Page 1

LZ

ENLZSTL8WS_1G

Enhanced

INSTALLATION & USE MANUAL

™

Series Bottle Filling Stations & Coolers

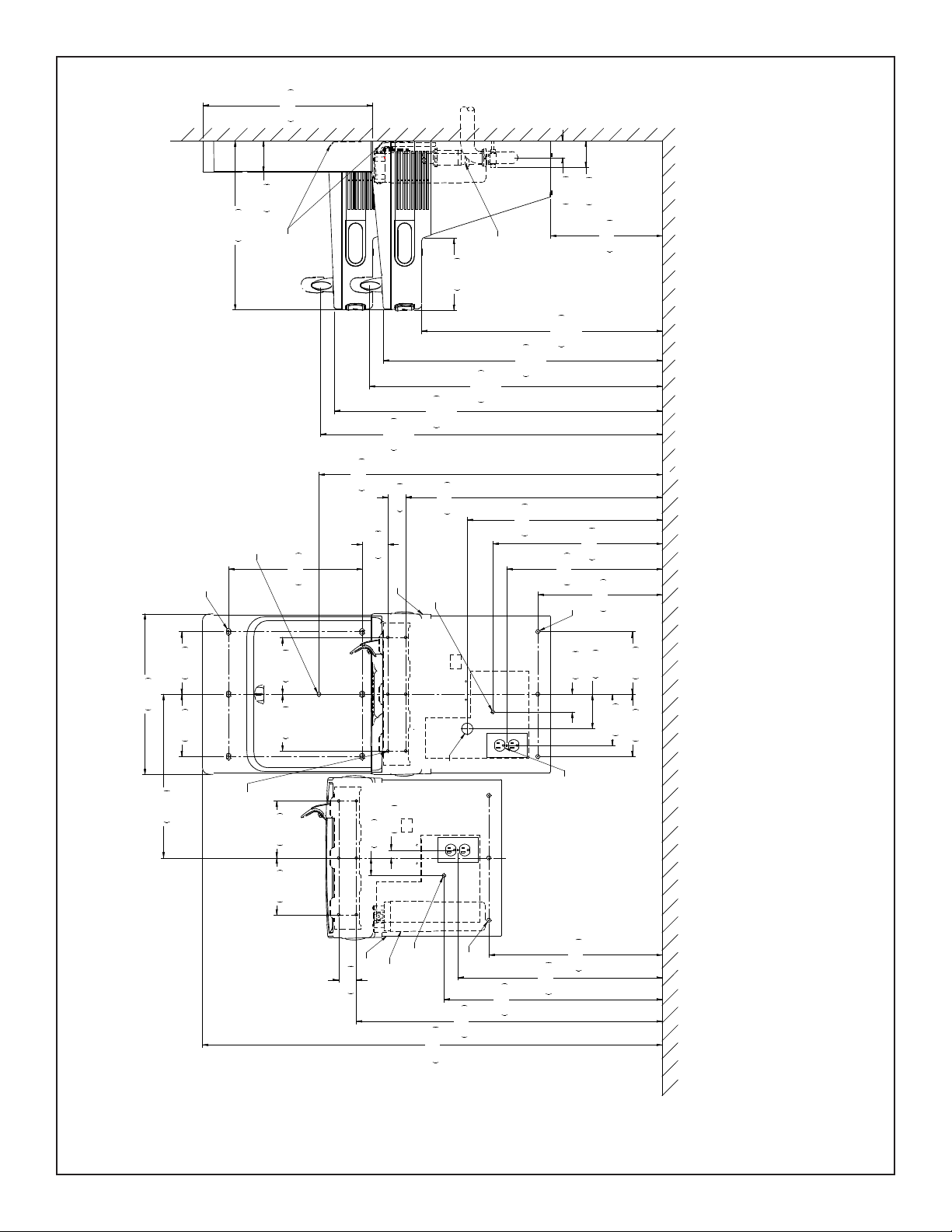

* Versatile cooler design allows units to be installed either left-hand high and right-hand low or left-low and right high.

Basin change may be required. See desired rough-in to help determine if the basin change is necessary.

Page 1 1000004543 (Rev. A - 10/18)

Page 2

ENLZSTL8WS_1G

19"

483mm

1 7/8"

48mm

3"

3 1/2"

90mm

19"

482mm

HANGER

BRACKET

RIM

36 13/16"

936mm

38 3/8"

975mm

HEIGHT

ORIFICE

38 1/2"

979mm

2"

51mm

28 13/16"

731mm

ACTIVATION

SENSOR

15"

7/16" X 3/4" (11mm X 19mm)

OBROUND HOLES (6)

381mm

2 7/8"

73mm

E

A

PREFERRED

C

205mm

8 1/16"

RIM

796mm

31 5/16"

HEIGHT

32 7/8"

835mm

HEIGHT

ORIFICE

HEIGHT

21 7/8"

556mm

LOCATION

76mm

12 1/2"

318mm

ADA

27"

686mm

REQUIREMENT

483mm

19"

17 7/16"

443mm

13 15/16"

354mm

F

LEGEND/LEYENDA/LÉGENDE

SUMINISTRO ELÉCTRICO (3) CAJA ENCHUFE DE ALAMBRE SALIDA DÚPLEX

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX DUPLEX OUTLET**

GABINETE HASTA LA PARED.

ALIMENTATION ÉLECTRIQUE (3) BOÎTIER ENCASTRÉ

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

PARA GARANTIZAR LA VENTILACIÓN ADECUADA, MANTENGA 152 mm (6") (MÍN.) DE SEPARACIÓN DESDE LAS REJILLAS DEL

L’ENCEINTE ET LE MUR.

**NEW INSTALLATIONS MUST USE GROUND FAULT CIRCUIT INTERRUPTER (GFCI)

**Las nuevas instalaciones deben usar un interruptor de circuito de falla a tierra (GFCI, por sus siglas en inglés)

**Les nouvelles installations doivent comporter un disjoncteur diérentiel (GFCI)

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL

POUR ASSURER UNE AÉRATION SUFFISANTE, PRÉVOIR UN DÉGAGEMENT DE 152 mm (6 PO) (MIN.) ENTRE LES ÉVENTS DE

ORIFICIOS PARA PERNOS DE 7/16, PARA FIJAR LA UNIDAD A LA PARED

TROUS DE VIS DE 7/16 PO POUR LA FIXATION DE L’APPAREIL AU MUR

7"

178mm

458mm

18"

7"

178mm

18 3/8"

467mm

C

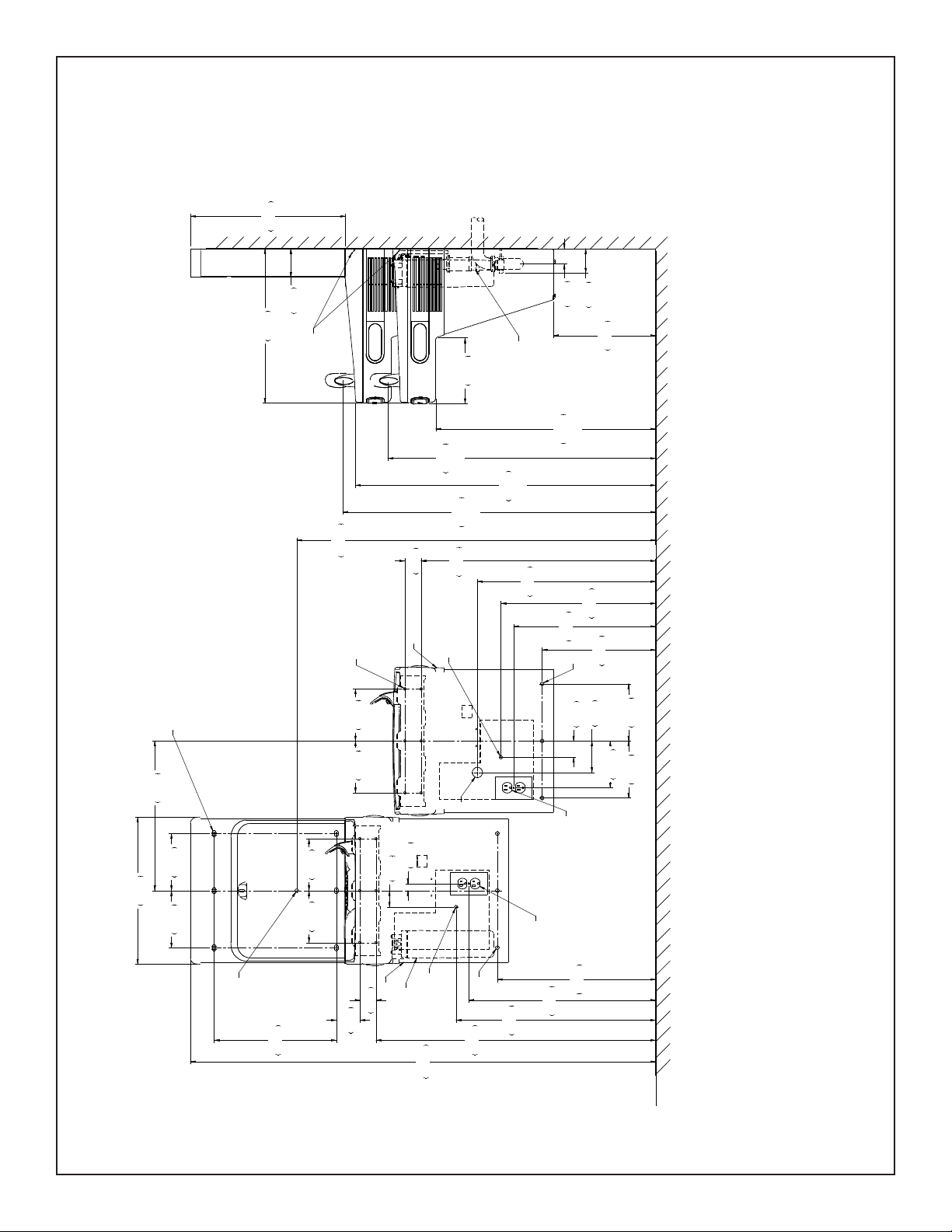

STANDARD ROUGH-IN FOR LEFT-HAND HIGH, BOTTLE FILLER LOW MODELS

BOSQUEJO ESTÁNDAR PARA MODELOS CON LA LLENADORA DE BOTELLAS BAJA Y LA PARTE IZQUIERDA ALTA

162mm

6 3/8"

L

6 3/8"

162mm

7/8"

HOLES (12)

6 3/8"

162mm

O 9/32" (7mm)

L

C

6 3/8"

162mm

2"

22mm

2"

51mm

E

51mm

FILTER

DISPOSITION DE CANALISATIONS STANDARD, POUR INSTALLATION GAUCHE HAUTE ET REMPLISSEUSE DE BOUTEILLE BASSE

3 7/8"

98mm

7"

2"

51mm

B

D

178mm

FINIS HED FLOOR

5 3/4"

146mm

7"

178mm

Réduire la hauteur de 76 mm (3 PO) pour les installations à la norme ADA enfants

REDUCE HEIGHT BY 3 INCHES FOR INSTALLATION OF CHILDREN’S ADA COOLER

LOCATION

ALTERNATE

A

F

LOCATION

ALTERNATE

24 1/2"

622mm

34 5/16"

872mm

1310mm

51 9/16"

494mm

19 7/16"

583mm

22 15/16"

Reduzca la altura en 76 mm (3") para la instalación del bebedero con clasicación ADA para niños

1000004543 (Rev. A - 10/18)

FIG. 1

Page 2

(76mm) MAXIMUM OUT FROM WALL

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WATER SUPPLY LOCATION 3/8 O.D. UNPLATED COPPER TUBE CONNECT STUB WITH SHUT OFF (BY OTHERS) 3 IN.

DE CONEXIÓN CON VÁLVULA DE CIERRE (DE TERCEROS) MÁXIMO A 76 mm (3") DE LA PARED.

CONDUITE D’ALIMENTATION AVEC UN ROBINET D’ARRÊT (NON FOURNI) À 76 mm (3 PO) MAXIMUM DU MUR

PARED.

51 mm (2 PO) HORS DU MUR

B = RECOMMENDED LOCATION FOR WASTE OUTLET 1-1/2" O.D. DRAIN STUB 2 IN. OUT FROM WALL

C = 1-1/2" TRAP NOT FURNISHED

EMPLACEMENT RECOMMANDÉ DE LA SORTIE D’ÉCOULEMENT. CONDUITE D’ÉVACUATION DE 1-1/2 PO DE DIA. EXT. DÉPASSANT DE

NO SE INCLUYE SIFÓN DE 1-1/2"

UBICACIÓN RECOMENDADA DEL SUMINISTRO DE AGUA. TUBERÍA DE COBRE SIN REVESTIMIENTO DE 3/8" DE DIÁM. EXT. ADAPTADOR

EMPLACEMENT RECOMMANDÉ DE L’ARRIVÉE D’EAU. TUBE EN CUIVRE NON PLAQUÉ DE 3/8 PO DE DIA. EXT. RACCORDER À LA

UBICACIÓN RECOMENDADA DE LA SALIDA DE DESECHOS. ADAPTADOR DE DESAGÜE DE 1-1/2" DE DIÁM. EXT., A 51 mm (2") DE LA

SIPHON DE 1-1/2 PO NON FOURNI

Page 3

51 5/8"

1311mm

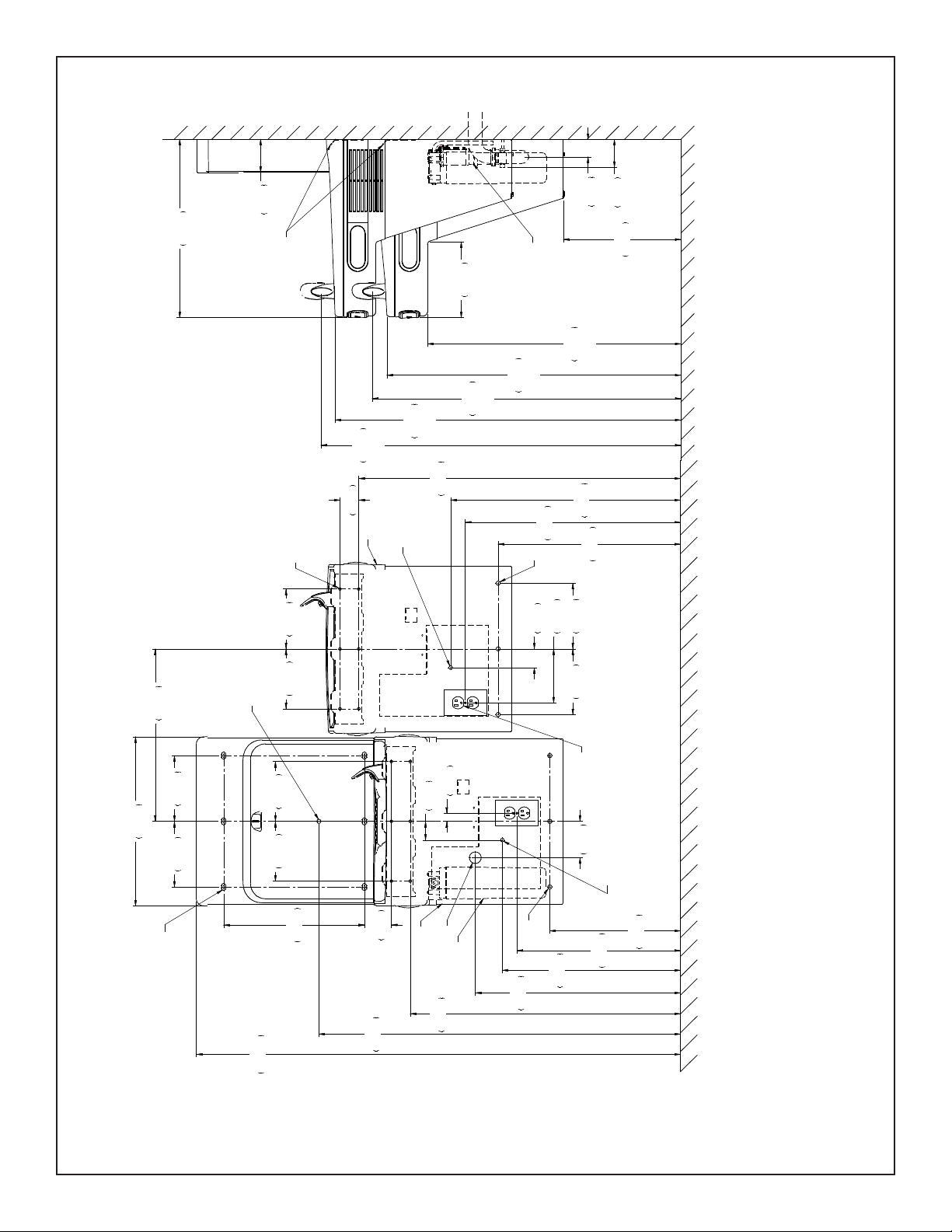

ENLZSTL8WS_1G

1 7/8"

48mm

3"

3 1/2"

90mm

19"

483mm

HANGER

BRACKET

205mm

8 1/16"

32 7/8"

835mm

RIM

36 13/16"

936mm

HEIGHT

38 3/8"

975mm

HEIGHT

ORIFICE

2"

51mm

E

A

PREFERRED

HOLES (12)

O 9/32" (7mm)

LOCATION

ORIFICE

871mm

34 5/16"

C

27"

RIM

31 5/16"

796mm

HEIGHT

HEIGHT

583mm

22 15/16"

F

76mm

12 1/2"

318mm

ADA

686mm

REQUIREMENT

24 1/2"

622mm

19 7/16"

494mm

ALTERNATE ROUGH-IN FOR RIGHT-HAND HIGH, BOTTLE FILLER LOW MODELS – REQUIRES BASIN ASSY CHANGE

GABINETE HASTA LA PARED.

ALIMENTATION ÉLECTRIQUE (3) BOÎTIER ENCASTRÉ

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

PARA GARANTIZAR LA VENTILACIÓN ADECUADA, MANTENGA 152 mm (6") (MÍN.) DE SEPARACIÓN DESDE LAS REJILLAS DEL

L’ENCEINTE ET LE MUR.

**NEW INSTALLATIONS MUST USE GROUND FAULT CIRCUIT INTERRUPTER (GFCI)

**Les nouvelles installations doivent comporter un disjoncteur diérentiel (GFCI)

**Les nouvelles installations doivent employer l’interrupteur de circuit moulu de défaut (GFCI)

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL

POUR ASSURER UNE AÉRATION SUFFISANTE, PRÉVOIR UN DÉGAGEMENT DE 152 mm (6 PO) (MIN.) ENTRE LES ÉVENTS DE

ORIFICIOS PARA PERNOS DE 7/16, PARA FIJAR LA UNIDAD A LA PARED

TROUS DE VIS DE 7/16 PO POUR LA FIXATION DE L’APPAREIL AU MUR

SUMINISTRO ELÉCTRICO (3) CAJA ENCHUFE DE ALAMBRE SALIDA DÚPLEX

LEGEND/LEYENDA/LÉGENDE

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX DUPLEX OUTLET**

2"

51mm

7"

178mm

5 3/4"

6 3/8"

162mm

L

C

6 3/8"

162mm

ACTIVATION

18 3/8"

467mm

7"

178mm

18"

458mm

7"

178mm

OBROUND HOLES (6)

7/16" X 3/4" (11mm X 19mm)

SENSOR

7/8"

6 3/8"

162mm

L

C

6 3/8"

162mm

7/8"

2

15"381mm

73mm

38 9/16"

979mm

22mm

2"

51mm

B

E

FILTER

732mm

28 13/16"

146mm

FINISHED FL OOR

7"

178mm

D

LOCATION

ALTERNATE

Réduire la hauteur de 76 mm (3 po) pour les installations à la norme ADA enfants

REDUCE HEIGHT BY 3 INCHES FOR INSTALLATION OF CHILDREN’S ADA COOLER

Reduzca la altura en 76 mm (3") para la instalación del bebedero con clasicación ADA para niños

3 7/8"

98mm

A

ALTERNATE

LOCATION

F

13 15/16"

354mm

17 7/16"

443mm

19"

483mm

21 7/8"

556mm

AUTRE DISPOSITION DE CANALISATIONS, POUR INSTALLATION DROITE HAUTE ET REMPLISSEUSE DE BOUTEILLE BASSE – MODIFICATION DE LA FONTAINE REQUISE

BOSQUEJO ALTERNATIVO PARA MODELOS CON LA LLENADORA DE BOTELLAS BAJA Y LA PARTE DERECHA ALTA: REQUIERE CAMBIAR EL CONJUNTO DE TARJA

CONDUITE D’ALIMENTATION AVEC UN ROBINET D’ARRÊT (NON FOURNI) À 76 mm (3 PO) MAXIMUM DU MUR

DE CONEXIÓN CON VÁLVULA DE CIERRE (DE TERCEROS) MÁXIMO A 76 mm (3") DE LA PARED.

PARED.

FIG. 2

(76mm) MAXIMUM OUT FROM WALL

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WATER SUPPLY LOCATION 3/8 O.D. UNPLATED COPPER TUBE CONNECT STUB WITH SHUT OFF (BY OTHERS) 3 IN.

EMPLACEMENT RECOMMANDÉ DE L’ARRIVÉE D’EAU. TUBE EN CUIVRE NON PLAQUÉ DE 3/8 PO DE DIA. EXT. RACCORDER À LA

UBICACIÓN RECOMENDADA DEL SUMINISTRO DE AGUA. TUBERÍA DE COBRE SIN REVESTIMIENTO DE 3/8" DE DIÁM. EXT. ADAPTADOR

B = RECOMMENDED LOCATION FOR WASTE OUTLET 1-1/2" O.D. DRAIN STUB 2 IN. OUT FROM WALL

51 mm (2 PO) HORS DU MUR

C = 1-1/2" TRAP NOT FURNISHED

EMPLACEMENT RECOMMANDÉ DE LA SORTIE D’ÉCOULEMENT. CONDUITE D’ÉVACUATION DE 1-1/2 PO DE DIA. EXT. DÉPASSANT DE

UBICACIÓN RECOMENDADA DE LA SALIDA DE DESECHOS. ADAPTADOR DE DESAGÜE DE 1-1/2" DE DIÁM. EXT., A 51 mm (2") DE LA

Page 3 1000004543 (Rev. A - 10/18)

NO SE INCLUYE SIFÓN DE 1-1/2"

SIPHON DE 1-1/2 PO NON FOURNI

Page 4

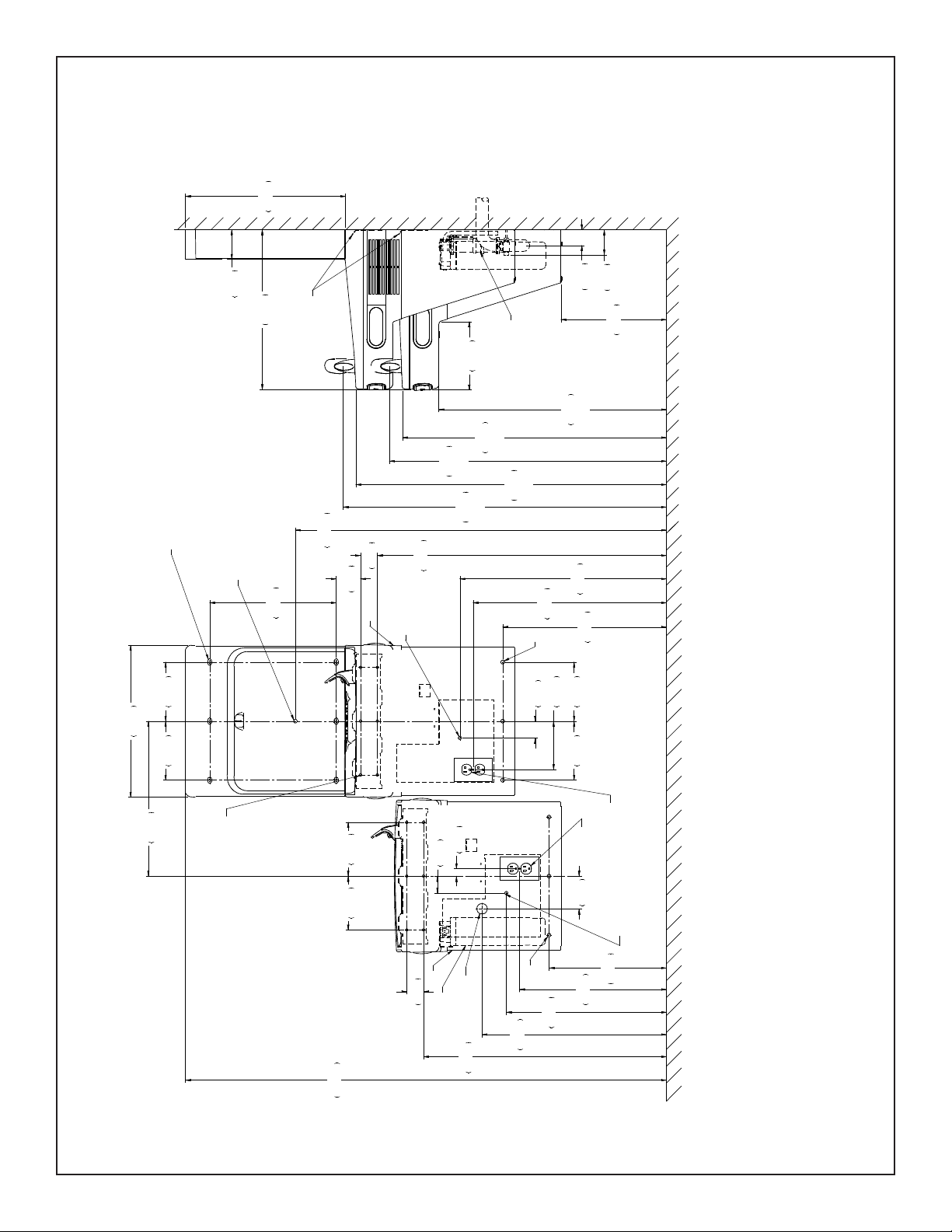

ENLZSTL8WS_1G

19"

483mm

1 7/8"

48mm

3"

3 1/2"

90mm

19"

482mm

7/16" X 3/4" (11mm X 19mm)

OBROUND HOLES (6)

ACTIVATION

SENSOR

HANGER

BRACKET

32 7/8"

835mm

ORIFICE

38 3/8"

44"

1118mm

2"

51mm

34 5/16"

871mm

2 7/8"

73mm

15"

381mm

E

A

PREFERRED

LOCATION

C

8 1/16"

205mm

RIM

31 5/16"

796mm

HEIGHT

HEIGHT

RIM

36 13/16"

936mm

HEIGHT

975mm

HEIGHT

ORIFICE

22 15/16"

583mm

F

76mm

12 1/2"

318mm

ADA

27"

686mm

REQUIREMENT

GABINETE HASTA LA PARED.

ALIMENTATION ÉLECTRIQUE (3) BOÎTIER ENCASTRÉ

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

PARA GARANTIZAR LA VENTILACIÓN ADECUADA, MANTENGA 152 mm (6") (MÍN.) DE SEPARACIÓN DESDE LAS REJILLAS DEL

L’ENCEINTE ET LE MUR.

**NEW INSTALLATIONS MUST USE GROUND FAULT CIRCUIT INTERRUPTER (GFCI)

**Las nuevas instalaciones deben usar un interruptor de circuito de falla a tierra (GFCI)

**Les nouvelles installations doivent comporter un disjoncteur diérentiel (GFCI)

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL

POUR ASSURER UNE AÉRATION SUFFISANTE, PRÉVOIR UN DÉGAGEMENT DE 152 mm (6 PO) (MIN.) ENTRE LES ÉVENTS DE

ORIFICIOS PARA PERNOS DE 7/16, PARA FIJAR LA UNIDAD A LA PARED

TROUS DE VIS DE 7/16 PO POUR LA FIXATION DE L’APPAREIL AU MUR

24 1/2"

622mm

19 7/16"

494mm

SUMINISTRO ELÉCTRICO (3) CAJA ENCHUFE DE ALAMBRE SALIDA DÚPLEX

LEGEND/LEYENDA/LÉGENDE

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX DUPLEX OUTLET**

7"

178mm

L

18"

458mm

7"

178mm

18 3/8"

467mm

C

HOLES (12)

O 9/32" (7mm)

ALTERNATE ROUGH-IN FOR LEFT-HAND LOW, BOTTLE FILLER HIGH MODELS

BOSQUEJO ALTERNATIVO PARA MODELOS CON LA LLENADORA DE BOTELLAS ALTA Y LA PARTE IZQUIERDA BAJA

AUTRE DISPOSITION DE CANALISATIONS, POUR INSTALLATION GAUCHE BASSE ET REMPLISSEUSE DE BOUTEILLE HAUTE

2"

51mm

5 3/4"

146mm

7"

178mm

FINISHED FLOOR

7"

178mm

Réduire la hauteur de 76 mm (3 po) pour les installations à la norme ADA enfants

D

D

LOCATION

7/8"

6 3/8"

162mm

L

C

6 3/8"

162mm

2"

57 1/16"

1450mm

22mm

2"

51mm

E

B

51mm

FILTER

28 13/16"

732mm

F

19"

483mm

21 7/8"

556mm

ALTERNATE

LOCATI ON

PREFERRED

3 7/8"

98mm

A

ALTERNATE

LOCATION

13 15/16"

354mm

17 7/16"

443mm

FIG. 3

REDUCE HEIGHT BY 3 INCHES FOR INSTALLATION OF CHILDREN’S ADA COOLER

Reduzca la altura en 76 mm (3 in) para la instalación del bebedero con clasicación ADA para niños

(76mm) MAXIMUM OUT FROM WALL

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WATER SUPPLY LOCATION 3/8 O.D. UNPLATED COPPER TUBE CONNECT STUB WITH SHUT OFF (BY OTHERS) 3 IN.

DE CONEXIÓN CON VÁLVULA DE CIERRE (DE TERCEROS) MÁXIMO A 76 mm (3") DE LA PARED.

CONDUITE D’ALIMENTATION AVEC UN ROBINET D’ARRÊT (NON FOURNI) À 76 mm (3 PO) MAXIMUM DU MUR

PARED.

51 mm (2 PO) HORS DU MUR

B = RECOMMENDED LOCATION FOR WASTE OUTLET 1-1/2" O.D. DRAIN STUB 2 IN. OUT FROM WALL

C = 1-1/2" TRAP NOT FURNISHED

EMPLACEMENT RECOMMANDÉ DE LA SORTIE D’ÉCOULEMENT. CONDUITE D’ÉVACUATION DE 1-1/2 PO DE DIA. EXT. DÉPASSANT DE

NO SE INCLUYE SIFÓN DE 1-1/2"

UBICACIÓN RECOMENDADA DEL SUMINISTRO DE AGUA. TUBERÍA DE COBRE SIN REVESTIMIENTO DE 3/8" DE DIÁM. EXT. ADAPTADOR

EMPLACEMENT RECOMMANDÉ DE L’ARRIVÉE D’EAU. TUBE EN CUIVRE NON PLAQUÉ DE 3/8 PO DE DIA. EXT. RACCORDER À LA

UBICACIÓN RECOMENDADA DE LA SALIDA DE DESECHOS. ADAPTADOR DE DESAGÜE DE 1-1/2" DE DIÁM. EXT., A 51 mm (2") DE LA

SIPHON DE 1-1/2 PO NON FOURNI

1000004543 (Rev. A - 10/18)

Page 4

Page 5

ENLZSTL8WS_1G

19"

483mm

1 7/8"

48mm

3"

3 1/2"

90mm

19"

482mm

HANGER

BRACKET

205mm

8 1/16"

32 7/8"

835mm

HEIGHT

ORIFICE

975mm

38 3/8"

ORIFICE

C

RIM

36 13/16"

936mm

HEIGHT

HEIGHT

76mm

12 1/2"

318mm

ADA

27"

686mm

REQUIREMENT

ALTERNATE ROUGH-IN FOR RIGHT-HAND LOW, BOTTLE FILLER HIGH MODELS – REQUIRES BASIN ASSY CHANGE

44 1/16"

1119mm

2"

51mm

28 13/16"

731mm

21 7/8"

556mm

19"

483mm

17 7/16"

HOLES (12)

O 9/32" (7mm)

6 3/8"

7/16" X 3/4" (11mm X 19mm)

OBROUND HOLES (6)

18 3/8"

467mm

7"

178mm

L

18"

458mm

7"

178mm

C

SENSOR

ACTIVATION

6 3/8"

6 3/8"

15"

381mm

162mm

6 3/8"

162mm

162mm

162mm

2"

2 7/8"

73mm

E

L

C

7/8"

22mm

2"

51mm

E

51mm

FILTER

LOCATION

A

PREFERRED

B

A

57 1/8"

1450mm

F

LOCATION

ALTERNATE

24 1/2"

622mm

872mm

34 5/16"

443mm

13 15/16"

354mm

F

3 7/8"

98mm

2"

51mm

7"

178mm

FINISHED FLOOR

5 3/4"

146mm

7"

178mm

REDUCE HEIGHT BY 3 INCHES FOR INSTALLATION OF CHILDREN’S ADA COOLER

D

LOCATION

ALTERNATE

D

LOCATION

PREFERRED

494mm

19 7/16"

583mm

22 15/16"

LEGEND/LEYENDA/LÉGENDE

Réduire la hauteur de 76 mm (3 po) pour les installations à la norme ADA enfants

Reduzca la altura en 76 mm (3 in) para la instalación del bebedero con clasicación ADA para niños

SUMINISTRO ELÉCTRICO (3) CAJA ENCHUFE DE ALAMBRE SALIDA DÚPLEX

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX DUPLEX OUTLET**

GABINETE HASTA LA PARED.

ALIMENTATION ÉLECTRIQUE (3) BOÎTIER ENCASTRÉ

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

PARA GARANTIZAR LA VENTILACIÓN ADECUADA, MANTENGA 152 mm (6") (MÍN.) DE SEPARACIÓN DESDE LAS REJILLAS DEL

L’ENCEINTE ET LE MUR.

**NEW INSTALLATIONS MUST USE GROUND FAULT CIRCUIT INTERRUPTER (GFCI)

**Las nuevas instalaciones deben usar un interruptor de circuito de falla a tierra (GFCI)

**Les nouvelles installations doivent comporter un disjoncteur diérentiel (GFCI)

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL

POUR ASSURER UNE AÉRATION SUFFISANTE, PRÉVOIR UN DÉGAGEMENT DE 152 mm (6 PO) (MIN.) ENTRE LES ÉVENTS DE

ORIFICIOS PARA PERNOS DE 7/16, PARA FIJAR LA UNIDAD A LA PARED

TROUS DE VIS DE 7/16 PO POUR LA FIXATION DE L’APPAREIL AU MUR

BOSQUEJO ALTERNATIVO PARA MODELOS CON LA LLENADORA DE BOTELLAS ALTA Y LA PARTE DERECHA BAJA: REQUIERE CAMBIAR EL CONJUNTO DE TARJA

AUTRE DISPOSITION DE CANALISATIONS, POUR INSTALLATION DROITE BASSE ET REMPLISSEUSE DE BOUTEILLE HAUTE – MODIFICATION DE LA FONTAINE REQUISE

DE CONEXIÓN CON VÁLVULA DE CIERRE (DE TERCEROS) MÁXIMO A 76 mm (3") DE LA PARED.

CONDUITE D’ALIMENTATION AVEC UN ROBINET D’ARRÊT (NON FOURNI) À 76 mm (3 PO) MAXIMUM DU MUR

PARED.

FIG. 4

(76mm) MAXIMUM OUT FROM WALL

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WATER SUPPLY LOCATION 3/8 O.D. UNPLATED COPPER TUBE CONNECT STUB WITH SHUT OFF (BY OTHERS) 3 IN.

UBICACIÓN RECOMENDADA DEL SUMINISTRO DE AGUA. TUBERÍA DE COBRE SIN REVESTIMIENTO DE 3/8" DE DIÁM. EXT. ADAPTADOR

EMPLACEMENT RECOMMANDÉ DE L’ARRIVÉE D’EAU. TUBE EN CUIVRE NON PLAQUÉ DE 3/8 PO DE DIA. EXT. RACCORDER À LA

B = RECOMMENDED LOCATION FOR WASTE OUTLET 1-1/2" O.D. DRAIN STUB 2 IN. OUT FROM WALL

51 mm (2 PO) HORS DU MUR

C = 1-1/2" TRAP NOT FURNISHED

EMPLACEMENT RECOMMANDÉ DE LA SORTIE D’ÉCOULEMENT. CONDUITE D’ÉVACUATION DE 1-1/2 PO DE DIA. EXT. DÉPASSANT DE

UBICACIÓN RECOMENDADA DE LA SALIDA DE DESECHOS. ADAPTADOR DE DESAGÜE DE 1-1/2" DE DIÁM. EXT., A 51 mm (2") DE LA

Page 5 1000004543 (Rev. A - 10/18)

NO SE INCLUYE SIFÓN DE 1-1/2"

SIPHON DE 1-1/2 PO NON FOURNI

Page 6

ENLZSTL8WS_1G

HANGER BRACKET INSTALLATION

1) Remove hanger bracket fastened to back of cooler by removing one (1) screw

2) Mount the hanger bracket as shown in Figures 1,2,3, or 4 (Pages. 2-5)

NOTE: Hanger Bracket MUST be supported securely. Add xture support carrier if wall will not provide adequate support. Anchor hanger securely to wall using all six

(6) 1/4 in. dia. mounting holes.

IMPORTANT: 5-7/8 in. (150mm) dimension from wall to centerline of trap must be maintained for proper t.

INSTALLATION OF COOLER

3) Hang the cooler on the hanger bracket. Be certain hanger bracket is engaged properly in the slots on the cooler back as shown in Figures 1,2,3, or 4 (Pages. 2-5)

4) Remove the four (4) screws holding the lower front panel at the bottom of the cooler (See Fig 7, Pg.5). Remove the front panel by pulling straight down and set aside.

5) Secure cooler frame to wall by installing (2) screws and washers (not supplied). (See Fig. 2, Pg. 4). Make sure the screws engage in a structural member.

6) Connect the supply water to the lter inlet tube.

7) Install trap. Remove the slip nut and gasket from the trap and install them on the cooler waste line making sure that the end of the waste line ts into the trap. Assemble the slip n ut

and gasket to the trap and tighten securely.

IMPORTANT: If it is necessary to cut the drain, loosen the screw at the black rubber boot and remove tube, check for leaks after re-assembly.

BOTTLE FILLER INSTALLATION

8) Remove two (2) mounting screws with 5/32" Allen wrench holding bottle ller to wall mounting plate (See Fig.8, Pg. 4). Note do not discard mounting screws, they will be

needed to secure bottle ller to wall mounting plate.

9) Remove wall mounting plate from Bottle Filler (see Fig 8, Pg. 4). Place wall mounting plate against wall on top of basin. Center the wall mounting plate side to side with the basin. Mark the

six (6) mounting holes with a pencil. Place tape over wiring harnes conection on top of cooler to prevent debris from falling into Connection.

10) Remove wall mounting plate from wall. NOTE: Mounting plate MUST be supported securely. Add xture support carrier if wall will not provide adequate support.

11) Install wall mounting plate to wall using six (6) 7/16" obround mounting holes (mounting bolts not included) (See Fig.4, Pg. 4). Use appropriate fasteners for your wall type.

12) Install gasket on bottom of bottle ller tower with gasket support bracket & (2) screws.

13) Connect water line from cooler to 3/8" john guest tting. Connect wiring harness to the top of cooler. (See Fig. 5, Pg. 4).

14) Place bottle ller on four (4) hooks on the mounting plate installed on wall. Make sure round boss in gasket ts in hole of basin. (See Fig. 8, Pg. 5).

15) Remove lter from carton, remove protective cap, attach lter to lter head by rmly inserting into head and rotating lter clockwise. Ensure that blue label can be read when

lter is installed. (Fig. 12, Pg. 7.)

16) Turn water supply on and inspect for leaks. In both cooler and bottle ller. Fix all leaks before continuing.

17) Once cooler and bottle lter has been inspected for leaks and any leaks found corrected, plug cooler into wall.

18) Reinstall two mounting screws from rst step (See Fig. 8, Pg. 5). Caution, do not over tighten screws.

19) Once power is applied to the cooler the GREEN LED light will illuminate on the bottle ller showing good lter status along with the LCD Bottle Counter.

20) Verify proper dispensing by placing cup, hand, or any opaque object in front of sensor area and verify water dispenses. Note: the rst initial dispenses might have air in line

which may cause a sputter. This will be eliminated once all air is purged from the line.

21) Once unit tests out, install Lower Panel back on water cooler(s). Units are now ready for use.

Instructions For Replacing Filters

1) Remove lower cover on cooler by removing (4) screws (See Fig.7, Pg. 5).

2) Turn o water supply; dispense water to relieve pressure.

3) Turn used lter counterclockwise 1/4 turn to remove from lter head.

4) Remove cap from new lter and use to seal used lter.

5) Insert new lter into existing lter head and turn fully clockwise. Make sure you can read the label on the front of the lter once it is installed. (See Fig.12 on Pg. 7).

6) Turn on water supply and run a minimum of two gallons of water through the lter to purge air any ne carbon particles from lter. Also run water through bottle ller

Note: Filter status light will automatically reset once new lter is installed.

1000004543 (Rev. A - 10/18)

Page 6

Page 7

ENLZSTL8WS_1G

Secure cooler frame to wall by installing (2) screws and washers (not supplied).

Para jar la estructura del bebedero a la pared, instale (2) tornillos y arandelas (no se proporcionan).

Fixer le bâti de la fontaine à eau fraîche au mur à l’aide de deux (2) vis et rondelles (non fournies).

FIG. 2

FIG. 3

Lay gasket along back of bottle ller mounting plate. Align BF and lay on cooler basin.

Fig. 4

Attach the 3/8 water line into the bulkhead tting

Fig. 5

Page 7 1000004543 (Rev. A - 10/18)

Page 8

ENLZSTL8WS_1G

Fig. 7

Connect the bottle ller electrical harness

Fig. 6

MOUNTING BOLT HOLES (6)

WALL MOUNTING PLATE

36

34

35

1000004543 (Rev. A - 10/18)

BOTTLE FILLING UNIT

Fig. 8

Page 8

Page 9

OPERATION OF QUICK CONNECT FITTINGS

ENLZSTL8WS_1G

115V Refrigerated Wiring Diagram

with Alpha/Numeric Display

BRACKET & SCREWS

Fig. 10Fig. 9

SOPORTE Y TORNILLOS

SUPPORT ET VIS

29

Superseal Fitting Assembly

30

26

Fig. 11

27

28

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

IMPLY PUSH IN

S

TUBE TO ATTACH

TUBE TO ATTACH

TUBE IS SECURED

TUBE IS SECURED

IN POSITION

IN POSITION

PUSH IN COLLET

PUSH IN COLLET

TO RELEASE TUBE

TO RELEASE TUBE

Note: Screw the locknut hand tight to seal2

Fig. 12

A

B C

B CA

Fig. 13

Page 9 1000004543 (Rev. A - 10/18)

Page 10

ENLZSTL8WS_1G

INSTRUCTIONS TO MOVE THE BOTTLE FILLER & BASIN TO THE LEFT SIDE

(NON-REFRIGERATED) FOR ALTERNATE MOUNTING VERSATILE BI-LEVEL

Fig. A

Fig. B

Using a 5/16" socket, remove the (4)

screws from the bottom of each cooler

to remove the wrappers.

Precautions need to be taken when replacing the Basin/shroud assembly:

1) Make sure all wires are inside frames so as not to become pinched.

2) Water line coming from bottle llter drain must be pulled down as not to interfere with the fan operation. The fan

blade needs to spin freely.

Using a #T20 (6 point star bit),

loosen the shroud screws. Both

sides, both coolers.

ONLY move the ller panel and j-clip

to the refrigerated (right) side if right

side will be mounted “high”

1000004543 (Rev. A - 10/18)

Page 10

Page 11

Refrigerated Cooler side:

Carefully lift and tip the shroud/basin

assembly o of the cooler frame.

Only disconnect the (2) black wires

coming from the shroud assembly that

go to the solenoid valve and to the cold

control.

Disconnect the water line at the solenoid

valve. Reference (Fig. 16, p.17) for the

operation of the quick connect ttings.

Non-Refrigerated Cooler side:

Carefully tip the shroud/basin assembly

toward the cooler frame.

Connect one of the black wires to the

solenoid valve and one to the power

cord.

ENLZSTL8WS_1G

Re-connect the water line at the

solenoid. Reference (Fig. 16, p.17) for

the operation of the quick connect

ttings.

Swap drain parts in shroud: Loosen each hose clamp retaining the drain pieces. Remove each drain piece and swap to other basin.

Tighten each hose clamp.

Enhanced EZH2O Error Codes

Error

Code

E01 Bottle ller area obstructed • Clean lens on IR sensor

E02 Missing or Incomplatible Filter • Check that lter is installed correctly (label facing forward, white tag fac-

E03 Missing NFC Board • Unplug unit for at least 30 seconds and restart

Error Description Corrective Action

• Unplug unit for at least 30 seconds and restart

• If error repeats, replace IR sensor with 1000002434 KIT - IR SENSOR

ing back)

• Unplug unit for at least 30 seconds and restart

• Replace lter

• Replace lter head assembly with repair kit - 1000002030 KIT - FILTER

HEAD-BRKT-FTGS

• If error repeats, contact certied service professional

• Verify cable connector is plugged into NFC board on lter head assembly

• Verify cable connector is plugged into control board (10 pin connector on

harness # 0000001225)

• Replace lter head assembly with repair kit - 1000002030 KIT - FILTER

HEAD-BRKT-FTGS

• If error repeats, contact certied service professional

Page 11 1000004543 (Rev. A - 10/18)

Page 12

ENLZSTL8WS_1G

INSTRUCTIONS CONTINUED... CONTINUACIÓN DE LAS INSTRUCCIONES... INSTRUCTIONS - SUITE...

Left Hand Wrapper (Low Side)

1) Remove existing wrapper by removing the (4)

screws from bottom.

2) Clip cover plate, sliding until plate sits ush with

the wall.

3) Re-install wrapper with (4) screws.

4) Dispose of unused trim piece.

Revestimiento del lado izquierdo (Lado bajo)

1) Retire los (4) tornillos de la parte inferior para

retirar el revestimiento existente.

2) Sujete la placa de la cubierta, deslizándola hasta

que quede alineada con la pared.

3) Vuelva a instalar el revestimiento con los (4)

tornillos.

4) Deseche la pieza de acabado que no usa.

Enveloppe gauche (côté bas)

1) Retirer les quatre (4) vis du dessous pour déposer

l’enveloppe existante.

2) Encliqueter la plaque de fermeture, en la glissant

jusqu’au ras du mur.

3) Remonter l’enveloppe avec quatre (4) vis.

4) Jeter la pièce

de garniture

inutilisée.

Right Hand Wrapper (High Side)

1) Remove existing wrapper by removing the (4) screws

from bottom.

2) Screw trim piece to wrapper with (2) screws (provided)

3) Re-install wrapper with (4) screws.

4) Dispose of unused cover plate.

Revestimiento del lado derecho (Lado alto)

1) Retire los (4) tornillos de la parte inferior para retirar el

revestimiento existente.

2) Atornille la pieza de acabado al revestimiento con los

(2) tornillos (proporcionados)

3) Vuelva a instalar el revestimiento con los (4) tornillos.

4) Deseche la placa de la cubierta que no usa.

Enveloppe droite (côté haut)

1) Retirer les quatre (4) vis du dessous pour déposer

l’enveloppe existante.

2) Visser la pièce de garniture à l’enveloppe avec deux

(2) vis (fournies)

3) Remonter l’enveloppe avec quatre (4) vis.

4) Jeter la plaque de fermeture inutilisée.

Wrapper Fill

Piece Location

(Right Side High)

Ubicación de la pieza de

llenado del recubrimiento

(lado derecho alto)

Emplacement de la pièce

de fermeture d’enveloppe

(côté droit haut)

1000004543 (Rev. A - 10/18)

Page 12

Page 13

ENLZSTL8WS_1G

Versatile Wrapper and Trim Kit Installation Instructions

Left Hand Wrapper (High Side)

1) Remove existing wrapper by removing the (4) screws

from bottom.

2) Screw trim piece to wrapper with (2) screws (provided)

3) Re-install wrapper with (4) screws.

4) Dispose of unused cover plate.

Revestimiento del lado izquierdo (Lado alto)

1) Retire los (4) tornillos de la parte inferior para retirar el revestimiento

existente.

2) Atornille la pieza de acabado al revestimiento con los (2) tornillos

(proporcionados)

3) Vuelva a instalar el revestimiento con los (4)

tornillos.

4) Deseche la placa de la cubierta que no usa.

Enveloppe gauche (côté haut)

1) Retirer les quatre (4) vis du dessous pour

déposer l’enveloppe existante.

2) Visser la pièce

de garniture à

l’enveloppe avec

deux (2) vis

(fournies)

3) Remonter

l’enveloppe avec

quatre (4) vis.

4) Jeter la plaque

de fermeture

inutilisée.

Wrapper Fill

Piece Location

(Left Side High)

Ubicación de la pieza de

llenado del recubrimiento

(lado izquierdo alto)

Emplacement de la pièce de

fermeture d’enveloppe (côté

gauche haut)

Right Hand Wrapper (Low Side)

1) Remove existing wrapper by removing the

(4) screws from bottom.

2) Clip cover plate, sliding until plate sits ush

with the wall.

3) Re-install wrapper with (4) screws.

4) Dispose of unused trim piece.

Revestimiento del lado derecho (Lado

bajo)

1) Retire los (4) tornillos de la parte inferior

para retirar el revestimiento existente.

2) Sujete la placa de la cubierta, deslizándola

hasta que quede alineada con la pared.

3) Vuelva a instalar el revestimiento con los (4)

tornillos.

4) Deseche la pieza de acabado que no usa.

Enveloppe droite (côté gauche)

1) Retirer les quatre (4) vis du dessous pour

déposer l’enveloppe existante.

2) Encliqueter la plaque de fermeture, en la

glissant jusqu’au ras du mur.

3) Remonter

l’enveloppe

avec quatre (4)

vis.

4) Jeter la pièce

de garniture

inutilisée.

Page 13 1000004543 (Rev. A - 10/18)

Page 14

ENLZSTL8WS_1G

PLUMBING DIAGRAMS

VERSATILE BI-LEVEL

Bottle Filler

Bottle Filler

Drain

Drain

Bottle Filler

Drain

Bottle Filler

Drain

1000004543 (Rev. A - 10/18)

Page 14

Page 15

ENLZSTL8WS_1G

11

Basin

Locknut

BUBBLER DETAIL

Filter Label Location

Fig. 14

NOTE:

Fig. 15

When installing replacement bubbler and pedestal, tighten nut only to hold parts

snug in position. Do Not Overtighten.

3

2

1

Fig. 16

WATERSENTRY® Filter Detail

WATERSENTRY® FILTER PARTS LIST

DESCRIPTIONITEM NO. PART NO.

1

2

3

51300C

1000002030

1000002443

Filter Assy - 3000 Gal.

Kit - Filter Head Fittings includes

John Guest Fittings & 3/8" Elbow

Filter Bracket/Screws

Kit - NFC Board/Cover

Page 15 1000004543 (Rev. A - 10/18)

Page 16

ENLZSTL8WS_1G

Service Instructions

Lower and Upper Shroud

To access the refrigeration system and plumbing connections, remove four screws from bottom

of cooler to remove the lower shroud. To remove the upper shroud for access to the pushbars,

regulator, solenoid valve or other components located in the top of the unit, remove lower shroud,

disconnect drain, remove four screws from tabs along lower edge of upper shroud, unplug two

wires and water tube.

Bubbler

To remove the bubbler, rst disconnect the power supply. The underside of the bubbler can be

reached through the access panel on the underside of the upper shroud. Remove the access

panel by removing the retaining screw. To remove the bubbler, loosen locknut from the underside

of the bubbler and remove the tubing from the quick connect tting per the Operation Of Quick

Connect Fittings section in the General Instructions. After servicing, replace the access panel

and retaining screw.

Switches Behind the Push Bar

The regulator in an EZ cooler is always held fully open by the use of a single regulator nut (See

Item 9, Fig. 15). Water is not dispensed until the pushbar is depressed to activate a switch which

then opens a solenoid valve.

To remove sidebars, from the inside compress the ared tabs and pull out carefully. To reinstall

side pushbars, the front of the pushbar is inserted rst. While keeping the switch depressed,

snap the rear of the pushbar into position.

Cleaning

Stainless Steel

• General cleaning: use an ordinary mild detergent and soft cloth, rinse and towel dry.

• Steel soap pads should never be used; particles can adhere to a stainless steel basin

surface and will eventually rust.

• Light scratches are normal for stainless steel basins; over time they will blend into the

uniform nish pattern.

Plastic Components

• General cleaning: use an ordinary mild detergent and soft cloth, rinse and towel dry.

• Wiping the surface clean to remove debris or build up will not hurt the antimicrobial

properties.

32A

20

6

12,13

REGULATOR

ASSEMBLY

SNAP

Refrigerated Unit

11

23

2B

11

23

10

12

ALIGNMENT

NOTCH

SNAP

20

6

12,13

REGULATOR

ASSEMBLY

ALIGNMENT

PEG

Fig. 15

Non-Refrigerated Unit

11

2A

11

32B

10

12

ALIGNMENT

NOTCH

1000004543 (Rev. A - 10/18)

Page 16

SNAP

SNAP

ALIGNMENT

PEG

Fig. 16

Page 17

ENLZSTL8WS_1G

Returns to Main Menu

Notes End Action

action

Action Sub Menu/

action

Returns to Main Menu

Returns to Main Menu

turned o

to lter, LED status display, lter error capability

Drops to next level when selected

Returns to Main Menu

Refrigeration on Returns to Main Menu

bottle needs to be to activate

Drops to next level when selected

and night light

Momentary Select time on 24 hours – 1-12AM and 1-12PM Drops to next level when selected

Momentary Select time o 24 hours – 1-12AM and 1-12PM Drops to next level when selected

Momentary Select time on 24 hours – 1-12AM and 1-12PM Drops to next level when selected

Select Weekday Drops to next level when selected

Select Weekend Drops to next level when selected

Momentary Select time o 24 hours – 1-12AM and 1-12PM Returns to Main Menu

Programming Instruction

Depress Button for 3 seconds to activate main menu - release

Cycles thru main menu items 2 seconds each for 2 cycles then exits menu unless selected

Cycles thru sub menu items 2 seconds each for 2 cycles then returns to main menu unless selected

Selections are saved when the menu is exited

Top level Action Sub Menu 1 Action Sub Menu/action Action Sub Menu/

on unit

Info Momentary Scrolls through all the settings

Day (Sunday-Saturday Momentary Use push button to select the day on the display Drops to next level when selected

AM/PM Momentary Use push button to select AM or PM Drops to next level when selected

Info Momentary Flashes error code Returns to Main Menu

Set time Momentary Drops to next level when selected

Hour (12 hour) Momentary Use push button to select Hour Drops to next level when selected

Min 0-69 in 5 minute increments Momentary Use push button to select closest minute Returns to Main Menu

No Momentary Turn o lter status and erros No Filter unit - Error codes related to lter status

Yes Momentary Default setting - Turn on lter status and errors Filter status has default ON / Default has read write

Filter Momentary Drops to next level when selected

1.1gpm

No Momentary Turns o power to E/S relay sets bottle ll time to 1.5gpm Refrigeration o Returns to Main Menu

Yes Momentary Default setting - Turns on power to E/S relay - sets time to

Refrig Momentary Drops to next level when selected

to be before turning before turning on or o the bottle ller

1-10 Momentary Default setting 5 - Adjusts distance from sensor the bottle needs

Range Momentary The lower the number, the closer to the sensor the

25% Momentary Returns to Main Menu

50% Momentary Returns to Main Menu

75% Momentary Default Setting Returns to Main Menu

B-Light Momentary The settings are for the brightness of the display

100% Momentary Returns to Main Menu

O Momentary Default Setting Returns to Main Menu

On Momentary Set Energy Save Schedule Drops to next level when selected

EnerSave Momentary Drops to next level when selected

Page 17 1000004543 (Rev. A - 10/18)

Page 18

ENLZSTL8WS_1G

Pictured is unit only without bottle ller.

Note: Danger! Electrical shock hazard. Disconnect power before servicing unit.

Uses HFC-134A refrigerant

Usa refrigerante HFC-134A

Utilise du uide frigorigéne HFC-134A

32B

14

1

32A

1

14, 29

22

9

16

20

12

31

8

5

6

3

12

See Fig. 9

2A

5

6

3

13

2B

See Fig. 9

20

12

17

9

25

9

7

20

1000004543 (Rev. A - 10/18)

20

22, 33

26

19

20

Fig. 18

Page 18

21

18

4

20

Page 19

ITEM NO. PART NO.

1

2A

2B

3

*4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32A

32B

NS

NS

NS

NS

NS

NS = Not Shown

NS = No se muestra

NS = Non représenté

28401C

55001109

0000001337

36216C

36322C

56092C

56229C

66703C

56213C

1000004572

1000004564

56073C

98734C

1000001600

1000002442

1000002437

1000002439

1000002456

98777C

98778C

98898C

0000000238

1000002438

1000001812

55996C

1000001602

1000004545

1000004546

1000004547

1000004550

1000004559

1000002055

98900C

97969C

1000000944

1000000888

1000000758

1000000759

28024C

28025C

1000001892

1000001891

1000001894

1000001893

115V PARTS LIST / LISTA DE PIEZAS DE 115 V / LISTE DES PIÈCES 115 V

DESCRIPTION DESCRIPCIÓN

Hanger Bracket

Basin - Stainless Steel

Basin - Bottle Filler Stainless Steel

Wiring - Front/Side Push Bar

Compr - Service Pak 115V EMIS70HHR

Tube - Poly (Cut To Length)

Assy - Shroud - Upper (Front Side Push)

Drier

Access Panel

Kit - Solenoid Valve/Regulator Assy

Kit-Regulator W/Holder & Nut

Bubbler Assy

Kit - Pushbar (Front/Side) TL

Kit - Pushbar (Front Only)

Kit - Power Cord/Strain Relief Bushing

Kit - Transformer/Board/Bracket

Kit - Fan Motor/Blade/Screws/Nut

Kit - Condenser/Drier/WireTies

Kit - Compr Mtg Hdwe/Grommets/

Clips/Studs

Kit - Heatx/Drier

Kit - Hardware

Kit - Elect/Relay/Overload/Cover

Kit - Evap. Replacement

Kit - Bottle Filler Drain

In-Line Strainer (non-ltered model)

Kit - 75583C Elbow 5/16" x 1/4" (3 Pack)

Wire - IR PC Board

Harness - Bottle Filler

Harness - Cooler

Wire - 6” Jumper

Wire Assy - Jumper

Wasteline Drain Assy BF

Kit - Drain Replace TL

Kit - Drain Replace (TL) LR

Kit - Panel (Wrapper) Light Gray TL

Kit - Panel (Wrapper) Stainless TL

Kit - Panel (Wrapper) Stainless LZTLD

Kit - Panel (Wrapper) Light Grey LZTLD

Filler - Wrapper Light Grey LZTLD

Filler - Wrapper Stainless LZTLD

Bracket - Trim Strip Light Grey LZTLD

Bracket - Trim Strip Stainless LZTLD

Panel - Universal Trim Light Grey LZTLD

Panel - Universal Trim Stainless LZTLD

*INCLUDES RELAY & OVERLOAD. IF UNDER

WARRANTY, REPLACE WITH SAME COMPRESSOR

USED IN ORIGINAL ASSEMBLY.

NOTE: All correspondence pertaining to any of the

above water coolers or orders for repair parts MUST

include Model No. and Serial No. of cooler, name and

part number of replacement part.

ENLZSTL8WS_1G

Soporte colgante

Tarja: Acero inoxidable

Tarja: Llenadora de botellas de acero inoxidable

Cableado: Barra de empuje delantera y lateral

Compresor: Paquete de servicio de 115 V EMIS70HHR

Tubería: Polietileno (corte a la longitud necesaria)

Conjunto; recubrimiento; superior (Empuje delantero y lateral)

Secador

Panel de acceso

Kit - Conjunto de válvula solenoide / regulador

Kit regulador con soporte y tuerca

Asamblea de burbujeador

Kit: Barra de empuje (Delantera y lateral) TL

Kit: Barra de empuje (Solo delantera)

Kit: Cable de alimentación y casquillo de alivio de tensión

Kit: Transformador, panel y soporte

Kit: Motor del ventilador, aspa, tornillos y tuerca

Kit: Condensador/secador/lazos de alambre

Kit: Piezas metálicas de montaje del compresor, arandelas,

sujetadores y remaches

Kit: Intercambiador de calor y secador

Kit: Piezas metálicas

Kit: Eléctrico, relé, sobrecarga y cubierta

Kit: Repuesto evaporador

Kit: Desagüe de la llenadora de botellas

Colador en línea (modelos sin ltro)

Kit: 75583C Codo 5/16" x 1/4" (Paquete de 3)

Wire - Tarjeta de circuitos impresos IR

Arnés - Llenadora de botellas

Arnés - Enfriador

Cable - Puente de 6 “

Asamblea de alambre - Puente

Conjunto de tubería de desagüe BF

Kit: Repuesto de desagüe TL

Kit: Repuesto de desagüe (TL) LR

Kit - Panel: (Recubrimiento) gris claro TL

Kit - Panel: (Recubrimiento) acero inoxidable TL

Kit - Panel: (Revestimiento): Acero inoxidable LZTLD

Kit - Panel: (Revestimiento): Gris claro LZTLD

Llenadora: Revestimiento gris claro LZTLD

Llenadora: Revestimiento acero inoxidable LZTLD

Soporte: Banda de acabado gris claro LZTLD

Soporte: Banda de acabado acero inoxidable LZTLD

Panel: Banda universal gris claro LZTLD

Panel: Banda universal acero inoxidable LZTLD

*INCLUYE RELÉ Y SOBRECARGA. SI ESTÁ CUBIERTO POR LA

GARANTÍA, REEMPLACE CON EL MISMO COMPRESOR QUE SE

USA EN EL CONJUNTO ORIGINAL.

NOTA: Toda la correspondencia que guarde relación con los bebedores

descritos anteriormente, o los pedidos de piezas de repuesto, DEBEN

incluir el n.° de modelo y el n.° de serie del bebedero, nombre y número

de pieza del repuesto.

DESCRIPTION

Ferrure de suspension

Cuve - Acier inoxydable

Cuve - Remplisseuse de bouteille en acier inoxydable

Câblage - Poussoir frontal/latéral

Compr - Ens. service 115 V EMIS70HHR

Tube - Poly (couper à la longueur)

Carénage supérieur (poussoir frontal/latéral)

Déshydrateur

Panneau d’accès

Kit - Assemblage électrovanne / régulateur

Kit régulateur avec support et écrou

Bubbler Assembly

Trousse - Poussoir (frontal/latéral) TL

Trousse - Poussoir (frontal seulement)

Trousse - Cordon alim./douille serre-câble

Trousse - Transformateur/carte/support

Trousse - Moteur de ventilateur/pales/vis/écrou

Trousse - Statiques/sécheur/Colliers

Trousse - Visserie x. compr./œillets/clips/goujons

Trousse - Échangeur chaleur/déshydrateur

Trousse - Visserie

Trousse - Élect./relais/antisurcharge/capot

Trousse - Évaporateur de rechange

Trousse - Écoulement remplisseuse de bouteille

Filtre en ligne (modèles non ltrés)

Trousse - 75583C Coude 5/16 po x 1/4 po (paq. 3)

Fil - Carte PC IR

Harnais - Remplisseur De Bouteille

Harnais - Glacière

Fil - Cavalier de 6 ”

Assemblage de ls - Cavalier

Écoulement conduite eau usée BF

Trousse - Écoulement de rechange TL

Trousse - Écoulement de rechange (TL) LR

Trousse - Panneau (Enveloppe) Gris clair TL

Trousse - Panneau (Enveloppe) Acier inoxydable TL

Trousse - Panneau (Enveloppe) Acier inoxydable LZTLD

Trousse - Panneau (Enveloppe) Gris clair LZTLD

Remplisseuse - Enveloppe gris clair LZTLD

Remplisseuse - Enveloppe inox LZTLD

Attache - Bande de garniture gris clair LZTLD

Attache - Bande de garniture inox LZTLD

Panneau - Garniture universelle gris clair LZTLD

Panneau - Garniture universelle inox LZTLD

*COMPREND RELAIS ET LIMITEUR DE SURCHARGE. SI SOUS

GARANTIE, REMPLACÉ PAR LE MÊME COMPRESSEUR QUE

CELUI DE L’APPAREIL D’ORIGINE.

REMARQUE : Toute correspondance concernant toute fontaine

à eau fraîche ci-dessus ou toute commande de pièces détachées

devra IMPÉRATIVEMENT inclure le numéro de modèle et le numéro

de série de l’appareil, ainsi que le nom et le numéro de pièce des

pièces de rechange.

ITEM NO.

NS

33

34

35

NS

NS

36

37

NS

NS

NS = Not Shown

BOTTLE FILLER REPLACEMENT PART KITS

KITS DE PIEZAS DE REPUESTO DE LA LLENADORA DE BOTELLAS

TROUSSES DE PIÈCES DE RECHANGE POUR LA REMPLISSEUSE DE BOUTEILLE

PART NO.

98546C

98549C

1000001622

1000001609

1000001981

1000001982

1000002433

1000002434

1000002436

1000001813

DESCRIPTION

Kit - Aerator Replacement

Kit - Hardware & Waterway (BF)

Valve - Solenoid 24V (BF)

Wiring Harness-Basin Feed to BF

Nameplate - Elkay Filtered

Nameplate - Elkay Non-Filtered

Kit - Top Cover Assy (BF)

Kit - IR Sensor

Kit - Alpha Numeric LED Board

Kit - Tower/Basin Gasket

Kit: Repuesto de aireador

Kit: Piezas metálicas y canales (LlB)

Válvula: Solenoide de 24 V (LlB)

Haz de cables: Paso de la tarja hacia la LlB

Placa de identicación: Elkay con ltro

Placa de identicación: Elkay sin ltro

Kit: Conjunto de cubierta superior (LlB)

Kit: Sensor infrarrojo

Kit: Panel LED alfanumérico

Kit: Torre y empaquetadura de la tarja

DESCRIPCIÓN

Trousse - Aérateur de rechange

Trousse - Visserie et circuit d’eau (RB)

Électrovanne 24 V (RB)

Faisceau câbles - Alim. fontaine à RB

Plaque signalétique - Elkay à ltre

Plaque signalétique - Elkay sans ltre

Trousse - Capot supérieur (RB)

Trousse - Capteur IR

Trousse - Carte voyant alphanumérique

Trousse - Joint tour/fontaine

Page 19 1000004543 (Rev. A - 10/18)

DESCRIPTION

Page 20

ENLZSTL8WS_1G

FCC COMPLIANCE STATEMENT

CAUTION: Changes or modications not expressly approved could void your authority to use this equipment

This device complies with Part 15 of the FCC Rules. Operation to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation

INDUSTRY CANADA STATEMENT

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de license. L’exploitation est autorisée aux deux conditions

suivantes : (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

PRINTED IN U.S.A.

IMPRESO EN LOS E.E.U.U.

IMPRIMÉ AUX É.-U.

ELKAY MANUFACTURING COMPANY • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484 • www.elkay.com

1000004543 (Rev. A - 10/18)

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.834.4816

POUR OBTENIR DES PIÈCES, CONTACTEZ VOTRE DISTRIBUTEUR LOCAL OU COMPOSEZ LE 1.800.834.4816

PARA PIEZAS, CONTACTE A SU DISTRIBUIDOR LOCAL O LLAME AL 1.800.834.4816

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

INFORMATIONS POUR LE SERVICE PAR NUMERO SANS FRAIS 1.800.260.6640

NÚMERO GRATIS DE SERVICIO 1.800.260.6640

Page 20

Page 21

ENLZSTL8WS_1G

This page intentionally left blank

Page 21 1000004543 (Rev. A - 10/18)

Loading...

Loading...