Page 1

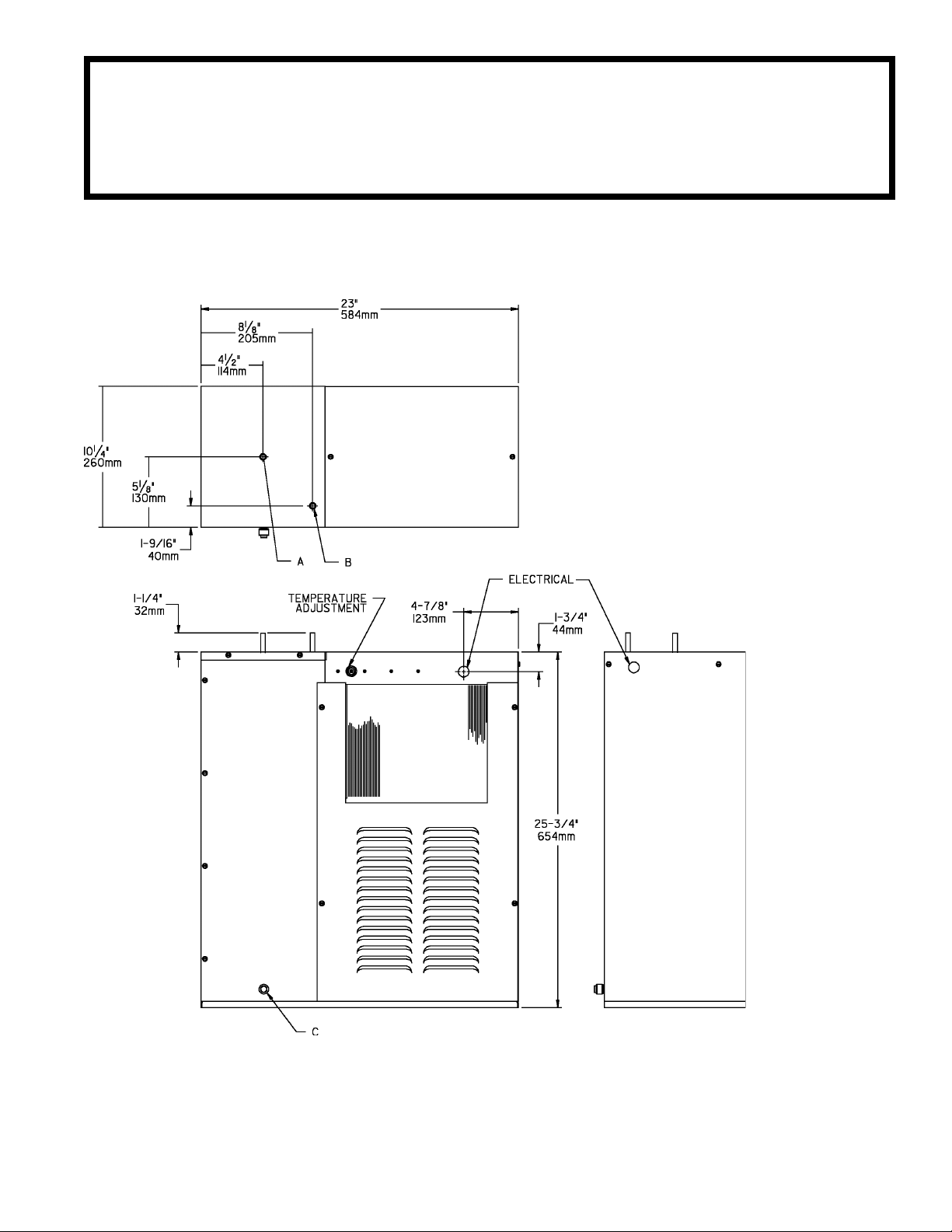

HRC4-191B HRC4-19-2B

Installation Instructions

HRC419 HRC41950

Refrigeration Packages

NOTE: It is important to insure proper ventilation. Allow a

minimum clearance of 12 inches (305 mm) in front and 3 inches

(76mm) in the rear of the unit. If unit is to be installed in an

enclosure, allow the following clearances around unit - 1 inch

(25mm) each side, 3 inches (76mm) in the rear, 3 inches

(76mm) inches above wall.

This chiller has been designed for use with potable water and

includes an o-ring seal on the drain plug. The fitting should

be replaced if the unit is to be used with more aggressive

fluids.

For use with photo processing applications, adjust

cold control to warmer settings.

LEGEND

A = 3/8" O.D. TUBE WATER OUT

B = 3/8" O.D. TUBE WATER INLET

C = 3/8" O.D. TUBE TANK DRAIN

97559C (REV. B - 1/00)

Page 2

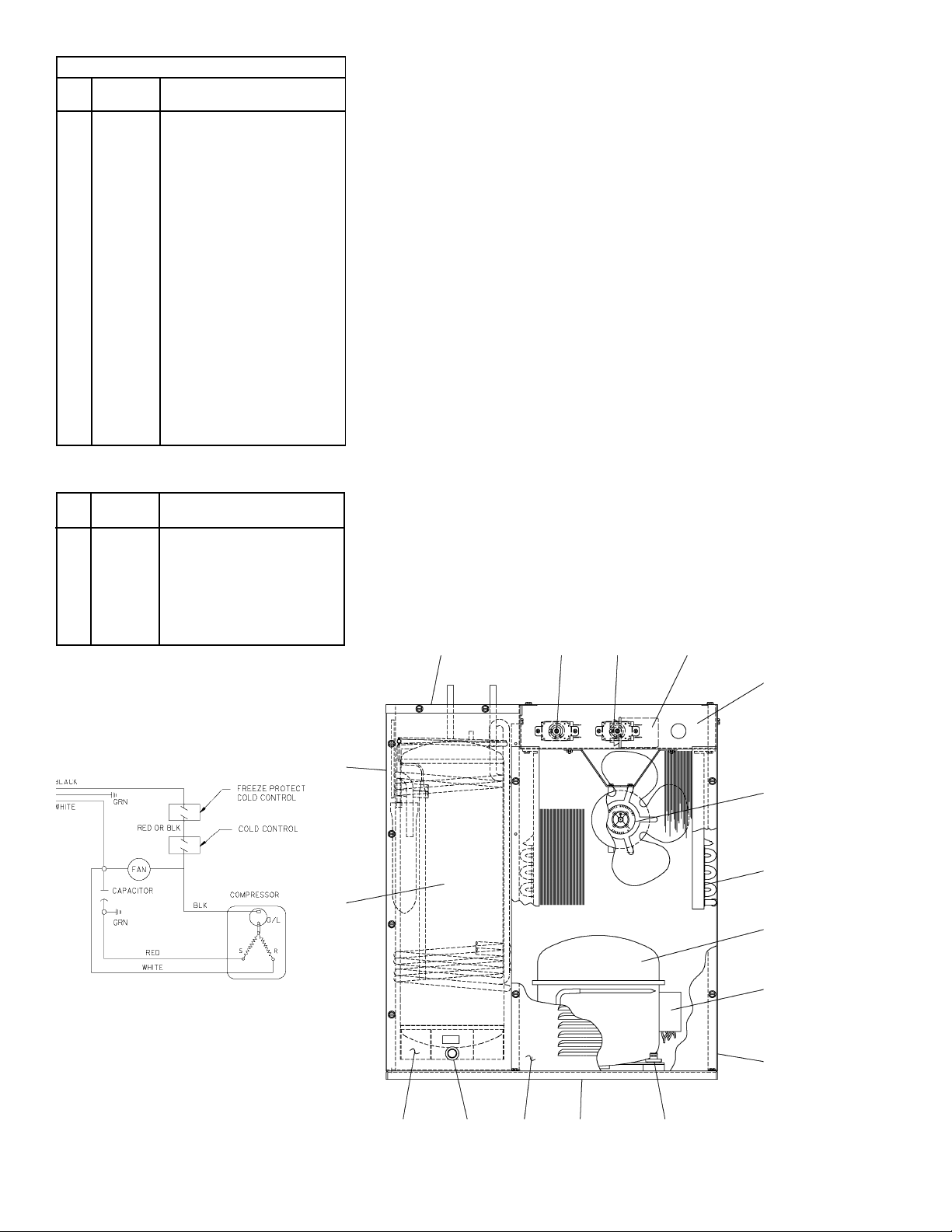

ITEMIZED PARTS LIST

ITEM

PART NO.

NO.

1

23089C

2

35882C

3

35895C

4

31757000

5

30502C

6

41991000

7

70018C

8

70009C

9

32824000

10

32817000

11

35977C

12*

35986C

13

35880C

14

30234C

15

30233C

16

30235C

17

19037000

18

100806740570

19

66563C

20

27597C

21

70772C

22

27197C

23

27844C

24

23100C

25

23101C

26

23104C

27

23103C

NS

27198C

HRC41950 - 220/240V, 50 HZ

ITEM

PART NO.

NO.

36015C

4

36000C

11

36003C

11A

36002C

12*

35997C

13

35998C

15

30560C

16

27981C

23

36001C

35999C

-

*INCLUDES RELAY & OVERLOAD. IF UNDER

WARRANTY, REPLACE WITH SAME COMPRESSOR

USED IN ORIGINAL ASSEMBLY.

NOTE: All correspondence pertaining to any of the

above water cooler or orders for repair parts MUST

include model number and serial number of cooler, name

and part number of replacement part.

DESCRIPTION

Terminal Box Cover

Cold Control

Cold Control (Freeze Protect)

Fan Motor

Fan Blade

Fan Bracket

Fan Nut

Motor Mounting Screw

Condenser

Shroud

Capacitor

Compressor Serv Pak (115v)

Overload

Clip Compressor

Overload Spring

Terminal Cover

Clip

Grommet

Evaporator Assy

Insulation Box Cover

Drain Plug

Grill (Front)

Base Assy

Insulation Box Panel (Rear)

End Panel

Insulation Box (Front)

Terminal Box

Grill (Rear)

DESCRIPTION

Fan Motor

Capacitor (run)

Capacitor (start)

Compressor Serv Pak

Overload

Overload Spring

Terminal Cover

Base Assy

Relay

Gasket

HRC4-19-1B HRC4-19-2B

INSTALLATION

1. Potable water inlet and outlet are 3/8" (9 mm) O.D. tube located on

top of unit. Contractor to supply connections as required.

2. Connecting lines to be of copper, thoroughly flushed to remove all

foreign matter before being connected to cooler. If flushing does

not remove all particles, a water strainer should be installed in supply

line.

3. Connect cooler to building supply line with a shut-off valve and install

a union connection between the valve and cooler.

4. Electrical: Make sure power supply is identical in voltage, cycle, and

phase to that specified on cooler serial plate. Never wire compressor

directly to the power supply.

START-UP

1. Open supply line valve.

2. Purge air from all water lines by operating bubbler valve of fountain.

3. Connect to electrical power.

TROUBLE SHOOTING & MAINTENANCE

Temperature Control: Factory set for 50° F water (+/- 5°) under normal

conditions. For colder water, adjust screw on item no. 2 CW.

Ventilation: Cabinet louvers should be periodically cleaned with brush,

air hose or vacuum cleaner. Excess dirt or poor ventilation can cause

no cold water and compressor cycling on the compressor overload

protector

Lubrication: Motors are lifetime lubricated.

20

2

3

11

1, 27

WIRING DIAGRAM

97559C (REV. B - 1/00)

24

19

26

21

22

23

4, 5, 6,

7, 8

9, 10

12

13, 14, 15,

16

25

19,20

Loading...

Loading...