Elkay HRC30-1A Installation Manual

HRC30-1A HRC30-50-2A

Installation Instructions

HRC30-1A HRC30-50-2A

Refrigeration Packages

IMPORTANT! INSTALLER PLEASE NOTE.

The grounding of electrical equipment such as telephone, computers, etc., to water lines is a common procedure. This grounding

may be in the building, or may occur away from the building. This grounding can cause electrical feedback into a water chiller,

creating an electrolysis which causes a metallic taste or an increase in the metal content of the water. This condition is avoidable by

using the proper materials indicated below. Drain fittings which are provided by the installer should be plastic to electrically isolate

the chiller from the building plumbing system.

INSTALLATION

1. This unit is intended for remote installation only. It is important to insure proper ventilation. A minimum of 6 inches (152mm) to the

front must be maintained, and 6 inches (152mm) to the rear of the unit.

2. This chiller has been designed for use with potable water and includes an o-ring seal on the drain plug. This fitting should be

replaced if the unit is to be used with more aggressive fluids.

3. Installer to provide air gap at condenser water outlet to comply with local plumbing specifications.

4. Connecting lines to be made of copper. Thoroughly flush all lines to remove all foreign matter before connecting to cooler. If

flushing does not remove all particles, a water strainer should be installed in the supply line.

5. Connect cooler to building supply with a shut-off valve and install a union connection between the valve and the cooler.

6. Electrical: Make sure power supply is identical in voltage, cycle, and phase to that specified on cooler serial plate. Never wire the

compressor directly to the power supply.

7. For use with photo processing applications, adjust thermostat to warmer settins.

START UP

1. Open supply line valve.

2. Purge all air from all water lines by operating bubbler valve of fountain to which cooler is connected. A steady stream assures that

all air is removed.

3. Rotate fan blade to assure proper clearance and free action.

4. Connect to proper electrical power.

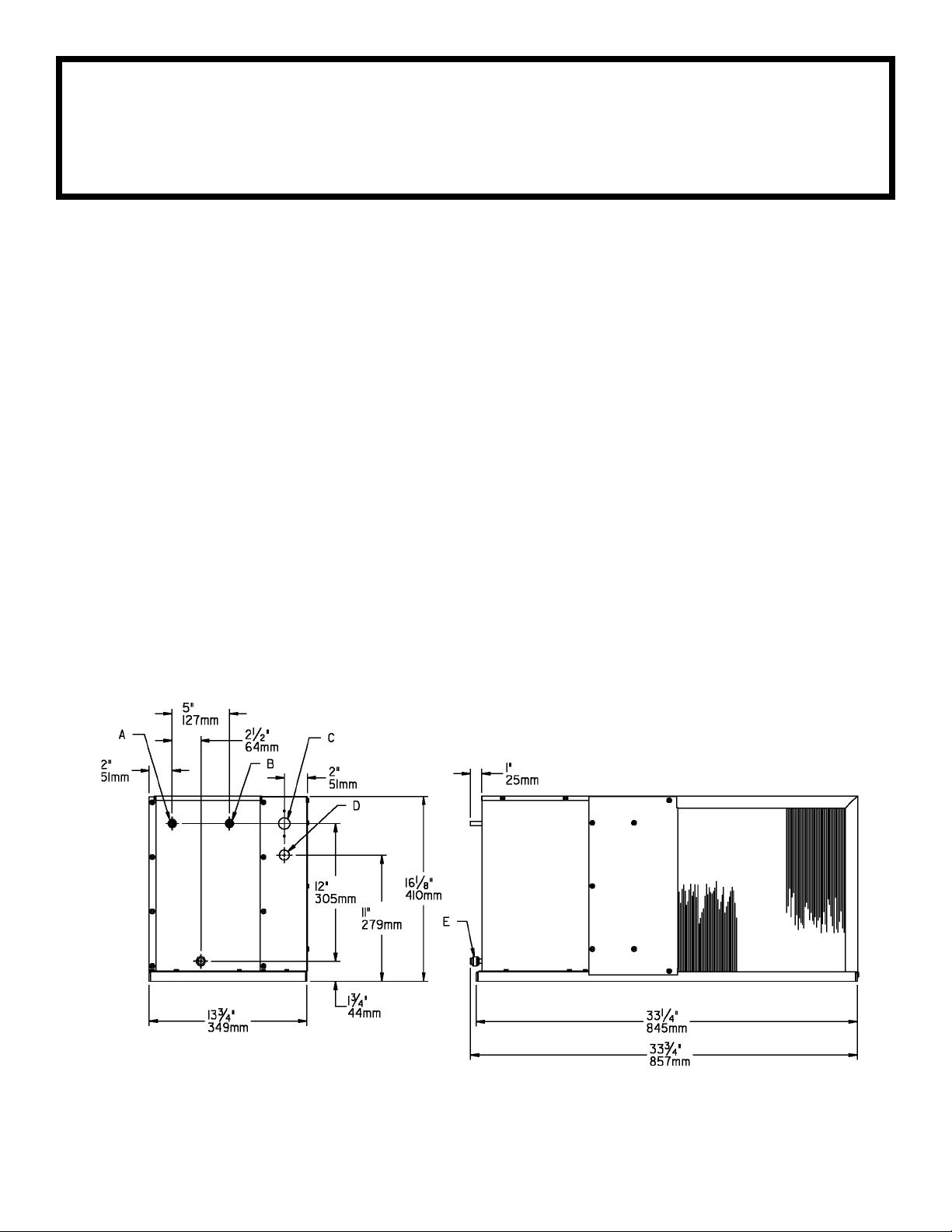

LEGEND

A = 3/8" O.D. TUBE WATER INLET C = TEMPERATURE ADJUSTMENT E = 3/8" O.D. TUBE TANK DRAIN

B = 3/8" O.D. TUBE WATER OUTLET D = ELECTRICAL

96458C (Rev. D - 3/00)

HRC30-1A HRC30-50-2A

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12*

13

14

*15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

NS

ITEMIZED PARTS LIST

PART NO.

23152C

28070C

27698C

27700C

23158C

23159C

27702C

35882C

35792C

31180C

31181C

33484000

19050000

30440C

48000036

30248C

48000070

48000067

48000069

48000068

19037000

100806740570

62277C

70772C

31738002

37268000

33075000

70020C

34783005

27701C

Box - Insulation

Base Assy

Panel

Panel - Front

Cover - Insulation Box

Bracket - Conduit

Cabinet

Control - Cold

Fan Motor

Fan Blade

Fan Bracket

Condenser

Strainer

Capacitor

Compressor

Overload

Gasket (Terminal Cover)

Overload Spring

Bale Strap

Cover Terminal

Clip

Grommet

Evaporator Assy

Drain Plug

Drier

Heat Exchanger

Valve - By Pass

Nut

Washer - Lock

Panel - Rear

DESCRIPTION

TROUBLE SHOOTING AND MAINTENANCE

Temperature Control: Factory set for 50°F water (± 5°) under normal

conditions. For colder water, adjust screw on item no. 8 clockwise.

Ventilation: Cabinet louvers and condenser fins should be periodically

cleaned with a brush, air hose, or vacuum cleaner. Excess dirt or poor

ventilation can cause no cold water and compressor cycling on the overload

protector.

Lubrication: Motors are lifetime lubricated.

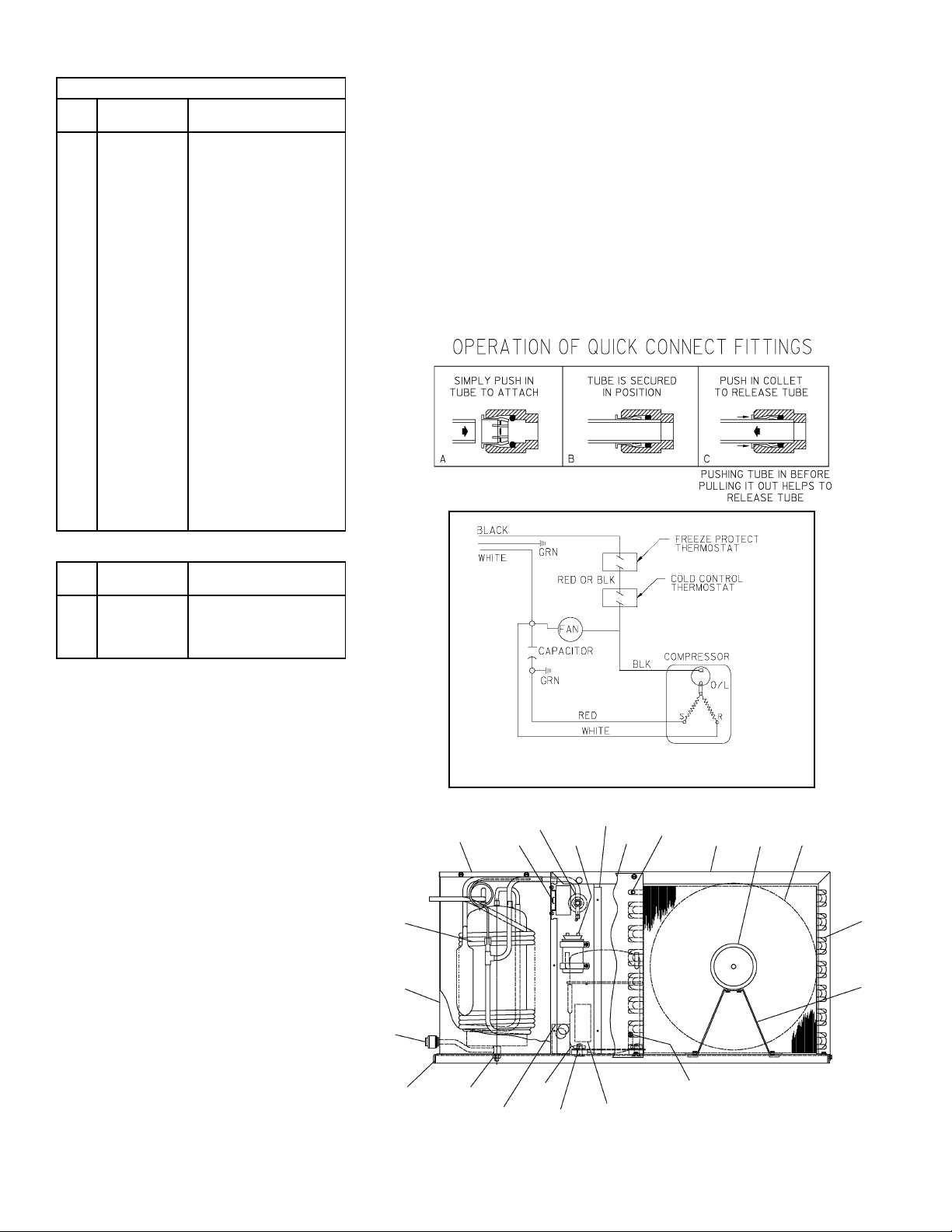

Actuation of Quick Connect Water Fittings: Cooler is provided with lead-

free plug which utilizes an o-ring seal. To remove plug from cooler, relieve

water pressure, pull the collar towards the fitting and pull the fitting off the

tube. To install plug, push fitting straight onto tubing until it reaches a

positive stop, approximately 3/4.

HRC30-2A 220V/50Hz

ITEM

NO.

*INCLUDES RELAY & OVERLOAD. IF UNDER

WARRANTY, REPLACE WITH SAME COMPRESSOR

USED IN ORIGINAL ASSEMBLY.

NOTE: All correspondence pertaining to any of the

above water cooler or orders for repair parts MUST

include model number and serial number of cooler, name

and part number of replacement part.

14

*15

16

9

PART NO.

35793C

30441C

37895000

40405028

DESCRIPTION

Fan Motor

Capacitor

Compressor

Overload

23,26

WIRING DIAGRAM

14

3

13

4

7

10

9

5

27

8

12

1

11

96458C (Rev. D - 3/00)

24

2

28,29

6

15

21,22

25

16,17,18,19,20

Loading...

Loading...