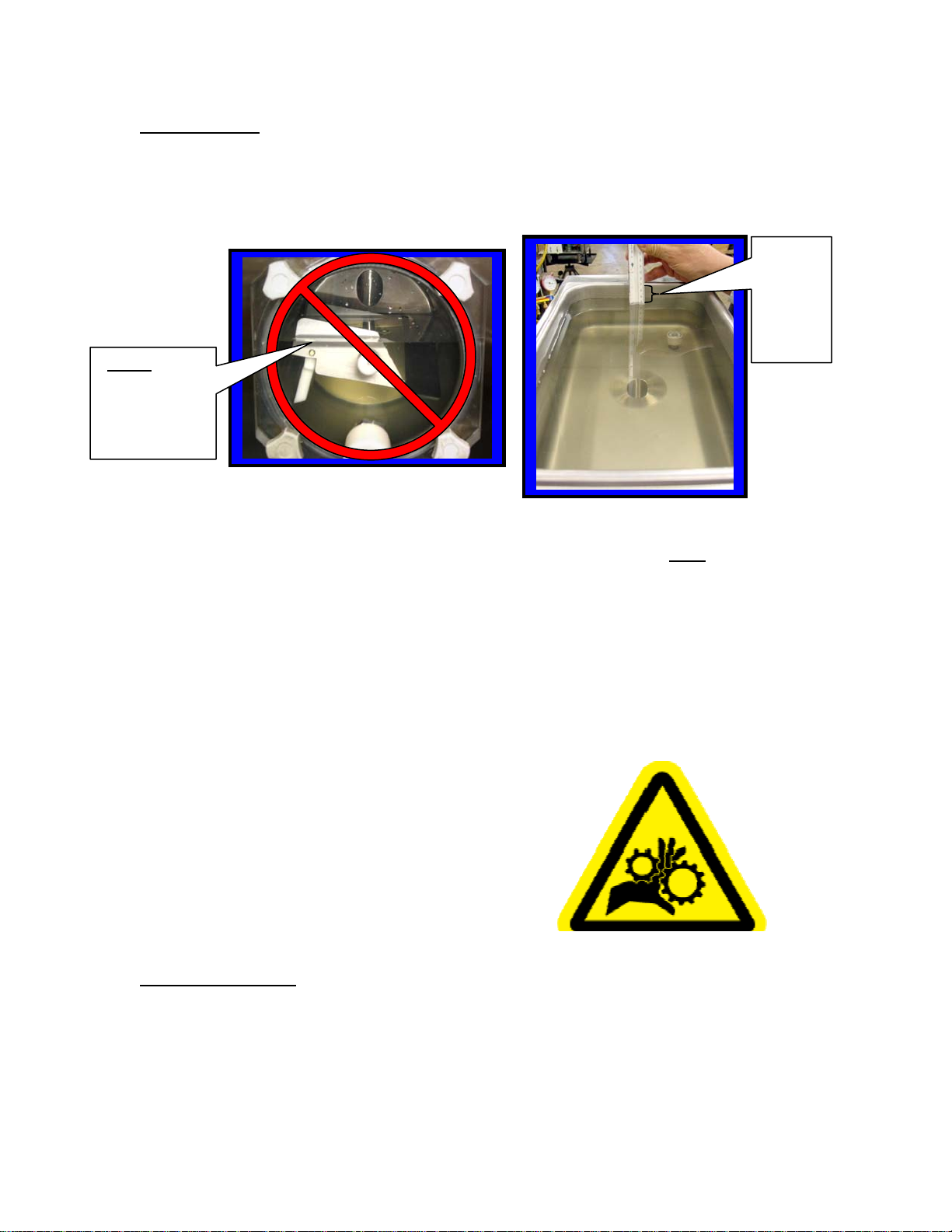

Pour the mix into the hopper and allow it to drain into the cylinder.

Do not run the

machine if the

freezing

cylinder is not

completely full!

When the cylinder is full and the hopper is filled to one inch from the top, the machine is

ready to run. Turn on by selecting the “right” (snowflake) position of both switches on

the front panel.

Fill the

Hopper

to about

1 inch

from the

top

NOTICE: Always add mix as soon as the red, level indicator light, above the

switches, comes on to prevent air from entering the cylinder.

CAUTION: Allowing air into the cylinder will cause a rocking motion of the machine.

If the mix is not yet frozen the air can escape by turning the machine off for

20-30 seconds.

WARNING:

Never under any circumstances,

place your finger or any other object

into the hopper or feed hole while the

machine is in operation. Serious

personal injury may occur.

3.5 FREEZE TIME

The freeze time on the Model 113A is approximately 25 minutes when ideal

conditions are met. Such as, pre-cooled starting mix temperature of 40 degrees and

room temperature at 80 degrees. The time will increase if the machine in not properly

ventilated or is operated in a hot environment. Recipes with high alcohol or high

sugar content will naturally take a little longer.

8

Loading...

Loading...