Page 1

Marine Nozzle

MAINTENANCE

Caution: Petroleum based solvents are not recommended for cleaning the nozzle.

Using petroleum based solvents components such as the O-rings, gaskets, or bumper

may degrade the causing premature failure.

1302 WEST BEARDSLEY AVE • ELKHART, IN 46514 • 1-574-295-8330 • 1-800-346-0250 98518000 REV REL

© 2013 ELKHART BRASS MFG. CO., INC. • WWW.ELKHARTBRASS.COM

SFL-CG-95 & SFL-GCG-95

Operating & Maintenance Instructions

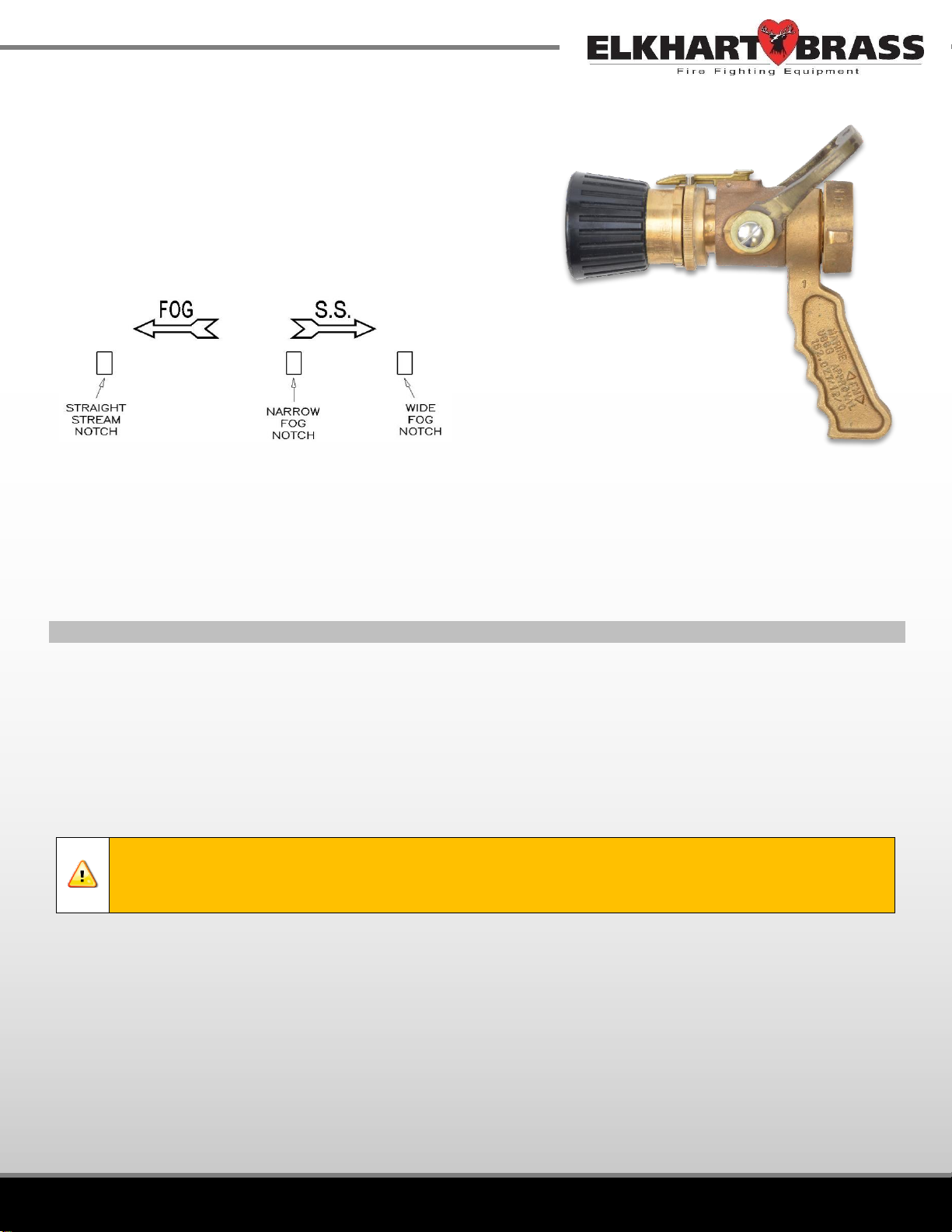

Before flowing water through the nozzle, ensure the

nozzle tip is in the Wide Angle Fog pattern and the

shutoff is in the CLOSED position.

Slowly move the bale handle from the CLOSED to OPEN position to avoid a water hammer scenario.

Test the range of operation from Wide Fog to Straight Stream and then back to ensure smooth rotation.

Inspect the water pattern for any gaps or disruptions as this could signal debris or damage.

See the Troubleshooting section for flush operation.

After each use the nozzle should be cleaned and inspected to maintain optimal performance.

Preventative Maintenance

It is recommended that the nozzle should be removed from the hose while the hose is being drained and

stored.

The nozzle should be cleaned with a mild detergent using a nylon bristled brush, and also flushed with

fresh water. Inspect nozzle for any damage at this time.

Reattach the nozzle to the stored hose in the CLOSED position, and in Wide Angle Fog. When possible,

the nozzle should be stored with the discharge facing downward to prevent contaminants and debris

from collecting in the outlet.

Nozzle Inspection

Nozzle Tip Rotation: Rotate the bumper/nozzle tip through all positions several times. The nozzle tip

should not bind or stick at any point along the way. Return to Wide Angle Fog position when done.

Page 2

Flush: Depress the Locking Lever until the blade disengages from the notch in the Center Barrel. Rotate

TROUBLESHOOTING

Situation

Solution

Uneven stream pattern or gaps in

stream pattern.

Pattern affected in all stream positions

and affected area does not rotate with

the turning of the nozzle tip.

The most likely cause is debris lodged inside the nozzle.

Flushing the nozzle may correct the issue. Follow the Flush

operation in the Maintenance section. If issue persists, shut

off water and remove the nozzle from the hose. Debris too

large to pass through during flush must be removed from

the inlet of the nozzle.

Uneven stream pattern or gaps in

stream pattern.

Pattern affected in all stream positions

and affected area rotates with the

turning of the nozzle tip.

The most likely cause is damage to the nozzle tip. Inspect

the metal teeth on the end of the nozzle, as well as the

inside face of the nozzle tip. If damage is found, the nozzle

should be replaced.

Leakage at the connection of the

nozzle inlet to the hose coupling

May be caused by a worn gasket in the nozzle inlet.

Replace the gasket and retest the connection. If issue

persists, look for damage to the threads or surfaces that

contact the gasket. If thread or surface damage is found on

either the nozzle or hose coupling, replace accordingly.

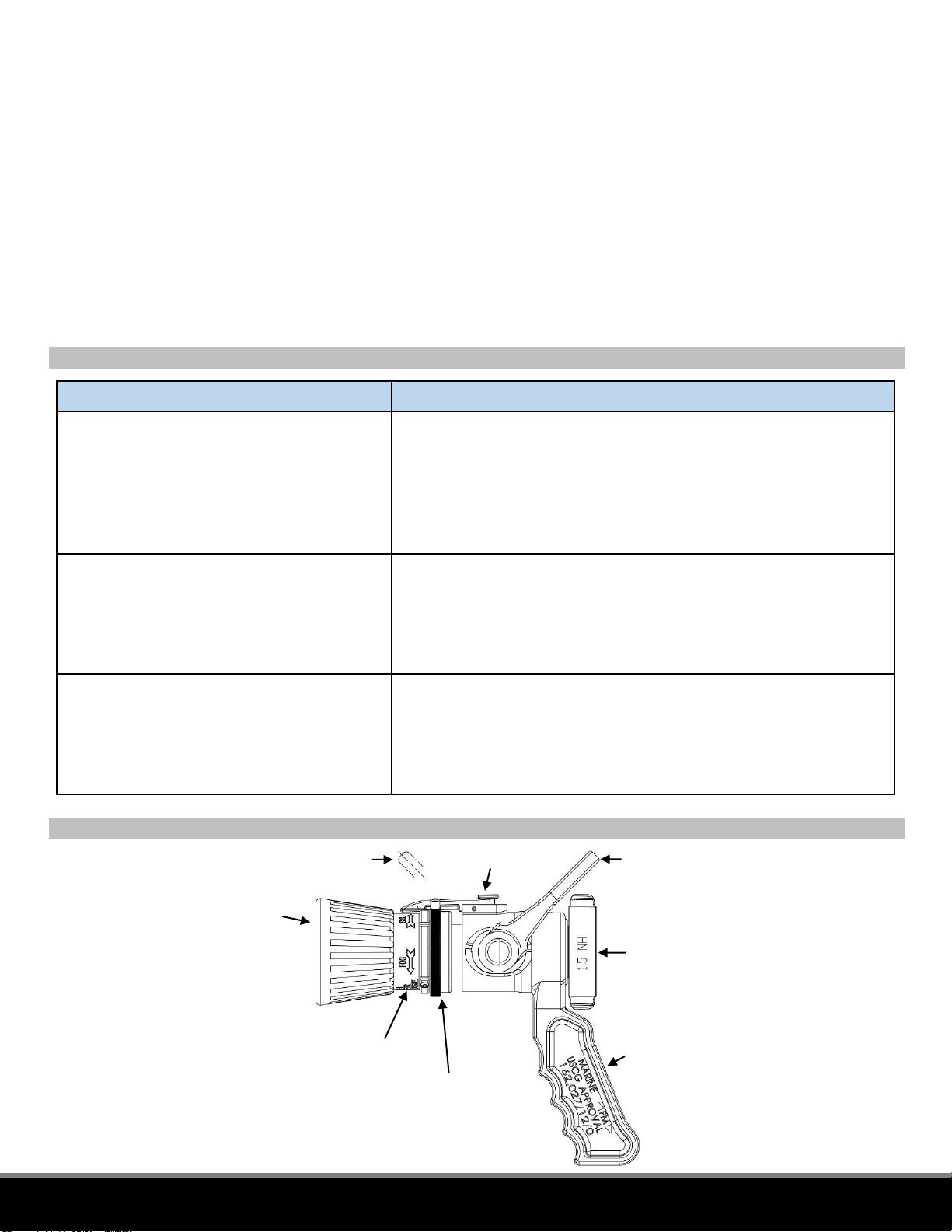

NOZZLE LAYOUT DRAWING

1302 WEST BEARDSLEY AVE • ELKHART, IN 46514 • 1-574-295-8330 • 1-800-346-0250 98518000 REV REL

© 2013 ELKHART BRASS MFG. CO., INC. • WWW.ELKHARTBRASS.COM

Locking Lever

Bumper

Nozzle Tip

Center Barrel

Pistol Grip

(On SFL-GCG-95 only)

Free Swivel Base Inlet

Bale Handle (Open Position)

Bale Handle (Closed Position)

the Center Barrel counterclockwise as far as possible to flush. When debris has been cleared, rotate the

Center Barrel back clockwise until the Locking Lever snaps into the notch.

To test wear, repeat the flush operation several times. The Center Barrel should not bind or stick and

Locking Lever should snap into place every time. If either fails, replace the nozzle.

Shutoff Valve: Open and close the shutoff several times. The bale handle should not bind or stick.

Nozzle Sealing: With water pressure on and the shutoff in the CLOSED position, water should not exit

the nozzle through either the discharge or any sealed joints. If leakage or more than 5 drips per minute

occurs, the nozzle should be replaced.

Loading...

Loading...