ERO8C*C

Installation/Care/Use Manual

Soft Sides™ Refrigerated Fountain with FLEXI-GUARD

12

SEE FIG. 4

31

14

31

®

Installer

T o assure you install this model easily and correctly ,

PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE ST ARTING THE

INST ALLATION. CHECK YOUR INST ALLA TION FOR COMPLIANCE WITH

PLUMBING , ELECTRICAL AND OTHER APPLICABLE CODES. After installation, leave

these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO

WA TER LINES IS A COMMON PROCEDURE. THIS GROUNDING MA Y BE IN THE BUILDING OR MA Y

OCCUR A WA Y FROM THE BUILDING . THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNT AIN, CREA TING AN ELECTROL YSIS WHICH CAUSES A MET ALLIC T ASTE OR AN

INCREASE IN THE METAL CONTENT OF THE WATER. THIS CONDITION IS A VOIDABLE BY USING

THE PROPER MA TERIALS AS INDICA TED. ANY DRAIN FITTINGS PROVIDED BY THE INST ALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALL Y ISOLA TE THE FOUNT AIN FROM THE BUILDING

PLUMBING SYSTEM.

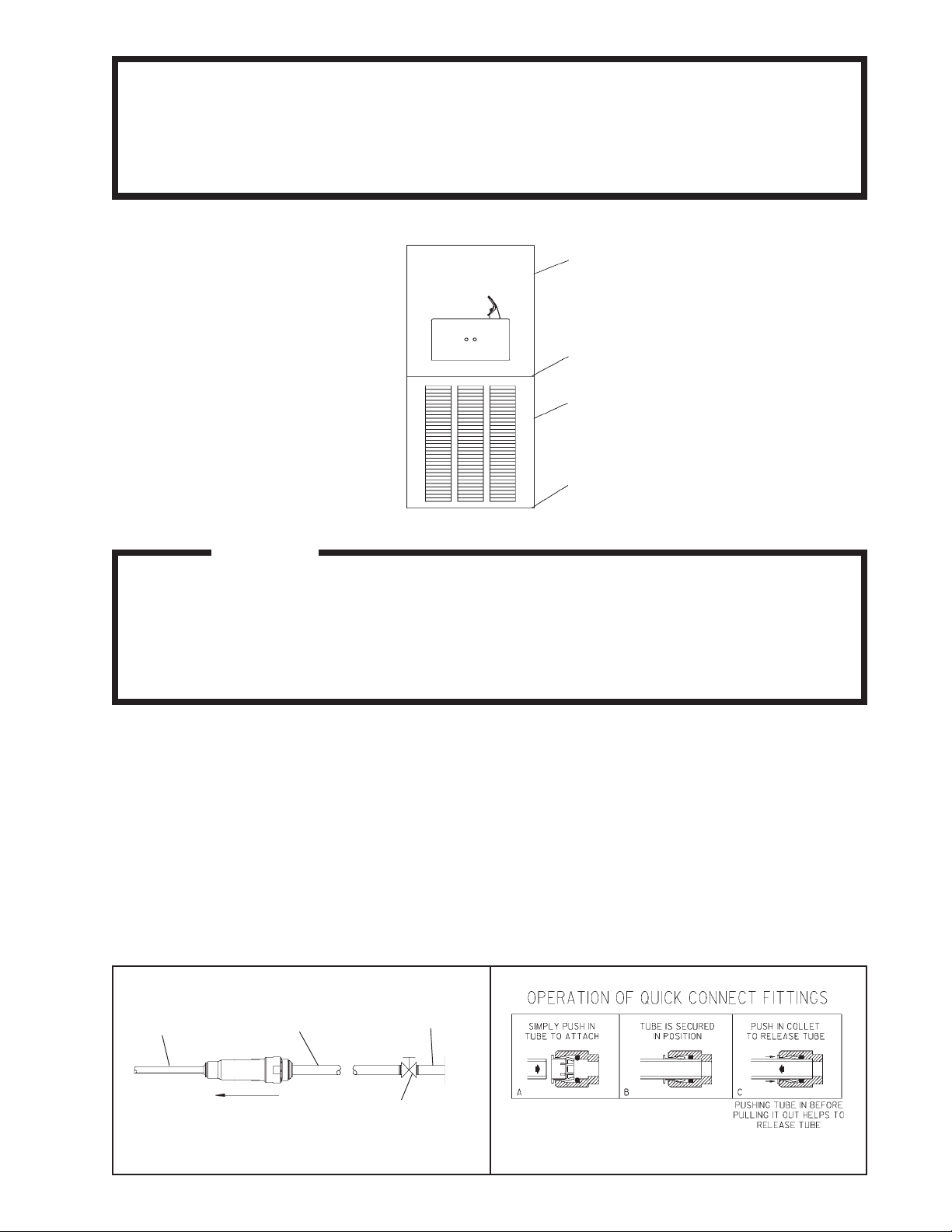

1/4" O.D. TUBE

WATER INLET

TO COOLER

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

BUILDING WATER

INLET

SERVICE STOP

(NOT FURNISHED)

FIG. 2FIG. 1

97873C (Rev. E - 8/07)

ERO8C*C

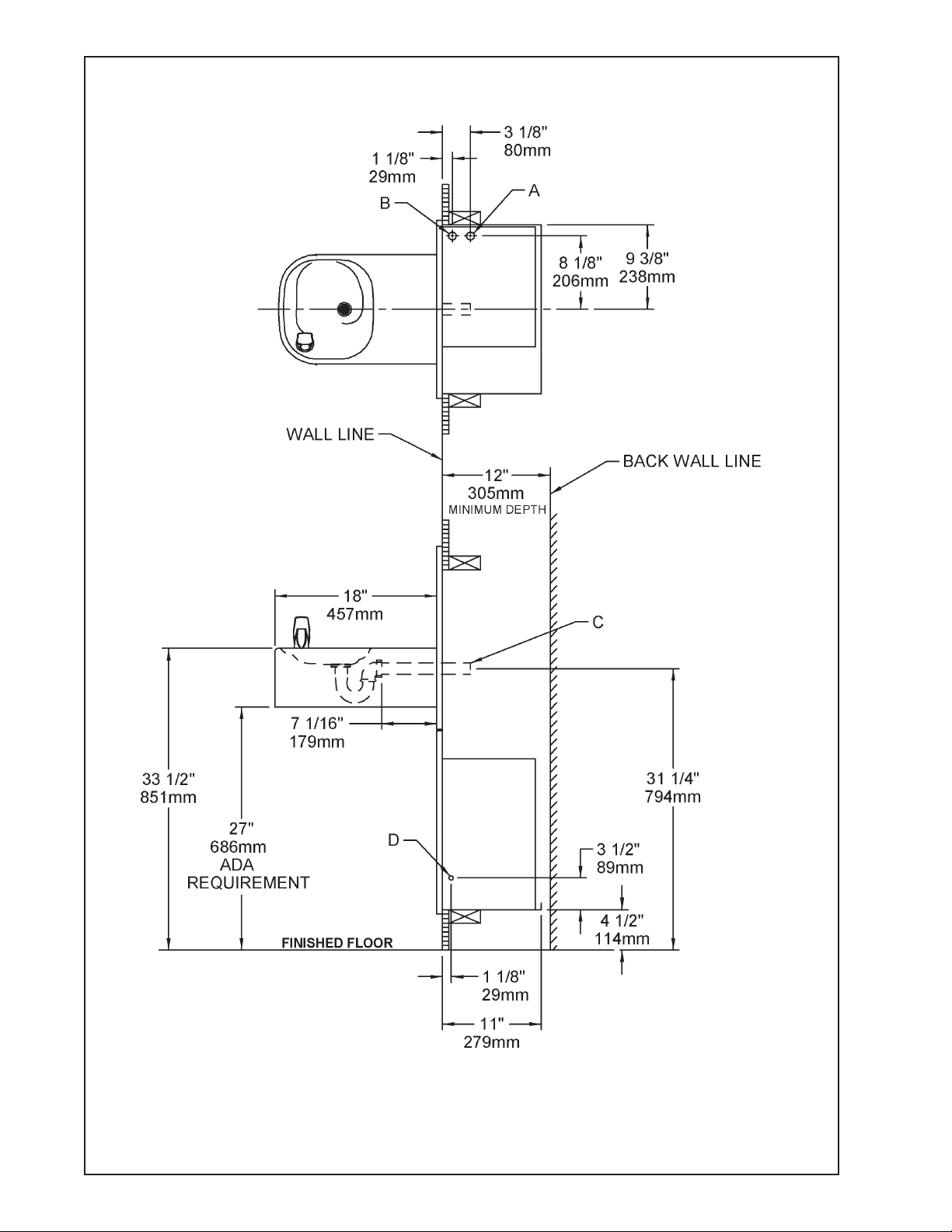

ERO8C ROUGH-IN

LEGEND

A = 1/4" O.D. TUBE CONNECT (CHILLER W A TER OUTLET)

B = 3/8" O.D. TUBE CONNECT (CHILLER WA TER INLET) SHUT OFF V AL VE BY OTHERS

C = 1-1/4" TRAP FURNISHED

D = ELECTRICAL INLET

FIG. 3

97873C (Rev. E - 8/07)

PAGE 2

ERO8C*C

INSTALLATION INSTRUCTIONS

1. Install mounting frame. See mounting frame instructions.

2. Install remote chiller. Remove front panel of chiller. Slide chiller onto the shelf and position it to the left within the guides on the shelf.

3. Attach solenoid valve assy to the underside of cross member of mounting frame. See Figure 7.

4. Make water supply connections. Install a shut-off valve and union connection to building water supply (valve and union not provided). Turn on the

water supply and flush the line thoroughly.

5. Make connection between remote chiller and building supply line. Install the strainer on the chiller inlet tube. Install a 3/8" O.D. unplated copper water

line between the valve and the cooler. Remove all burrs from the outside of the water line. Insert the 3/8" water line into the inlet side of the strainer

by pushing it in until it reaches a positive stop, approximately 3/4" (19mm). See Figures 2 and 5. DO NOT SOLDER TUBES INSERTED INTO THE

STRAINER AS DAMAGE TO THE O-RINGS MAY RESUL T. Inst all the 1/4" x 1/4" union (provided) on the chiller outlet tube.

6. Make connection between remote chiller and solenoid valve assy. Insert end of 1/4" O.D. poly tubing (provided) into union on chiller outlet and the

other end into straight fitting on solenoid valve assy.

7. Hang the upper panel on the mounting frame hanger. Align holes in the panel with holes in the mounting frame. Be sure that panel is engaged with

hanger at top of frame before releasing it.

8. Install fountain. Remove bottom cover plate on underside of fountain and save the screws. Mount the fountain to the upper panel and the wall frame

with (4) 5/16" x 3/4" (19mm) long bolts and nuts (provided). Tighten securely.

9. Connect solenoid valve assy and regulator holder in fountain by inserting 1/4" O.D. poly tubing (provided).

10. Remove elbow from end of p-trap and attach it to drain tube. Re-attach elbow to p-trap and cut waste tube to required length using plumbing

hardware and trap as a guide.

11. Connect power cord of sensor to solenoid valve by running it through the back panel and connecting it as shown in Fig. 8. Connectors may be

connected to either terminal on solenoid valve. Attach ground wire to solenoid valve bracket with green ground screw.

12. Turn on water supply. Release air from tank by interrupting infrared beam; steady stream of water assures all air is removed. The sensor has a 30

second maximum ON time. It may be necessary to step away from beam a few times to allow chiller tank to refill. Check for leaks.

13. These products are designed to operate on 20-105 PSIG supply line pressure. If inlet pressure is above 105 PSIG, a pressure regulator must be

installed in the supply line. Any damage caused by reason of connecting these products to supply line pressures lower than 20 PSIG or higher than

105 PSIG is not covered by warranty.

14. Make electrical connections to chiller. See chiller instructions.

15. Check stream height from bubbler. Stream height is factory set at 35 PSI . If supply pressure varies greatly from this, remove item 11 (bottom

cover plate) and adjust the screw on the regulator (item 7). Clockwise adjustment will raise stream height and counter-clockwise will lower stream

height. For best adjustment stream height should hit basin approximately 6-1/2" (165mm) from the bubbler.

16. Mount lower panel. Loosen the (2) #10-24 x 5/8" (16mm) screws at frame bottom lip. Slide upper tongue of lower panel under lower edge of already

installed upper panel. Tighten previously loosened screws securely.

17. Replace bottom cover plate to fountain basin using screws provided. Tighten securely.

CHILLER

FIG. 5

34

OUTLET

15

34 (TO BUBBLER)

34

9

CHILLER

INLET

FIG. 4

SEE FIG. 8

FIG. 6

PAGE 3

2

1

NOTE: WHEN INSTALLING

REPLACEMENT BUBBLER AND

PEDEST AL, TIGHTEN NUT

(ITEM 4) ONLY TO HOLD

3

PAR TS SNUG IN POSITION.

DO NOT OVER TIGHTEN.

4

34

10

35

5

8, 1 1

97873C (Rev. E - 8/07)

32, 33

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

PAR TS LIST

PAR T NO.ITEM NO.

A54874

56011C

55997C

75580C

LK464

50986C

61313C

112627543890

55996C

28784C

55000665

26837C

40045C

26833C

70683C

22525C

22526C

27240C

31272C

31376C

31384C

38417001

56082C

70016C

50203C

51409C

70208C

70256C

70817C

75507C

111008343890

111577243890

111577343890

56092C

56280C

DESCRIPTION

Orifice Assy

Housing Assy

Pedestal

Bubbler Locknut

Drain

Regulator Holder

Regulator

Screw - #10-24 X .50 PHTC

Strainer

Fountain Body

Bottom Cover Plate

Back Panel

Hex Nut

Lower Panel

Union-1/4 X 1/4

Regulator Mounting Bracket

Solenoid Mounting Bracket

Sensor Support Bracket

Solenoid Valve Assy

Power Cord

Sensor - Clear

Screw- #8-18 X .37 HHSM

Nut - Regulator

Hex Nut #10-32

Strain Relief

Spacer - 1/2 X .44

Screw - #10-24 X .38 PHTC

Screw - 1/4-20 X .38 HHTC

Elbow - 1/4 X 1/4

Fitting - 1/4 NPTF X 1/4 O.D.

Screw - #10-24 X .62 HHMS

Screw - 5/16-18 X .75

Hex Nut - 5/16-18

Poly Tubing (Cut To Length)

Edge Trim

ERO8C*C

TROUBLE SHOOTING AND MAINTENANCE

1. Orifice Assy: Minerals deposits on orifice can cause water flow to spurt

or not regulate. Mineral deposits may be removed from the orifice with a

small round file not over 1/8" diameter or a small diameter wire.

CAUTION: Do not file or cut orifice materials.

2. Stream Regulator: If orifice is free of material deposits regulate water

flow according to instructions on page 3.

3. Sensor Control: The sensor has a 2 second delay time. If sensor fails to

operate valve mechanism or operates erratically, check the following:

a) Ensure there are no obstructions within a 40 inch radius from the front

of fountain.

b) Check wire connections at the solenoid valve and at the sensor.

CAUTION: Make sure unit is unplugged before checking any wiring.

c) Ensure proper operation of solenoid valve. If there is an audible clicking

sound yet no water flows, look for an obstruction in the valve itself or

elsewhere in the water supply line.

WARNING: Do not expose sensor to direct sunlight.

4. Sensor Range Adjustment: The electronic sensor used in this fountain

is factory pre-set for a "visual" range of 36 inches. If actual range varies

greatly from this, or a different setting is desired, follow the range

adjustment procedure below:

a) Remove bottom cover of fountain.

b) Remove sensor by removing washers and nuts that secure sensor on

studs.

c) Locate range adjustment screw between the red lenses of the sensor,

then with a small tip screwdriver, rotate the range adjusting screw

clockwise to increase range or counter-clockwise to decrease range.

1/4 turn of screw is equal to approximately 12 - 18 inches of range.

CAUTION: Complete range of sensor (24 - 46 inches) is only one turn of

the adjusting screw.

d) Remount sensor on studs and replace bottom cover.

19

22

25

13

23

27

20

30

6

19

16

29

7

22

17

28

24

21

26

18

FIG. 8

FIG. 7

ELKAY MANUFACTURING COMP A NY • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484

97873C (Rev. E - 8/07)

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

FOR PARTS, CONT ACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

PAGE 4

Loading...

Loading...