INSTALLATION, CARE & USE MANUAL

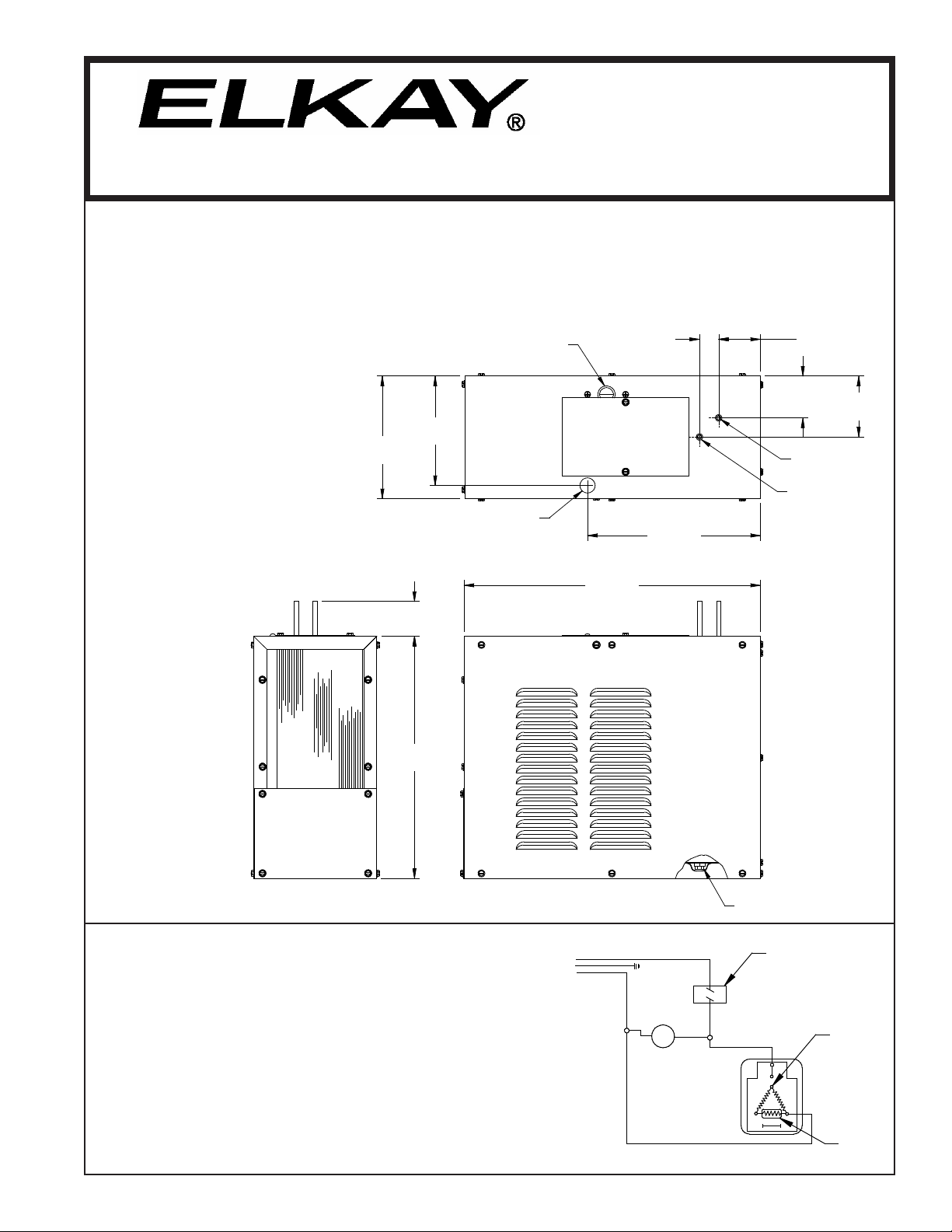

LEGEND

A = 1/4" O.D. TUBE WATER OUTLET

TUBO DE 1/4" DE DIÁMETRO EXTERNO

DE SALIDA DE AGUA

TUBE DE SORTIE D'EAU DE D.E. 1/4"

B = 1/4" O.D. TUBE WATER INLET

TUBO DE 1/4" DE DIÁMETRO EXTERNO

DE ENTRADA DE AGUA

TUBE DE ENTRÉE D'EAU DE D.E. 1/4"

C = TEMPERATURE ADJUSTMENT

AJUSTE DE TEMPERATURA

RÉGLAGE DE TEMPÉRATURE

D = ELECTRICAL

ELÉCTRICO

ÉLECTRICITÉ

E = 1/4" O.D. TUBE TANK DRAIN

TUBE DE 1/4" DE DIÁMETRO EXTERNO

DESAGÜE DEL TANQUE

TUBE DE D.E. 1/4" DE VIDANGE DU

RÉSERVOIR

ERS1*1E ERS1*2E EWC100

Refrigeration Package

C

6 1/4"

7"

179mm

160mm

D

1 1/8"

28mm

10"

253mm

2 3/8"

61mm

2 3/8"

61mm

A

B

3 1/2"

89mm

Fig. 1

A) WHITE

BLANCO

BLANC

B) BLACK

NEGRO

NOIR

C) GROUND

TIERRA

MISE À LA TERRE

D) FAN

ABANICO

VENTILATEUR

2"

51mm

14"

354mm

115V Wiring Diagram

E) COLD CONTROL

CONTROL DE FRÍO

THERMOSTAT

F) INTERNAL OVERLOAD PROTECTOR

PROTECTOR INTERNO DEL SOBRECARGADOR

SYSTEME DE PROTECTION DE SURCHAGE INTERNE

G) PTC STARTER

INICIADOR CPT (CONTROL POSITIVO DE TEMPERATURA)

DEMARREUR CTP

Fig. 2

17 1/8"

434mm

B

A

E

E

C

A

B

D

B

8 C

S

4

1

A

F

2R

G

Page 1

97574C (Rev. J - 2/15)

ERS1*1E ERS1*2E EWC100

1. This unit is intended to be installed underneath a conventional

INSTALLATION

kitchen sink, in a cabinet not less than 36" (914mm) wide (inside

dimension). Two air openings with a minimum of 40" square

(1016mm/square) each, minimum of 75% open area, must be

provided in the cabinet. One opening must be in the overhang of the

toe space. The other opening near the top of the cabinet. The remote

unit must be installed with a minimum of 3" (75mm) clearance

betwen the unit and the rear wall of the cabinet. It can be installed

ush against either side wall of the cabinet. The side louvers which

are not against the cabinet must not be blocked by objects located

within 4" (102mm) of the louvers. In addition, a minimum of 1" to 2"

(25mm to 51mm) clearance must be provided between the toe space

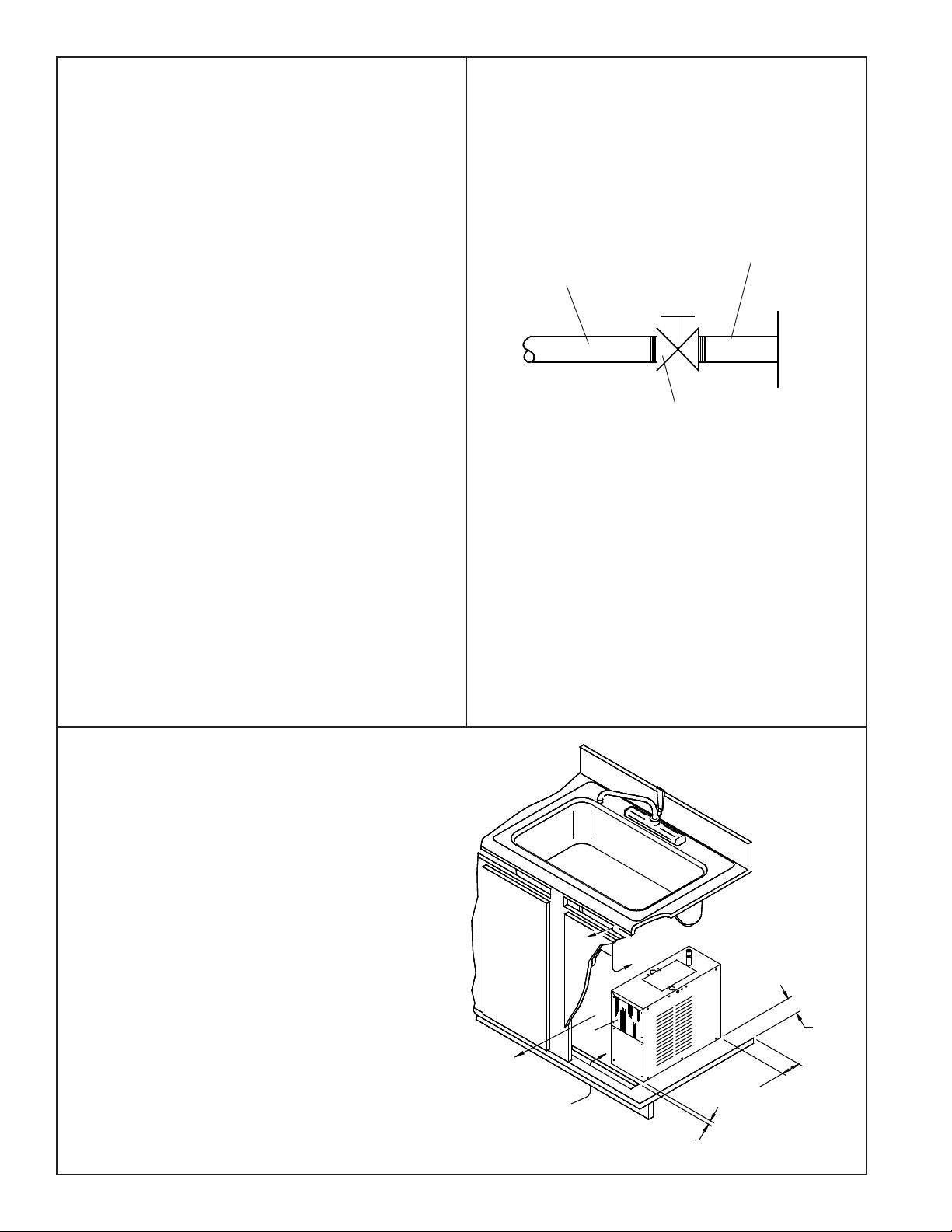

air opening and front of the unit. (See Fig. 4)

2. Water inlet and outlet are 1/4" (6 mm) O.D. tubes.

3. Connecting lines to be of unplated copper, thoroughly ushed to

remove all foreign matter before being connected to cooler.

4. Connect cooler to building supply line with a shut-off valve and

install a 1/4" O.D. (6mm) unplated copper tube between the valve

and cooler. (See Fig. 3)

5. Electrical: Make sure power supply is identical in voltage, cycle,

and phase to that specied on cooler serial plate. Never wire

compressor directly to the power supply.

START-UP

1. Open supply line valve.

2. Purge air from all water lines by operating bubbler valve of

fountain to which cooler is connected. Steady stream assures all

air is removed.

3. Rotate fan to insure proper clearance and free fan action.

4. Connect to electrical power.

1/4" O.D. TUBE WATER INLET TO COOLER

ENTRADA DE AGUA DE TUBO DE 1/4" DE

DIÁMETRO EXTERNO AL ENFRIADOR

TUBE DE D.E. 1/4" POUR ENTRÉE DE L’EAU

DANS LE REFROIDISSEUR

SERVICE STOP (NOT FURNISHED)

VÁLVULA DE PARADA (NO ES PROPORCIONADA)

BLOC D’ARRÊT (NON FOURNI)

Fig. 3

BUILDING WATER INLET

ENTRADA DE AGUA DEL EDIFICIO

ENTRÉE DE L’EAU DE L’ÉDIFICE

TROUBLE SHOOTING & MAINTENANCE

Temperature Control: Factory set at 50°F (± 5°) under normal

conditions. For colder water, adjust screw on item no. 8 in

clockwise direction. (See Fig. 5)

Ventilation: Cabinet louvers and condenser ns should be

periodically cleaned with brush, air hose or vacuum cleaner.

Excess dirt or poor ventilation can cause no cold water and

compressor cycling on the compressor overload protector.

Lubrication: Motors are lifetime lubricated.

Installation of Remote Chiller

A = AIR VENT

ORIFICIO PARA VENTILACION

BOUCHE d'AERATION

B = CONDENSER SIDE FORWARD

LADO DEL CONDENSADOR HACIA EL FRENTE

PARTIE LATERALE DE CONDENSEUR VERS L'AVANT

C = CAN BE MOUNTED FLUSH AGAINST EITHER SIDE OF CABINET

PUEDE INSTALARSE NEVELADO CONTRA CUALQUIER LADO

DEL CABINETE

PEUT ETRE MONTE EN ALIGNANT SUR L'UNE DES PARTIES

LATERALES DU PLACARD

A

97574C (Rev. J - 2/15)

Fig. 4

PAGE 2

C

B

3" MIN.

A

1" TO 2" MIN.

25 TO 51 mm

76mm

Loading...

Loading...